BUSINESS UNIT TURNING

Turning machines for chucked and shaft parts

Turning machines for chucked parts

Turning machines for shaft parts

TURNING MACHINES CHUCKED PARTS FOR

VL MODULAR SOLUTIONS

The VL Series vertical pick-up turning machines were specially developed for manufacturing precision chucked components. To cover as wide a range of parts as possible, the VL Series is available in four versions for a workpiece diameter ranging from 10 mm to 400 mm.

MAXIMUM PRECISION – DIRECT POSITION MEASURING SYSTEMS

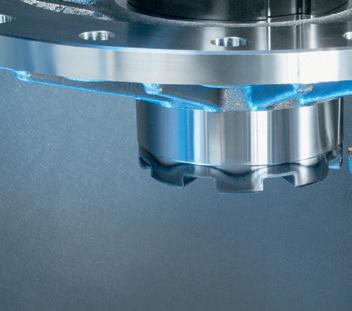

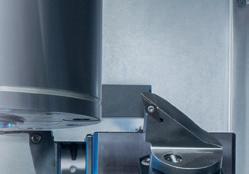

THE PATENTED EMAG TURRET

Measuring

+ Glass scales – Fully encapsulated linear glass scales in all linear axes.

0.3 SEC. TURRET SWIVELING

+ Fast, with zero play and wear – the EMAG turret is equipped with a direct drive (torque motor) for swiveling.

+ Precise – Thermal stability is ensured thanks to an ambient temperature controlled cooling system.

+ Flexible – The turret has space for twelve tools (featuring either a VDI or BMT interface). Driven tools can be used in all tool stations. The optionally available Y-axis ensures maximum fl exibility.

BENEFITS OF THE VL SERIES

+ High strength

Large working spindle bearing diameter + MINERALIT® polymer

concrete machine body

+ Complete automation

Including raw and finished parts storage areas

+ Simple handling

All the service units are easy to reach

+ Minimum footprint

Compact machine design

+ Maximum performance

Short distances between the machining area and pick-up automation system

+ Latest generation of control systems

- Fanuc 32iB+

- Siemens Sinumerik ONE

VL MODULAR SOLUTIONS

VL 2/VL 100 and VL 4/VL 200 for small and medium-sized workpieces

The VL 2/VL 100 and VL 4/VL 200 pick-up turning machines are ideal for workpieces with a diameter up to 100/200 mm. They feature integrated automation and a parts storage area, which enables them to operate completely autonomously, relieving the strain on production personnel. Efficient mass production of varying batch sizes is possible and, thanks to flexible clamping systems, they can also easily machine whole part families.

Intermediate gear

Machines: VL 2

Sawn part diameter: 60 mm Material: C45 2 OPs

Cover

Machines: VL 2

Sawn part diameter: 100 mm

Material: X5CrNi1810 2 OPs

Main hub

Machines: VL 4

Forged part diameter: 120 mm Material: 16MnCr5 2 OPs

Sprocket

Machines: VL 2

Pre-forged part diameter: 50 mm

Material: 16MnCr5 2 OPs

Piston

Machines: VL 4

Sawn part diameter: 100 mm Material: 46S20 2 OPs

VL 6/VL 300 and VL 8/VL 400 for large workpieces

Machine larger workpieces, or achieve maximum flexibility in production with a VL 6/VL 300 and VL 8/ VL 400 pickup turning machines. Integrated conveyor belt makes loading the machines with heavy parts a breeze. Place parts on the conveyor belt by crane and the machine takes care of everything else.

Drive gear

Machines: VL 6

Forged

TECHNICAL DATA

Spur gear

Machines: VL 8

External diameter: 320 mm

Housing

Machines: VL 6

Sawn

VL MULTI-SPINDLE MACHINES – VL 3 DUO

EMAG has extended the VL Series product range with the VL 3 DUO, a twin-spindle machine solution for the highly productive manufacturing of chucked parts up to 150 mm (6 inches) in diameter.

The VL 3 DUO integrates all of the EMAG technological developments (including self-loading spindle, the TrackMotion automation system and the modular design of the machine) to create a highly productive manufacturing system with a minimum footprint. The latest generations of controllers from FANUC and Siemens enable easy operation of the machines.

HIGH-PERFORMANCE TURNING WITH THE VL 3 DUO

The VL 3 DUO scores highly for heavy-duty machining due to its rigid machine design. High feed forces with a large cutting depth reduce the machining time.

