INLINE CLEANING

OptoTech Optikmaschinen GmbH Sandusweg 2-4 35435 Wettenberg / Germany

Phone: +49 641-98203-0

Email: info.de@optotech.net

Web: www.optotech.net

Spring is around the corner. The Vision Expo East has taken place in New York after a long time. Soon Mido will open again in Milan, thus also attracting many international optometry enthusiasts to a live event in Europe again. Finally, for the first time since 2019, we are seeing the beginning of a return to normality – or at least that’s how it might appear ...

... as this nascent optimism may soon be nipped in the bud, when one takes into account what is going on in the world – war in Europe. As if the corona pandemic and the natural disasters of recent years had not already claimed enough victims.

Over four million people have already fled Ukraine. This is a catastrophe for the people who have had to flee, for families, now separated and living in uncertainty, as well as for the many people – especially men – who have remained in their country despite imminent danger and of course the relatives on all sides, who lost their loved ones.

The economic consequences may initially seem of secondary importance, and yet in time they will affect us all. Inflation in Europe is rising and raw materials are becoming scarcer. While oil and gas are becoming significantly more expensive, raw materials like nickel, palladium and chrome are already increasingly difficult to source.

This will have a serious impact on our in dustry too. In addition, many corporations have branches and staff in the affected regions on both sides of the border. Here, too, there are many challenges and uncertainties still to be resolved.

Particularly in such difficult times, it is good to keep sight of the silver lining. For example, that hard times can also lead to great cohe sion. In this case, for example, the general re cognition that innocent people need to be helped. Our industry has already demon strated in an impressive way that everyone can make a contribution, and many have done so already.

Many companies have pulled out all the stops and mobilized employees to help in the crisis region, either through donations or through direct help where it is needed. On pages 12 and 13 you will find a small selection of the various activities and a field report, although of course there are many other activities and people involved through out the industry.

Besides all this, this issue of MAFO also features the usual mix of exciting articles, reports and news about technological develop ments that will hopefully give you a breather from world events.

For example, the follow-up report on the Vision Expo East in New York, or market data from 2021 concerning Europe and the USA, together with various technical articles.

In this issue, you will hear from three experts how lens design can be further improved by taking accommodation into account. Another expert explains why virtual reality glasses are a good tool for studying gaze dynamics and how this can then contribute to improved design. And, finally, a chemist demystifies the dip coating process for hard coating. We hope you find this issue both interesting and stimulating!

By Pau Artús

By Pau Artús

Richard Chang has been appointed as President and CEO of SDC Technologies, Inc. He joined SDC Technologies in 2010, having most recently served as Chief Operating and Financial Officer for SDC Technologies, and General Manager of FSI Coating Technologies, a wholly-owned subsidiary of SDC.

Antonios (Tony) Grigoriou has been ap pointed Executive Officer, CEO and President of Mitsui Chemicals Americas to support parent Mitsui Chemicals Inc. (MCI) towards its 2030 Global Vision with particular emphasis to grow the Life & Healthcare Business Division in the Americas. Tony has been with SDC since 2003 and served as President and CEO of SDC for more than a decade and will remain as a member of the Board of Directors of SDC Technologies.

James White has been appointed Chief Financial Officer for SDC Technologies Inc. Prior to joining SDC Technologies in 2007, James worked in both public and private accounting. He has more than 20 years of experience within the coatings industry.

From April 30 to May 2, 630 exhibitors from 45 countries will be at Mido to showcase their collections and products for an audience of Italian and international buyers, opticians, designers and journalists.

“After two years of pandemic and in light of the complexities of the current extremely unsettling geopolitical situation – first and foremost from the human standpoint – industry firms have an urgent need to gather, in order to share information and exchange ideas to glean the energy needed to cope with challenges in the coming months – stated Giovanni Vitaloni, President of Mido.

The entire eyewear supply chain, from the large brands to the smaller companies focused on innovation and experimentation, will be on display in the five Mido pavilions at Rho Fiera.

Ocuco announced the company’s rebrand to a more contemporary, refined version of its original brand. Leo Mac Canna, Ocuco’s CEO, explains “this year Ocuco will launch Acuitas 3 OmniChannel Edition. It will provide the optical industry with an omnichannel platform with both in-store and consumer-facing facilities. It will remove the need for independent solutions, with cumbersome integrations from different solution providers.”

Over the last 29 years, Ocuco has developed and strategically acquired comprehensive management systems for labs, independent practices, and chains. More recently Ocuco has extended its offering with digital marketing and website services.

From a design point of view, Ocuco has retained its name but paired back its wordmark logo to a more streamlined version.

EssilorLuxottica and CooperCompanies are pleased to announce the finalization of their joint venture agreement for SightGlass Vision. This collaboration of two global vision care leaders accelerates the commercialization of novel spectacle lens technologies to expand the myopia management category. SightGlass Vision’s Diffusion Optics Technology incorporates thousands of micro–dots into the lens that softly scatter light to reduce contrast on the retina, which is intended to reduce myopia progression in children.

SCHNEIDER presents the only auto blocker today with automated block size exchange

One auto blocker covering virtually all of a labs’ blocking requirements at highest speed and unprecedented efficiency. CCU Modulo ONE comes with multiple block sizes – a minimum of three and up to six – readily available at all times. Time-consuming manual changes are a thing of the past. And the best part: The exchanges are carried out automatically and without increasing cycle time. Inefficient block size distribution and poor machine utilization are avoided. For any lab size, a wider range of blocking requirements can be met with a smaller number of machines. The proprietary lens measuring unit guarantees perfectly oriented lenses. An intelligent fill control provides highly consistent and precise fillings.

The result: Non-stop uninterrupted blocking for highest throughput, at lowest cost per lens.

Visit www.schneider-om.com

Trust DBA. Trust TSA. Trust the originals. Trust Insomec. Insomec Optical Technologies is proud to celebrate the 10 years of success of our patented process of deblocking and detaping carried on our DBA and TSA machines. Incomparable characteristics and performance still make alloy the best option and our machines help labs all around the world reach their goals with our complete automated process. The help of our market leading partner, Schneider Optical Machines, makes it even easier to reach any part of the world. An affordable price and a low cost per lens ratio make both machines a great investment. More than 400 machines around the world guarantee our success. Transform your batch and manual process into a complete automated task while reducing the man labour cost and the downtime. Visit www.insomecgroup.com

Satisloh celebrated its 100-year anniversary. Founded in 1922 in Wetzlar, Germany by Wilhelm Loh, it is a global leader in ophthalmic and precision optics manufacturing machines. The organization has played a key role in bringing innovations and technologies to both markets during the past 100 years. In the aftermath of World War I, the company started producing machines for canning jars, and cast iron lapping tools for numerous local optical factories.

With its strong foundations and knowledge, the manufacturer has shaped the present landscape of optical manufacturing and is continuing to create the future of lens processing.

“Celebrating our 100th anniversary is an exciting milestone for the company and our employees.

It is also an opportunity to thank everyone who has been on this incredible journey with us – our customers, suppliers, business partners, and the extended Satisloh Group family. Your support helped us reach this milestone,” said Bruno Fischer CEO for Satisloh Group. The anniversary will be recognized throughout 2022 at tradeshows and events worldwide for both customers and employees. Satisloh’s 100th year will culminate with a celebratory global SLUGFest from the 4th to 6th of October 2022 in Wetzlar, Germany – right where its story began. Follow Satisloh on LinkedIn or visit www.satisloh.com/100-years to keep up with the latest news and to find out more about the 100-year anniversary.

Coburn introduces the Integrity Alloy Recovery System

Coburn introduces groundbreaking technology with the Integrity Alloy Recovery System, the first and only automated waterless alloy recovery system. The Integrity system avoids the hazards of traditional alloy reclaim systems while enhancing efficiency of the lens making process. Whereby traditional reclaim systems completely melt the alloy puck in a hot water tank to remove it from the block, the Integrity system uses induction heating technology to melt a thin layer of alloy where it engages the block, allowing the alloy puck to separate cleanly and completely intact. This method only eliminates the use and contamination of water, but also facilitates the storage and safe handling of alloy and blocks.

