12024 (96)

Special

• 50th Anniversary of EFCLIN

Company Profile

• Larsen Equipment Design

Fitting Background

• State of the Art(ificial) Pt.2

• The importance of contact lens characterization Business & Marketing

• Chat GPT –a new language for the industry?

ISSN:1386 0194

Eyepress Fachmedien GmbH Saarner Str. 151 45479 Muelheim a. d. Ruhr Germany

Even more to love.

Boston XO2® is everything you love about Boston XO® lens material + hyper Dk.

At 141 Dk, Boston XO2® provides even higher oxygen delivery than Boston XO.® Having these two material choices available offers you:

More Flexibility

Accommodates lens designs for common vision conditions, as well as demanding visual needs such as keratoconus and ocular surface disease.

More Peace of Mind

Backed by the exceptional service and support you’d expect from a company that’s been around since 1853.

More Confidence

All our lens materials are precision manufactured by experienced technicians followed by rigorous quality control.

While it features even higher oxygen delivery than Boston XO®, Boston XO2® is still precision manufactured by experienced technicians and undergoes the same rigorous quality control— all backed by exceptional Bausch + Lomb service and support.

Visit www.fit-boston.eu or contact your authorized Boston® Lab.

Visit bostonlensmaterial.com or contact your authorized Boston Lab.

Visit bostonlensmaterials.com for important safety information.

Visit bostonlensmaterials.com for important safety information.

© 2023 Bausch & Lomb Incorporated or its affiliates. BL.XXXX.USA.23

© 2023 Bausch + Lomb.

This issue is somewhat more extensive than usual. The reason is the 50th anniversary of EFCLIN. Our magazine has been closely involved with the organization throughout our 32-year history. For the years 1992 to 2008, we have the complete archive of issues 1 to 50 as hardback editions, which Wim Albers kindly handed over to us. After that, we kept our own complete archive from issue 51 to 94. During my research, I came across a huge treasure of the history of contact lens manufacturing, which I could have dug into for days (or probably weeks). This alone could have filled an entire issue of GlobalCONTACT.

What was it like back then, when crossing borders between European countries was still hindered by border controls? And what was the best way to behave at these controls? The first column "Something Else" provided an amusing insight into this. Speaking of Europe: a useful conversion table for the European currency of the time, the ECU, was printed as a service, knowing full well that it was probably already outdated due to currency fluctuations when the magazine was delivered. That was just a small example, it's too easy to fall into the rabbit hole of historical research.

EFCLIN had a crisis of purpose in those early 90s – and as I read in the editorial by then EFCLIN President Tony Koller, not only was the entire contact lens industry undergoing dramatic changes at that time, but the circumstances in the emerging EU were also leading to significant adjustments.

A meeting in a fancy location was simply not enough. New life had to be breathed into the organization and, in addition to the very active support of its members and the association's

50 years of EFCLIN

membership of EUROMCONTACT, it was decided to develop a magazine that would act as a ‘glue’ for the industry. Information brochure, network, advertising – all this in every issue of CONTACT. It was very quickly accepted and after a few years distributed worldwide – GlobalCONTACT was born.

For this issue's report, we therefore let some of our companions have their say. First and foremost, Marion Beeler, who has been managing the association's fortunes as Executive Director since the beginning of Armin Duddek's presidency in 2015. Wim Albers has also accompanied the organization for almost 20 years as Executive Director and it is a special pleasure for us that he gives our readers an insight into this time.

It was particularly exciting to find out what happened in the association before the close monitoring of our magazine, i.e. before 1992. Andy Chryssolor, one of the founding members and a former president, can provide information about this and has done so wonderfully in our special.

Together with my colleagues from Eyepress Fachmedien, the publishing house of GlobalCONTACT, we congratulate the association and look forward to the next 50 years! ■

3

ONLINE VISIT OUR BRAND NEW WEBSITE WWW.GLOBAL-CL .COM SILKE SAGE Editor-In-Chief silke@global-cl.com LETTER FROM THE EDITOR GlobalCONTACT 1-24

50th EFCLIN CONGRESS EXHIBITION

25TH – 27TH APRIL 2024

VILAMOURA, PORTUGAL

The Algarve in Portugal is one of the most beautiful holiday destinations anywhere. The great infrastructure in Vilamoura makes this combination the perfect congress location.

The 50th EFCLIN Congress & Exhibition takes place there from 25th – 27th April 2024. For an engaging lecture program, EFCLIN forum and the best trade exhibition in the business, it can’t be beaten. It’s where the Contact Lens & IOL Industry from Europe, the Far East, North America and beyond come together… will you be there?

REGISTER NOW WHILE THERE IS STILL TIME AT www.efclin.com/congress or e-mail us on info@efclin.com

EUROPEAN FEDERATION OF THE CONTACT LENS AND IOL INDUSTRIES MORE INFORMATION WEB www.efclin.com MAIL info@efclin.com PHONE +41 41 372 10 10 FACEBOOK search: EFCLIN TWITTER @EFCLIN#efclincongress ADDRESS EFCLIN | Winkelbüel 2 | CH-6043 Adligenswil | Switzerland ENGAGING

EMPOWERING SUCCESS

MINDS

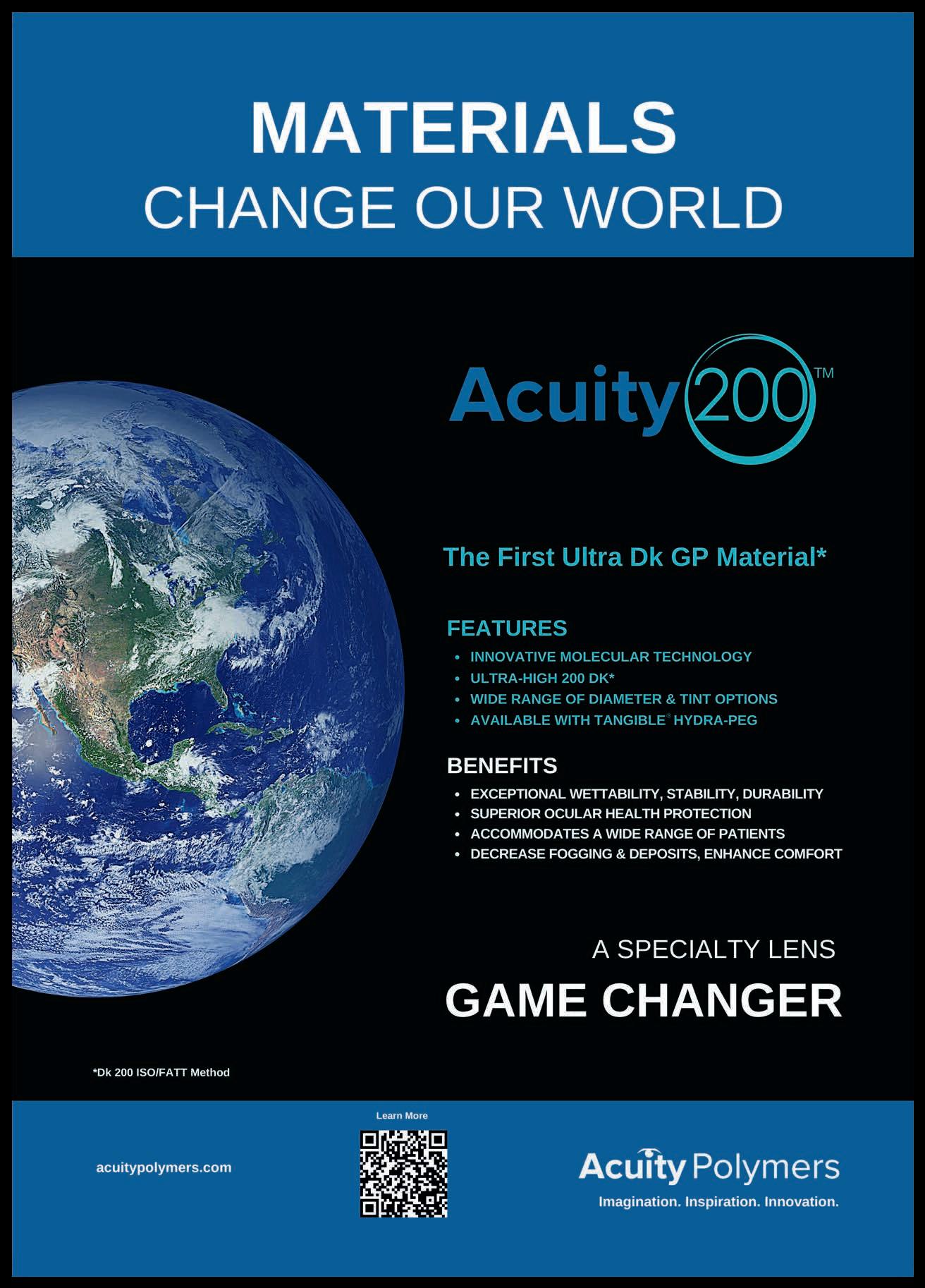

Page 7: Acuity Polymers, Inc. www.acuitypolymers.com

Page 9: DIATEC Diamanttechnik GmbH, www.diatec-pforzheim.de

Page 11: LAMBDA-X S.A., www.lambda-x.com

Page 13: K & Y Diamond Ltd, www.kydiamond.ca Special 50 YEARS EFCLIN : Page 17: Contamac, www.contamac.com

Page 19: Bausch + Lomb Inc., www.bausch.com

Page 21: Acuity Polymers, Inc, www.acuitypolymers.com

Page 23: Efclin, www.efclin.com

Page 25: Larsen Equipment Design Inc., www.larsenequipment.com

Systems Ltd., www.optimecsystems.com

Page 41: SCHNEIDER GmbH & Co. KG, www.schneider-om.com

Page

12024 (96) Special • 50th Anniversary of EFCLIN Company Profile Larsen Equipment Design Fitting Background State of the Art(ificial) Pt.2 The importance of contact lens characterization Business & Marketing Chat GPT –a new language for the industry? Eyepress Fachmedien GmbH Saarner Str. 151 45479 Muelheim a. d. Ruhr Germany 01_Titel.indd 1

TO ADVERTISERS

Contamac, www.contamac.com Inside front cover: Bausch + Lomb Inc., www.bausch.com

INDEX

Title:

Page 4: Efclin, www.efclin.com

37:

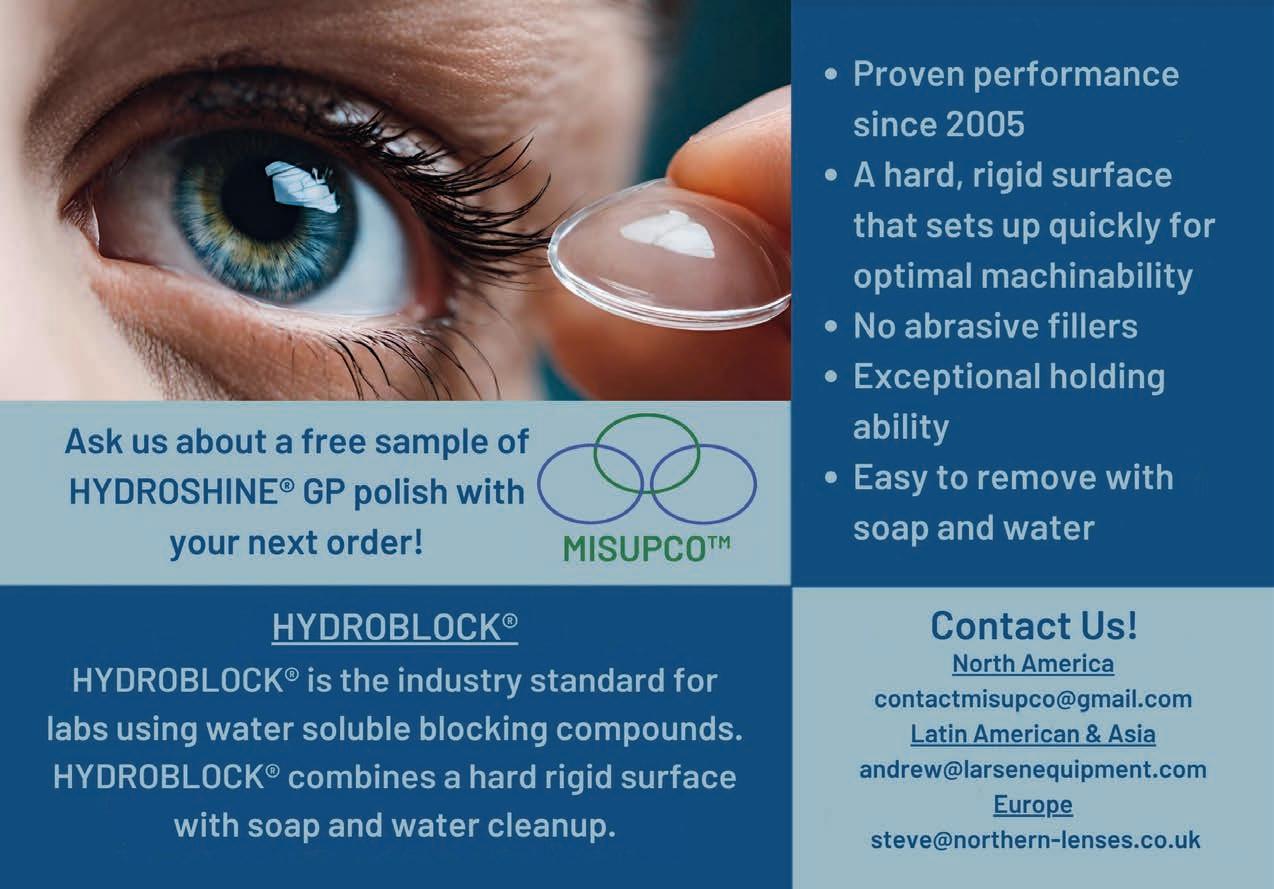

Page 27: OPTOCRAFT GmbH, www.optocraft.com Page 35: Misupco, Inc., www.customcraftlens.com Page

Optimec

43:

SAS,

45: AMETEK Precitech, Inc., www.precitech.com Page 47: REM Vision Technologies SL, www.remvt.com Outside back cover: DAC International, Inc., www.dac-intl.com LETTER FROM THE EDITOR 3 50 years of EFCLIN Silke Sage INTERNATIONAL NEWS 6 A ll about you 9 A ll about products 10 A ll about research SPECIAL TOPIC 14 50 th anniversary of EFCLIN Andy Chryssolor, Marion Beeler-Kaupke, Erik Smidt, Silke Sage 22 Something else: looking back Wim Aalbers REPORT 28 C ompany profile: Larsen Equipment Design Silke Sage FITTING BACKGROUND 32 State of the art(ificial) – part 2 Eef van der Worp and Bart van der Linden 38 The importance of contact lens characterization Daniele Costa, Mariafrancesca Cascione, Valeria De Matteis, Maurizio Martino and Giancarlo Montani. 42 I nnovative contact lens cleaning Cornelius Doniga MANUFACTURING 44 C omparing bladder polishing systems with traditional polishing systems Erik Larsen HISTORY 32 The therapeutic contact lens Hans-Walter Roth BUSINESS + MARKETING 48 Chat GPT and other KI ‒ a new language for the industry Interview with Philipp Schmid MAGAZINE 52 Yellow Pages 54 Closing words: Steve Cleverly CONTENT 5 GlobalCONTACT 1-24

V-Optics

www.v-optics.fr/en Page

All about you

Tohoku University, The University of Tokyo, and Menicon start joint research

Tohoku University, The University of Tokyo, and Menicon will start joint research on fundamental technology for contact lenses in April. A statement of the research partners says that the aim of bringing together the research expertise of Tohoku University and University of Tokyo and the contact lens technology of Menicon, is to establish a fundamental technology to transform the industry with respect to the design of new contact lens materials and recycling of various plastic materials used for manufacturing and distribution of the contact lens materials. Tohoku University established the Research Center for Green X-Tech in January 2023 as part of the Green Goals Initiative, aiming to create an industry–academia co-creation and innovation hub that can solve social issues and business challenges related to the field of green technology through practical research using combinations of advanced technologies, including science, engineering, data science, and IT.

Similarly, University of Tokyo established the Institute for Solid State Physics and the Synchrotron Radiation Collaborative Research Organization in NanoTerasu to promote research for the establishment of a recycling-oriented theory that helps academia lead industry–academia collaborative creation and accelerates academic fusion.

Menicon has been working on the elucidation of structure–function relationship of contact lens materials by utilizing quantum beam sources at various facilities, including X-ray

sources at SPring-8 and the Aichi Synchrotron Radiation Center and neutron sources at the Japan Proton Accelerator Research Complex, with the ambition of leveraging the results to achieve new material design.

This April, Menicon and Tohoku University will establish the Menicon × Tohoku University Co-creation Research Center for Miru Mirai on the Aobayama Campus of Tohoku University. Additionally, the Institute for Solid State Physics and the Synchrotron Radiation Collaborative Research Organization of University of Tokyo will commence operations in April 2024. The joint research on fundamental technology for contact lenses will use NanoTerasu and the Co-creation Research Center as research hubs.

CooperVision enhances North American academic programs

CooperVision has introduced several enhancements to provide additional educational opportunities to U.S. and Canadian optometry students and residents. These include the integration of specialty contact lens initiatives, the rebranding of its student-focused philanthropic program, and a new in-person educational summit for members of the CooperVision Student Leadership Societies.

The company's Give Brightly program offers optometry students with additional fitting experience while enabling them to gift a one-year supply of contact lenses to patients in need. While the company previously offered a separate and similar initiative for its specialty lenses, the program now includes CooperVision’s diverse portfolio of soft and specialty contact lenses. Through the program, each student may select one patient per academic year to fit with complimentary

CooperVision contact lenses, then provide the appropriate follow-up care.

Members of the company’s student leadership societies will also have access to a new benefit this year. These students, who represent schools and colleges of optometry across the U.S. and Canada, will attend an educational meeting with networking opportunities at the company’s facilities. The three-day summit includes tours of two of the company’s global, Rochester-based manufacturing and distribution sites, as well as a variety of educational sessions.

Student leadership society members are second- or third-year optometry students selected by faculty at their schools to serve a one-year term. Selected students receive several other opportunities throughout the year, including a grant to attend the American Academy of Optometry annual meeting.

CooperVision’s academic programs also include the Best Practices Student Program, complimentary contact lenses for students, and myopia management certifications.

6

From left: Hideo Ohno, President Tohoku University, Teruo Fujii, President The University of Tokyo and Koji Kawaura, President and COO Menicon.

GlobalCONTACT 1-24 INTERNATIONAL NEWS

Bausch + Lomb Announces Appointment of Karen L. Ling to Board of Directors

Bausch + Lomb has announced that Karen L. Ling has been appointed to its board of directors effective immediately. Current director Richard De Schutter will retire from the board effective as of the company’s 2024 annual meeting of shareholders. With Ms. Ling’s appointment, the board has been temporarily expanded to eleven members and is expected to revert to ten directors following the annual meeting.

“Since my return to the company, Richard has been a trusted advisor,” said Brent Saunders, chairman and CEO, Bausch + Lomb. “I join the rest of the Board in thanking him for his service and wishing him well as he pursues his many other interests.” Saunders continued, “With her extensive industry leadership experience and time as a public company director, Karen brings significant human capital management, corporate governance, and

Johnson & Johnson Medtech launches new presbyopia-correcting IOL in EMEA

Johnson & Johnson MedTech has announced that its new presbyopia-correcting IOL Tecnis PureSee is now available in EMEA. The company describes it as featuring a proprietary, purely refractive design that delivers uninterrupted, highquality, vision with high best-in-category contrast and low-light performance, comparable to a monofocal IOL.

“Cataract surgery is the number one surgery performed globally, with 28 million procedures each year. But only 10-15% of patients are getting advanced optical IOLs specifically designed

Menicon acquires new site in Hokuriku area

Menicon has acquired a site in Fukui City, Fukui Prefecture, in the Hokuriku Area, Japan, for the manufacturing and production of contact lenses and lens care products. The company is also considering the establishment of research and development functions related to production at the new site for the purpose of bridging between development and production. The area of the new Fukui base is about 93,000 square meters, which will be the largest domestic production site of Menicon. The company’s supply chain is concentrated in the Chukyo area and by including Fukui Prefecture, it aims to establish a strong production economy zone that includes both areas and establish a rapid production structure according to demand.

shareholder engagement expertise to the organization. We’re confident her perspectives will be highly additive in the boardroom as Bausch + Lomb continues its evolution.” Ling stated, “I have long admired Bausch + Lomb’s reputation in eye health and am excited to join such a dynamic and innovative organization as it executes an ambitious global growth strategy. I look forward to helping the company deliver value for all stakeholders in 2024 and beyond.”

Karen L. Ling is the former executive vice president and chief human resources officer at American International Group, Inc. and, prior to that, at Allergan. She previously held senior human resources roles at Merck and Wyeth. Ling is currently a director – and chair of the compensation and human capital management committee – of iRythym Technologies and has served on the boards of Mallinckrodt Plc and TherapeuticsMD Inc. She also serves as a member of the advisory committee of Galderma. Additionally, Ling is a member of the board of two nonprofits: ExpandEd Schools and the JED Foundation. She holds a B.A. in economics from Yale University and a J.D. from the Boston University School of Law.

for astigmatism and presbyopia,” said Jacqueline Henderson, President Vision, EMEA, Johnson & Johnson. “Today, we’re proud to launch the Tecnis PureSee IOL, giving surgeons and patients the choice of a premium IOL that combines clarity of vision and reduced visual symptoms.”

Today, when choosing an IOL, surgeons and patients must make trade-off decisions. For example, you can have a lens that offers clear sight at all distances without spectacles, but at the price of possible glares and halos. According to the company, their new IOL combats these issues and improves the overall outcomes for both patients and surgeons.

