▶

What

Adaptive

AR

▶

▶

2/2024

Special topic: Smart Technologies

labs need to be successful in the future

smart glasses for future?

and MR devices as the next computing platform

Live on site

atmosphere at this year's MAFO –The Conference

2024back in force

- a successful start to the new optical year

Great

Mido

Opti

Market Surveys Industrial edger

Business Risk management strategic and structured ISSN 1614-1598 66527 Volume 20 OPHTHALMIC LABS & INDUSTRY Eyepress Fachmedien GmbH Saarner Str. 151 45479 Muelheim a. d. Ruhr 66527 Germany Connect, discover, stay up-to-date $ $ $

paperless and innovative digital solution converts traditional printed job tickets into a reusable and dynamic format allowing labs to update job information on the fly while retaining all the advantages of visual data. satisloh.com Instant visibility into real-time job status to make efficient decisions. DYNAMIC SUSTAINABLE SCALABLE Risk-free, step-by-step implementation as your needs grow. COST-EFFECTIVE Reduces lab operating expenses Reusing E-Ticket Tags, significantly reduces paper & ink waste STEP INTO THE FUTURE WITH DIGITAL JOB TICKETS E-TICKET SYSTEM BETTER THAN PAPER! Contact us to learn how the E-Ticket System can streamline your operations! $

▶

This

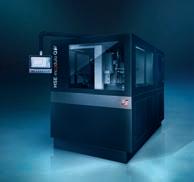

CHC200: The Choice of Leading Labs Worldwide.

Optimize your lab with the CHC200's cutting-edge dip coating capabilities, offering efficient cleaning and hard coating for up to 200 lenses per hour. Experience swift and flexible lens processing with two automated robotic systems. Achieve complete control and customization of the coating process through a user-friendly digital HMI for seamless operation.

The CHC200 comes fully equipped, providing everything you need to initiate or enhance your lens coating journey.

t: +44 (0) 1462 491616

e: sales@optimal-technologies.com

www.optimal-technologies.com

The euphoria is back

After several years of disruptions to international trade shows, followed by a slow return to normality, this year the European trade fairs Mido and Opti are finally back. High visitor numbers, lots of exhibitors, but above all an excellent atmosphere, were all very impressive. Mido reported record numbers with over 40,000 visitors in total, while the opti had 21,500 visitors – a significant increase on last year when around 15,500 people came to the event. After years of infighting and tussles about dates, locations and in some cases the absence of major exhibitors, the Opti now seems to have overcome the troubles of the past.

Incidentally, this optimism also applied to ‘MAFO – The Conference’ which MAFO itself organizes one day before Mido every year. This meeting point for the industry, with its insightful lectures on developments in the spectacle lens industry, was also better attended than it has been in years, with 90 participants – and most of them submittted extremely positive feedback.

Visitors are obviously excited to come to trade fairs and other events again, and are keen to discover new things. This maybe because there are a lot of interesting developments to get to grips with right now. Blockless manufacturing is a much-discussed topic both for machine and lens manufacturers that many labs are watching closely.

Other interesting new machines – especially for larger labs – include automatic cosmetic inspection or machines for unpacking blanks

automatically. But these are just a couple of individual examples. Things get really exciting when a lab introduces the latest technology at multiple levels. You can find out more about what such a lab looks like and about the advantages that smart technologies have to offer, starting at page 22.

Another topic that is currently gaining traction concerns lenses with variable refraction. The refractive index, for example, can be changed at the press of a button, or even using autofocus, and can thus correct distance or near vision as required. This technology is based on liquid crystal lenses (LCL).

Back in 2011, PixelOptix demonstrated glasses but was ultimately unsuccessful. This time round, however, things could turn out differently, as at least two companies already have products on the market and others are soon to follow. You can find out more about this topic in the detailed article starting on page 28.

And for everyone who likes to think outside the box, or is already putting out feelers to find out more about Augmented Reality (AR), Mixed Reality (MR) or Extended Reality (XR), turn to the article on page 34.

And finally – besides reading trade journals – be sure not to miss the upcoming trade shows, so you can experience the machines, processes and products at first hand. In March, the Vision Expo East is being held in New York for the last time, before it moves to its new home in Orlando as from 2025. Many visitors will certainly visit this last fair in New York with mixed feelings. But as the saying goes: When one door shuts, another opens.

us your opinion, ideas and suggestions: hanna.diewald@mafo-optics.com MAFO 2-24 3 LETTER

Hanna Diewald Chief editor

Tell

MAFO 2-24 5 MARCH / APRIL 2024 MAFO issue March / April 2024 Content Topics in this edition At a glance 6 All about you News from the international ophthalmic industry 7 All about markets Infographics 8 All about products Innovations and products for your lab 54 Suppliers Guide 48 Closing Words Carla Moncunill Cabré 49 Outlook Technology 22 What labs need to be successful in the future By Sandra Stry and Kim Kathrin Leidig 28 Adaptive smart glasses for future? By Lena Petzold 34 AR and MR devices as the next computing platform By Mandy Gebhardt and Matthias Nestler Live on site 10 Great atmosphere at this year´s MAFO – The Conference By Hanna Diewald 14 Mido 2024 ‒- back in force By Hanna Diewald Live on site 20 Opti - a successful start to the new optical year By Daniel Groß and Frank Sonnenberg Business 38 Risk management - strategic and structured By Russell Kenrick and Sidra Sammi Surveys 42 Industrial edging Page 10 Page 34 Page 38 Special Topic Special Topic Special Topic

All about you

News from the international ophthalmic industry

Steve Sutherlin to be honored posthumously with the 2024 Goodfellow Award

Steve Sutherlin will be honored posthumously with the 2024 Goodfellow Award during the Lab Leadership Forum on Thursday, April 11, and Friday, April 12, 2024, at the Temecula Creek Inn (Temecula, California). The Goodfellow Award is designed to recognize an outstanding individual who actively contributes to the advancement of the optical industry. Steve’s contributions to the optical industry are vast. He died of a heart attack on December 28, 2023. Steve was 70 years old and lived in Overland Park, Kansas. The optical laboratory executive was instrumental in the success of his family’s business, Sutherlin Optical, and later played a key role in merging the Optical Laboratories Association (OLA) into The Vision Council.

ANFAO introduces CSE (Certified Sustainable Eyewear)

The first international sustainability certification, CSE (Certified Sustainable Eyewear) was presented at Mido 2024. Created, registered, and promoted by ANFAO, the Italian Association of Optical Goods Manufacturers, in collaboration with CERTOTTICA, this certificate is destined to become the new product sustainability standard for the eyewear industry, certifying glasses and their components: frame fronts, temples, lenses, small metal and plastic parts. The certification identifies the most sustainable products, it is voluntary and based on UNI EN ISO 14020 and UNI EN ISO 14024 standards. It is open now to all eyewear companies, both Italian and international, who will apply for the program. The CSE label, issued by the independent body, CERTOTTICA, will be issued by ANFAO based on a number of industry-specific assessment criteria that take into account the entire life cycle of the product (resource extraction, raw materials, production, distribution, use and disposal).

Landmark event: final NYC show

Vision Expo East 2024, co-hosted by The Vision Council and RX, is on track to be a landmark event for the eyecare and eyewear industry worldwide. Over 450 eyewear and eyecare companies gearing up to display their latest products and technologies across an expansive 150,000 square feet of exhibit space for one final show in New York City, taking place from March 14-17 at the iconic Javits Center. But this show is also the end of an era. From 2025, the Vision Expo East will take place in Orlando, Florida.

Zeiss Vision Care acquires IP portfolio for electronic eyewear from Mitusi Chemicals

Zeiss Vision Care announced the successful acquisition of a comprehensive intellectual property (IP) portfolio, including a suite of patents, from Mitsui Chemicals. This strategic move solidifies Zeiss’ commitment to advancing technology in the eyeglass lens industry and further opens new opportunities for the development of electro-active lenses and spectacle frames. Modern eyeglass lenses can protect the eyes from harmful UV radiation, reduce perceived glare when driving, or reduce digital eye strain when working with computer screens. An innovative area for eye care will be the combination of electrically controlled functions with lenses and spectacles. The acquired IP portfolio comprises a range of groundbreaking patents that encompass various electric functionalities tailored for eyeglass lenses and frame electronics.

You have news for the ophthalmic industry? Submit your press releases to: hanna.diewald@mafo-optics.com or constanze.classen@mafo-optics.com

MAFO 2-24 6 INTERNATIONAL NEWS

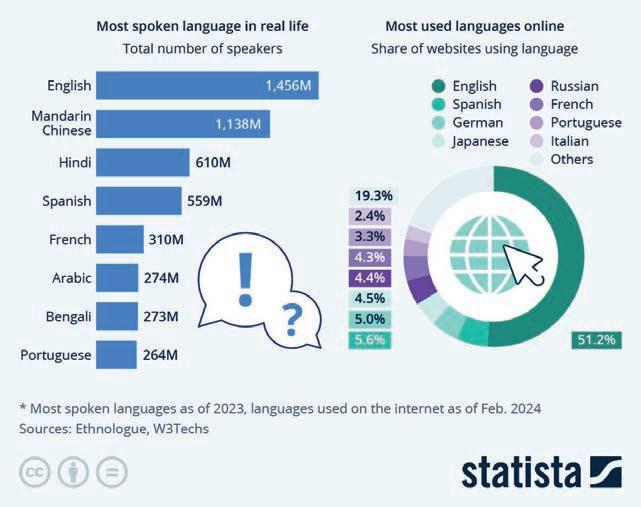

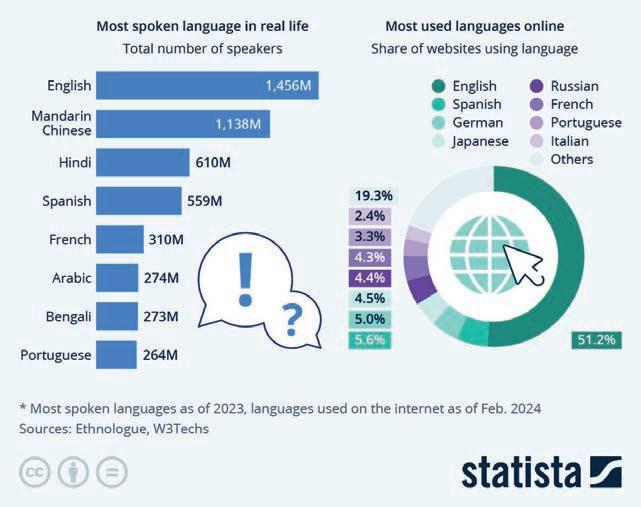

All about markets

Graphical data

On average, in 2024, every person worldwide is expected to generate a revenue of USD 19.17 in the Eyewear market.

