12023 (93)

International News

• PFAS forever?

Fitting Background

• Soft Lenses for the irregular cornea

• Visual performance of Ortho-K and LASIK patients

Business + Marketing

• High quality data

• Setting priorities

History

• Casting glasses

Contaflex

Clinical Guide for Scleral Lens Success

ISSN:1386 0194

Employee, where are you?

Are you having trouble finding employees? And to keep them?

There's a specter haunting the EU – and unfortunately, it's very real: The shortage of skilled workers. And it's particularly noticeable in some EU countries. That's because demographic change is in full swing here – and often more advanced than in other regions of the world. This poses challenges not only for the financing of pensions in European countries. It's a dilemma, as no one wants to work longer, but neither do they want to forfeit their financial opportunities.

The economy is also affected: Immense expertise is being lost due to the high number of future retirees, while fewer and fewer young people are entering the labor market due to the persistently low number of children. As a result, there is a shortage of fresh skilled workers at all fronts. One could say that the term "Old World" has never been so appropriate for Europe as it is today.

Companies are therefore doing well to retain their specialists and maintain a healthy corporate image. Today, money alone is not enough to keep skilled workers, because the next one might offer more flexible working hours, childcare, home office or other interesting opportunities.

Many countries in Europe have this problem and have currently developed their own strategies for counteracting the impending void in skilled labor and companies. Finland, for example, recently introduced a system that determines the retirement age depending on the year of birth: Everyone born in 1955 or later must work until 67.

Poland has a different concept: recruiting IT specialists from abroad, such as Belarus, who want to escape the dictatorship there. Polish companies also look to Latin America, Asia and Africa for suitable specialists (despite difficult work permits for foreigners).

The Italian Government wants to approach it from the other side: Boosting the birth rate. It has been falling sharply for years. It currently stands at 1.17 children per woman – lower than during World War l. In order to boost the birth rate again and integrate women more strongly into the workplace,

the previous government had already initiated the construction of new childcare facilities, an increase in child benefits, longer parental leave and financial incentives for women to start their own businesses. It will probably take 20 years for these measures to take root.

France's move to implement pension reform is a sensitive issue, driving people into the streets. Although French women have 1.83 children per capita – a top figure in the EU – the shortage of skilled workers in France also threatens to become an ever-greater problem in the coming years.

A problem that is often observed in Spain and Portugal is the rural depopulation. Compared with other European countries, young people in Spain seem to be drawn to the cities to study or work to a particularly large extent. In some regions of Spain, it is mainly senior citizens who live there today. Here, both countries have created attractive incentives for returnees. The Portuguese government even provides bonuses to those who move out to the provinces and sweetens the job for returnees from abroad with financial incentives, such as half the income tax rate.

Incidentally, the Czech Republic is leading the way in the negative trend of the shortage of skilled workers in the EU. At the beginning of 2021, the rate of unfilled positions there was already 5%. In Austria, the main aim is to get unemployed employees back into jobs.

One thing is clear: The urgently needed skilled workers need incentives; the problem will not be solved on its own. So be nice to your employees! Be creative too and come up with something to retain your employees. ■

SILKE SAGE Editor-In-Chief silke@global-cl.com

3

LETTER FROM THE EDITOR GlobalCONTACT 1-23

49th EFCLIN CONGRESS EXHIBITION

20TH – 22ND APRIL 2023

THE HAGUE, THE NETHERLANDS

Dutch culture combined with ancient and modern science has found The Hague to be the perfect location for business and leisure time as well.

The 49th EFCLIN Congress & Exhibition takes place there from 20th – 22nd April 2023. For an engaging lecture program, EFCLIN forum and the best trade exhibition in the business, it can’t be beaten. It’s where the Contact Lens & IOL Industry from Europe, the Far East, North America and beyond come together… will you be there?

www.efclin.com/congress or e-mail us on info@efclin.com

EUROPEAN FEDERATION OF THE CONTACT LENS AND IOL INDUSTRIES

SAVE THE DATE

INNOVATIVE SOLUTIONS PROFESSIONAL COMMUNITY MORE INFORMATION WEB www.efclin.com MAIL info@efclin.com PHONE +41 41 372 10 10 FACEBOOK search: EFCLIN TWITTER @EFCLIN#efclincongress ADDRESS EFCLIN | Winkelbüel 2 | CH-6043 Adligenswil | Switzerland

VISIONARY PEOPLE

INDEX TO ADVERTISERS

Title: Contamac, www.contamac.com

Inside front cover: Bausch + Lomb Inc., www.bausch.com

Page 4: Efclin, www.efclin.com

Page 7: K & Y Diamond Ltd, www.kydiamond.ca

Page 9: AMETEK Precitech, Inc., www.precitech.com

Page 15: LAMBDA-X S.A., www.lambda-x.com

Page 19: OPTOCRAFT GmbH, www.optocraft.com

Page 27: Larsen Equipment Design Inc., www.larsenequipment.com

Page 33: Schneider GmbH & Co. KG, www.schneider-om.com

Inside

Outside

12023 (93) International News • PFAS forever? Fitting Background Soft Lenses for the irregular cornea Visual performance of Ortho-K and LASIK patients Business + Marketing High quality data Setting priorities History Casting glasses Contaflex Clinical Guide for Scleral Lens Success 01_Titel.indd 1

Inc,

back cover: Acuity Polymers,

www.acuitypolymers.com

back

NAMES TO NOTE Diewald, Hanna 16 Fischer, Hartmut 37

Elena 3 4 Hüsemann, Gina 26 L arsen, Erik 20 Marx, Sebastian 28 R adovčić, Katharina 26 Roth, Hans-Walter 32

THE EDITOR

cover: DAC www.dac-intl.com

Fomenko,

LETTER FROM

mployee, where are you?

Sage INTERNATIONAL NEWS

3 E

Silke

about you & event dates

about markets

A ll about products

A ll about research

PFAS forever? Hanna Diewald

Start acting! Frank Sonnenberg MANUFACTURING

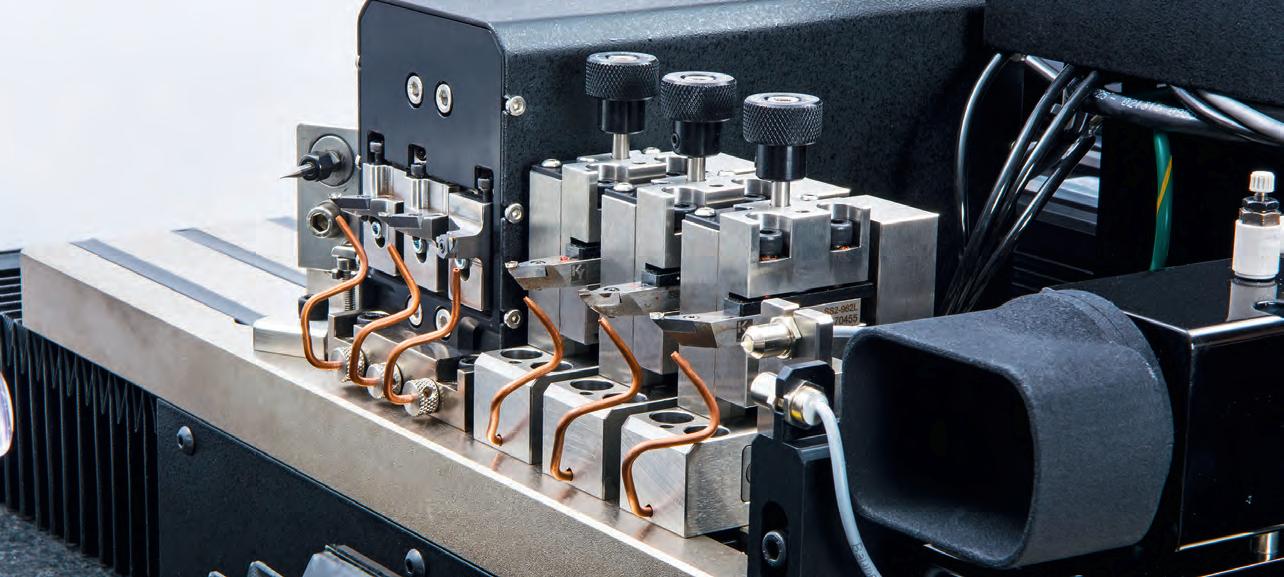

Blocking tooling and process Erik Larsen FITTING BACKGROUND

Bringing soft lenses for the irregular cornea HOME again Eef van der Worp

I maging techniques – Case study Katharina Radovčić & Gina Hüsemann

Visual performance of Ortho-K and LASIK patients Wolfgang Sickenberger and Sebastian Marx HISTORY 32 C asting glasses Hans-Walter Roth BUSINESS + MARKETING 34 H igh quality data Elena Fomenko 37 Setting priorities Hartmut Fischer NEWS 40 Yellow Pages CONTENT 5 GlobalCONTACT 1-23

6 A ll

10 A ll

11

12

16

19

20

22

26

28

All about you

BostonSight introduces Lensy as educational ambassador

BostonSight, a nonprofit eye healthcare organization that advances the treatment of diseased and damaged corneas and dry eyes, has announced that Lensy, an animated scleral lens, will be its ambassador. Daniel C. Brocks, MD,

Change of ownership Ercon

Ercon has announced that the company will continue under new ownership. Erwin Jansen, a seasoned employee, has decided to run the business as an entrepreneur. The acquisition has already been completed by a notary.