Integrity processes up to 240 blocks per hour making it the fastest alloy recovery system on the market.

Integrity completes Coburn’s Automated Post Polishing system which includes the Agility Autodeblocker, Integrity Alloy Recovery System, Duality De-Taper and Cleaner, and Velocity Coater. Lenses can be deblocked, de-taped, cleaned and coated within minutes while blocks and alloy are simultaneously separated and recovered. www.coburntechnologies.com

The new OWS 80 Twin-A was especially developed for automatic cleaning and drying of blocked ophthalmic lenses on a very small footprint. It is equipped with 2 cleaning and drying stations, allowing a performance of more than 240 lenses/h. Polish residuals as well as calcium deposits will be removed from the lens and blocking piece to ensure perfect conditions for subsequent engraving and inspection processes. The very compact machine uses a sustainable green process with low air consumption and a closed cleaning water cycle including pumps and filters. The open system can easily be integrated in any existing ophthalmic production. Visit www.optotech.de/en

A meeting place especially for the ophthalmic spectacle lens industry to exchange news, provide networking opportunities and learn more about new technologies – this has been the idea of MAFO - The Conference for more than 20 years now.

To make this format internationally accessible in today´s world, we have established the new video format MAFO | Talks. The idea: experts from the industry present technical talks online, accompanied by enlightening Q&A-sessions, chaired by Prof. Dr. Peter Baumbach.

As a special highlight, MAFO also published an exciting video panel discussion in which cutting-edge topics are discussed with industry experts. We present the highlights of MAFO | Talks:

What does the future of ophthalmic optics look like? That is what MAFO wanted to know from five very different industry experts at the “Future Lab” discussion panel. Different specialists were taking part from the fields of lens design, machinery, liquid crystal lenses, coating and optometry in general. In a two-hour panel discussion, the experts discussed three topics:

Spectacle lenses – how individual is individual enough?

Automation – chances and challenges

The future of spectacle lens production –smart technologies, disruptive technologies

Watch the entire discussion or individual topics in the video, moderated by Prof. Dr. Peter Baumbach.

Please note: MAFO - The Conference, the unique industry meeting place in Europe, will of course also soon take place again as usual. Unfortunately, this was not possible in recent years due to the pandemic. However, MAFO-The Conference 2023 is already in the starting blocks and will take place as usual one day before Mido 2023 in Milan, Italy.

The war in Ukraine is an immense tragedy for all people who live or have lived in Ukraine and are now on the run. The whole world, and Europe in particular, is watching anxiously for any further developments. For this special we asked people from the industry how they are affected and what companies in the ophthalmic optics sector do to help – as not least eyeglasses are an important medical device. Status as of April 11th

By Hanna Diewald Bruno Fischer, CEO at SatislohWe as a company will support by raising funds within the employees and double that collected amount. These donations will go towards services and supplies offered directly on the ground by the humanitarian organizations UNHCR (United Nations High Commissioner for Refugees) and the International Red Cross, both respected and trusted international institutions providing meaningful support to Ukraine since the beginning of the conflict.

Since the beginning of the war, more than four million people have fled Ukraine. More than half of them have found shelter in neighboring Poland for the time being.

We at Zeiss condemn the Russian government´s war against Ukraine. People are dying or fleeing, cities and infrastructure are being destroyed. Innocent people are suffering. Our thoughts and sympathies are with all the people affected; especially our colleagues, their families and friends, whose safety and support are our top priority.

At the end of February, Zeiss decided to stop all orders, deliveries and other services to Russia in accordance with the EU sanctions package until further notice. Exceptions are the deliveries that are explicitly still permitted in the EU sanctions package, e.g. in the medical area. Profits from these explicitly permitted deliveries will be donated for humanitarian purposes in the affected regions.

Many employees show great commitment in helping personally and, for example, provide accommodation, donations and relief supplies. Together with hundreds of customers, Zeiss Vision Care Germany launched the “Augenoptik hilft direkt” campaign, which offers free spectacles for people who have had to flee the war in Ukraine. Similar offers exist in other countries such as Poland and Hungary.

We are monitoring the current situation throughout the region, and the international task force is continuously reviewing potential impacts on business or logistics processes and coordinating appropriate measures.

The ECOO (European Council of Optometry and Optics) announced that: “Polish opticians and optometrists are providing free eye care to people fleeing Ukraine who forgot, lost, or simply need glasses, contact lenses, or eye care. More details including a map showing practices of fering care: https://ptoo.pl

The lens manufacturer Shamir is operating a mobile lab on a large truck in Warsaw to offer on-site eye tests to those fleeing the war and to produce new eyeglasses immediately afterwards, free of charge. The mobile lab is equipped with the latest technological machinery to ensure the fastest possible production of the required spectacle lenses. Shamir´s delegation on the ground consists of a total of 16 employees from Israel (including former immigrants from Ukraine), Portugal, Poland and France who are volunteering their time to help the refugees. The team is led by Nir Shmuel, COO of Shamir Group, Ronen Tsur, Managing Director in Poland and Luis Feijo, Managing Director in Portugal.

I had created a JV in Russia (Kazan) with the Institute of Nanotechnologies of Tatarstan in December 2019.

The idea was a technology transfer from France to Russia with the opportunity to penetrate the CIS countries market from the inside. The main obstacle was coming from the fact that Russian companies have only little trust in other Russian entities, so they prefer buying from western countries than locally. Thus, it takes time to demonstrate the quality of Russian made goods.

From March 2020 until March 2021, I could not come back to Russia because of the COVID crisis. Since only VKS (Highly Qualified Specialists) were allowed to enter the country, it took me seven months and 26 flight ticket changes to be allowed to get the precious visa allowing me to come back! From that point on, we made progress and started selling our lacquers to RX labs in Russia. We could see our sales growing in a nice way until the war started!

Unfortunately, most of our raw materials were coming from Germany or France and suddenly we were no longer able to produce, hence to supply. Since there was no embargo from China to Russia, local lens production was stopped and replaced with massive lens imports. It is not sure that our customers will have the opportunity to resume their production once the western import bans will have been lifted … Ophthalmic lenses, although sometimes expensive, should not be considered as luxury goods but more like medical devices. As such, raw materials necessary to manufacture them should be excluded from the western sanctions.

EssilorLuxottica is deeply concerned by the tragedy in Ukraine and stands in solidarity with all those af fected. In this difficult time, the safety of our employees remains our priority and we are offering our affected teams in the crisis region every possible support, including continued payment of wages and early payment of the 2021 annual bonus. In ad dition, we are doubling our employees' donations to Ukraine. We coordinate crisis management teams of our employees in Poland, Hungary, Romania, Slovakia and Turkey, among others, to provide accommodation, logistical support, psychological care and administrative and financial assistance.

In Germany, we offer employment in the logistics sector to refugees from Ukraine at our sites in Braunschweig and Hanau, among others. Our employees also help the people in need on site on their own initiative and with great commitment, for example, with accommodation, visits to authorities and with food and clothing.

In addition, EssilorLuxottica provides the refugees with free eye tests, frames and contact lenses. We will monitor the situation and adapt our measures accordingly.

In recent years, the rise of personalized lenses using freeform technology has resulted in a significant improvement of the optical quality of the lenses prescribed worldwide. More and more eye-care professionals are offering these customized lenses based on individual user parameters such as morphological data and frame parameters. The complete use of the wearer’s accommodative ability is a step forward in lens customization. The use of the accommodation results in the ability to optimize the lens using a more realistic object space as well as the ability to modulate lens oblique aberrations in a more intelligent way. Along this article, it will be explained how accommodation can be included in the lens calculation to reduce the oblique aberrations in personalized lenses in a more efficient way. By José Alonso, Eva Chamorro, José Miguel Cleva

Oblique errors are second-order aberrations that appear when the rays of light from a fixated object refract through the lens at oblique angles. These aberrations cause a shift of the lens power, which in general can be astigmatic, resulting in spherical and cylindrical errors that cause blurred vision as the wearer’s gaze moves away from the optical center of the lens (Fig. 1).

