Electrical Apparatus

More than Motors

At the pinnacle of service with

Apex Industrial Automation

The British pump awards of Romeoville, Ill.

Coaching vs. managing EASA Convention exhibitors

Improving EV accessibility

Wallace Brithinee looks back

A BARKS PUBLICATION JUNE 2024 / $10

EA Reader Profile

20 Foodie adventures

For Krista DeSocio, there’s nothing more satisfying than bringing happiness to others with food lovingly made

By Colin Gregory-Moores, EA Contributing Writer

Electric Avenue

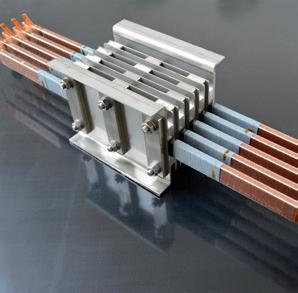

25 Improving EV accessibility

Addressing the challenge of providing charging options for multi-unit dwellings

By Maura Keller, EA Contributing Writer

Conventions & Trade Shows

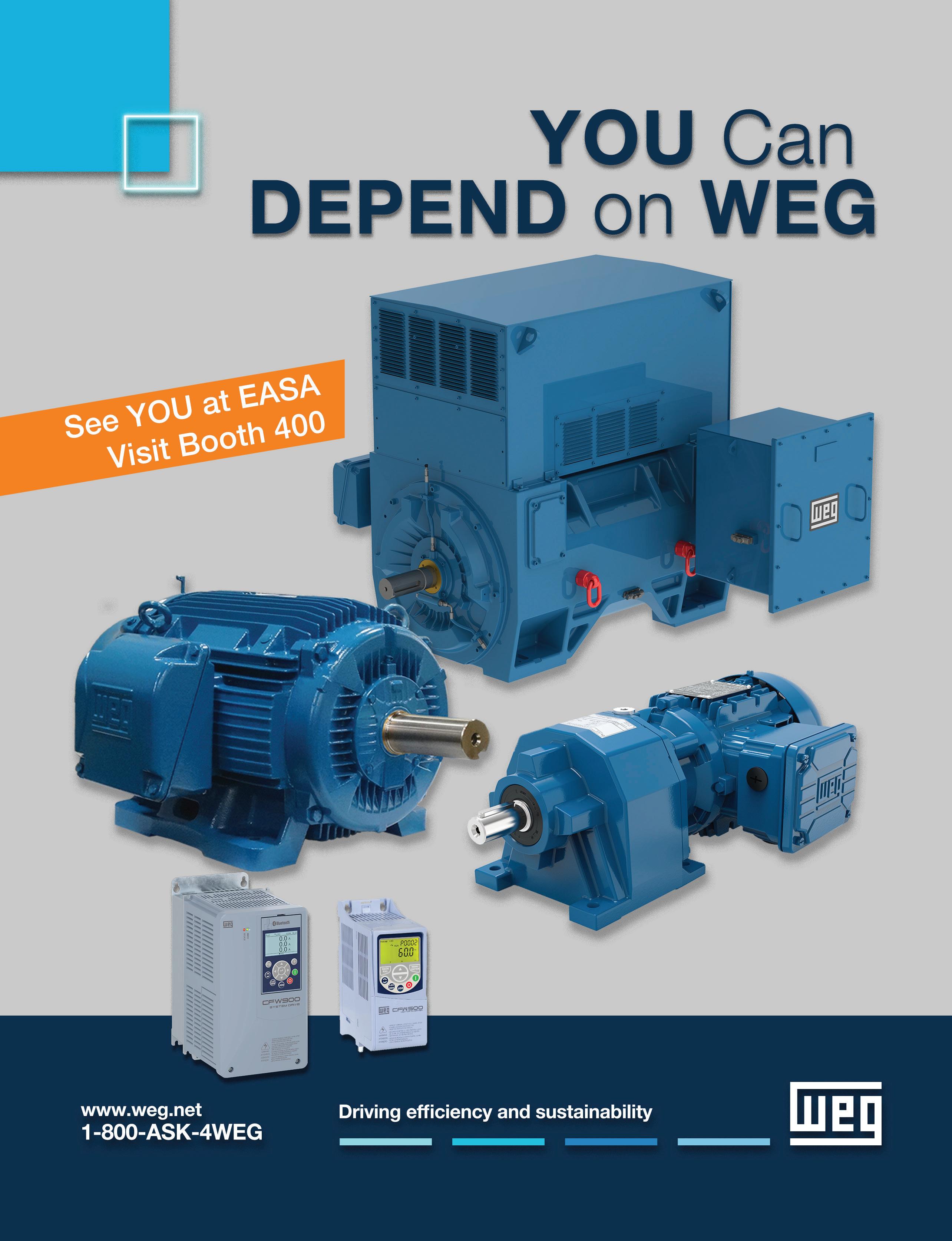

28 On display in Vegas

Highlights of the products and services being shown at the convention of the Electrical Apparatus Service Association

By the Electrical Apparatus staff

Service & Sales Companies

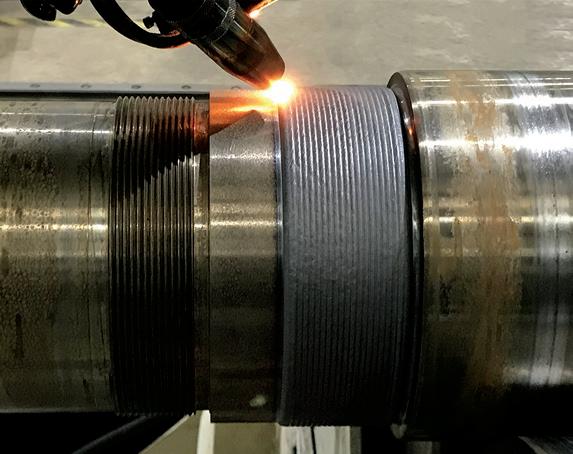

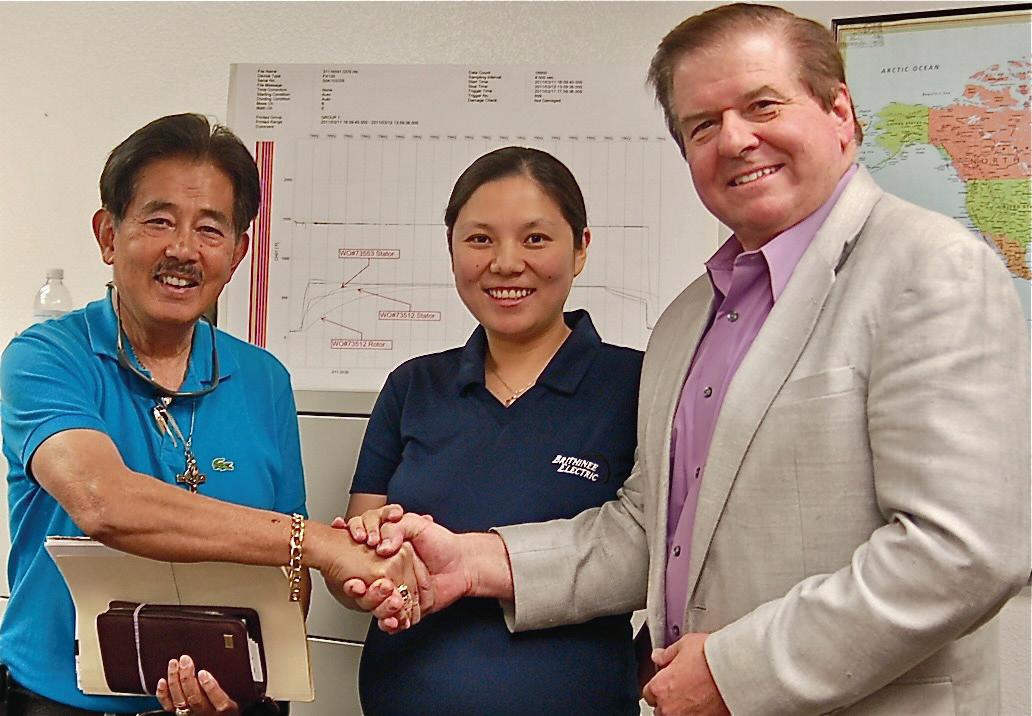

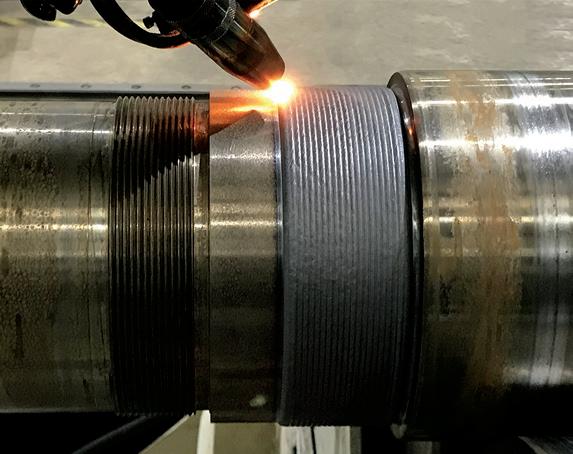

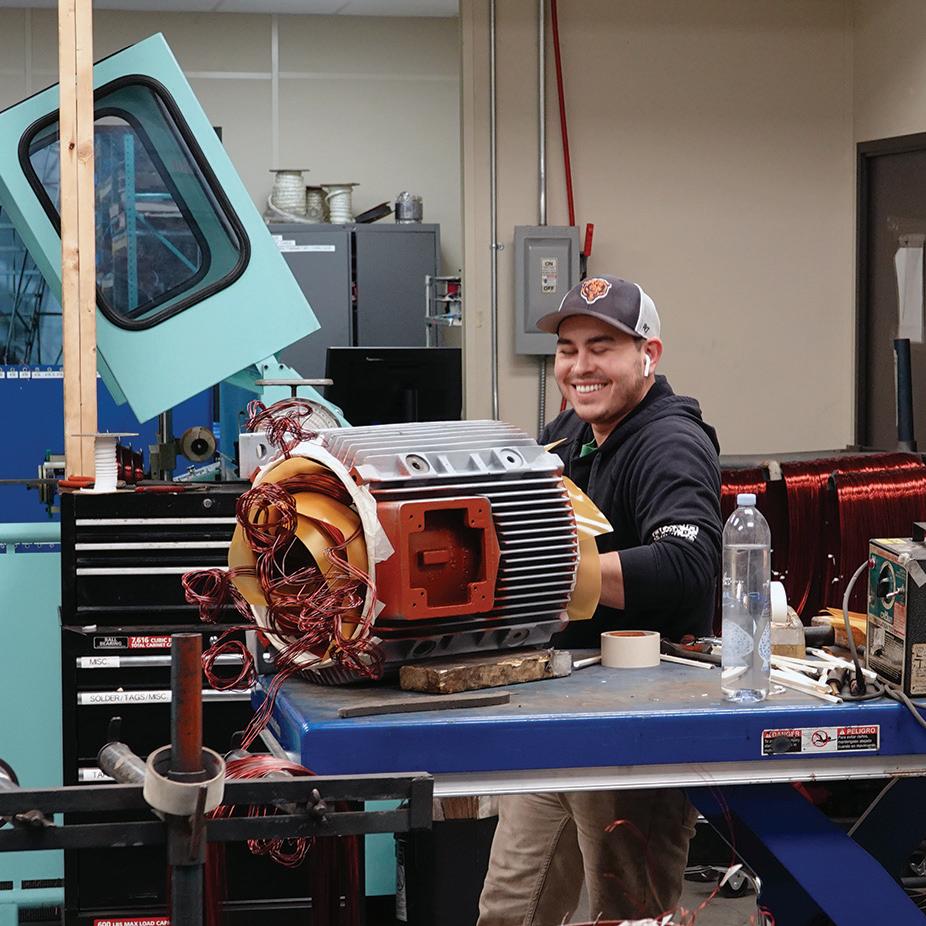

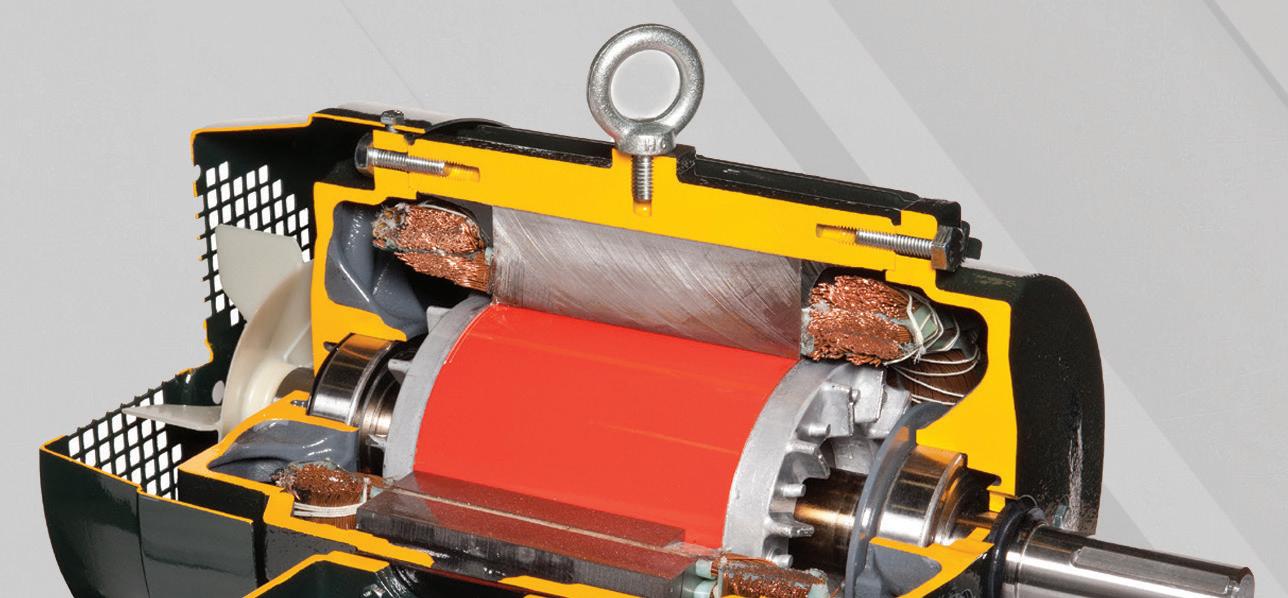

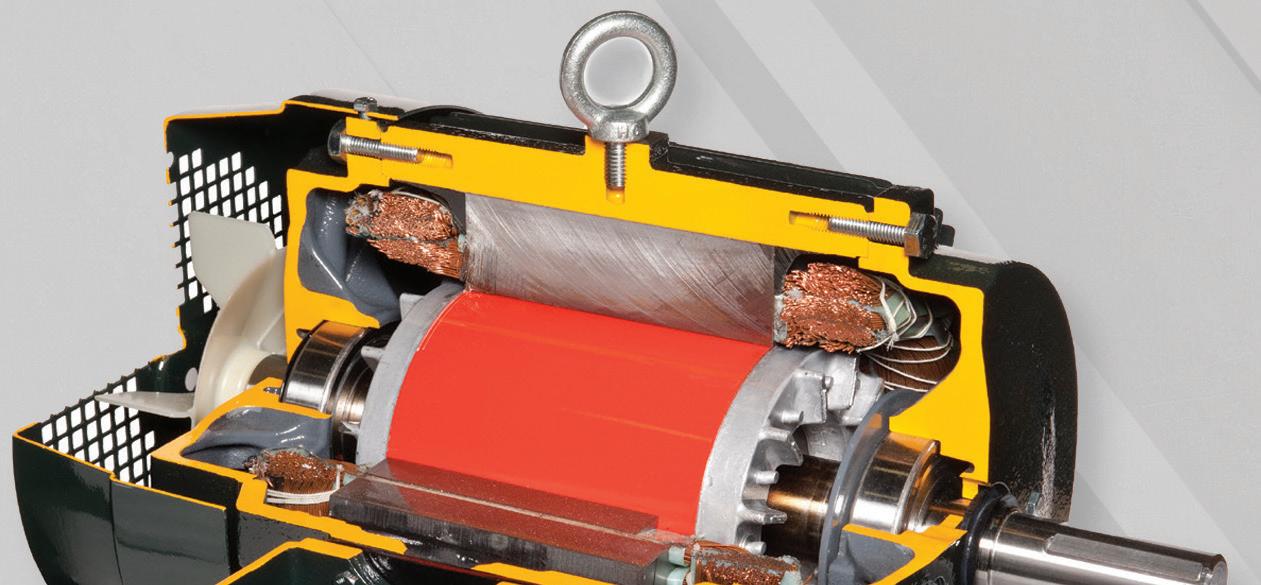

41 At the pinnacle of service

Apex Industrial Automation has reached the top of its class by selling service and staying on the hunt for acquisitions

