Data is the gold of the digital age. Everyone has probably heard this sentence before, but very few people act on it. Or would you simply leave gold coins or other valuables lying around in the open? Probably not.

But that is exactly what a lot of people do with sensitive data. Largely unprotected, they lie around openly ready to be pirated by hackers. The figures are alarming.

The number of cyber attacks and their frequency has increased continually in recent years. Cyber attacks can potentially cause companies a huge amount of trouble, even threaten their very existence.

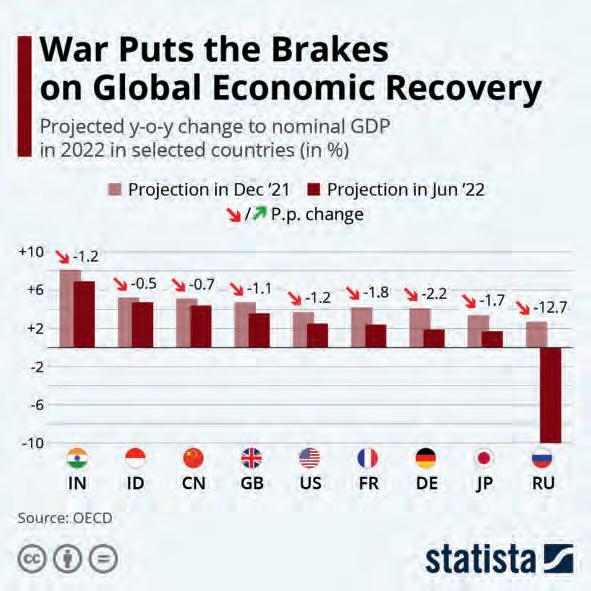

According to IT security company Drive Lock, the costs are enormous: "Worldwide, the costs caused by cyber crime are growing. If cyber crime was measured in terms of gross domestic product (GDP), it would be the third-largest economy in the world after the USA and China."

Despite this, the risk of attack can be con siderably reduced relatively easily, for ex ample by implementing basic cyber hygiene measures (for the full article, see page 30).

Leaving aside the risk of attack, the potential of information technology is completely underestimated in the eyes of many experts.

For example, Dr. Bernd Freyermuth, founder of LensWare, believes that IT in the lab is a decisive factor for the success of a company – and yet it is hardly ever talked about.

This is in stark contrast to new products, an innovative R&D department and the like, which are naturally perceived by outsiders as indicators of a company's potential.

But IT is no less important. This is particu larly true in the case of optical labs, compared to other industries, as the one-off production of individual spectacle lenses is an even greater challenge for IT. Thus, according to Freyermuth, more attention should be paid to digitization in the lab – after all, it is fundamental to the success of a company. (The full interview can be found starting on page 20).

In addition to the exciting focus topics, this issue also includes a very topical article by Prof. Mo Jalie about the increasing indi vidualization of spectacle lenses and the limits to this: “What do we mean by a 'perfect lens', and can we produce it?”

And in part 1 of the article “Blue light – facts and trends”, by author Fritz Passmann, you will learn everything you need to know about blue light. Enjoy reading this issue!

The Vision Council announced the publication of version 3.13 of the Data Communications Standard. The standard, which is used by manufacturers of optical lab equipment and producers of software used in optical labs, was developed by The Vision Council’s Lens Processing & Technology (LPT) Division, super sedes all prior versions and contains updates that are needed to stay current with changing technology. Many of the updates to the standard have been under revision for the past three years by a group of volunteer experts. Questions regarding the updated standard should

be directed to Michael Vitale, Vice President, Membership & Technical Affairs, at mvitale@thevisioncouncil.org.

The Rodenstock Group announced an agreement to acquire Indo Optical, one of the leading Spanish manufacturers of corrective lenses. With this acquisition, Rodenstock continues with its strategic ambition to gain market share and further accelerates its regional expansion. The transaction is expected to be completed in Q3 2022 and is subject to approval by the usual anti-trust authorities. Financial details of the transaction will not be disclosed. Indo Optical is a market leader in the manufacturing of ophthalmic lenses as well as the commercialization of diagnostic equipment and optical instru ments for opticians and ophthalmologists. Founded in 1937, Indo Optical is present with 440 employees in Spain, Portugal, Morocco, and France today, with two main manufacturing sites in Barcelona and Tangier. The company has a strong reputation in building and maintaining relationships with independ ent opticians, holding the third largest value share in Spain, and leading the market in Morocco. While Indo Optical’s markets in Spain and Portugal are expected

to grow in line with the broader European market, the Moroccan market is forecasted to grow with 10% CAGR between 2022 and 2027 and could become a significant revenue contributor in the future.

Anders Hedegaard, CEO Rodenstock, said: “The acquisition of Indo Optical is an important step for our strategic ambition to increase Rodenstock’s global footprint and to drive the transformation of our industry. Indo Optical’s product offering is an ideal fit to our new brand architecture and will allow us to lift synergies for the benefit of our customers.”

In order to continue to successfully align the company’s development and, in particular, to accelerate the transformation of the Zeiss Group’s digital infrastructure, the supervisory board of Carl Zeiss AG has resolved to expand the executive board to include the function of Chief Transformation Officer (CTO), and to appoint Susan-Stefanie Breitkopf to this position on the executive board effective 1 July 2022. She has been Head of Corporate Human Resources at the Zeiss Group since 2021. There will be an other change on the executive board of Carl Zeiss AG be cause Dr. Matthias Metz, the executive board member re sponsible for the Zeiss con sumer markets segment, will switch to BSH Hausgeräte GmbH, Munich. The supervisory board of Carl Zeiss AG has appointed Sven Hermann as Dr. Matthias Metz’s successor and new member of the executive board effective 1 July 2022. Hermann is currently Chief Sales & Marketing Officer at the Zeiss Vision Care strategic business unit. As of 1 July 2022, the executive board of Carl Zeiss AG will thus consist of the President and CEO, Dr. Karl Lamprecht, Chief Financial Officer (CFO), Dr. Christian Müller, and Chief Transformation Officer (CTO), Susan-Stefanie Breitkopf ‒ as well as the Head of the Zeiss Consumer Markets segment, Sven Hermann, the Head of the Zeiss Industrial Quality & Research segment, Dr. Jochen Peter, the Head of the Zeiss Medical Technology segment, Dr. Markus Weber, and the Head of the Zeiss Semiconductor Manufacturing Technology segment, Andreas Pecher.

Data breach costs rose from USD 3.86 million to USD

Of the countries sur veyed by Statista for the Global Consumer Survey, Russia stood out the most. There, with extensive international sanctions hitting the economy hard due to the invasion of Ukraine, a majority of

million in 2021, the highest average total cost in the 17-year history of the Cost of a Data Breach Report, featuring research by the Ponemon Institute.

of the adults surveyed said they are worried about their finan cial future.

According to the German industry association Spec taris, German manufacturers of ophthalmic optics and consumer optics were able to recover from the negative effects of the corona pandemic in 2021. Overall, sales in 2021 increased by 11.4 percent to

billion euros compared to 2020.

Advertisement

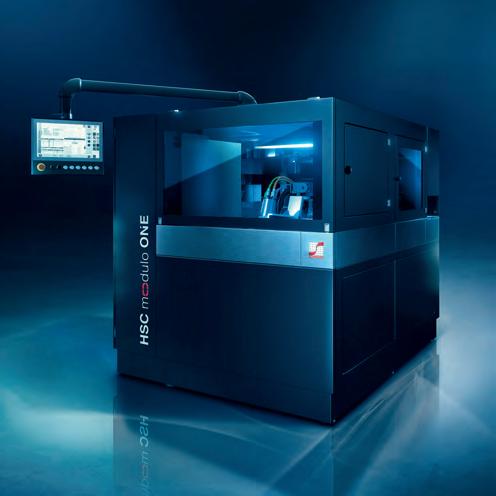

SCHNEIDER’s new one-of-a-kind generator excels on every level and forms the very heart of the Power Lab of the Next Decade – Modulo ONE. With an added performance of more than 50%, HSC Modulo ONE is not just a little bit better but a revolution. It is built on a brand new kinematic concept facilitating even faster process times. The high-performance generator relies on the proven two-motor concept featuring the most powerful XS-Tec motor for maximum dynamics and highest quality. The proven RS-Tec motor is known for its high robustness and provides added versatility. A new ultra-fast workpiece changer transfers the lenses and facilitates shortest chip to chip times. The result is insane generating speed and performance at the same great lens quality you know from SCHNEIDER generators. www.schneider-om.com

IOT: innovation and knowledge everywhere IOT recently presented their latest designs and technologies with attendees at Vision Expo East, MIDO, and Expo Optica Brasil. IOT scientists presented new scientific research at ARVO and EAOO congresses. The two years of near isolation caused by the COVID-19 pandemic prompted many companies around the world to analyze their current businesses and prepare for new opportunities in a post COVID world. IOT, a company dedicated to the research and development of ophthalmic lenses, decided at the end of 2021 to approach the next chapter of its history with renewed strength and enthusiasm. This new commitment by IOT was evident in their expanded presence at Vision Expo East, MIDO, and Expo Optica Brasil. These fairs, held in the USA, Italy, and Brazil, proved to be a great opportunity for IOT to showcase its new corporate image and identity, new technologies and services, and a completely new portfolio of free-form digital lens designs. Visit www.iot.es

What is and what is not possible in designing best form lenses.