Erwin has been employed at Ercon since April 2013 and has become an important player in the organization over the years. His financial and logistical expertise has proven crucial to the organization, and he has developed a deep understanding of Ercons’s product. One of the conditions of the acquisition for Erwin was that Erik Smidt, the founder of Ercon, had to remain connected to the company as an advisor. Erik has been advising SMEs for some time and will advise Ercon on a broad range of topics.

BostonSight’s Chief Medical Officer, drew Lensy for his young children to explain his work. His 2D drawing was transformed into a graphic and has been brought to life as a 3D plush toy. Education is a core component of BostonSight’s mission, and Lensy’s goal is to assist in educating young patients about scleral lenses and PROSE devices. BostonSight describes Lensy as a quadrant-specific scleral lens, with lens applicators for arms and legs and says that her engaging smile and large eyes make her an exceptionally friendly tool for working with pediatric patients. Lensy was introduced to the scleral lens world at BostonSight’s 2021 and 2022 FitAcademy™ for Residents retreats, the International Congress of Scleral Contacts (ICSC) in 2022, and the Global Specialty Lens Symposium (GSLS) in January of this year. BostonSight reports that the toy has been warmly received by the eye care community, who look forward to Lensy helping introduce scleral lenses to their patients, especially in pediatric settings. With input from Anna Maria Baglieri, OD, of Boston Children’s Hospital, who fits pediatric patients with scleral lenses, and Gail Windmueller, a Certified Child Life Specialist affiliated with Boston Children’s Hospital, BostonSight developed Lensy: A Scleral Lens Story, a picture book about the basics of scleral lenses. In the story, Lensy follows her friend, Sophie Sheep, who needs scleral lenses due to extremely dry eyes. BostonSight is running a fundraising campaign called Give (or Get!) the Gift of Lensy. A limited number of Lensy plushies and printed books are available for donation to pediatric patients at PROSE Network sites via the campaign. The campaign as well as the book for digital download can be found at www.bostonsight.org/give-lensy.

6

Lensy. (Picture: BostonSight

GlobalCONTACT 1-23 INTERNATIONAL NEWS

Erik Smidt and Erwin Jansen. Picture: Ercon

John Clamp joins Contamac Ltd as Director, Strategic Projects

Contamac has announced the appointment of John Clamp as Director, Strategic Projects. In this role, John will drive long-term strategic initiatives for the business in partnership with our R&D Group and Operations Team. John joined Contamac on 3 April 2023, having spent 30 years at UltraVision as CTO and Joint CEO. During this time, John was responsible for 10+ patent families and numerous inventive developments within lathing, moulding and hybrid manufacturing processes, as well as lens designs from soft keratoconic lenses to smart contact lenses incorporating liquid crystal layers and sensors. John has also developed software ranging from full system-wide applications, through to full contact lens 3D design and creation of machining files.

John commented, “I’m immensely appreciative of Rob’s and his team’s support of UltraVision CLPL over many years and am now very excited to join Contamac and immerse myself in the supply side of the contact lens industry. I hope my perspective as an ex-manufacturer and customer will further enhance Contamac’s renowned customer support.”

Robert McGregor, Managing Director at Contamac said, “I am delighted and honored to have John join Contamac. His extensive

background and knowledge in our industry will help our teams continue their drive to deliver the next generation materials. John brings valuable know-how and unique capabilities that complement the Company’s extensive knowledge, in its drive to deliver new and innovative materials in the future. To be clear, John has not joined the Company for us to make finished lenses; this is not something Contamac has any interest in, as that is entirely our customers’ business. John’s finished-lens background will, however, help us further understand the importance of our next generation products. It is John’s extensive experience in engineering, manufacturing, design and software, coupled with his industry knowledge that is exciting to the company and will ultimately shape his role at Contamac. John will further complement our continued drive to place our customers’ needs at the heart of our business.”

DAC Optoform Moore Nanotech UPL Precitech Nanoform REM Vision

LENS AND IOL www. ky diamond.ca Advertisement

Ultra Precision Diamond Tools

CONTACT

INTERNATIONAL NEWS

John Clamp. Picture: Contamac

New high-tech startup developing smart contact lenses

Purdue University has announced the launch of a startup that will commercialize smart contact lenses. BVS Sight Inc. is the first company created through a partnership between Boomerang Ventures Studio, Purdue Foundry and the Purdue Research Foundation Office of Technology Commercialization. The partnership develops Purdue-related health care startups and health care-related intellectual property yet to reach the market.

Chi Hwan Lee, the Leslie A. Geddes Associate Professor of Biomedical Engineering in Purdue’s Weldon School of Biomedical Engineering, led a research team that developed new ocular technology to continuously monitor intraocular pressure (IOP) in a person’s eye. Some of the current wearable tonometers — or devices that measure the pressure inside one’s eyes — are equipped with an integrated circuit chip, which leads to increased lens thickness and stiffness compared to a typical commercial soft contact lens, in many cases causing discomfort for patients. Lee’s device is a unique class of smart soft contact lenses built upon various commercial brands of soft contact lenses for continuous 24-hour IOP monitoring, even during sleep at home.

Lee says that the smart soft contact lenses retain the intrinsic lens features of lens power, biocompatibility, softness, transparency, wettability, oxygen transmissibility and overnight wearability.

Dr. Eric Beier, partner and chief medical officer at Boomerang, said Lee and his smart contact lens innovation piqued his and his colleagues’ interest for several reasons, one of them being that interviews with optometrists and ophthalmologists

CooperVision announces 2023 Best Practices Honorees and Student Scholarship Recipients

Following its annual nationwide search for current and future leaders in optometry, CooperVision has named its 2023 Best Practices honorees and student scholarship recipients. The initiative—now in its eighth year—honors eye care practices across the US that advance the profession through innovation, industry leadership, and providing exceptional patient care. The scholarship program provides third-year optometry students the opportunity to learn from and collaborate with some of the best in the profession. The ten new honorees join a prestigious group of 70 other extraordinary optometry practices that have been featured and supported through the initiative since 2016.

“Success in optometry comes in many different forms, and we love that Best Practices sheds light on practices that truly view challenges as opportunities. These practices are constantly evolving in response to changes not only in the industry, but in

demonstrated that Lee’s technology has the potential to become a new standard of care for diagnosing and managing glaucoma patients.

Beier will be a director on BVS Sight’s board and continue to support the company through his chief medical officer and management roles at Boomerang Studio.

Beier said BVS Sight must achieve several milestones to bring the smart contact lens technology to market, among them optimizing the integrated system for patient and clinician use. He states the company will need to work through multiple challenges including clinical studies, regulatory approval, reimbursement and fundraising. Boomerang brings resources and expertise in these areas to help its portfolio companies navigate through these complexities.

the wants and needs of today’s patients—and they are among the best in the country because of this mindset,” said Michele Andrews, OD, Vice President of Professional and Government Affairs, Americas, CooperVision. “As always, we have great things in store for our new honorees, including collaboration and sharing their stories. We welcome them all to the Best Practices family.”

CooperVision expanded its Best Practices program in 2020 to include a scholarship for third-year optometry students, providing them the opportunity to attend the annual educational summit and hear firsthand the honorees’ experiences and secrets to success. Scholarship recipients were selected based on their academic standing at a US optometry school, their demonstration of leadership and participation in school or community activities, honors, and additional optometry-related experience.

More information about this year’s honorees can be found at coopervision.com/practitioner/best-practices.

8

New smart soft contact lens technology developed by a multidisciplinary team of engineers and health care researchers at Purdue University and Indiana University School of Optometry looks to gather important intraocular pressure measurements for 24-hour cycles as a way to detect glaucoma. A company called BVS Sight Inc. has been launched to develop the technology. Picture: Purdue University photo/Rebecca McElhoe.

GlobalCONTACT 1-23 INTERNATIONAL NEWS

Advertisement EFCLIN 2023 www.efclin.com Apr 20-22 The Hague (NL) OCCSEE www.occsee.hr Apr 21-23 Split (HR) ARVO 2023 www.arvo.org Apr 23-27 New Orleans, LA (USA) EAOO 2023 https://eaoo.online/cms/front-page.php May 11-14 Poznań (PL) BCLA 2023 https://www.bcla.org.uk/ June 9-11 Manchester (UK) Vision By Design www.orthokmeeting.com Sep 6-10 Chicago, IL (USA) IOFT 2023 www.ioft.jp/en-gb.html Oct 10-12 Tokyo (JPN) ▪ Unmatched performance and reliability ▪ Optomized production with no-polish surfaces capabilities ▪ In-house proprietary design and manufacturing of all critical mechanical components ▪ Evolve into the next generation lenses with today’s FTS-5000 capabilities Optoform 60 with FTS-5000 the ultimate solution www.sterlingint.com · +1 727 538 6110 s cal 000 apabilities www WEBINARS, CONFERENCES & TRADE FAIRS 2023

All about markets

Visual impairment in the older U.S. population

Spectaris industry figures for 2022

According to preliminary calculations by the Spectaris industry association, German manufacturers of ophthalmic optics and consumer optics were able to increase their sales by 2.5% to 4.87 billion euros in 2022, despite the difficult underlying conditions. Domestic business remained at the previous year's level with a value of 2.42 billion euros. The number of employees also remained unchanged at 20,600. International business, on the other hand, increased by around 5%, with foreign sales climbing to 2.45 billion euros.