By

Charlie

Barks,

EA Managing Editor

Industry History

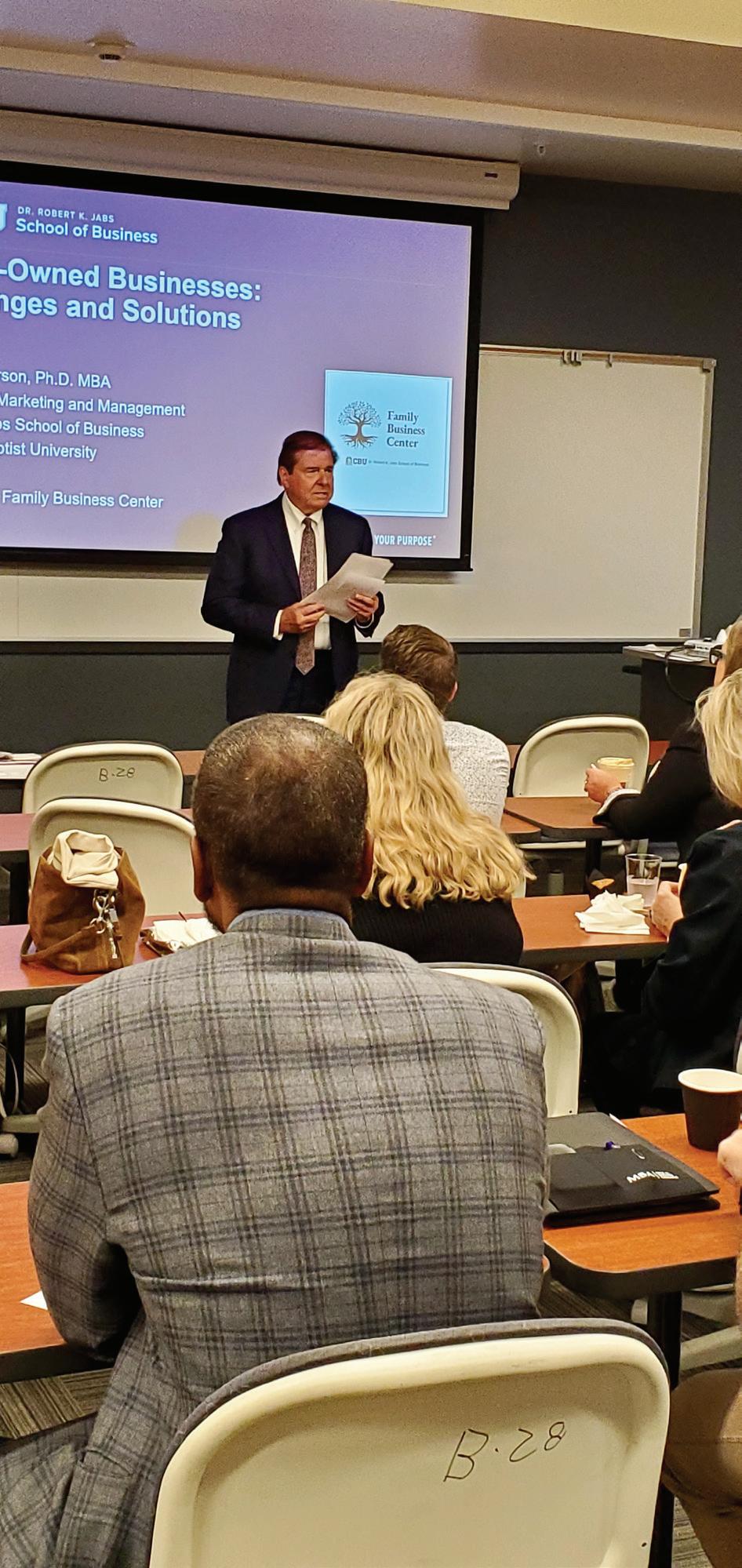

45 Raising expectations and spreading the word Dr. Wallace Brithinee looks back at changes in the industry and the role Brithinee Electric played in helping to bring them about

