Low-Flow Rate Spray Nozzle Selection Guide with a Simple Selection Flowchart

Searching for a low flow rate spray nozzle

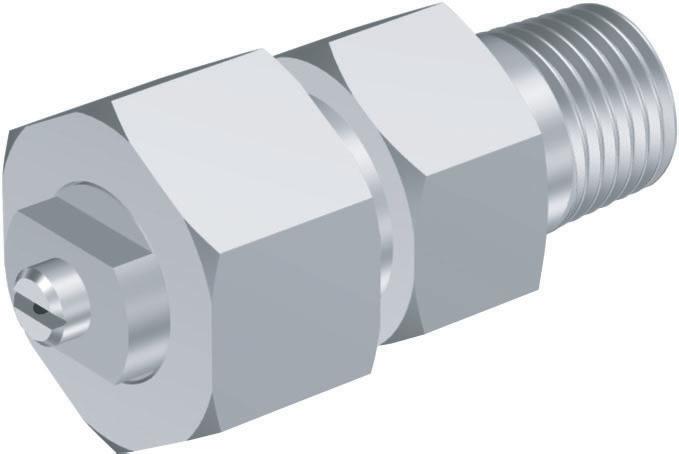

Hydraulic nozzle

Hollow-cone Pattern Flat Pattern 0.5~100mL/min 20~500 mL/min15~254 mL/min

Full-cone Pattern

Flat Atomizing Nozzle

Hollow Cone Atomizing Nozzle

Mini Atomizing Nozzle

MMAE9

MMA10

MMA30

MMA50

MMA10-PEEK

Mini Atomizing Nozzle

MMA100

MMA200

*1 Since it is based on the basic spray performance, the flow rate may vary depending on the required spray condition.