Based on objective assessments of visual function with habitual correction in the 2021 nationally representative National Health and Aging Trends Study, 27.8% of US adults 71 years and older had vision impairment (VI). Distance and near visual acuity and contrast sensitivity impairment were present in 10.3%, 22.3%, and 10.0%, respectively; a higher prevalence of VI was associated with older age, less education and income, non-white race, and Hispanic ethnicity

Source:KilleenOJ,DeLottLB,ZhouY,etal.PopulationPrevalence ofVisionImpairmentinUSAdults71YearsandOlder:The National Health and Aging Trends Study. JAMA Ophthalmol.2023;141(2):197–204.doi:10.1001/ jamaophthalmol.2022.5840

International visitors at Mido 2023

Around 35,000 visitors attended Mido 2023, 80% from Europe and 20% from the rest of the world. This represents a 60% increase over 2022, despite being well short of the record mark of 59,500 visitors in 2019.

Source:MidoWest

Source:https://www.statista.com/chart/28744/ world-population-growth-timeline-and-forecast/

10

GlobalCONTACT 1-23 INTERNATIONAL NEWS

Source:Spectaris

All about products

Optimizations for IOL production testing

OptiSpheric® IOL PRO 2 is TRIOPTICS’ fully automated optical IOL test stand. Developed for use in production, it provides a throughput of up to 100 lenses per batch. The ISOcompliant measurement of hydrophobic and hydrophilic lenses in air or in-situ can be performed with an accuracy of 0.3 % (power) for all types of intraocular lenses (incl. EDOF, multifocal and trifocal). With the latest software module, the system can be connected to your database in accordance to FDA 21 CFR PART 11. This allows you to retrieve samplespecific data and measurement scripts from the server as well as to archive your measurement results in conformity with the standards. www.trioptics.com / sales@trioptics.com

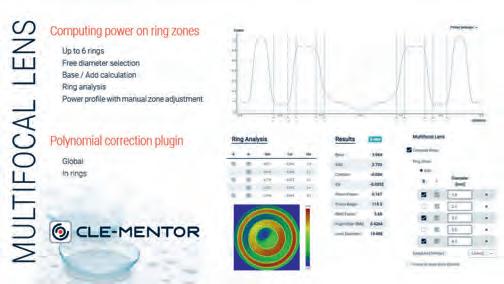

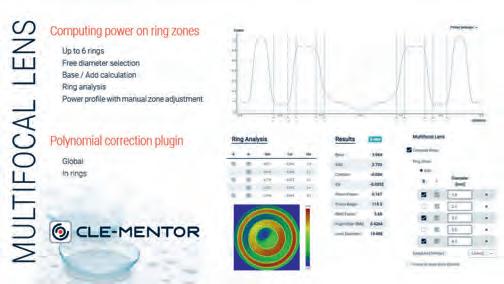

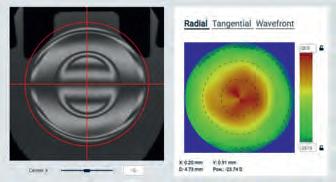

Multifocal Lens measurement in CLE-MENTOR

The Multifocal Lens measurement feature available in CLE-MENTOR provides detailed representation of the power profile for fine adjustments of the ring borders, and results are presented independently for each ring, as well as a relation of selected base and addition. This advanced functionality ensures that you have the most accurate measurements for your quality control processes. This state-of-the-art software is the perfect solution for measuring complex contact lens designs with unique precision and ease, allowing you to select up to 6 rings (zones), adjust the diameter, and position the lens for optimal measurement accuracy. In addition, NIMOevo’s most precise wavefront sensor allows you to visualize the measurement in a selection of power maps, providing you with a detailed understanding of the power distribution across the lens. This is just one of many impressive features of NIMOevo and CLE-Mentor software, making it the perfect tool for the measurement and evaluation of modern contact lenses. Let’s discuss your specific needs and challenges on the Lambda-X booth at EFCLIN 2023: April 20th to 22th in The Hague, NL. Ophthalmics.lambda-x.com / sales-ophthalmics@lambda-x.com – +32 67 79 40 80

Transforming Lives Together

Full Range of Materials – Led by industry insights and developed by our in-house team of specialists, Contamac offers a complete range of contact lens and intraocular lens materials to suit all indications. This includes our Optimum family of gas permeable materials, Definitive silicone hydrogel materials, Contaflex hydrophilic soft lens materials, and our hydrophilic IOL material CI26. Each material has its own unique properties to benefit machinability, comfort and ocular health.

Educational Initiatives – We also believe that by investing in the professionals of our future, we can ensure they are fully-equipped to transform the lives of patients. Whether through publications, videos or industry events, Contamac is proud to support an exchange of knowledge within the industry. www.contamac.com / sales@contamac.co.uk

11

GlobalCONTACT 1-23 INTERNATIONAL NEWS

All about research

Dry eye prevention, smart CL for glaucoma diagnosis and treatment, IOL for Alzheimer's diagnosis, 3D-printing of smart CL

A team from the Terasaki Institute for Biomedical Innovation (TIBI) in the U.S. has developed a contact lens prototype specifically designed to prevent dry eye caused by contact lenses. Three new smart lens developments were reported by Korean scientists. A research team at POSTECH has developed a smart contact lens by combining an IOP sensor and a flexible drug delivery system to manage IOP measurement and medication administration. Collaboration among experts in mechanical engineering, materials and medicine resulted in intraocular lens technology developed for early diagnosis of Alzheimer's disease. Another new technology is set to enable the production of smart contact lenses using 3D-printing.

By Rebekka Nurkanovic

Contact lenses to treat dry eye syndrome

A collaborative team from the Terasaki Institute for Biomedical Innovation (TIBI) has developed a contact lens prototype that is specifically designed to prevent contact lens-induced dry eye (CLIDE). The researchers report that the lens alleviates this condition by facilitating tear flow in response to normal eye blinking and that this approach can relieve the discomfort, visual impairment, and risk of inflammation experienced by contact lens users suffering from CLIDE.

Of the 140 million contact wearers worldwide, 30%-50% suffer from CLIDE. The problem arises from the insufficient flow of

tears from the contact lens's outer surface to the surface behind the lens. This leads to excessive tear evaporation and all the problems associated with CLIDE.

There have been previous attempts to use contact lenses in treating dry eye syndrome, such as graphene-coated lenses designed to minimize moisture loss and self-moisturizing lenses stimulated with metallic electrodes. The TIBI team’s approach uses a contact lens design that incorporates microchannels to facilitate tear flow movement and flow so that dry eye can be avoided. This flow can be achieved by pressure applied by normal eye blinking so that no external devices are needed.

12

GlobalCONTACT 1-23 INTERNATIONAL NEWS

In fabricating their contact lens prototype, the team utilized a lens mold made from a silicone polymer mixture; this allowed for easy removal of the lens cast on it by gently bending the mold. The approach resulted in smooth microchannels, as well as lenses that could be thirty times thinner than previous lenses. A custom device was used to fabricate reservoirs at the ends of each microchannel for the inflow and outflow of liquids.

Innovative techniques were also utilized when encapsulating the microchannels in a sandwich-like assembly under a capping lens layer. Initially, the preparation of the two lens surfaces for stronger bonding dehydrated the lenses, causing them to curl. This problem was solved by affixing the two lenses to holders using water-soluble glue. This served not only to enable a more uniform bonding of the lenses but protected them from damage as well. After rigorously testing their encapsulated microchannel lenses for stability and leakage, the lenses were subjected to a series of experiments using a device that the team designed to simulate a blinking eyelid. This device was integrated with the lens prototype to create artificial eyelid pressure on the lens to stimulate tear flow.

Smart contact lens that diagnoses and treats glaucoma

Glaucoma is a common ocular disease in which the optic nerve malfunctions due to the increased intraocular pressure (IOP) caused by drainage canal blocking in the eye. This condition narrows the peripheral vision and can lead to vision loss in severe cases. Glaucoma patients have to manage IOP levels for their life-time. Automatic monitoring and control of the IOP in these patients would significantly improve their quality of life.

Recently, a research team at POSTECH has developed a smart contact lens by combining an IOP sensor and a flexible drug delivery system to manage IOP measurement and medication administration. The team led by Professor Sei Kwang Hahn and Dr. Tae Yeon Kim (Department of Materials Science and Engineering) has developed a wireless theranostic smart contact lens for monitoring and control of intraocular pressure in glaucoma. Their findings were published in Nature Communications.

After various experiments, a configuration that proved effective was microchannels with square cross-sections arrayed in a novel circular pattern on the lens surface; this was compatible with the function and curvature of the lens and allowed for optimum liquid flow.

The team demonstrated a proof-of-concept validation of their lens’ ability to guide tear flow originating from the lens surface to the underside of the lens to combat dry eye syndrome. The team quantified these flows and established that they were driven by low-pressure levels like those from normal eye blinking. Further experiments could be devised to test these lenses on animal models and in patients.

“The inventive methods that our team has employed bring a potential solution for millions of people,” said Ali Khademhosseini, TIBI’s Director and CEO. “It is the hope that we may extend our efforts to bring this solution to fruition.” This work was supported by Cooper Vision, Inc. The results were published in the journal Small.