Source: https://www.statista.com/outlook/cmo/ eyewear/worldwide

The most spoken languages: on the internet and in real life

The global eyewear market size is expected to grow from USD 146.1 Billion in 2023 to USD 215 Billion by 2033, at a Compound Annual Growth Rate (CAGR) of 3.9% during the projected period.

Source: Spherical Insights & Consulting

It is estimated that in 2024, 85%

of sales in the eyewear market will be attributed to non-Luxury.

Source: https://www.statista.com/outlook/cmo/ eyewear/worldwide

MAFO 2-24 7 INTERNATIONAL NEWS

All about products

Innovations and working materials for your lab

MEI launches ClearXM

ClearXM, the innovative integrated solution developed by MEI for cleaning and inspecting eyeglasses edged lenses. It’s a very compact system that combines a loading system able to accommodate any shape of edged and uncut eyeglass lens with a cleaning section made of sealed chambers designed to avoid contamination. With the incorporated imaging technology, ClearXM scans and recognizes the contours and dimensions of the lens, ensuring a secure and precise clamping mechanism. By understanding the specific shape and size of the lens, the system can optimize the cleaning process and apply the appropriate pressure and movement patterns needed to effectively remove dust, smudges, or other particles from the lens surface while avoiding the risk of scratching or other damages. Additionally, ClearXM has the option of the integrated cosmetic control, which learns from each lens and auto-improves its performance continuously, without impacting the working cycle time. Visit www.meisystem.com

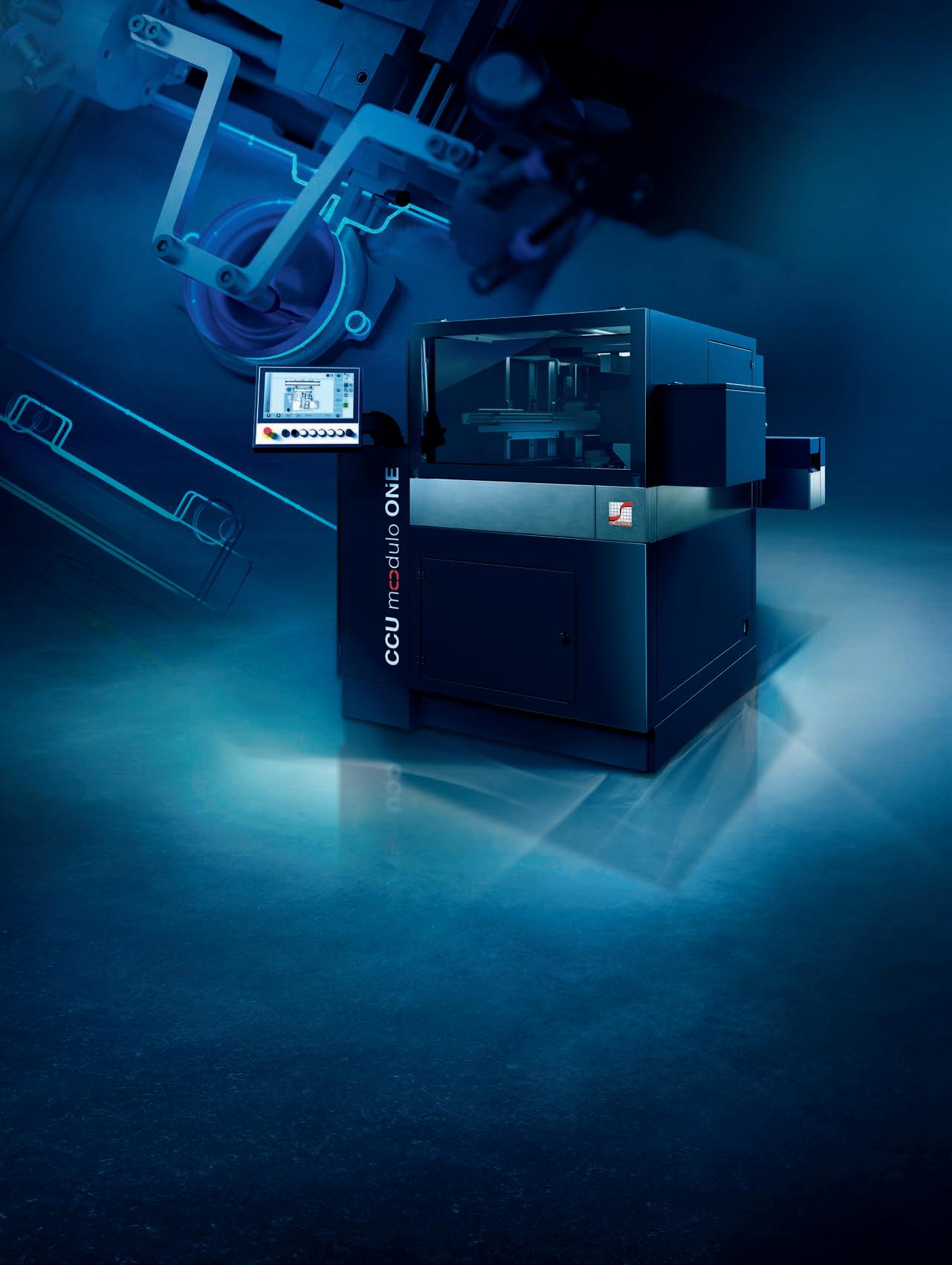

Awarded for innovative power!

Newly crowned innovation champion: SCHNEIDER GmbH & Co. KG from Germany has received the TOP 100 seal 2024. This German award is only given to particularly innovative medium-sized companies. SCHNEIDER convinced a team of renowned jurors, among them is a leading innovation researcher Prof. Dr. Nikolaus Franke (Vienna University of Economics and Business), in a scientific selection process. For the second time, SCHNEIDER has been selected as one of the top innovators (2014, 2024).

"Innovation is our corporate purpose," says Gunter Schneider, Managing Director and owner of the company. "Our vision was and still is to create a fully automated and intelligent 'Power Lab of the Next Decade' that increases efficiency and saves resources," says Schneider. Visit www.schneider-om.com

Horizons Optical Showcases Groundbreaking mimesys Office at MIDO 2024

Horizons Optical proudly announced its participation at MIDO 2024, held on February 3rd. The event served as the platform for the unveiling of mimesys Office, the latest innovation in lens creation technology. For the first time, users can craft their daily work environment to analyze gaze dynamics in their office setting. This breakthrough application allows for the creation of customized office lenses that not only address visual strategies but also study visual posture in front of screens, resulting in unparalleled visual comfort. With mimesys Office, users can expect a tailored approach to lens design that prioritizes both visual clarity and ergonomic comfort. This cutting-edge technology marks a significant milestone in the optical industry, offering users unprecedented control over their visual environments. Visit www.horizonsoptical.com or contact@horizonsoptical.com

Advertisement

Craft your workspace, Ensure your comfort

MAFO 2-24 8 INTERNATIONAL NEWS

Highest 3+

Little

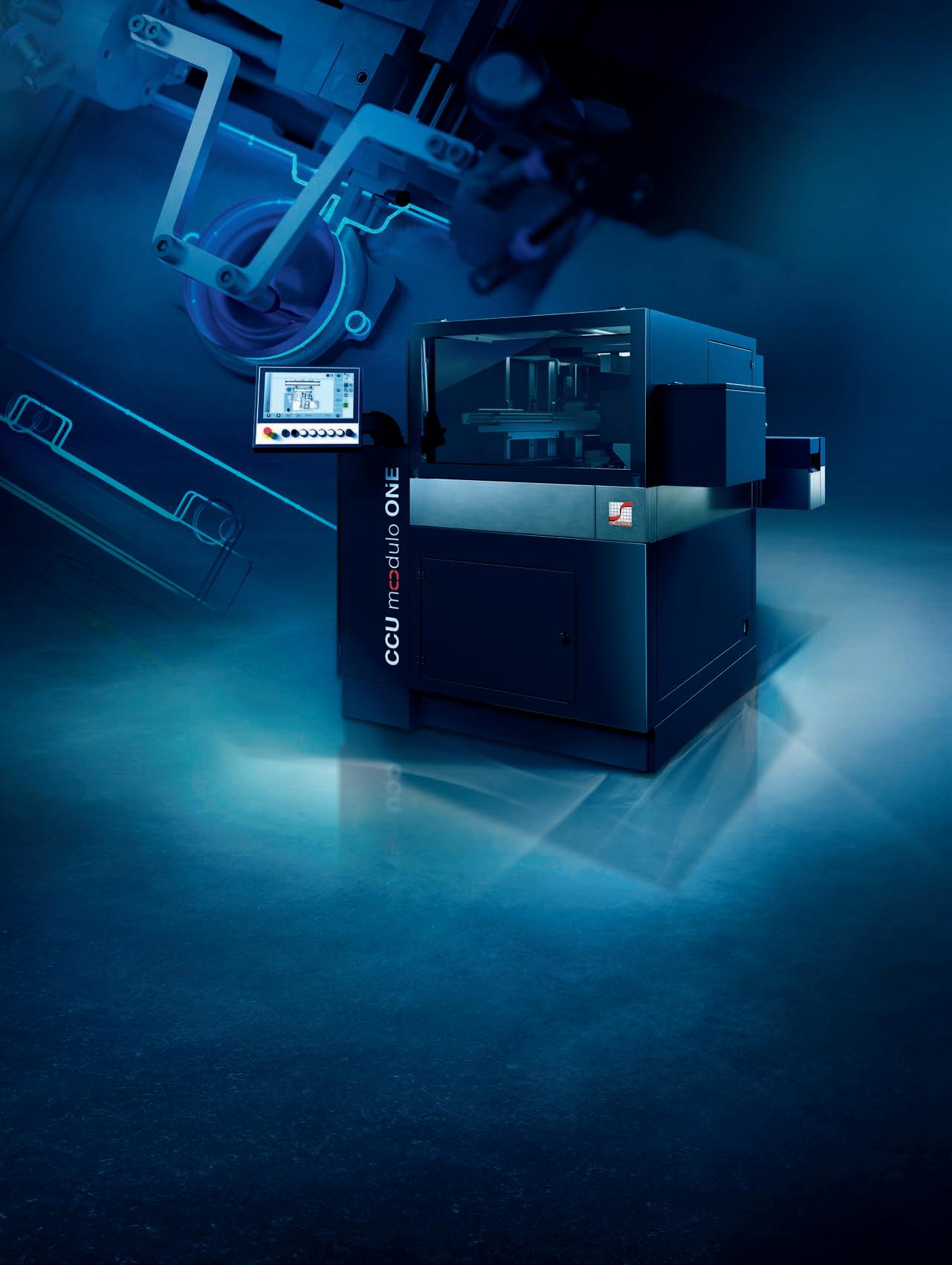

CCU m dulo

Highest

One auto blocker covering virtually all of a labs’ blocking requirements at highest speed.

