VL 200 WITH CRC ROBOT CELL:

HIGHLIGHT:

Minimal chip-to-chip time due to direct loading/ unloading into the spindle

Fast automation solution for planetary gears

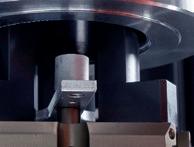

At this year's AMB, EMAG is presenting the VL 200 vertical turning machine equipped with a CRC robot cell for the machining (OP 10) of planetary gears in the agricultural sector.

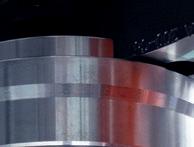

Instead of a conventional conveyor belt, the CRC robot cell is mounted directly on the VL 200. This enables the robot to load the workpiece directly into the spindle. The robot takes over the loading and unloading function by means of a double gripper.

The workpieces are loaded directly into the spindle! THE NEW EMAG STANDARD FOR THE VL, VT & VL 3 DUO SERIES

ADVANTAGES

» Minimal non-productive time: Direct loading into the spindle reduces the loading/unloading time to just 4 seconds.

» Compact automation solution: Space-saving design and easy integration.

» No shuttle required: Direct transfer between robot and machine.

FANUC iHMI with 19” multi-touch screen and intuitive user interface.

Advantages of FANUC iHMI:

» Consistent menu navigation: FANUC Home Screen with the applications Planning, Editing, Improvement & Utilization.

» Simple setup: Integration of EMAG-specific masks, e.g. for simplified setup of the clamping device

» Improved diagnostic options:

Extensive machine/control documentation directly on the machine control system and easy integration of additional documents

» 3D simulation: Manual measurement of the workpiece possible within the simulation

THE VL SERIES

BACKGROUND

TO THE CRC ROBOT CELL The CRC stacking cell is

for components with a diameter of up

The vertical pick-up turning machines of the VL series are specially designed for the the production of precise chucked parts. In order to cover the widest possible range of parts, the VL machines are available in four versions for workpieces from 10 mm to max. 400 mm diameter.

Highlights:

» Fully vertical lathe model family with modular design

» All VL machines use direct path measuring systems in all axes

» Ideal for series production - from small to large series

» The complete automation and handling technologies are included in every machine

» Simple automation of several machines possible thanks to uniform automation

» Height Particularly suitable for multi-machine operation

mm. It is loaded using workpiece carriers, which are housed in drawers and can carry up to 45 kilograms per drawer. A robot handles the parts and loads and unloads the machines. The machine operator is only responsible for replacing the workpiece carriers, which takes place simultaneously with the main processing time to ensure a continuous production flow.