Mini Mist Nozzle External Mixing Type

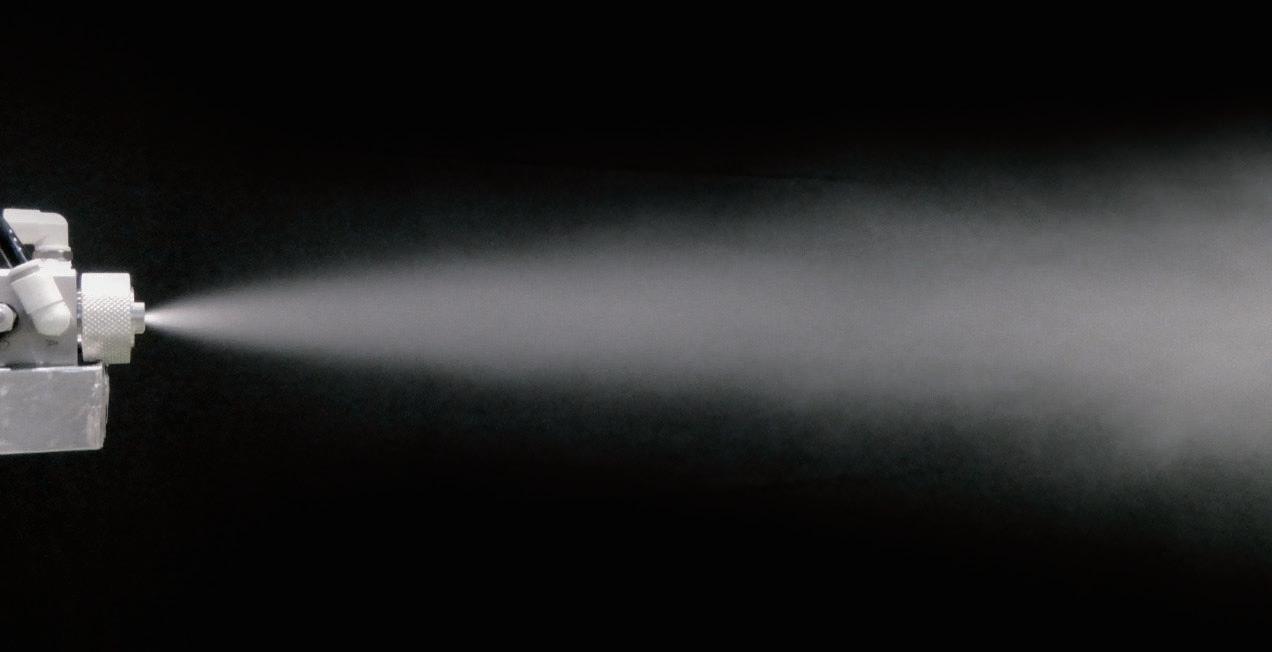

Two fluid nozzle

Pattern

Mist Nozzle Internal Mixing type MPC Nozzle with Cylinder

Nozzle with Cylinder MPC Nozzle

Droplet size

Atomizing Nozzle (Adjustable Spray Type with ON/OFF Valve)

AS type

・Low flow rate spray without air injection.

・Soft spraying with fine droplet.

・Interchangeable nozzle tips.

KSN type FeatureApplication

・Coating with rolling oil and rust preventive oil (and similar lubricants).

・Spraying of chemicals and water.

Material

・Stainless steel (SUS303)

・Brass

FeatureApplication

・Low flow rate spray without air injection.

・Soft spraying with fine droplet.

・Combustion, humidification, disinfection, oil application, airless painting, etc.

Material

・Stainless steel (SUS303)

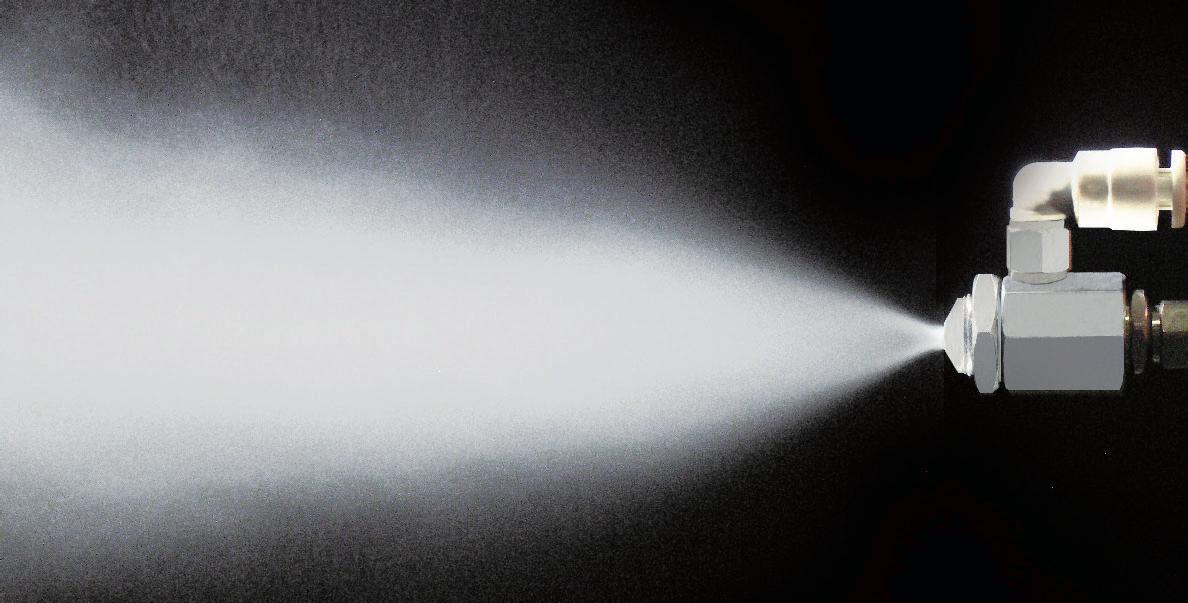

KSMMS Type

FeatureApplication

・Capable of controlling a wide range of flow rate, from low to relatively large volumes.

・Compact and lightweight design allows installation even in limited spaces.

・Wide-angle spray for covering large areas.

・Fine droplets for quick evaporation.

・Simple design minimizes clogging and allows for easy disassembly and cleaning.