Standard spindle: High torque spindle:

ap = 4.75 mm

0.2 in

f = 0.4 mm/rev

0.02 in/rev

v c = 250 m/min 1,000 in/min

ap = 8.5 mm 0.3 in f = 0.4 mm/rev 0.02 in/rev

v c = 250 m/min 1,000 in/min

TECHNICAL DATA

Travel distance, X/Y (optional)/Z

Main spindles (2x)

» Power rating, 40%/100%

» Torque, 40%/100%

» Speed, max.

High torque spindle – Option

» Power rating, 40%/100%

» Torque, 40%/100%

» Speed, max.

Turrets (2x)

» Turret tool positions

» Speed driven tools

» Torque driven tools

Rapid-traverse rate, X/Y/Z

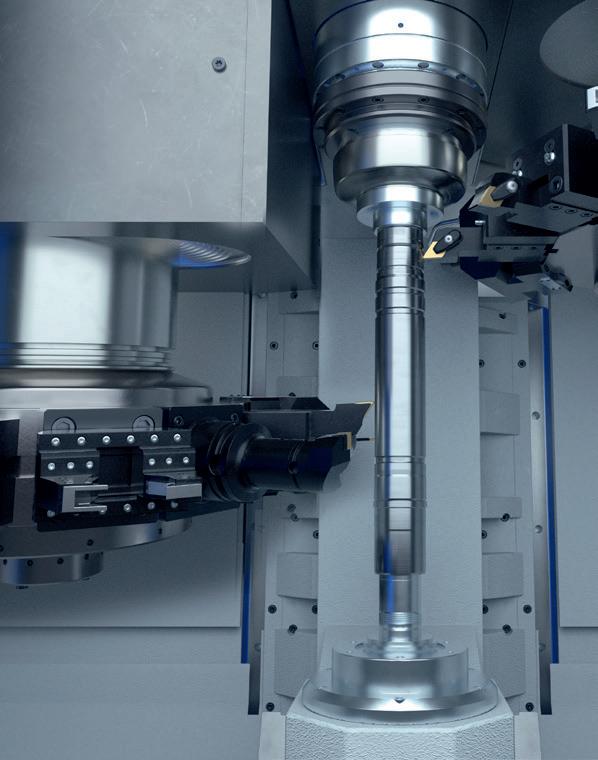

MACHINING AREA OF THE VL 3 DUO:

Highly productive machining of chucked parts with a diameter of up to 150 mm (6 inches) with minimum space requirements

VL 3 DUO FOR DEMANDING TURNING WORK

+ Working spindle with 5,000 rpm/32 kW/255 Nm at 40% duty cycle

+ Sturdy mechanical design – spindle fl ange to DIN 55026, size 6

+ Motor spindle with DirectDrive for minimum run-up times, maximum true running and diameter tolerances

+ Maximum torque over large range of speeds

+ Water-cooled motor spindle for maximum thermal stability

VSC CUSTOMIZED SOLUTIONS

VSC – Multi-functional production centers

Machining + automation + measuring: The machines of the VSC Series are configured for individual production requirements. Their patented design guarantees the shortest travel times between the pick-up station and the machining area, reducing idle times. The MINERALIT® polymer concrete machine base and the twin-wall construction have an excellent vibration damping effect.

In addition, there is a consistently symmetrical slide and machine design for a closed power fl ow and thermally stable production.

The hydrostatically mounted working spindle in the Z-axis ensures high part quality and long tool life during soft and hard machining.

C Measuring station

Working spindle

Turret

Pick-up station

Hydrostatic guideway (standard) Machine body made of MINERALIT® polymer concrete

TECHNICAL DATA

THE EMAG TURRET

The high-speed 12-station disk-type turret features very short swiveling times. Driven tools can be used on all twelve turret stations for drilling or milling operations. The EMAG turret gearbox combines high speeds with high capacity while requiring minimum fl oor space.

+ Very high speed

– Very short swiveling times

– High speeds when using driven tools

+ Very high capacity

– Very small design with high torque

+ Very high precision

– Turret firmly embedded in the machine base = High rigidity

– Very high degree of repeat accuracy when indexing from tool position to tool position

+ Very high availability

– Inured to collisions, owing to the use of torque motors

– No raising of the turret for swiveling. This means that no chips or dirt can get into the turret.