8

GlobalCONTACT 1-24 INTERNATIONAL NEWS

Karen L. Ling

All about products

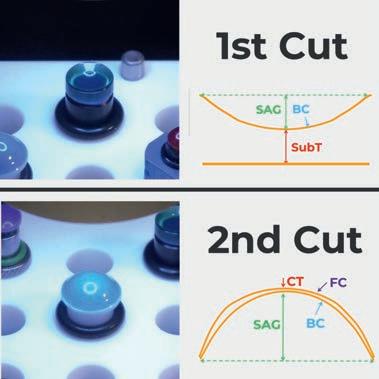

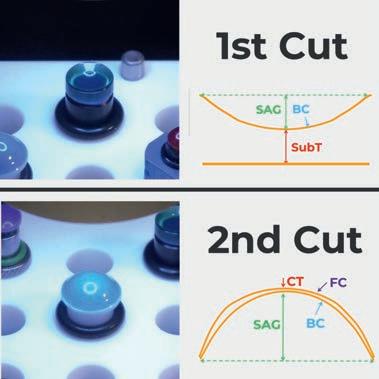

OPTIMEC SYSTEMS MAP TRAY+ — transform your quality control

Metrology is essential to quality control in your production process but can often be a bottleneck. The Optimec Systems MAP TRAY+ offers a solution, utilising advanced OCT technology to provide measurement at every stage of production, whilst lenses are blocked. Base curve and thickness after the first cut; front and base curve, CT and sag after the second cut, all completed whilst on-arbour and in a lathe autoloader tray. Automation on its own is not enough – you also need integration, which is where the MAP also shines, with in built APIs to allow connectivity to production control software. The MAP could solve your production QC issues, contact us today for more information. www.optimecsystems.com/map – info@optimecsystems.com

Contamac: Proven Products, Leading Brands

Contamac’s website has been updated and designed to provide customers with an enhanced user experience. With a more user-friendly interface, enriched content, and improved navigation, it provides visitors with seamless access to the resources they need. Alongside the complete range of contact lens and intraocular lens materials, the website now includes Global Insight, Contamac's digital publication. Alongside the website launch, Contamac released a refreshed look to its familiar product logos. This transformation brings greater alignment to the Contamac brand, and to that of our industry partners. Visit www.contamac.com to see more.

DIATEC Diamanttechnik GmbH Gmuender Str. 6 D-75181 Pforzheim Phone +49 (0) 72 31 - 7 80 12 - 0 info@diatec-pforzheim.de www.diatec-pforzheim.de Diamond tools for highest demands for the production of Intraocular Lenses and Contact Lenses monocrystalline and polycrystalline diamond tools Diamond turning tools with controlled waviness Diamond milling tools Advertisement INTERNATIONAL NEWS

All about research

UV protective contact lenses, smart contact lenses, eye color & retinal health

A team of researchers at Khalifa University, Abu Dhabi, United Arab Emirates, has developed UV protective contact lenses. Researchers from Dresden, Germany, investigated how four Drosophila genes, known to control eye color, are essential for health of retinal tissue. Scientists from Nanyang Technological University, Singapore (NTU Singapore) have developed a flexible battery as thin as a human cornea, which stores electricity when it is immersed in saline solution, and which could one day power smart contact lenses. By Rebekka Nurkanovic

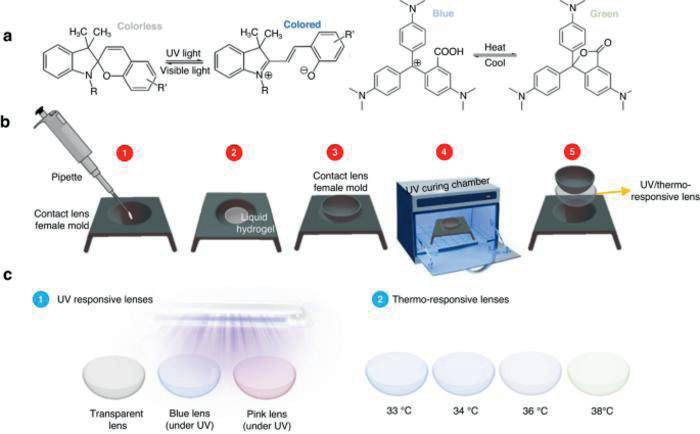

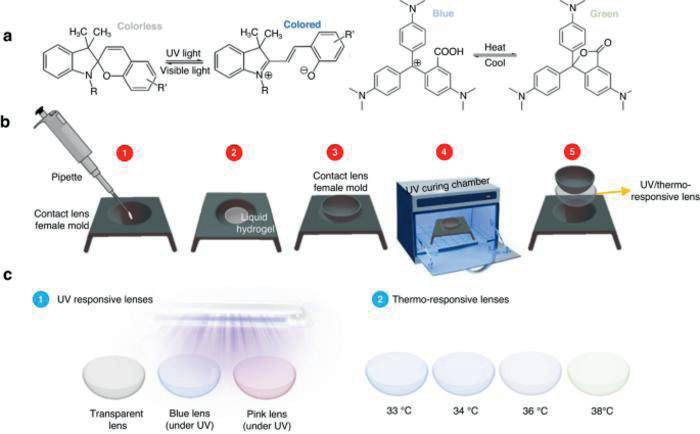

New contact lenses respond to UV and temperature changes

A team of researchers at Khalifa University, Abu Dhabi, United Arab Emirates, has developed UV protective contact lenses. Prof. Haider Butt and PhD student Ahmed Salih, both Department of Mechanical Engineering, developed their lenses using smart materials such as photochromic and thermochromic powders. They have unique optical attributes depending on their activated and inactivated states. Photochromic powders change their structure in response to UV, while thermochromic ones react to temperature variations. When integrated into lenses, they should be able to help protect the eyes. Under regular lighting, these transition contact lenses effectively block about 45% of UV and 20% of blue light. When exposed

to UV radiation, the lenses darken in real time, absorbing portions of visible light. The speed and intensity of this transition vary based on the specific photochromic material used.

The use of different thermochromic and photochromic powders allows for user-specific customization, allowing wearers to choose lenses based on their unique needs. For instance, blue transition lenses react swiftly, with 95% of their color change reverting in less than five seconds after exposure to UV light.

Pink lenses offer more intense coloration, but they take more than 30 seconds to return to transparency.

UV isn't the only factor impacting eye health. Fluctuations in ocular surface temperature, normally between 31 to 37° C, have been connected to issues like dry eye, glaucoma, and diabetic retinopathy. This has spurred interest in real-time temperature

10

GlobalCONTACT 1-24 INTERNATIONAL NEWS

monitoring using advanced contact lenses. The Khalifa University team’s lenses are temperature-sensitive and multifunctional, displaying optical changes within physiological conditions. They darken outdoors due to UV rays from sunlight and respond to changes in temperature.

The team’s multifunctional lenses showcase UV and blue light filtering capabilities alongside colorimetric temperature responses. The researchers think that the lenses stand poised to serve as both therapeutic and diagnostic tools. Their findings were published in the journal Light Science & Applications in 2023.

a: Chemical structure of photochromic and thermochromic powders (l.) spiropyran structured material (colorless) switching to merocyanine (colored) and (r.) Fluoran leuco dyes at protonated and deprotonated states. b: Schematic of the lenses’ fabrication process. c: Multifunctional contact lenses under different stimuli. Picture: A. Salih, and H. Butt

Eye color genes are critical for retinal health

Metabolic pathways consist of a series of biochemical reactions in cells that convert a starting component into other products. There is growing evidence that metabolic pathways coupled with external stress factors influence the health of cells and tissues. Many human diseases, including retinal or neurodegenerative diseases, are associated with imbalances in

metabolic pathways. Elisabeth Knust leads a team of researchers from the Max Planck Institute of Molecular Cell Biology and Genetics (MPI-CBG) in Dresden, Germany, who describe an essential role for one such metabolic pathway in maintaining retinal health under conditions of stress. They studied the classic Drosophila genes cinnabar, cardinal, white, and scarlet, originally characterized decades ago and named due to their

Precision & Gage R&R in the industry Operator independent

Best

World leader in wavefront metrology

for full characterization & report

www.ophthalmics.lambda-x.com Software

INTERNATIONAL NEWS

role in eye color pigmentation, in particular the formation of the brown pigment of the fly eye. These genes encode components of the kynurenine pathway, whose activity converts the amino acid tryptophan by various steps into other products. In this study, the authors have highlighted the function of this metabolic pathway in retinal health, independent of its role in pigment formation.

It is an evolutionary conserved metabolic pathway that regulates a variety of biological processes. Its disruption can result in the buildup of either toxic or protective biomolecules or metabolites, which can worsen or improve, respectively, the health of the brain, including the retina. Knowledge on this important metabolic pathway was recently extended by the research team, led by Elisabeth Knust, Director Emerita at the MPI-CBG, in their publication in the journal Plos Genetics. Being aware of the remarkable conservation of this metabolic pathway and the genes that regulate it, they used flies as a model system to unravel the role of individual metabolites in retinal health. The researchers looked at four genes – cinnabar, cardinal, white, and scarlet – named after abnormal eye colors following their loss in flies. “Since the Kynurenine pathway is conserved from flies to humans, we asked whether these genes regulate retinal

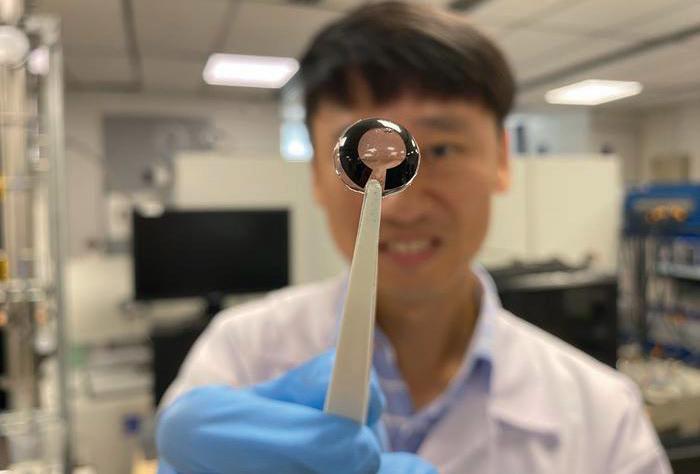

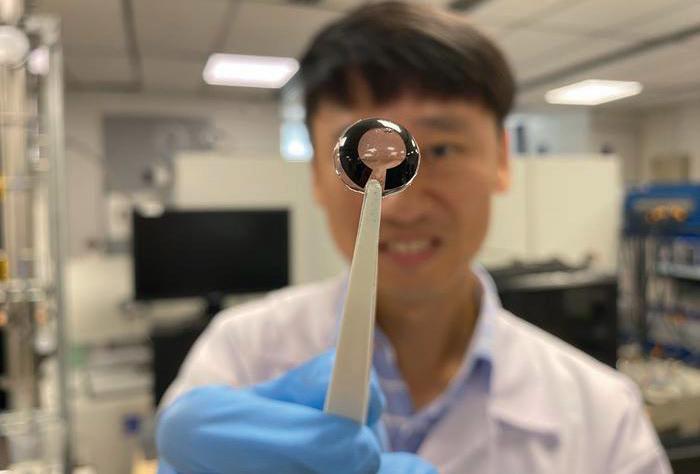

Battery charged by saline solution that could power smart contact lenses

Scientists from Nanyang Technological University, Singapore (NTU Singapore) have developed a flexible battery as thin as a human cornea, which stores electricity when it is immersed in saline solution, and which could one day power smart contact lenses. The NTU-developed battery is made of biocompatible materials and does not contain wires or toxic heavy metals, such as those in lithium-ion batteries or wireless charging systems. It has a glucosebased coating that reacts with the sodium and chloride ions in the saline solution surrounding it, while the water the battery contains serves as the ‘wire’ or ‘circuitry’ for electricity to be generated.

The battery could also be powered by human tears as they contain sodium and potassium ions, at a lower concentration. Testing the current battery with a simulated tear solution, the

health independent of their role in pigment formation,” says Sarita Hebbar, one of the lead authors of the study.

