Issue : Spring 2024 Exyte Hargreaves Ltd Lord Street, Bury, BL9 0RG Exyte-hargreaves.net @Exyte-Hargreaves Around the world we go Quality in practice Engineering Young Talent On the projects Features: 05 14 03 11 AI Bringing AI into Hargreaves 15

Foreword

I write this foreword as I’m travelling back from our Exyte Group and Technology & Services Global Leadership Conferences in Frankfurt/Munich, Germany. I’m grateful to have had the opportunity to meet my fellow leaders in Exyte on two occasions during February. Collaborating with colleagues from around the world provokes reflection on a number of topics. First, to be surrounded by talent from Europe, the Americas and Asia is humbling, but also sparks a real sense of pride in the fact that our Exyte Hargreaves team is part of this global family. Second, it brings home the importance of our collective work to transform and improve high tech facilities across many sectors. Finally, it gives motivation for the challenges we face in 2024 to deliver on time, on budget and with safety and quality at the heart of our service.

Technology & Services

For those who are unaware, Exyte Hargreaves is owned by the Germanbased Exyte Group. Our parent company is split into four divisions comprising Advanced Technology Facilities, Biopharma & Life Sciences, Data Centres and Technology & Services.

Hargreaves forms part of the Technology & Services (or T&S) division. My boss is Dr Michael Loeffelmann, our Senior Vice President, a professional with

James Bevis Managing Director

vast leadership experience in petrochemical, chemical, energy, engineering and manufacturing industries. The T&S division includes our sister companies based in USA, Malaysia, Singapore, Germany, and Czech Republic. Together we deliver an array of services for high-tech production facilities, technology products and MEP solutions.

In this issue

This is our first 1872 magazine of the new year and it’s packed full of engaging content. In issue one, we included a feature on the technological investments made in our manufacturing facility. This time we switch the focus to the work being done by our people as Production Manager, Jordan Birtwistle shares his highlights. Building on the themes of quality and safety, we take an inside look at our approach to Occupational Health and ISO 9001.

And there’s much, much more!

Engineering Young Talent

Our EYT programme returned in 2023 for the first time since COVID.

Engineering Young Talent has been

a fixture of the Exyte Hargreaves business since Henry Hargreaves started building bikes in the 1870’s. To celebrate this, and kick off our apprenticeship recruitment campaign for 2024, we held an EYT Party in our Bury Head Office. It was a fantastic day as we brought together our newest 2023 cohort alongside their colleagues from our 1970’s intake.

See photos from the event on page 5&6.

Innovation and Diversification

I’ve said this before but in a business like ours with a 150-year history, it is important to remain dynamic. Our ability to innovate sets us apart and I’m pleased to see the evidence of this in our early 2024 activity. If you search @ExyteHargreaves on your social media channels you’ll also find our newest profile addition on Instagram, a platform which is being managed by one of our apprentices. We’ve also included some insight into our approach with AI technology shared by our Head of Digital Innovation.

NEWS IN BRIEF

Here’s a quick look at some of the recent news from Exyte Hargreaves.

DPRTE 2024 Review!

DPRTE 2024 is the defence sector’s biggest procurement event. It was our pleasure to exhibit this year on stand 71. Exyte Hargreaves has spent more than a decade working on the UK’s defence estate as the specialist HVAC contractor of choice. We enjoyed seeing our clients and partners at the show. Read more on page 7.

Follow us in an Insta-nt

Did you know? Exyte Hargreaves has now launched on Instagram! You can follow us on the platform by searching @ExyteHargreaves. Our Instagram profile is one of the cornerstones of this year’s Apprenticeship campaign (see page 5&6).

Edition three 1. 2.

Taking Hargreaves around the world

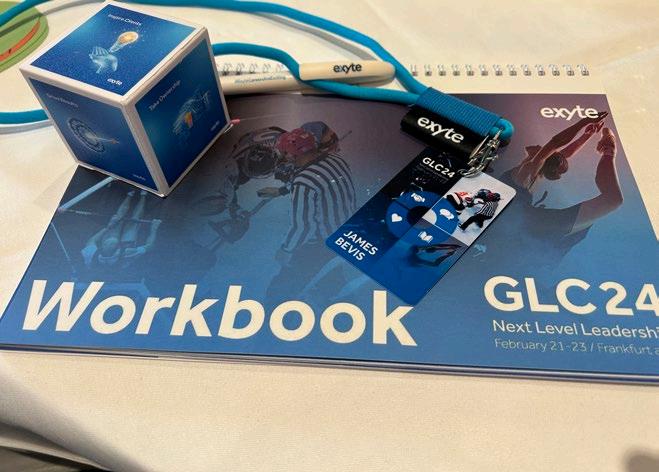

We’re reflecting on two successful events with our colleagues from across the Exyte Group. In February, our Managing Director (James Bevis) attended Exyte’s Global Leadership Conference. Later in the month, James was joined by our Finance Director (Neil Harrison) for the Technology & Services divisional leadership conference.