Main spindle

»

Turret

»

VSC MULTI-SPINDLE MACHINES

VSC DUO – the twin-spindle machine for sequential operations

The VSC DUO principle offers a highly efficient solution for the machining of medium to large numbers of parts on a minimal footprint. The work areas are completely separated, allowing the axes to be programmed independently of each other. This makes it possible to achieve sequential operations in one machine.

MACHINING

Both turrets accommodate not only stationary turning tools but also driven drilling and milling tools. This allows for either identical or different operations to be carried out in the two spindles:

+ After the first set of operations have been carried out on the workpiece, using the first spindle, the back of the component is machined in the second one; or the second spindle could be used to machine the workpiece in the same clamping position.

+ Two workpieces can also be machined with identical operational sequences.

VSC 250 DUO: Separate, extremely sturdy machine bodies (workspaces) made of MINERALIT® polymer concrete; the two overhead slides are independently programmable.

Classic MACHINES – MSC 5 DUO, HSC 1, USC 850

The efficient entry into precision manufacturing

Classic machines combine maximum efficiency with the high quality you expect from EMAG. These machines focus on the essentials and offer an optimized range of functions for typical machining requirements.

The base machine is purchased from selected partners and equipped by EMAG with proven process and machining technology, such as chucks and tools. You benefit from EMAG‘s worldwide service network and fast spare parts supply – the ideal choice for cost-efficient production without compromising on reliability.

TECHNICAL DATA

Main spindle

MSC 5 DUO

The MSC 5 DUO is a twin-spindle CNC lathe engineered for high-performance batch production. With its innovative split-bed design, powerful spindles and fully integrated 3-axis gantry loader, this machine delivers exceptional precision, reliability and efficiency. Whether in automotive, hydraulics, pneumatics or medical component production, the MSC 5 DUO ensures faster cycle times, reduced downtime and superior machining results.

USC 850

The USC 850 is a state-of-the-art universal lathe that has been specially developed for the precision and efficient machining of large turned parts. With its robust design, state-of-the-art control technology and excellent machining accuracy, it is ideal for use in the supplier industry, aviation and general mechanical engineering.

HSC 1

The HSC 1 is a compact, powerful CNC lathe for the economical machining of turned parts in two consecutive machining operations (OP 10 / OP 20). Equipped with main and counter spindles as well as a turret with driven tools, the machine enables turning, drilling and milling in a continuous production process - on a single machine. Automatic spindle transfer ensures high precision and efficient machining of both sides of the workpieceno manual reclamping required.

TURNING MACHINES SHAFT PARTS FOR

VT MODULAR SOLUTIONS

Fast processes are required for machining large quantities of shafts. Both the machining process and the loading and unloading processes must be completed extremely quickly. The VT 2/VT 100 and VT 4/VT 200 machines are guaranteed to achieve the maximum performance you require.

Four axes, short distances, and a powerful main spindle – these are the strengths of the VT Series. The full effect of these can be felt, in particular, when machining large quantities. A key factor is the machining of parts from two sides. This greatly reduces the machining time. Two tool turrets, each with eleven tool positions which can be equipped with turning tools or driven tools, ensure machine fl exibility.

AUTOMATION SEQUENCE

THE BENEFITS

+ Ready for integration with the TrackMotion automation system.

+ Reduced machining times due to four-axis machining

+ Shorter idle times with simultaneous loading and unloading of components

+ Lower investment costs thanks to integrated automation

The gripper in turret 1 takes the workpiece from the raw parts storage area and transports it to the main spindle/tailstock. At the same time, the gripper in turret 2 takes the machined workpiece from the main spindle/tailstock, transports it to the finished parts storage area and deposits it there.

Turret 1

Working spindle with C-axis

Turret 2

Tailstock Automation

THREE KEY SUCCESS FACTORS

+ Reduced machining times due to four-axis machining

+ Shorter idle times with simultaneous loading and unloading of components

+ Highly productive shaft manufacturing thanks to integrated automation

WORKPIECE CHANGEOVER TIME

VT LINE

Complete machining of shafts and shaft-shaped workpieces in a manufacturing cell, including automation.

With standardized automation components, two or three machines from the VT series can be easily combined to form a manufacturing cell. The machine can be optimally configured for each machining step, resulting in a highly productive solution.

Shaft machining: Centring, drilling, end machining

Axle journal machining: Soft turning of the outer contour

Rotor shaft machining: Twist-free turning thanks to skiving

Component changeover: The finished component is removed and taken to its storage area. The new raw part is loaded (sequence from right to left).