By Colin Gregory-Moores, EA Contributing Writer

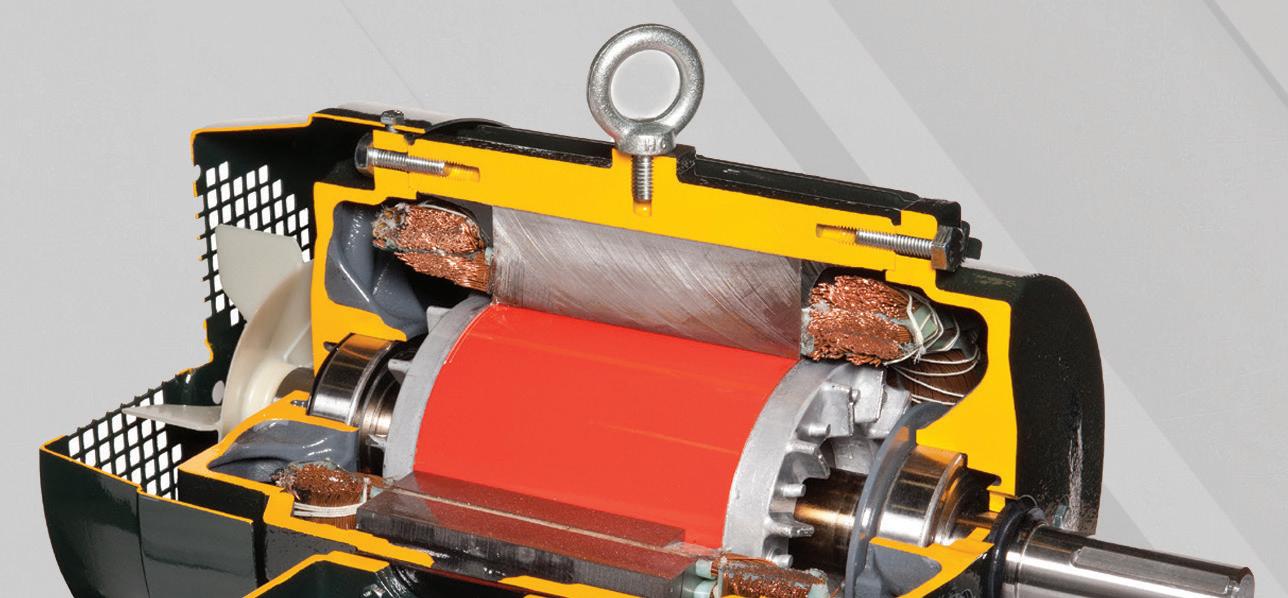

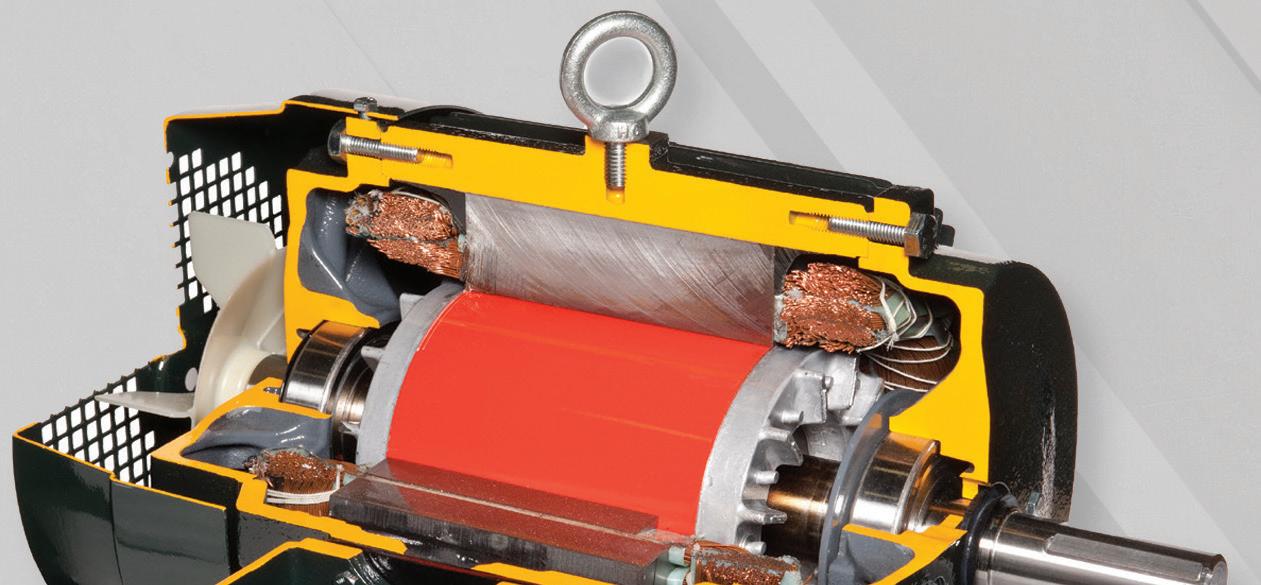

Motors & Generators

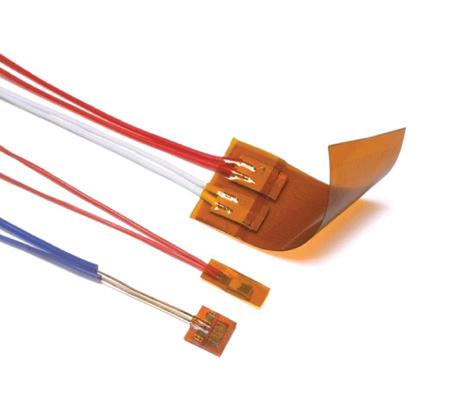

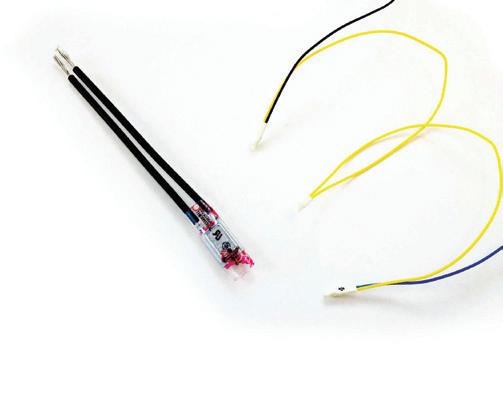

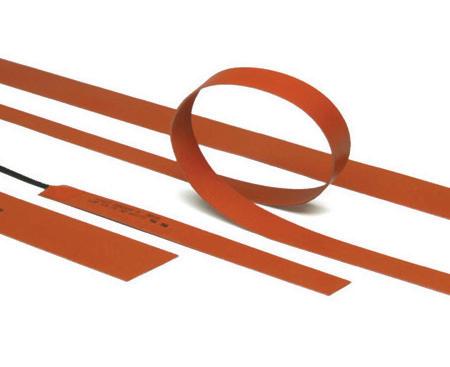

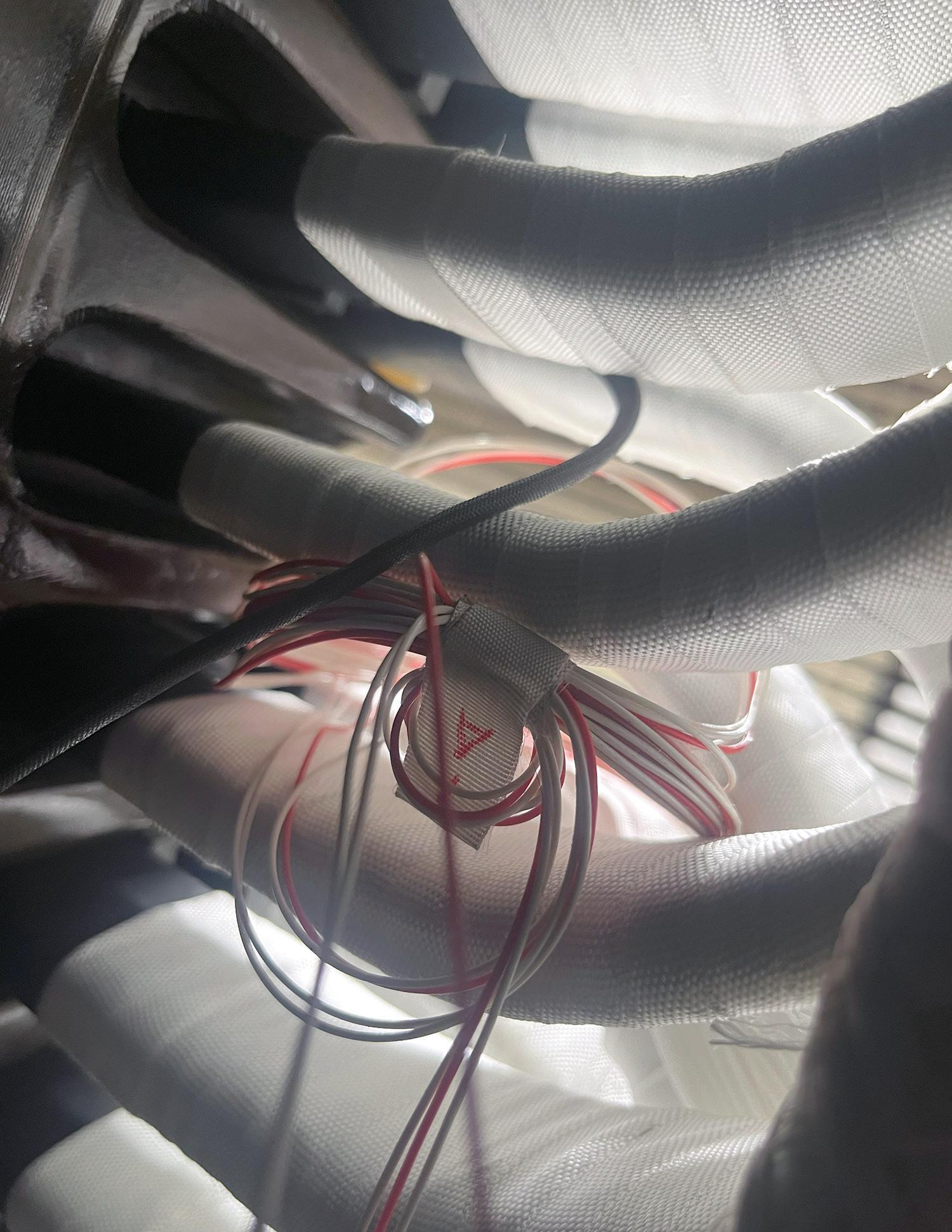

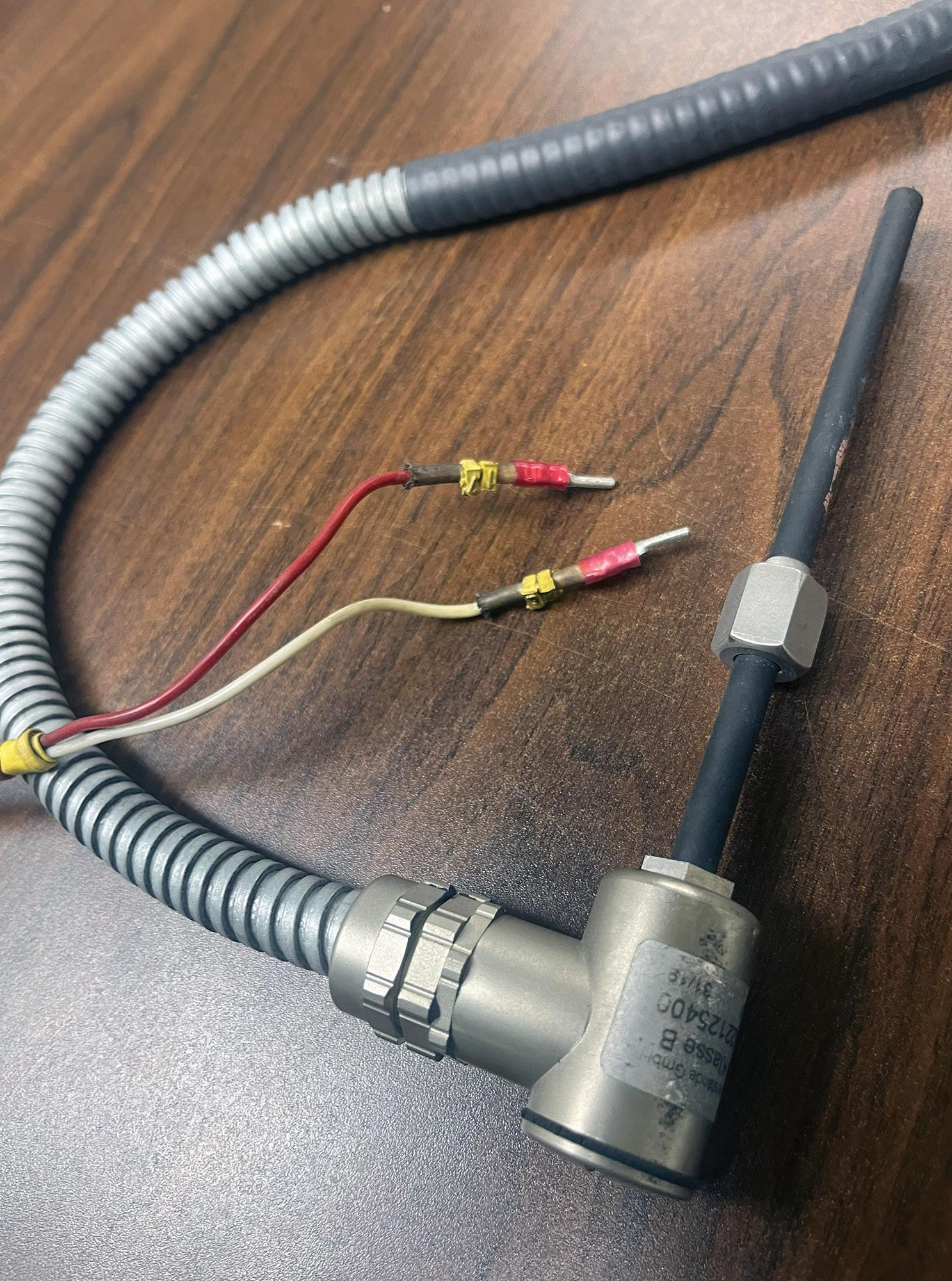

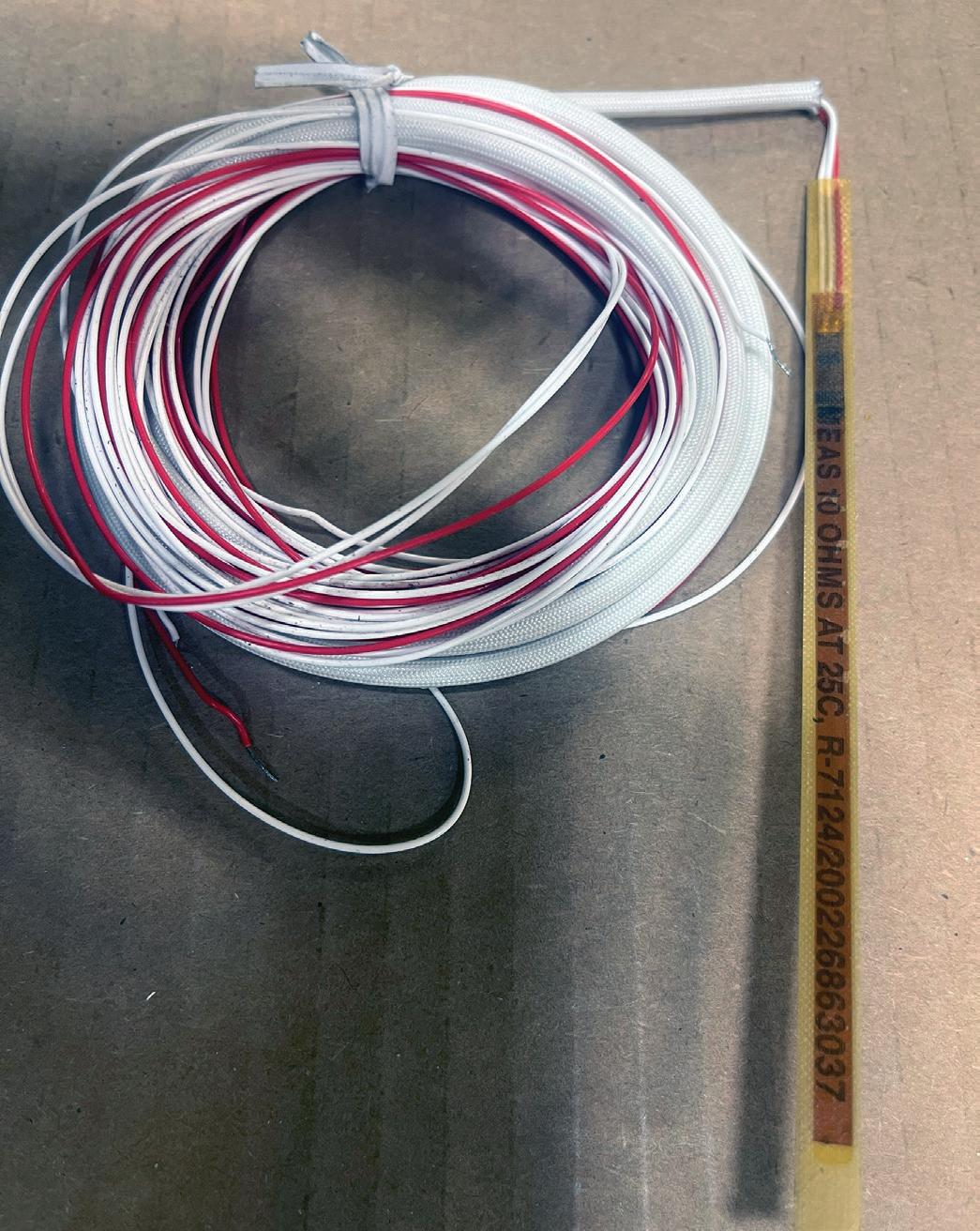

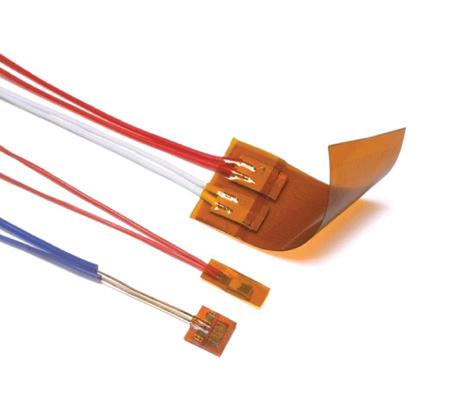

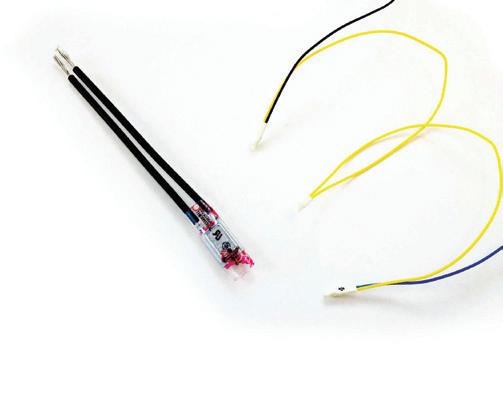

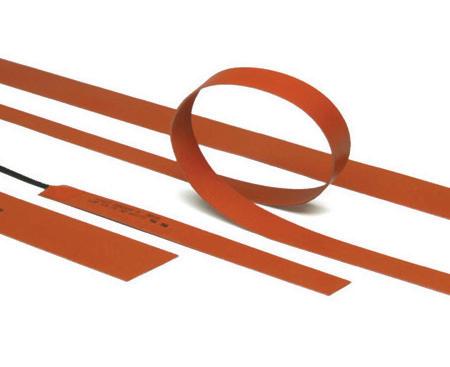

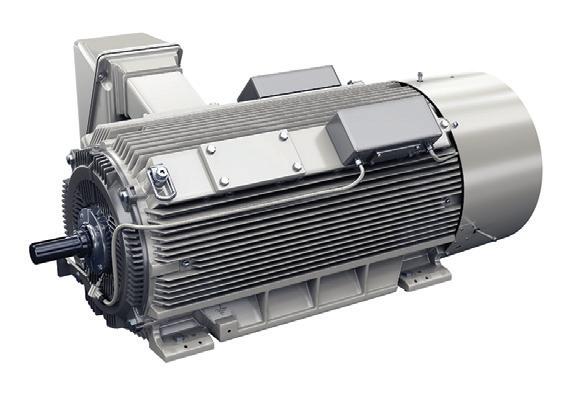

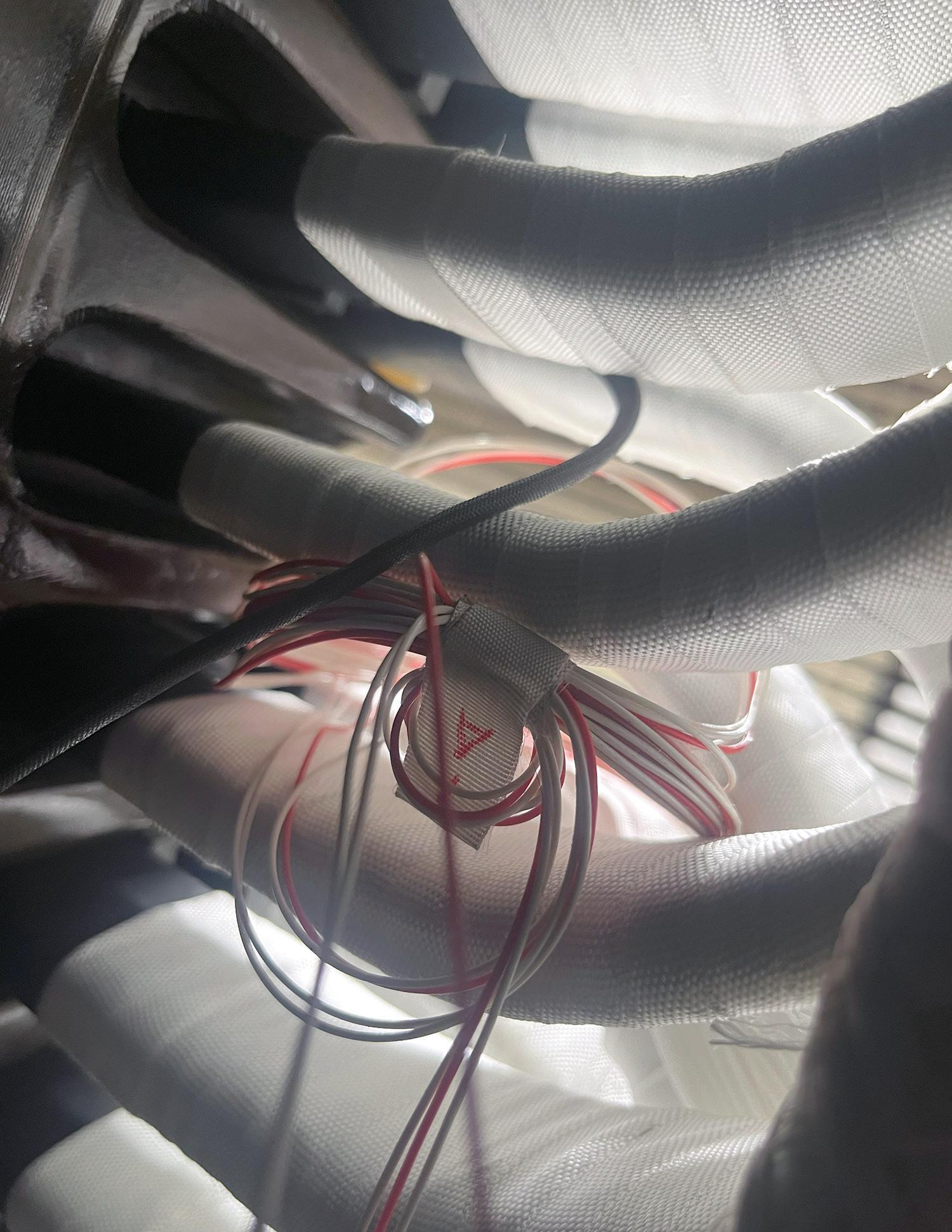

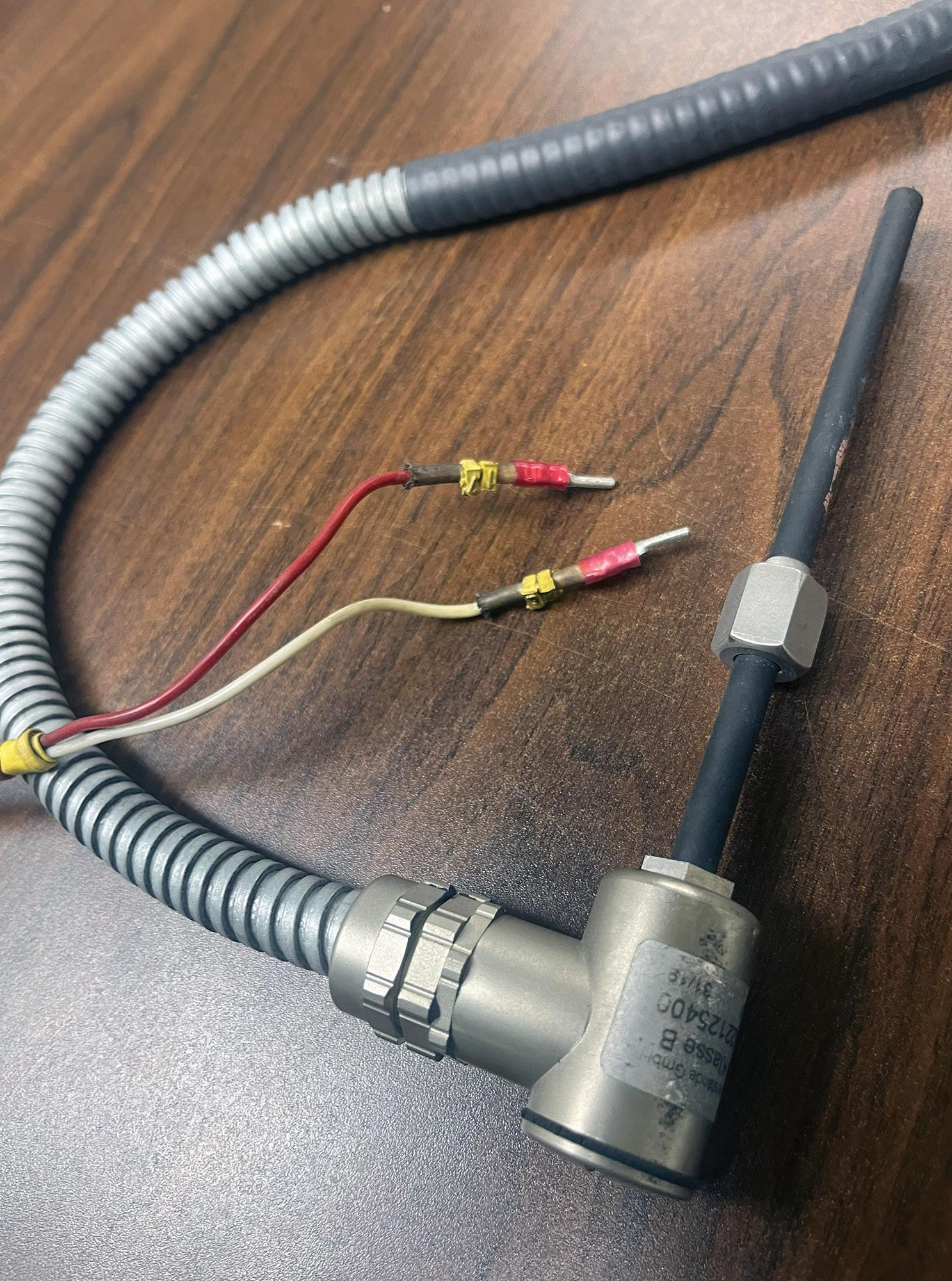

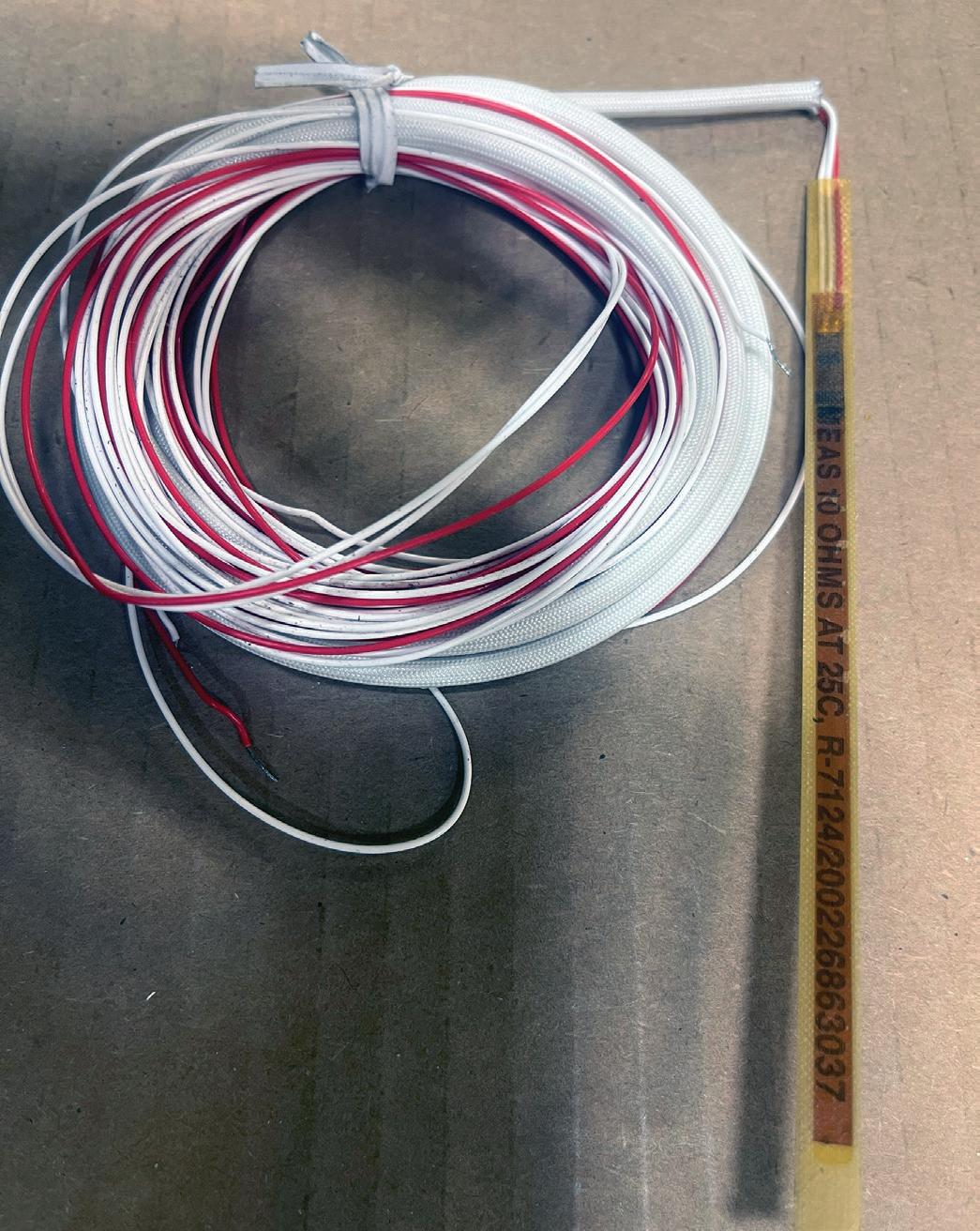

51 Heat index warning

Resistance temperature detectors in motors and generators

By Chase Fell, EA Contributing Writer

Finance

55 M&A on a roll

At a time when middle-market mergers and acquisitions are strong, it’s good to know the basic rules of the game

By William H. Wiersema, CPA, EA Contributing Editor

Energy

57 Updates on the U.S. energy workforce

Employment trends and funding needs are revealed in recent reports and statements

By Charlie Barks, EA Managing Editor

Safety & Health

60 Phased-out products

Servicers and operators of HVACR systems need to familiarize themselves with new restrictions on Refrigerant-22

By Bill O’Leary, EA Contributing Writer

Electrical Manager

62 Coaching vs. managing

The world of sports provides us with a useful analogy we can use when coordinating the work of others

By Bill O’Leary, EA Contributing Writer

Pump It Up

69 Pumped up across the pond

An annual awards ceremony recognized the best and most innovative in the British pump industry

By Kevin Jones, EA Senior Editor

20 41 51 Contents A BARKS PUBLICATION VOLUME 77 / NUMBER 06 WWW.BARKS.COM 06/24

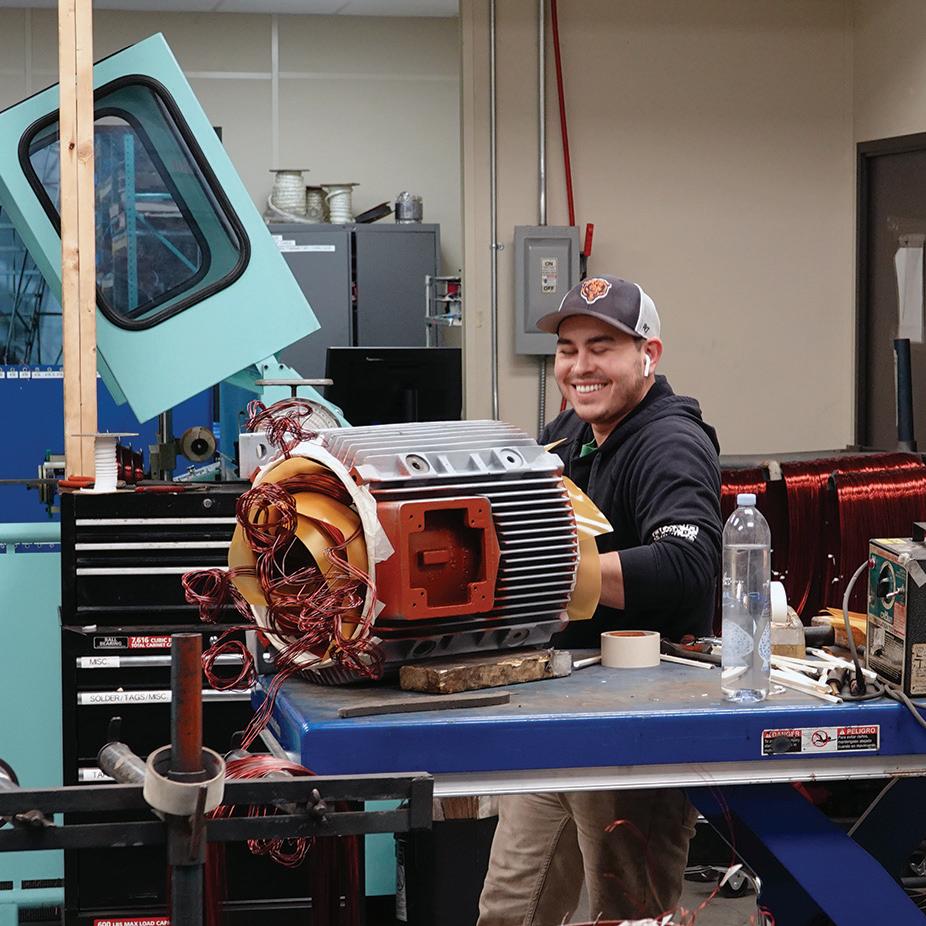

— Electrical Apparatus photo by Charlie

— Chase Fell photo ELECTRICAL APPARATUS | JUNE 2024 1

— Krista DeSocio photo

Barks

