6 minute read

Cover Story: Establishing A Safety Culture

BY KURT CAYWOOD, EDITOR-IN-CHIEF, HASKELL AND JOE VAN HOOSE, MANAGING EDITOR

Safety has long been of paramount focus for architectural, engineering and construction firms. A plethora of workplace and worksite safety guidance is available at the national and industry level, and many firms have used these frameworks to develop their own.

But as prominent as safety is as an issue, workers in the AEC industry – and particularly the construction industry –continue to face dangers that can turn deadly. The Bureau of Labor Statistics (BLS) reported 1,075 fatal work injuries in the U.S. construction industry in 2023, the highest total since 2011 and capping off a five-year stretch of year-overyear increases.

Those numbers don’t tell the whole story, however. Analysis conducted by the American Road & Transportation Builders Association (ARTBA) shows that between 2011 and 2023, fatal injuries in the Highway, Street, and Bridge sector declined 15%, while fatal injuries for the rest of the construction sector increased 41%.

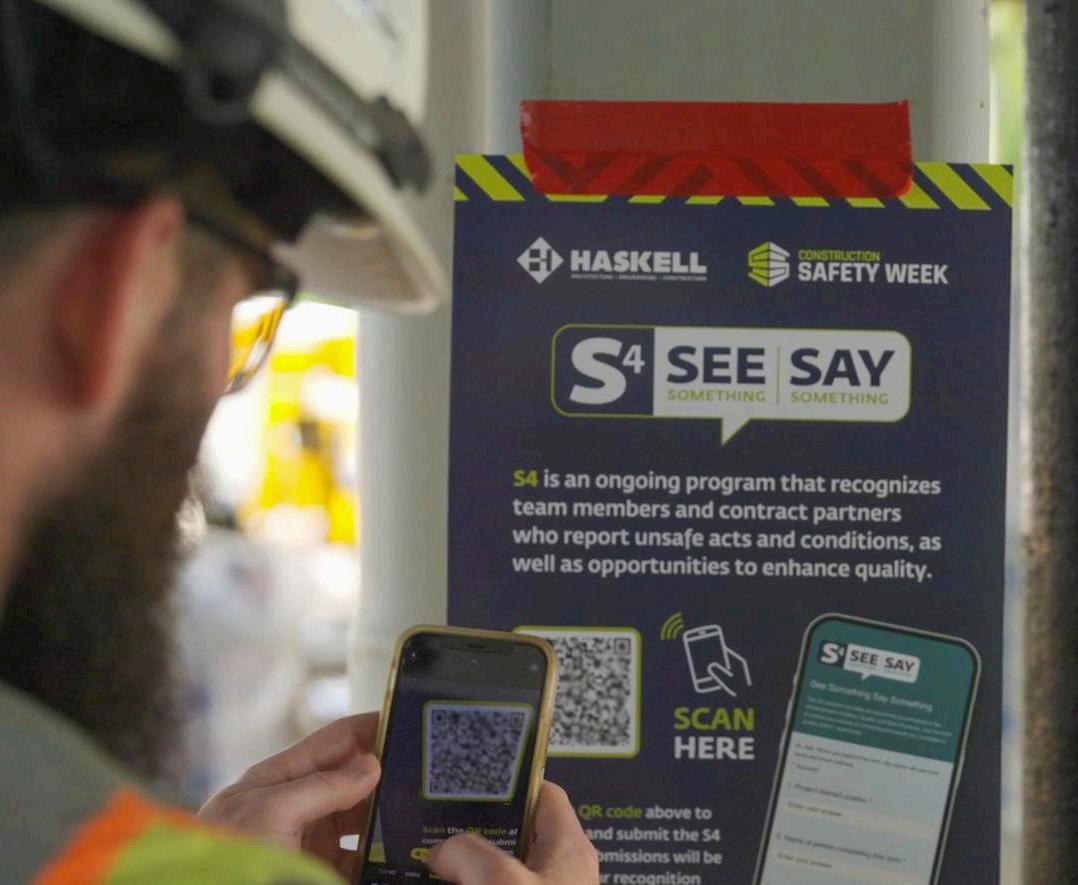

The AEC industry and its firms have developed innovative programs to create a culture of safety to continue to bring those numbers down. At Jacksonville-based Haskell, that culture shows up in daily rhythms of work and in the investments that have made the company a recognized leader in construction safety.

Earlier this year, Haskell received the Associated Builders and Contractors’ National Safety Excellence Pinnacle Award for the fifth time. In 2024, the firm received the Construction Industry Safety Excellence Award from the Construction Users Roundtable.