There are four main aberrations which affect spectacle lens wearers. For two of them, designers have no simple method of control by modifying the surfaces of the lens, transverse chromatism and distortion –no matter what lens manufacturers promise in their marketing texts. So, what is and what is not possible in designing best form lenses? By Mo Jalie

Marketing literature from lens manufacturers has many statements concerning the optical performance of their finished lenses;

▶

“Sharper vision in a thinner flatter lens.”

▶

“As every pixel on the lens surface has its own calculation value, each prescription can be uniquely cut into the lens. The result, you can provide your patients with pixel-perfect precision and outstanding visual performance.”

▶ “These lenses are fitted to the particular wearer and are optimized for good vision, even in the periphery of the lens.”

▶ “Superior optics with aspheric lenses.

With conventional lens designs, some distortion is created when you look away from the centre of the lens — whether your gaze is directed to the left or right, above or below. Aspheric lens designs, on the other hand, reduce or eliminate this distortion, creating a wider field of view and better peripheral vision. This wider zone of clear imaging is why expensive camera lenses have aspheric designs.”

The first is clearly related to the difference in weight and thickness of aspheric lenses used for moderate to high power lenses but it speaks to the unenlightened of an improvement in vision.

The second actually tells us nothing! We could have made that statement 100 years ago, long before the advent of freeform technology, since a best-form lens with spherical surfaces has different z-heights across each

surface and we can say that “each pixel on the lens surface has its own calculation” and a best-form spherical lens provides “outstanding visual performance” compared with the flat-form lenses of yesteryear.

The third tells us that if you tell the lens designer what the actual fitting parameters are for the lenses, vertex distance, form of trial lens, pantoscopic and wrap angles, the lens can be individually calculated with the optimum values taken into account in the design software. But this has been possible to do in real time since the 1960s with the arrival of computers. The fourth is both misleading and incorrect, the person who made the statement clearly doesn`t understand the principles of aspheric lenses. Let me put these statements into full perspective by considering the main aberrations which affect spectacle lens wearers, of which there are four: Transverse chromatic aberration – referred to as “lateral color” in the United States.

Oblique astigmatism, curvature of field often described as “power error” and distortion.

I will first look at the two aberrations over which the designer has no simple method of control by modifying the surfaces of the lens, transverse chromatism and distortion.

When a narrow pencil of light passes through the optical center of a lens it suffers no refraction and no deviation (Fig. 1(a)). When the eye rotates behind the lens to view through extra-axial points it encounters an ever-increasing amount of prismatic effect. At any given point, it is as though the light was passing through a prism of power, P, prism diopters and if viewing a small white object this will be imaged as a continuous spectrum with, for the base up prism shown in the figure, red which is deviated least, at the top of the image and blue at the bottom. A large white object would appear fringed with red/yellow at the top and blue/violet at the bottom (Fig. 1(b)).

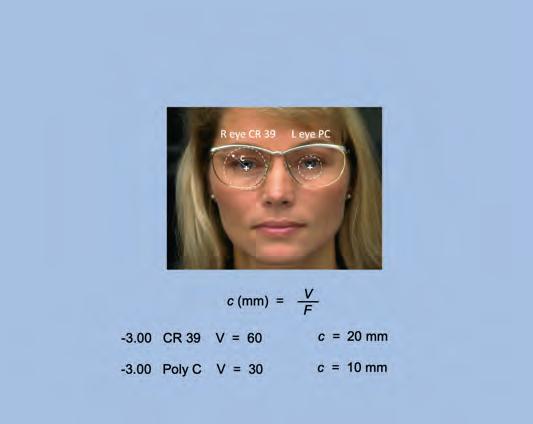

The transverse chromatic aberration, TCA, is easily shown to be equal to the prismatic effect, P, divided by the Abbe number, V.

Now the prismatic effect at the point, P, is given by Prentice’s rule, P = cF, where c is the distance of the visual point from the optical axis and F is the power of the lens. So we can write,

The threshold value for the human eye is considered to be 0.1∆ which leads to the simple result that the radius of the zone centered on the optical center of the lens, expressed in mm, is the Abbe number divided by the power of the lens (Fig. 2).

The significance of this rule is shown in figure 2. With a -3.00 D lens made in CR 39 material (R eye), whose Abbe number is about 60, the eye can roam 60 divided by 3, or, 20 mm from the optical center of the lens before the threshold value of 0.1∆ of transverse chromatism is reached. Within this zone, the effects of chromatism are unlikely to be noticed. If the lens was made in polycarbonate, however, whose Abbe number is 30 (L eye), the zone for a -3.00 D lens would have a radius of just 10 mm and TCA might be troublesome for this spectacle wearer.

All the designer can do is recommend a material that has as high an Abbe number as is possible!

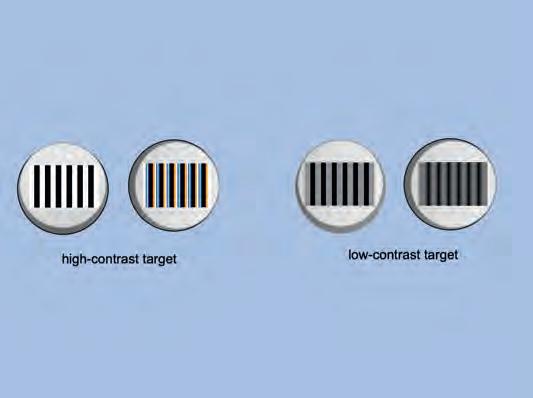

The effect of chromatic aberration is shown in figure 3. Under conditions of high contrast, along the base-apex direction, colored fringes are seen on the white parts of the target. Under conditions of low contrast the target becomes blurred, the effect often referred to as “off-axis blur”.

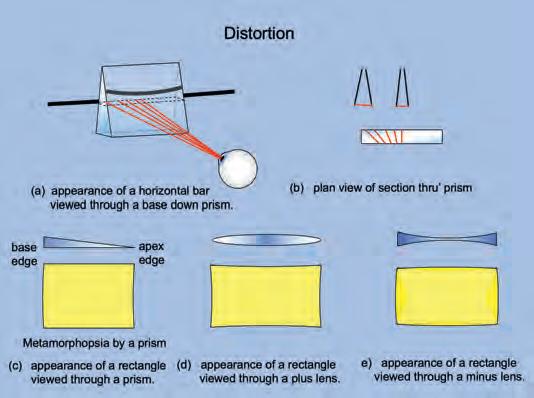

Fig. 1: Transverse chromatic aberration (US lateral color). Fig. 2: Zones for -3.00 D lens in which TCA does not exceed 0.1∆.The second aberration over which the spectacle lens designer has no real control is distortion which, again, is due to an ever-increasing prismatic effect being encountered as the eye rotates away from the optical center of the lens. For example, a horizontal bar viewed through a base down prism appears curved as shown in figure 4(a). The reason for this is immediately understood by considering the ever-increasing path length travelled by the light as it passes through the prism and the apical angle which the path appears to subtend at the apex of the prism (Fig. 4(b)). The path length is seen to increase as the ray passes more and more obliquely through the prism, the effective apical angle of the prism increasing also. The effect obtained when viewing a rectangular object through a prism is shown in figure 4(c). It is known as metamorphopsia produced by the prism. In the case of a plus spherical lens, the base of all prismatic effects lies at the optical center, so that a rectangular object will take on the characteristic pincushion shape exhibited by plus lenses (Fig. 4(d)) and in the case of a minus lens where the base direction of the prismatic

effect lies towards the edge, the metamorphopsia takes on the appearance shown in figure 4(e).

Under normal circumstances distortion is compensated for by the plasticity of the visual system and its reduction or correction by the necessarily steep bending of a spectacle lens is not attempted.

