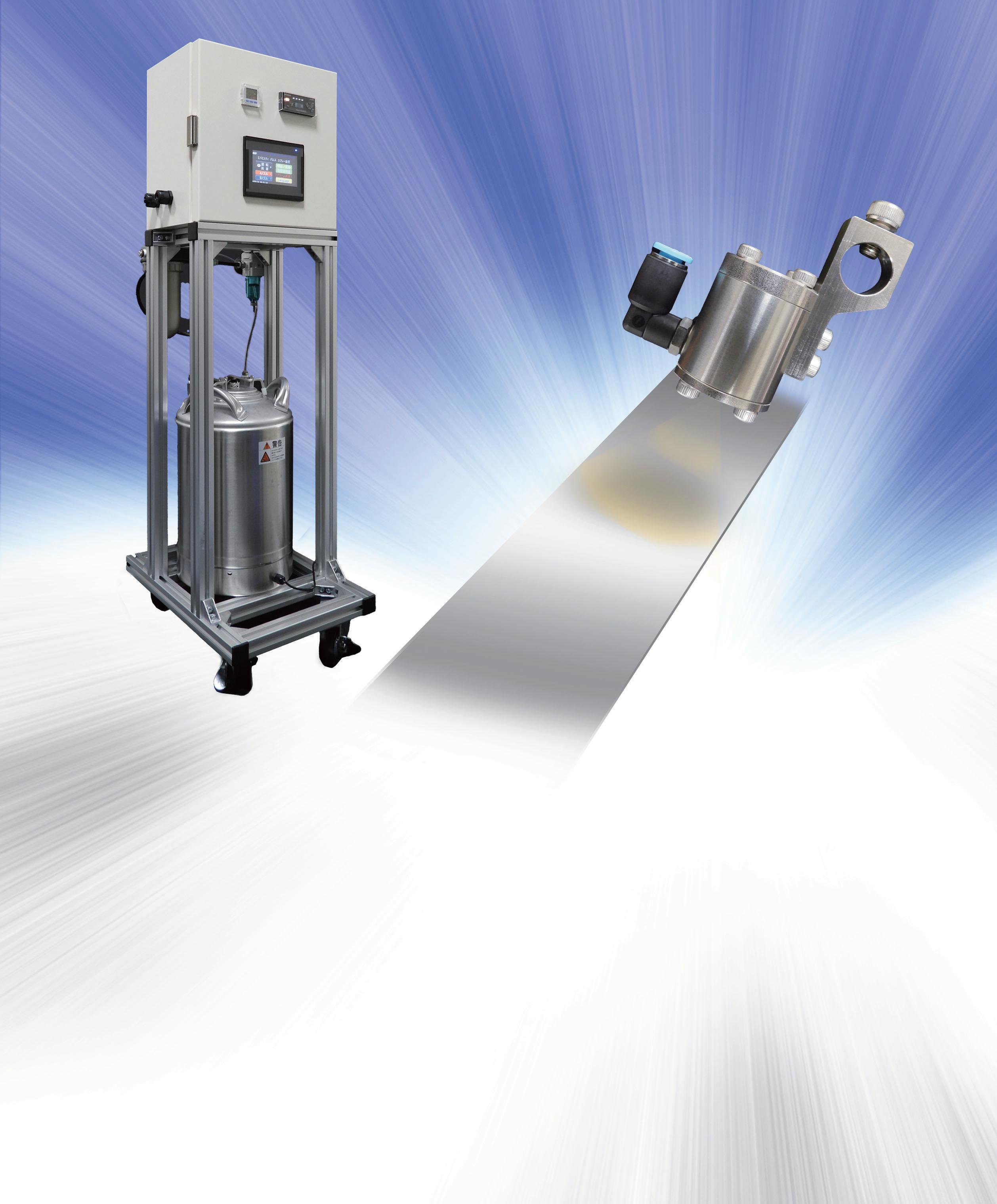

PULSE SPRAY DEVICE KSPD-001

Connected to spray nozzle with tube and cable

Spray nozzle [Optional] Digital pressure switch

touch panel

Level switch

Specification

Nozzle quantity

Dimensions

Control box

Input Voltage

Output Voltage

Filter regulator

LCD touch panel

operation!

regulator

*Shape, dimensions, materials and specifications are subject to change without notice.

Measuring/displaying flow rate

Displays tank pressure, outputs a decompression alarm signal [Optional] Digital pressure switch*2

Alarm activated at 1.5 liters remaining [Optional] Level switch*3 [Optional] Flowmeter and Amplifier unit *1

*1 The measurement range is from 0 to 200mL/min. Setting of upper and lower limits and flow rate control is possible.

*2 Circuit is connected when pressure in the oil tank becomes lower than specified value.