To find this out, the scientists used a combination of genetics, dietary changes, and biochemical analysis of metabolites to study different mutations of the fruit fly, Drosophila melanogaster. Sofia Traikov, a co-author, developed a method for the biochemical analysis of the metabolites of the Kynurenine pathway. This allowed the researchers to link different metabolite levels to the health state of the retina. They found that one metabolite, 3-hydroxykynurenine (3OH-K), is damaging to the retina. More importantly, they could show that the degree of degeneration is influenced by the balance between toxic 3OH-K and protective metabolites, such as Kynurenic Acid (KYNA), and not just by their absolute amounts. Sarita continues: “We also fed two of these metabolites to normal (non-mutant) flies and found that 3OH-K enhanced stress-induced retinal damage, whereas KYNA protected the retina from stress-related damage.” This means that retinal health in certain conditions can be improved by altering the ratio of metabolites of the Kynurenine pathway.

DOI: https://doi.org/10.1371/journal.pgen.1010644

Source: Max Planck Institute of Molecular Cell Biology and Genetics (MPI-CBG)

researchers showed that the battery’s life would be extended an additional hour for every twelve-hour wearing cycle it is used. The battery can also be charged conventionally by an external power supply.

Associate Professor Lee Seok Woo, from NTU’s School of Electrical and Electronic Engineering (EEE), who led the study, said: “This research began with a simple question: could contact lens batteries be recharged with our tears? There were similar examples for self-charging batteries, such as those for wearable technology that are powered by human perspiration. However, previous techniques for lens batteries were not perfect as one side of the battery electrode was charged and the other was not. Our approach can charge both electrodes of a battery through a unique combination of enzymatic reaction and self-reduction reaction. Besides the charging mechanism, it relies on just glucose

12

Photos of fly eyes with different colors ranging from normal (left, red) to abnormal (bright red, middle, mutation in the cinnabar gene), and white, right (mutation in the white gene). Abnormal eye color arises due to mutations in genes that regulate pigment formation and a specific metabolic pathway. Credit: Hebbar et al., Plos Genetics, 2023 / MPI-CBG

GlobalCONTACT 1-24 INTERNATIONAL NEWS

and water to generate electricity, both of which are safe to humans and would be less harmful to the environment when disposed, compared to conventional batteries.”

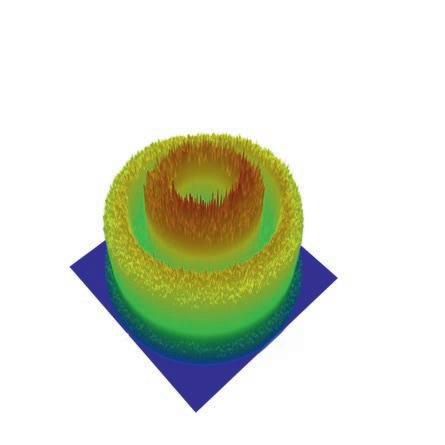

The team demonstrated their invention using a simulated human eye. The battery, which is about 0.5 millimeters-thin generates electrical power by reacting with the basal tears – the constant tears that create a thin film over our eyeballs – for the devices embedded within the lenses to function.

The flexible and flat battery discharges electricity through a process called reduction when its glucose oxidase coating reacts with the sodium and chloride ions in the tears, generating power and current within the contact lenses. The team demonstrated that the battery could produce a current of 45 microamperes and a maximum power of 201 microwatts, which would be sufficient to power a smart contact lens. Laboratory tests showed that the battery could be charged and discharged up to 200 times. Typical lithium-ion batteries have a lifespan of 300 to 500 charging cycles. The team recommends that the battery should be placed for at least eight hours in a suitable solution that contains a high quantity of glucose, sodium and potassium ions, to be charged while the user is asleep. The NTU team will be conducting further research to improve the amount of electrical current their battery can discharge.

They will also be working with several contact lenses companies to implement their technology.

The findings were published in the scientific journal Nano Energy in June 2023. The research team has filed for a patent through NTUitive, NTU’s innovation and enterprise company. They are also working towards commercializing their invention.

DOI: 10.1016/j.nanoen.2023.108344

Source: Nanyang Technological University

Advertisement

Optoform

Nanotech UPL

Nanoform REM Vision

www. ky diamond.ca

Associate Professor Lee Seok Woo, from NTU’s School of Electrical and Electronic Engineering (EEE) holding up the flexible battery that is as thin as a human cornea. Picture: NTU Singapore

Ultra Precision Diamond Tools DAC

Moore

Precitech

CONTACT LENS AND IOL

INTERNATIONAL NEWS

50 Years of EFCLIN

The organization we all love so much is turning 50. It's a matter of honour for us at GlobalCONTACT, which has been supporting the organization for 31 years, to bring you a big special. We asked some of EFCLIN's companions: what was it like back then? What were their personal memories and, above all, what were the congresses like? Wim Aalbers wrote an amusing version of his long-running column "Something else". But now, ladies and gentlemen, let's take a look back together. By Silke Sage

• Vilamoura

• Glasgow Brussels • Nice

Den Haag •

• Amsterdam

• Antwerp

• Berlin

• Prague Venice •

• Vienna

• Budapest

• Dubrovnik

• Riga

• Barcelona Sitges • Valencia •

• Malaga

GlobalCONTACT 1-24

•

EFCLIN Congresses & Exhibitions have been organized in these locations over the past 50 years. In some places several times.

Andy Chryssolor: Founding Member and Past President of EFCLIN

GlobalCONTACT: When did you join the contact lens industry?

Andy Chryssolor: February 1969 when I joined Allergan in California as Area Manager Europe, Middle East & Asia. At that time, Allergan was producing Ophthalmic Rx and OTC products and contact lens solutions which they sold under their label and also for B&L. I travelled internationally and began visiting contact lens laboratories and looked for distributors in those countries as Allergan was a very young company and was looking to enter the international market.

Many ophthalmic congresses had an exhibition and did not allow contact lens manufacturers to exhibit and if they did, the delegates would not bother to visit the exhibition or there were too few to make the exhibition worthwhile financially.

In January 1972 I was asked to relocate to Europe to set up European Headquarters, look for acquisitions, find distributors in European countries where Allergan was not represented. Headquarters were established in the UK. I was introduced to George Nissel at a Contact Lens meeting in London. He introduced me to other contact lens laboratories in the UK and also gave me a list of potential customers for the solutions in the rest of Europe to contact.

GlobalCONTACT: What organizations existed back then?

Andy Chryssolor: Each European country had at least one or two organizations that were only for the Profession such as Scandinavian Contact Lens Specialists, German Ophthalmologist Society, Chambre Syndicale des Adaptateurs d’Optique de Contact, Hungarian Ophthalmological Society. There was also the European Contact Lens Society of Ophthalmologists but were involved in fitting contact lenses only by Ophthalmologists. Opticians and Optometrists were not allowed to fit contact lenses during this period. Ophthalmologists insisted that this was a specialty and only they were qualified to fit. Many countries allowed Ophthalmologists to fit and give the prescription to the patient who would go to an optician to buy the lenses and return to the Ophthalmologist for the final fit.

GlobalCONTACT: How and why was EFCLIN founded?

Andy Chryssolor: Because the contact lens labs and equipment suppliers were not able to exhibit at many of these Ophthalmic congresses, George Nissel, after returning from a very poorly attended exhibition decided to speak with a few European colleagues and proposed setting up a trade association that would be strictly for the manufacturing trade where contact lens labs and suppliers could exchange ideas, review new products and see what products would be on offer. A big plus was that manufacturers would have the opportunity to exchange new ideas about manufacturing lenses. This was in 1971.

On March 18, 1972 EFCLIN was formally founded with Jack Gallimore as President and George Nissel as Secretary. The other founding members were: Javier Chamorro (Spain), Klaus Bjorn Bulle (Germany), Pierre Rocher (France), Rene Leroy (France), Roger Cotterau (France).

As time went on, the structure of the original idea for the creation of the Association was modified to hold lectures by the professions, allow solution manufacturers and any other industries that would be used in manufacturing. Workshops, commercial presentations during the exhibition were instituted, and IOL companies joined EFCLIN.

Today, EFCLIN is the premiere event for the contact lens and IOL industries world-wide with 32 countries represented and over 300 delegates at the 2023 Congress.

GlobalCONTACT: From when to when were you active in EFCLIN and in what function?

Andy Chryssolor: I became a Board member in 1975 and also 2004-2010, President in 2007, organizer of the golf tournament,

15 GlobalCONTACT 1-24

started “first of its kind” EFCLIN journal, “CONTACT” in 1981 (strictly for the trade and not for the Profession), as President and with the Board’s agreement, invited the IOL manufacturers to join EFCLIN in 2008 as they did not have a manufacturers’ association. Many IOL labs started as contact lens labs as the IOL industry uses many of the same manufacturing equipment such as lathes and analytic instruments. The development of computerized milling machines was a game changer in producing one-piece IOLs.

GlobalCONTACT: What novelty, innovation or achievement do you remember in this industry?

Andy Chryssolor: Manufacturing was greatly improved by the introduction of High spec CNC lates, moulding technology for soft lenses making disposable lenses affordable and readily available, measuring and analytical equipment to a very high standard.

GlobalCONTACT: Which was the best congress for you and why?

Andy Chryssolor: The last Congress, 2023 was a huge success! After Covid, this event was what the doctor ordered. Excellent speakers, good location, enthusiastic exhibitors, the idea of dressing in country traditional attire was very entertaining as was the cartoon drawings! Overall, it was very well organized and meeting colleagues after Covid was most enjoyable.

GlobalCONTACT: Which venue did you like best?

Andy Chryssolor: Venice in May, 2015 was a venue I shall never forget. Just being in Venice was magic. Although I have been to Venice at least 5 times, I never really saw it for what it is, as my

trips there were on business. This time, I went as a tourist and with the organized sightseeing it was more than beautiful. Not only the city, but the atmosphere at the Congress was relaxed and the delegates all seemed to be in very happy moods. The organization was also well prepared and speakers very interesting. The President’s dinner Saturday evening was most enjoyable with the good food and pleasant conversations. My pictures of Venice with the beauty of the city and those that I took of some delegates who were all enjoying themselves will live with me forever!

GlobalCONTACT: Was there moving moment for you that you would like to share with our readers?

Andy Chryssolor: Very early in EFCLIN’s life as in 1973, EFCLIN delegates came with their wives and the 15 or so delegates spent more time socializing than doing serious business all day long. We had our sessions in the mornings and then after lunch we went sightseeing. At this meeting we were in Spain and would hold our meeting at one of the Islands off the coast at Mallorca. We would travel there on an overnight boat in our own cabin. This would be an interesting experience as my wife and I never travelled and slept in a cabin on a boat.

We arrived at the port and were shown to our “boat” which was nothing more than a small ferry that travelled between the Mainland and Majorca. We were shown to our cabin – a very small space with a small bed and washroom. I turned to the crewman that showed us to the cabin and said to him: “This so small and the bed tiny. How do you expect me to make love to my wife in such as small bed?” (Joking, of course.) He replied, “Would you like me to show you how?”

EUROPEAN FEDERATION OF THE CONTACT LENS AND IOL INDUSTRIES SPECIAL TOPIC

Advertisement GlobalCONTACT 1-24 EUROPEAN FEDERATION OF THE CONTACT LENS AND IOL INDUSTRIES SPECIAL TOPIC

Marion Beeler- Kaupke, Executive Director

GlobalCONTACT: What novelty, innovation or achievement can you remember in connection with the contact lens industry in general and the EFCLIN Congress in particular?