DOI 10.1002/smll.202207017

Source: Terasaki Institute for Biomedical Innovation

The IOP sensors currently available for glaucoma patients do not have the function to administer the appropriate amount of drug in response to the IOP levels. The smart contact lens developed by the POSTECH team has an IOP sensor that uses hollow nanowires made of gold. It is integrated with a flexible drug delivery system, wireless power and communication system, and an application-specific

13

A collaborative team from the Terasaki Institute for Biomedical Innovation (TIBI) has developed a contact lens prototype that is specially designed to prevent contact lens-induced dry eye (CLIDE). The lens alleviates this condition by facilitating tear flow in response to normal eye blinking. Picture: Terasaki Institute for Biomedical Innovation

GlobalCONTACT 1-23 INTERNATIONAL NEWS

Schematic illustration of a theranostic smart contact lens for glaucoma treatment. Picture: POSTECH

integrated circuit chip for both monitoring and control of IOP in glaucoma. The researchers report that the IOP sensor has exhibited high sensitivity to ocular strain, excellent chemical stability, and biocompatibility. Furthermore, the flexible drug delivery system can provide the on-demand delivery of the IOP decreasing drug timolol. The team successfully demonstrated that the theranostic smart contact lens enabled the IOP measurement in real-time and the appropriate amount of drug release to match the degree of IOP in rabbits with glaucoma.

The new smart contact lens is expected to make possible a personalized glaucoma treatment with maximum efficacy and minimal side effects. In addition, the feedback system would be applicable to various wearable devices other than

smart contact lenses as well. Professor Hahn who led this study commented, "We hope the early commercialization of the newly developed theranostic smart contact lens for diagnosing and treating glaucoma intraocular pressure to provide glaucoma patients’ compliance.”

This study was supported by the Basic Science Research Program, the Korea Medical Device Development Fund grant, BRIDGE Research Program, and Bio & Medical Technology Development Program of the National Research Foundation (NRF) funded by the Ministry of Science and ICT, Korea.

DOI 10.1038/s41467-022-34597-8

Source: Pohang University of Science & Technology (POSTECH)

Smart IOL technology for early-stage dementia diagnosis

The Korea Institute of Machinery and Materials (KIMM), a non-profit government-funded research institute under the Ministry of Science and ICT, has collaborated with with Yonsei University, Yonsei University College of Medicine

Yongin Severance Hospital, and Gangnam Severance Hospital, to develop an intraocular implant that can diagnose Alzheimer's, a degenerative brain disease, at its early stages. The results of this research study were published in the journal Bioactive Materials.

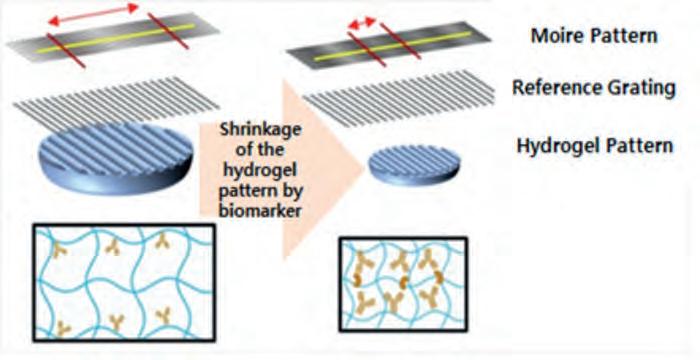

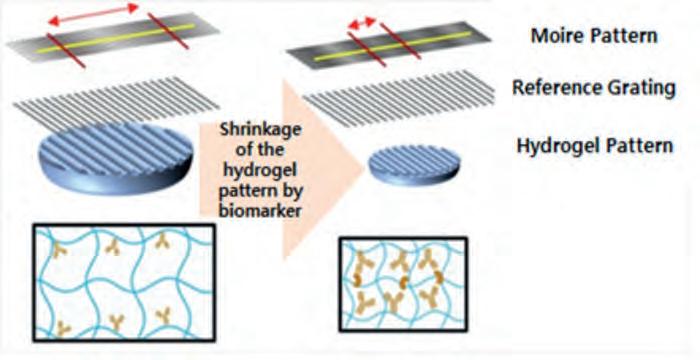

The collaborative team focused on the characteristics of the eye, which is directly connected to the brain, and detected various biomarkers. The researchers developed an implantable biosensing system by mounting a bioresponsive hydrogel-based sensing module capable of detecting various

biomarkers on an intraocular lens to express a signal in a moiré pattern. Moiré patterns are characterized by regularly repeating shapes that are combined and recombined continuously, creating visual stripes according to differences in the overlapping shapes.

When the hydrogel pattern, to which the antibody is bound, reacts with the target biomarker, it contracts. The target biomarker is then detected using changes in the moiré signal, which are generated when the hydrogel pattern, which becomes narrower by the contraction response, overlaps with the designated reference grid. By using a moiré signal, detection is possible with greater sensitivity than that of other methods that directly detect change in the hydrogel pattern.

Furthermore, unlike traditional biosensors, the moiré signal-based biomarker detection method can directly detect biomarkers without using electrochemical or fluorescent labels. Since this method does not require external power or a light source, one of its advantages is that it can be implanted within the body.

KIMM plans to continue to promote further research on this technology until it can be made available for commercial use.

DOI 10.1016/j.bioactmat.2022.11.010

Source: National Research Council of Science & Technology, Korea

14

GlobalCONTACT 1-23 INTERNATIONAL NEWS

Biomarker detection using reactive hydrogel patterns and moiré signals. Credit Korea Institute of Machinery and Materials (KIMM)

New technology for smart contact lens

Dr. Seol Seung-Kwon's Smart 3D Printing Research Team at KERI and Professor Lim-Doo Jeong's team at Ulsan National Institute of Science and Technology (UNIST) developed core technology for smart contact lenses that can implement augmented reality (AR)-based navigation, with a 3D printing process.

In implementing AR with smart contact lenses, electrochromic displays that can be driven with low power are suitable, and the color "Pure Prussian Blue" is attracting attention as the lens’ material. The color has a high price competitiveness and quick contrast and transition between colors but in the past, it was coated on the substrate in the form of a film using the electric plating method, which limited the production of advanced displays that can express various forms of information, e.g. letters, numbers or images.

The developers say that the technology of KERI-UNIST can realize AR by printing micro-patterns on a lens display using a 3D printer without applying voltage. Prussian blue is crystallized through solvent evaporation in the meniscus formed between the micronozzle and the substrate. The team reports that the great advantage of using the meniscus

phenomenon is that there is no restriction on the substrate that can be used because crystallization occurs by natural evaporation of the solvent.

Through the precise movement of the nozzle, the crystallization of Prussian Blue is continuously performed, thereby forming micro-patterns. Patterns can be formed not only on flat surfaces but also on curved surfaces. The research team states that their micro-pattern technology is very fine (7.2 micrometers), it can be applied to smart contact lens displays for AR, and the color is continuous and uniform.

The main expected application area is navigation. Dr. Seol Seung-Kwon's of KERI said that the team’s achievement is a development of 3D printing technology that can print functional micro-patterns on non-planner substrate that can commercialize advanced smart contact lenses to implement AR. He is convinced that it will greatly contribute to the miniaturization and versatility of AR devices. The related research results were published as a cover article in the journal Advanced Science.

DOI 10.1002/advs.202205588

Source: Korea Electrotechnology Research Institute (KERI)

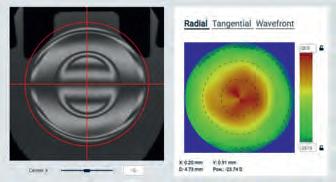

Advertisement Ophthalmics.lambda-x.com +32 67 79 40 80 - sales-ophthalmics@lambda-x.com Meet us at EFCLIN 2023 April 20th-22th in The Hague, NL World leader in wavefront metrology

Wavefront sensor for contact lenses

INTERNATIONAL NEWS

PFAS forever?

Long lasting chemicals – restrictions, chances and challenges

For some, they are “forever chemicals” that should never be released into the environment; for others, they are necessary substances for the production of everyday consumer products or medical devices, for instance contact lenses. We are talking about per- and polyfluoroalkyl substances – in short PFAS. At first glance, two interests seem incompatible: On the one hand to save the environment and human health and on the other hand to satisfy consumer desires and to not restricting an entire industry. But one authority has now created facts.

By Hanna Diewald

In early February 2023, the European Chemicals Agency ECHA published a ban proposal on all PFAS – or per- and polyfluoroalkyl substances. It is a message with huge implications. A choice for the environment and human health but at the same time, the industry faces huge challenges and stakeholders are lobbying for exemptions – at least for longer transition periods. But why is the topic so hotly debated?

BROADEST RESTRICTION IN HISTORY

According to the latest estimates, this group of substances comprises more than 10,000 different substances. It is the broadest restriction proposal in history and many different industries are affected. Among those industries that work with PFAS on a daily basis is also the ophthalmic industry. This is because PFAS are used in spectacle lens coatings as well as in contact lenses.

16

GlobalCONTACT 1-23 INTERNATIONAL NEWS

The European Chemicals Agency (ECHA) defines PFAS as follows: “PFAS have a wide range of different physical and chemical properties. They can be gases, liquids, or solid highmolecular weight polymers. Some PFAS are described as long-chain or short-chain, but this does not cover all of the different kinds of structures that are present in the PFAS class, which is very diverse. PFAS can be sorted in many ways based on their structure”.

Individual PFAS had already been banned but ECHA reports that global manufacturers have started to replace certain PFAS with other PFAS or with fluorine-free substances over the past decades: “This trend has been driven by the fact that scientists and governments around the world first recognised the harmful effects of some PFAS (particularly long-chain PFAS) on human health and the environment. As the focus shifted to other PFAS, these have also been found to have properties of concern” says the agency. This is why such a comprehensive restriction is being discussed.