・Flower cultivation, aquascapes, and gas cooling.

・Spraying chemicals, humidification, etc.

Material

・Stainless steel (SUS303)

KSMME type

FeatureApplication

・Capable of controlling a wide range of flow rate, from low to relatively large volumes.

・Compact and lightweight design allows installation even in limited spaces.

・Fine droplets for quick evaporation.

・Simple design minimizes clogging and allows for easy disassembly and cleaning.

・Self-suction spraying is available.

・Flower cultivation, aquascapes, and gas cooling.

・Spraying chemicals, humidification, etc.

Material

・Stainless steel (SUS303)

・Designed for easy disassembly and assembly, and simple cleaning after disassembly.

・Designed to be as compact and lightweight as possible.

・Capable of a wide range of flow control.

The nozzle-integrated cylinder enables flexible intermittent spraying. (CL only/with cylinder)

・Humidification, deodorant spraying, and coating

・Cooling, disinfection, and dust suppression

・Coating , cleaning, chemical spraying, etc.

Material

・Stainless steel (SUS316 + SUS304)

MPV type

・Designed for easy disassembly and assembly, and simple cleaning after disassembly.

・Adjustment of the pattern air pressure allows for a spray pattern ranging from a full cone (approx. 20°) to a flat (approx. 70°) pattern.

・Designed to be as compact and lightweight as possible.

・Capable of a wide range of flow control.

The nozzle-integrated cylinder enables flexible intermittent spraying.(CL only/with cylinder)

・Humidification, deodorant spraying, and coating

・Cooling, disinfection, and dust suppression

・Coating , cleaning, chemical spraying, etc.

Material

・Stainless steel (SUS316 + SUS304 or SUS303 + SUS304)

・Fine droplets.

・Suitable for spraying at micro flow rates.

・A large-diameter liquid orifice reduces the risk of clogging.

・Capable of spraying high-viscosity liquids.

・Using the self-suction spraying eliminates liquid dripping.

・Precision thin film coating.

・Spraying of various oils (lubricants and mold release agents).

・Combustion, humidification, and disinfection.

Material

・Principal parts: Stainless steel (SUS316L)

・Adopted PEEK resin with superior acid and alkali resistance.

・Lightweight (15g)

・Simple structure for easy disassembly and maintenance.

Feature Application

・Precision cleaning of wafers, glass substrates, and components.

・Precision thin film coating.

Material

・PEEK

・Capable of a wide range of flow control.

・The nozzle-integrated cylinder enables flexible intermittent spraying.

・Enables flexible adjustment of the spray pattern, from full cone to flat pattern.

・Uniform spray coverage across the width is achieved by fine atomization.

・Capable of spraying high-viscosity liquids.

・Precision thin film coating.

・Spraying of various oils (lubricants and mold release agents).

・Cooling, cleaning, chemical spraying, etc

Material

・Principal parts: Stainless steel (SUS303)

・Seal part: Fluororubber

Head Office

12-16,lmazu-yamanaka-cho, Nishinomiya, Hyogo-pref. 663-8211, Japan

Kaibara Works Nozzle Division

95-2, Ohniya, Kaibara-cho, Tamba, Hyogo-pref. 669-3315, Japan

Subsidiary Company

EVERLOY (SHANGHAI) CO., LTD.

Room 2206, 2207, No.345, Xian-Xia Road, Chang-Ning District, Shanghai, China

TEL: +86-21-5206-9733/9730 FAX: +86-21-5206-9755

Affiliated Company

TOKALOY CO., LTD.

236-1, Bogane-cho, Seto, Aichi-Pref. 489-0979, Japan

General Agent

EVERLOY SHOJI CO., LTD.

Overseas Sales Department 4-2-24, Sagisu, Fukushima-ku, Osaka 553-0002, Japan TEL: +81-6-6452-2273 FAX: +81-6-6452-2187

WEB E-Mail https://www.everloy-spray-nozzles.com/en/ overseas_sales@everloy.co.jp

Our web site

facebook LinkedIn