Marion Beeler: Having worked in contact lens fitting since the early 1980s, I have witnessed all kinds of innovations. It started with CAB, the first "gas-permeable" material, continued with newer gas-permeable materials and aspheric geometries and ended with quadrant-specific lenses. Toric lenses – rigid and soft – as well as bifocal and multifocal lenses completed the range. Each development took the industry one step further. Then came special ortho-K lenses and finally sclerals, which brought us almost back to the beginning of contact lens history.

In the same way, as an optician's apprentice at the end of the 1970s, I was still making prescription glasses. Glasses with +20.0 dpt were not uncommon. Attempts with rigid contact lenses were often only somewhat successful, as these people were usually elderly and no longer at their best in terms of fine motor skills. The liberation came with IOLs.

I have been working with EFCLIN for 9 years now. During these years, something new has been launched at practically every congress. Another new aspect is the enormous development in the digital field.

GlobalCONTACT: What setback, scandal, or almost unsolvable problem can you remember during your time as EFCLIN Executive Director?

Marion Beeler: For example, the total collapse of the freight elevator in Prague in 2017 because the specified capacity did not correspond to reality. The technicians had to spend half the night repairing it and we were only able to set up the exhibition after a long delay. In the end, thanks to this night-time operation, everything went smoothly and we had a great EFCLIN conference there. And also when the German government imposed the coronavirus quarantine on March 8, 2020 with a bang and we had to cancel the EFCLIN conference in Berlin, which was planned for the second half of April. The Board and I were sitting in a strategy workshop and had to make a decision within a few hours. A fully prepared congress had to be re-developed, which took as much time as organizing the congress. Thanks to insurance, EFCLIN was not left with the costs. In one case, however, this unfortunately ended in a legal dispute.

When Ukraine was invaded in February 2022, we had planned the EFCLIN Congress 2023 in Eastern Europe, in Budapest. Initially, everyone thought that this war would be short-lived, but unfortunately we were taught otherwise. After concerned EFCLN members contacted me in the summer of 2022, the Board and I decided to move the congress to Western Europe.

My PCO partner and I were faced with the great challenge of finding a suitable venue in the shortest possible time that was also available for the date we had already communicated. Fortunately, after dozens of inquiries, we found what we were looking for in The Hague.

GlobalCONTACT: Which was the best congress for you and why?

Marion Beeler: Every congress had its highlights and "pitfalls". "Best EFCLIN ever" is something I've often heard after a congress. This may be because I am a perfectionist myself and want to have everything organized before I leave for the congress. You can also see year after year how hard the exhibitors try to remain attractive and offer their customers something. The 2022 congress in Sitges was very emotional after the two-year Covid break. You could really feel how much everyone was looking forward to this reunion of the EFCLIN community.

GlobalCONTACT: Which venue did you like best?

Marion Beeler: First of all, I would like to say that the demands on an EFCLIN conference are extremely high. We need both a good exhibition infrastructure and suitable lecture rooms. I really liked Sitges as an organizer, all the other venues had a weak point somewhere. Unfortunately, sometimes these only came to light when we wanted to set up on site, sometimes we simply had to accept them and find a solution.

GlobalCONTACT: Was there a moving moment for you that you would like to share with our readers?

Marion Beeler: Yes, when Pam Larsen returned to work on the booth alongside her husband Erik in 2018 after a serious illness.. I don't think she missed a single congress apart from 2017.

I was also very happy when I found out that Helga Seiler and Ken Payne had said "I do" for life. We are not just an association but also an EFCLIN family.

EUROPEAN FEDERATION OF THE CONTACT LENS AND IOL INDUSTRIES SPECIAL TOPIC GlobalCONTACT 1-24 18

For 50+ years, Boston Materials has brought you innovative, high-quality products with unmatched service and support. Bausch + Lomb’s ongoing commitment to research has helped make us a world leader in GP material technology.

2000s 1980s

• Bausch + Lomb acquires Polymer Technology Corporation

• Boston® II and Boston® IV silicone acrylate materials introduced

• Boston® Equalens® introduced: first fluoro silicone acrylate GP lens material

• FDA approval for Boston® Orthokeratology lens as Vision Shaping Treatment VST® using Equalens® II GP material for overnight wear

• Plasma treatment FDA-approved for all Boston® GP lens materials

2020s

• Boston Materials celebrates 50th anniversary

• Boston SOFT introduced

• With more innovations to come

1990s

• Boston® Equalens® II GP lens material introduced

• Boston ES® and Boston EO® GP lens materials introduced

• Boston XO® with high Dk introduced

2010s

• Boston XO2® hyper-Dk GP lens material introduced

• Boston XO® and XO2® US receive indication for ocular surface disease and dry eye

• 510(k) clearance for Tangible® Hydra-PEG® custom contact lens coating technology

To Learn More:

+

©2024 Bausch

Lomb. Visit our booth at EFCLIN 2024. We look forward to meeting with you. Proud of our history. Focused on the future.

EUROPEAN FEDERATION OF THE CONTACT LENS AND IOL INDUSTRIES SPECIAL TOPIC Advertisement GlobalCONTACT 1-24

Erik Smidt, EFCLIN President 2011 – 2013

GlobalCONTACT: When did you join the contact lens industry?

Erik Smidt: In 1997, I founded "ERCON contactlenzen & consultancy", a distributor of soft contact lenses with our first supplier Igel, now Ultravision. Before I started my own company, I worked at Friedrichs, a wholesaler, and at CIBA Vision, so I already had experience in the entire supply chain as a contact lens fitter. Ultravision is still a main supplier for ERCON today.

GlobalCONTACT: From when to when were you active in EFCLIN and in what function?

Erik Smidt: At that time, monthly disposable lenses were just being introduced and in the Netherlands, soft contact lenses were mainly replaced every six months. When I started my business, I had no idea that I would ever be a member of EFCLIN until Wim Aalbers asked me if I wanted to become a member, I think that was in 2000.

of RGP materials with high oxygen permeability was also a breakthrough in the industry. The latest innovations are myopia control and the revival of Ortho-K lenses. Not least because of the success of the new materials in contact lenses.

GlobalCONTACT: Which was the best congress for you and why?

Erik Smidt: To be honest, the best congress for me in 2018 was because of a personal issue. As I mentioned earlier, we changed the format of the manufacturers' forum. We were very pleased with the number of participants, which, if I remember correctly, was over 120. The plan to have lively discussions between EFCLIN members, who in other situations would sometimes never speak to each other, was successful. Besides great conversations and great contributions to the members, this was a goal to achieve.

In 2005 I was elected to the board by the EFCLIN members and after two years I was appointed treasurer of EFCLIN, succeeding Henk van Bruggen.

After serving as treasurer for some time, I became president of the association, which was extended for another year, when I should have stepped down as I had been a member of the board for six years. Naturally, I was delighted to have the trust of the members.

In 2016, the Board asked me to moderate the Manufacturers' Forum. Together with Hannes Pfund, we had a lot of fun preparing these forums. When EFCLIN held its first post-Covid live event in 2022, the forum in this format was the last one I moderated. For me, it was an honor and a privilege to moderate it and I always enjoyed it immensely.

GlobalCONTACT: What novelty, innovation or achievement do you remember in this industry?

Erik Smidt: The industry is constantly evolving, right down to new materials and modalities. I still remember the introduction of the first monthly and daily disposable lenses. The introduction

GlobalCONTACT: Which venue did you like best?

Erik Smidt: The venue I enjoyed the most was Vilamoura in 2013, what a great place, and even better, we are having the 50th EFCLIN Congress again in Vilamoura. The organization couldn't have picked a better place for an anniversary.

GlobalCONTACT: Was there a moving moment for you that you would like to share with our readers?

Erik Smidt: In my opinion, EFCLIN is a great community, not only for business, but also for meeting friends. My wife Ingrid and I have made some of our best friends through participating in EFCLIN. Steven and Angela Wheeler, who have been retired for a few years, are still our best friends and we visit them and them us whenever possible. So EFCLIN isn't just great for business reasons. You can make friendships that last for years, even if you are no longer in the industry.

For these reasons, I am delighted to become a member again with my new company, BOX 14 Consultancy, and I hope to meet new and old friends in Vilamoura.”

EUROPEAN FEDERATION OF THE CONTACT LENS AND IOL INDUSTRIES SPECIAL TOPIC 20 GlobalCONTACT 1-24

Advertisement SPECIAL TOPIC EUROPEAN FEDERATION OF THE CONTACT LENS AND IOL INDUSTRIES EFCLIN President Duddek Armin 2015 - 2024 Prolens AG Kopito Marcel 2014 - 2015 Bausch & Lomb, Polymer Technology, Germany Smidt Erik 2011 - 2013 Ercon, NL Bear Jeannie 2009 - 2010 Contamac, Menicon Chryssolor Andy 2007 - 2008 Contour Fine Tooling, UK Avery Graham 2005 - 2007 Bausch & Lomb Payne Ken 2000 - 2002 DAC, USA Behar Shimon 1999 - 2000 Soflex, IL Walker David 1995 - 1998 Vista Optics, UK Koller Tony 1992 - 1995 Optik Koller Gfoeller Werner 1990 - 1992 Jaggs Michael 1982 - 1990 Nissel George 1979 - 1982 Cantor&Nissel, UK Gallimore Jack 1972 - 1979 NuSyte, UK Executive Director Aalbers Wim 1991-2010 retired, Belgium Wheeler Steve 2011-2015 retired, UK Beeler-Kaupke Marion 2016 - Comsy, Switzerland

Something else

From 1991 to 2011 we had the pleasure of organizing the EFCLIN congresses. I write 'we' because my wife Kitty, our successive secretaries Paula and Renée formed a close team during that period. When asked by GlobalCONTACT if I wanted to write an article about our experiences in the context of the 50th EFCLIN congress in Portugal, I said ‘yes!’. And it was a great pleasure, too. A pleasure to reminisce with our former team. Memories that you may share with us, but may bring a smile to the younger generation. Yes, boys and girls, that's how it used to be at those congresses. By Wim Aalbers

Let's start in the period when no more congresses were planned. That was in 1992. One or two years earlier there had been another congress in Luxembourg. And back then it was still the case that if you said something at the meeting, you had the chance to immediately get on the board. That happened to me in Luxembourg...

THE ONE WITH THE QUESTION: “CONTINUE WITH EFCLIN OR CANCEL IT?”

In spring 1992 the board decided to have a meeting in Spain. Thenboard member Frances Llapart organized that meeting. EFCLIN had become an “English gentlemen's club” with few activities and that was not what the Board had in mind with this organization. There was only one agenda item: “Continue with EFCLIN or cancel it?” We used the organization's entire (but tiny) remaining cash sources for this meeting. After a few good dinners and great discussions, it was decided that we would give it a try. This was partly due to my offer to try it, but entirely at my own risk. So I (Eurolens, my company) would do everything in my power to get things back on track. And since the till was completely empty, Eurolens would pre-finance it.

A MAGAZINE CALLED GLOBALCONTACT AND A NEW CONGRESS

It was also decided to publish a magazine in the name of EFCLIN: the magazine was called “Global Contact”. The intention was to distribute the magazine among European laboratories and related contact lens organizations. In the same year, 1992, we organized a new congress in Amsterdam.

There was an exhibition with a limited number of exhibitors, but the number of participants was satisfactorily. In any case, enough to continue with another congress next year.

CE MARKING AND MEDICAL DEVICE STATUS

EFCLIN suddenly became more interesting for the industry when the CE marking was announced. Contact lenses were given medical device status and our entire industry was concerned about the consequences this would have.