“FOREVER CHEMICALS”

Together with 15 European partner media reporters, the Forever Pollution Project located more than 17,000 sites across Europe with relevant PFAS pollution, including just over 2,000 hotspots with significant human health risks.

Some PFAS are very effective at resisting heat, stains, grease and water and they are used in high tonnages in a variety of applications. The majority of PFAS are persistent in the environment.

According to ECHA, “Some PFAS are known to persist in the environment longer than any other synthetic substance. As a consequence of this persistence, as long as PFAS continue to be released to the environment, humans and other species will be exposed to ever greater concentrations. Even if all releases of PFAS would cease tomorrow, they would continue to be present in the environment, and humans, for generations to come”.

PFAS tend to pollute groundwater and drinking water. Certain PFAS are known to accumulate in people, animals and plants and cause toxic effects. Certain PFAS are toxic for reproduction

17

GlobalCONTACT 1-23 INTERNATIONAL NEWS

and can harm the development of foetuses. Several PFAS may cause cancer in humans. Some PFAS are also suspected of interfering with the human endocrine (hormonal) system. According to ECHA the expected mean PFAS tonnage in the EEA is 49 million tonnes, leading to emissions of about 4.5 million tonnes during the manufacture and use phase when no action is taken. The overall annual health costs following from exposure to PFAS in Europe has been estimated in a Nordic Council report from 2019 to be between €52 and 84 billion.

ARGUMENTATION

The proposal states that: “Different regulatory risk management options have been considered, e.g. CLH and authorisation, but these options follow a substance by substance approach. In contrast, a restriction offers the possibility to define a broad chemical scope, thereby avoiding regrettable substitution of one PFAS by another PFAS (which may not even be engineered yet). […]

A restriction can cover a wide range of uses and can address the risks arising from the manufacture and use of the substances as such as well as in other substances, in mixtures and in articles, including imported articles from outside the EU. Hence, a restriction is the most appropriate and effective option to adequately control such a large and complex group of substances which are used in numerous applications.

The chemical scope of the restriction proposal is defined as: Any substance that contains at least one fully fluorinated methyl (CF3-) or methylene (-CF2-) carbon atom (without any H/Cl/ Br/I attached to it). There are however a few exceptions.”

CURRENT SITUATION

In January 2023, Denmark, Germany, the Netherlands, Norway and Sweden submitted to ECHA a proposal for restriction on the manufacture, placing on the market and use of around 10.000 PFAS.

Two restriction options (ROs) have been assessed. A full ban with no derogations and a transition period of 18 months (RO1), and a full ban with use-specific time-limited derogations (18 month transition period plus either a five or 12 year derogation period). As specific information on costs of a ban of PFAS for the different actors associated with the addressed uses was scarce and mainly qualitative, the derogations and their duration were mainly based on the availability and applicability of alternatives to PFAS.

RO2 also includes a few time-unlimited, more general derogations, e.g. for PFAS used as active substances in Plant Protection Products (PPP), Biocidal Products (BP) and human and veterinary Medicinal Products (MP) but there is no general derogation for medical devices.

Besides the proposed derogations, the dossier submitters also identified uses for which a derogation could be warranted, but for which the evidence base is weak. These uses are between brackets, which indicates that additional information is needed

and should be provided during the third party consultation of the restriction proposal to substantiate a derogation. Only if substantial evidence is provided, the dossier submitters can assess this and consider whether a derogation is warranted. For the time being, uses between brackets should be read as ‘no derogation’.

IMPACT ON THE OPHTHALMIC INDUSTRY

The potential derogation covers fluoropolymer coatings on ophthalmic lenses and fluorinated monomers used in the polymer matrix of rigid gas permeable contact lenses. According to Euromcontact: “An internal survey ran by Euromcontact showed that 3 PFAS are used to manufacture RGP contact lenses (HFPM, TFEM, BHI), for which there is currently no alternative. The dossier submitters identified uses for which a derogation could be warranted, but for which the evidence base is still weak. Among them: fluoropolymers and perfluoropolyethers for the use in rigid gas permeable contact lenses. Additional information is needed and should be provided during the consultation of the restriction proposal (MarchSeptember 2023) to substantiate a derogation. Only if substantial evidence is provided, the dossier submitters can reconsider whether a derogation is warranted or not.”

NEXT STEPS

• January 2023: Restriction proposal submitted to ECHA

• 22. March 2023: Start of a six month open consultation

The European Chemicals Agency invites interested parties to send in scientific and technical information on the manufacture, placing on the market and use of per- and polyfluoroalkyl substances (PFAS)

• 25. September 2023: Open consultation closes ECHA’s scientific committees for Risk Assessment (RAC) and for Socio-Economic Analysis (SEAC) will use the consultation input to evaluate the proposed restriction and to form an opinion on it.

• Opinions of ECHAs committees sent to the European Commission

SOME QUESTIONS REMAIN UNANSWERED

So there is still a long way to go before all questions can be answered. For example:

• Which products will finally end up with exemptions?

• Is it legitimate to ban all PFAS without a proper demonstration that each and all of them present an unacceptable risk?

• How to ensure that production and associated environmental problems do not simply shift to other countries?

• What about the competitive disadvantage for the European industry compared to other continents? �n

18

GlobalCONTACT 1-23 INTERNATIONAL NEWS

Start acting!

The deeper you delve into the topic of sustainability, one thing becomes clear: Sustainability has many dimensions. The whole thing is complex. Everything is interwoven. It's more than just climate and environmental protection. Carrying on as before is no longer an option. It takes a new way of thinking to make your company fit for the challenges of the coming decades to align it economically, ecologically and socially.

We all have the goals, such as the so-called SDGs – the UN's Sustainable Development Goals – in front of our eyes. Where can we start and take action? Prof. Dr. Rene Schmidtpeter, economist and professor of business administration and sustainability management at the International University of Applied Sciences in Erfurt/Germany, even says that a new mindset is currently emerging as a result of the public discourse. This could have a fundamental impact on innovative

entrepreneurship and the functioning of our economy. It could even have a strong impact on corporate strategies and our understanding of the economy.

For those who have not yet initiated their own corporate transformation, it is helpful to exchange ideas with like-minded people. These can be found not only in the optical industry, but also in other sectors that have already begun their journey towards greater sustainability. n

Frank Sonnenberg, head of sustainability at FOCUS magazine is a certified CSR manager (IHK), he is a member of the IG Sustainability at the international trade fair Opti Munich and a participant in the Sustainability Hub at the trade fair in January 2023. The cross-media journalist and trained optician is one of the founding members of the still young D-A-CH association CSR Manager which was launched in 2022.

Advertisement

COLUMN

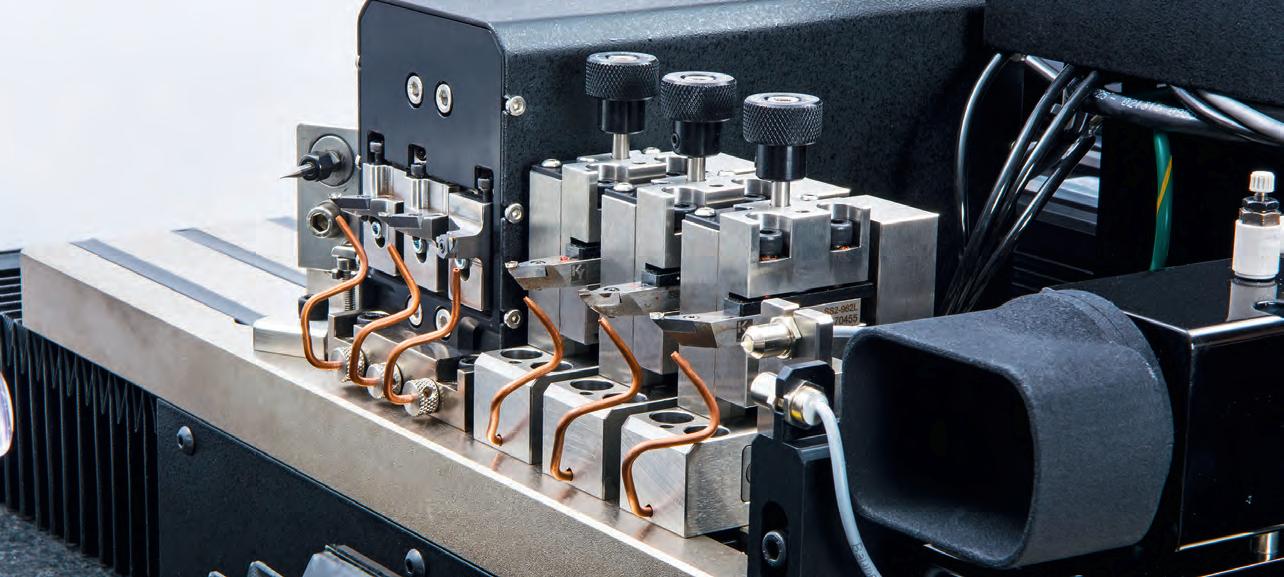

Blocking tooling and process

The challenge of making an Rx product (specialty contact lens SCL) in a production environment is the wide variation of parameters. Unlike IOLs which are made in batches with no parametric variation within the batch, making SCLs can be a challenge. The goal is to provide machines and processes that allow each lens to proceed through the process without special fixtures and procedures.