With CCU Modulo ONE, SCHNEIDER introduces the only auto blocker today with automated block size exchange and achieves unprecedented efficiency in blocking.

Time-consuming manual changes are a thing of the past. CCU Modulo ONE has multiple block sizes –a minimum of three and up to six – readily available. And the best part: The exchanges are carried out automatically and without increasing cycle time.

With the added flexibility, CCU Modulo ONE solves a well-known problem: Inefficient block size distribution and poor machine utilization. For any lab size, a wider range of blocking requirements can be met with a smaller number of machines.

The proprietary lens measuring unit guarantees perfectly oriented lenses. An intelligent fill control provides highly consistent and precise fillings – no under or over fillings. The alloy and block pieces can be refilled during operation.

flexibility

to no downtime

Non-stop uninterrupted blocking for highest throughput, at lowest cost per lens. throughput

www.schneider-om.com

BLOCKING PERFORMANCE AT A NEW LEVEL

Great atmosphere at this year's MAFO – The Conference

Exciting topics and many participants in Milan

Smart Glasses, blockless manufacturing, myopia management and artificial intelligence – these were just some of the topics presented at this year's MAFO – The Conference. The varied program attracted visitors from all over the world, ensuring a record number of participants. By Hanna Diewald

90

participants from the global spectacle lens industry attended this year's MAFO – The Conference in Milan. The number of participants was thus considerably higher than in previous years and many visitors were enthusiastic about the exciting topics presented and the excellent atmosphere at the venue.

The meeting place for the ophthalmic optics industry in Europe

As usual, the unique meeting place for the spectacle lens industry took place the day before Mido, on Friday, February 2 in Milan. It brought together people from labs from all over the world, as well as representatives from machine manufacturers, lens designers, software developers

Smart Technologies

MAFO 2-24 10 LIVE ON SITE

and many other professionals involved in the development of ophthalmic lenses or who simply wanted to be up to date with the latest developments in the eyewear industry.

The event started at 8.30 a.m. with a welcome breakfast before participants gathered in the conference hall to eagerly await the first presentation.

This was introduced by long-term Chairman Peter Baumbach, who, as usual, led the audience through the program in an entertaining manner and – thanks to his wide experience in ophthalmic optics –repeatedly challenged the speakers with interesting questions.

Baumbach is Professor of Ophthalmic Optics and Psychophysics at Aalen University in Germany and is a sought-after expert for the calculation of spectacle lens designs, patent analyses and much more.

Spectacle lens analyses in a driving simulator

The first lecture by Dr. Judith Ungewiss from Aalen University (Germany) began very realistically with the topic: “Psychophysical evaluation of optical lenses in the Aalen Mobility Perception and Exploration Lab (AMPEL).” As spectacle-lens experts know, vision in a car at night poses particular challenges.

The risk factor for accidents increases significantly when driving at night – an aspect that should not be neglected when developing lenses.

Ungewiss presented the university's driving simulator, where vision while driving is simulated and analyzed in an Audi A4. The laboratory is also equipped with a steering and pedal unit, two projection units, 180° curved screen, a monitor behind the car and the SILAB simulator software. There are also different sources of glare, and the system has a CE certification.

Ungewiss explained convincingly how psychophysical tests are carried out under realistic conditions. For example, the assessment of halo areas (“halometry”), visual acuity and contrast sensitivity, with clinical examination methods and driving (at night) with and without glare.

And, of course, there is no shortage of fun and experimentation in the driving simulator: “We have found that people also enjoy trying out things that are not allowed!” Ungewiss said with a grin at the end.

Much discussed: blockless generating

The first blockless generator has been on the market for a few months now, so it is no wonder that labs are wondering how well the new technology works and what advantages and disadvantages it has. So it was good that two speakers gave presentations on this topic, to shed light on the topics from all sides.

Stefano Sonzogni from MEI System began with the topic: “The block-free lens generation process – an effective step ahead in preserving the environment ”

For Sonzogni, the advantages of the new technology are obvious: Without a block, there is no need for tape, no block, no alloy, no glue and, of course, no taper and no blocker or de-blocker.

This is sustainable, too, as it saves space, energy and entire process steps. Sonzogni also emphasized that thinner blanks could be used in the future, so that more than 60% residual material could be saved, as it will no longer be necessary to use thick blanks to avoid deformation during the alloy-cooling and solidification process.

Nevertheless, the head of the company made no secret of the fact that the current generator still has limitations, such as in curvature and working range; these were also addressed at length in the Q&As.

This lecture was followed by Dr. Michael Kreis from Satisloh on the topic of: “Opportunities and challenges of blockless surfacing technology” , shedding light on the same subject from a different angle. Satisloh makes no secret of the fact that they, too, are working on a blockless generator. However, it is still in the development stage and has not yet been deemed as market-ready due to certain limitations which still exist.

Dr. Kreis began his talk with explanations of what processes are currently available, and what tasks blocking in general fulfills. For example, the accurate positioning of a semi-finished blank in six degrees of freedom or holding the blank in position during processing is required; both to secure the position of the blank/lens in a tray when being moved as well as to support it during each and every manufacturing operation.

The machine manufacturer also emphasized the ambitious goal that new blockless generators should eliminate the existing operations of

Smart Technologies

MAFO 2-24 11 LIVE ON SITE

Smart Technologies

blocking etc. while still fitting 100% into an existing line. Thus the aim of the machine manufacturer is to offer the latest generator in a blockless version, and to adapt the polisher to suit the next operation.

Nonetheless, there still remain certain limitations: reduced working range, front and back curvature is restricted, limited range of materials, reduced throughput, non-rotationally symmetric surfaces like front side progressives cannot be handled, and a poor balance of the overall production line. According to Kreis, the technology therefore has enormous potential – but whether it can ever be applied to the entire range of ophthalmic lenses remains uncertain.

New data: “Plug-and-produce and create benefits!”

Data from machines is the basis for making Industry 4.0 possible in labs, but in order to really use and reuse it sensibly, common standards for labs and machine manufacturers are needed too. This was the subject of the talk by Dr. Jens Buergin and Heiko Schlump from Zeiss: “Connectivity as enabler for Industry 4.0.”

For the two experts, the motto for production is clear: “Plug-and-produce create benefits!” For this to work, however, some conditions have to be met: One keyword here is “connectivity.” This forms the basis for generating value from data and can be achieved by standard machine interfaces, for example.

One example is the standardized order-related data connectivity flow, compliant with the Vision Council’s Data Communication Standard (DCS). Also relevant here is the Open Platform Communications Unified Architecture (OPC UA) which offers potential for enhanced connectivity. It is the industrial communication protocol that has become the preferred communication standard in modern industries.

Automatic cosmetic inspection

Dr. Marcel Mahner from Schneider continued with a slightly different take on standardization in his presentation: “Empowering the Ophthalmic Industry through Artificial Intelligence – new possibilities on the example of cosmetic inspection”.

Inspecting every single lens by hand at the end of production, holding it up to the light to detect even the smallest defect and searching for

every flaw could become a thing of the past – at least for large labs. Thanks to machines that take over cosmetic inspection, defects should become easier to detect, classified and subsequently even avoided altogether. In his talk, Mahner explained exactly how this works and what role artificial intelligence can play in the process.

Standardization is an important keyword here, too, as it enables labs to be more objective and makes them less dependent on the subjective assessment of a person, which may vary from day to day. For this purpose, the first step after measurement is to carry out lab-independent pattern recognition with the aid of artificial intelligence. In the second step, a lab-specific quality standard evaluation based on certain quality criteria is carried out, which can be individualized. What kinds of defects occur, and whether these are specific to the location and how often they occur, are all relevant to determining the individual situation in each lab.

Disruptive technologies: additive manufactured optical coatings

The last presentation before the lunch break was about a completely new, unprecedented technology: “Going digital: How Additive Manufacturing (AM) will change the ophthalmic coating industry” by Jonathan Jaglom from the start-up flō.

The company is working on machines for labs that can be used to create e.g. photochromic coatings or colors using 3D printing, for example. This is intended to increase flexibility, as almost any design can be printed, because everything is controlled at pixel level. And, acccording to Jaglom, it is more sustainable as only the area that is actually needed can be printed.

Jaglom reported confidently that in the future, it should be possible to print as much of the lens as possible. He maintained: “We are very motivated to find a solution for AR coating and we have two directions how to get there.” However, Jaglom was not permitted to reveal any further details. The first three machines are due to be installed in US labs at the end of 2024.

During the break, the guests then gathered in the adjoining room for lunch and chat with others in a relaxed atmosphere.

MAFO 2-24 12 LIVE ON SITE

After lunch, the event continued with two sessions focusing on lens design and smart glasses – the latter discussed from two completely different aspects.

A myopia management design for every lab

José Miguel Cleva from IOT kicked off with an interesting talk on myopia management design that has also been corroborated by studies in the EU: “Revolutionizing Myopia Management – a novel approach to treating myopia in children”. The design is particularly exciting for labs, as there is no need to purchase semi-finished products.

After a brief introduction to the problem of myopia in general, Cleva explained the theoretical background to the Asymmetric Peripheral Defocus lens (MPDL) before going on to discuss the results of the study in Europe. The effectiveness of this lens for the treatment of myopia was investigated in the first randomized double-blind study conducted specifically in a European population. After a follow-up period of 12 months, the study showed a remarkable 39% reduction in axial length progression, which distinguishes this solution from conventional single-vision lenses.