We organized various meetings for members in several regions. We invited specialists who explained what could be expected. EUROMCONTACT also played an important role as an interest group. As Executive Director of EFCLIN, I was invited to join their board. This meant that EFCLIN was first in terms of information provision. All that turned out to be very useful. This also allowed us to share meaningful and up-to-date information in GlobalCONTACT.

THE ONE WITH THE FIRST MACHINE AT AN EFCLIN CONGRESS

After a while machine manufacturers also became more interested in the exhibition. If I remember correctly, it was DAC International that brought the first machine to an EFCLIN congress. And that didn't happen without a fight...

The exhibition space was one floor higher than the ground floor. (In Europe this is the first floor, elsewhere it may be called the second floor…). Anyway, the machine had to go up in the elevator. And because it was the first time that we had seen a machine like this at the exhibition, we as an organization had not yet 'learned' how to check whether this would be easy to arrange.

EUROPEAN FEDERATION OF THE CONTACT LENS AND IOL INDUSTRIES SPECIAL TOPIC GlobalCONTACT 1-24 22

Photos: Wim Aalbers

WHY JOIN EFCLIN?

“It’s the best form of business networking I have ever done”

“If you can’t support your own industry who can you support?”

“A great source of information”

“Everyone seems to help each other, it’s amazing”

“It’s run by its members, for its members”

“Why wouldn’t you?”

“It’s like having a whole network of experts available at all times”

“There is always someone you can contact who will have experiences you can benefit from”

“I’d pay the membership just to come to the congress”

“The members all understand each other”

“It’s our representative body”

“The congress and exhibition is the best there is”

CONTACT US: INFO@EFCLIN.COM // +041 (0)41 372 1010

EFCLIN OFFERS TWO TYPES OF MEMBERSHIPS: Lens Manufacturers, Wholesalers & Distributors pay an Annual Subscription based upon the number of employees in their organization Suppliers to the Industry and Consultants pay an Annual Subscription based upon the value of their Annual Sales to the lens manufacturing industry 1 2 YOU CAN FIND FULL DETAILS OF ALL THE ANNUAL SUBSCRIPTION CHARGES AT EFCLIN.COM VISIT EFCLIN.COM/BECOME-A-MEMBER Advertisement GlobalCONTACT 1-24 EUROPEAN FEDERATION OF THE CONTACT LENS AND IOL INDUSTRIES SPECIAL TOPIC

The machine was wheeled to the elevator and slid into it. There appeared to be barely 2 cm of space left on each side. We could no longer reach the buttons to operate the elevator. So someone walked up the stairs and 'ordered' the elevator there.

THE ONE WITH JEANNIE AND THE BOAT

From the first congress we organized, we included an entertainment dinner into the program. In Amsterdam it was obvious to organize a dinner on a tour boat. Right from the start, I made it clear to everyone that time was sacred during the congress, but also in all other activities. The program stated that we would leave by boat at half past seven, and so we did – even if people were late. And so it happened. We left and Jeannie Bear wasn't there yet. But Jeannie wouldn't be Jeannie unless she came up with a plan. She ordered a cab and instructed the driver to follow the boat, eventually boarding elsewhere to loud applause. Another entertainment dinner in Amsterdam took us to a fake nightclub: the Eccentric Club, including casino. In that casino you were allowed to cheat. This was immediately put into practice by many participants.

THE ONE WITH THE PUB CRAWL

Between 1994 and 1998 there were congresses in Belgium in Antwerp and Brussels and in the Netherlands in Zeist. For the transport from the airport to the congress hotel, we hired two students. Guests who indicated they wanted this service were picked up. One of this students was my son and he used my wife’s car. So the complete family was involved…

In Antwerp, we organized a pub crawl that ended with a great dinner in a good restaurant. That was quite a task to organize. Nobody was allowed to stay too long in a pub, otherwise people would be late for the restaurant. Fortunately, we had hired a number of guides who led the participants through the pubs with iron discipline.

THE ONES WITH LETTERS TO THE FRENCH AND SAILING TO THE NEW WORLD

At one of these congresses, I was made responsible in the General Assembly for the fact that so few French laboratories were present. I told the members in my best English that we had done everything we could to attract these people. I said: "We even sent French letters!". The English almost fell under the table laughing. While I wondered

It was also during that period that the idea arose to organize a joint congress with the CLMA. We could do that on a cruise ship sailing from Ireland to the USA. The Europeans only had to arrange a return journey and the Americans only had to arrange an inbound journey. However, the machine manufacturers had major objections to these plans, so it never happened. Their argument: “How could we produce a good contact lens at an exhibition on a ship, with wind force eight or more…? Good argument, but a shame, we already had wild plans about possible entertainment.

THE ONE WITH RICK IN NICE

And speaking of entertainment, in 2001 we were in Nice. For the entertainment we hired Rick, an American standup comedian who worked in Amsterdam. We called him in a day early and asked him to talk to the exhibitors. He would then base his act on what he had heard from the exhibitors. He visited the exhibitors with the story that he wanted to set up a contact lens lab in Amsterdam, where he wanted to produce lenses exclusively for artists. Well, such a story naturally provokes quite special reactions. Since Kitty and I were the only ones who knew what would happen the night his act took place, we sat in anticipation when he started. Could our Rick have based an act on what he had heard and seen? He started off fantastically, mentioning names of exhibitors and even products. It was all very funny. Until… Rick lost his lines and fell back on an act he did in nightclubs, with mainly male audience and only after 2 am. Kitty and I were panicking. This couldn't be possible! So I ran on stage and "shortened" his performance and complimented him backstage.

THE ONE WITH THE LIMITED AIR SUPPLY

We also had a very special technical problem in Nice: the number of machines on display had never been so large. At previous congresses, we had adequately regulated the power supply and compressed air, but now there were many more machines. Their exhibitors all wanted visitors to see what beautiful contact lenses these machines could produce. Unfortunately, the amount of compressed air supply was not sufficient. As a result, the exhibitors warned each other when they wanted to give a demonstration. When one machine started, the others had to wait in line. Of course, we also learned

EUROPEAN FEDERATION OF THE CONTACT LENS AND IOL INDUSTRIES SPECIAL TOPIC

>>

Larsen Equipment

In 2004, Keith Parker and I opened Advanced Vision Technologies (AVT). At that time, the economy was going through a very bad recession and as a result, it was impossible for a new business starting up to get a loan. We immediately reached out to Erik and Pam at Larsen Equipment to get refurbished equipment to use in our Laboratory. As AVT’s business grew, we invested in many different pieces of new equipment from Larsen Equipment and this helped us grow into one of the Premiere Labs in the United States. Our success is due in part to Erik and his Team with their state-of-the-art equipment and maintenance of their products. AVT is forever grateful for Larsen Equipment’s support of AVT. It is great to know AVT is working with Industry leaders with the Larsen Equipment and their Team!

Janine Bungo, VicePresident

QUALITY MANAGER: RANDY MINGOY

I have known Erik Larsen since 1992. Since then I have used just about every piece of equipment his company has built. My experience with Erik and the Larsen team has been one of great appreciation as they have always helped me in my needs of fully understanding equipment used to manufacture quality contact lenses. Erik has also been able to engineer any part needed for me even it was a custom part.

Erik (Larsen Equipment) has been and still is a pioneer in the contact lens and optical industry, and I am thankful to him for his support over the years.

Randy Mingoy Quality Manager

Advanced Vision Technologies

DIRECTOR OF OPERATIONS: JORDAN GOBEL

There can be a lot of moving parts when it comes to managing operations, so it is key to have reliable precision equipment that assists in overall efficiency. Larsen Equipment delivers just that! I have been utilizing Larsen manufacturing equipment for over 15+ years and have yet to run into an issue they could not resolve. I am a satisfied owner of bladder polishers, edge roller’s and auto-blockers etc. Each one of these units greatly assists in the reduction of rejects and manufacturing waste. Their ability to customize and retrofit specific tools certainly sets them apart from the competition. Larsen stands behind their equipment with a knowledgeable staff that provides exceptional service. Simply put, we are a better laboratory because of our relationship with the folks at Larsen.

Jordan Gobel

Director of Operations/Consultant

Advanced Vision Technologies

PRESIDENT: KEITH PARKER

I have had the pleasure of working with Erik since the beginning of Larsen Equipment. The first piece of equipment, a 6 spindle horizontal arm polisher revolutionized our production of GP contact lenses. Through the years, I watched his business grow as he and his team listened to our Industry needs and developed now numerous products not only simplifying many tasks of manufacturing but improving the consistency of quality in our finished products. Innovation has been an ongoing experience of our Company only made possible through the innovation of necessary equipment developed and made available by the Larsen team.

Larsen Equipment is a family owned business hosting a team of willing Staff all having the attitude of serving their Customer’s needs. As a Customer, we are made to feel like we have a friend in the business helping us develop a more efficient process allowing our Company to deliver better products for our Customers. Our success of AVT simply could not have been possible without the help, assistance and dedication of Larsen Equipment. I will be forever grateful for my opportunity to work with Erik and his very capable Staff.

Keith

25

Parker President 969 S. Kipling Parkway, Lakewood, CO 80226 Phone: 303-384-1111 888-393-5374 Fax: 303-384-1124 www.AVTLENS.com GlobalCONTACT 1-24 PR-Advert

a lot from this. From the following year we had Henk van de Bogaard present, who took excellent care of the compressed air for many years. From then on, we also organized the transport of all material for the exhibition better than before. Instead of all exhibitors sending everything directly to the congress venue, we had everything sent to a freight forwarder. That carrier brought all the materials in a large truck to the hotel where we were that year. That went well for years with the same carrier, although I was always worried. Suppose that truck had an accident... Then we would have a completely empty exhibition. Fortunately, that never happened.

THE ONE WITH THE BUILT-IN METRO STATION

In 2002 and 2003 we were in Barcelona. Good hotel, excellent facilities and a practical location. The hotel is literally built on top of a metro station. And the metro takes you to the center of Barcelona in a few minutes. The entertainment dinner was in a Flamenco restaurant. In 2003 we introduced the first EFCLIN website during that congress.

THE ONE IN FRONT OF THE AIRPORT

In 2005 we settled in Vienna. The congress hotel was opposite the airport exit, less than a 50 meter-walk. Still, we received several phone calls from congress attendees who had gotten into a taxi and asked us what the address of the hotel was. The entertainment dinner was in some kind of castle with an orchestra playing classical music. Toni Koller, who was on the Board at that time had organized that for us.

THE ONE WITH THE TWO PRESIDENT DINNERS

The congress in 2006 was in Venice. The hotel was built above and around a harbor that was directly connected to the canals in Venice. When we visited the hotel to inspect it, fortunately we now had the experience to check everything for the possibilities of bringing in machines. The proposed exhibition space looked excellent. Large, with a bar and well decorated. When I jumped (my standard check on the condition of the floor...) I bounced up and down. The floor turned out to be made of (thin) wood. Every machine we run there would produce special lenses… Entertainment on a boat in Venice, of course. But...

The number of participants who signed up exceeded expectations. Never before have we had so many participants. On the opening day, our secretary Renee Ong was behind the reception desk. That went well until a bus with about 45 Italians stopped in

front of the hotel. They all turned out to be people who still wanted to register.

So the restaurant where the president's dinner was being held turned out to be too small for the whole group. We had to quickly organize a second dinner at a different location. Kitty led this group and I led the other group. This was the only congress where there were two presidential dinners...