04 The editor’s comment What time is it? Game time, at least for EASAns. 06 Business Earnings reports reveal steady, if slow, recovery 07 Let’s solve your problem Answers to questions about efficiency and ASDs 08 Associations Associations here and in the U.K. offer fresh training resources 10 Know your industry The Institution of Engineering & Technology’s deep roots 14 Utilities Recent initiatives in electric grid cybersecurity 16 Calendar Upcoming events on HVACR, pumps, safety, and repair 18 Names & faces Changes at the Manufacturing Institute and Border States 18 Deaths Doug Moore, industry leader and former chairman of EASA 58 Product showcase What’s new from Marelli, Dewalt, Tormach, and Kyocera 71 Classified advertising Your monthly marketplace for equipment, businesses, and more 71 Cy’s Super Service

electrical service industry’s most prominent curmudgeon

The

08 14 10 Departments 72 Plant happenings

Alabama 73 EA puzzle

75 Moe, Genny & friends

76 Direct & current

regulations

pollution

76 Advertising index Who’s who—and

— Illustration by Bing generative AI — Illustration by Bing generative AI — Wikipedia photo 2 ELECTRICAL APPARATUS | JUNE 2024

COVER PHOTO: By Charlie Barks, at Apex Industrial Automation of Romeoville, Ill. Mike Dragusica (left) and Mike Assell go over some company records.

Semiconductors in Boilermaker country, and sunny days for

A word search puzzle based on this month’s “EA reader profile”

The surreal world of an anthropomorphized motor and generator

New

address

from plastics and fossil fuels

who’s where—in this issue of Electrical Apparatus

Quality

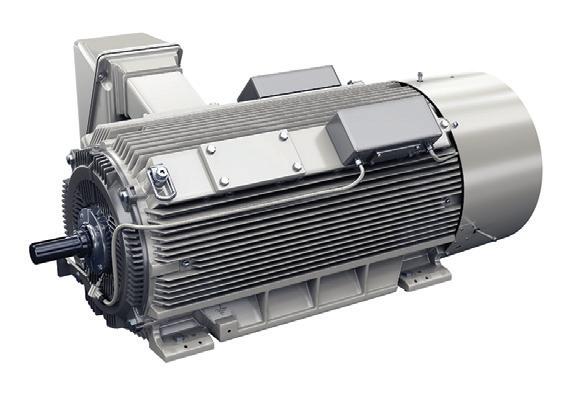

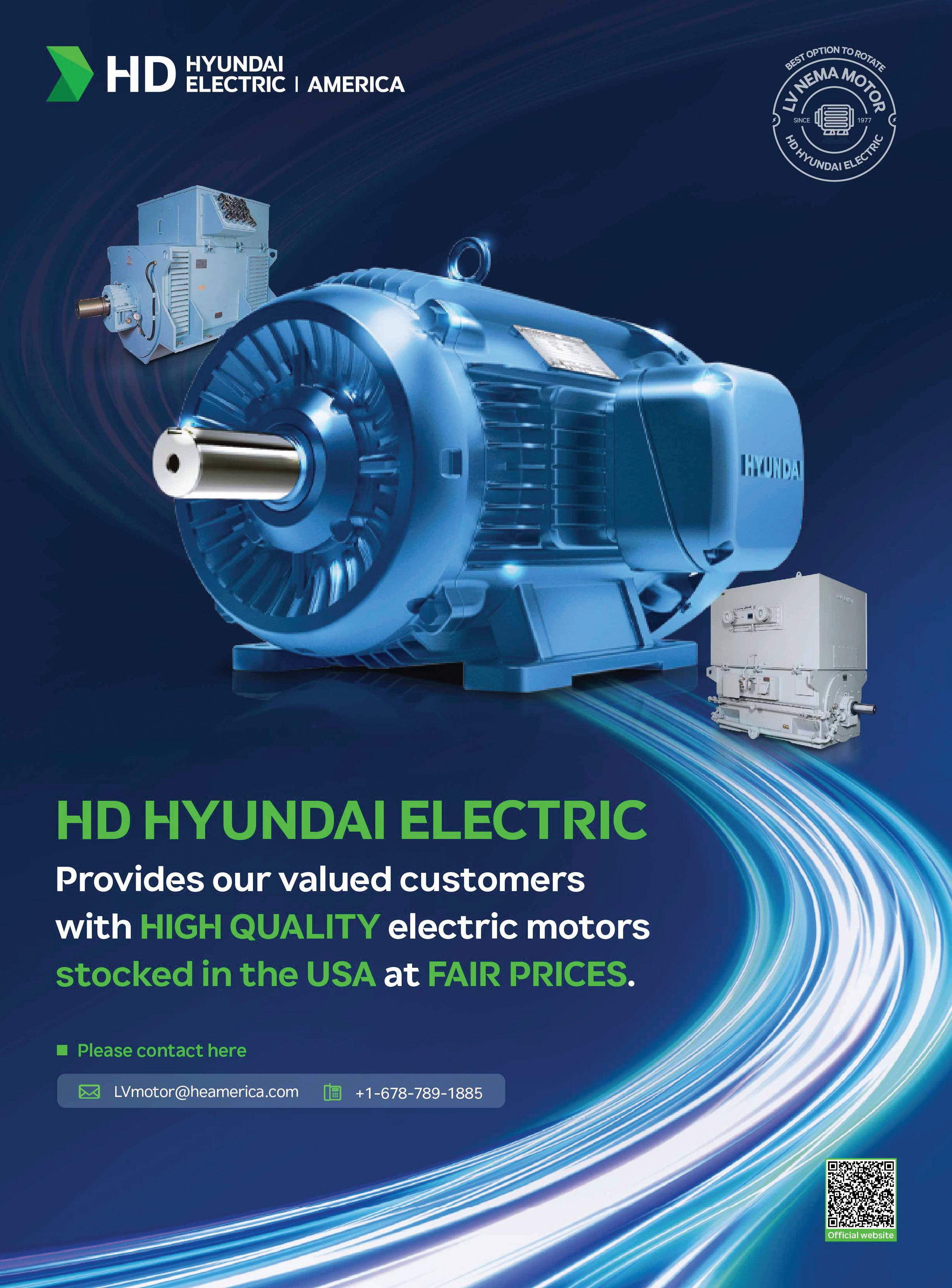

BEARINGS •LOW VIBRATION •HEAVY DUTY CONSTRUCTION •100% QUALITY TEST

WITH WIDE THERMAL CAPABILITY

INTER-LAMINATION MATERIAL

TORQUE OUTPUT

QUALITY CONSTRUCTION WWW.TOSHIBA.COM/TIC (US) 1-800-231-1412 EQP Global SD, 840, 841 Low Voltage Motors Performance and

•OVERSIZED

•INSULATION

•C5-RATED

•HIGH

•HIGH

The Editor’s Comment

What time is it? Game time, at least for EASAns.