The special free-form technology distributes the positive progressive lens power at the periphery. The free-form technology enables production using any material, so that no special semi-finished products are required.

Artificial Intelligence for spectacle lens design

The next lecture by Dr. Gaetano Volpe and Pasquale Fanelli from ProCrea Tech was also about lens design and how it can be improved with the aid of artificial intelligence: “AI and Neural Networks in Freeform Lens Design Software.”

After the experts had discussed the term “artificial intelligence”, and explained what neural networks and machine learning have to do with the topic, the second part of their talk dealt with the integration of AI into software for spectacle lens designs.

In short: It is possible to create an AI algorithm that, thanks to a neural network, guarantees the best performance of the progressive lens. The algorithm seeks to maximize output values (increasing customer satisfaction). And generative-type AI can also be applied to the development of progressive freeform surfaces. Research is leading to continuous development in this area, and the frontier is interesting as new relationships between variables could be discovered and further improve PALs.

Calculation: back to the roots

After this excursion into the future, the next presentation was more about going back to the roots. Because as great as the new technologies are, specialists still need to understand the basic principles that underpin the calculation of lens designs.

Mo Jalie from the University of Ulster, who has participated in MAFO –The Conference for decades, addressed the topic of “The Minimum Thickness of Spectacle Lenses.”

Step by step and accessible to everyone, Mo explained in his calm manner how to calculate the minimum thickness for a given prescription so that the thinnest and lightest lens for a given strength can be made in the appropriate material.

Electronic glasses with active optics

Unfortunately the penultimate speaker, Varsenik Nersesyan from Morrow, was unable to attend the conference in person as she was suffering from corona, so her presentation was transmitted via video link. Nonetheless, this did not dampen participants’ interest in her presentation, nor in the exciting topic itself: “Morrow Electronic glasses with active optics for vision correction.”

Her presentation was about electronic glasses that change their refractive power at the touch of a button, and can therefore be used for distance and/or reading correction. They correct sphere and cylinder and the possible addition value is 1dpt but the glasses are currently only available in Belgium. However, both availability and the amount of addition are expected to change in the future. The company would also like to collaborate with the industry and labs in the future because, as Varsenik Nersesyan made clear: “We don't want to sell our glasses in MediaMarkt, we want to sell them at opticians!” (MediaMarkt is a German multinational chain of stores selling consumer electronics). For more on this topic, see the detailed report about LCL lenses starting at page 28.

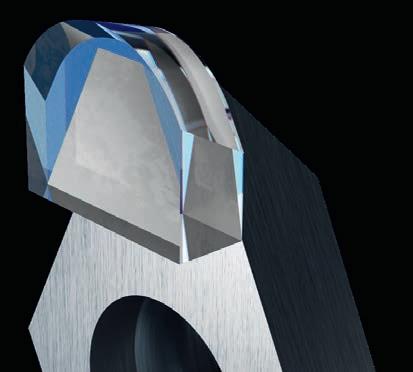

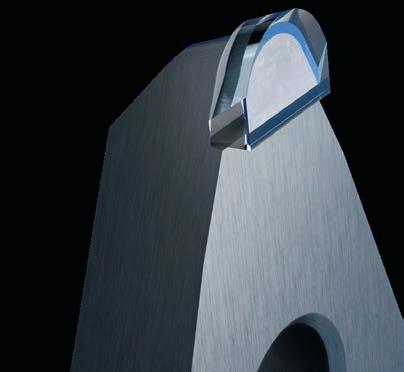

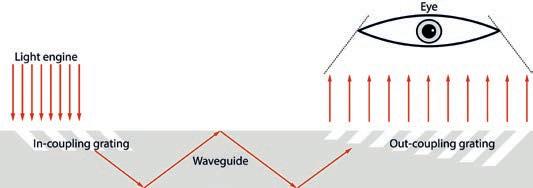

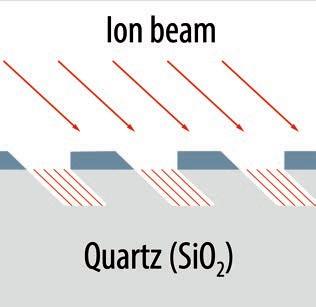

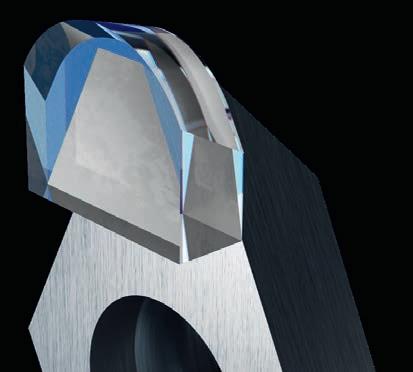

Smart glasses by laser cutting of high-index glass waveguides

In the final presentation, participants were able to immerse themselves in the world of AR glasses and learn about the challenges involved in their production. This presentation by Arved Kampe from 3D-Micromac brought the day to a very technical close. It was entitled: “Shaping the Future of Eyewear: How to create AR glasses by laser cutting of highindex glass waveguides.”

After an introduction to AR glasses in general – how they work and what components they require – the focus moved specifically to the processing of the waveguide combiner. In a joint project involving Schott and 3D-Micromac, the experts are working on a promising approach for scalable freeform glass cutting with high strength and precision, based on ultrashort-pulsed lasers. The experts perfected a laser-based separation process for achieving high and predictable bending strength in order to guarantee high production yields. This was then integrated into a modular machine concept, scalable from lab to mass production.

After being immersed in so much technology, new processes, innovations and much more input, the participants were finally given the chance to digest everything they had learned over a cocktail – or simply exchange ideas with other participants and speakers in a relaxed atmosphere –before heading back to the hotel in anticipation of their first day at Mido the next day.

The next MAFO – The Conference will be held on Friday, February 7, 2025, in Milan; as always one day before Mido.

Smart Technologies

MAFO 2-24 13 LIVE ON SITE

Mido 2024 - back in force

40,000 visitors in Milan

The Mido seems to be back. There were seven halls again and more than 40,000 visitors. Over 1200 exhibitors in seven pavilions and overall a great atmosphere. In fact, the world's largest optical trade fair was at its best this year and there were many innovations for the industry and labs. Read more about the most important machinery trends, designs and industry news in this report. By Hanna

Diewald

The terms trade fair and trade show are often used interchangeably. However, in the case of Mido, the term “show” clearly hits the spot, because this is about much more than just exhibiting products. At Mido, everything is art. Everything is creative. And everything is extraordinary. So it is easy to imagine that one extravagant frame followed the next among the frame newcomers. But also the machine area here always seems to be a little more exotic than that at comparable trade fairs. Anyway, it is one of the largest machine areas for ophthalmic optics in the world. The attraction of Mido is therefore assured.

After the event, the organizers proudly reported that there had been 11% more visitors than last year, with visitors coming from all over the world – from Asia to the United States and all over Europe. The figure of 40,000 visitors is impressive, even though Mido once hosted 59,500 visitors in pre-corona times. But, of course, as is so often the case, quantity does not always have much to do with quality. In addition, social channels reached 50% more people than last year and the media coverage is also worth mentioning: after all, 400 accredited journalists attended the show, publishing reports throughout the world. The Mido 2024 | Digital Edition, with nearly

Gunter Schneider from Schneider in front of the auto blocker CCU modulo ONE.

Laurence Vaudolon and Hajo Follert at the AGP booth.

Giovanni Spreafico from MEI System in front of the ClearXM.

MAFO 2-24 14 LIVE ON SITE

Picture:

MIDO

12,000 subscribers, saw an increase in showcase pages, up from 650 in 2023 to 845 this year, thus highlighting the extent to which exhibitors increasingly consider it advantageous to combine in-person participation with virtual activity.

As usual, the focus of interest for MAFO was Hall 6 and 4. This is where (almost) all the machine manufacturers, but also lens designers, software developers and many other companies associated with lens manufacturing are located; and all the major names are to be found here.