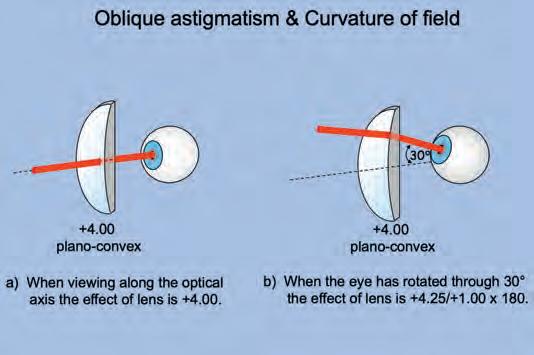

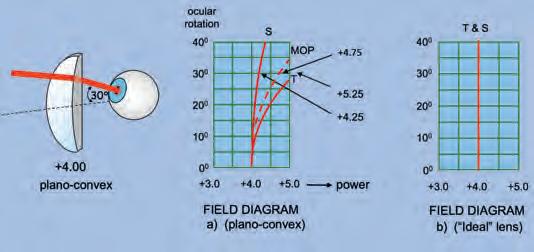

When we say a lens has a power of +4.00 D, what is meant is that the back vertex power of the lens, achieved when the eye looks along the optical axis, is +4.00 D (Fig. 5(a)). When the eye rotates to view through extra-axial points, that is points away from the optical centre, the effect of the lens changes, depending upon the form in which the lens has been made. For a plano-convex form, when the eye has rotated through 30° to view through a point some 15 mm from the optical centre, the effect of the lens has become +4.25 / +1.00 x 180, the axis direction assumes that the eye has rotated along the vertical meridian of the lens (Fig. 5(b)). These off-axis powers are determined from suitable lens design software and the results often plotted in the form

Fig. 3: Effects of Transverse chromatic aberration on high and low contrast targets. Fig. 4: Effects of distortion on square objects.

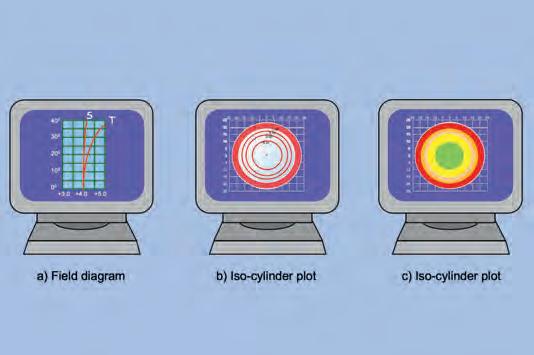

Fig. 6: Field diagram and corresponding contour plots.

Fig. 5: a) Back vertex power. b) Aberrational astigmatism and power error for a 30° rotation of the eye.

Fig. 3: Effects of Transverse chromatic aberration on high and low contrast targets. Fig. 4: Effects of distortion on square objects.

Fig. 6: Field diagram and corresponding contour plots.

Fig. 5: a) Back vertex power. b) Aberrational astigmatism and power error for a 30° rotation of the eye.

Oblique astigmatism & curvature of field

of a field diagram which shows the variation in the tangential and sagittal powers of the lens as the eye rotates away from the optical center of the lens (Fig. 6(a)).

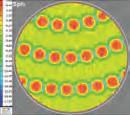

The results might also be displayed in the form of a contour plot which shows how the oblique astigmatism, or the power error, varies for different zones of a spherical lens (Fig. 6(b)). These plots are usually provided in the case of progressive power lenses! The distribution of powers might also be shown using color codes, the colors shown in figure 6(c) representing those recommended by the Vision Council of America and reproduced in the ANSI document

Z80.28-2004 “Methods for reporting Optical Aberrations of the Eyes”.

Instead of plotting the rotation of the eye in degrees, the zones could be indicated by how far the eye has rotated away from the optical center as has been done in figures 6(b) and 6(c). Notice the rule that the rotation expressed as a distance is about half that when expressed in degrees. The distance between the tangential and sagittal powers for any zone rep resents the oblique astigmatism, here at 30° (Fig. 7(a)), it is seen to be +1.00 D, and the mean oblique power which represents the position of the disc of least confusion in the astigmatic pencil with respect to the retina is midway between the tangential and sagittal powers, here +4.75 D.

The power error, correctly called the mean oblique error, is the difference between the mean oblique power and the back vertex power, which here amounts to +0.75 D.

If the lens could be made free from both oblique astigmatism and power error the field diagram for a +4.00 D lens would appear as shown in figure 7(b). Unfortunately, this is impossible to achieve, whether either spherical or aspherical surfaces are employed, or freeform manufacturing methods are used to produce the lens. However, we can choose to eliminate either the oblique astigmatism or the power error, leaving a small residual amount of the other aberration.

We might choose to eliminate the oblique astigmatism as was chosen by Zeiss at the beginning of the 20 th century with their classic Punktal series of lenses (Fig. 8(a)). It can be seen that the tangential and sagittal powers are the same but there is a residual power error of almost half-a-diopter at 40° from the optical center of the lens. Notice the steep +9.50 D base curve required for this design when spherical surfaces are employed.

Or, one might choose to eliminate the power error as shown in figure 8(b), placing the disc of least confusion on the retina, and leaving a small amount of oblique astigmatism (about a-quarter diopter), at the

Fig. 7: Field diagram for plano-convex and “Ideal” forms for a +4.00 D lens. Fig. 8: Field diagrams for three typical best form lens designs for a +4.00 D lens.

Fig. 7: Field diagram for plano-convex and “Ideal” forms for a +4.00 D lens. Fig. 8: Field diagrams for three typical best form lens designs for a +4.00 D lens.

edge of the field. Note that this form is nearly 2.00 diopters shallower that the point focal form, making the lens easier to produce and handle compared with the steeper point focal form. This flattening of the lens form was considered to be a huge advantage early in the 20 th century as lens sizes gradually increased from those in use in earlier years. The modern concept is to place the tangential image on the retina, with the so-called minimum tangential error form. The result is shown in figure 8(c) where both the oblique astigmatism and the power error are now each less than 0.25 diopters. However, they are not equal to zero, so even this design is not perfect and point-by-point correction across the whole lens cannot really be claimed.

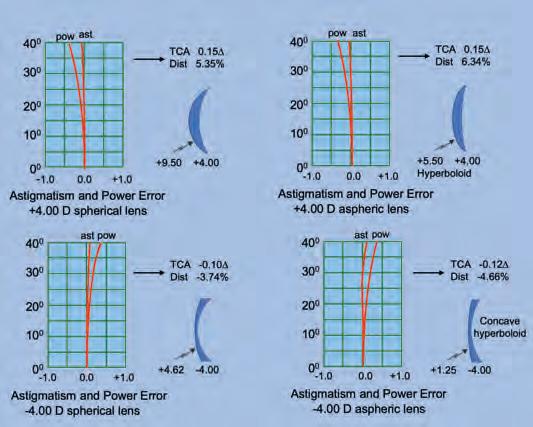

Relating the analysis to the +4.00 D lens, if it is made using spherical surfaces in point focal form it requires a +9.50 base curve and is quite steeply curved. If the form is flattened to a +5.50 D base curve, retaining spherical surfaces, the lens now suffers from large amounts of both oblique astigmatism and power error, albeit, is thinner in this flatter form. If the convex spherical surface is then replaced by an aspherical surface of the correct eccentricity, it restores the off-axis performance to that of the spherical lens. However, the use of an aspherical surface does not provide sharper vision than the spherical lens. Comparing the aberrational data at 35°, the TCA is the same, the distortion is slightly greater, and the oblique astigmatism and power error are virtually the same (Fig. 10).

Another way of expressing the aberrations across the lens is by showing astigmatism and power error plots, such as those shown in figure 9 for point-focal and Percival lens forms. These plots show how the astig matism and power vary from the optical center to the 40° zone of the lens. Note that if the astigmatism is made equal to zero across the whole lens there is still some power error, or, if the power error is made equal to zero across the whole lens there remains some astigmatism. This last statement is true whether we make the lens with spherical surfaces or in aspheric form using freeform technology So, in the light of these facts concerning the off-axis performance of spectacle lenses, I will re-examine some of the marketing statements concerning their performance.

Professor Mo Jalie DSc, SMSA, FBDO (Hons), Hon FCGI, Hon FCOptom, MCMI, is Visiting Professor in Optometry to the optometry course at Ulster University in the UK and to the educational facility Essilor Academy Europe. He also works as a consultant to the ophthalmic industry. He was the Head of Department of Applied Optics at City & Islington College from 1986 to 1995 where he had taught optics, ophthalmic lenses and dispensing from 1964. He is recognised as an international authority on the design of spectacle lenses and has written several books. Furthermore he is the author of some 200 papers on ophthalmic lenses, contact lenses, intra-ocular lenses and dispensing and a consultant editor to the Optician magazine. He holds patents for aspheric spectacle lenses and intra-ocular lenses. He has also produced several educational CDs and runs a web-based course in Spectacle Lens Design leading to the qualification FBDO (Hons) SLD.s.