“We’re pleased but never satisfied,” said Haskell Vice President of Safety and Quality Lance Simons. “We continue to improve and have an obligation, as a leading general contractor and builder, to make the industry better. We think there is room for continued improvement within Haskell and industry-wide to create the safest work environments and best craft experience.”

Industry Resources Provide Path

The Occupational Safety and Health Administration publishes a “Recommended Practices for Safety & Health Programs in Construction,” which provides a framework for employers to establish proactive safety programs on jobsites.

The guide contains seven core elements:

Management Leadership;

Worker Participation;

Hazard Identification and Assessment;

Hazard Prevention and Control; Education and Training;

Program Evaluation and Improvement; and

Communication and Coordination for multiemployer worksites.

Additionally, OSHA’s “Fatal Four” focuses on tips to avert the leading causes of death in the construction industry –falls, stuck-by, electrocutions, and caught-in or -between incidents.

Several AEC industry organizations also provide resources for firms and professionals to ensure a safety culture.

The American Council of Engineering Companies (ACEC) provides a Design for Construction Safety review and Health and Safety Plan template to help member firms manage risks and ensure compliance with regulations. The templates are designed to identify site-specific hazards, safety measures, required safety equipment, mandatory staff competencies, and emergency response and preparedness information that may be required for many typical field work assignments.

Likewise, the American Society of Civil Engineers (ASCE) offers its members risk management resources, as well as publications that focus on best safety practices for construction sites.

Firms Evolve Safety Plans

Many AEC firms have created their own custom programs to ensure safety at the workplace and on the jobsite. The programs have only grown more robust as the industry moved through the COVID-19 pandemic and incorporated more focus on mental health and wellbeing.

Jacobs launched its BeyondZero approach to the health, safety and security of its employees in 2007 and has been expanding the program ever since. In 2016, the international firm grew its safety reach to include mental health and within five years had nearly 2,000 trained mental health champions.

In 2020, Jacobs expanded its mental health focus and developed a free mental health check-in tool called One Million Lives to help enhance users' understanding of their current state of mind and provide proactive strategies for personal mental health development. Available for free, the tool is accessible to everyone both inside and outside the organization.

For its efforts, the firm has been recognized in Mind's annual Workplace Wellbeing Index, receiving the Gold award for continued commitment and leadership in workplace wellness.

AECOM has instituted “Life-Preserving Principles” to help demonstrate the commitment of the firm to its own Safety for Life program. The nine principles range from mandating management and employee participation to a commitment to budgeting and staffing for safety initiatives. The ninth principle calls for employees to report to work each day fit for duty and not to pose a health and safety hazard to themselves or others.

Kimley-Horn requires employee training and firmwide compliance with its safety policies to reduce accidents and injuries in the work environment. In addition to the resources available in every office, the firm’s in-house SafetyNet, an internal website that puts safety information, tools, and resources within quick and easy reach of every employee.

Realizing that end users of their safety manual would be unlikely to read a book that could be hundreds of pages long, Haskell created its Code of Safe Practices in 2002, a 10-page document filled with simple language and practices everyone can understand.

“It’s in every contract and it sets the minimum expectation that everybody on a Haskell project, regardless of the size of the project, is going to follow,” Simons said. “These are the rules we’re going to play by. Now everybody has the opportunity to look across a Haskell jobsite, and everybody should look the same, act the same, and hold each other accountable.”

Giving A Voice To Every Worker

Haskell’s longstanding Take 5 program requires members of Haskell’s upper management to visit jobsites each quarter and talk with craftspeople about training, habits and real conditions. They ask questions about training, what to do if something goes wrong and how tasks can be done more safely.

“We’ve found a lot of ‘Aha’ moments where the craftspeople are like, ‘Wow, nobody’s ever asked my opinion on stuff before,’” Simons said.

The firm’s jobsite safety orientation program has also been nationally recognized, earning a Best Practice Award from Training magazine. Regardless of role, every new worker receives the same introduction on what behaviors are expected, how to speak up, and where to go with questions or concerns.

For those in the AEC industry, the pattern is clear, Simons said, who has more recommendations to ensure an all encompassing culture of safety.

“Put leaders in the field to listen and learn,” he said. “Coach proactively with short, frequent inspections that chase leading indicators. Make speaking up easy and visible. Invest where it’s worn. Teach in context. Then prove it with credible benchmarks that test and tune your system.”