Coming next month in Electrical Apparatus:

Our annual electric vehicle issue; CWIEME and Hannover Messe reports; changes in the works for NEMA MG 1; cruising the Autobahn in a hybrid electric auto.

Read Electrical Apparatus online

The entire contents of this issue are available online. Scan the QR code below:

The annual convention of the Electrical Apparatus Service Association is no longer just approaching; it’s right around the corner. The 2024 EASA Convention and Solutions Expo, live from Las Vegas at Caesars Forum and Harrah’s Las Vegas, will be complete by the time you receive your next issue of this magazine. It marks an exciting time of year for so many of our readers, as well as many of our advertisers — who make up a crucial part of this edition by way of the Exhibitors’ Section (page 28). Look for familiar names and their latest, greatest products and o erings before you head to Vegas June 23-26.

It’s becoming our custom at EA to make each issue as diverse as possible. A lot of this is due to our gifted sta branching out from areas in which they already excelled. For example, Chase Fell (page 51) covers resistance temperature detectors in motors and generators, and Maura Keller discusses “Improving EV accessibility” for EV owners (page 25). Kristine Weller provides another “Know Your Industry” (Institute of Engineering and Technology, page 10), as well as a proper memorial to Doug Moore, a former EASA award recipient who sadly passed away earlier this year (page 18).

Regular contributor Bill O’Leary provides two articles this month: “Phased-out products” in the Safety & Health column (page 60); and “Coaching vs. Managing” in the Electrical Manager article — something that sports fans might nd particularly compelling (page 62).

You might also notice two contributions from Colin GregoryMoores, another monthly contributor whom EA is recognizing as more blessed to have on board with each passing day. This month, Colin gives us yet another immersive “Reader Pro le,” one that’s perfect for EASA month (page 20). You might know Krista DeSocio from her bright presence at the ICC International booth during the annual EASA conventions. What you may not know is she has a passion for cooking. Colin dives into Krista’s story, as he does with Wally Brithinee, another household name for EASAns, in an extended special feature this month (page 45).

As usual, Senior Editor Kevin Jones is the glue that secures the entire, nished product of each issue you receive.

Thanks to everyone who contributed to this issue, from our writing sta to our devoted advertisers, who bring each issue into bloom.

We look forward to seeing you all at Caesars Forum, or along the Strip, at the end of the month. We’d be remiss without wishing you some good luck!

Electrical Apparatus

17 N. State St., Suite 435 Chicago, Illinois 60602-3598

(312)321-9440; fax (866) 228-7274

E-mail: EAMagazine@barks.com www.barks.com

Founded 1948 as Volt/Age

Horace B. Barks, Founding Publisher

Elsie Dickson, Founding Publisher

STAFF

Elizabeth Van Ness, Publisher

Kevin N. Jones, Senior Editor

Richard L. Nailen, Engineering Editor

Charlie Barks, Managing Editor

Contributing Editors

William H. Wiersema

John Malinowski

Special Correspondents

Jane Powell Campbell

Christopher Wachter

Cartoonists

John D’Acunto Tim Oliphant

ElectroMechanical Bench Reference

Supplement mailed with the December issue

Elizabeth Van Ness, Editor & Publisher

ADVERTISING

Barbara Wachter, Advertising Director

CIRCULATION

Circulation@barks.com

Electrical Apparatus (ISSN 0190-1370), Vol. 77, No. 6, is published monthly by Barks Publications, Inc., 17 N. State St., Chicago, Ill. 60602; (312) 321-9440; fax (866) 2287274. www.barks.com. Periodicals postage paid at Chicago, Ill., and at additional mailing o ces. Postmaster: Send address changes to Electrical Apparatus, c/o Barks Publications, Inc., 17 N. State St., Suite 435, Chicago, Ill. 60602. PM #40830553

U.S. subscriptions: 2 years—$100; 1 year— $60. Foreign airmail: 2 years—$250; 1 year—$140. Subscriptions also include an annual directory supplement, the ElectroMechanical Bench Reference. Single copies: $11 each plus postage; December issue, $30 with the supplement ElectroMechanical Bench Reference.

Copyright 2024 Barks Publications, Inc.

Reproduction of any part, by any means, including photocopy machines and computer networks, without the written permission of Barks Publications, Inc., is prohibited. Electrical Apparatus and ElectroMechanical Bench Reference are trademarks registered with the U.S. Patent O ce.

Or enter the URL directly:

https://bit.ly/JUN 24SALE

See page 74 for links to upcoming issues that you can bookmark.

Copies of articles in print or PDF format may be ordered from our Marketing Department (312)321-9440. Prices available on request. Libraries and companies registered with Copyright Clearance Center, 222 Rosewood Dr., Danvers, Mass. 01923, should send 75¢ per page copied direct to CCC.

Material also available in microform and CD-ROM from Pro Quest information service, (800) 521-0600 ext. 2888 (US) or 01734-761-4700 (International); https://www. proquest.com/.

Printed in the U.S.A.

CHARLIE

WWW.BARKS.COM CHARLIE@BARKS.COM

BARKS

4 ELECTRICAL APPARATUS | JUNE 2024

Earnings reports reveal steady, if slow, recovery

As quarterly earnings reports rolled in during April and early May, several major suppliers to the electrical industry reported that an ironing-out of supplychain kinks and a smoothing of di cult geopolitical currents were re ected in their gradually improving bottom lines.

Global electrical and automation supplier ABB reported April 18 that orders for the rst quarter of the year were slightly lower than the same quarter last year, while revenues were about even. Orders, at $8.97 billion, were 5% lower than the rst quarter of 2023, while revenues, at $7.87 billion, were e ectively unchanged. Gross pro t, however, was up 8%, to $2.94 billion. The rst quarter’s performance “shows the year has started o well with stronger-than-expected order momentum, record-high margin, and strong cash delivery,” said CEO Björn Rosengren.

Emerson Electric Co. of St. Louis, the industrial manufacturer and provider of engineering services, reported May 8 that net sales for its scal second quarter were up a whopping 17%, to $4.4 billion. President and CEO Lal Karsanbhai said, “Our second-quarter performance, especially our gross margin performance, demonstrates the strength of our transformed portfolio and our Emerson Management System” — a strategy introduced in 2022 that focuses the company on three “value-creation opportunities”: organic growth, portfolio management, and “operational excellence.”

Regal Rexnord Corp., the Milwaukeebased manufacturer of electric motors and power transmission components, having completed the sale of its Industrial Systems business May 1, reported May 6 that net sales for the quarter ended March 31 were $1.55 billion, for an adjusted gross margin of 36.5% compared with an adjusted gross margin for the same period last year of 33.5%. CEO Louis Pinkham described this as being “well on our path to 40%.” Automation & Motion Control net sales were $400.2 million, an increase of 96.9%, or a decrease of 4.5% on a pro forma organic basis. Net sales for Industrial Systems were $118.8 million, a decrease of 13.3%, or a decrease of 12.6% on an organic basis.

The steady growth in sales at Grainger continued, meanwhile, as the Chicagobased distributor of industrial products reported April 25 that sales for the rst quarter, at $4.2 billion, were up 3.5%

compared with the same quarter last year. Gross pro t, at $1.6 billion, was up 2.1%. “We’ve produced solid results amidst a slow but steady demand environment,” said D.G. Macpherson, Grainger’s chairman and CEO. “Looking to the remainder of the year, we are well-positioned to achieve our guidance outlook as we work to provide a awless experience and deliver tangible value for our customers.”

WEG Electric Corp., the manufacturer and provider of services in electric engineering, power, and automation, on May 2 reported “solid operating margins and return on invested capital” during the rst quarter. Net operating revenue, at 8 billion Brazilian reals (about $1.5 billion U.S.) grew 4.4% compared to the same quarter last year, up 6.5% in the domestic Brazilian market and 2.5% in the external market. “In Brazil,” the company said, “industrial activity has shown good results in some of the markets where we operate, with short-cycle goods, such as serial automation equipment and gearboxes, showing good demand distributed across di erent segments.”

French electrical manufacturer Schneider Electric on April 25 reported “strong demand dynamics across most sectors and geographies, particularly in data centers and infrastructure.” First-quarter revenues were €8.6 billion (about $9.2 billion U.S.), up 5.3% organically and up 1.3% on a reported basis. In North America — which accounted for 35% of the company’s rst-quarter revenue — revenues of €2.6 billion represented reported growth of 8.9%. According to the company, strong contributions to the quarter’s revenues came primarily from three regions: China, India, and the Africa and Middle East region.

Industrial automation provider Rockwell Automation of Milwaukee stumbled somewhat in the most recent quarter, reporting May 7 that sales for the second quarter of its scal year, at $2.13 billion, were down 6.6% year-over-year while organic sales slid 8.1% for the same period. Annual recurring revenue, however, was up 20% year-over-year, and acquisitions contributed 1.4% to growth. “There is more excess inventory at our customers, particularly machine builders, than we originally expected,” explained Rockwell chairman and CEO Blake Moret. “As a result, we are not yet seeing the accelerated order ramp this scal year and are reducing our full-year guidance.” Despite this lower outlook, he said, the company is gaining share across its most important product lines. — Kevin Jones

EA Business 6 ELECTRICAL APPARATUS | JUNE 2024

Let’s Solve Your Problem

How charges are affected by efficiency

Please explain how electrical demand may be influenced by the use of more efficient induction motors.

We understand that energy usage and kilowatt draw are reduced, but their relationship to the demand charge is not clear.

Although the newer electronic meters allow electrical demand to be measured in kVA, most utilities use kilowatts as the measurement. When motor efficiency goes up, motor power factor — which may either rise or fall with higher efficiency design — doesn’t influence demand measurement or demand charges, because they are not based on current but on power only.

If demand is measured in kVA instead, then what happens to demand can vary with the motor power factor. For example:

>Higher efficiency and higher power factor: Motor current drops, as do both energy usage and demand.

>Higher efficiency and lower power factor: Motor current may go up, go down, or stay the same. Energy usage will go down in any event; demand may or may not.

> Higher efficiency, without starting torque reduction: Means higher inrush current, which may lead to peak demand charges, depending on starting cycles.

Higher motor efficiency despite power factor

The overall power factor in our plant runs 99% to 100% because of capacitor correction. Some recent literature tells about improving power factor to gain higher efficiency.

We’re looking at replacing a 500 hp motor and could choose a higher-efficiency unit, but since our power factor is so high, it doesn’t seem that we would gain

anything by paying the higher price for that premium motor. What do you think?

A higher motor efficiency always means a direct saving in kilowatt-hours on your monthly energy bill. That saving will apply, at a given motor load, regardless of either the motor or the system power factor. A higher overall power factor means higher efficiency in the distribution system (lower losses in conductors, transformers, or switchgear); it has nothing to do with motor efficiency, or vice versa.

Additionally, if this is a low-voltage motor, the Dept. of Energy regulations may require it to be a premium efficiency motor and you won’t be able to purchase a new 500 horsepower motor. If the motor is medium voltage, there are no efficiency requirements.

Standard behind nameplate’s nominal efficiency

We understand the NEMA standard provision for marking motor efficiency on the nameplate. This is supposed to be a “nominal” efficiency, and there is a specific minimum or guaranteed value associated with it even though that minimum value may not also be on the nameplate. Some industrial customers have asked us about motors of theirs on which the nameplate efficiency isn’t identified as “nominal” and the number itself doesn’t agree with catalog information they’ve seen for the product. How can they tell what the nameplate efficiency really represents?

They can’t, which is why NEMA worded the standard (MG1-12.58) to require that efficiency be identified on the nameplate as “NEMA Nominal.” This wording completely ties down the method of efficiency determination.

The exceptions to this are small electric motors covered by the Dept. of Energy (1/4 –3 hp, single- and three-phase, NEMA two-

digit frames). These small electric motors will be marked with an average efficiency number as required by the DOE.

Without this phrasing, whether or not the value agrees with a catalog, no one can be sure what a nameplate figure means, or how accurate it may be.

If the efficiency on the nameplate and printed data are incorrect, the manufacturer may be in violation of DOE regulations on represented data.

Two-speed motor or adjustable-speed drive?

For a centrifugal fan load that runs most of the time at reduced flow, we’ve been told that an adjustable-speed drive could save a lot of power compared to a fixedspeed motor and damper control. This particular fan runs either at full flow or at reduced flow that would be the equivalent of about 55% full speed.

Wouldn’t a simple two-speed high-efficiency motor be just as effective, and at less cost?

A conventional variable-torque motor and two-speed controller may have a lower cost than the adjustable-speed drive. No efficiency standards apply to multispeed motors, however, so it may not be so easy to tell just what you’re getting.

Look closely at the energy usage both ways. Suppose the fan needs 50 hp at full speed. You would use a 50/12.5 hp motor. At half speed, the fan probably draws only about 7 hp.

So the 12.5 hp motor rating is supplying only 60% load. How will its internal losses at that load compare with a physically smaller — and less expensive — 50 hp motor running at 7 hp with the ASD?

Dept. of Energy studies show that a variable torque load will save 30% or more energy, so this is the best choice for long-term savings. — Edited by the EA staff EA

ELECTRICAL APPARATUS | JUNE 2024 7

Associations o er fresh training resources

School may be out for summer, but that doesn’t mean people looking to hone their skills in electromechanical repair need to let up on their search for knowledge and expertise. Two major associations on both sides of the Atlantic serving companies in electromechanical service have some fresh o erings for members who are looking to improve their skills.