The modern concept is to place the tangential image on the retina, with the so -called minimum tangential error form.Mo Jalie

What is light? This question was answered by Albert Einstein in 1905 in his treatises on electromagnetic radiation with dualism. The Copenhagen interpretation states that all radiation has both wave or particle character. The electromagnetic spectrum ranges from extremely long-wave radio radiation, with wavelengths of several meters up to kilometers, to high-energy short waves, gamma radiation. The part of the radiation which can be processed by our eye is called visible light, ranging from wavelengths of 390 nm to 780 nm. By Fritz Paßmann

The wavelength of blue light is at the short end of this range and red light at the long end. Blue light is therefore more energetic, reaching deeper into the eye and thus endangering the eye more than lower-energy light.

In numbers, this is indicated by high values of the frequency in Hertz,

i.e. the oscillations per second, and the color temperature in Kelvin. Short-wave blue light has a frequency of around 700 THz (7 x 1014 Hz), boring red light only around 400 THz (4 x 1014 Hz). A black body, which does not emit any light, has a temperature of 0 Kelvin, reddish candlelight about 1000 Kelvin and the blue light of the sky about 10 000 Kelvin.

Visible light diagram.

At this point I would like to point out the extreme efficiency of our visual system. Radiation hitting the eye does not only produce a visual reaction. Our internal clock, our day-night rhythm – or circadian rhythm – is controlled via the hypothalamus. Any variation of natural light influences our (well)being.

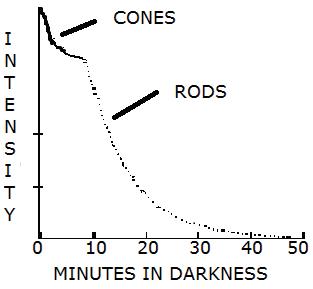

Adjustment to the prevailing ambient luminance, i.e. switching from photopic to scotopic vision, is called adaptation. To adjust from bright to dark surroundings, the system requires about eight minutes. As from the “Kohlrausch break”, the rods take over. The system is only fully adapted after about 25 minutes.

Blue ray light filter lens.In normal brightness, the cones are more suitable for seeing because the rods are too sensitive. In darkness, the more sensitive rods are more suitable. Therefore, there is not only an increase in the sensitivity of the sensory cells, but also a change from one type of sensory cell to another: from the cones to the rods. Since the rods adapt more slowly than the cones, their stimulus threshold does not decrease continuously, but remains constant for a certain time. Namely, at the point where the minimum threshold of the cones is reached. Only when the stimulus threshold of the rods has reached this point, it starts to decrease further due to the further adaptability of the rods. So here is the transition from cone to rod vision – also called Kohlrausch break.

The transition from dark to light occurs much faster. It is an erroneous assumption that adaptation to light or dark is done by the pupil. This is a fast initial protective measure and the incident light can only be reduced by a factor of 50 (r2 x π at 1 mm up to 7 mm) via the diameter of the pupil. The real adaptation to the surrounding brightness is performed by the adaptation of the retinal receptors. When the state of adaptation does not correspond to the prevailing level of luminance, this is called glare. Glare greatly impairs vision. Here are a few tips that opticians can give their customers to avoid the discomfort of glare:

▶ “Avoid looking directly at the source of the glare, for example oncom ing car headlights. This should definitely be taken seriously. Keep looking straight ahead or at the road markings.”

▶ “Don't point your air-conditioning nozzle directly at your face. The faster evaporation of the tear film will affect the quality of image formed, leading to more scatter.”

▶

“Have your eyes checked for any opacity or onset of cataracts. Scattering on a cloudy eye lens also impairs vision and increases glare.”

▶

“I recommend slightly tinted lenses (brown 12%/UV420), which reduces the amount of light that is scattered, thus increasing contrast”.

I would like to remind you of the classic line in Rambo III: “What does this one?” Rambo: “It’s a blue light.” “What does it do?” Rambo: “It turns blue.”

There is a lot of discussion about the hazards of blue light. As always, there are two sides to it: both a curse and a blessing. Today's energy-efficient light emitting diodes (LEDs) come in all colors. It all started in the early 1960s with a red LED. Over the next few decades, things got more colorful. The first bright blue LED was developed in Japan, for which the inventors received the Nobel Prize in Physics in 2014. After that, it also became possible to produce white light. Today LEDs can be found in almost all sources of light and have replaced fluo rescent lighting. Modern light systems (for example car headlights) can be controlled to take account of human needs. If LEDs emit an amplified portion in the short-wave range, the display appears to us to be bright and very rich in contrast. However, this does not correspond to the composition of the light we are used to. Sunlight has a relatively uniform spectrum across all wavebands of visible light. Especially at dusk, when we change over to sleep mode, the release of the sleep hormone melatonin is suppressed by an increased amount of blue light. We stay awake longer, the ability to fall asleep and sleep itself is negatively affected, especially when display screens are used in bed. Studies prove this, although they did not examine what exactly was being watched. This means that action games, emotions and exciting images also disturb our sleep behavior.

Dark Adaptation. Color temperature in Kelvin.Nevertheless, it is recommended to switch on the so-called night-shift function. This certainly can't do any harm. Basically, the radiation which one is exposed to from the display can be considered low compared to that from sunlight outside – in fact about 100-times lower. Here's a quote from Dr. Christian Lappe, PhD., Director Scientific Affairs & Technical Communications, Carl Zeiss Vision International GmbH: “However, the studies show no increased risk of damage to the human eye from modern displays with regard to the recommended standards.”

In conclusion, current research suggests that there is no acute risk of retinal damage where blue light is concerned. However, there are negative effects on our sense of well-being and sleep patterns. Humans need the change in color composition of natural light throughout the day.

Basically, the retina has a natural protective mechanism against short-wave light. The so-called macular pigment envelops the ends of the receptors and protects the visual pigment rhodopsin, which is responsible for the conversion into an electro-chemical stimulus. However, increased incidence of blue light can cause damage to the receptors, referred to as blue light hazard.

With increasing age, however, this protective effect decreases. Toxic compounds increasingly damage the pigment epithelial cell. The negative effect of these free radicals can be counteracted with a vitamin E rich diet. Native oils, grains and nuts are said to have an antioxidant effect. There is no definitive proof of the AMD-promoting effect of blue light, because this continuously progressive process takes years to take effect. Since mankind as a whole is living longer, the time scale

in which increased blue light may impinge on the retina, and thus may cause damage, is being extremely prolonged. In the end, what counts is: “It is the dose that makes the poison.”

AMD stands for age-related macular degeneration, where degeneration refers to any kind of progressive tissue damage. In AMD, the macula is not damaged directly, but secondarily by pathological changes in the underlying pigment epithelium. However, the protection, and thus the proper function of the macula is immensely important to our vision, as it is the location of the sharpest vision, the highest resolution. This process is highly energetic and very metabolic. The waste products produced must be disposed of by the pigment epithelium. This is done by breaking up the molecules, removing them and returning them to the metabolic cycle. However, over time, fatty substances accumulate on the pigment epithelium, i.e. under the photoreceptors. These are so-called drusen and are referred to as dry AMD.

Statistically, 40% of all people over the age of 90 develop dry AMD. While dry AMD progresses slowly and tends to cause little impairment to vision, there is a risk that it will go on to become wet AMD. In wet AMD, new blood vessels and accumulations of fluid form, leading to massive visual deterioration and thus an increased risk of blindness. For prevention, the optometrist should ask questions about this and offer screening during anamnesis.

