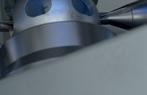

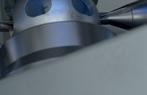

TWIN SPINDLE MILLING MACHINE

Flexible manufacturing concept for window milling

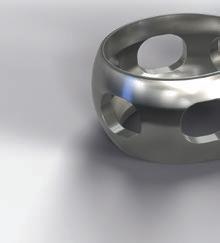

EMAG can now supply a fl exible manufacturing solution for the window milling of all types of cages for CV joints with the HCM 110 twin spindle milling machine. This system allows for a major reduction in running costs compared to traditional manufacturing with grinding processes.

Hard and soft milling performed in the same machine configuration

Specifically designed for the development of ball cages, the HCM 110 milling machine uses EMAG’s shuttle or DUO principle to achieve the highest levels of productivity. Hard or soft milling are available as options for ball cages, and the process can be performed dry, with KSS, or MQL.

To ensure maximum component handling speed, a robot is completely integrated into the machine.

Operations in OP 10 and OP 20 maximize the freedom and fl exibility during the production of machining cages. Instead of 4-axis simultaneous machining using both milling spindles, in this system each milling spindle performs a separate operation. This means that cages with different radii or window designs can be manufactured in a single machine, with two clamping cycles.

OP 10/20 MODE for machining cages with different window designs

Using the shuttle principle, both milling spindles will simultaneously machine one cage, alternating workpiece spindle with each part. During this process, the workpiece spindle not in use will be loaded and unloaded outside the machining area allowing the shuttle principle to achieve the shortest possible cycle time.

The DUO principle means that the left-hand milling spindle will only machine the cage on the left side of the workpiece, and the right-hand milling spindle only machines the right side of the cage.

A third method is required for cages that have two different radii or window designs and therefore, have to be machined with two different tools. This is known as an OP 10 / OP 20 operation.

+ Hard and soft milling on one machine

+ Modern, fl exible, highly productive machine concept

+ Reduces running costs compared to grinding applications

+ Very short cycle times

+ Logical development of technology competence

+ Global service network with propeller shaft specialists

+ The machine can be designed with no hydraulics

+ Three different methods available: DUO, shuttle and OP 10 / OP 20

TECHNICAL DATA