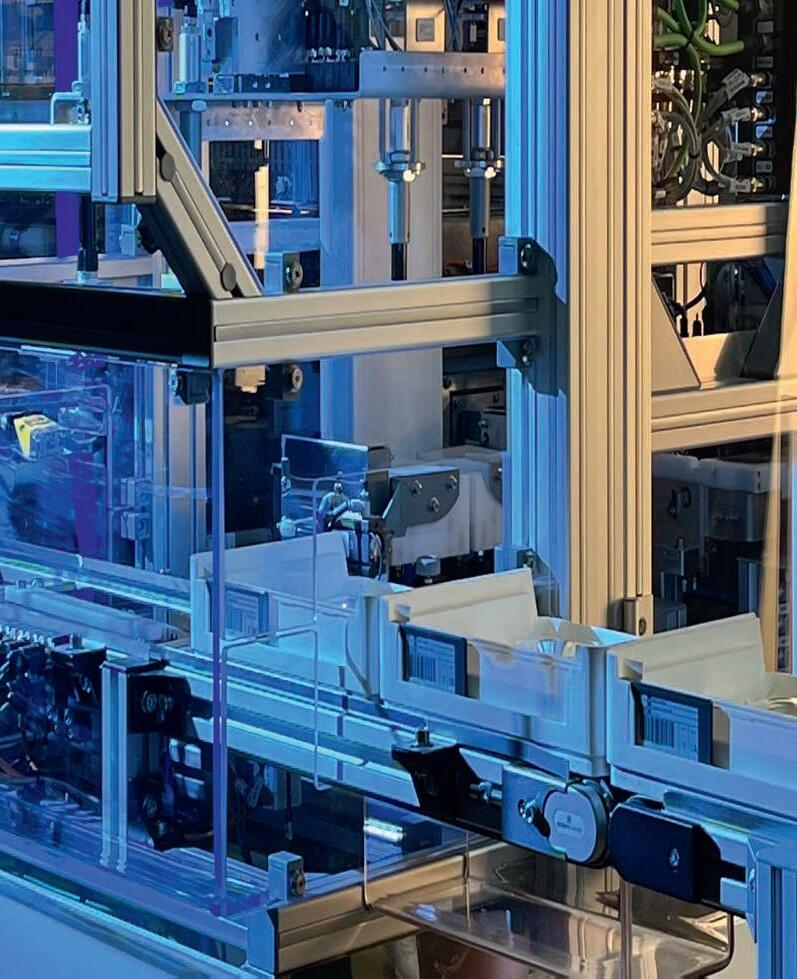

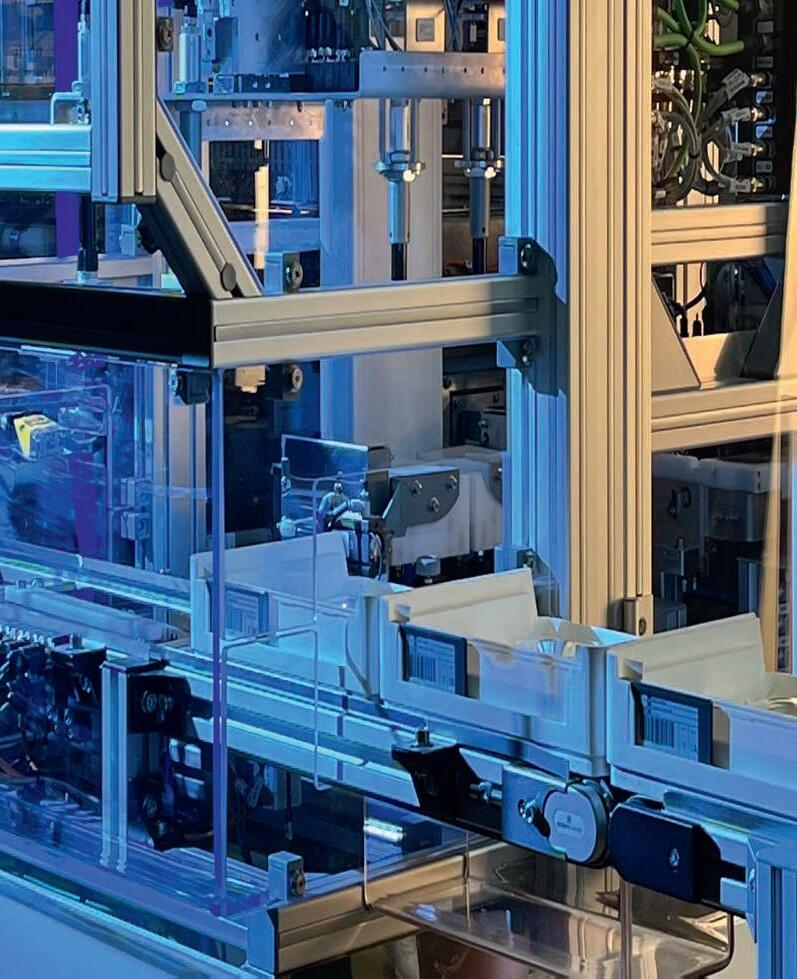

One trend in particular has recently become very apparent: the automation of every process step in the lab that was previously carried out manually. This applies to automatic cosmetic inspection, the automatic unpacking of blanks, automated storage options for blanks and the seamless integration of cleaning machines into the line without lenses having to be touched.

70th anniversary

This year, Cotec , the thin-film coating technology company, and machine manufacturer Coburn Technologies shared a joint stand; both are part of SCL. Coburn Technologies has a special anniversary this year: the company is celebrating its 70th birthday and it did so in style at Mido. Their stand was not only packed during the official celebration but also on the remaining days as well.

Among other innovations, the machine manufacturer presented the new Nexus DGT generator. The generator is characterized by faster

No lab functions without good software. Bernd Freyermuth and Andreas Schmitt from LensWare were happy to inform interested visitors about their offerings.

processing and higher throughput, auto calibration and on-board engraving of semi-visible marks. The Nexus DP digital lens polisher is designed for high-volume production of freeform Rx lenses and can process 80% of the product range using a single soft tool.

Also on display was the CrystalCrome, a photochromic spin coating system. A unique machine that enables the production of photochromic lenses on demand, rendering semi-finished photochromic blanks obsolete.

Automated cosmetic inspection and deboxing

Holding lenses up to the light in order to inspect them with eagle eyes and scanning them for even the smallest defect may become a thing of the past. At least a number of machine manufacturers are currently working on this.

One of Schneider's highlights was the CSI Module ONE, a machine for fully automated cosmetic inspection. The system uses AI-based pattern recognition. On first step a pattern is recorded with a camera. In step two, the system makes a cascaded defect-specific evaluation. In the final step, a lab-specific quality standard evaluation is carried out, based on specific quality criteria. This solution detects cosmetic defects fully automatically with absolute reliability. Also on show was the new deboxer DBX Modulo ONE, capable of unpacking any common kind of box – cardbox, blisters, even sleeves – in

F.l.t.r.: Alex Incera, César Collazo (SDC) and Carla Moncunill Cabré at the Coburn Technologies and Cotec booth.

Coburn Technologies celebrated their 70th anniversary.

Steffen Runkel and Johanna Vistbacka at the Bühler booth.

At Comes visitors could see a whole range of machines for the production of spectacle lenses.

MAFO 2-24 15 LIVE ON SITE

a highly efficient and eco-friendly way. Unpacking is done by levering open the box ‒ without the need for a laser, etc.

Visitors were also able to see a further step on the way to more automation in the LCU Modulo ONE. The fully automated in-line unit is now equipped with automatic ticket transfer. This means that job tickets can now be transferred fully automatically from the surfacing tray to the coating, without the need to transfer the tickets by hand. And, of course, many more machines were on display for visitors to inspect.

Rx-Bot-LUKE, a new brush cleaner and the latest generator

This time, the Satisloh Group stand brought together Satisloh, SCL International, DAC Vision and Ultra Optics , now all part of the Satisloh Group.

Visitors to the stand saw the Rx-Bot-LUKE, for example. The system, now on the market, unpacks semi-finished lenses. The robot takes the lens boxes, opens them, unpacks them and sorts them, putting the waste into separate bins and placing the lenses back into the job tray for further processing – all without human intervention.

Visitors could also inspect the new Hydra-Brush-4, a fully automated compact and water-efficient soft-brush cleaner for the fronts and backs of ophthalmic lenses as well as the new e-ticket system, which replaces paper tickets and therefore has the potential to make labs completely paper-free. The VFT-orbit-2i, the manufacturer's latest digital lens generator, is

now on the market and has already been successfully installed. It works with AI and machine learning for predictive maintenance. There was also a technology previous to be seen: ACI-Theia for automated cosmetic inspection. The machine, sealed against dust, is designed for automatic detection of defects and is expected to be able to process 300 lenses an hour.

Another technology previous was the NEO-edge, a next-generation industrial blockless edger for standard and complex shapes, characterized by extremely high processing speeds and unmatched versatility.

A strong partnership

At Bühler Leybold Optics visitors to the Mido were the first to learn about the new partnership between the coating experts Bühler and the cleaning experts FISA. Now customers can look forward to perfectly matched processes and an expansion of the Bühler product range in the future. In addition, Bühler is now offering the Boxer series in all sizes with more energy-efficient pumps.

Automated cleaning

Automation all along the line that is the focus at FISA . Here, visitors saw the fully automated ultrasonic cleaning machine FISA Inline CS, used for cleaning lenses after surfacing, polishing and deblocking. The machine is flexible and can meet all demands: tape, alloy or protective coating residues, all indexes and more. Two collaborative robots, in

François-Charles Laberge and Hugh McAllister from K&Y Diamonds.

The Ocuco booth attracted many visitors.

Jared Snow and Christian Tuss from Satisloh in front of NEO-edge.

The FISA-team at their booth f.l.t.r.: Matteo Rasi, Bernat Casaramona, Francesco Bertoja, Philippe Vaudeleau, Riccardo Strizzi

The company Ultra Optics presented their fully automated spin coating machine 54R.

François-Charles Laberge and Hugh McAllister from K&Y Diamonds.

The Ocuco booth attracted many visitors.

Jared Snow and Christian Tuss from Satisloh in front of NEO-edge.

The FISA-team at their booth f.l.t.r.: Matteo Rasi, Bernat Casaramona, Francesco Bertoja, Philippe Vaudeleau, Riccardo Strizzi

The company Ultra Optics presented their fully automated spin coating machine 54R.

MAFO 2-24 16 LIVE ON SITE

Many visitors at the OptoTech stand party.

the beginning and the end of the machine for loading and unloading, allow the integration in the production flow. The machine is Industry 4.0 ready, contains Wifi, Power Line Communication (PLC) via low voltage, ethernet remote connection, camera and sensors that measure all data in the baskets such as temperature etc. The machine is also equipped with a user-friendly MCU (Machine Controller Unit) with Open Platform Communications (OPC).

Brush cleaning and cosmetic inspection

MEI System proudly showcased a new technology that is expected to be available on the market as from next month. The ClearXM combines automatic edged lens brush cleaning and cosmetic lens inspection in one machine. The combination reduces the footprint, avoids contamination on the way to the next station and enables handling of both edged and uncut lenses. As the machine scans the contours, cleaning is particularly efficient and the cosmetic inspection is carried out on a completely clean lens.

Visitors were also able to see the final version of EasyBuddy, the robotic arm that feeds the EasyFit Trend lens edger. EasyBuddy can manage up to five trays at the entrance and five at the exit. It supports the option of adding an automatic stacker/ destacker system or connecting external conveyors, to further increase production autonomy. Orders can either be prepared via the LMS, an offline station or directly at the machine. And, of course, the blockless generator was also on display. The CoreTBA is a blockless freeform lens production system. For the first time ever, the blockless system allows laboratories to avoid the use of tapes, blocks, wax or alloy. Furthermore, the machine does not require a water filtration system thanks to its dry-cut technology. CoreTBA combines seven stages of the production process in a single device, e.g. digital generation, engraving, polishing and washing.

Lens inspection

At Automation & Robotics , visitors could see inspection equipment for a wide range of applications. From the ProMapper table-top inspection device to the AutoMapper for larger labo ratories, which performs automatic inspection for any type of lens, power measurement (ISO/ANSI compliant) and mapping inspection (error maps).