Over the course of the day, the spectral composition of the light we absorb through our eyes changes. As already mentioned, we observe more blue light shortly before sunrise and shortly after sunset – the so-called “twilight hour”. When the proportion of short-wave light

Symptoms of AMD.Stages of macular degeneration.

increases at dusk, the eye becomes myopic compared to the daylight spectrum. This is called night myopia. Colloquially, this is often confused with night blindness. However, night blindness is a defect or failure of the rods that cannot be corrected by optical means. Night myopia is caused by the stronger refraction of the short-wave range of light and can be compensated for with appropriate corrective lenses. Where the myopia is greater than 0.36 D, “glasses for night driving” are recommended. However, the cause of night myopia is extremely complex and still has not been explained entirely. In addition to the spectral composition of the light, spherical aberration also has an effect, i.e., peripheral rays are refracted more strongly than rays close to the axis. In the eye system, an interaction of two refracting surfaces of the cornea and two refractive surfaces of the eye lens can also result in a spherical aberration in the “plus” direction. In general, higher order aberrations increase with a widening of the pupil diameter in the dark. To obtain an accurate analysis of these errors, the use of a wavefront aberrometer is recommended. Another issue in the de velopment of night myopia is the resting state of accommodation. Where there is a severe loss of contrast and in the absence of a fixation point, the accommodative system settles on an adjustment point 1-2 meters in front of the eye, in extreme cases of as little as 50 cm. This corresponds to a refractive value of 0.50 up to 2 D. This physiological component varies greatly from individual to individual and is difficult to measure. A tip for opticians is to give their customers binocular visors with sph -0.25 D and -0.50 D and a super antireflective lens, or a UV420 with a blue mirror coating. Some people will certainly notice the difference in twilight.

To quote Prof. Dr. Stephan Degle, Ernst-Abbe-Hochschule Jena / Yvonne Hoffmann (DOZ 08/2009): “In conclusion, it is not possible to make a generally valid statement as to whether the eye becomes myopic in twilight or not. Subjectively, small refractive changes were observed. A refraction determination adapted to special visual require ments can be suggested in order to determine optimal correction values. Based on this, values for spectacle or contact lens fitting can be determined to provide the client with maximum visual quality in each situation.”

Following his training as an optician, Paßmann completed his master's degree. Since 1991 he has worked as a freelance lecturer at various chambers of crafts and technical schools in the areas of theory, workshop and refraction. The lecturer for optometry was head of the optometry department at the HWK Dortmund (Germany) from 20072018. He is interested in modern teaching and learning methods. Paßmann is a co-developer of the PASKAL 3D experience refraction.

Nothing works in the modern lab without IT, even if its central role sometimes gets lost in the background. LensWare is one of the few companies on the market that concentrates on software and services exclusively for the ophthalmic industry. The system house aims to set a worldwide standard for Enterprise Resource Planning (ERP) complete packages. MAFO spoke with Dr. Bernd Freyermuth, Engineer, CEO, Project Management, Sales and Marketing at LensWare about the importance, status and developments of IT in the ophthalmic lab. By Rebekka Nurkanovic

The focus of this issue of MAFO is Data Handling & Security. What comes to mind spontaneously when you think of these two keywords in relation to our industry?

Freyermuth: This is an incredibly broad field. If we start on the outside, it is first the protection of the systems in general against virus attacks. That is always the responsibility of the local IT. Either the company itself is in a position to do this or it has a provider who looks after the hardware and firmware accordingly. This does not fall within our scope of responsibility; we deal exclusively with software. However, most companies are quite well equipped against these attacks.

The second issue is the internal security of the SQL server and the protection of the system against incorrect handling by lab employees. Authentication concepts are important for this as well as a complete separation of the data area from the application area. This also prevents possible virus attacks on the system itself, because reading and writing is only allowed in the data area, where these dangers do not exist and it is uncritical if anything happens. The database itself has to be protected. Otherwise, due diligence is a central issue, i.e. the user's duty of care. If the user himself abuses the system or destroys things due to his own incompetence, the system provider no longer has any influence.

Clean backup and recovery strategies are also very important. This applies to both the database and the application area or application server. Then, of course, there is the issue of interruption-free power supply and Windows updates. These two central topics are normally taken care of by the service provider. An interruption-free power supply ensures that the server cannot fail abruptly, which would result in an undefined data situation. This factor is self-evident for large companies. For small companies, the situation is completely different.

Windows updates are a critical point because the machine restarts. There is always a residual risk, so the updates have to be planned carefully.

Do you have the impression that most labs already have a good IT infrastructure?

Freyermuth: One thing is clear: IT is essential. Un fortunately, this is emphasized far too little in our in dustry. Technical innovations are constantly being talked about and published. However, the fact that IT is a decisive factor for success is not verbalized anywhere. Without the perfect IT solution, you are lost these days. You do not even need to show up on the market.

is analyzed, a “clean” IT infrastructure is recommended. On rare occasions, some entrepreneurs are nevertheless resistant to advice.

Freyermuth: The size of the companies, the general level of development and the owner's sensitivity to IT issues all play a role. There are companies that are happy to be advised and we are happy to advise them. Awareness of problem areas in the IT field varies, regardless of geographic location. Some companies attach great importance to perfection in this area and spend money on it, while others do not.

It can also be a generational issue. An older owner may not have the same feeling for digitization as a young one. But awareness of digitization is a decisive criterion in terms of the overall success of business processes, not just IT security.

Our industry is special because every product is basically a batch size of one. There is nothing like it in any other industry, in terms of form and mass. That is why we are facing some very big challenges. It is probably also the reason why there are hardly any independent companies left that offer comprehensive software solutions for labs.

The question has to be considered in an extremely differentiated way, also according to the level of development of the continents. There are of course differences. The whole spectrum is represented: From perfectly managed systems to sometimes chaotic situations. In many labs, the IT infrastructure is now well established. When a difficult situation

We see a tendency to map all processes entirely automatically with a minimum of work force, in order to be able to concentrate fully on the customers, i.e. on the opticians. Interestingly, however, nowhere is there much talk about the importance of secure and perfect digital mapping of business processes in the labs. This probably has to do with the fact that the industry is more concerned with products and manufacturing capabilities than with what is behind them. Digitization is not front and center, but it is the foundation on which we all stand. What it entails to bring perfection into this process is not immediately clear to most people. Yet suitable new IT solutions offer enormous development potential in the markets and give small and medium-sized companies the opportunity to compete with large corporations.

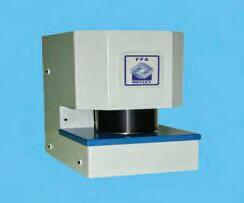

solution for verifying your free form production lenses. It’s fast, robust, and easy to use. Maps the whole lens compares to the intended lens and makes the Go/No go decision, all in 8 seconds.

High-resolution lens mapper especially designed for the new generation of myopia control designs. An essential tool that your sold lenses are of superb quality !

The world leader in ophthalmic metrology is proud to present two advanced tools for your Lab.

A lot of consulting is needed to create good solutions. The worst part is migration. Labs have different systems and to migrate from one to another is a science. One needs more than half a year to transfer previous IT assets to a new system without any interruption or problems smoothly.

Standardization is therefore a crucial step towards success. You need an industry standard to keep the costs of the basic solution in check for everyone involved. Then you can concentrate on customizing and change management, that is, on customer-specific adaptation.

Standardization in ophthalmic optics is not as advanced as in other industries. Above all, this is also due to the product. Our product combines medicine, fashion, physics, material sciences and more. You do not find that in other industries, where the areas are quite nicely separated. That also makes this field difficult in terms of software design, because everything has to be modular.

What do you think will be the biggest challenge for the industry in the coming years?

Freyermuth: Due to free-form technology and the emergence of more and more distributors, the complexity of products is increasing. In this context, IT solutions can hardly keep up in change management. As a result, there are only a few IT companies left that can deliver software packages independently. “One-man shows” are dying out because they can no longer cover the range of software requirements at this pace. LMS software companies are being bought up and con solidated for a variety of reasons, which does not make things any better. Many independent midsize companies have a single IT person who handles many areas in-house. Here lies the great opportunity for an independent system house that can offer complete solutions and customizations profitably while not losing sight of its own stability. If you can no longer “modernize” your own systems, death is inevitable. In addition, perfect support is a central issue. This can only be organized with an appropriate team.

There is an extreme monopolization in the industry. Does that also affect the IT infrastructure?

Freyermuth: We cannot confirm that. By acquisition of labs some consolidation is happening, but new ones are also being created. There is constant change. This has no impact on the IT landscapes. It is understood that the big players have clear requirements for IT security. We have the fewest problems there, because the internal IT department manages the infrastructure professionally and does not pass on re sponsibility to us.

As a system house, we are not affected by this monopolization at all. If labs are purchased, in general the installed LMS is kept, at least in Europe. Therefore, it does not have a big impact on the IT landscapes. Most of the labs are Independent Distribution Partners (IDP's) and they buy the LMS from us or from the competitor and then things are connected, like the freeform technologies, blank purchasing, or market ing. But the labs are still mostly fully or partially independent. Mo nopolization is more likely to affect the opticians, the point of sales.