To begin with, “An Introduction to Rewinding Electric Motors” is available as an online video from the U.K.’s Association of Electrical & Mechanical Trades. The video course — available to members only — costs £300.00 (about $375 U.S.) to purchase. Its purpose is to take the student step by step through the rewind process, ensuring along the way that best practices are adhered to while the integrity and e ciency of the machine isn’t compromised. Because the course is lmed, viewers can see “exactly how an experienced winder handles the machinery,” according to the AEMT. The course is intended for novices.

In the course, the association’s lead trainer, Karl Metcalfe, gives a detailed narration to describe what he’s doing, as he’s doing it. Metcalfe explains how a rewind can be completed using the best practice as outlined in the AEMT/EASA Good Practice Guide to Rewinding Electric Motors and in IEC 60034-23, The Repair, Overhaul and Reclamation of Rotating Electrical Equipment.

These are the highlights of the course, as described by the AEMT:

Essential Tools. “We start the learning process by recommending the tools needed to rewind an electric motor, not least a notepad and pen!”

Identifying a motor. “A guided tour of the motor, critical dimensions, and its nameplate data outlines the vital information needed to carry out a rewind.”

Best Practice. “The course guides learners with the best practices expected from an AEMT service center

Multi-angled video capture. “Shots of the rewind process have been recorded from multiple angles, providing an intimate and thorough learning experience.”

Expert support. “Members of the AEMT can access one-to-one bespoke technical support from our lead trainer before, during, and long after completion of the course.”

Another useful educational resource o ered by the AEMT — one designed for the more experienced as well as for newcomers — is the Hazardous Area (Ex) Repair Course, typically o ered twice per month, with some sessions online and others in person. The course consists of two separate presentations, one more general in outline and the other a refresher course. Inperson versions of this course are scheduled to be held over the next six

VISIT US @ THE EASA SHOW BOOTH 529

Associations

EASA SHOW SEASON SPECIALS Online Shopping Discount Code for Big Savings Specials on Select Industry Products Shop Equipment Savings TAILOR-MADE SOLUTIONS Warehousing Inventory Fabrication Service. Everything we sell is

everything you do.

— Illustration by Bing generative AI

in

ESSEX BROWNELL EASA SHOW SPECIALS Online Shopping Discount Code for Big Savings

on Select Industry Products Shop Equipment Savings 8 ELECTRICAL APPARATUS | JUNE 2024

Specials

A three-day structure begun in January of this year mixes experienced rewinders with newcomers. “The refreshers now have a whole extra day to ensure they are up to speed, and newcomers can network and learn with seasoned competent repairers,” the AEMT explains. The online version of the course gives the student the exibility to learn at his or her own pace. Like any other tool, this online educational resource from the AEMT is constantly being evaluated for possible improvement.

The AEMT is an IECEx-Recognized Training Provider, which means that its training complies with IECEx Unit 005. Members of the AEMT are entitled to ongoing technical support. More about the AEMT’s training resources may be found at www.theaemt.com/learn-with-aemttraining-academy.html.

Another association that’s constantly improving its training tools is the Electrical Apparatus Service Association, which announced in the April 2024 issue of its Currents newsletter that it was adding management content to its Online Learning Center, which already included many useful resources that we’ve described in Electrical Apparatus.

The nearly 30 hours of management training the association began rolling out April 1 consists of management courses “designed to hone skills that address today’s most critical business, management, and leadership challenges,” according to EASA. The training is the result of “steep discounts” negotiated with the American Management Association on behalf of EASA members, EASA says.

There are 80 sessions in the new management section of the Online Learning Center, each about 20 minutes in length. They are grouped as 34 courses along these ve tracks:

Analytical intelligence. Six courses including 13 lessons covering analytical thinking, creativity, innovation, decision making, managing data, and strategic thinking.

Introduction to business basics. Six courses including 13 lessons on customer focus, introduction to nance, becoming a “trusted advisor,” management projects, and the American Management Association’s Legal Guide for Managers and Supervisors and Diversity and Inclusion in the Workplace.

Professional e ectiveness. Eight courses including 24 lessons on numerous topics, including communication, con ict management, presentation skills, time management, and organizational politics.

Relationship management. Eleven courses including 24 lessons. This track covers topics that may be “softer” than such things as data management and nance but are no less essential to the management of a business, including techniques to in uence others, emotional intelligence, giving and receiving feedback, managing change, and creating a motivational climate.

Training and facilitation. Five courses totaling 103 minutes in length on such things as experiential learning, facilita-

tion skills for trainers, and the “ADDIE Model,” an approach to training whose acronym stands for “analyze, design, develop, implement, and evaluate.”

The new management training courses are available to EASA member companies that have a General Learning subscription and to students who have a subscription to the Electromechanical Repair Technician Certi cate Program. You can nd more about EASA’s training resources at https://easa.com/training. — Kevin Jones EA

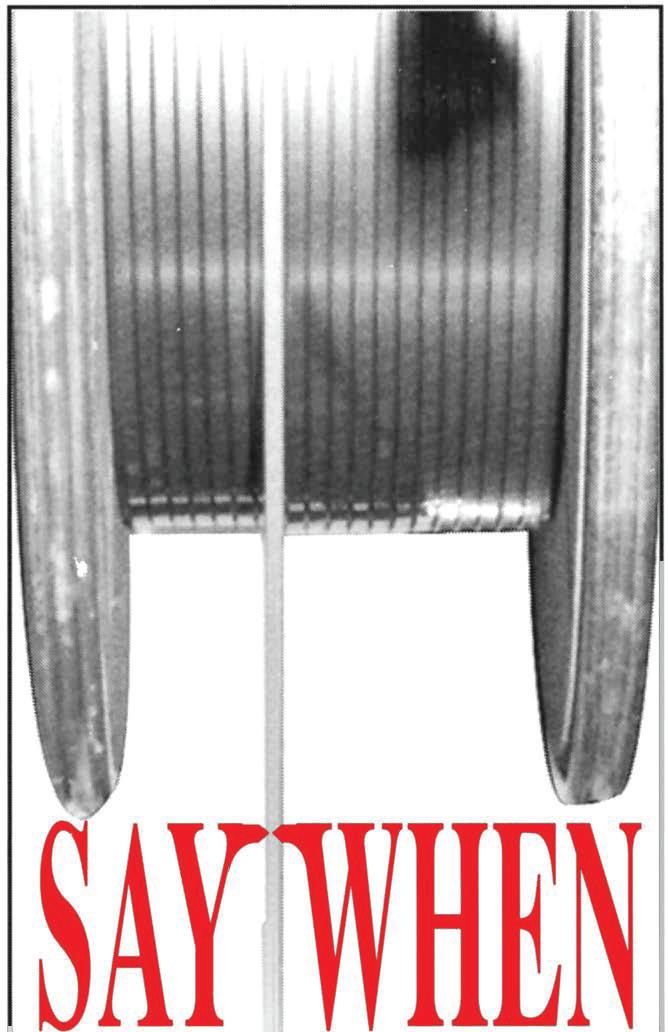

Electrical bearing damage causes unplanned downtime

Variable frequency drives (VFDs) are used to control pumping systems. But VFDs create a motor shaft voltage that discharges through the bearings, blasting millions of pits in bearing surfaces. Both motor and pump bearings are at risk. These discharges oxidize the bearing grease and cause bearing fluting, premature failure, and costly downtime.

Protect motor bearings with AEGIS® Shaft Grounding Rings

By channeling VFD-induced discharges safely to ground, AEGIS® Shaft Grounding Rings prevent electrical bearing damage. Proven in millions of installations worldwide, AEGIS® Rings provide unmatched protection of motors against electrical bearing damage, motor failure, and unplanned downtime.

1-866-738-1857 | sales @ est-aegis.com

Fluting Damage VFD-InducedShaftVoltages DestroyBearings! Destroy Bearings! See our shaft grounding case studies

resources

and

at: est-aegis.com/resources/case-studies

Booth 737 Visit us at EASA 22-176 Electrical Apparatus SGR Ad.indd 1 5/2/24 11:46 AM

ELECTRICAL APPARATUS | JUNE 2024 9

Know Your Industry

From telegraphs to STEM. STOP.

Institution of Engineering & Technology

Founded: 2006, merging many older organizations

Headquarters: Futures Place, Kings Way, Stevenage, Hertfordshire SG1 2UA, U.K.

Annual dues: Approximately $234.18 (£188 U.K.) for most memberships

Phone: +44 (0)1438 313311

Website: www.theiet.org

The story of the Institution of Engineering & Technology (IET) begins with a telegraph. Two practical electric telegraph models were invented and patented around the same time by Sir William Fothergill Cooke and Sir Charles Wheatstone of the U.K. and Samuel Morse of the U.S. The expansion of railroads in the U.S. led to the boom of new transportation networks using the telegraph. Back in the U.K., the telegraph grew in popularity, so during the latter half of the nineteenth century, telegraph engineers still had only two options for joining a scientific society: the Institution of Civil Engineers or the Institution of Mechanical Engineers.

Professional societies were the precursors of trade organizations. By 1871, the Society of Telegraph Engineers was founded to better meet the needs and technical standards of the industry — motivated in large part by Major Frank Bolton. Less than ten years later, with the increase of electrical services, the Society of Telegraph Engineers changed the organization’s name to the Institution of Electrical Engineers

Flash forward to 2006 and the IET is the official organization of the eventual merger of the Institution of Electrical Engineers and more than 35 other professional societies since the Society of Telegraph Engineers. There are 154,000 members from 148 countries with membership categories

Please turn to page 12

INTRODUCING:

William Fothergill Cooke and Charles Wheatstone’s electric telegraph (“needle telegraph”) from 1837, now in the London Science Museum. The Institution of Engineering & Technology can trace its lineage all the way back to technology of this type.

— Wikipedia photo

10 ELECTRICAL APPARATUS | JUNE 2024

ranging from member, technician member, associate, student, apprentice, to fellow.

Associate membership is reserved for those in a related field or anyone sharing a passion for engineering, while the Fellowship level is for the vanguard engineering professionals with at least five years of experience. International membership is divided into almost 100 local networks — the IET’s term for chapters — that make up the IET in the Americas, Asia Pacific, EMEA, and South Asia. The organization also holds offices in China, Hong Kong, India, and the U.S. outside of the U.K. headquarters.

Rebecca Gillick, external communications manager for IET, shared that member “benefits include support with professional registration to obtain chartered engineer status; networking and knowledge sharing via our many local and technical networks; access to leading publications, journals and archives, and our wide-ranging in-person and virtual events – many of which are filmed and available on demand to our members.”

These events cover everything from educational courses to conferences. Back in May, two notable IET events that took place were the Electrical Safety Management Training Course and the ACDC Europe AC and DC Power Transmission European Industry Symposium in the Netherlands. While it did not include the band AC/DC performing, the conference hosted two days of technical programs on the latest transmission innovation and research. Twentythree industry experts presented on topics like grid development, policy, and the high-voltage d-c supply chain. The ACDC Europe Symposium’s sponsors included some familiar names in the electric motor industry, too.

IET members also benefit from a global network of engineering resources. The main website connects members to the IET digital library and the IET library and archives, which is “a purpose-built repository housing core collections and the rare books libraries,” according to the website. Many of the archive materials preserve the history of science and technology.

The most notable of the archive collections is the Faraday Collection, consisting of “notebooks, correspondence, and manuscripts covering [Michael Faraday’s] travels in Europe with Sir Humphry Davy, his chemical notes, and some 600 letters from many famous names in science and current affairs,” according to an online catalog.

Outside of membership benefits, IET provides educational resources and support for the next generation of STEM professionals. The organization offers funding for FIRST LEGO League and free curriculum resources for teachers of STEM students, aged four to nineteen. For college students, the IET educational support extends to undergraduate programs. More than 1300 undergraduate programs in the U.K. have IET accreditation.

The STEM encouragement efforts are most visible in the IET campaigns. Gillick said that IET runs a variety of campaigns aimed at “promoting equality, diversity, and inclusion across the engineering sector and inspiring the next generation of engineers and technicians.” She highlighted the annual “Engineer a Better World” campaign, with its competition focused on children four to thirteen submitting designs to a themed engineering topic.

All the strides made by IET show how far the organization has developed since the early days of the Society of Telegraph Engineers, now encapsulating a wide variety of engineers. So, in honor of its beginnings, the most fitting end to this look at the Institution of Engineering and Technology can only be this homage to the telegraph message: STOP. — Kristine Weller EA

KNOW YOUR INDUSTRY continued from page 10 12 ELECTRICAL APPARATUS | JUNE 2024

Recent initiatives in electric grid cybersecurity

As the technology we daily rely on becomes more sophisticated, so too does the methodology of the people who want to rip us off or otherwise do us harm. Nowhere is this more evident than in the electric utility industry, an enormous national target whose vulnerabilities cyber criminals are constantly trying to exploit.

According to the North American Electric Reliability Corp., the number of points in electrical networks vulnerable to attack is increasing at a rate of about 60 per day, making the job of cyber security an endless game of whack-a-mole. “It’s very hard to keep pace with addressing all those vulnerabilities,” Manny Cancel, senior vice president of NERC, told Reuters in April.

Hacking attempts on the U.S. grid appear to be accelerating, and geopolitical events are only contributing to the increased rate. “Geopolitical conflict, including Russia’s invasion of Ukraine and the war in Gaza, have dramatically increased the number of cyber threats to North American power grids,” Reuters said. Threats from China also appear to be on the rise.

Remember a couple of years ago when people were taking shots at utility substations and committing other types of vandalism? That’s still going on, although we may not hear about it as much as we did back then. Assaults on the grid have remained high since 2022, with about 2,800 reports of gunfire, vandalism, and other attacks on electrical networks last year, according to the North American Electric Reliability Corp.

Despite the continuing high rate of cyberattacks — or perhaps because of it — electric utilities still “face serious difficulties in finding and retaining the skilled professionals needed to defend themselves,” according to a report published last year by Marc Casanovas and Aloys Nghiem of the International Energy Agency, an energy forum comprising 29 industrialized countries under the Organization for Economic Development and Cooperation.

While digital technologies improve energy security in some ways, they also introduce the risk of new entry points for cybercriminals, Casanovas and Nghiem warned. “Recent cyberattacks in the electricity sector have disabled remote controls for wind farms, disrupted prepaid meters due to unavailable IT systems, and led to recurrent data breaches involving client names, addresses, bank account information, and phone numbers,” they said.

Cyberattacks are often followed by spikes in demand for cybersecurity professionals. This suggests that utilities aren’t adequately planning ahead for future attacks, Casanovas and Nghiem said. Once utilities hire cybersecurity professionals, the utilities often have difficulty retaining them, because salaries for such specialists in the utility industry lag other sectors, such as finance and insurance.

To solve this problem, Casanovas and Nghiem argue, utilities need to make cybersecurity a “core element of their business strategy.” Regulators and other policy makers need to be involved too, working with utilities in a coordinated way in order to reach desired outcomes.

Now we’re seeing indications that such coordinated efforts are underway.

The U.S. Dept. of Energy‘s Office of Cybersecurity, Energy Security, and Emergency Response announced in late March that it has earmarked $15 million in funding to establish six university-based electric power cyberse-

Utilities

14 ELECTRICAL APPARATUS | JUNE 2024

— Illustration by Bing generative AI

curity centers “that will foster collaborations across the energy sector to address gaps in energy security research and provide cybersecurity education programs.”

Each university will work with energy sector owners and operators, vendors, and national laboratories to conduct cybersecurity research and develop training “that will meet the needs of the energy workforce in their regions,” according to the announcement.