The main goal of any technology aimed to improve the visual quality of the wearer of spectacles is to reduce the effect of oblique aberrations. For that, we must compute these aberrations with the highest possible accuracy,

which in turn requires a model of the lens-eye system. The model parameters are the personalization parameters measured by the ECP. Using this model, an iterative algorithm is used that adjusts the local curvatures of the free form surface to compensate for the local oblique aberrations. However, complete cancellation of both the spherical and the cylindrical component of the oblique aberration is not mathematically possible [1] .

Although this approach delivers custom lenses performing significantly better than standard spherotorical lenses, there is always a small power error that cannot be removed and produces a certain amount of blur

• Light focused on the retina

• Lens delivers the right prescription

• Light NOT focused on the retina

• Lens delivers the right perceived cyl and sph errors

Fig. 1: Oblique aberrations. Central and peripheral viewing position.

[3,5]

IOT’s previous lens design technology compensates for oblique aber rations by looking for the freeform surface that minimizes the average size of the retinal blur patch, which is equivalent to maximizing visual acuity across the whole field of view [3-4]. But is this the optimal way to compensate for oblique aberrations? How can we go further in lens personalization? We will see that we can harness the natural ability of the visual system to accommodate to push the limits of surface geometry

in lens design.

Accommodation is the natural mechanism by which our eyes can focus on different distances. When the fixation object gets closer, the crystalline lens inside the eye, driven by the ciliary muscle, increases the curvature of its surfaces and gets thicker, raising the total spherical power of the eye. Accommodation acts as a reflex and it adjusts until the retinal image

Fig. 2: Accommodation reserve according to age (A: minimum, B: mean and C: maximum). Adaptation of classical Duane’s curve.

Fig. 3:

Fixed object space. The object space typical of a single vision lens is fixed in one plane, usually infinity. For each point of the lens, oblique aber rations have been minimized for its corresponding point at infinity.

Variable object space. The object space typical of a progressive power lens. Each point of the lens is assumed to be used for a different wor king distance differently. The lens upper region is optimized for far vision, the lower region for near vision, and the points along the corridor have a target intermediate object distance.

is in focus. The maximum accommodation the eye can exert is called accommodation amplitude; it is maximum at birth and continuously decreases over time. When this amplitude drops below 4 D (around 40 years of age), accommodation is not enough for comfortable sustained near vision (presbyopia); then we need to compensate with reading glasses or multifocal lenses.

This decline continues into the mid-fifties when accommodation amplitude reaches its minimum value. Even in that limiting situation, optical and physiological properties of the eye grant an effective ac commodation that the patient can bring into play to make slight adjust ments of focus [6,7] (Fig. 2).

The oblique aberrations of spectacle lenses not only depend on the lens-eye model parameters, but also on the distance from the lens to the object. Traditionally, single vision lenses are optimized considering a single object distance, for example, infinity for a lens mainly intended for far vision. However, the lens optimized for distance vision will not be optimal for near vision, and the other way around. Progressive lenses require a more complex object space. Different regions of the lens are assumed to be used with different object distances. The classical approach has been the use of a variable object space in which each gaze has a corresponding object distance. However, for each gaze, even the presbyopic eye can increase or relax accommodation to

Accommodative object space. It is the set of object points within the field of view and in the range of sharp focus through accommodation. IOT Digital Ray-Path 2 uses a set of sampling points along the depth dimension of the accommodative object space to compute the lens that performs better in real-life use.

focus objects at different distances. We call the set of these points the accommodative object space.

IOT Digital Ray-Path 2 (DRP2) will optimize the lens by including the computation of oblique aberrations for a set of points that fully sample the accommodative object space. This will mean a better compensation of oblique aberrations, not only across the complete field of view, but along the total depth of the accommodative object space.

As stated before, sphere and cylinder oblique errors cannot be compensated by surface curvature at the same time, and the previous IOT optimization technology, Digital Ray-Path (DRP), sought for the maximization of visual acuity in the complete field of view. However, depending on the prescription, the base curve, and the object distance within the accommodative object space, the spherical component of the oblique aberration can be partially or totally compensated by the eye accommodation. That means the optimization algorithm may put more stress on the reduction of the cylindrical component of the oblique error.

According to this, for each gaze direction, DRP2 seeks the solution that minimizes the oblique aberrations considering that a small amount of the spherical component can be compensated by the accommodation while the cylindrical component cannot. The algorithm considers the base curve, its asphericity (if any), the lens material, all the traditional personalization parameters, the multiple object distances for each gaze direction according to the depth of the accommodative object space, and the accommodation that can be safely used in each step.

The result: oblique aberrations are minimized in a more effective way, improving the wearers visual quality. Besides, IOT has imple mented this complete physiological optimization with more efficient optical computation strategies and improved optimization algorithms that allow the use of the much richer lens-eye model without a sig nificant increase of job computation time.

The distribution of the oblique power for a single vision lens with power

The oblique aberrations of spectacle lenses not only depend on the lens-eye model parameters, but also on the distance from the lens to the object.

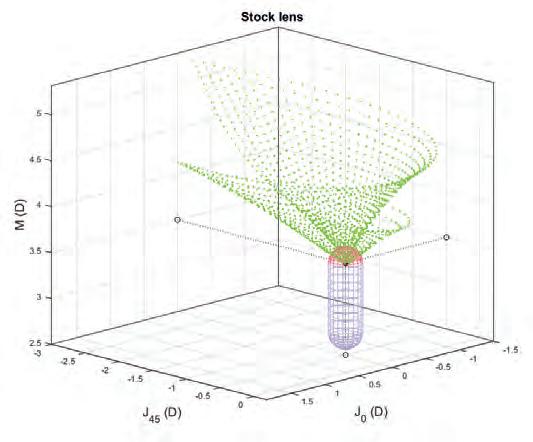

[3.0, 1.0 x 45°], base curve 6 D and refractive index 1.5 is shown in figure 4. We use the vector representation of power [M, J0, J45] [8], where “M ” is the spherical equivalent, and the “J ” components describe the cylinder projections over axes at 0° and 45°.

With this representation, the three components of the power have the same units and form a 3D dioptric space in which each point represents a prescription and the geometric distance between points uniquely determines the closeness between the corresponding prescriptions.

The clouds of green points in figure 4 represent oblique powers. From left to right, the three plots correspond with a spherotoric lens, a DRP lens, and a DRP2 lens. Oblique gazes have been uniformly sampled in the complete field of view.

The surface formed by the pink semi-sphere and the purple cylindrical region below it determines the volume of dioptric space for which the user would not notice any blur (using up to 0.75 D of accommodation, if necessary). We see that the point cloud of the standard lens extends beyond 2 D of dioptric length from the target. Also, the oblique error is positive, and cannot be compensated by accommodation for distance vision. Only 11% of the oblique gazes lie inside the region of nondiscernible blur.

For the lens optimized with DRP, the point cloud is more compact and 43% of the oblique gazes lie within the region of non-discernible blur. DRP2 manages to shrink the cylinder error (both J0 and J45) to virtually zero, while keeping a certain amount of spherical error that

Fig.4: Distribution of oblique aberrations of a single vision lens with prescription [3.0, 1.0 x 45°], for three different lens designs. On top: standard lens. Central: lens optimized with DRP technology. At the bottom: lens optimized with IOT Digital Ray-Path 2 technology.

For each gaze direction, D igital Ray-Path 2 seeks the solution that minimizes the oblique aberrations considering that a small amount of the spherical component can be compensated by the accommodation while the cylindrical component cannot.

Fig. 5: Performance comparison between DRP (X axis) and DRP2 (Y axis) technologies. The percent area for which the blur from oblique aberrations is hardly noticeable (blur smaller than 0.25 D) is represented for both technologies. The plot to the left contains 1309 jobs with standard frames, while the plot to the right shows the results for 1095 jobs with high-wrap frames.

can be compensated by accommodation. Now, 99.5% of the oblique gazes lie inside the volume of non-discernible blur.