Our industry is strongly driven by IT solutions. Everything is supposed to be interconnected. There are new developments in products and lab equipment, but the central issue is a stable and development-ready hardware and software solution with investment security and a fair price-performance ratio. Sometimes, however, the decision-makers do not understand the correlations at all. One problem with interconnectivity is the free-form technology itself, which is quite complex. And there are always new suppliers emerging in the market, who need to be integrated. The second problem is the supply chain, i.e. end to end, the chaining of order processes. You have to imagine this like complicated dictionaries in which the connection of the product portfolios of these companies is translated among each other in such a way that what one automati cally feeds to the other is also delivered as a product. This is all about cost and specialization and presents a huge challenge in terms of complexity.

And then, of course, we have the constant development of tech nologies in the IT sector. A revolution is taking place, but we are not even aware of it because we are living in it. We now have internet technologies that have to be fully integrated into the actual business automation.

To roll-out and maintain such systems, specialists from all areas are required, who are familiar with all the new technologies that nobody knew about thirty years ago. The difficulty for independent lab manage ment package providers is to build a team that is large enough to cover the broad knowledge requirements. The tendency is to move from pure automation packages to ERP, even for small and medium-sized companies. In their complexity, ERP cannot be managed by a one-man operation, especially if the necessary experience in the production area is lacking.

Thank you for the interview.

We see a tendency to map all processes en tirely automatically with a minimum of work force, in order to be able to concentrate fully on the customers, i.e. on the opticians.

The fully automated CDS 1000 is the most reliable hard coating machine. Producing up to 160 lenses/h, it is a perfect fit for medium and large size labs. It features six cleaning tanks and offers continuous and fast processing without any batching. Varnishing takes place by thermal polymerization. An automatic refill system provides consistent and stable process control - keeping detergent and varnish tanks at the same level and condition. A unique water cascading and filtrating system enables city water savings up to 75%, making the CDS 1000 an environmentally-friendly coater.

After three years, it is finally back: the largest ophthalmic optics fair in Europe, held in the fashion capital of Milan, Italy. Live and in color, Mido opened its doors from April 28 to May 2 and was finally able to celebrate its long-awaited 50th anniversary, which ought to have been celebrated in 2020. By Hanna Diewald

The organizers as well as the visitors and the exhibitors had been longing for the famous ophthalmic optics fair to reopen. After all, the Mido offers not only the latest and most ex travagant eyewear fashions, but also the entire breadth of the ophthalmic optics supply chain – from spectacle frames, via materials to all the equipment needed to produce spectacle frames and lenses.

On Saturday morning, the joy of meeting up again was palpable, among both visitors and exhibitors, although the five exhibition halls filled up rather slowly. In 2019 there had been seven halls, but the organizers explained the reduction in the number of halls with the absence of Asian exhibitors.

According to the organizers, about 22,000 visitors came to Milan over the weekend, with 660 exhibitors from 45 countries represented. The number of visitors was thus significantly lower than in 2019, when

approximately 59,500 visitors flocked to the fair. However, this decline had been expected, as Mido traditionally also attracts an international audience and some countries were still affected by travel restrictions. Thus, this year the aisles were uncongested and a pleasure to walk through – unlike previous years, when you sometimes had to push your way through the scrum in the packed halls.

The number of visitors in the machines & equipment halls was also not excessive, and the fact that some of the entrances were more difficult to find than other halls did not improve the situation. Nevertheless, many machine exhibitors were impressed by the keen interest shown by visitors. True to the motto: quality before quantity. In addition, there were many great highlights, making a visit definitely worthwhile. After all, the machine manufacturers had had a couple of years to mull over improvements to their machines, before finally being able to present them again live in Milan. Some of the innovations

Satisloh booth. Andy Huthoefer (left) and Michael Kreis (right). K&Y booth. Dave Slaperud (left) and Francois-Charles Laberge (right).

had already been shown at Vision Expo East, but for the Europeans – apart from Silmo – it was the first chance to see many of the new machines in action.

Satisloh was not only celebrating its centenary this year, but also showcasing a completely new coating technology. So-called “Film Lamination” is a process whereby the entire coating – i.e. the AR coating and the hard coating – is laminated as a film to the blank using the Satisloh Film-Pod machine and the Tech-Film AR. The whole process takes about 15 minutes and completely replaces conventional vapor coating in the box coater.

Up to now, the process only works on the back surface and Satisloh recom mends that it is used with pre-coated blanks. In the near future, however, t he technique will be extended to the front surface as well. In addition, the application could be expanded to include various other layers, such as tints, photochromic layers, etc. The target group for this technology is primarily smaller laboratories, as the investment costs for machines has been drastically reduced, and individual lenses can be coated instead of entire batches. According to Satisloh, the laminated surface is extremely durable, even exceeding that of conventional coatings. Another innovation that could be seen in action was the Rx-Bot Luke, an automated system for unpacking semi-finished lenses – up to 300 lenses per hour – which is expected to become available next year.

Schneider has done a lot in general since 2021. One new machine after the next has been unveiled by the company as part of the initiative “11 Innovations in 11 months” under the motto: “The Power Lab of the Next Decade”. The high-performance blocker CCU Modulo One scores points in terms of speed and cost reduction, with operations being performed in parallel by a variety of individual handling systems. These include lens pick-up, block piece supply, lens measurement and the three blocking stations. In addition, changeover times have been eliminated, because several block sizes – up to a maximum of six – are available at any one time.

According to Schneider, the new HSC Modulo One generator has been designed to double the throughput and is being marketed with the advertising slogan “two generators in one”. It has been possible to increase the speed significantly through various features, such as the two-motor concept, an ultra-fast workpiece changer, and more.

Even easier polishing can be achieved with the CCP Modulo One, thanks to the new spindle design and pad architecture combined with smarter process technology. Only a single pad is needed to achieve the best quality, thus making tool changing unnecessary.

And last but not least, the proven HSC Sprint generator has been en hanced to include the “X-version” and thus upgraded to the latest state-of-the-art Schneider technology, thereby further improving the machine’s performance and throughput.

There was also a lot to see and discover on the OptoTech stand. For example, the new OWS 80 Twin-A cleaner and dryer. The machine,

Schneider booth. A&R booth. Sandra Fonticoli (left) and Helmut Ahn (right).with two cleaning and two drying stations, can clean and dry up to 240 blocked lenses in an hour.

Or the new highlight for unpacking semi-finished lenses. The DeBoxer unpacks up to 300 lenses per hour fully automatically and, if required, can separate and shred plastic and cardboard as well, by means of two outgoing conveyors.

Also on show was the latest generator in the FLASH series: the digitalsurfacing-turning machine FLASH-A NG. The machine works very fast, thanks in particular to an optimized auto-loader and fast spindle exchange system. It is also extremely versatile and can even handle very small diameters using the integrated cribbing spindle.

Machine manufacturer MEI for its part was tremendously proud of their new EasyBuddy robot arm. Thanks to this technical aid, the EasyFit Trend lens edger no longer has to be replenished by human hand but can be loaded fully automatically – without a break – by the EasyBuddy.

Another highlight was the latest version of their BispheraTBA Phoenix edger. According to MEI, the throughput of the BispheraTBA Phoenix has been increased. The system, with two edger heads cutting two lenses simultaneously, has been improved by means of a second spindle on each head. Furthermore, the dual-arm manipulator allows loading and unloading operations to be per formed while edging is in progress. Other advantages include independent left and right heads, making it possible to run jobs in

parallel with two different lens shapes, or to mark different logos on lenses with engraving tools.

Although the American machine manufacturer Coburn had no ma chines physically on display this year, it did showcase their latest technology via video. The company has managed to bring to market a lens deblocker and alloy-recovery system that for the first time works without water. This makes the process much more sustainable but without having to renounce alloy. The Agility Autodeblocker is a water less deblocking system. Thanks to the new machine, which mechanically separates the lens from the block, water is no longer contaminated with alloy. The Integrity Alloy Recovery System only melts a thin layer of alloy, thus eliminating splashes of molten alloy. It can separate up to 240 lenses an hour without water.

Despite lower visitor numbers, Mido proved a worthwhile experience for many visitors. Next year, Mido 2023 in Milan will be held from February 4 to 6, just one week after the Opti in Munich from January 27 to 29. Some exhibitors have already expressed their dissatisfaction about this unfortunate timing, meaning many exhibitors will have to decide which event to attend.

How this schedule came about – together with the organizer’s assessment of this year's Mido – was addressed by Giovanni Vitaloni in an interview with MAFO which was carried out live at the Mido.

OptoTech booth (Claude Volken).

Coburn Technologies booth. Marina Vaynberger (left) and Alex Incera (right).

Bühler booth.

MEI booth, Giovanni Spreafico (left) and Alessia Donati (right).

OptoTech booth (Claude Volken).

Coburn Technologies booth. Marina Vaynberger (left) and Alex Incera (right).