By Erik Larsen

By Erik Larsen

In the past five years there has been a dramatic increase in the use of scleral lens designs around the in visual performance and comfort have been nothing short of life-changing. However, with all of their advantages, scleral lenses have also presented us with some unique, never seen before, complications. If you are making IOLs for example, making a batch of identical lenses is reducing the variation in the process. There is variation from batch to batch, but that can be managed by a supervisor rather than the line person. In contact lens processing, each lens is different and can vary widely in several parameters. The variation in parameters requires the technician to make decisions with each lens as to how to process it. The standard operating procedure has changed a lot.

POLISHING

In the mid 90's, the free-form back surface became a reality as did the need to polish it. The bladder system solved the individual lens polish problem, and also provided a means to use just one bladder to polish all back surfaces. The result is an essential

elimination of the variation in the process. So much so, that a one spindle polisher will produce up to 500 back surfaces per shift.

BLOCKING

The static blocking process took over from traditional blocking techniques in the mid 90's but really took off in the early 2000s with auto-blockers. A later milestone was the move into transfer blocking, then on to fully automated transfer blocking for both corneal and scleral BCs. This is currently done on the same machine without the operator needing to adjust the machine to accommodate variations in center thickness. The result is an essential reduction in process variation.

Two colleagues who are familiar with the concept of reduction of variation in a process have graciously lent their perspective on the subject: Mr. Pat Murphy and Mr. Nir Karpik, both of CooperVision Specialty Eyecare. They have been given the daunting task of coordinating the lens processes throughout the family of CooperVision companies. In particular, the standardization of the blocking tooling (arbors, chucks) and

20

GlobalCONTACT 1-23 MANUFACTURING

Base blocker wax pattern, source: Erik Larsen

what that means. Mr. Murphy’s contribution was more generic, discussing the merits of blocking the lens bank to reduce distortion in the material:

“The aim of all lens manufacturing processes is to manufacture lenses within a controlled, consistent, repeatable and reliable process that induces as little stress as possible into the material during all phases of the process. The control of stress on the button, semi-finished and finished lens is extremely important to ensuring the production of a lens within specification each and every time. Excessive stress applied to material will result in warpage and/or stability problems

Material hardness (Shore D) and Modulus of Elasticity (MN/ m2) are key mechanical properties as they provide insight into how susceptible materials are to external mechanical forces and fluctuations in temperature. Due to the mechanical properties of materials there are certain dos and don’ts regarding the manufacturing process. Careful attention to the following steps will help maximize yields and give greater satisfaction working with materials.

Base curve lathing : Directly holding the button in the lathe may result in excessive radial stress being applied to the button. In addition, these radial stresses may not be distributed evenly around the circumference of the button. This could lead to warpage of the button. The result is a lens with dimensions out of specification. The difficulty with this system of holding the button is that you cannot measure the stress on the material. Having a critical variable in the process which you cannot accurately measure is not desirable as it can lead to a process that is hard to control. If collet tension is minimal and consistent you may have no issues but as this variable cannot be measured, ideally it should be designed out of the process. Collets with depths of 0.040 inches have been seen to produce some lenses

with toricity. Deeper collets have been used and no toricity has been detected at final inspection. The fact that a greater surface area of the button is being used to distribute the gripping force results in less stress (stress = force/area) being transferred to the material being gripped.

Materials with low modulus of elasticity exposed to the same collet squeeze force as materials with higher modulus of elasticity may result in issues. Because of all of the above potential issues and the direct relationship between stress and modulus of elasticity it is recommended that the button is blocked to an arbour for base curve cutting. This fully eliminates the potential issue of radial stress being applied to the material. Also remember that lathe feeds, speeds and depths of cut can introduce stress and heat into the material as well which may impact dimensional and optical results. Delrin or Delrin tipped arbours are preferred as these do not require heating thus eliminating another potential negative input into the process. Using water-soluble wax due to the non-use of solvents for cleaning the lens also may help. Overall, the aim is to reduce, minimize or eliminate external stress and variables within the process”. My thanks to Pat Murphy. In the next issue we will discuss the concept of standardization of blocking tooling. Yes, it is possible. n

21

Erik Larsen graduated from the University of Washington with a Mechanical Engineering degree in 1981 and started Larsen Equipment Design later that year. Erik Larsen has industry awards from CLMA and EFCLIN.

Blocked BC on hollow tool

Arbors with O rings

GlobalCONTACT 1-23 MANUFACTURING

Scleral front arbors

Bringing soft Lenses for the irregular cornea HOME again

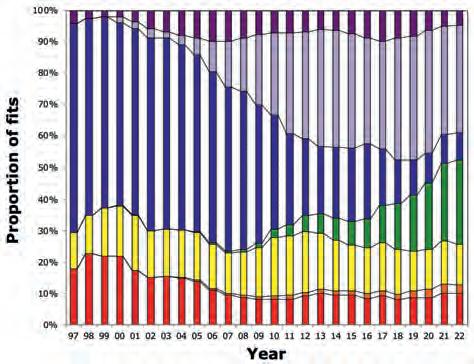

A home run via four bases

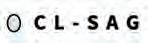

According to the global survey of contact lens prescribing in 2022 by Eurolens Research (Fig. 1)1, about 12% of all lens fits worldwide are with rigid lenses (corneal and scleral), and an additional 2% are with orthokeratology. That also means that most lens fits are with soft lenses (86%); this is for normal eyes, of course. How about the irregular cornea? The most common type of irregular cornea is keratoconus, and hence this is by far the main indication for scleral lens wear.2 From the podium at the latest Global Specialty Lens Symposium 2023 and in many papers, it has become increasingly clear that the incidence of keratoconus may be much higher than previously thought. According to a study by Godefrooij et al3 in the Netherlands, the annual incidence of keratoconus is reported to be 1 in 7500 for the relevant age category, or 13.3 cases per 100,000. The prevalence of keratoconus in the general population was estimated to be 1:375. These values appear to be 5-fold to 10-fold higher than previously reported. In some parts of the world, such as in the Middle East, the incidence of keratoconus is considered to be even higher.4 By

Eef van der Worp

It is noteworthy that the landscape of keratoconus management is changing rapidly. Across Europe and increasingly in other parts of the world, corneal cross-linking (CXL) is becoming the standard of care for young patients with progressive ectatic corneal disease. The mentioned study by Godefrooij reported that 25% fewer corneal transplants were performed in the 3-year period in which CXL became available and popular in the Netherlands. 5 We will most likely not see fewer keratoconus patients (supposedly more), but we will most likely see corneas in the earlier stages of the condition. In addition, topography and wavefront-guided excimer laser treatments are performed now that can improve corneal contour and improve corneal

symmetry, 6 which makes the patient more correctable with spectacles and soft lenses. Anecdotally, this way patients can improve to a point that they can go from a scleral lens to a custom soft lens.7

These developments may impact what management methods we offer and apply; glasses and certainly soft (specialty) lenses may become more common as a first-line method of vision correction. In addition, there have also been major developments in the field of corneal transplants for keratoconus (and other diseases). While a penetrating keratoplasty (replacing the entire cornea in its full thickness with donor tissue) not too long ago was standard procedure, now an array of lamellar techniques,

22

GlobalCONTACT 1-23 FITTING BACKGROUND

in which only a portion of the cornea is replaced by donor tissue, are increasingly used. This can provide many advantages, one being that the corneal irregularities are far less prominent, as a part of the patients’ original cornea remains intact. This opens up opportunities for soft specialty lens correction. But what are the options, and in what order can they be applied? In an algorithm by Visser et al, published in Contact Lens & Anterior Eye, the soft lens option was prominently listed as an option for ‘mild’ cases of corneal irregularity.9 The idea is that soft lenses can mask the irregularity of the cornea, at least partly. Increasing the thickness of the lens helps in that regard, but this does reduce oxygen transmissibility. A potential step to evaluate whether a soft lens will provide an adequate outcome is to perform corneal topography before and after placing the lens on the eye.10 By looking at the irregularity indexes such as the I-S value (analyzing the corneal differences inferiorly and superiorly), the SAI (surface asymmetry index) and SRI (surface regularity index), one can get a good sense of the potential improvement for the various options. Here, four steps or ‘bases’ are defined to optimally achieve this goal.

BASE 1 – STANDARD SOFT LENSES

As a first option, standard soft lenses can and should be considered for the mild irregular cornea. In terms of lens fit, we have better understanding of that now than ever before. By looking at the Pacific University soft lens sagittal depth charts,11 (Fig. 2) one can see that there are considerable differences between ‘flat’ and ‘steep’ (or shallow and deep) lenses. In cases of keratoconus, it

makes sense to look to the right side of the graph, as the sagittal height of a keratoconic eye is greater than in normal eyes. The graph in figure 2 shows the daily disposables, but there are also graphs for reusable lenses and for toric lenses. The toric lens sagittal depth graph shows that toric lenses typically can offer slightly higher sagittal depth values (about 150 microns extra), which can be a good tool to achieve an acceptable lens fit (especially when an astigmatic correction is desired anyway). These standard lenses do not offer anything special in terms of masking corneal irregularities. Normally these lenses are molded. Lathe-cut lenses can be somewhat thicker than molded lenses, though, which in theory could make a small difference (daily disposable and

1 SPHERICAL DAILY DISPOSABLE LENSES 16 LENS TYPES

23

Fig 1: Global contact lens survey 2022 by Eurolens Research8, - red indicates rigid lenses (corneal and scleral), orange orthokeratology.