The results presented in figure 4 are quite impressive, but, how does DRP2 perform for other prescriptions and real-world personalization parameters? The answer to this question is presented in figure 5. Here, each point represents a prescription, and each pair of points a job. The plot to the left shows 1309 jobs with standard frames, while the plot to the right shows 1095 sport frame jobs with high wrap and frame curvature. The dot color encodes the sign of the prescription

mean sphere (blue for positive and red for negative lenses).

For each prescription, we compute the percent area in which blur is hardly noticeable, less than 0.25 D, for the two optimization technologies, DRP (X axis) and DRP2 (Y axis). We see that, invariably, DRP2 outper forms DRP, in most cases by a large amount. DRP2 delivers up to a three-fold increase of undisturbed area with standard frames, and up to an eight-fold increase with sport frames.

Many real-world tests and some clinical studies corroborate the superiority of DRP2 as personalization technology. One example of such a test is a double-blind clinical trial conducted with progressive power lenses [9] The comparison involved the same PPL design (same power profile and power distribution) optimized with DRP and DRP2 technologies (Fig. 6). The users wore the lenses in a randomized order for seven days. After the testing period, the participants were asked to fill a questionnaire about visual quality (satisfaction) in a scale 1-5 for different visual tasks/ vision distances. Results showed that lenses optimized with the new calculation method provided higher visual performance. The main benefits of the lenses were related to the quality of vision and comfort, providing a better overall visual experience. ◆

Fig.

The new video series MAFO | Talks presents a lecture and Q&A about Digital Ray-Path 2.

Alonso is Scientific Advisor at IOT and part-time Professor at the University Complutense of Madrid, faculty of Optics and Optometry. He got a MSc degree in Physics in 1988, and a PhD in Optics in 1992. His main research interests are vision and optical metrology.

In 2005, Dr. Alonso co-founded Indizen Optical Technologies

In 2018 José Miguel Cleva took over the management of Operation and R&D of IOT as VP of Technical Operations. Cleva has a master degree in Mathematics (major in Computer Science), received at Complutense University of Madrid and he is specialized in Computer Sciences from the same University.

Eva Chamorro

Eva Chamorro

Eva Chamorro is the Clinical Research Director at IOT. Chamorro holds a PhD in Visual Sciences, a degree in Optics and Optometry, a MSc in Optics, Optometry and Vision, a MSc in Visual Rehabilitation and she is an expert in new methods and advanced techniques of visual examination.

References:

[1] E. Pascual, J.A. Gómez-Pedrero, J. Alonso. Improved Analytical Theory of Ophthalmic Lens Design. Applied Sciences 11, no. 12: 5696. https://doi.org/10.3390/app11125696

[2]. G. Smith. Relation between spherical refractive error and visual acuity. Optom Vis Sci Off Publ Am Acad Optom. 1991;68(8):591–8.

[3] J.A. Gómez-Pedrero, J. Alonso. Phenomenological model of visual acuity. J Biomed Opt.

[4] Blendowske R. Unaided Visual Acuity and Blur: A Simple Model. Optom Vis Sci. 2015;92(6):1–5.

[5] J. Alonso J, Gómez-Pedrero JA, Quiroga JA. Modern Ophthalmic Optics. Modern Ophthalmic Optics. 2019.

[6] W.N Charman. The eye in focus: accommodation and presbyopia. Clin Exp Optom 2008; 91: 3: 207–225.

[7] D. Atchison, G. Smith. The optics of the human eye. Butterworth-Heinemann. Edinburgh, 2002.

[8] L .N. Thibos, W.Wheeler, D. Horner. Power vectors: and application of Fourier analysis to the description of statistical analysis of refractive error. Optom. Vis. Sci. 1997:74(6):367-375

[9] G onzález A, Álvarez M, Concepcion P, Dotor P, Cleva J, Alonso F. Accommodative object space and progressive lens desig

Advertisement José Miguel Cleva

José Alonso

José Miguel Cleva

José Alonso

For most of the ophthalmic laboratories, among the many steps for lens manufacturing, the most critical one is certainly the hard coating process. This is probably linked to the fact that it is a chemistry related process and not a purely mechanical one. Most laboratory managers have a good knowledge of optics, mechanics and IT, but little or no knowledge of chemistry. Besides, machine manufacturers share the same knowledge features as their customers. Most of them believe that there is a cleaning/rinsing operation before the dip coating of the lenses, but this is not really the case. Some others may know that it is not really the case, but since they also sell consumables, including lacquers, their interest is to maximise the consumption of the chemicals in their machines. By François Breton

Actually, there are two parts in a dip coating machine, the first part being the lens surface preparation, and the second part being the dip coating itself. The truth is that 90% of the problems observed when taking lenses out of the machine come from the first part. Why is it so? Mostly because the key ingredient of this process is the water and moreover the tap water! This process is not at all a

cleaning process because lenses are clean already when they are placed in the machine. What we are explaining here is that the lens substrates are made out of organic polymers with a given porosity. These polymers need to be ‘activated’ in order to create a chemical bonding with the hard coating lacquer. This activation requires a strong alkaline species (Fig. 3) in order to withdraw protons from the substrate.

In order to maximize the effect of either sodium or potassium hy droxide, it is necessary to use a surfactant for a good wetting of the lens surface, since lens materials are more hydrophobic than hydro philic. Ultrasonic waves help also a lot in that activation process, although for most of the machines, transducers are placed under the tanks which leads to waves going from bottom to top, therefore not hitting the lens surface directly.

This is the reason why activation times may be quite significant and increasing with the lens refractive index which substrates are much less chemically reactive than standard 1.5 material. Once this activation is achieved to a significant level, comes the rinsing stage and this is where most of the commercial dip coating machines are doing it wrong …

We can compare what is happening to the lenses to what is happening to our hands when washing them. In such a case, it is obvious that the soap goes away much faster with warm than with cold water and with hard than with soft water.

Yet, as can be seen on those machines, this tap water rinse tanks are neither heated nor ultrasonically powered. As a consequence, surfactants are carried forward into the DI water tank which, even fitted with heat and ultrasonics, is not able to remove the surfactant.

What is then happening is that the remaining surfactant, carried forward by the lenses, is finally removed from the lacquer by the solvent. This leads to a lacquer contamination which will expire faster than it should. This is rather easy to understand, so it is pointing out the wrong design of many commercial dip coating machines.

In some cases, it can even be worse, as there is sometimes an extra tank with an acidic soap, supposed to neutralize alkaline residues. This makes sense if this process would simply be a cleaning/rinsing one. But it is not!

Rinsing with an acidic soap is nonsense because it is actually reducing the activation level at the surface of the lenses. It is much better to replace the acidic soap with straight tap water if such a tank is available. Not only it will not decrease the surface activation, but it could also improve the rinsing process because that tank is generally fitted with heating and ultrasound.

Of course, since it is a static tank, this water will need to be changed from time to time, the frequency depending on the number of lenses that would go through it. In some cases, the city water may be too hard (presence of Ca 2+ and/or Mg 2+ cations); in such a case, it is advisable to soften it (meaning replacing alkaline-earth cations with Na+) in order to avoid limestone deposit at the surface of the lenses. Ideally, this should be monitored with a conductivity meter.

The conductivity is a way to measure the ionic strength, that is the power of removing surfactants from the lenses. An ideal situation is when the city water conductivity ranges between 300 and 400 µ S.cm-1

If it is lower, the ionic strength is insufficient and it could be needed to increase the temperature and/or the rinsing time. If it is higher, the resins used to maintain the low conductivity of the DI water may get saturated too fast.

It should be considered that the maximum conductivity for the DI water to ensure optimum results is 0.3µ S.cm-1. When the DI water conductivity becomes higher, dots start to appear at the lens surface, as the alkaline pH value of the lens favors the formation of carbonates, given the fact that there is always a significant amount of CO2 around the machine caused by breathing of the operators.

