— WORLDWIDE LOCATIONS

WORLDWIDE DISTRIBUTION OVER 60 COUNTRIES

The presence of Emmegi and Tekna on the territory is organised through a radial system. The same principle used by airlines to optimise coverage of all routes.

A HUB routes toward itself all the activities within a certain zone whose area is determined based on the type of market. The various units operating within the area therefore refer to the reference HUB, which organises and coordinates the commercial flows and is in charge of the results within its zone.

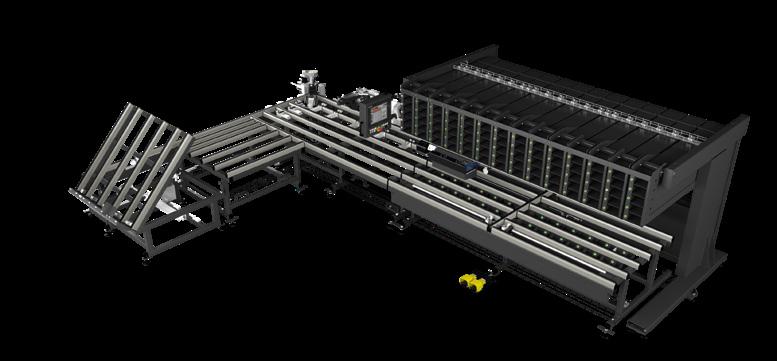

INSERMATIC

Automatic workbench for the automated screwing of hardware with uniform or variable pitch on door and window frames, with large worktable that allows large sashes to be handled and rotated.

It can be programmed via a console or can receive data from a hardware management system which automatically programs machine operations. Two screwdrivers with automatic screw feed process two sides of the frame at the same time.

Insermatic H2B is equipped with a pre-assembly workbench with 8 containers for small components and a 42-compartment hardware magazine for long elements: analogue compartment identification.

The Insermatic H2 is equipped with a more extensive hardware magazine with 24 containers for small components and 70 compartments for long rods, with LED identification guiding the operator through the correct assembly sequence.

The workbench is complete with NC shearer for cutting hardware to size at a uniform or variable pitch and a scrap drawer.

A conveyor system allows for the automatic movement of the sash from the assembly workbench to the automatic screwing area.

BMF 3500

Bench for hardware assembly. The wide work bench for working large size doors and frames, and the 3 covering options (hard anti-friction PVC for aluminium, brushes for PVC, felt for wood) allow to handle any type of door/window.

The BMF 3500 is capable of hardware measuring, cutting by hydro-pneumatic shear and screwing by means of automatically fed screwing unit. Whereas the 3-spindle cremone bolt drilling unit, the cremone bolt milling unit, the hinge hole drilling unit, the scrap collecting tank, the hardware storage and the automatic glass stopper magnetic sensor measuring unit are available on request.

MOD-END RIFILA

MOD-END RIFILA is a semiautomatic-cycle trimming machine for PVC and aluminium frames with two controlled axes. It is equipped with a CN cutting unit with adjustable advancement speed.

BA 411 FIVE CS

Assembly bench for glazed sashes with work table tilting from 0° (horizontal) to 85°. The drop-away roller conveyor is adjustable in height (from 170 to 460 mm) independently from the work table. The work table is adjustable from 895 to 965 mm while the feet are drilled with holes for floor anchoring. The bench is provided with a central spider clamp for hoisting and positioning the glass.

Test bench for frames in aluminium. It allows re-create the conditions of use of the frame. The casement is locked by a system of vices adjustable throughout the casement height; the operator can assemble the sash and the glass inside the casement and finally test it. The roller conveyor allows the operator to feed/outfeed heavy frames in complete autonomy.

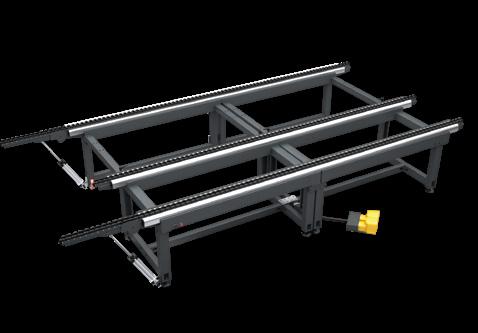

SPIN BENCH ROLL BENCH

Modular bench for assembly and in-line handling of curtain wall frames. It is provided with two roller tracks covered with soft PVC sheathing; the distance between the two tracks is adjustable according to the width of the curtain wall section. A pneumatically operated system allows clamping the rollers during the work phases.