3,398 3,468 3,469 3,479 3,588 3,595 3,700 3,706 3,743 3,756 3,764 3,792 3,861 3,877 3,912 4,009 3,000 3,100 3,200 3,300 3,400 3,500 3,600 3,700 3,800 3,900 4,000 4,100 1-DayAVTrueye (9.0/14.2) 1-DayAVMoist (9.0/14.2) 1-DayAVOasys (9.0/14.3) DailiesAqua ComfortPlus (8.7/14.0) Clariti1Day (8.6/14.1) Miru1Day (8.6/14.2) Biotrue1Day (8.6/14.2) 1-DayAVTrueye (8.5/14.2) Proclear1Day (8.7/14.2) Infuse(8.6/14.2)1-DayAVMoist (8.5/14.2) 1-DayAVOasys (8.5/14.3) Miru1Day (8.4/14.2) MyDayDaily Disposable (8.4/14.2) DailiesTotal1 (8.5/14.1) Precision1 (8.3/14.2) 600micron CATEGORY

GlobalCONTACT 1-23 FITTING BACKGROUND

Fig 2: Sagittal depth values of a 16 different daily disposable lenses.

11

monthly replacement molded lenses are often in the 80-micron thickness range for a 3D lens, lathe-cut monthly and quarterly lenses are often 100 microns or more thick for that power, depending on the material used) – but maybe not as much as you might expect.

BASE 2 – EXTENDED PARAMETER RANGE

Step two in this cascade of soft lens fitting for the irregular cornea, and specifically for keratoconus, are lenses that have expanded parameters for diameter, base curve and power options (no limitations for toric prescription, etc). These lenses are lathe-cut (see remark on slightly higher center thickness of these lenses). For eyes that are particularly steep (stage 2 or 3 keratoconus) or flat (post-refractive surgery and often postgraft as well), these lenses can be a welcome addition to the arsenal of options available to contact lens practitioners in terms of lens fit. Our calculations have indicated that eyes with a sagittal height (OC-SAG measured in the horizontal meridian and over a 15mm chord) outside the range of 3500 to 4000 microns (one standard deviation from the normal eye, figure 3) could theoretically benefit from these lenses. Again, there are no special thickness considerations other than that the lenses are lathe-cut and by default have slightly greater center thickness compared to molded lenses.

BASE 3 – CUSTOM-MADE LENSES

The relatively new “kids on the block” are truly custom-made lenses based on corneal topography. These lenses not only better follow the shape of the ocular surface in a circular manner

from center to periphery, they also can incorporate “toricity” and more complex shape characteristics on the back surface of the lens. Some of these lenses use tangential peripheral shapes, in line with scleral lens fitting characteristics. In essence, soft lens fitting is not that different from fitting a scleral lens, using sagittal heights and (as in scleral lens fitting) allowing for a “clearance” between the ocular surface and the lens (the delta-SAG). The main difference here is that the soft lens flexes and conforms to the shape of the eye because of the nature of the (soft) material. Special optics can be applied to the front of these lenses to, in theory, upgrade the visual performance. Other than that, these lenses are of normal center thickness in line with other lathe-cut lenses – although alterations in lens thickness should be easily applicable. These lenses can be made in silicone hydrogel materials, and some are offered as monthly disposable lenses.

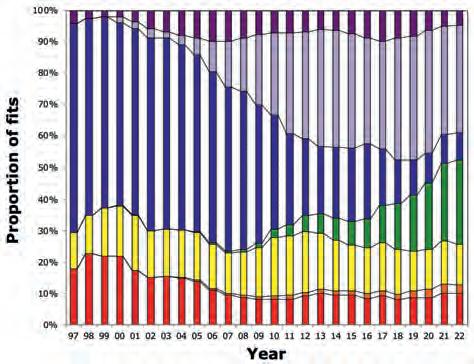

BASE 4 – KERATOCONUS LENSES

If “bases 1-3” do not provide satisfactory results, there is always base 4: soft specialty lenses for keratoconus (Fig 4). These are specifically designed for the purpose, with the main characteristic that they are thicker over the optical zone compared to normal lenses and are usually indicated for quarterly replacement. The thickness of these lenses is typically in the 300-500 micron range, varying with lens design. Some soft keratoconus lens designs feature sagittal height adjustments in 100-micron increments to accommodate the amount of corneal irregularity if needed. In their new book “Keratoconus,” Melissa Barnett et al have listed all soft lenses for the condition (chapter 21,

24

GlobalCONTACT 1-23 FITTING BACKGROUND

Fig 3: Ocular surface with high OC-SAG (4173 microns), which is outside the 1 standard deviation range of the normal eye (not-keratoconus). Courtesy Gerard Smits – Ralph Optiek, Amsterdam (The Netherlands)

table 21.3): 15 lenses from different manufacturers. This is a hot topic apparently, as new soft lenses for keratoconus keep emerging. Newer lens designs feature improvements such as front-surface spherical aberration control, sagittal height fitting processes, and segment management control (one or more segments can be ordered flatter or steeper). While these lenses keep improving, eyecare practitioners need to be fully aware that they can be three times the thickness of standard lenses, and oxygen transmissibility (despite the use of silicone hydrogel materials) can be significantly reduced, so potential complications of hypoxia need to be monitored for closely. In addition, as these are quarterly replacement lenses, extra attention toward lens care and hygiene is warranted. On the future “wish-list” for sure are newer materials with higher oxygen permeability and improved manufacturing techniques (other than lathe-cut) to further enhance this modality.

CLOSING REMARKS

In our field, we try as much as possible to make sure our work is evidence-based. But not everything in the specialty lens field can be “proven”. Evidence-based practice, by the way, does not mean that everything is required to be scientifically backed up by the literature. Evidence-based practice is defined as “a combination of the literature, clinical experience, and patient values”. And most likely, soft lenses fare well in these last two categories. At the end of the day, it is about patient satisfaction. And if a soft lens provides satisfactory results, that option should not be overlooked. Simple is sometimes better. Or, as the title of a poster and presentation by Sydney Krisa et al from Massachusetts Eye & Ear Infirmary (US) at the recent GSLS 2023 read: “your weapon of choice in early keratoconus and mild corneal scars: soft toric lenses”.13 Let’s bring soft lenses for the irregular cornea home again. Covering four bases, this could potentially be a home run for many patients. n

References

1 Morgan P, Efron N, et al. International Contact Lens Prescribing 2022. Contact Lens Spectrum, January 2023: 28-35.

2 S chornack MM, Fogt J, Nau A, Nau CB, Harthan JS, Cao D, Shorter E. Scleral lens prescription and management practices: Emerging consensus. Cont Lens Anterior Eye. 2023 Feb;46(1):101501.

3 G odefrooij DA, de Wit GA, Uiterwaal CS, Imhof SM, Wisse RP. Age-specific Incidence and Prevalence of Keratoconus: A Nationwide Registration Study. Am J Ophthalmol. 2017 Mar;175:169-172.

4 Staff RO. Middle Easterners Rank High for Keratoconus. Review of Optometry, Nov 2018

5 G odefrooij DA, de Wit GA, Uiterwaal CS, Imhof SM, Wisse RP. Age-specific Incidence and Prevalence of Keratoconus: A Nationwide Registration Study. Am J Ophthalmol. 2017 Mar;175:169-172.

6 Nattis AS, Rosenberg ED, Donnenfeld ED. One-year visual and astigmatic outcomes of keratoconus patients following sequential crosslinking and topography-guided surface ablation: the TOPOLINK study. J Cataract Refract Surg. 2020 Apr;46(4):507-516.

7 G elles JD. Cornea and Laser Eye Institute-Hersh Vision Group and CLEI Center for Keratoconus, Teaneck, NJ; and Department of Ophthalmology, Rutgers-New Jersey Medical School, Newark, NJ. Personal communication.

8 Morgan P, Efron N, et al. International Contact Lens Prescribing 2022. Contact Lens Spectrum, January 2023: 28-35.

9 V isser ES et al. Objective and subjective evaluation of the performance of medical contact lenses fitted using a contact lens selection algorithm. Cont Lens Anterior Eye. 2016 Aug;39(4):298-306.

10 De Vecht A, Schut B. Top(o)tips voor de contactlens- en optometriepraktijk. Webinar. Oct 10, 2022.

11 Van der Worp E, Lampa M, Kinoshita B, Fujimoto MJ, Coldrick BJ, Caroline PJ. Variation in sag values in daily disposable, reusable and toric soft contact lenses. Cont Lens Anterior Eye. Jan 2021 (44) 101386.

12 B arnett, Lee, Mannis. Non-surgical management of keratoconus. In ‘Keratonus’, Izquierdo, Henriquez, Mark Mannis (Eds) 2022. ISBN: 9780323759786

13 Krisa S, Deakins I, Watts A. Your Weapon of Choice in Early Keratoconus and Mild Corneal Scars: Soft Toric Lenses. Poster #103 & Rapid-Fire Session GSLS 2023 Las Vegas (US)

Eef van der Worp, BOptom, PhD, FAAO, FIACLE, FBCLA, FSLS is an educator and researcher. He received his optometry degree from the Hogeschool van Utrecht in the Netherlands (NL) and has served as a head of the contact lens department at the school for over eight years. He received his PhD from the University of Maastricht (NL) in 2008. He is a fellow of the AAO, IACLE, BCLA and the SLS. He is currently adjunct Professor at the University of Montreal University College of Optometry (CA) and adjunct assistant Professor at Pacific University College of Optometry (Oregon, USA). He lectures extensively worldwide and is a guest lecturer at a number of Universities in the US and Europe.