The partner universities are: the University of Connecticut at Mans eld, Iowa State University of Ames, the University of Pittsburgh, the Illinois Institute of Technology of Chicago, Texas Tech University of Lubbock, and Florida International University of Miami.

The idea behind the funding is to help each university’s cybersecurity center tailor its research to t the needs of its region. “Their research will combine multidisciplinary expertise, such as power system engineering and cybersecurity, to nd solutions that will reduce the risk of power disruption resulting from a cyberincident in an energy delivery system,” according to the DoE.

While each university is being encouraged to explore how it can tailor its research to t the needs of its particular state or region, the universities are also looking at ways to produce results that can be more broadly applied. Iowa State University, for example, plans to investigate real-time cyber situational awareness for distribution management systems. The University of Pittsburgh plans to use digital twins to evaluate the e ectiveness of protections against cyberattacks.

The University of Connecticut announced April 9 that it would soon launch the Northeast University Cybersecurity Center for Advanced and Resilient Energy Delivery, or CyberCARED. The Center’s mission: to “simultaneously grow the U.S. cyber workforce and build the expertise we need to take on the evolving cyber threats to our nation’s energy systems,” according to Puesh Kumar, director of the Dept. of Energy’s O ce of Cybersecurity, Energy Security, and Emergency Response.

In addition to conducting research and developing training programs, UConn’s cybersecurity center will engage in “highlevel research to further development of new tools for the energy sector that consider the distinctive characteristics of the northeast’s electric system and infrastructure network,” according to the university. — Kevin Jones EA

Come see YOUR SENIOR PARTNER! TM EASA BOOTH 645! AKARD FAMILY OWNERSHIP SINCE 1993 Experts consistently delivering ACTually CERTIFIED COMPLIANT! TM Commutators & Slip rings BACKED BY SCIENCE! TM at competitive prices... with exclusive ACTion! TM 24-7-365! TM by literally the longest continuous management/ownership of any domestic commutator & slip ring manufacturer! 645 Like ACT AKARD COMMUTATOR of TENNESSEE ACTion@commutator.expert • 1-800-889-ACTion! ( (2284) • FAX: 1.800.891. ACTion! WHEN YOU KNOW THE DIFFERENCE! TM See ACT’s latest video! Copyright © 1993 - 2024 ACT MANAGEMENT, Inc. Dba AKARD COMMUTATOR of TENNESSEE ( ACT ) ALL RIGHTS RESERVED

ELECTRICAL APPARATUS | JUNE 2024 15

less than REEL Quantities Very REALISTIC Prices UNREAL Delivery Times

•Bare, Glass, Enamel, Kapton and Mica Insulation

•Multiple Glass/Kapton Serving Machines

•Copper, Aluminum, and hollow conductor

•Same-Day Capabilities

• Complete inventory online at www.swwireco.com

America's Premium Wire Service

P.O. Box 2517 45 Progress Avenue

Cranberry Township, PA 16066

800.635.8467 Toll Free

724.772.0049 Phone

724.772.0052 Fax

412.585.4936 Cell Phone

E-mail: mark@swwireco.com Website: www.swwireco.com

Calendar

Update your calendar with these upcoming trade shows, conferences, and other events.

• June 22-26, 2024 — 2024 ASHRAE Annual Conference, JW Marriott Indianapolis, Indianapolis, Ind. American Society of Heating, Refrigerating and AirConditioning Engineers, www.ashrae.org/ conferences/2024-annual-conference-indi anapolis.

• June 23-26, 2024 — EASA Convention 2024, Caesars Forum and Harrah’s Casino Hotel, Las Vegas, Nev. Electrical Apparatus Service Association, https:// easa.com/convention.

• June 24-27, 2024 — Hydraulic Institute 2024 Technical Meeting, Portland Marriott Downtown Waterfront, Portland, Ore. The Hydraulic Institute, www. pumps.org/event/2024-technical-meeting.

• August 7-9, 2024 — Safety 2024 Conference & Expo, Henry B. Gonzalez Convention Center, Denver, Colo. American Society of Safety Professionals, https:// safety.assp.org.

• August 7-9, 2024 — NSPECon24, Raleigh Marriott Crabtree Valley, Raleigh, North Carolina. National Society of Professional Engineers, www.nspecon.org.

• September 9-14, 2024 — IMTS 2024, McCormick Place, Chicago. International Manufacturing Technology Show, www. imts.com.

• September 15-17, 2024 — EGSA Fall Conference, Hyatt Regency Bellevue, Bellevue, Wash. Electrical Generating Systems Association, https://egsa.org/Events/ Future-Conferences.

• September 15-18, 2024 — Power 2024, the Madison Hotel, Washington, D.C. American Society of Mechanical Engineers, https://event.asme.org/power.

• September 19, 2024 — Golf Day 2024, Portal Golf & Spa Resort, Tarporley,

Cheshire, U.K. British Pump Manufacturers Association, https://bit.ly/BPMA-golf day.

• September 25-27, 2024 — AEE World Energy Conference & Expo, Music City Center, Nashville, Tenn. Association of Energy Engineers, https://aeeworld.org.

• October 7-10, 2024 — The Battery Show North America, Huntington Place, Detroit, Mich. The Battery Show, www.the batteryshow.com/en/home.html.

• October 9-11, 2024 — IFMA World Workplace 2024, Henry B. Gonzalez Convention Center, San Antonio, Tex. International Facility Management Association, https://worldworkplace.ifma.org.

• October 15-17, 2024 — Fabtech 2024, Orange County Convention Center, Orlando, Fla. Fabtech Event Partners, www.fabtechexpo.com.

• October 28-30, 2024 — Offshore Windpower Conference & Exhibition, Atlantic City Convention Center, Atlantic City, N.J. American Clean Power Association, https://cleanpower.org/offshore-wind power.

• November 21, 2024 — AEMT Awards 2024, Doubletree by Hilton, Coventry, U.K. Association of Electrical & Mechanical Trades, www.theaemt.com/ems-event-cal endar/aemt-awards/categories.html.

• February 10-12, 2025 — AHR Expo, Orange County Convention Center, Orlando, Fla. The Air-Conditioning, Heating, and Refrigeration Institute, www.ahrexpo. com.

• July 19-22, 2025 — EASA Convention 2025, Gaylord Opryland Resort and Convention Center, Nashville, Tenn. Electrical Apparatus Service Association, https://easa.com/convention/future-easaconventions. EA

Edited by Kevin Jones

The Portland Marriott Downtown Waterfront hotel, site of the Hydraulic Institute’s 2024 Technical Meeting June 24-27, is a short walk from Portland’s scenic Willamette River.

— Marriott International photo

The Portland Marriott Downtown Waterfront hotel, site of the Hydraulic Institute’s 2024 Technical Meeting June 24-27, is a short walk from Portland’s scenic Willamette River.

— Marriott International photo

16 ELECTRICAL APPARATUS | JUNE 2024

If a breakdown happens out of business hours, you can rely on Bartlett Bearing Company, Inc. to provide 24/7 bearing support with seven fully stocked locations, unbeatable customer service, and an experienced, knowledgeable team. Our competitive pricing and 24/7/365 availability mean we are dedicated to being your go-to bearing distributor.

INDEPENDENT AUTHORIZED BEARING DISTRIBUTOR bartlettbearing.com | 800-523-3382 | sales@bartlettbearing.com Philadelphia, PA | Gastonia, NC | Hebron, KY | Pelham, AL | Tampa, FL | Grain Valley, MO | Las Vegas, NV ON-THE-SHELF

INVENTORY FROM COAST

EXPERIENCE DEPENDABILITY BOOTH 809 | SUPPORT | TO COAST

Names & Faces

The Manufacturing Institute — the workforce development and education affiliate of the National Association of Manufacturers — announced that Sarah Dale, plant general manager at International Paper, has been recognized for a 2024 Women MAKE Award.

This annual national awards program honors women “who have demonstrated excellence and leadership in their careers and represent all levels of the manufacturing industry, from the factory floor to the C-suite,” according to TMI.

“I was delighted to be selected for the Women MAKE Award,” Dale said. “For the organization to take time, which is in short supply, to consider me for this notable award, was a treasure, but then, for an external group to review my nomination alongside impressive leaders and recognize my work — I am honored.”

Eric Gudino, formerly security supervisor at Applied Signal Technology, has been appointed vice president of security at Fornax Advanced Materials, a developer of advanced materials for defense and aerospace applications.

The U.S. Navy veteran will lead a team of security professionals at Fornax-AM and manage the company’s security program, the Chicago-based company said.

“He brings a wealth of experience in managing and overseeing the execution of industrial security programs at the highest levels of classification,” said John Havermann, president and CEO of Fornax-AM. “Considering the nature of his military and industry experience, he appreciates, firsthand, the pre-eminence of the security function and compliance to the strategy and values of our company.”

Gudino brings decades of experience in protecting sensitive national security data, critical infrastructure and company assets.

Fargo, N.D., electrical distribution company Border States announced the retirement of CEO David White, effective March 31.

White began his career in the electrical industry with a degree in engineering from Ohio University and roles with Cooper Industries (now Eaton) and Square D (Schneider Electric) before joining the team at Shealy Electrical.

During his years with Shealy, White worked alongside leaders, including Bill DeLoache and Brent Spear, as the family-owned company grew into 17 locations in North and South Carolina, conducting business both in the U.S. and abroad.

With White’s retirement, Jason Seger, president at Border States, took on the role of CEO.

“Like most, I found the electrical distribution industry by accident, and I’m so glad I did,” White said. “Along the way, I’ve had the opportunity to learn from so many in the industry who were willing to share their knowledge and experience. I’ve had the privilege to work for great companies and develop lifelong relationships with teammates, customers, vendors, and distributors. The future of the electrical distribution industry is bright, and I have confidence in Border States and Jason’s leadership.” — Charlie Barks EA

Doug Moore, industry leader and former chairman of EASA

Craig Douglas “Doug” Moore, 62, died in Georgetown, Ky., on Jan. 21, Electrical Apparatus has learned.

He was born to the late Charles and Barbara Riddell Moore on Feb. 27, 1961, in Lexington, Ky. His father founded Kentucky Service Co. in 1968 with Ronald Riggs, and Doug would later go on to operate and own the company from 1990 through its acquisition by HECO of Kalamazoo, Mich., in May 2021.

Mr. Moore served as International Chairman of the Electrical Apparatus Service Association from 2014 to 2015 and dedicated twenty years to EASA’s Technical Education Committee. In 2021, EASA presented him with the Exceptional Achievement Service Award. His influence on the electromechanical industry is evident in the nomination letters for the award; one letter commended him as “one of the giants in the industry, and [he] deserves the recognition this award would bestow, for all of EASA has been able to benefit from this great leader and communicator.”

Mr. Moore married Mary McBeath in the late 1980s. He is survived by his wife and by his daughter, Margaret Moore. Outside of EASA, Doug enjoyed woodworking and spending time with his family and dogs. As another colleague said in Doug’s 2021 nomination letter, “When I think of my friend and EASA leader, three words come to mind: committed, passionate, and proficient.”

Funeral services took place on Jan. 26 of this year. Memorial contributions in Doug’s name can be made to the Scott County Humane Society in Georgetown, Ky. — Kristine Weller EA

One letter recommending Mr. Moore for the award said that ‘all of EASA has been able to benefit from this great leader and communicator’

David White

Sarah Dale

David White

Sarah Dale

Deaths

Past EASA chairman Gary Byars (left) presented the 2021 Exceptional Achievement Service Award to Doug Moore during the association’s convention in Fort Worth, Tex., that year. — EASA photo

18 ELECTRICAL APPARATUS | JUNE 2024

Foodie adventures

For Krista DeSocio, there’s nothing more satisfying than bringing happiness to others with food lovingly made

By Colin Gregory-Moores, EA Contributing Writer

You might know Krista DeSocio from her bright presence at the ICC International booth during the annual conventions of the Electrical Apparatus Service Association. As the company’s director of marketing, she works closely with all lines of the business — sales, production, and even HR.

What you may not know is that she has a passion for cooking. As an only child, Krista grew up cherished and loved by her parents and grandparents in a small Mountain State town, which was almost heaven. Her conversation is interwoven with suncaressed and lovingly spun gossamer memories of childhood and growing up: spending summers at her grandparents’ riverside cabin, running around barefoot, and oating on the river in a pink paddle boat, watching the orange-bellied sunnies darting in the water. Collecting badges and patches for good deeds around the neighborhood as she progressed

from being a Daisy to a Brownie and then a Girl Scout. Tap dancing and cheerleading, rhythmically twirling and throwing the baton into the skies. Intuitively, Krista has always known that life, without any guarantee of tomorrow, is that one chance you get to let yourself be the person you want to be.

The ingredients for Krista’s love of bringing people together and serving good, wholesome, and soulful food come from childhood. Cradled in the warmth and avors of her southern grandmothers’ kitchens, she would learn to make food from scratch: from baking savory biscuits, cooking up chicken and noodle soup with homemade stock, to cleaning and frying fresh sh. “I still make a lot of their recipes to this day,” she says. “It’s comfort food for your heart and your soul.”

Later, when she started combining food and traveling, Krista got to see how celebrating life and companionship around the table — which had always been important to her — is done throughout the world. “I really found out so much about people, and their cultures, and the history of food, and I fell in love with all things food,” she says. Something clicked. From having been a picky eater as a child, she lost her fear

Feature | EA Reader Profile 20 ELECTRICAL APPARATUS | JUNE 2024

of trying out new things. She laughs, “What’s one bite? How terrible could it be?” Now she was fearful of missing out on something wonderful. “Touching the ingredients, feeling them come together, and then being able to serve someone, getting to visit another country is a moving thing for me,” says Krista. “It makes me happy.”

Cooking was something that Krista enjoyed, but it was not, however, something that she envisaged making a living at. Born in 1980, she says that “food and cooking was not as hip as it is now.” She studied media studies and mass communication at Frostburg State University in Frostburg, Md., from 1998-2001 before moving to Knoxville, Tenn., where she has a successful career spanning some 22 years

Please turn to next page

Baking pastries in an industrial burnout oven

Who knew that you can use a burnout oven to bake delicious Nutella turnovers? Scan the QR code above to watch Krista DeSocio of ICC International do just that, in a demo made just for Electrical Apparatus readers. If you want to try this in your shop, you’ll need pu pastry, Nutella, an orange, confectioners’ sugar — and probably permission from your shop foreman. You can follow Krista’s food blog at desociointhekitchen.com.

Value Engineered Pump Parts

—

•Mica Undercutting Saws &Rotary Burs in H.S.S. & Solid Carbide •Commutator Undercutters • Hand Tools TOOLSFORELECTRICMOTORMAINTENANCE •Test Equipment • Electric Etchers • Blowers •Demagnetizers • &So Much More PH. (216) 521-8567 Fax (216)521-9476 Website: www.martindaleco.com E-mail: sales@martindaleco.com 4-1/2 W. x 4-7/8 H. (1/3 Page) ABRASIVES &COMMUTATORGRINDERS: OTHERPRODUCTS&SOMUCHMORE: Since 1913 Cleveland, OH. CUTTING &HANDTOOLS: •Commstones • Brush Seaters •Rubrite Flexible Abrasives •Contact Cleaning Flex Files •Diamond Spatulas PO Box 28 Morris, NY 13808 607-263-5959 chris@ht-pumps.com

Video by Krista DeSocio

See us at EASA, Booth #545

ELECTRICAL APPARATUS | JUNE 2024 21

in TV production and marketing. “Putting together a show that takes an idea and brings it to fruition is just . . . .” She breaks off, unable to capture that one word expressing her love of TV production, and her enjoyment of being both in front of and behind the camera.