The entire bench can be rotated by 360° in order to facilitate the assembly and sealing of the curtain wall; the angular position is clamped pneumatically.

Large size modular bench for assembly and in-line handling of curtain wall frames. It is provided with two roller tracks covered with soft PVC sheathing; the distance between the two tracks is adjustable according to the width of the curtain wall section. A pneumatically operated system allows clamping the rollers during the work phases.

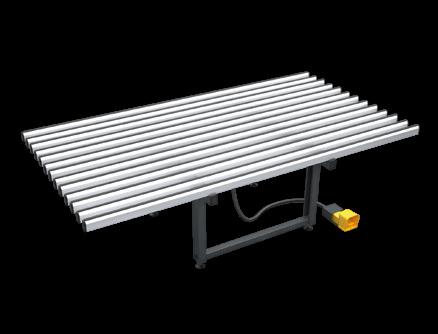

MODULE BENCH FIT

Large size and extendible modular bench for assembling of windows and curtain wall frames. It features 3 distinct work tables: one of soft PVC for assembly operations, one of antifriction hard PVC for the rotation and a roller conveyor for inline movements.

Sash and casement assembly bench. Horizontal bench with pneumatic exchange between the soft PVC resting surface (for assembly operations) and the anti-friction hard PVC resting surface (for handling operations). The work table height is adjustable from 895 to 965 mm and the mounting feet are complete with holes for floor anchoring.

FIT MA

Bench dedicated to the assembly of perimeter band-sawed hardware on aluminium, wood and PVC sashes. A retractable clamp system locks the sash. The bench is equipped with a shearing unit and an automatically fed screwing system as well as a system for hardware measuring and cutting with hydropneumatic shears.

FIT T

Sash and casement assembly bench. Tilting table from 0° (horizontal) to 85°, with pneumatic exchange between the soft PVC resting surface (for assembly operations) and the antifriction hard PVC resting surface (for handling operations). The roller conveyor can be manually tilted and it is adjustable in height (from 170 to 460 mm) independently from the work table height. The work table height is adjustable from 895 to 965 mm and the mounting feet are complete with holes for floor anchoring.

V-LINK LINK

Vertical roller conveyor for easy transport of frames and fenestration products including very heavy ones between the various assembly stations.

Roller bench designed for connecting workstations and allowing extremely easy frame transfer, even in case of heavy pieces.

ACCA XL EDGE

The bench is suitable for any fitting and assembly operation of door and window frames. The sliding and extendable tops allow operations with every size frames and very big structures in complete safety.

The bench is suitable for accessories and gaskets assembly. It can rotate on a central fulcrum and can be adjustable in length, thus allowing the frame rotation.

SPIN 4 FOCUS C4

Gasket trolley. Reel with brake and gasket-guide ensure troublefree gasket unwinding. It is equipped with a quick gasket roll change system.

Trolley for accessories, small parts and tools, servicing the assembling workstations.

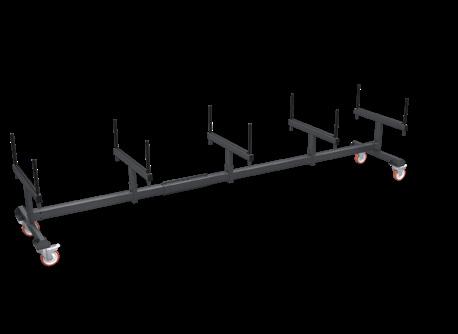

BAR STACK

Big size trolley designed for transportation and storage of profiled bars during the cutting phase.

Trolley dedicated to horizontal transportation and storage of cut profiles.

TAGLIO WT 450

Trolley dedicated to vertical transportation and storage of cut profiles.

End of line trolley which allows both the storage of finished door/window frames in the shop and their transportation to the site using the same equipment.

TRANSIT YP

Trolley designed for transportation and storage of glasses and panels in the assembly lines.