Bühler booth.

MEI booth, Giovanni Spreafico (left) and Alessia Donati (right).

Vitaloni: It is really fantastic and amazing to be here because actually the last physical edition of Mido was in 2019. So we are back after more than 36 months! And just the fact of being here is amazing. What is absolutely encouraging is that I am breathing an excellent vibe. We have close to 700 exhibitors and visitors coming from over 150 countries. Mido is really the place to be when you want to grab some new ideas in the optical industry. I think the vibe is very good and the people really needed to meet physically together. Although we had a digital edition of Mido in 2021, which was a success in terms of communication, people need to meet and look each other in the eyes.

There are fewer halls this year than before. What kind of feedback did you get from the visitors about this new concept?

Vitaloni: We have five pavilions this year. Compared to 2019, we do not have two extra pavilions with Asian exhibitors that could not get the visa to travel to Europe due to sanitary travel restrictions. So, it does not really depend on the market or on Mido itself, but it is about their regulations. That is an important part we are missing, but considering all the other exhibitors, we are satisfied. And this is the only optical show that is exhibiting everything in the supply chain, from raw materials, to components, final products, frames, sunglasses and distribution.

We are living in difficult times at the moment. In your experience, what impact does the war in Ukraine have on the Italian industry and the trade show?

Vitaloni: Well, economy and enterprises need stability to grow. The state of the world is very difficult at the moment and it is something that will probably last for some time. But if I look at the Italian optical industry, the Russian market represents just 1% of our operations. Markets like the United States, France and Germany are important to us. Of course, it is a problematic situation, but at the same time, we believe that this can be an opportunity for Italian enterprises to further improve, because they are consolidated and they are focusing more than ever on sustainability, transparency and how the product is made. This is really requested by the market. Of course, the environment is difficult and we are living in different times, but the economy will go on and the Italian enterprises have good cards in their hands. And for this show – it has an impact of course, for people and visitors coming from Russia, but overall I think the power that the industry has and the needs that the visitors really have in meeting face to face is above everything. It is sad and it is difficult, but people, as you can see, want to meet.

Vitaloni: We have, of course, a lot of ideas. For sure, the trade shows of the future will be different from the ones that we were used to in pre-pandemic times, with a lot more digital support for the visitors who cannot be here physically.

But for now, it was important for us to restart. We have many new projects for 2023 where we will mix even more physical and digital elements. And we have positioned Mido for 2023 in the beginning of February, because that is convenient to all companies. And then, we are looking really forward to a big come back for Asian industries.

However, we have realized, this year is really a huge success because it was not easy to postpone the trade show and get all the exhibitors and all the visitors involved. So, we have done a tremendous work. This is because of the team that has been working with exhibitors and visitors convincing every body that this is the place to be.

In 2023 Mido will take place just one week after opti in Germany. How did this come about? And do you believe this will have a negative impact on the number of exhibitors?

Vitaloni: In February 2020 we communicated and made official our Mido upcoming dates until 2026.

Of course, we have been forced to make different temporary choices due to the pandemic situation in these past two years but we never mentioned any change for the post-pandemic future.

Unluckily, probably opti didn’t take our calendar into consideration when setting their 2023 dates. In addition, opti focused its communication on the moving to Stuttgart in order not to change the period of the year. We don’t really understand this decision but, after these difficult years, we really cannot mess up with our schedule anymore.

We’d like to remind our exhibitors and companies in general that Mido is the most important tradeshow of our industry in terms of business, quality, visitors, international attendance. If you have a look at our pre-pandemic numbers: in 2019 Mido opened its doors with 1,323 exhibitors, 110 of them first-timers, occupying 52,000+ m 2 of net exhibit space making completely sold out seven pavilions and we had almost 60,000 visits of professionals over the three days from 159 countries.

We are sorry for those that will be forced to make a choice but we are sure our audience will follow our precise communication (www.mido.com/en/upcoming-mido) and will express their disap pointment regarding the dates that were chosen for opti 2023.

Thank you for the interview.

After the pandemic-related break, opti was held again at the Munich trade fair center from May 13 to 15. For many exhibitors and visitors, the industry meeting was a long-awaited opportunity for personal contacts. Even though the fair was smaller than before the pandemic, the organizers were satisfied and described the spring opti as an important signal and the right first step. By Rebekka Nurkanovic

Halls C1 and C2 featured the eyewear frame collections of the licensed and manufacturer brands, the YES independ ent design area, and the opti BOXES with start-ups. In Hall C3, more licensed and manufacturer brands presented themselves in the frame area, and there was everything for the stationary optician. Hall C4 was all about lenses, contact lenses and accessories, refraction and diagnostics as well as IT and machines. In terms of content, the focus from May 13 to 15 was on two major topics: sustainability and myopia management. Lenses that help to control myopia and are designed to slow down progressive myopia were presented. Another focus topic was sustainability. Paying attention to the ecological footprint and ensuring short transport routes for raw materials and preliminary products are playing an increasingly important role in the ophthalmic optics industry. Opti Forum XT pre-show webinars also covered the topics of myopia management and sustainability in the run-up to the trade fair.

GHM Gesellschaft für Handwerksmessen, the organizer of opti, reported that almost 370 exhibitors from 25 countries and 13,000 visitors from 71 countries attended the industry meeting. According to the visitor survey, the aim of around three quarters of the trade visitors was to exchange ideas with colleagues in the industry and to initiate business relationships.

Dieter Dohr, Chairman of GHM, said: “The opti 2022 is first and foremost an emotional experience. Finally a trade show again! Finally personal exchanges again! The conditions were not easy, and we are delighted to see how many have deliberately chosen the May edition. Visitors, exhibitors, trade show specialists – like never before, the focus was on bringing together all the stakeholders in opti and conducting exchanges between everyone. At this spring opti, everyone once again became fully aware of what we have missed over the last two years.” Even though the fair did not reach pre-pandemic levels, the organizers

were satisfied: “We certainly couldn’t pick up exactly where we left off before the pandemic, and that was also never the goal. Holding the opti was an important signal and the right first step. In times of global change and challenges, sustainable discussions are a fundamental need. Now more than ever, it is important to find new solutions and opportunities together and through exchanges with all”, said Dieter Dohr. The conclusions drawn by many exhibitors were also positive. “The opti 2022 was the first trade show worldwide where Thélios presented its Maisons. […] We have made good contacts and reached quite a few new customers,” said Imke Nietfeld, Managing Director/Country Manager DACH at first-time exhibitor Thélios Deutschland GmbH (LVMH Group).

Samuel Puaud, Product Manager Finishing Visionix, found the opti very well organized, even though attendance seemed to be lower than in previous years, “maybe because of COVID and the fact that Mido was only two weeks before.”

At the opening press conference by GHM, the German central association of opticians and optometrists ZVA and the German industry association Spectaris, the ZVA presented its annual industry report. „As we all know, a great deal has happened since the last opti in January 2020 – for this reason, there could be no better venue for presenting the latest ZVA industry report, which now looks back over three turbulent years,” explained Thomas Truckenbrod. Despite the pandemic, the ZVA president had positive news to report: Even though traces of the crisis can still be found e.g. in the training sector, the ophthalmic optics sector

managed to get through the difficult months relatively well. Once again, companies are more willing to invest and operating profits have developed better than turnover for more than 25 per cent of them.

The ophthalmic optics industry achieved exactly the same level of sales in 2021. For Josef May, Chairman of Spectaris, ophthalmic optics clearly remains an industry of the future. "2021 was a quite pleasing year for our German ophthalmic optics industry," May emphasized, but pointed out that some general conditions have changed since then, also due to the Ukraine war. He noted that on the one hand, despite the current progress in the fight against corona, the pandemic still harbors risks. For another, the sharp rise in the cost of living may dampen consumer sentiment. May also re minded of the supply chain issues as well as increased logistics and energy costs, which make it extremely difficult to make a forecast for this year.

The expectations for the next opti in January 2023 are high. Many key players have already signaled their participation, GHM announced afterwards. Accordingly, the date in Munich is also fixed for a large proportion of the visitors: almost 70% of all those surveyed during the trade fair weekend stated that they wanted to visit opti exclusively as a trade fair.