Once the lenses have been immersed into the DI water, it is important to check that there is no water left at their surface when coming out from the tank during a slow (less than 1m m/s) lift-out. This is a sign that the lens activation and rinsing has been well performed. There might be still some water on the lens holders and this is why a good IR drying is neces sary in order to introduce any water in the lacquer.

However, when using a water-based primer, it is obviously no longer necessary to dry the lenses prior to entering the tank. The IR power for drying lenses and lens holders can be set to maximum power as there is a need to remove all remaining water for avoiding any lacquer contamination.

Nevertheless, some lens substrates may have lower heat resistance and may distort from the combined effect of the temperature and the pressure from the lens holders. In such a case, it is necessary to reduce IR power while increasing the drying time.

Drying times mostly depend on relative humidity and air flow within the machine, that is why it is impossible to set a general rule for that stage. Anyway, it is necessary to allow the lens and its holder to cool down prior to entering the lacquer tank. There should not be a temperature difference of more than 10°C with the lacquer temperature in order to avoid formation of micro bubbles at the lens surface. These micro bubbles are actually made of fast evaporating solvents such as methanol or ethanol that are trapped within the already close to drying hard

What is then happening is that the remaining surfactant, carried forward by the lenses, is finally removed from the lacquer by the solvent. This leads to a lacquer contamination which will expire faster than it should.

coating surface. This phenomenon being likely to happen again if the IR drying station next to the lacquer tank delivers too much power too early. That is the reason why it is desirable to have either a program mable IR pre-curing station or two contiguous IR tanks, the first one delivering half power before going to full power in the second one.

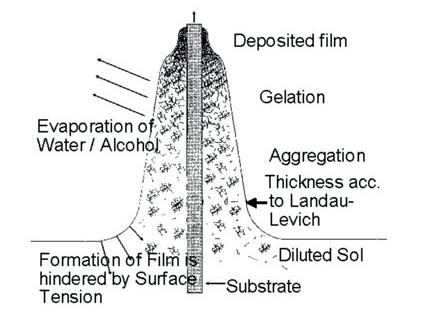

The most complex and critical stage in the dip coating process, is, of course, the dip coating itself! Nevertheless, it has been studied intensively by two Soviet scientists, Lev Landau and Veniamin Levich who described it back in 1942 with their famous equation allowing to calculate the coating thickness: h = coating thickness, η = viscosity, γLV = liquid-vapour surface tension, ρ = density, g = gravity.

As it can be expected, the coating thickness is mainly defined by the withdrawal speed, by the solid content and the viscosity of the liquid. The withdrawal speed must be chosen such that the shear rates keep the system in the Newtonian regime, in such a case the Landau-Levich equation becomes really accurate.

As shown by James and Strawbridge for an acid catalyzed silicate sol, thicknesses obtained experimentally fit very well to calculated values. The interesting part of dip coating processes is that by choosing an appropriate viscosity the coating thickness can be varied with high precision from 20 nm up to 50 µm while maintaining high optical quality. The schematics of a dip coating process are shown in figure 1.

process and the formation of a transparent film due to the small particle size in the sols (nm range). This is schematically shown in figure 2.

Fig. 1: Stages of the dip coating process: dipping of the substrate into the coating solution, wet layer formation by withdrawing the substrate and gelation of the layer by solvent evaporation.

When reactive systems are chosen for coatings, as it is the case in sol-gel types of coating using alkoxides or pre-hydrolyzed systems – the socalled sols – the control of the atmosphere is indispensable. The at mosphere controls the evaporation of the solvent and the subsequent destabilization of the sols by solvent evaporation, leads to a gelation

Fig. 2: Gelation process during dip coating process, obtained by evaporation of the solvent and subsequent destabilization of the sol (after Brinker et al).

In general, sol particles are stabilized by surface charges, and the stabiliza tion condition follows the Stern’s potential consideration. According to Stern’s theory the gelation process can be explained by the approaching of the charged particle to distances below the repulsion potential. Then the repulsion is changed to an attraction leading to a very fast gelation. This takes place at the gelation point as indicated in figure 2. The resulting gel then has to be densified by thermal treatment, and the densification temperature is depending on the composition. But due to the fact that gel particles are extremely small, the system shows a large excess energy and, in most cases, a remarkably reduced densifica tion temperature compared to bulk-systems is observed.

However, it has to be taken into consideration that alkaline diffusion in conventional glasses like soda lime glasses starts at several hundred degrees centigrade and, as shown by Bange, alkaline ions diffuse into the coated layer during densification. In most cases, this is of no dis advantage, since the adhesion of these layers becomes perfect, but influ ences on the refractive index have to be taken into consideration for the calculations for optical systems.

Of course, this thickness calculation mostly corresponds to the value measured at the center of the lens. Ideally, to get a homogeneous thickness on the lens, a speed gradient should be applied, but only a few machines allow it. Yet, this is the best way to overcome the famous tear problem on bi-focal lenses along the segment.

Some machine manufacturers who cannot offer the gradient speed feature either recommend extremely slow speed leading to insufficient coating thickness to guarantee the scratch resistance, or extremely high-speed leading to potential cracking of the coating layer during the curing stage.

The best solution being to run those lenses at the nominal speed specified by the lacquer supplier followed with the maximum acceleration that the robot can deliver as this is increasing the centrifugal effect to expel the tear out of the lens. Anyway, with the spreading of freeform lenses in the market, the bi-focal lenses are likely to become just a piece of ophthalmic history.

Back to what is creating the chemical bonding of the lacquer to the lens. It is of course linked to the chemical composition of the lacquer which must contain a certain amount of epoxy groups to ensure the maximum adhesion to the lens substrate as can be seen in figure 3.

is generally the case), condensation occurs, reducing the pot life of this family of lacquers that was originally developed for fast drying and high throughput.

It is clear that the outcome of a dip coating process is purely driven by physical and chemical parameters. When knowing this, there is no surprise with the result obtained from it. Machine manufacturers must understand that, from now on, actual and potential customers will no longer accept equipment which do not comply with the minimum requirements needed to ensure the maximum quality for their lens production. ◆

Fig. 3: Reactions occurring in the machine during the pre-curing of the hard coating.

It is clear that with this covalent bonding, an extremely strong adhesion level can be reached, making it difficult to remove the coating layer.

It is of prime importance to control temperature and Relative Humidity (RH) within the machine. However, because of the lower flash point of methanol and its high evaporation rate, methanol-based lacquers require a tank temperature around 10°C. Yet, when RH is set at 40%, condensation occurs when temperature difference with air gets higher than 6°C. This, in practice, requires that operators should work in a room where temperature is lower than 16°C, or that (what

Breton graduated with an engineering degree in Chemistry followed by a PhD in Organic Chemistry and a PostDoc in Polymer materials. He started his career in big US companies such as GE and Goodyear before entering the Optical sector back in 1999 with SDC Coatings. He successively worked with NGL and FISA before creating his own company named Chemoptics. This company later became HPMAT (High Performance MATerials) to reflect activities outside the Optical sector and a JV was created in Russia under the name of FBOptics but as can be expected, it is now ‘on hold’ until further notice!

solution for verifying your free form production lenses.

fast, robust, and easy to use. Maps the whole lens compares to the intended lens and makes the Go/No go decision,

in 8 seconds.

High-resolution lens mapper especially designed for the new generation of myopia control designs. An essential tool that your sold lenses are of superb quality !

François Breton

François Breton

The desire to design the ideal progressive addition lens for each user has been a constant over the years. The tools that have emerged along the years to offer customization demonstrate this. One new tool is a lens calculation technology that can take into account the gaze dynamics diagnosis of each person´s unique way of looking at the world. By Pau Artús

Since the first progressive addition lenses were industrially produced in 1959, a variety of companies have offered similar technical solutions. All the designs around that time were of a similar type giving birth to what today is known as the hard design philosophy, i.e. more abrupt transitions between the areas with and without unwanted lateral astigmatism. The first soft designs appeared in the 1980s, with a more gradual transition between those areas, but in exchange they suffered from some invasions of astigmatism into the usually clear areas. This led to trials and studies to try to understand people´s preference for one philosophy or another. First recommendations were based on the wearer´s experience with progressive lenses.