Journey to the Next Level

Over 100 Exyte Group leaders convened in Frankfurt to discuss pivotal topics for the Group’s continued growth. The theme of the conference was “Operational excellence and outstanding leadership.”

Exyte Group understands that effective leadership fuels performance and fosters an environment for innovation, collaboration, and growth. Every individual is valued and encouraged to excel in support of business growth.

“The GLC was an opportunity for the leaders of the business to connect and engage with each other. In addition the board and shareholder took us through the business strategy for 2024 and beyond. We all participated in a workshop focused on leadership principles and collaboration.”

Technology & Services

The Technology & Services division of Exyte Group is truly global, stretching across the world from Singapore to Texas. With many of the divisional companies working in the same high tech facilities sectors as Exyte Hargreaves, there was potential for shared strategy work and sharing best practice.

Led by the divisional Vice President, Dr Michael Loeffelmann, we presented on our successful 2023 performance.

“It was great to meet colleagues from around the globe and start to build those relationships where we can share best practice, knowledge and experiences. We are part of the T&S section of the business which is one of the fastest growing in the Group and in time will become a major part of the Exyte Group. Challenging but exciting times are ahead and we should all look forward to being part of that.”

Neil Harrison, Finance Director

Edition three 3. 4.

James Bevis

In February, we launched our Apprenticeship campaign to find our young professionals for 2024. Our Engineering Young Talent (EYT) programme returned from its COVID-enforced hiatus in 2023 as we recruited new apprentices in Manufacturing, Business Development, Marketing, IT and Digital Innovation. We celebrated the progress of our current apprentices, bringing them together with former apprentices from the 2010’s and as far back as the 1970’s!

Young Engineering Engineering Young Talent

“Apprenticeships at Exyte Hargreaves are part of the heart beat of the business, we are extremely lucky to have colleagues who started with us over 50 years ago, to colleagues who started their career path with us in September 2023. Developing future talent is essential to our business, offering apprentices not only the opportunity to develop their skills and knowledge via the chosen apprenticeship standard, but they can enhance their growth through harnessing the vast breath of skills and knowledge from working alongside their peers.

It is a privilege to watch our young colleagues grow in knowledge and confidence throughout their apprenticeship and beyond.”

Jane Gregory, L&D Coordinator

Edition three 5. 6.

Here are some of the best bits from our EYT Party, which was organised by our Marketing Apprentice, Oliver Muscat.

Talent

Engineering Young Talent

DPRTE – WEDNESDAY 27 MARCH 2024

Visit our event web page

Exyte Hargreaves was proud to join the Defence procurement community at this year’s DPRTE event. Bringing

Engineering

• HVAC Commissioning Manager

• Estimators

Manufacturing

• Sheet Metal Workers

• Machine Operatives

• Welders

Operations

• Planners

• Package Managers

• Project Managers

Commercial

• Commercial Managers

• Quantity Surveyors

Plus, roles in Digital Innovation, Marketing & Safety.

Apply now at exyte-hargreaves.net/vacancies

Recruiting! Do you know the next member of the

Hargreaves family? We’re actively recruiting for a number of positions across the business. 7. 8. Edition three

We’re

Exyte

the Future of Technology to Life

EXPLORE EXCEL EXYTE

ways we’re addressing the construction skills shortage

The battle for talent in the construction industry is far from a new challenge for many businesses. The CITB estimated in January 2023 that an additional 225,000 workers would be required to fulfil the total sector pipeline by 2027. A year on from that report, we explore some of the initiatives ongoing at Exyte Hargreaves to address this talent shortage.

So proud of our Apprentices!

It was a blow to pause our Engineering Young Talent programme when COVID struck, so its return in 2023 was most welcome. We’ve partnered with education providers like Rochdale Training and JGA Group to support our young professionals in Marketing, Manufacturing, Business Development, IT and Digital Innovation. They’re all doing a fantastic job and we’re also about to start the search for our 2024 intake!

