HOBBING MACHINE

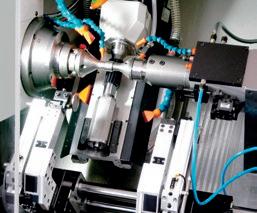

The K 160 machine combines an innovative design principle with state-of-the-art technology and a wealth of experience gained over generations in gear cutting technology. Whether for dry or wet machining, customized automation solutions and a comprehensive technology package make the K 160 the ideal high-speed gear hobbing center for modules up to 2.5.

In addition to a perfectly coordinated process design, the cost-effectiveness of a gear cutting process depends largely on the characteristics of the gear cutting machine. The K 160 enables such high-speed machining thanks to modern direct drives that provide the required speeds on both the main spindle and the milling head. In addition, the machine impresses with its small footprint and excellent accessibility, regardless of whether only the hob is being changed or the machine is being loaded manually for small series production.

Steering pinions: Soft pre-milling and hard finish-milling (skin milling) of the gear teeth. Manufacturing quality: Pre-milling (soft) DIN 7–8, skin milling (hard) DIN 7

Dry high-speed gear hobbing of planetary gears

Straight and helical gears, pinions, and shafts can be machined with the K 160.

Worm gears can be cut not only using the radial milling method, as is often the case, but also using tangential milling for high-precision designs. The setup of the end mill is performed using a hydraulic expansion chuck.

Equipped with a latest-generation 8-axis control system, the K 160 gear hobbing machine offers high speeds on the milling head and main spindle, enabling high cutting speeds even for shafts and pinions with very few teeth.

The base of the machine is a torsion- and bending-resistant, vibration-damping machine base made of MINERALIT® polymer concrete in a slanted design with correspondingly favorable chip and coolant removal.

NC axes:

A – Hobbing head swivel movement

B – Hob rotation

C – Workpiece rotation

W – Tailstock travel

X – Radial movement of hobbing head

Y – Tangential movement of hob (shifting)

Z – Axial movement

V – Gantry loader travel

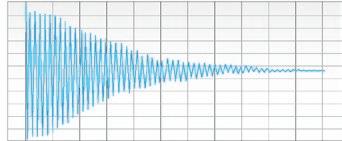

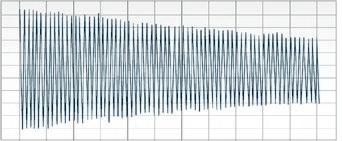

The machine body is made of high-grade MINERALIT® polymer concrete and provides excellent vibration damping properties. This results in better surface quality and longer tool service lives.

The advantages:

+ Excellent vibration damping, resulting in extended tool life and superb surface finishes

Vibration damping effect on EMAG machine base made from MINERALIT® polymer concrete

+ MINERALIT® polymer concrete is thermally stable which ensures constant production results

In comparison to: Vibration damping effect on machine bases in cast iron

The slanted bed design of the machine allows excellent access to the milling head and workpiece, as well as outstanding chip and coolant drainage.

As an alternative to wet machining, the machine can also be equipped with dry dust extraction and blow nozzles for dry machining.

+ The machine is equipped with a touch panel that off ers maximum convenience for operation. It forms the basis for the EMAG Dialog software, which allows even complex gear cutting applications to be easily programmed using intuitive dialog inputs.

+ The control system enables comprehensive diagnostic functions and can be equipped with various interfaces, allowing it to be integrated into an MES system or communicate with an external handling system, for example.

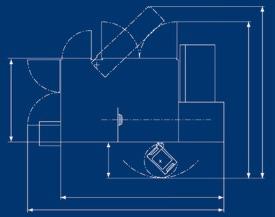

Floor plan K 160

The integrated gantry loader with double rotary gripper enables extremely short loading and unloading times. Raw-parts and finished part magazines are available for a wide range of parts and autonomy requirements.

The use of multiple feeder rail for workpieces rolling by gravity can significantly increase the magazine capacity and thus the autonomy of the machine.

A triple distributor can also be used as a double or single distributor. Moving the distributor fingers results in a virtually unlimited number of adjustment options for different workpiece lengths.

Alternatively, the machine can be automated with robot cells or integrated into complete manufacturing systems.

» Integrated gantry loader with flexible workpiece magazines, feeder chain, and belt conveyor

» Chain magazine for top-heavy workpieces with differences in diameter.

» Multiple distributor with multiple feeder rail

Auxiliary tools can be supplied in single or double versions. The double version is used, for example, when workpieces need to be positioned and deburred at the same time.

In addition to deburring with a disc or steel, the auxiliary tool can be used as a vibration damper or sensor carrier for automatic orientation. The auxiliary tools are also available for special applications, such as powered deburring tools.

» Clamping devices for wheel, pinion, shaft parts, and milling cutters

» Hydraulic expansion chucks for clamping shank hobs

» Hydraulic quick-clamping device for workpieces and for gear hobs

» Clamping the workpiece with expanding mandrels

» Deburring device (vibration damper, sensor carrier) in single or double design

» Automatic sliding-type chip conveyor

» Oil mist extractor

» Extraction device for dry milling

» Automatic orientation for peeling gear hobbing

» Software for special instructions, such as skipping a damaged area on the gear hob, for positioning tasks, etc.

» Various magazine systems for blanks and gear cutting workpieces

» Loading and unloading with robots