Later began the customization race where the position of wear of the frame would also be taken into account. Three additional parameters were required for this purpose: back vertex distance, pantoscopic tilt, and wrap angle. This had a significant contribution to the user’s visual quality.

In the on-going search for personalization, the relationship between head and eye movements were also studied. For this purpose, a coefficient relating these two parameters was established and users were classified according to whether they moved their head more or less than their eyes. But in spite of the improvement in visual quality, progressive lenses did not provide completely comfortable vision for all of the users.

Then lens manufacturers began to show interest in understanding the effect of the lifestyle of presbyopic patients and in assigning designs based on their daily activities. By means of a questionnaire, the practitioner collected qualitative information about the patient´s activities and lifestyle to offer a solution that was adapted to the specific needs. However, although this method is still widely used nowadays it relies on subjective information that depends on the patient’s perception and the circumstances they may be living at that particular moment. For example, when asked “how often you play sports,” or even “how much time you spend using electronic devices,” the same person can give different answers at different times of the week, or even answers that are strongly conditioned by his or her wishes rather than by reality.

Furthermore, knowing the time spent on different types of activity does not give very relevant information about how lenses are used, since two people may behave very differently when doing the same activity.

In short, the various tools developed to customize progressive lenses have no doubt improved presbyopic users’ vision but are still far from achieving the ideal solution that perfectly adapts to each patient’s needs.

Gaze dynamics can be defined as the movement of your direction of gaze with time. It involves the whole human oculomotor system (head, neck [1], eyes) while individuals follow objects with their gaze that draw their attention or that are relevant to the activity they are performing. This combination of head, neck and eyes movements is unique to each person, as each individual has a different way of combining them [2]

For gaze dynamics to be considered as reliable, the user’s visual environ ment must be free of any visual impairment, meaning that no element in the system should prevent the individual from looking at objects naturally. So, we define the visual environment as the spatial area a person can reach by naturally performing a combination of eye and head movements.

Development of perceptual [3] and oculomotor abilities of vision occurs as the necessary anatomical and physiological maturation of the visual structures is acquired. The visual system is immature at birth. The motor response is limited due to the immaturity of the fovea, reduced visual acuity, and low contrast sensitivity. All of this limits fine control of accommodation, tracking movements, and precision of monocular and binocular alignment. A baby will be able to dem onstrate a range of eye movements that, while less sophisticated than those of adults, indicate normal visual development [4]

Similarly, as you become older, some muscles and joints become less and less flexible and the tracking movements gradually increase eye movement ratio. In other word, gaze dynamics changes along the life of a person.

Eye movements [5] depend on the oculomotor system and have two main functions: to locate the image of the objects in the visual field in the fovea and to keep the image in that position. Among the various types of eye movements [2], tracking movements (Fig. 1) are the most relevant in the study of gaze dynamics.

Tracking movements are oscillatory, rapid and have a clear fixation stimulus [6]. They are voluntary, i.e., they are produced in a coordi nated manner by both eyes. Their function is to maintain the gaze a gainst involuntary eye drifting. They also regulate fixation [7] in vergence movements [8]

These movements are brief and intermittent in babies, interrupted by saccadic movements that help restore fixation. Tracking movements are not smooth until 8-12 weeks. Horizontal tracking appears before vertical (as is the case for saccadic movements).

The individual also re sponds sooner to fixa tions at constant speed and later to fixations at variable speed.

Fig. 1: Tracking movements

These are necessary to observe the whole visual environment. Their function within gaze dynamics is to compensate for eye movements to ensure correct fixation on the fovea.

Head movements are defined by the head-neck [1] combination. From a mechanical point of view, this is defined as a set of masses supported by a practically rigid system (the skeleton) connected by viscoelastic soft tissues.

When the head is tilted, the oculomotor system causes a torsion of the eyes intended to compensate for the loss of verticality that the retinal image would suffer under these conditions. The torsional VestibuloOcular Reflex (VOR) is responsible for this process (Fig. 2).

So, when the head is tilted to the right, there is a shift of the eyes to the left, while tilting to the left causes a shift of the eyes to the right. In short, the visual system is responsible for compensating for the displacement generated in the image due to a head movement. In this way, gaze dynamics is the mechanism that ensures that the image will be as static as possible on the retina all the time.

Fig. 2: Torsional VOR (Vestibulo-Ocular Reflex)

When the concept of gaze dynamics was introduced above, we talked about the required absence of impairments in the visual environment to make sure a person can perform eye and head movements without limitations. However, things change when progressive lenses are used. With the use of progressive lenses, gaze dynamics encounters limitations. Progressive lenses have clear areas for all visual distances but as a side effect, they have other areas, typically on the sides of the corridor, with aberrations that the user perceives in the form of blurring. This is usually known as unwanted astigmatism. This means that the visual environment will be limited, and therefore the user’s gaze dynamics will be altered.

There are many commercial devices that allow the measurement of gaze dynamics. Eyetrackers are among the most common ones. These devices can trace the user gaze direction while he or she is exposed to different kinds of stimulus. Many studies use the measurement of gaze dynamics to understand preferences and priorities of users when being presented a lot of information simultaneously or when looking at different stimuli that keep their attention.

However, gaze dynamics applied to ophthalmic also need to track the users head movement to truly understand the real use of each area of the lens. In other words, recording only the gaze direction might not give you the full lens use information since the position of the head will ultimately determine through what area of the lens the gaze will go. Recent technology advances in virtual reality headsets (Fig. 3) have brought this technology to a point that makes it specifically suitable to be used as a gaze dynamics measurement device. A virtual reality headset with software specially designed can be used to diagnose the gaze dynamics of a specific patient, i.e. by enabling controlled measurement of eye and head movements in a controlled environment free of external factors.

This immersion allows the user to live the experience in first person, as they can see as if they were really inside the virtual world, minimizing the sensation of user-device interface and establishing a direct relation ship between them.

Virtual reality headsets are composed of cameras and sensors that integrate the subject in the virtual environment and precisely record user movements in it. They also ensure an optimal binocular visual field, which gives an unrestricted space by simulating natural gaze movement. Speakers are usually present to enhance a fully immersive sensory experience.

In addition, given the three-dimensional nature of these systems, they can also allow gaze dynamics evaluation at many visual distances to register whether there are significant differences while the person looks at a stimulus that is at a near, intermediate or far distance.

Gaze dynamics diagnosis for ophthalmic applications can be nicely represented using frequency maps (Fig. 4). These maps can be readily calculated by taking into account eye and head movement and they allow you to identify what areas of the lens will be used in a higher or lower frequency.

Many parameters can be extracted from each of these maps. Overall size can be considered important since it is related to the total area of the used lens. Vertical to horizontal size ratio can also be relevant since it will show preference for longitudinal eye or head movements over transversal.

And, obviously, the actual location of the maximum frequency areas should also be taken into account since it will show user preferences for certain parts of the lens. Finally, when different maps registered at different distances are combined, the quality of the gaze dynamics study for that person can be greatly increased. All the information relevant for a fully personalized lens design can be revealed.

Fig. 3: Virtual Reality headset. Fig. 4: Example of a frequency map. Red color shows high frequency of use of that area while blue color shows low frequency of use.We know that user satisfaction with progressive lenses is subjective, i.e. it depends on each person’s perception. This means that, when trying two progressive lenses of the same category (e.g. premium) but different manufacturers, two users may feel more comfortable with one over the other.

The reason behind this is that optical features that are significantly different among two designs can have different perception and ac ceptance by different users, but this is also telling us that a preferred ideal solution may exist for each person. That is why one of the major challenges in the ophthalmic sector has been to understand and characterize users to try to identify which parameters could reveal their preferences. And accordingly, the major challenge in the lens designing field is to be able to provide a wide enough range of optical features in progressive lens designs that can fulfill user preferences.

But what happens nowadays is that the progressive lens market offers a finite set of solutions. This means that a user has a limited list of lens design options available at a given selling point, often strongly biased by the previously established business relationship between the optical shop and its supplier.