Recruit to Recruit

Liz Bedford joined our HR team in September 2023 as our Talent Acquisition Specialist. She brings a wealth of experience in dedicated recruitment and engineering resourcing and has been a fantastic addition to the team. We’re already seeing her experience bear fruit with Liz helping us to bolster talent in our Quality, BIM and Engineering teams. So far in 2024 we have welcomed 24 new starters. We’re certainly keeping her busy!

Investing in the Future

Our strong financial performance in 2023 alongside the support we receive from our parent company, Exyte Group, is enabling us to deliver a strategic programme of people and infrastructure investment. This includes an imminent reconfiguration of our factory set-up following the delivery of new machinery during 2023. We’re also excited about plans to refurb our office in Bury later on this year. We’ve also committed to new training, professional qualifications and CPD for our people. The future is excting!

Starting with Schools

Our Learning & Development team works throughout the education pyramid to source the best talent for our business. Local connections with schools are incredibly important to educate and introduce young people to the construction industry, manufacturing and engineering. The response this year from school leavers interested in experiencing a taste of life at Exyte Hargreaves has exceeded even our own expectations.

Training our People

One of our strategy commitments in 2024 has been further investment in training and development. So far this year we’ve funded courses in Site Safety, Project Management, Mechanical Engineering, Document Control, Leadership & Management, Internal Auditing, PAT Testing, Working at Height and many more!

Recruitment that Works

Say ‘Hello!’ to some of the newest members of our team in 2024!

Gary Blackburn Mechanical Design Engineer

Stephen Holmes Quality Manager

Vanita Hirani Quality Engineer

Kundai Mubatapasango BIM Manager

Andrew Mills Quality Engineer

Josh Atkins Site Operative

Lyn Hughes Buyer

Lewis Cullen Commercial Trainee

Ryan Cullen Trainee Quantity Surveyor

Dorothea Place Purchasing Assistant

Anthony McGrath Site Operative

Rhys Milton Site Operative

Kenneth Nzemeke Site Operative

Aaron Whitehead Site Operative

Mark Collins Site Operative

Karl Rixham Site Operative

Abeel Akhtar Document Controller

Andrew Morgan Site Operative

Hadley Coulson Site Operative

Andrew Busby Site Operative

Lee Stevenson Site Operative

Jennifer Sears Document Controller

Kelly Moore Document Controller

Connor Robinson Site Operative

9. 10.

Edition three 5 1 4 2 5 3

Special Feature: Oche Health

Part of our strategy for continuous improvement in worker health involves an enhanced focus on Occupational Health in 2024.

Employment Stage

We engage with an Occupational Health Surveillance provider to deliver:

• Initial Health Checks

• Employee Assistance Programme

• Ongoing Occupational Health Surveillance

• A wide range of benefits to support health and wellbeing

Work Stage

We deploy equipment to reduce Occupational Health Risks in the factory and on site:

• Low noise & vibration plant and tools

• Chemicals & substances as safe as possible

• Extraction & suppression systems to remove airborne contaminants

• Suitable & sufficient PPE

Plus, foundation principles for Safe Systems of Work and training & awareness of OH hazards.

Monitoring Stage

We monitor for HAVS (Hand Arm Vibration):

• Manual calculations for HAVS risk

• Digital monitoring systems (Reactec / HAVIwear)

• Environmental monitoring & grab sampling

• Ongoing health surveillance

11. 12. Process Employee starts work Health check Plant & equipment check Robust RAMS Ongoing monitoring Periodic surveillance

1 2 3 4 5 6

Edition three

Special Feature: Quality in

Practice ISO9001

Throughout the entire company, Quality is a huge part of the work which Exyte Hargreaves delivers. It is evident everywhere, whether it be in the products we manufacture, the installation we do on site, or the documentation we produce.

“Exyte Hargreaves has been delivering specialist HVAC systems for years, and we know that we are very good at providing high quality products, but how do we demonstrate this externally?

One of the most important tools we have is our accreditation to ISO 9001. 9001 is a globally recognised standard helping Hargreaves ensure consistent product and service quality. We work in highly controlled and regulated environments, so this accreditation is vital to ensure the ongoing success of our business and commitment to our stakeholders.”