*3 Circuit is connected when remaining amount in the oil tank becomes lower than specified value.

*4 Capacity 20L is available(Optional)

Scan the QR code to view the spraying in action.

Frequency:

Number of ON/OFF cycles per second. Flow rate increases with higher frequency.

Valve-open time: Duration at which valve remains open. Flow rate increases with longer duration.

Valve-close time: Automatically calculated from inputs for frequency and valve-open time.

Duty cycle(%): Ratio of valve-open time to time of one ON/OFF cycle.

PULSE SPRAY NOZZLE KPSN-AS type

Compact nozzle with responsive solenoid valve which sprays up to 1mL/min.

Flow rate can be controlled by setting the frequency and duty cycle of the valve.

Specification

Dimensions (including fitting)

Weight

Main materials

Flow rate

Spray angle

Liquid inlet

Minimum orifice diameter

Voltage

Frequency

Liquid pressure

Valve-open time

kinetic viscosity

L35.5 mm × W40 mm

Approx. 110 g (excluding mounting jig)

SUS303, Viton/FKM

1 mL/min ~

Approx. 80°

φ4mm (Tube)

Approx. 0.1 mm

DC24V

1Hz or more, less than 200Hz(Increments of 1Hz)

0.3 MPa (recommended)

1ms or more, less than 200ms(Increments of 0.1ms)

21 mm 2/s or less

*Flow rate and spray angle can vary according to condition.

*Shape, dimensions, materials and specifications are subject to change without notice. Frequency [Hz]

Flow rate

Pressure: 0.3 MPa Liquid: Tap water

Valve-open time: 1ms

Valve-open time: 3ms

Valve-open time: 5ms

Valve-open time: 10ms

Spray

Condition: Frequency 5Hz, Valve-open time 5ms, Flow rate 2.2mL/min

Liquid: Tap water

Flow rate: Low

Flow rate: Low Spray angle: Narrow Flow rate: From Low to High Spray angle: Small difference

Flow rate: High Spray angle: Wide

Condition: Frequency 20Hz, Valve-open time 5ms, Flow rate 9.4mL/min

Liquid: Tap water

Flow rate: High

Hydraulic nozzle

Hydraulic nozzle with solenoid valve

What is pulse spraying?

Frequency at 5Hz

e.g. Frequency at 5Hz and valve-open time at 5ms

Time of one cycle: 200ms

Valve-open time: 5ms

Valve-close time:200ms-5ms 195ms

Duty cycle: 2.5%

Flow rate: 2.2mL/min

Frequency at 20Hz

e.g. Frequency at 20Hz and valve-open time at 5ms

Time of one cycle: 50ms

Valve-open time: 5ms

Valve-close time:50ms-5ms 45ms

Duty cycle: 10%

Flow rate: 9.4mL/min

Flow rate is controlled by frequency and valve-open time. Spray as low as 1mL/min using the high speed solenoid valve!

Case study

Do you experience the challenges below? Achieve working environment improvement and cost reduction. Pulse spraying

・Oil does not spread evenly across the surface

・Cannot lubricate bottom surface

・Incidents of foreign matter contamination by roller

Uniform oil lubrication across surface

Spraying with minimal spreading

Can lubricate bottom surface

Non-contact lubrication (prevents foreign matter contamination)

System diagram

*Components and connection may change depending on the options selected.

*Wiring connections to customer's equipments (press machine, compressor, etc.) shall be carried out by the customer.

Application

and dimensions

KYORITSU GOKIN CO., LTD.

Head Office

12-16,lmazu-yamanaka-cho, Nishinomiya, Hyogo-pref. 663-8211, Japan

Kaibara Works Nozzle Division 95-2, Ohniya, kaibara-cho, Tamba, Hyogo-pref. 669-3315, Japan

Subsidiary Company

EVERLOY (SHANGHAI) CO., LTD.

Room 2206, 2207, No.345, Xian-Xia Road, Chang-Ning District, Shanghai, China

TEL: +86-21-5206-9733/9730 FAX: +86-21-5206-9755 Shape

Affiliated Company

TOKALOY CO., LTD.

236-1, Bogane-cho, Seto, Aichi-Pref. 489-0979, Japan

*Shape, dimensions and materials are subject to change without notice.

General Agent

EVERLOY SHOJI CO., LTD.

Overseas Sales Department 4-2-24, Sagisu, Fukushima-ku, Osaka 553-0002, Japan

TEL: +81-6-6452-2273 FAX: +81-6-6452-2187

WEB E-Mail

https://www.everloy-spray-nozzles.com/en/ overseas_sales@everloy.co.jp

Our web site

facebook LinkedIn

ISO 9001/14001 certification LEAF.45E-R1-2408

Shapes and dimensions are subject to change without notice.