A particular highlight, however, was the presentation of the NeoMapper. A technology previous that is set to gain traction in the future, particularly thanks to its very small footprint and many interesting characteristics such as automatic inspection of every type of lens. This inspection feature includes precise and automatic positioning, inspection of geometric properties such as thickness, diameter, shape, optical power measurement, polarization axis measurement, power mapping of the entire

PHOTOCHROMIC SPIN COATING SYSTEM

• Best-in-class photochromic performance on all lens materials

• Fast darkening and fading speeds

• Compatible with anti-reflective and metalizing treatments

• Fast drying thermal cure

• Photochromic coatings suite from SDC Technologies

Advertisement

MAFO 2-24

INNOVATIVE NEW PRODUCT

1-800-COBURN-1 See our full line of products at coburntechnologies.com Vision Expo East Booth F2435

lens surface (error maps) and uploading of the measured data for preventive maintenance and troubleshooting.

AR-coating and cosmetic inspection

Machine manufacturer OptoTech also held a stand party at the Mido which proved very popular. The company presented its brand new OAC-90 AR-coating machine, which has a significantly reduced cycle time and a new ergonomic design. In addition, the pumping and cooling system ensures a lower cost per lens.

The manufacturer has also recently added the VISTA to its range, a machine for automated lens inspection that detects all known cosmetic defects with maximum precision and speed. Other machines that contribute to full automation in labs include the De-Boxer, a machine for automatically unpacking semi-finished blanks, as well as the IQ-Star intelligent storage and distribution solution which enables automated job tray handling.

Printing, new designs and much more

In addition to the many machine highlights, there was of course plenty else for visitors to discover: Innovative eyewear fashion, news from the lens manufacturers and much more. For example, Rodenstock is positioning ColorMatic as an independent technology brand with a specific brand design. This means that Rodenstock is now giving independent lab partners access to the ColorMatic technology and brand. IOT presented MyoLess, an optical solution designed to effectively address childhood myopia. Backed by advanced technology and a study conducted

on a European population, MyoLess offers a 39% reduction in axial length growth in children. Furthermore, IOT presented a comprehensive international campaign for Neochromes, its flagship line of photochromic lenses.

Horizons Optical showcased mimesys Office. For the first time, users can now craft their daily work environment to analyze gaze dynamics in their office setting. This application allows the creation of customized office lenses that not only address visual strategies but also study visual posture in front of screens.

TECO presented its new X-Cube DECO to print permanent logos on the lenses. The machine facilitates the printing of glossy, satin or matt multicolored logos, with impressive rendering and very good scratch resistance. The company is now proud to offer two printers for decoration: the X-Cube DECO to print permanent logos on lenses and the X-DTS DECO (Direct-To-Shape Robot) for permanent printing of logos on lenses and frames. Both models use fully ecological inks.

And EssilorLuxottica presented a preview of Nuance Audio, a product embedding hearing technology seamlessly into eyeglasses. It is expected to launch in the second half of 2024.

There were also many exciting specialist presentations and news announcements at Mido. For example, the new Sustainability CSE certificate and the Empowering Optical Women Leadership Program and much more to experience. The next Mido will take place in Milan from February 8 to 10, 2025. Thus, there will be just a few days between opti in Munich and Mido in Milan.

The General Optics booth in Hall 6.

Rupert Katritzky from the RAX Group in front of a storage solution for spectacle lenses.

F.l.t.r.: Thomas Zangerle, Sandra Fonticoli and Laurent Provost in front of the automated lens inspection NeoMapper.

At the teco-booth visitors could experience the new X-CUBE DECO to print permanent logos.

The General Optics booth in Hall 6.

Rupert Katritzky from the RAX Group in front of a storage solution for spectacle lenses.

F.l.t.r.: Thomas Zangerle, Sandra Fonticoli and Laurent Provost in front of the automated lens inspection NeoMapper.

At the teco-booth visitors could experience the new X-CUBE DECO to print permanent logos.

MAFO 2-24 18 LIVE ON SITE

The IOT team at its booth. F.l.t.r.: Jose Miguel Cleva, Alicia López, Ivan Sincek, Javier Trujillo, Carlos Muñoz and Eder Granado.

See the difference Discover how collaborating with us can revolutionize your operations. www.iotlenses.com Contact our Sales Team! New ground-breaking technologies and discover our groundbreaking portfolio of lens designs with a brand new suite of marketing materials. Visit us at Vision Expo East 2024 Stand F2625 Your lens design and innovation partner Try Neochromes, our latest photochromic lenses Embrace the light A completely new suite of marketing materials IOT Digital Ray-Path 2 Steady Plus Methodology Camber Technology Steady Methodology

A successful start to the new optical year

Opti in Munich 2024

For some it is an important order fair, for others a platform for personal contacts and customer communication vis-à-vis. It is also often referred to as the kick-off event right at the beginning of the new (optical) year. Whichever group you belong to: Opti 2024 in Munich (Germany) in mid-January once again attracted significantly more interested parties than in previous editions, and whetted the appetite for more. Why might that be? Let us take a look at it. By

Daniel Groß and Frank Sonnenberg

New Opti = new optical year. That is what we are used to in Europe. And so this January in Munich (Germany) it was once again a meeting with familiar faces, but also new, promising players from the world of ophthalmic optics. After all, a trade fair should also offer the opportunity to look beyond the horizon. And it succeeded. So much in advance. It was packed at the entrances right from the start and many exhibitors had plenty to do at their stands, especially during the core times on Saturday.

Strolling through the four well-attended exhibition halls, however, it was noticeable right from the start of the fair on the first day: people

are in the mood for trade fairs. A desire to see, touch and test. Over the course of the day and especially on Saturday, the day with the most visitors, business was already in full swing. This is exactly how we experienced the Opti this time, after somewhat quieter post-corona editions recently.

The „who is who“ of the industry

From the major frame suppliers to independent companies and hungry newcomers with new products and innovative processes, the trade fair covered the entire spectrum. Shopfitters, equipment and software manufacturers, ophthalmic lenses (trade fair comeback

MAFO 2-24 20 LIVE ON SITE

of industry giants Zeiss and Rodenstock in Hall C4), equipment suppliers, opticians' associations and contact lens companies etc. all came to Munich.

Only the machine manufacturers for industrial ophthalmic lens production were hardly represented – here only individual companies such as Schneider and MEI Systems held their own. However, the principle of „see and be seen“ seems to apply again to Opti.

This positive trend is also reflected in the number of visitors: 21,500 participants contributed to well-filled order books, new contacts and an optimistic mood at the start of the optical year. A veritable increase compared to last year's trade fair, which attracted 15,500 visitors.

The number of exhibitors also made a big leap from 307 exhibitors in 2023 to 390 exhibitors from 28 countries at this year's edition.

Information and food for thought

Several „hubs“ also contributed to a lively, informative trade fair this time. These are areas that bundle important questions and trends from a specific subject area in order to impart specialist knowledge and give the audience new impetus for their own work.

Located next to the “Innovation Area“, Selin Olmsted, for example, took the audience on her journey through the optical trends for 2025 (Trend Hub). Industry experts also provided new input in presentations and discussion rounds on myopia management and sustainability, and the topic of careers was not neglected either.

As part of the Career Hub, there was also a scavenger hunt (campaign initiated by Oculus: „On the trail of knowledge“), in which invited master students and students from universities and colleges of ophthalmic optics visited exhibitor stands and tested their specialist knowledge.

A campaign that attracted a large audience, „Lens in focus“, which used iris photography to draw attention to the topic of contact lenses, should also not go unmentioned here.

Meeting point: sustainability hub

What is happening in the optical industry when it comes to sustainability? Over the three days of the trade fair, visitors to the sustainability hub supported by FOCUS (MAFO's sister magazine) were able to see for themselves how industry representatives passionately discussed topics such as the recycling of demo lenses and contact lens blisters, the avoidance of microplastics and the sustainability responsibility of the industry and opticians.

Individual aspects were also explored in greater depth in presentations. One highlight was undoubtedly this year's Sustainability Award, which was presented for the first time at the Sustainability Hub for particularly sustainable ophthalmic optics companies.

Three finalists were selected from all the submissions, all of them medium-sized companies, who competed against each other in a pitch lasting several minutes for the prize money of € 5,000. They had to present their ideas on sustainability in the three key areas of economy, ecology and social issues. In the end, the winner was Andreas Schmidt from Augenblick Brillen Kontaktlinsen GmbH.

From the industry for the industry

Universities and aid organizations are also represented at Opti with their own areas. This is where members meet, make new contacts and bump into old friends and supporters.

The organizer himself explains how it was possible for key industry players to pull together and, compared to previous years, to put their own vanities aside, when he emphasizes that the discourse that took place in the run-up to the event was crucial to its success.

True to the „We are Opti“ motto. „The close cooperation and the development of a joint concept with all trade fair stakeholders over the course of last year was crucial to the success. It's great to see how the Opti community loves its trade fair and believes in it – it was the sense of community that made this success possible!“ said Cathleen Kabashi, Exhibition Director of Opti.

Whether the Opti would have found its way back on track without this new approach after the inconsistencies and challenges of recent years, which in all fairness were not just home-grown, is something we will not and need not know. And that is a good thing.

The next Opti will take place in Munich from January 31 to February 2, 2025. However, Mido in Milan is just one week later, which is likely to be a challenge for many exhibitors and trade fair organizers in the coming year. But perhaps the motto „competition stimulates business“ will also apply here - we will see in 2025.

MAFO 2-24 21 LIVE ON SITE

The Sustainability Award, which was presented for the first time at Opti 2024 and comes with prize money of € 5,000, attracted particular attention.