Therefore, an unprecedented lens calculation technology needs to be created that can smoothly vary optical features continuously and gradually, without jumps, to accommodate any registered gaze dynamics.

Other industries, such as aeronautics, had a dream many years ago of continuously changing the geometry of physical objects applying what they call the morphing technique. Aeronautic engineers dreamed of modeling aircraft wing flaps in such a way that geometry changes could happen like those in a bird’s wings to optimize performance at any given moment.

The optical industry needs to incorporate a similarly disruptive technol ogy into designs to create infinite solutions for infinite individuals that enable the generation of the optimal solution for each of them, incor porating his or her frequency map as one of the main inputs. The result could finally be a truly tailor-made progressive lens for a particular user, which can take into account the gaze dynamics diagnosis of someone's unique way of looking at the world around them.

The combination of gaze dynamics measurements using Virtual Reality headsets with the appropriate design flexibility can become the last frontier for the progressive design personalization. Thanks to it, a presbyopic patient will be offered a progressive solution that perfectly matches his or her visual requirements.

A careful study and interpretation of the gaze dynamics can allow an accurate and reliable diagnosis for each patient to create a solution for them that will be the preferred one. And probably more important, the gaze dynamics measurement using a virtual reality device can

take the lens shopping experience to an unprecedented exciting level where the lens selling step is no longer a disorienting moment of pain where customers need to cope with the idea of paying the highest cost of the spectacle for a round transparent piece of material that the ECP prescribes. Instead, the customer perceives now he has become an active part shaping the lens features through an immersive and unique experience. ◆

Acknowledgements: Ivette Bruguera and Elisabeth Meliá

References:

[1] https://es.slideshare.net/Natt-N/movimientos-del-cuello-55378548

[2] A lberich, J. Ferre, A. Gómez, D. Percepción Visual. Universitat Oberta de Catalunya.

[3] Peter N.T. Wells, William R. Hendee. The Perception of Visual Information. Second Edition.

[4] Pacheco, M. Desarrollo Postnatal de la Función visual. Universistat Politècnica de Catalunya.

[5] Motilidad y Percepción Binocular: Tipos de Movimientos Oculares. Universitat Politècnica de Catalunya

[6] A ntony, F. Coordination of Eye and Head Movements during Reading. Article in Investigative Ophthalmology & Visual Science · July 2003

[7] Federico, A. Federighi, P. Rosini, F. Rufa, A. Veneri, G. Evaluating gaze control on a multi-target sequency task: The distribution of fixations is evidence of exploration optimization. Computers in Biology and Medicine.

[8] Pons, A. Fundamentos de visión Binocular. Universidad de Alicante.

[9] Azadi, R. De Vries, J.P. Harwood, M.R. The saccadic size-latency phenomenon explored: Proximal target size is a determining factor in the saccade latency. Vision Research.

Pau ArtúsThe Chief Innovation Officer (CIO) at Horizons Optical studied Chemistry at Universitat de Barcelona and got his M.Sc. in Molecular Magnetism at Indiana University. His ophthalmic career started in the R&D department of Indo in 2002 where Artús has developed most of his professional career as a Material Chemist and Coatings Developer until he became the R&D manager in 2008. In parallel, he got his Ph.D. in Mechanical Properties of Plastic Materials for Ophthalmic Lenses (UPC in 2009) and a masters degree in Innovation Management (UPF in 2011). In 2017 the company Horizons Optical was created as a spin-off of Indo where Artús initially was the Operations Director and later became the CIO.

Vision Expo East 2022 concluded on Sunday, April 3. The four-day event, which took place March 31–April 3 at the Javits Center, marked Vision Expo’s first show in New York City since 2019 and brought enthusiastic members of the vision care industry from the United States and around the globe together under one roof.

By Hanna DiewaldVision Expo East featured more than 360 exhibiting companies and the education program offered more than 230 hours of education. On the main stage there were various discussion rounds on current topics, ranging from fashion trend forecasts to the metaverse and cryptocur rency. Various prominent guests could be seen live on stage, for example the fashion innovator and author Dapper Dan. Fran Pennella, Vice President, Vision Expo, at RX, co-organizer of Vision Expo, expressed his enthusiasm: “It was incredible to bring the vision care community together again in New York City for the first time since 2019. The Show Floor was buzzing with activity and the energy, especially on day one, was palpable as motivated attendees and exhibitors reconnected with their peers, conducted business and engaged with the education offerings [...].” he said.

Also, the companies in the lens processing area seemed satisfied for the most part. Coburn Technologies showcased the fully automated post-polishing system, which includes the new Integrity Alloy Recovery System, Coburn’s latest technology in lens processing. “Integrity generated much interest as it is the first and only automated waterless alloy recovery system in the industry”, announced the company. Its induction heating technology makes Integrity a cleaner and more efficient solution, leaving detached alloy pucks completely intact for safe reuse.

Satisloh unveiled their new and inventive film lamination technology. With 1/3 the investment of a conventional coating lab, a film lamination can coat lenses ten times faster and in a fraction of the space with top quality. Customers were highly interested in the new technology that was demonstrated live at the show, reported the company.

The Schneider team was busy offering customers a first look at many new technologies and products for release this year, eleven in total, shaping the power lab of the next decade. “The first VEE back in New York in three years turned out to be a good show for Schneider,” said Kurt Atchison, President Schneider US. “Although show overall attendance was down a bit from previous years, it is finally approaching normal again. Customers seemed anxious to experience an important industry event for the first time in a few years for many of them. […] Larger automation projects were in focus from customers looking to build modern, integrated production systems, especially after the difficulties they’ve faced with COVID and now supply chain and offshoring challenges. It was great to showcase what the future holds from Schneiders’s new innovations.”

Back in New York City after three years, MEI showed to the audience all the new machines and solutions developed over the last months. The Italian company presented Easy Buddy, an innovative robotic lens loading system developed for the EasyFit Trend compact lens edger. With Easy Buddy, the lab operator no longer has to spend all day feeding

The team from Coburn Technologies at VEE. Source: Coburn Technologies Satisloh´s new film lamintaion technology was unveiled at the show Source: Satislohthe machine but can prepare several trays and let the robot directly load the lenses, then take them once edged. An ideal solution for small labs that do not have space for an industrial lens feeding system but want to take advantage of an automation process. Besides that, MEI presented for the industrial customers BispheraTBA Phoenix, the new lens edger, for any kind of small and big lab, offering excellent throughput, great flexibility, and best quality control capability.

IOT presented the new portfolio of lens designs based on new groundbreaking technologies and methodologies of lens calculation: Camber, IOT Digital Ray-Path 2, Steady and Steady Plus methodologies. These technologies completely renew the company´s portfolio and have shown that they are up-to-date with the latest industry trends. “Combining a trade show and launching new technologies is a great way to attract and show all the effort, R&D and innovation behind the company”, said IOT.

In summary, Vision Expo East was a good show, which was especially convincing because of the atmosphere, as Robert L. Kohn, President North America at Automation & Robotics, concludes for MAFO:

Kohn said: „The general attendance was perhaps slightly below normal, but the business negotiations were plentiful, and productive. The mood of the attendees was very positive, with many laboratories prepared to

invest in capital equipment as we progress through the year. I personally met with attendees from Canada, Mexico, Latin America, the Caribbean, across the US, and a few from Asia and Europe. Much of the world was represented, and everyone was very enthusiastic to reconnect at the show! There was not much talk about new product release at the show; rather, it appeared that most exhibitors took a cautious approach by bringing fewer staff, and fewer pieces of equipment to display. By the end of the show, the feeling was that we are moving in a good direction and getting back to normal!”

The next Vision Expo East in New York will take place from March 16 – 19, 2023, in the Jacob Javits Convention Center again.