25

LET’S BRING

SOFT LENSES FOR THE IRREGULAR CORNEA HOME AGAIN. COVERING FOUR BASES, THIS COULD EASILY BE A HOME RUN

GlobalCONTACT 1-23 FITTING BACKGROUND

Fig 4: Example of a specialty (“base 4”) keratoconus lens on the eye. Courtesy Thibaut Syre (France)

Imaging Techniques

Photo presentation: Students present their findings

Photographers

Katharina Radovčić & Gina Hüsemann (HFAK, Cologne, Germany)

What can be seen here?

Superficial punctate in the lower corneal area due to incomplete blinking, colored with fluorescein.

Imaging technique

Slit Lamp (Haag-Streit BQ 900, Koeniz, Schweiz)

Figure 1: Diffuse illumination, 6.3 x magnification

Figure 2: Fluorescence observation, 16 x magnification

Figure 3+4: Optical slit, 16 x magnification

Finding

During routine examination of the anterior segment of the eye of a patient (female, 25 years), inspection of the cornea reveals defects in the inferior region of the cornea. A general overview initially shows an inconspicuous eye (Fig. 1).

In the next step, the tear film is colored with fluorescein to view confluent specks as well as individual specks under blue illumination with a yellow filter (Fig. 2). If the defects are only in the epithelial layer, they can heal again.

In addition, when viewed with fluorescence, a separating edge becomes visible. This dark edge is associated with an incomplete blink. An incomplete blink prevents sufficient wetting of the cornea, which is why the inked tear film cannot be optimally distributed.

Characteristics

Due to the poorly lubricated cornea, slight lesions may also occur. Two scars are made visible with the optical slit (Fig. 3). Due to the permanent dryness, the cornea experiences a permanent lack of oxygen supply (hypoxia), which is why blood vessels for oxygen supply already grow into the cornea (Fig. 4).

Further procedure

The patient is recommended to use eye drops with hyaluron to support the healing process of the surface defects. In addition, eyelid blink training can serve as another possible measure to improve the lubrication of the cornea and thus improve the oxygen supply to the cornea.

26 1 2 4 3 GlobalCONTACT 1-23 FITTING

BACKGROUND

Larsen Equipment

In 2004, Keith Parker and I opened Advanced Vision Technologies (AVT). At that time, the economy was going through a very bad recession and as a result, it was impossible for a new business starting up to get a loan. We immediately reached out to Erik and Pam at Larsen Equipment to get refurbished equipment to use in our Laboratory. As AVT’s business grew, we invested in many different pieces of new equipment from Larsen Equipment and this helped us grow into one of the Premiere Labs in the United States. Our success is due in part to Erik and his Team with their state-of-the-art equipment and maintenance of their products. AVT is forever grateful for Larsen Equipment’s support of AVT. It is great to know AVT is working with Industry leaders with the Larsen Equipment and their Team!

Janine Bungo, VicePresident

QUALITY MANAGER: RANDY MINGOY

I have known Erik Larsen since 1992. Since then I have used just about every piece of equipment his company has built. My experience with Erik and the Larsen team has been one of great appreciation as they have always helped me in my needs of fully understanding equipment used to manufacture quality contact lenses. Erik has also been able to engineer any part needed for me even it was a custom part.

Erik (Larsen Equipment) has been and still is a pioneer in the contact lens and optical industry, and I am thankful to him for his support over the years.

Randy Mingoy Quality Manager Advanced Vision Technologies

Randy Mingoy Quality Manager Advanced Vision Technologies

DIRECTOR OF OPERATIONS: JORDAN GOBEL

There can be a lot of moving parts when it comes to managing operations, so it is key to have reliable precision equipment that assists in overall efficiency. Larsen Equipment delivers just that! I have been utilizing Larsen manufacturing equipment for over 15+ years and have yet to run into an issue they could not resolve. I am a satisfied owner of bladder polishers, edge roller’s and auto-blockers etc. Each one of these units greatly assists in the reduction of rejects and manufacturing waste. Their ability to customize and retrofit specific tools certainly sets them apart from the competition. Larsen stands behind their equipment with a knowledgeable staff that provides exceptional service. Simply put, we are a better laboratory because of our relationship with the folks at Larsen.

Jordan Gobel Director of Operations/Consultant Advanced Vision Technologies

PRESIDENT: KEITH PARKER

I have had the pleasure of working with Erik since the beginning of Larsen Equipment. The first piece of equipment, a 6 spindle horizontal arm polisher revolutionized our production of GP contact lenses. Through the years, I watched his business grow as he and his team listened to our industry needs and developed now numerous products not only simplifying many tasks of manufacturing but improving the consistency of quality in our finished products. Innovation has been an ongoing experience of our company only made possible through the innovation of necessary equipment developed and made available by the Larsen team.

Larsen Equipment is a family owned business hosting a team of willing staff all having the attitude of serving their customer’s needs. As a customer, we are made to feel like we have a friend in the business helping us develop a more efficient process allowing our company to deliver better products for our customers.

Our success of AVT simply could not have been possible without the help, assistance and dedication of Larsen Equipment. I will be forever grateful for my opportunity to work with Erik and his very capable staff.

Keith Parker President

27

969 S. Kipling Parkway, Lakewood, CO 80226 Phone: 303-384-1111 888-393-5374 Fax: 303-384-1124 www.AVTLENS.com GlobalCONTACT 1-23 PR-Advert

Visual performance of Ortho-K and LASIK patients

– with regard to legal requirements of driver license in comparison to a normal population in Germany

The so called fitness to drive related to vision isn´t harmonized. The visual standards for driving vary across European countries from a visual acuity (VA) of 0.5 to 1.0. Different systems and protocols are in place to screen drivers’ vision both for acquisition and renewal of driving licenses. The ECOO (The European Council of Optometry and Optics) reported those differences in a consensus paper published in 2017.1 For a regular car driving license a candidate should reach a monocular VA of 0.7 and a binocular VA of 1.0 at a vision screening. The majority of candidates are in the age group around 18 years and the measurements are typically conducted by a qualified optician using standardized vision tests. It is documented if the test result is achieved with or without visual aid. However, it is not requested to ask for or to document, which kind of visual aid was used if this was the case. It is also not intended to ask if a screening candidate has a history of refractive surgery such as Lasik. This unregulated situation results in an insufficient documentation, which becomes also visible for orthokeratology contact lens wearers. The screening candidate performs and may pass the test without contact lenses on eye but needs them during the night to achieve the Ortho-K effect. The investigators are unsure if they should document that the test is performed with or without the usage of a visual aid. This counts for the case, that they are aware that the screening candidate is using Ortho-K lenses which must not be, because there is a free choice where the vision test is performed.

By Wolfgang Sickenberger and Sebastian Marx

By Wolfgang Sickenberger and Sebastian Marx

28

GlobalCONTACT 1-23 FITTING BACKGROUND

Beside these regulative issues, it has to be mentioned that the vision of a person who passed the vision screening test to achieve the fitness to drive, will for sure change during the life time period. In some Asian countries and some European countries like Italy a repeated vision screening test is mandatory in specific time intervals. There is no duty to repeat a vision screening test in Europe for car and motorcycle drivers in general. For the group of Ortho-K lens wearers it was controversially discussed if they may drive at all due to the reversible nature of the procedure. Non-controlled orthokeratology studies showed a stable condition after the initial adaptation in the case of a correct use of the lenses. 2,3,4 In order to create a scientific basis to conduct a fair discussion a retrospective study was performed5 by ophthalmologists and optometrists taking into account the German Driving Permit Ordinance (FeV) and the recommendations of the German Ophthalmological Society (DOG).6

29

GlobalCONTACT 1-23 FITTING BACKGROUND

FOR THE GROUP OF ORTHO-K LENS WEARERS IT WAS CONTROVERSIALLY DISCUSSED IF THEY MAY DRIVE AT ALL DUE TO THE REVERSIBLE NATURE OF THE PROCEDURE.

STUDY CONTENT

This following section reflects the key elements of a peer reviewed publication. In this mentioned study the fitness to drive of Ortho-K users and LASIK patients were compared to an emmetropic population divided into two age groups. In addition to photopic VA as well as vision under mesopic condition was assessed with and without glare according the FeV and DOG guidelines.

Overall, 333 eyes of 167 subjects were assessed. 65 subjects were habitual wearers of orthokeratology contact lenses and 60 subjects were treated by LASIK. All of them had a pre-treatment VA of more than 0.7 and both groups showed a similar mean value of pre-treatment ametropia. A reference group with 42 subjects used glasses, contact lenses or none of them if they were emmetropic. The follow-up time was 22.8 ± 11.9 months. It can be mentioned that the data for the Ortho-K users was captured six to eight hours post lens removal at the day of the follow up visit. The measurement of the visual acuity was based on DIN standard 58220 part 3 and the ISO standard 8596. The Mesotest II (Oculus Optikgeräte, Wetzlar) was used for testing contrast sensitivity under mesopic conditions and glare contrast sensitivity. This was of interest because LASIK

and Ortho-K treats not the entire cornea but an ametropia specific central part. The low luminance level at night leads to increased pupil size, maybe bigger than the treated area, which may potentially compromise vision under night driving conditions. In addition, the personal evaluation of vision and satisfaction of the subjects were captured by the questionnaire NEI-RQL - 4 2.