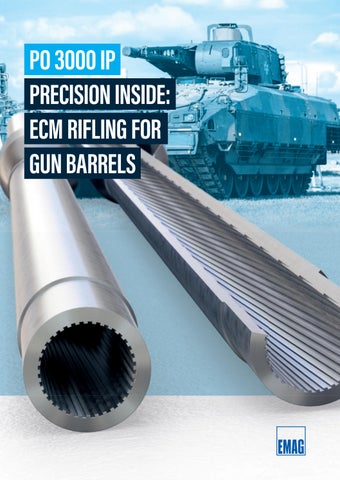

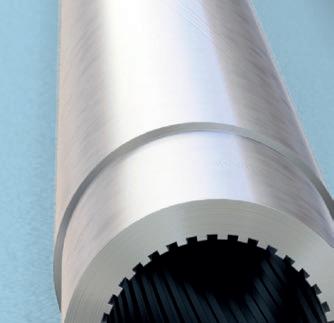

Manufacturing gun barrels places the highest demands on dimensional accuracy, repeatability, and material compatibility. The internal profile with grooves and fields (rifl ing) in particular requires a precisely defined geometry over the entire length of the barrel—even with tempered or difficultto-machine materials. Conventional processes are reaching their limits here, which is why new, more reliable manufacturing methods are needed.

With its electrochemical machining principle, the PO 3000 IP from EMAG ECM sets new standards for the rifl ing of gun barrels. The machine enables contact-free, stress-free internal machining with exact reproducibility— ideal for calibers up to 63 mm and barrel lengths up to 9,000 mm.

Inner Diameter mm in 20–63 (ooptional up to 160) 0.8–2.5 (optional up to 6.30)

Outer Diameter (optionally extendable) mm in up to approx. 121 up to approx. 4.76

Component length mm in 1,000–3,000 (optionally expandable up to 9,000)

39.4–118.1 (optionally expandable up to 354.3)

Processable calibers (Typical applications in areas such as air defense, small and medium calibers)

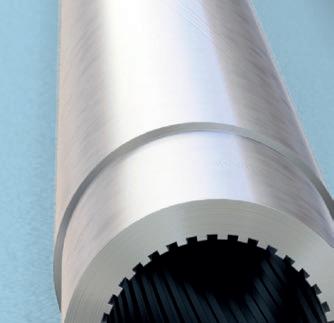

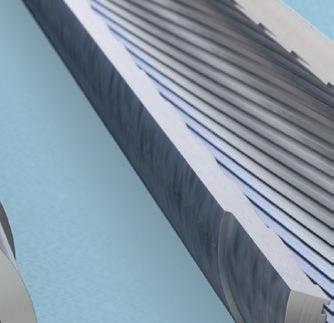

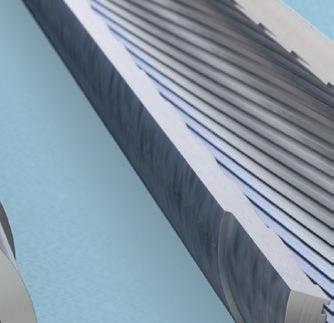

The rifling, i.e., the spiral-shaped internal profile of a gun barrel, gives the projectile a stabilizing rotation as it exits the barrel. This geometry is introduced into the workpiece via the shape of the cathode. The PO 3000 IP enables the economical and highly precise production of these structures.

ADVANTAGES OF ECM RIFLING:

+ Machining irrespective of material hardness or structure

+ Feasible for complex geometries (e.g., gain twist)

+ No influence on the edge zones or mechanical stresses

+ No need for straightening processes or thermal posttreatment

ECM rifling is ideal for machining complex internal contours in high-strength materials, such as those used in the defense industry.

In the ECM (electrochemical machining) process, material is removed by anodic dissolution of the workpiece in an electrically conductive liquid (electrolyte). The workpiece is the anode, and the tool is a contouring cathode.

Workpiece = anode

Electrolyte

Tool = cathode

Feed

Electrolyte

Machining time per workpiece

Electrolyte flow

tool (-)

Power source

KEY FEATURES OF THE ECM PROCESS:

» Contactless material removal without mechanical cutting forces

» No thermal infl uence on the workpiece

» No tool wear, as there are no mechanical stresses

» Maximum reproducibility thanks to controlled process parameters

» Low cathode wear

TECHNICAL DATA PO 3000 IP

Machining process Electro Chemical Machining (ECM)

Inner Diameter mm in 20 – 63 (optional up to 160) 0.8 – 2.5 (optional up to 6.30)

Outer Diameter (optionally extendable) mm in up to approx. 121 up to approx. 4.8

Component length mm in

1,000 – 3,000 (optionally up to 9,000)

39.4 – 118.1 (optionally expandable up to 354.3)

Feed rate mm/min up to 85

Cycle time (reference) ~35 min at Ø 22 mm / 3,000 mm length

Electrolyte monitoring Temperature, pressure, flow, pH, Cr⁶+

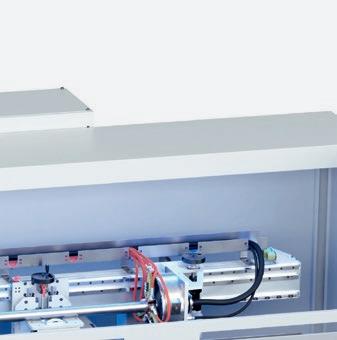

Workholding technology

Cathode guide

Machine design

Double sleeve with guide rollers

Non-conductive multipoint guide

Portal structure with side loading

1

2

Contact-free removal ✔ ✖

Tool wear

Machinable materials

Post-processing

Cycle time

Geometric flexibility

Low cathode wear

Irrespective of hardness

Not required

~30–60 minutes

Very high (gain twist, etc.)

SCALABILITY AND SPECIAL SOLUTIONS

The PO 3000 IP is designed for pipes with a length of up to 9 m. Proven concepts are available for larger diameters (> 100 mm) or lengths (> 6 m). In previous projects, systems with a length of up to 24 m (e.g., oil drilling pipes) have already been implemented. This means that the platform can be scaled to specific requirements.

(high mechanical stresses)

High tool wear

Limited choice of materials

Straightening, grinding

~4 hours for the same length

Limited