As the commencement bell rang to begin VEE 2022, the excited attendees began flooding into the exhibit hall like beautiful waves crashing on Hawaii’s North Shore. At least that is how it felt after three years of waiting for the return of this show!”Schneider´s booth at VEE. Source: Schneider IOT´s team at the booth at VEE. Source: IOT MEI´s booth at VEE. Source: MEI Automation & Robotics booth in New York. Source: A&R

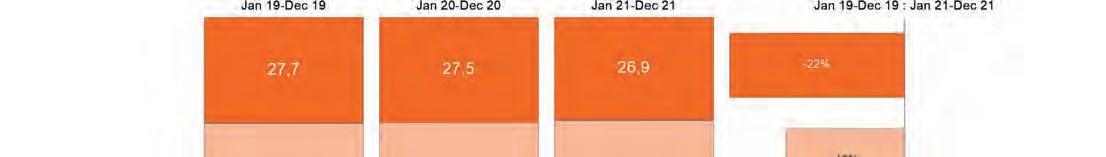

n 2021, the group of European core markets France, Germany, restrictions have not disappeared yet, the European opticians and their

Fig.

GfK

in 2021 only caused sales declines by less than 10% compared to prepandemic levels (Fig. 1). Between the lockdown phases postponed purchases that could not be done during the lockdowns took place.

Looking at absolute sales volumes for spectacle lenses, the European market has reached its pre-pandemic level again in 2021 (Fig. 2). Im portant for the market recovery were increased sales of plastic progres sive and proximity lenses, which were in higher demand than normal due to many people working from home. The mineral lenses continued former sales declines and remain a small market niche. In terms of materials and refraction indices, European customers and opticians moved their focus further towards thin, high quality lenses

(refraction indices of 1.6 and plus, figure 3). These types of lenses gained market share over 2020 and 2021, while the shares of lenses with refrac tion indices of 1.59 and below declined.

Although the opticians’ core business with spectacle lenses seems to be back on track, the more social products in the optics portfolio still struggle with the pandemic effects.

The sales volume of sun glasses could grow by 14% in 2021 compared to 2020 but still is about 20% behind its pre-pandemic level of 2019 (figure 4, retail only). Similarly, the contact lenses sales still lack about 6% before reaching former sales levels again (figure 5, value, retail only).

Fig. 3: Plastic spectacle lenses sales (volume, EU4) by type and refraction index. Panel markets are Germany, France, Italy and Spain. Retail sales units. Source: GfK

Graph 2: Spectacle Lenses sales (volume, EU4) by correction type and material

Graph 3: Plastic Spec. Lenses sales (volume, EU4) by type and refraction index

Fig. 3: Plastic spectacle lenses sales (volume, EU4) by type and refraction index. Panel markets are Germany, France, Italy and Spain. Retail sales units. Source: GfK

Graph 2: Spectacle Lenses sales (volume, EU4) by correction type and material

Graph 3: Plastic Spec. Lenses sales (volume, EU4) by type and refraction index

Fig. 4: Sun glasses sales (volume, EU4) by gender type.

Panel markets are Germany, France, Italy and Spain. Retail sales units. Source: GfK

Fig. 5: Contact lenses sales (value, EU4) by replacement frequency.

Panel markets are Germany, France, Italy and Spain. Retail sales units. Source: GfK

However, when looking at the sun glasses and contact lenses segments from a total market perspective, it can be assumed that online sales (that were not taken into account here) could compensate for a good part of the corona losses in the retail channel.

Summarizing, the market recovery in EU4 during 2021 shows the resilience of the optics segment even in times of crises. With a little bit of luck and less unforeseen changes in life and market conditions compared to the past two years, 2022 can become a good year for the European optics business. ◆

As Senior Marketing Consultant, Roland Lorek is responsible for the Point-of-Sales-Panel Optics of GfK Germany. He joined the German Optics team in 2015 and consults customers and retail partners within the optics industry. He lives in Bamberg, Germany, with his wife and two daughters.

Roland Lorek

Roland Lorek

Globally, the North American market is the most important market for eyewear. MAFO has taken a closer look at the data from 2021 and summarized the most important key figures for the eyewear sector.

The global eyewear market is expected to grow annually within the next years and, according to Statista, the market is forecasted to be worth around 154 billion U.S. dollars in 2022. The largest market worldwide for eyewear is North America. However, market researchers predict the AsiaPacific-region and China in particular as the fastest growing markets in the next years.

The U.S. market 2021

According to the VisionWatch market research report, released by The Vision Council, 45.83 billion U.S. Dollar worth of eyewear was purchased during the 12-month period ending December 2021,

representing a 24.3% increase over the 12-month period ending December 2020 and a 5% increase over the 12-month period ending December 2019. Lenses account for the largest financial share at 15,903.3 million of current dollars (not adjusted for inflation), followed by frames in 2021. The total Rx lenses market in units was 95.6 million of pairs.

It is worth mentioning that the market for refractive surgery has increased significantly. While it was worth 1,869.2 million of current dollars year-end December 2018, it was already 2,199.7 millions of current dollars year-end December 2021 – a significant increase.

In the area of spectacle lenses, single-vision lenses still account for the most significant share with 55%. Followed by progressive lenses (PAL) with 32%. Overall, 46% of the lenses were AR-coated.

Market share of units by

AR-coating,

attributes:

and more.

multifocal. Source: Vision Watch Report, The

Council

In the overall market for ophthalmic lenses, it was found that independent practices (with three or fewer locations) still generate the largest market share for ophthalmic lenses (51.7%). Optical chains such as LensCrafters, Pearle, EyeMasters,

account for 26.7% of the share.

Mass Merchants / Wholesale Club such as WalMart, Target, or Costco contribute 9.9% of lens sales and Department Stores (eg. Sears, JC Penney, or Macys) for only 0.3%. Online/Internet retailing (eg. Warby

Zenni,

accounts for 7.3% of the market.

was found that independent practices still generate the l argest market share for ophthal mic lenses (51.7%)

The market for spectacle lenses for myopia management continues to grow further. Products from a wide range of manufacturers are now available in many countries throughout the world. The topic is both hugely important but at the same time controversial, since it remains unclear how objective eye doctors and ECP´s are when giving their patients and customers advice, and to what extent a meaningful myopia management is practiced at all, that justifies the name. One reason being that, according to current research, the typical myopia development in children in Asia differs significantly from that in Europe, the USA or other countries. MAFO spoke to two German experts in the field: a representative from the industry and an academic and practice-oriented expert, who himself is involved in myopia management. An interview with Mareike Noé (Marketing Manager at Visall) and Prof. Dr. Stephan Degle (Ernst-Abbe University, Jena).

By Hanna DiewaldHow does the situation in Germany differ from that in Asia, for example?

Degle: There is quite a well-known discrepancy according to region as far as myopia and myopia progression are concerned. In our region (editor`s note: in Germany), only a very small proportion of children aged four, six or eight experience strong myopia progression. In Asia,

by contrast, the proportions are much higher. As a rule, myopia progression here starts much later, at the age of ten or twelve or even later, i.e. in young adults and students. This is very different from the situation in Asia, where most of the studies have been carried out. Many people don´t realize this. And right now, we have a lot of products that are actually focused on this market (directed to Ms. Noé: with a few exceptions).

People with very high myopia of 6 D or more make up only a small proportion of spectacle wearers. For which children does myopia management make sense at all?

Degle: It has been known for some years that the risk of pathological myopia is not due to the dioptric value. The issue is eye length growth and it has been more or less agreed that the length should be more than 26.5 mm, that is 2.5 mm more than the theoretical Gullstrand eye. Actually, it´s not even about the length itself, but about the progression of the eye length growth. In essence it is a matter of preventing the eye from growing rapidly in a short period of time, in a way that would result in a vision change.

Currently, a variety of lenses for myopia management are available on the market, based on different concepts. Can we assume that all of them are equally effective in slowing down myopia progression?

Degle: Each of these concepts has advantages and disadvantages in specific cases. This means that it needs to be decided on a case by case basis, which lens, which product or which treatment plan is most suitable for whom. This is an important prerequisite which, with few exceptions, currently does not exist in the market.

Ms. Noé, what do you do from a manu facturer’s point of view to inform people about the differences?