TRANSIT YA

Trolley designed for transportation and storage of frames, sashes and casements.

TRANSIT KA TRANSIT KT

Trolley for transportation and storage of sashes. The base of each compartment is equipped with rolls for easier handling of heavy or large size pieces.

Trolley for transportation and storage of casement and finished door/ window frames. The resting base has rollers for easier handling of heavy or large size pieces.

DUAL SKIN ROTO

Machine for application of protective film on aluminium profiles. The profile is fed automatically via motorized rolls while the perfect adhesion of the film to the profile is ensured by pressure rolls. An optional additional kit allows applying the film simultaneously also on a third face.

Vertical wrapping machine for door/window frames. The rotary mounting base is complete with roller conveyor for easier handling of heavy or large size pieces. The machine requires only one operator.

ZERO-G

ZERO-G is an exclusively pneumatic manipulator for handling flat glazing and windows in absolute safety. By means of the load gripping equipment the spatial positioning of the object handled can be monitored constantly across an extensive working area. Its ergonomic design allows for tilt and rotation movements that ensure high speed and flexibility throughout the entire work process. The suction cup gripping system in conjunction with the weight balancing system enable movements to be made along two axes throughout a working area having a diameter of up to 6000 mm. The configuration on a free-standing base allows maximum freedom of movement within the production facility.