David Cree, Head of Quality & Governance

ISO9001 ISO9001 ISO9001

ISO9001

Inspiring Excellence

Excellence is one of our core values at Exyte Hargreaves. Here’s how ISO 9001 informs our Quality processes across the business:

• IMS – Our Integrated Management System is our internal quality and document control hub

• Recruitment – We’ve expanded our Quality team this year to meet client demands

• Manufacturing – Our Quality team carry out numerous quality inspections before product leaves the factory

• Internal Auditing – Our internal team meets quarterly, reporting quality trends to the Senior Leadership Team

• Quality Plans – Our customer focused and client led site activities include meeting LTR’s, ITP’s and Quality Plans

A Perfect Score

After a 100% record of successful external audits in 2023, we have continued in the same strong vein in 2024.

After three audits so far in January and February we have passed with flying colours without any non-conformities.

• ISO 19650 - Building Information Modelling (BIM) – 24/25 January

• IMS Surveillance – 21/22 February

• The Welding Institute (TWI) - BS EN ISO 3834 / 1090 – 22 January

Our internal audit team is committed to Excellence in line with our company values.

Through regular internal reviews, we want to maintain the highest standards in our external audit record.

ISO13. 14. Edition three

From the Factory Floor

Jordan Birtwistle, Production Manager, gives an update on the latest happenings from our Manufacturing facility.

A New Plant for the Factory

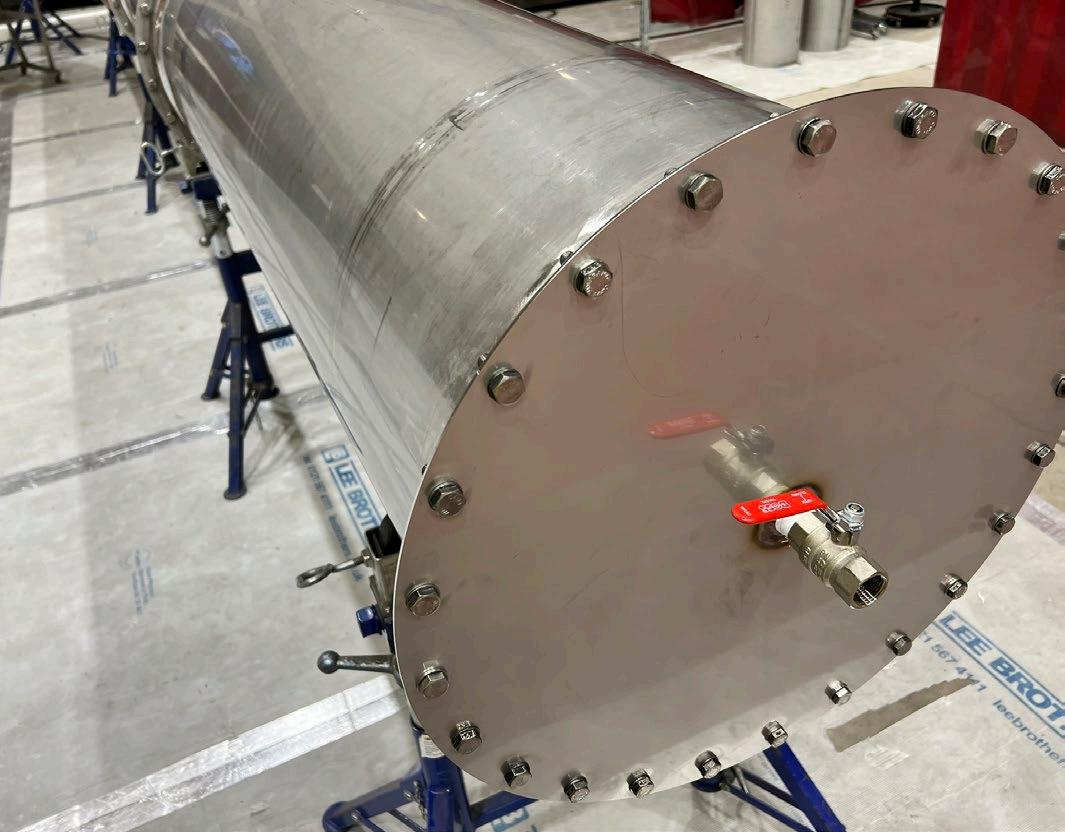

We’ve just taken delivery of a plantroom for one of our major defence sector clients. A team have now commenced work to fit sophisticated ductwork systems within the shell. This approach, led by DfMA and modularisation techniques, is vital in delivering project efficiencies for our client and reducing time on site with installation.