What labs need to be successful in the future

8 points that constitute the power-lab of the next decade

The economic trend in the ophthalmic industry is obvious: Due to demographic changes associated with rising demands and new markets, there is a continuing request for more. At the same time, labs are confronted with an immense cost pressure. Labs are trying to meet these demands for higher throughput and reduced costs per lens while striving for unique products. However, in the face of a shortage of people and rising costs, this is not easy. Labs’ spendings must be reasonable, and investments need to be future proof. But what constitutes a lab that will work for them in the future? Not just the implementation of automation and a continuous improvement of machines. A future lab requires smart solutions, artificial intelligence, and more. Simply put: a system that works for you. By

Sandra Stry and Kim Kathrin Leidig

Imagine a power-lab, built on intelligent systems, that makes smart decisions on its own – an integrated system with the intellectual power to work for you. What once was a vision, today sets the benchmark for an ophthalmic lab 4.0. Intelligent machines and integrated solutions solve many problems of the past, when lab managers and their teams still worked manually to keep the production running. Back then, all core elements like lab management systems and machines, production management and conveyor systems as well as quality inspection were not integrated. Missing communication and insufficient

integrated workflows made the whole production dependent on the expert’s constant action, observation and cutting out the errors. Supervising the whole production process was hard, troubleshooting often painful and time consuming. The overall processes: not as efficient as they could be. Needless to say, a lab manager’s workload was continually high, and it might have felt like always being behind, chasing the process. Fortunately, this has changed for the good. Integrated systems can now work for you and make the whole work shift easier to control. Once installed, a real future lab will streamline and simplify the lab managers’

Smart Technologies

MAFO 2-24 22 TECHNOLOGY

life, and completely change his or her role in the lab towards more strategic decision taking. By boosting productiveness and efficiency of the overarching process, economic aims will become achievable. This future lab exists. So, what does it take to make smart lab management happen and benefit from this new production era?

1. Working smarter:

Innovation for economic growth

The first key aspect of a power-lab (editor's note: power-lab is a brand name of the Schneider company) remains high-end machines: To lower the production costs of each job, increased investment utilization is important, as well as reduced labor costs.

High-end machines tackle this need and can be seen as a vital investment to remain competitive today and in the future. “We understand that only best in class machinery will equip labs for rising demands and cost pressure by ensuring high throughput of lenses per hour, while saving resources,” says Stephan Huttenhuis, Vice President Technology at Schneider. “If you look at generating for example, the newest solution in the market achieves up to 50 percent higher throughput than previous generations – at the same footprint.”

This is important since smallest footprint becomes a major requirement because space is highly limited in many locations. Another example for improvements are the latest cleaning solutions with radically reduced equipment size that save precious production space. Many labs today also opt for centralized swarf management to save space.

Another opportunity to look for is time savings: smart machines that are more integrated and cover several steps in one, or run steps in parallel, improve lab productivity by saving precious time. In the best case, functionality even reduces the number of machines – which again saves space and money. This is possible with highly versatile blockers that can switch block rings or edging machines that work with four processing stations at the same time.

Huttenhuis: “Our new generations of machines are always designed to meet the major market needs; with the investment our customers put in, they simply get more results – or save money.”

2. Holistic optimization: System wide

Knowing that every second counts, to date machines have always been optimized for speed. Faster. Faster. And once again faster. But can simply improving the machines by their speed and performance be enough progress?

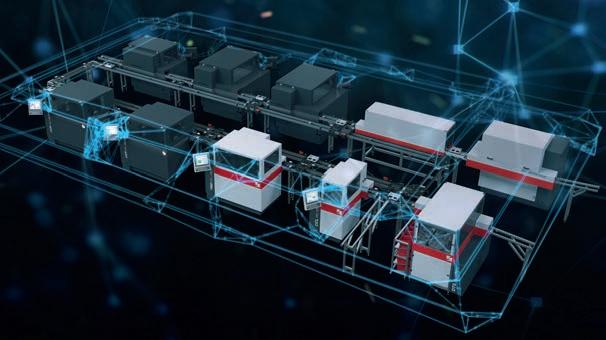

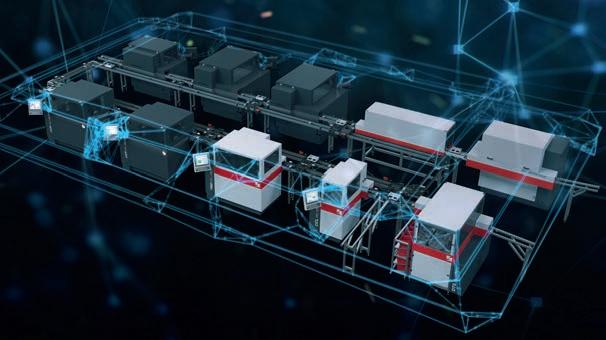

The company Schneider came to the crucial point that it requires more to cross the line of a new era; and instead of focusing on individual machines, they decided years ago to concentrate on more holistic and systematic approaches: Their vision is to create a fully-automated lab – hands free with intelligent solutions.

This strong vision has been realized with the Modulo system, which combines machines, measurement systems, accessories, and conveyors in one single, intelligently interlinked unit. The cognitive machines manage the production flow fully self-sufficient.

This avoids inefficiencies between machines or processes, e.g. jobs waiting to pass a production bottle neck, causing immense time delays and ultimately production losses. “We observed very often that in many labs the machines worked nicely, and the process was good, but not the overall workflow,” says Gunter Schneider, President at Schneider. “That’s where we saw great potential: Tackling those inefficiencies would definitely boost efficiency.”

One can say that this systematic approach was designed to leverage lab work to a new level, leading to an overall balanced workflow and workload. Today, it allows fluent processes e.g. from surfacing, to coating to edging.

New systems in the making will automate and integrate the coating process to streamline overall production. A potential alternative to batch coating, the current go to solution that causes a significant slowdown of the overall flow. “An integrated system accomplishes smoother production and makes the most of all resources and capacities. The highest machine utilization possible means taking full advantage of what you have got. Still, maximizing productivity isn’t everything, instead we want to offer solutions that really help the people who work with our system.” concludes Schneider.

Smart Technologies

Fig. 1: New technologies minimize non-productive times – e.g. HSE Modulo QS that is equipped with 4 work stations and performs multiple finishing steps simultaneously.

MAFO 2-24 23 TECHNOLOGY

Fig. 2: System wide instead of individual optimization is the key for dramatically increased throughput, machine utilization and cost per lens.

Smart Technologies

3. Built-in intelligence and communication

The most modern systems are now equipped with top-notch intelligence. This helps a lab manager to become less dependent on having the right people at the right time – one of the scarcest resources nowadays. This will be ensured through smart machines with cognitive features utilizing the Internet Of Things (IOT) including sensors and software, fluent communication between all core elements of the system and throughout all processes as well as efficient and transparent data analysis, reporting and visualization.

A smart machine knows its own condition at any time. Far beyond the current process, it knows all the details e.g. the status, consumable wear and lifetime, processing parameters etc. It knows every factor that might have an impact on product quality, consumption of resources and ultimately lab performance. It will constantly report and can be benchmarked against goals.

And most importantly, it will immediately provide information on critical aspects. This helps the lab manager to intervene as quickly as possible to tackle an occurring problem and prevent machine downtime. This way,

troubleshooting can be streamlined and taken care of much faster. Lowest harm for productivity equals lowest stress for the lab manager. Communication systems make sure that the overall workflow is clear and transparent at any time. Far beyond the processes within single machines, a smart system always knows what is happening. To do so, every machine checks their jobs “in” before the process starts and checks them “out” when it is finished. The overarching systems scan all this data and condenses it to become actionable information. It will process the data to support reasoned decision-making as it provides all relevant information at a glance. No more time-consuming walks around the production hall needed, just to check and see if things are running smoothly.

All smart components combined realize the great vision to build a smart organizing intelligent system, managing the production flow by itself, based on smart algorithms. This supersedes an old, rigid system; with operators telling machines what to do. The whole process changes from pre-planned job routing to condition based, in-situ routing. Saying that, now the system works out the best flow by itself – better than any single person could. The result: No more bits and pieces, but a comprehensive network of machines exchanging information.

4. Utter transparency facilitates better decision making

With all this data sourced, great new options come about. Future labs will want to make good use of this information giving rise to Management Execution Systems (MES), that provide lab managers with a transparency into their production as has never been seen before. An MES like the Schneider Modulo Control Center is a key tool to help lab managers to supervise and control the production in real-time and handle all tasks and priorities. It provides insights into the overall lab performance 24/7.

“In fact, it serves all the key positions in the lab – lab manager, quality manager, line driver and service manager – with relevant information,” says James Monaghan, Senior Director of Lab Operations at National Vision Inc. The MES seamlessly interacts with the intelligently interlinked machines, conveyors, and support systems to capture and analyze real-time data:

▶ Machine status

▶ Utilization factors like Overall Equipment Effectiveness (OEE)

▶ Quality/Breakage

▶ Tool lifetime

▶ Root cause analysis

• Error recognition

• Error prevention

▶ Statistical error analysis

▶ Routing options

With this, the lab manager will receive a new role in the lab ‒ a much more strategic one. He or she e.g. will be able to better determine when maintenance is due and how and when it is best carried out, decide about tools and lifetimes based on the operation results and assess

Fig. 3: Smart systems rely on built-in intelligence and communication to manage the production flow more efficiently than any pre-planned model..

Fig. 3: Smart systems rely on built-in intelligence and communication to manage the production flow more efficiently than any pre-planned model..

MAFO 2-24 24 TECHNOLOGY

Fig. 4: Lab managers have all the information they need at their fingertips to make smart and strategic decisions with a modern MES system that monitors and controls the lab.

whether it is possible to take the next order or not – whole production shifts and ranges can be planned more thoroughly. Lab managers can even handle priority orders for their customers without hesitation.

On the digital management cockpit, the lab manager can keep track of all data to understand the current lab performance, the throughput of different machines, and how well the capacities of the machines were being used.

The operator can see – in real-time and well-structured– if there were any interruptions or failures that need to be controlled, adjusted or fixed. Data sourcing and advanced analysis provide deeper insights and feedback.

5. Trouble shooting at the next level

Big data might be a buzzword that in some context overpromises advancement. However, the smart MES proves how data can really make a difference: Especially, the error recognition is a game changer for lab managers, compared to how annoying troubleshooting used to be in the past. “Before the smart system, this equaled the work of detectives: sequentially tending from one error to the following, digging deeper to find its origin,” says Monaghan: Whereas the MES tackles the underlying big error straightaway. This prevents aftereffects, production losses and time-consuming analysis.

6. Self-Sustaining

Monaghan concludes: “In a nutshell: It delivers the shortcut to immediately solving the problem at its roots, while the lab manager does not waste time on investigating and chasing one error after the other. Moreover, with trend recognition a MES system can initiate counteractive measures before a severe problem arises.”

Latest versions can even calculate the cost per lens – a valuable strategic advantage for the economic and financial management.