THE ONE WITH THE AUDITION OF STREET MUSICIANS

In 2007, the congress was held in Málaga, Spain. Nice hotel, good facilities. We had planned a Spanish party evening with Spanish music as entertainment. We hadn't been able to book a music group in advance and we thought we could organize it on site. When we arrived in Málaga, it turned out that it was a public holiday in Spain, so all the music groups were fully booked. What should we do? The solution: Kitty and I went to the center of Málaga and looked for street musicians. We listened to them to assess their quality and if they were good enough, to perform at our congress. We signed six musicians who gave a perfect performance on the night itself. A nice side effect was that we stayed well below our budget.

THE ONE WITH THE SHOOTING AND THE PYJAMA PARTY

In 2008 we went to Glasgow. Glasgow City Council has an enthusiastic and inventive urban development department. Two representatives of this department convinced us to choose this city.

Opposite the congress hotel was a pub. A murder had been committed there the night when most of the convention delegates arrived. Perhaps some thought that this was part of our entertainment program, but that was not the case. The entire street was cordoned off by the police and we were only able to enter the hotel with some difficulty. There were also some problems on the first night. In the evening, the hotel had announced (through a note in the rooms) that the water would be turned off from 12:00 am to 2:00 am. Not really a problem, right? But yes, someone had decided to take a bath at 11:55 pm and hadn't read the note. So he opened the tap, but the water supply ended after five minutes. The guest then fell asleep, but at 2:00 am the water was running again. Anyway, around 3:00 in the morning, all the alarms in the hotel went off. Everyone thought it was a fire alarm.

This was the first time that EFCLIN had "spontaneously organized a pyjama party". Everyone in the hotel lobby in nightgowns! Except for a few EFCLIN members who had apparently been sitting in

EUROPEAN FEDERATION OF THE CONTACT LENS AND IOL INDUSTRIES SPECIAL TOPIC

We had booked a typical Scottish restaurant for our entertainment dinner. The haggis was brought in with lots of traditional bagpipe music. The arrival was festive, but haggis was less festive for many attendees. Fortunately, the rest of the food and entertainment was fine. Also in Glasgow: GlobalCONTACT was officially handed over by Kitty and me from Eurolens to Jörg Spangemacher from Mediawelt (which is since 2019 in the hands of Silke and two other shareholders under Eyepress Fachmedien).

THE ONE WITH NO CONGRESS AT ALL

During a board meeting after the congress in Glasgow, the board decided to hold the congress in spring instead of October. The result was that there was no congress in 2009, because that would have been much too soon after the congress in Glasgow.

THE ONE WITH THE INTERFERENCE OF A VOLCANO

The next congress was therefore in 2010 in Riga, Latvia. That location also attracted some criticism in advance. It would still

snow and freeze there in April, there was nothing to do and it was too far away. But it turned out, it was summerly, and everyone enjoyed their stay in Latvia and the old town of Riga.

But leaving Latvia became a bit of a problem for many guests. In Iceland the eruption of the volcano Eyjafjallajökull caused a near standstill of most flight connections and some detours or extra days of stay.

THE ONE THAT WAS OUR LAST AS ORGANIZERS

In 2011 during the congress in Barcelona, Steve Wheeler took over from us, but we remained and will remain interested guests.

Kitty, Renee, Paula and I are convinced that EFCLIN in the future will keep playing the important role which it did in the last half century. Of course, there were ups and downs, but with motivated Board members and the professional Executive Director of the kind we presently have, the future is ours!

Maybe one little advice from this old man: keep things pleasant, make fun, next to the serious business. Make a visit to an EFCLIN congress a party. As long as we do so, we keep coming as visitors and many others will also.

SPECIAL TOPIC EUROPEAN FEDERATION OF THE

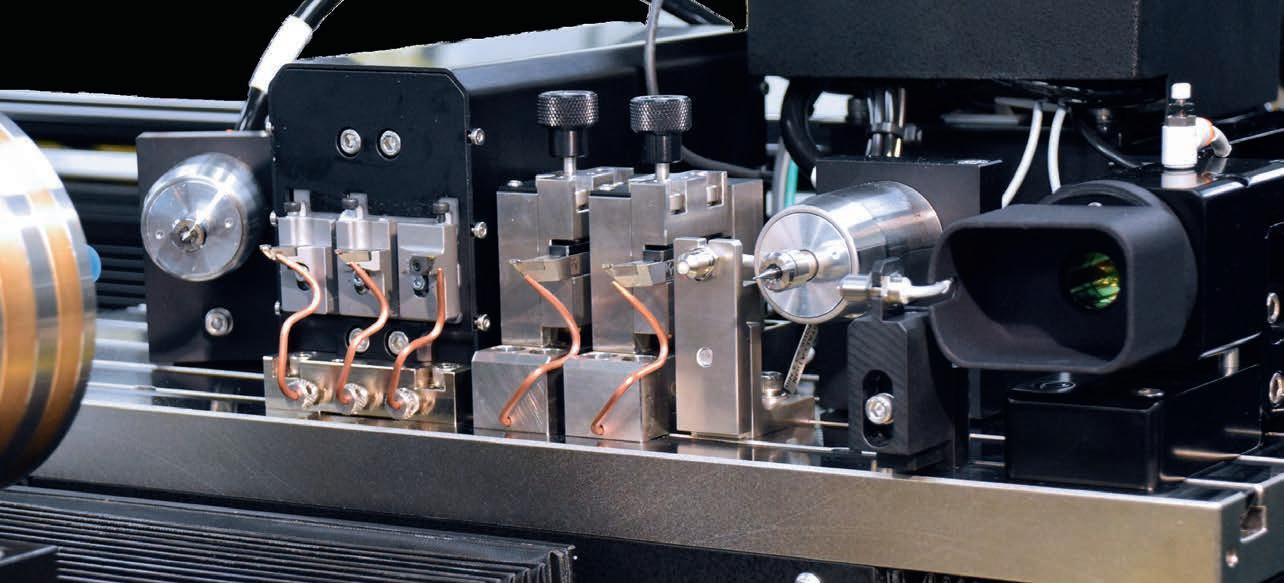

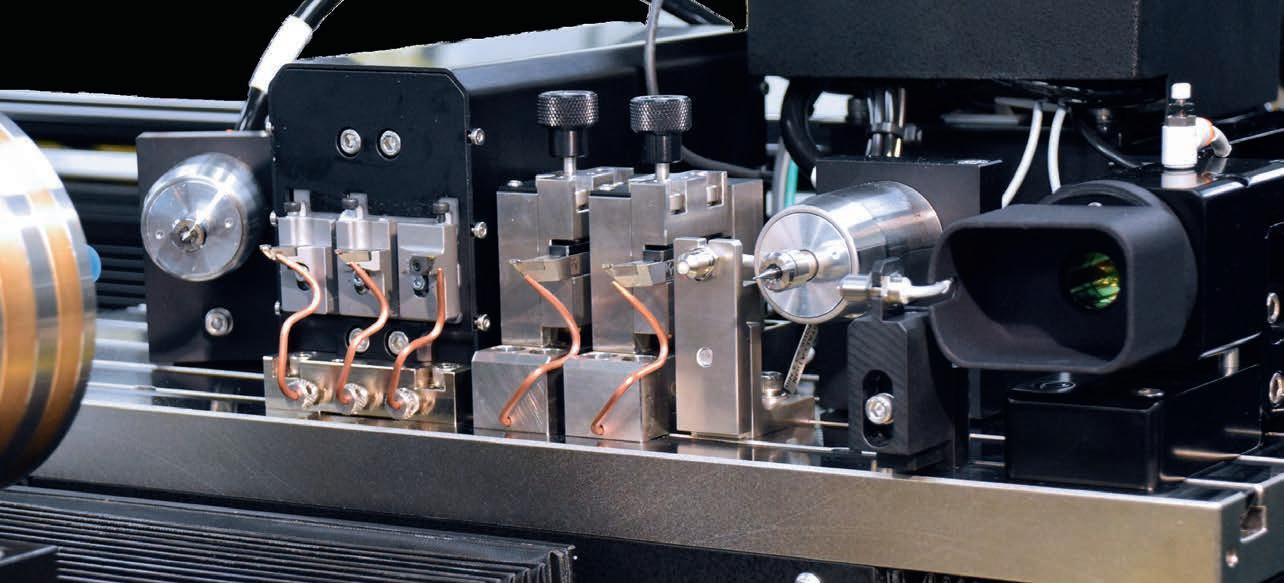

A row of auto blockers sits on the large workbench in the middle of the workshop. They are being assembled here and are not yet finished. One by one, the employee responsible for the electronics has to lay various cables and connect them to the electronics. This device is one of Erik Larsen's bestsellers. But his polishers are also known all over the world in contact lens manufacturing. A world map in the workshop marks the places to which his machines are delivered. It contains many pins that testify to the success story of the family business Larsen Equipment Design (LED). In the past there were many, many pins in North America, today there are few.

"In the 1970s, there were once around 500 labs in the USA – today there are only 15," says Erik. What would be a difficulty for other companies, the globally-minded and inventive engineer has turned into a success: today, 90% of his turnover is generated outside North America.

Since his beginnings in 1981, he has been thinking internationally and he soon looked over to Europe and showed his machines at the European EFCLIN conference.

THE BEGINNING: AN ENGINEER THROUGH AND THROUGH

Let's start at the beginning: Erik Larsen was born with a love for mechanical engineering. He was raised in a mechanical environment. He had his first “playground” in the workshop of

The Problem Solver

A visit to Larsen Equipment Design

Together with his son Andrew, Erik Larsen shoulders a steel bar and carries it into his workshop. It smells of oil and metal here. A whole battalion of machinery is installed here. Large, old, new and small. And the really big ones, which easily have a footprint of 6 m² and reach far over the heads of the employees who operate them. Countless boxes of machine parts, screws, cables and the many components needed to build his blockers and polishers and other products are lined up here. We visit Erik Larsen. He opened the door to his workshop in Seattle for GlobalCONTACT and gave us a tour. By Silke Sage

his father, a boat builder on Vashon Island, where he was able to create things and took great pleasure of it. There he learned early on what it took to get things done. Later he graduated at the University of Washington as a mechanical engineer. He initially worked for a few years at a company that manufactured contact lenses as well as its own machines for the emerging contact lens industry. "At one point they got bought out by CooperVision (Medi-Cornea) and stopped producing machines. But I loved making machines, so I quit and started LED about six months later," recalls Erik.

THE LEAP INTO INDEPENDENCE

During his time as an employee, he had already made numerous contacts. He developed a 6-spindle polishing machine and took that to the CLMA congress in 1982. But at first he didn't receive a single order. "There wasn't much money involved and it was just a try – but I knew I could do it," he recalls.

He waited and didn't hold out much hope at first, but the discussions and the presentation of the machine paid off. After around a month, the first order came in. He had obviously been remembered. Even though he hadn't even brought a business card with him, let alone thought of a suitable marketing concept. More orders came in over the next few months. His former boss also ordered six machines. Finally, Bausch+Lomb ordered

28

GlobalCONTACT 1-24 REPORT

a set of machines. But that was just the start, as numerous orders followed. The six-spindle polisher was awarded the first patent for Larsen.

INVENTIVENESS AND PRECISION

At that time there were five companies that also made contact lens machines, so there was competition. After a short time, he got a call from an employee who worked at Wessley Jessen and placed a large order. It was George Glady, who was working there at the time.