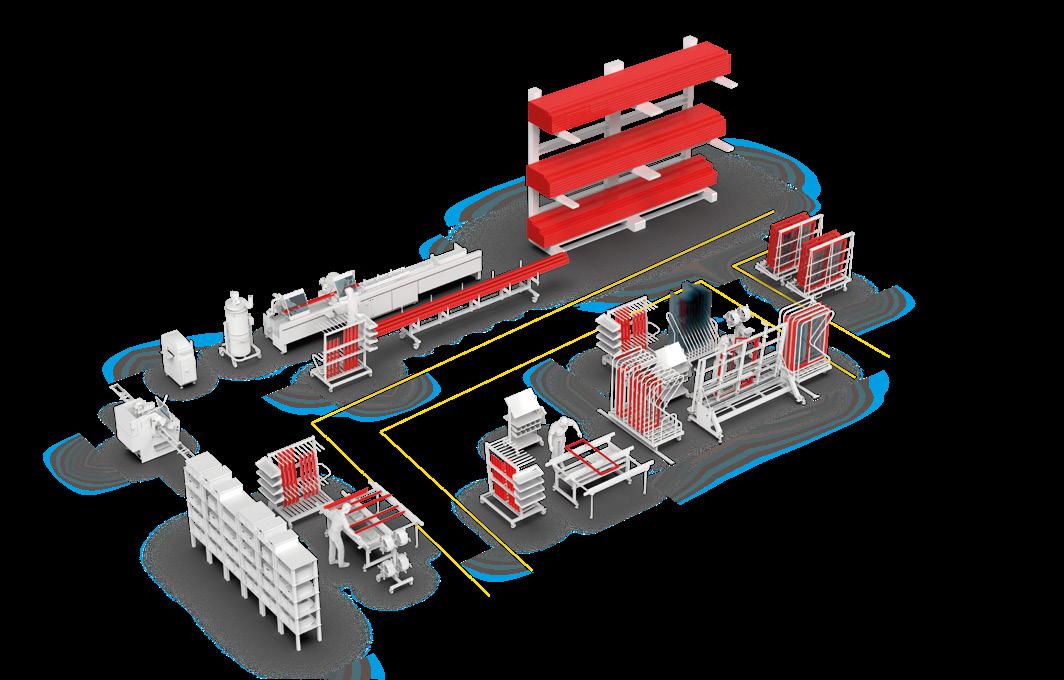

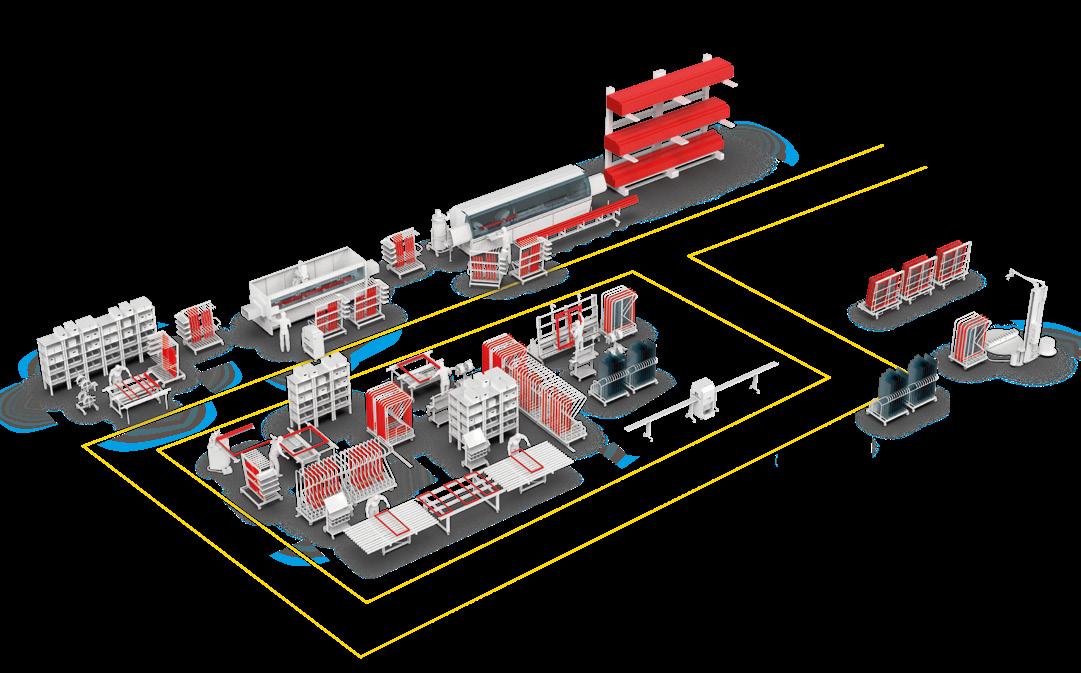

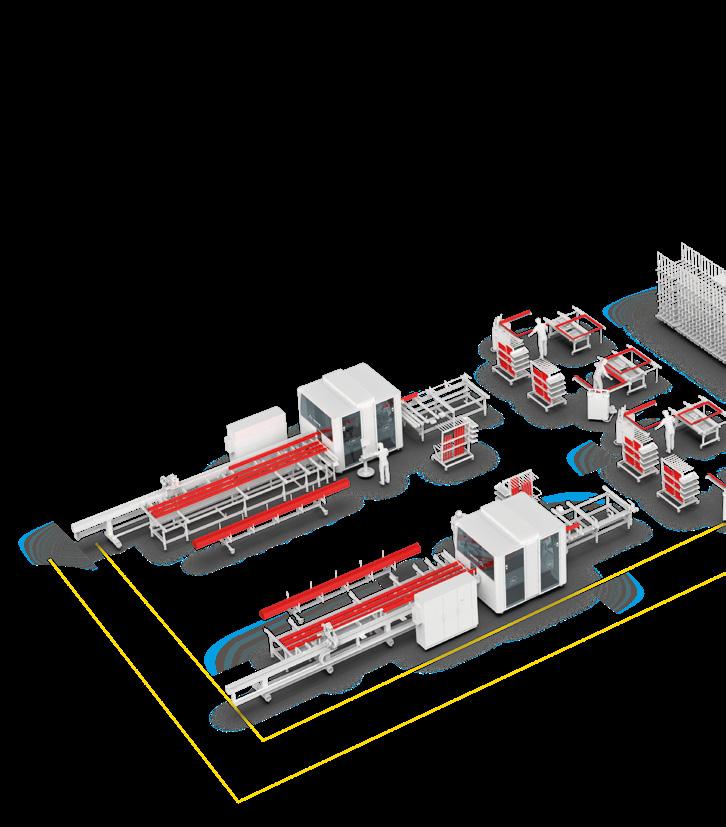

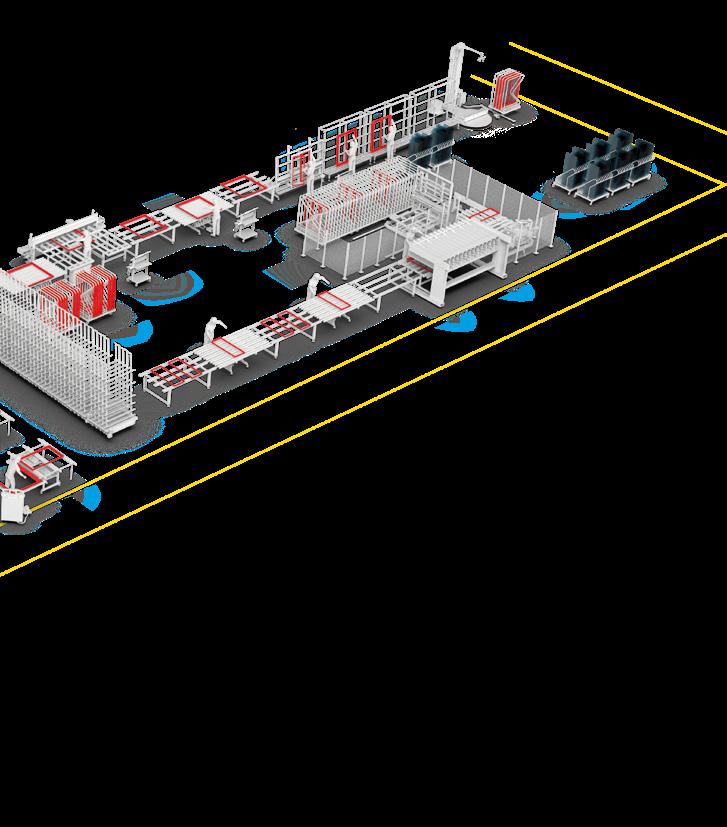

DESIGN OF INSTALLATIONS

Emmegi, a company of the Voilàp group, is increasingly shifting its role in the window, door, and building envelope sector from that of a simple manufacturer of machinery and equipment to that of a reference company in the design and construction of complete and complex systems, characterised by high technological content.

— 10 windows/shift ALU 4

operators

END MILLING MACHINE

TWIN HEAD CUTTING-OFF MACHINE

COPY ROUTER

— 20-40 windows/shift ALU

9 operators

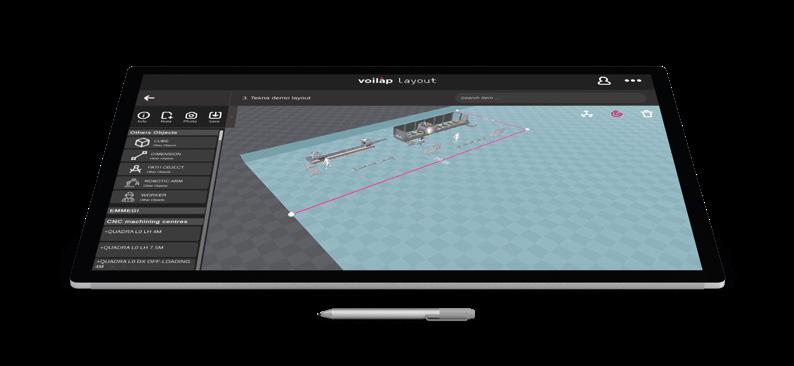

What is V-Layout?

A tool to speed up the sales process and remove any doubts regarding the layout of a production plant, involving customers in the solution it designs.

LAYOUT CREATION WITH THE ABILITY TO SWITCH BETWEEN 2D AND 3D VIEWS

SIMULATION OF PRODUCTION FLOWS

DEFINITION OF CUSTOMISED, CLEAR AND INTUITIVE LAYOUT PROPOSAL

POSSIBILITY OF AUGMENTED REALITY VISUALISATION OF PRODUCTS IN THE WORKING ENVIRONMENT (FUNCTION ON TABLET)

The product data, descriptions and illustrations appearing in this catalogue are shown for advertising purposes; they are given as examples only, and shall not be binding on the manufacturer or the vendor under any circumstances. For marketing reasons, products may be reproduced or portrayed with non-standard configurations, colours or optional extras, in older versions or withspecial customisations or different technical characteristics, possibly for supervening manufacturing reasons. The manufacturer and the vendor reserve the right to make any modification whatsoever to the products. Please contact the sales personnel if you have any queries.