When it comes to the organization of tasks, priorities and maintenance, a smart lab will help to establish new agile structures and adds remote solutions – easing daily business. Helpful tools like a Computerized Maintenance Management System (CMMS), allows scheduling, the procurement of parts and personnel planning.

It provides a comprehensive picture of what needs to be done. It shares instruction manuals – video tutorials or PDF handbooks – or supports reactive maintenance to make sure that the user receives real time support from the supplier. In interactive sessions, any specific questions or issues can be handled. Downtimes are being prevented with this software.

Smart Technologies Advertisement

TECHNOLOGY SPECTACLE LENS TOOLING ky diamond.ca ULTRA PRECISION DIAMOND TOOLS FOR ANY GENERATOR EXCELLENT SERVICE QUICK TURNAROUND

Fig. 5: Advanced modules like the cost tracking in Schneider’s Control Center allow for real-time cost control and production value offering unprecedented insights into financial aspects.

Smart Technologies

7. Modular system for continuous evolvement

Just like the bricks and stones of a Lego system, the modular Modulo system can be arranged easily in different ways, building a unique future lab. There is a standard arrangement, but with the easy extension possibilities there are many possibilities and options that can be used to arrange the lab exactly to the individual needs. It is possible to install such a lab from zero or convert an existing lab. Important to mention that it is conceived to be a lab that stays relevant in a given structure and can „grow“ and become better.

“As a very elaborated standardized system, with easy to install modular options – that does not require widespread reconstructions – it is a highly flexible system that can be easily extended. A real high performing power-lab is never a static condition, it means continuously optimizing lab production for the future market, handling resources, and serving the demands of the market,” Schneider says.

New machines on the market, such as the automated deboxer or AI-based cosmetic inspection, can be added simply to the modular system. And if the lab-layout needs to change to meet higher production requirements, the modular loop allows rearrangement or the addition of the machines in any order.

Schneider summarizes: “Modulo can show its full potential as an integrated system – still, the machines also work individually. We wanted

labs to have the option to switch step by step, or let their dream-lab rise over time, following a systematic approach.“

8. No future without sustainability

There is no denying – when it comes to climate protection things have to change. Economic enterprises have huge potential to help form these changings. As in any other producing sector, an ophthalmic power-lab has to reflect this need to save resources.

Modern state-of-the-art machinery can build the foundation for this value: Schneider shows efforts e.g. with innovative lens protection, where a small amount of UV-cured lacquer film protects the lens instead of conventional tapes and thus eliminates a high amount of plastic waste. Also, the deboxer that supports recycling of lens boxes by separating waste materials.

More holistically, the implementation of a smart lab dramatically reduces breakage thanks to early error recognition. By preventing breakage, resources for reproduction can be saved completely. In addition to waste reduction, also power consumption and resources such as water in the washers are being minimized with every new generation of machines.

A real power-lab continuously works towards that goal to have clean and resource saving production and low waste – for our future on this planet.

Fig. 6: A future-proof lab will increasingly rely on artificial intelligence solutions, e.g. fully-automated cosmetic inspection systems that reliable detect defects and assess overall quality.

Fig. 7: A high level of integration and smart communication is key to a holistic perspective that may boost overall lab performance and factors in every element of a lab’s daily business.

MAFO 2-24 26 TECHNOLOGY

The conclusion of a power-lab

Many words to say what a future lab is since it has many faces. Most importantly, it is a smart and complex system that facilitates operating cycles and creates seamless workflows to improve lab work and serves the operators. An average lab can be run by one lab manager, who has highest control over resource management, lab productivity and thus the lab’s profitability.

A power-lab allows high productivity and reduces complexity where needed. Fewer steps cause fewer errors, therefore creating machines, processes, and

Sandra Stry holds a PhD study of physics from Heinrich-Heine Universität, Düsseldorf, Germany. She started her career as project engineer at her alma mater and worked as head of R&D at Sacher Lasertechnik, n-Sigma Microsystems and PHIcom before joining Schneider in 2011 as senior project manager. Since 2019 she is the head of project management at Schneider.

communication as simple as possible evens the path for great achievements. No unneeded waste of energy – neither the energy of people who work there nor unnecessary energy of the machines in operation. Digitization and remote services leverage lab management to a modern era with fast ability to react on new parameters and circumstances. This changes labs in many more aspects than just higher cost-effectiveness. Lab managers can follow their own strategic vision to lead their lab to economic growth. The results: improved working conditions, best products, highest competitive advantages. ◆

Kim Leidig has a master’s degree in literature & media studies. As professional multimedia storyteller in a content marketing agency, she made scientifical subjects more tangible for the public. As project manager and marketing consultant, she helped her customers in developing unique strategies. In 2023, she joined Schneider as marketing specialist and journalist.

Smart Technologies

Kim Kathrin Leidig

Sandra Stry

TECHNOLOGY Advertisement 704 & 705 SILICONE DIFFUSION PUMP FLUIDS 617-227-1133 • 800-743-17 paula@filtech.com www.filtech.com SCAN FOR OUR FULL CATALOG QUAL SAVINGS FROM STOCK QUAL SAVINGS FROM STOCK QUALITY& SAVINGS FROM STOCK IONIZATION, THERMOCOUPLE & INSTRUTECH CONVECTION GAUGES INFICON RATE/THICKNESS CONTROLLERS & MONITORS

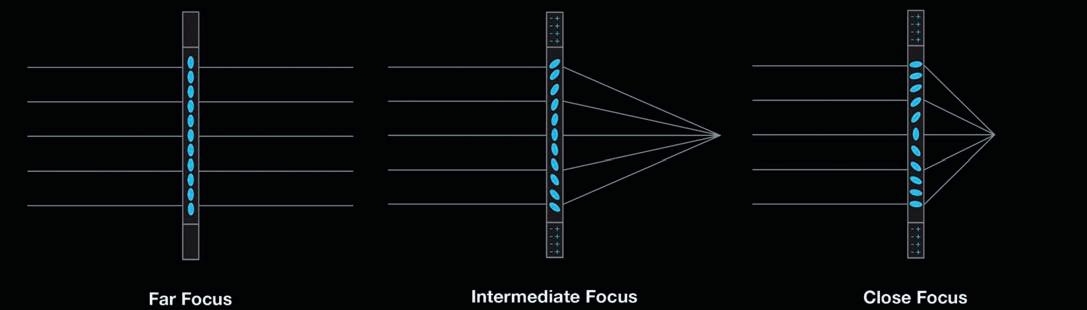

Adaptive smart glasses for future?

The innovation of liquid crystal technologies in spectacle lenses

When your arm gets longer and longer after the age of 40 and the words in the newspaper seem to get smaller with every issue, it is time to take a look at the natural ageing process of the eye. With advancing age, changes in vision occur, particularly in the near vision range. Presbyopia affects everyone at some point and experts believe that more than one billion people worldwide have presbyopia and that the number will continue to rise in the future. Ground-breaking progress has been made in recent years, particularly in the field of spectacle lenses with liquid crystal lenses. The term smart glasses can be used for adaptive optics as well as for microcomputers integrated into spectacle frames, which can be used to communicate, take pictures or even navigate. This article, gives a brief insight into the developments of adaptive optics, the corresponding structure of liquid crystal lenses and the resulting benefits in practice. By Lena Petzold

Presbyopia

But first the basics ‒ what is presbyopia? Presbyopia is a progressive loss of near vision. It is caused by the lens of the eye, which is part of the optical apparatus. Usually, the lens can change its curvature and its refractive power due to its own elasticity, so that objects can be recognized sharply both at a distance and close up.

Over the years, however, the natural ageing process of the eyes continues. In this context, the flexibility of the lens is reduced, and it becomes more rigid, which in turn leads to a reduced ability to accommodate. Once this happens, a visual aid is required. However, there are various types.

Options of visual aids

Contact lenses are one option for correction. In addition to single vision and multifocal variants, these are also available as monovision so that

objects can be recognized both close-up and in the intermediate range as well as at a distance. According to the latest findings, an alternative option is orthokeratology lenses, which can create a multifocal effect of the cornea when worn at night.

Another group is (refractive) surgery, which includes intraocular lenses, intracorneal rings or laser surgery. The disadvantage is that precise centering is necessary during the operation, as the changes to the cornea are irreversible.

With the aim of reducing the disadvantages of previous correction options, research is currently being carried out into drug therapy for presbyopia using various eye drops.

But by far the best-known correction option for presbyopia are reading glasses, which are available on the market in single vision, multifocal and progressive versions. The disadvantages of these spectacles are reduced visual acuity in the intermediate and very near ranges. In

Smart Technologies MAFO 2-24 28 TECHNOLOGY

addition, very precise centering of the spectacles in relation to the optical axis of the eye is necessary. Progressive lenses in particular can lead to a severe limitation of the field of vision, while this can occur with reading glasses due to the spectacle frame.

In this context, various companies are researching the development of liquid crystal lenses in order to minimize or eliminate the disadvantages through innovative lens designs. At least two companies already have such glasses on the market and others are working on them.

History of liquid crystal lenses

The liquid crystal was first described in 1888 by the Austrian botanist Friedrich Reinitzer. He observed that cholesterol benzonate melted at a heat of 145.5 °C (≈ 294 °F), but in a cloudy composition. If the temperature was increased by 30°C (≈ 86 °F), its appearance changed abruptly to a clear melt. He thus recognized that the cholesterol benzonate molecules in the cloudy phase had a certain arrangement that was responsible for the light-scattering properties.

100 years later, C. W. Fowler and E. S. Pateras reported on the use of liquid crystals in spectacle lenses to change the refractive power of the corrective lens. Liquid crystals have undergone remarkable development, particularly in recent years, for example in the (smartphone) camera and spectacle glass industries.

In the early 2000s, a team led by American scientist Tom Krupenkin developed one of the first liquid lenses. Internationally, these are known as liquid crystal lenses (LCL). Liquid crystals represent the mesophase of a material in which the properties of both liquids and solids (crystals) are at work. For this reason, the state of order of these substances is often referred to as a fourth state of aggregation.

Beginning in 2009, the company PixelOptics became well-known in the industry as many trade journals reported on it. In 2011 the company launched the product emPower! ‒ the first electronic focusing prescription eyewear. The patented technology was developed by PixelOptics and Panasonic Healthcare. However, the company filed for bankruptcy in 2013 and the patents were later bought up by Mitsui Chemicals [1]