Countdown!

Our factory is gearing up to start manufacture for the HPC Nuclear Island. Our go live date is imminent and we can’t wait to begin!

On The Tools

We congratulate Matthew Band who has successfully completed training and transitioned from the logistics team to the Manufacturing Team. He is working on equipment such as laser cutters, press brakes, and is now on the way to gaining his first seam welder coding.

TWI Audit

Mike Bond and the Quality and Production teams have cleanly passed our TWI welding audit with great feedback and 0 NCR’s/ Observations!

QR Codes Trial

We have successfully trialled QR codes and new digital technology for HPC Nuclear Island. This has improved information transfer efficiency and control of work in progress. We expect to roll this process out into other projects over the coming months.

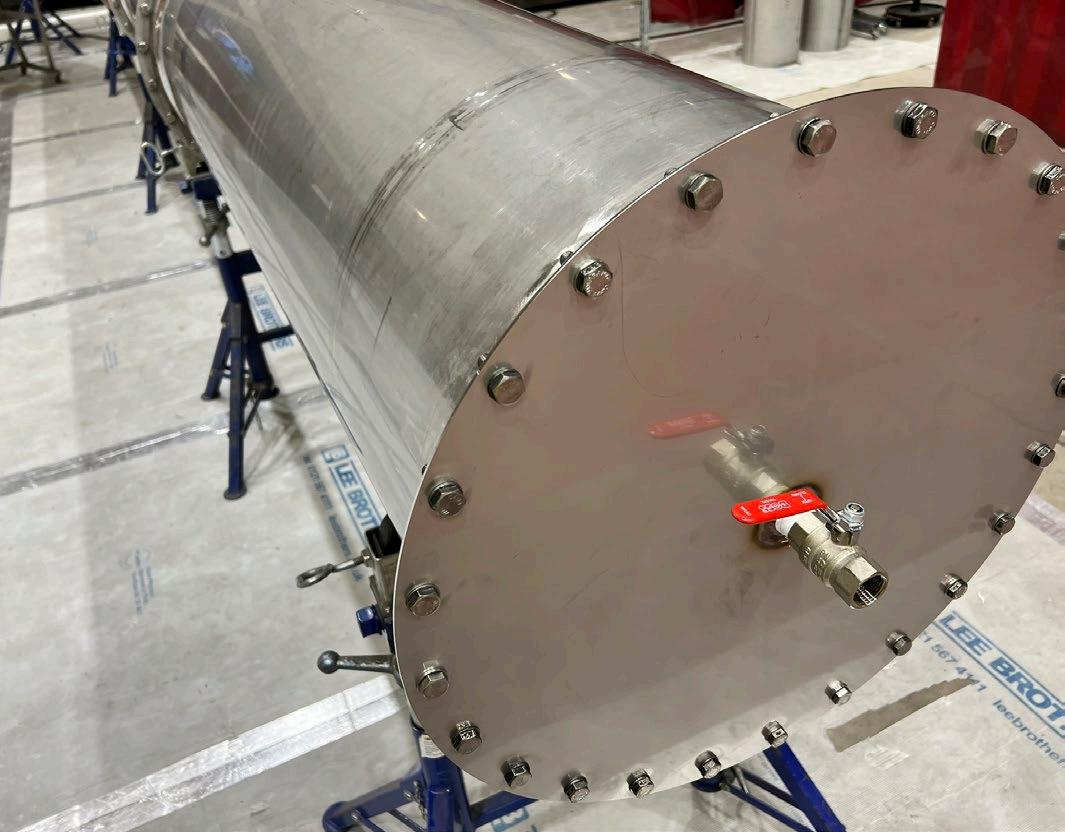

Under Pressure

Read about the importance of pressure testing ductwork for quality assurance. We feature a recent successful pressure test on our website and explain why conventional testing kits are not sufficient to properly analyse our high integrity products.

On the Projects

We asked some of our Project Managers about their teams and key achievements so far in 2024.

Dom Thomas (Rolls Royce Neptune)

The Rolls Royce Neptune team is a new team working on a project together with expertise in different sectors of the business. We have a variety of skills from project controls, engineering and installation, however we work well as a team and support each other which allows us to excel and build relationships with tier 1 clients.

We have achieved mechanical GR3 early with only minor comments. This is the complete submission of the mechanical design for all areas on the project.