However, not everybody is happy about the next regular date from January 27 to 29, 2023, because of the temporal proximity to the Mido in Milan (read also the interview with Giovanni Vitaloni starting on page 27). It remains to be seen if some companies are unwilling or unable to attend both events and decide to skip one of the shows. ◆

Visionix introduced their new edger, the Weco E7. The edger uses the power of 3D to preview the adaptation of the lenses in the frame, combined with the new intelligent software TrueFit, to assist the work of the optician. MEI presented the EasyFit Trend, a new block-less compact solution tailored for optical shops and small labs. OptoTech booth. Schneider booth.Cyber hygiene – these are simple security principles that every organization should know and implement to keep all sensitive data under control and protect it from theft or attack. Worldwide, the costs caused by cybercrime are growing. If the business of cybercrime were measured as a gross domestic product, it would be the third-largest economy in the world after the US and China. Cybercrime is a profitable business, with relatively low risks compared to other forms of crime. By DriveLock

Not only is the number of cyber attacks continuously increasing, but attackers are also becoming more and more tricky. They specifically exploit the human factor, which often becomes a gateway. IT security must adapt to changing hybrid working models and the increase in human error. It must keep pace with attack methods, distributed workplaces and infrastructures, and at the same time not interfere with daily work.

There are ways for companies to implement security measures that do not inconvenience users or make them feel restricted in their freedom.

If not, then here is a brief explanation: By cyber hygiene we mean simple security principles that every IT department must know and implement. The main goal is to keep all sensitive data under control and protect it from theft or attack. Cyber hygiene deliberately includes the association with personal hygiene, where we take precautions to maintain our health. Thus, if a person neglects hygiene, he or she can catch an infection. If a company neglects IT hygiene, it can lead to data breaches and infection with malware.

Like personal hygiene, cyber hygiene starts with basic measures that contribute to good health. Although people like to attribute cyber hygiene to the IT department, it is a whole-business organizational task. It affects everyone. For example, the IT department can set password policies, but users must also set strong passwords and keep them secret.

The principles of cyber hygiene are not new, but they are easily forgotten in everyday life. Simple rules make it easier to follow the hygiene protocols regularly and completely.

We carry out hygiene measures regularly – at the very least when we are exposed to a significant threat. Thus, many of these measures are actually basic cyber security measures. We focus here on what needs to be regularly checked and adhered to:

Every time malware develops further or a new vulnerability becomes known, software manufacturers respond with system and software updates. A regular patch helps to reduce your attack surface.

A prerequisite of cyber hygiene is that you as a company know what you have in your inventory. Before you can adequately protect your attack surface, you need to identify all the assets within it. The basics of patch management include a complete inventory of all hardware and software assets across the corporate network. A vulnerability management solution continuously assesses risks from vulnerabilities and becomes a daily routine through automation.

Say goodbye to the idea of trusting everyone in the company, even if you know them well. "Never trust, always verify" is the maxim of

Zero Trust, which applies to data, devices and users. An HR employee needs different access rights to contracts, for example, than an IT employee. Give users the minimal access they need and minimize the potential points of attack on your data.

Use data encryption. If all else fails and your firewalls and access protocols are breached, or your laptop is stolen, encryption means that any important data you have stored is useless to the attackers.

Basic cyber hygiene means encrypting your files and data before sharing them via removable media or, in the case of computers and laptops, the entire hard drive. The same applies to the encryption of removable media.

Implementing two-factor authentication more rigorously verifies that the right person is granted access. And the more personal you make the authentication, the more secure your network. Thumbprint ID and facial recognition create even more security.

Employees who work from home and use their personal computers (and also those who use a company-owned device) should adopt basic cyber hygiene practices. These include:

Employees should have antivirus and anti-malware software for use on their private computers. While this does not provide fail-safe protection, it does prevent many low-level attacks. Application control with application whitelisting is a necessary addition, preventing the execution of programs not detected by the virus scanner.

Employees should be regularly educated on cyber security best practices and procedures. This includes raising awareness of the need to be vigilant when receiving emails and checking the au thenticity of the sender's address.

Employees working in a home office should ensure that their home Wi-Fi is protected by a secure password.

Virtual private networks provide another layer of protection for home internet use. While they cannot prevent cyberattacks on their own, they can provide a useful barrier against cyberat tacks. There are some basic cyber security strategies that companies can adopt.

This article was first published on the DriveLock blog. (March 28, 2022)

DriveLock SE is one of the leading international specialists for cloud-based endpoint and data security with offices and representa tions in Germany, Australia, Singapore, the Middle East, and in the USA. Their mission is to protect companies' data, devices and systems. To achieve this, DriveLock utilizes state-of-the-art technolo gies, experienced security experts and solutions based on the zero trust model. In today's security architectures, zero trust means a paradigm shift according to the maxim "never trust, always verify". This way, data can even be reliably protected in modern business models. www.drivelock.com

Diamond tools for any generator • Excellent service and quick turnaround www.

diamond.ca

Artificial Intelligence (AI) is still considered a promising technology that can drive the innovation engine. Many areas, such as medicine and healthcare, but also trade, transport, industry and administration, are finding revolutionary uses for AI. Expectations for AI are high; after all, innovative courage wants to be rewarded. The "Future of Health" study by Roland Berger[1] shows: AI as a technology is predicted to cause the greatest impact in healthcare by 2026, closely followed by sensor-based monitoring, which can also lead to even more accurate analyses with the help of AI. By Elena Fomenko

Analytics are already scoring high on expectations, such as for screening and diagnosis. However, there are a number of obstacles along the way that need to be overcome if the data project is not to end with insufficient insights and thus disillusionment. The key is good data quality.

The course for success is already set during planning before the start of the actual AI project. The problem has to be defined in as much detail as possible, just like the goal, because: The problem

definition determines the AI model. Within the model type, it is usually necessary to experiment between different model instances so that the best model emerges. The model can then be trained and thus it forms the technical core of any AI system. There are already existing systems that can be used, but companies can also create their own models. It can also be useful to test in advance with different models how the prediction and accuracy of the respective systems perform. Various factors influence this, such as the respective configuration, the amount and distribution of the training and test data, or the frequency of the tests (epochs). From the observations

of the tests, conclusions can be drawn as to which model type best fits the predefined question.

However, the systems and also their analyses can only be as good as the underlying data basis, the definition of the problem in connection with the selected model. The underlying algo rithms are developed by humans who are subject to cognitive biases or prejudices. These algorithms, in turn, are presented with data sets for training, which have also been selected by people who are not free from prejudice and value, and patterns are derived from them. This "bias" can lead to limited analyses, or even to discriminatory or racist results. Everything that the AI is supposed to learn must be taught to it based on the training data – and since, for example, the development team is not always diverse and thus brings in different aspects, special care must be taken here.

Data is therefore the critical foundation for the success of any AI project. When selecting test and training data, project managers must ask themselves three questions: What data and in what quality do I need for my use case? Which data and data sources are available to me? What additional data do I need?

If the data is not yet available, it must be collected again within a specified period or obtained from external sources, such as open-source sites or so-called data marketplaces. Data protection aspects must of course be taken into account.

There is also the option of selecting models that can be trained with little data – however, this requires the support of data scientists who have the appropriate knowledge of models, in fluencing factors and training parameters. A third option would be to use synthetic, i.e. generated data.

If real, personal data is required for the project, the training and test data must be anonymized and pseudonymized. Project managers must then carefully check whether the data modified in this way is still meaningful enough for training. When collecting new data, the permission of the respective person could be obtained in accordance with the relevant data protection regulation (e.g., GDPR in Europe). Collaboration with project partners and the use of the cloud for data storage require special attention in terms of data protection. If companies make use of synthetic data, they have to be correctly distributed according to the problem and map a representative cross-section of the real data to be expected. Once the AI has been trained with synthetic data, the step into application with real data requires close validation and monitoring. The guiding principle "The AI can only learn from the fed data and patterns!" must always remain in mind to avoid negative learning effects.

We understand why labs prefer alloy, and sought to change how it is recovered. Traditional methods are unsafe, messy, and outdated. We developed a solution that is more efficient and more eco-friendly by creating a completely waterless system.

How did we do it? Learn more about our new methods at coburntechnologies.com/reimagine

The data provided to the AI for learning must always be of high quality, regardless of whether it is real or synthetic. "Crap-in/crap-out" applies to every intelligent and smart system – with faulty and incorrect data, only unreliable or incomprehensible results can emerge. The merging of the data is in itself important; this is referred to as the ETL process, short for Extract, Transform, and Load. The following criteria can be applied to data quality:

This refers to various dimensions. Data sets are considered complete when content and data have been completely transferred in an ETL process. Representation of completeness is based on the company's business rules.

If the data set matches reality, it is considered correct.

A data set must not have any logical contradictions within itself or with other data sets within a data source.

If the (real) objects described by the data set are represented only once, they are considered unique.

The data conforms to the defined format.

The data corresponds to the defined value ranges.

Potential sources of error may include:

Zero values

Outliers

Duplicates

Incorrect spellings

Multiple languages

problems