"Looking back now, I can say that B+L had provided us with an income, but George Glady turned LED into a thriving business”. Later Wesley Jessen was bought by Ciba Vision, which then became Alcon – and today LED ist still working with Alcon in addition to B&L. George Glady, on the other hand, later founded Euclid Systems and Erik continued to work with him. Sadly, George Glady passed away in the fall of 2023.

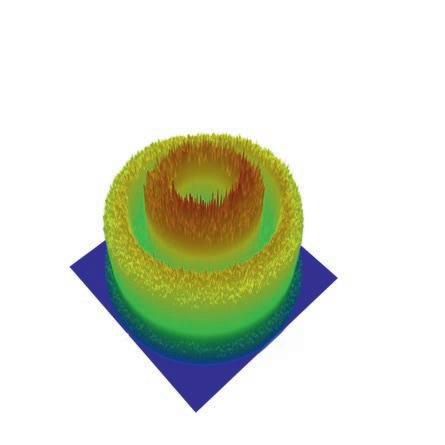

THE ROAD TO THE WORLD STAGE

Over the years, Erik Larsen developed a family of polishing machines in various sizes. And in 1990, the lathes were developed to produce ‘freeform optics’. “I was approached to develop a polisher for aspheres and torics. It seemed they needed someone who could solve the problem. So, we did!" he recalls. The “bladder polisher” was awarded a patent. For beta testing, he took his bladder polisher to a small trade show in Las Vegas. He met with Larry Nygren from Custom Craft Lens Services. The reason was that Larry Nygren was using a state-of-the-art lathe from Opto-form at the time. "I wanted to see if the bladder polisher would change the lens instead of just polishing it. It was a good test: we ran about 20 lenses through it and then he started packing them," he recalls. "I said, 'You can't do that, you don't know if they're any good!" He said, "Oh no, they're gorgeous!" He shipped the lenses out of that prototype polishing machine. He said, "This is going to change the industry."

29

1 3 5 6 7 4 2 GlobalCONTACT 1-24 REPORT

1: Erik has long since swapped his drafting board for digital design programs. His daughter-in-law Stephany supports him. 2: Every part is checked. 3: Michael takes care of the large machines. 4: No compromises with the measurements. 5: The electronics are installed by Matt. 6: A picture of his machines at an EFCLIN exhibition. 7: Many of the large machines in his workshop each serve a specific task.

ATTENTION TO DETAIL

A few years earlier, Erik had started publishing articles for Wim Aalbers (the former publisher) in GlobalCONTACT. Always with his perspective of a mechanical engineer in contact lens manufacturing. “Shortly afterwards, my younger brother and I went to an EFCLIN conference in Brussels for the first time and we took our machines with us. But the people were first pretty skeptical about it because they were using different tools", says Erik. "They thought everything had to be converted to our system. So we brought a 6-spindle-machine with 6 different spindles. And the first came and said: 'we can't use that!’ Well, we showed him a tool and said: 'maybe your tool looks like this? We can make it for you then'”. That's when many people realized that Erik adapts his machines to his customers' requirements and not the other way around.

Erik Larsen is his own brand. His machines sell because they are so customizable and easy to integrate into the production process. He didn't achieve his success with a sophisticated marketing plan or fancy presentations. He is an honest soul and simply says what he does. He remembers: "In the mid 1990’s I went with my wife Pam to an EFCLIN Show in Amsterdam

8: Erik shoulders a steel part several meters long together with his son Andrew. 9: Pam Larsen in her office. 10: Erik Larsen shows where his customers are located around the world. 11: Andrew Larsen grew up in the workshop and knows all the operations there.12: The Larsons (center) with Andrew and Stephany Larsen (left) and the two employees Matt and Micheal (right). Not in the picture are two other employees of the company.

and I had to prepare a presentation. I remember I was very nervous to prepare my speech, since I am not the kind of guy who likes to be on stage. So Wim Aalbers, who then also was Executive Director of EFCLIN said: 'Just tell us what you do...' and that got me talking. So after that we picked up the European market really well."

However, not all machines were always a success, "We also had a few flops," he recalls. These setbacks were always an incentive for him not to give up. Different processes with different levels of automation, for example, always require adaptation. We have learned from this and then offer customized solutions.

BUILT TO LAST

Today he offers 6 different models of Blocker, 4 for Contact Lenses and 2 for IOL. Depending on how they make their lenses. "We are the only ones who do that," says Erik. The differences depend on how the specific company manufactures its lenses. “We have to look at that and get an idea of how to solve the process problem. In the last few decades, the main challenge is process, but the industry is maturing to standardization. This is ironic since in contact lens production, each lens is unique. We offer machines

30

8 10 11 12 9 GlobalCONTACT 1-24 REPORT

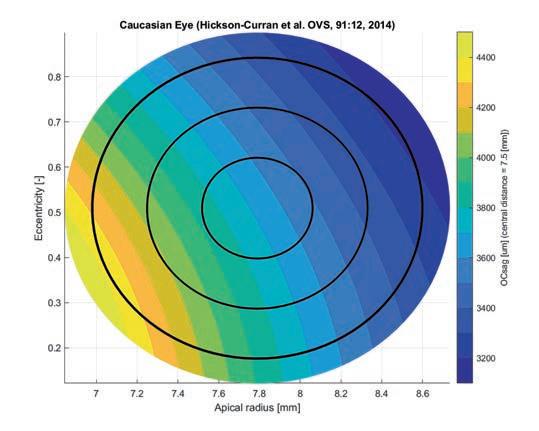

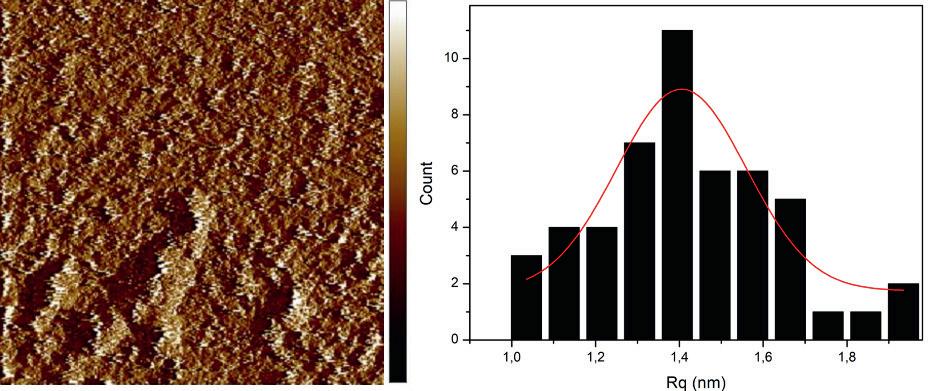

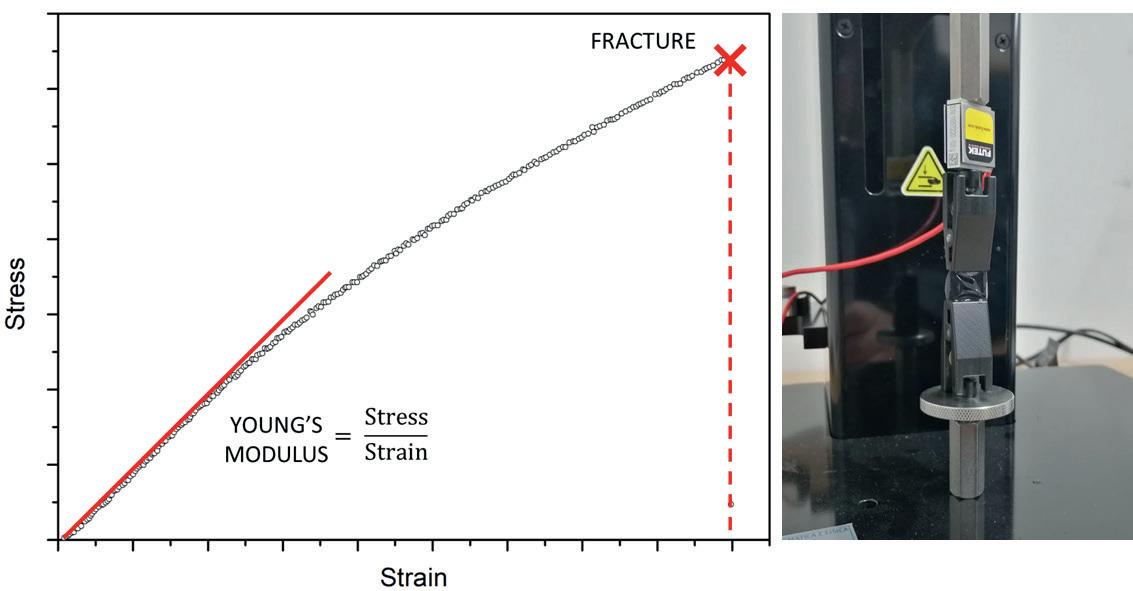

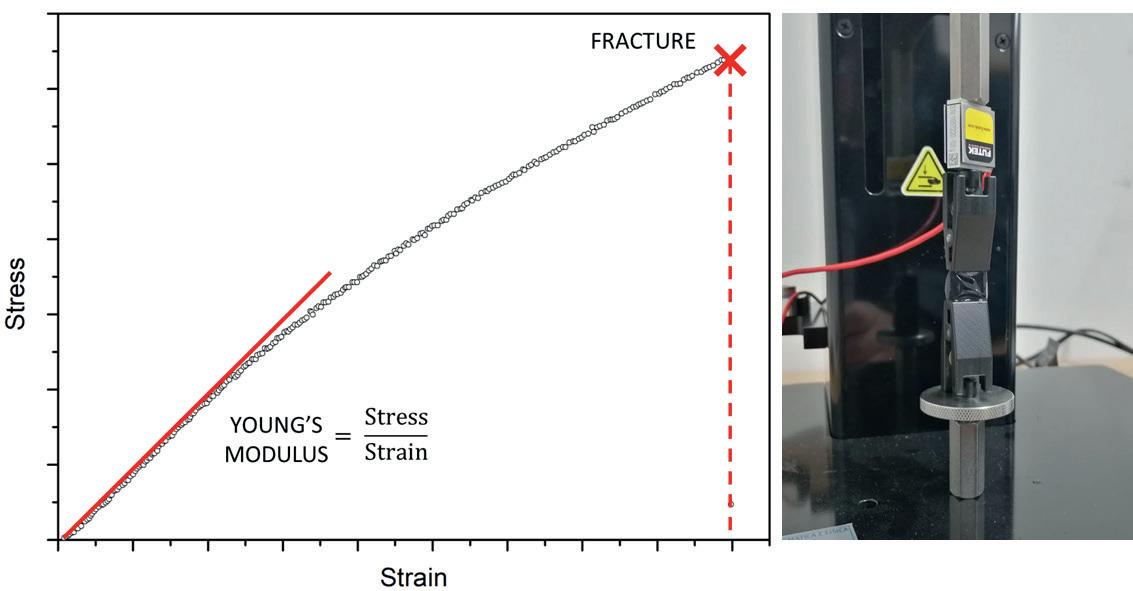

and processes that are ‘immune’ to the variation in product. Sometimes it takes a whole month of consultation before we fully understand the process and offer an appropriate machine," he adds. "Sometimes people joke: 'Erik, your machines last too long!' That is nice to say but the fact is: good design lasts. They’re supposed to. I know there are some of my polishers that have 50,000 hours on them." However, it is also important for him to mention that there are constant updates for many older machines, which should also be used.