We received the GR4 order for the project – this covers all manufacturing and installation.

We’ve mobilised on site with permanently based operatives both white collar and blue collar.

James Marshall, IHC (HS2)

The HS2 team has grown significantly over the past 6 months, with the core team now being based full time at the South Ruislip offices and the engineering/design/ BIM teams being based in Bury. We have cultivated a close team structure despite the teams working in sperate locations and have a healthy mix of experience as well as developing team members (who are excelling in their roles).

The HS2 project has increased to 3 assets now:

South Ruislip Ventilation Shaft

Mandeville Road Ventilation Shaft

Copthall Tunnel

This is a testament to the continued positive relationship between EHL and Costain (Part of the SCS JV), and the positive feedback on the performance of the team working at South Ruislip.

Glen Nolan (Defence portfolio)

Our team has been working all winter on an external roof duct refurb for one of our defence clients. Battling poor weather conditions, our first building has been signed off and the second is close to completion. The fantastic work of our site team has been well received by our client, resulting in additional scope being awarded. This is great news!

The project involved:

Extending the vent’s lifecycle by grinding it down and applying a repairing seal/bond

Sealing all upstands and protrusions from the roof to prevent leaks

15. 16. Edition three

Bringing AI into Hargreaves

By Mark Naylor, Head of Digital Innovation (this article has been written with the help of AI)

In the digital age, Artificial Intelligence (AI) has emerged as a transformative force across industries, revolutionizing the way businesses operate and innovate. Among the vanguards of AI integration stands Exyte Hargreaves, renowned for its innovative solutions in the fields of digital technology, building information modelling, and process systems. Leveraging the latest advancements in AI, Exyte Hargreaves has embarked on a journey to enhance efficiency, accuracy, and sustainability across its operations.

Enhancing Design and Engineering Practices

In the realm of design and engineering, AI algorithms are revolutionizing traditional practices, enabling Exyte Hargreaves to deliver innovative solutions with unprecedented speed and precision. By harnessing the power of generative design algorithms, engineers can explore a myriad of design possibilities and optimize complex systems for performance, cost-efficiency, and sustainability. Additionally, AI-driven simulations facilitate rapid prototyping and iterative optimization, empowering designers to create bespoke solutions tailored to the unique needs of each project.

Advancing Sustainability with AI-driven Solutions

As sustainability emerges as a global imperative, Exyte Hargreaves is committed to leveraging AI-driven solutions to minimize environmental impact and promote sustainable practices. Through the integration of AI into energy management systems, the company optimizes resource utilization, reduces waste, and lowers carbon emissions across its projects. Moreover, AIpowered predictive analytics enable proactive identification of potential environmental risks, empowering Exyte Hargreaves to implement pre-emptive measures and ensure compliance with stringent sustainability standards.

Empowering DecisionMaking with Data-driven Insights

In an era defined by data abundance, Exyte Hargreaves harnesses the power of AI to transform raw data into actionable insights, empowering stakeholders to make informed decisions with confidence. Through advanced data analytics and machine learning algorithms, the company gains valuable insights into operational performance, market trends, and customer preferences. From demand forecasting to risk management, AI-driven analytics provide decision-makers with unparalleled visibility and foresight, enabling them to navigate complex challenges and seize opportunities in a rapidly evolving landscape.

Pioneering Innovation through AI Research and Development Conclusion

At Exyte Hargreaves, innovation is not just a goal but a way of life. Through ongoing research and development initiatives, the company is pushing the boundaries of AI technology, exploring new frontiers and unlocking novel applications across its business domains. From AI-driven robotics for automated assembly processes to computer vision systems for quality control, Exyte Hargreaves continues to pioneer groundbreaking solutions that redefine industry standards and propel human progress forward.

In the digital age, AI has emerged as a transformative force, reshaping industries and redefining the possibilities of human innovation. At Exyte Hargreaves, AI serves as a catalyst for progress, empowering the company to optimize processes, enhance design practices, advance sustainability, and drive innovation across its operations. As Exyte Hargreaves continues to harness the power of AI, it remains at the forefront of engineering excellence, poised to shape the future of technology and make a meaningful impact on a larger scale.

17. 18. Edition three

It’s been a busy start to the year in our Manufacturing facility. Here are some of our favourites. Follow @ExyteHargreaves on LinkedIn for the latest updates from #DuctWorld

Edition three 19. 20.

DuctWorld