Refining the ingredients of success

At one point, her production skills and cooking started to come together, as if it were always meant to be. Encouraged by her family and friends, she went beyond her own four walls and reached out to the world with

her food blog. People found that they could immediately relate to her. “It was clunky at first, and the photos were terrible,” she recalls. “I cringe; I don’t know why anyone stuck with me.”

Krista has always shot her photos and films using an iPhone. The images, however, became perfect once she invested in props and equipment to improve the depth and lighting. Then the sky was the limit. Things just started snowballing once she had gotten into a rhythm. On her food blog and Instagram, her followers grew to 6,000. Krista’s aim was never to put quantity over quality. It was always to have people who engage with what she is doing. The level of viewer engagement on her Instagram is particularly high, which is an important parameter for brands.

Once she started her food blog, she had to face the challenge of developing her own point of view and finding an audience. Besides consistency, this, of course, takes patience. Eventually, Krista found her voice. Her blog and videos communicate that universally relatable feeling of dropping by a good friend or neighbor for coffee and a chat, and to share a recipe. It’s a magical atmosphere infused with memories of the warmth and flavors of her grandmothers’ kitchens, and her mother’s empathetic kindness, and with the southern-belle authentic charm and wit of Krista herself. She makes it all look so natural and as easy as pie.

With her blog, Krista serves and accommodates a broad range of followers, from those with culinary experience to those starting from scratch. Particularly, for the latter, she wants to show that food does not have to be complicated to be delicious and can be fun too.

Your Universal Servo Motor Test Station! NEW Developments in Technology, Training, and Support! Mitchell Electronics, Inc. Athens, OH 740-594-8532 sales@mitchell-electronics.com www.mitchell-electronics.com Manufacturer Support List Continues to Grow... Allen Bradley. B+R. Baumuller. Berger Lahr. Bosch/Rexroth/lndramat. Elau. Fanuc, Heidenhain, Kawasaki, Matsushita, MFE, Mitsubishi, Nachi, Sanyo Denki, Sick Stegmann, Siemens, Sumtak, Tamagawa, Yaskawa, and many more ..

Please turn to page 24 EA READER PROFILE continued from previous page 22 ELECTRICAL APPARATUS | JUNE 2024

Krista (left) behind the scenes on set in 2023. — Krista DeSocio photo

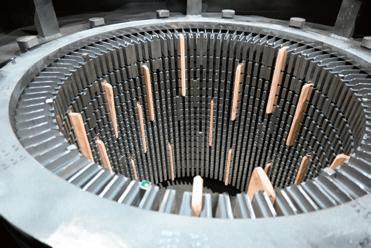

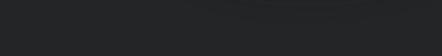

Founded in 1973, by Bob Ross, Jasper Electric has provided quality motor and rotor repair by being on the cutting edge of technology and using high-quality materials, such as Ml 9 electrical steel. Handling large and small motors alike, we are the future. We have almost every tool needed to repair or rebuild your rotor and stator. Most motors we repair will run as efficiently if not better than when they were new from factory. Our personnel allow us to work smoothly while giving our customers a peace of mind.

JASPER ELECTRIC MOTORS INC.

Core Loss & 15' VPI

, 300 KVA 20 HP to 10,000 HP

• Computer printout sent with eidl .klb

, Water stripping for fmn v.ound stators

, Full rewindwith 15ftVPI available

, 1 HP to 10,000 HP

• Infrared hot spot check on each job

• Quality core loss report with each job

, Loop testing for 10,000 HP+ stator cores

Motor Load Testing Laminations

Pole pieces (laser cut)

Load test up to 1500 HP A(. 925 HP

Voltage test up to 7200 volts A(, 600 volts DC

, Run test as long as necessary, 7500 HP

, Government and utility approved

• Synchronous motor testing

, Computer print-out with efficiency rating

Any size or thickness

•Emergency pick-ups

, Emergency deliveries

, Segment or whole

• Estimate over the phone

• On-site quotes and repairs

• Stacked in your housing, spider/shaft or shipped loose

New Rotors

• All copper alloys to match conductivity

, Normal turnaround 15-24 Days

• In house aluminum and copper extrusion

, R.O.T. Available

Codi- . ·1 D ,.. , _ ic ... 1, ,,.., ::__ ------· ) .., , ;.co,� Ce- ·e�.r/ �) .Ji •. -=--- __J ---=-__J

The Electro,Mechonlcol Authority

Cores• Fiber Optic Laser Cutting• Large Machine Shop• Water Jet• Loose Lams

& Armature

,

•

•

,

•

Full 4-Hour load test available or until

Punch or laser cut temperature stabilizes

DC

,

I TWO SERVICE LOCATIONS! Box 1494 • 175 Curry Hwy•Jasper AL 35502 205-384-6071 • Fax 205-384-6073 jemi@bellsouth.net 0 22673 Hand Rd • Harlingen • Texas 78552 /-, 1 956-421-2446 • Fax956-421-3616 �m/ info@newcoreinc.com , R.D.T. Available

NEW CORE INC. newcoreinc.com G FACEBDDK.CDM/ NEICDREINC Gt IN STAG RAM.COM/ NEICDREINC Majority woman-owned busines

Everyone is invited to go with Krista on what she describes as her “foodie adventures.” It’s the call to have the courage to try something new, whether that is eating food, making food, growing food, or learning about food. Using obtainable ingredients to create recipes that are attainable and inclusive, she shows that cooking can be a relatable and welcoming experience. To this end, Krista employs a blend of American and European or Asian cuisine. “If you can do a fusion, the recipe might seem more achievable,” she says. “And, honestly, I just like being creative in the kitchen and seeing what’s going to work out.”

Food Network comes knocking

Once her food blog started to take off in 2019, a casting agent reached out to her on Instagram to ask if she would like to be a contestant on Food Network’s “Grill of Victory.” Krista was ecstatic. Since she was 16, it had always been her “pie-in-the-sky dream” to be on Food Network. She would watch Emerald Lagasse, Sandra Lee, and Rachael Ray and say to herself, “I want to do that so bad,” although she would never tell anyone. Krista went through a roller-coaster two months of auditions and was accepted. Then Covid happened. The production date was pushed back, and the show with Krista did not air until mid-2022. She jokes, “For years, I am sitting on this, I am on Food Network, and I can’t tell a single person.” She is now on the newsletters and e-mails of various casting companies, and her next “pie-in-the-sky dream” is to become a TV cook. “That would be amazing,” she enthusiastically laughs. In addition, Krista is a food stylist for various brands. This all began when a producer, searching for a stylist for a famous American whiskey, reached out to her. Krista thought, “That looks pretty. I can do fun garnishes.” Her triadic dream came true, combining her love of cooking, TV production, and art. When she is making food images for her blog, she wants the images to be indicative of what the food will look like and not overly styled. When she is styling for a print or TV advertisement, she augments the look of the food or beverage. In a world of competing images, there needs to be a certain level of immediate mouth-watering aesthetic appeal. As the adage goes, we eat and drink with our eyes first.

Krista DeSocio’s food advice for people on the go

> It’s best to meal prep and plan ahead on Sunday for the week.

> Avoid going to business lunches ravenously hungry

> All foods have value in moderation.

> Be mindful of what and how much of a thing you are eating.

> Include proteins in meals for satiety

> Go easy on the carbs, as they’ll make you sleepy.

> Pair carbs with proteins to reduce spikes in blood sugars.

> Pack your bags with on-the-go healthy protein snacks with really low sugar.

> Carefully read food labels.

> Don’t be afraid to combine home-cooked food with pre-cooked food from a restaurant or a store.

> To save time, think about buying an air fryer or slow cooker. — CGM

Close to Krista’s heart are her social activities in the local community. “It makes me sad that there are so many people, especially children in this world, whose basic needs of food are not met,” she says. She uses her platform as a way to give back to the community that has been supportive of her. Whenever she can, she helps her local Second Harvest Food Bank by supporting their fundraising events, raising awareness, and volunteering.

Krista’s “foodie adventures” are journeys in faith, familial love, friendship, and fellowship, as well as in unwavering support from her employer ICC International of Maryville, Tenn. For there is, perhaps, nothing better under the sun except to eat, drink, and enjoy in the company of others, and these memories will accompany us throughout all the days we have been given. EA

EA READER PROFILE continued from page 22 24 ELECTRICAL APPARATUS | JUNE 2024

Improving EV accessibility

Addressing the challenge of providing charging options for multi-unit dwellings

By Maura Keller, EA Contributing Writer

As electric vehicle technology continues to sweep the nation and grab the attention of manufacturers, policymakers, and consumers alike, one thing is evident: There is a distinct accessibility issue facing the EV industry. From charging infrastructure to a ordability to policy support, EV accessibility is proving to be a multifaceted challenge that needs to be addressed for the technology to reach the next level.

Elaina Farnsworth, co-founder of SkillFusion, a customer success platform for electric vehicle service equipment operations and maintenance (O&M) providers, says “in order to have EVs, you have to be able to charge them. The United States government is mandating that in the next few years, there will have to be a 97% uptime for the charging stations themselves. That means they’ll have to be available and working 97% of the time. The challenge is that in the U.S. right

now, the uptime is only 40% to 60%. We need to do better.”

SkillFusion’s approach provides charger-agnostic skill enhancement and certi cation, creating a proprietary database of certi ed workers available to service the country’s growing EV charger network. The program developed by SkillFusion covers the full spectrum of skills needed to support charger operations, including licensed electricians and technicians specializing in technical support, networking and communications, cybersecurity, and more.

Multi-family dwellings

Farnsworth says one of the biggest, less talked about challenges the EV market faces lies within a subset of the market that lives within multi-family dwellings or apartment buildings. Consumers face

Please turn to next page

Feature | Electric Avenue

ELECTRICAL APPARATUS | JUNE 2024 25

Elaina Farnsworth

challenges in the ability to charge at home – whether that be at an apartment building, townhouse, or condo – with additional limitations of availability to charge at the workplace.

“Electrical utility service upgrades at multi-unit complexes are costly and engulfed in red tape from planning and permitting with new codes and standards that have to be enforced upon the owners (such as ADA requirements),” Farnsworth says. In addition, availability of EV chargers at multi-unit housing complexes are limited due to cost of utility upgrades required for installations. As Farnsworth explains, property owners and property management companies are reluctant to allocate funds for multiple parking stalls.

“However, it has been proven that apartments and complexes with allocated EV charging spaces rent easier and quicker than complexes without dedicated spaces for EV charging,” Farnsworth says.

The challenge the automotive industry is overcoming is offering EV and hybrid vehicles comparable in purchase price, says Steve Christensen, executive director of the Responsible Battery Coalition (RBC). “As battery costs continue to decline, the purchase price of EVs and hybrid vehicles will decrease accordingly,” he says.

Christensen points out that the automotive industry needs to communicate better the cost of ownership between internal combustion, hybrid, and EV. The RBC recently supported landmark research from the University of Michigan that examined the cost of owning the three types of vehicles and found that hybrid vehicles might have a higher purchase price than internal combustion but reach cost parity with internal combustion cars within a few years as a result of the savings in fuel expenses.

From a cost and affordability perspective, there are undoubtedly challenges that have emerged for lower-income individuals considering purchasing EVs. A new EV costs more than a new similar internal combustion engine vehicle. Additionally, buying a used EV isn’t always a good option because there aren’t many available and by the time an EV is over five years old, its battery life is significantly lower, resulting in the need to purchase an expensive replacement battery.

The federal government also has attempted to bridge the cost gap by offering tax credits. In January of this year, the Clean Vehicle Tax Credit was introduced. This credit, which is available as an instant rebate at approved car dealers, offers up to $7,500 toward a new electric, hydro-

gen, or plug-in hybrid vehicle, and up to $4,000 for a used one. Those who are striving for EV equity said this new tax credit will put buying an electric vehicle within reach of more buyers from various income levels.

Offering targeted subsidies and tax incentives for lower-income households can significantly reduce the up-front cost of EVs. These financial incentives should be designed to be easily accessible and substantial enough to make a real difference to potential buyers at the lower end of the income spectrum. With the recent introduction of the instant tax credit rebate on EV purchases, many owners found easier access to savings. And when state and local governments add to these rebates, low-income buyers will have more ability to purchase an EV.

Infrastructure needs

To further close the gap, property owners, property management companies, electrical utilities, and building and local AHJ [authority having jurisdiction] municipalities need to come together with a plan that expedites EV charger implementation within a fast-track mechanism. A key concern for potential EV owners from all income levels is the availability of charging stations. Investing in widespread, accessible charging infrastructure, particularly in low-income and rural areas, can alleviate one of the significant logistical barriers to EV ownership.

“There are also two types of interventions that can help increase EV accessibility so that all Americans can benefit from the electrification transition,” Farnsworth says. “First, design and implement educational programs for schools, colleges, and workforce development centers towards the imminent nationwide auto electrification. Secondly, enforce EV Evening ‘Time of Use’ reduced cost for home charging by utility companies making cost of EV ownership desirable and affordable.”

Experts also agree that it is imperative that the knowledge gaps about the benefits and feasibility of EV ownership that can hinder adoption be addressed. Educational campaigns and community

— Manuel Schmid / Shutterstock photo

Steve Christensen

26 ELECTRICAL APPARATUS | JUNE 2024

ELECTRIC AVENUE continued from previous page

programs can raise awareness about the long-term cost savings, environmental bene ts, and available incentives for owning an EV. Businesses should be encouraged to o er EVrelated bene ts – such as on-site charging stations or lease assistance programs, which can make EV ownership more feasible for various income levels.

And EV manufacturers can o er their vehicles as a subscription-based service. This was done in the U.K., where the Electric Vehicle Experience Centre partnered with local organizations to o er access to electric cars on a pay-as-yougo basis. This type of initiative allows low-income buyers to experience EVs without the long-term nancial commitment of EV ownership.

There is a lot of work that still needs to be done to prepare dense urban areas for the EV transition. For example, Farnsworth says necessary upgrades of utility transformers are holding up projects for up to nine months from completion of the project to being operational. This is made more complicated with policies and plans for utility infrastructure upgrades not fully aligning with EV implementation forecasts and mandates.

“We also need to encourage the electrical industry towards lucrative business opportunities within the EV charging sector – which also bene ts their direct communities in a positive way,” Farnsworth says. “This means we need more education and awareness for skill development programs to increase the number of available EV charger technicians.”

Other additional challenges that need to be addressed include that potential EV consumers are still continually put o purchasing an EV due to the poor reputation of the existing nationwide charger network – both for availability and reliability.

“The billions of dollars which have been allocated to x this have not yet reached shovel-ready projects,” Farnsworth says. “Red tape is holding back immediate distribution of funds, and the public still has to gain con dence that things will get better soon.”

From a battery perspective, Christensen says developing a domestic supply chain for battery materials, innovations in battery chemistries, and advancements in battery recycling will all contribute to lowering the cost and emissions associated with EV and hybrid batteries. Incentivizing the use of recycled materials in batteries can also contribute to lower battery costs, therefore lowering the cost of the vehicle.

“Access to charging is imperative when owing an EV regardless if the owner lives in a dense urban area or the suburbs,” Christensen says. “In areas where home charging is not feasible due to high costs or zoning laws, there must be public access to su cient charging locations to support EV owners.”

Range anxiety also continues to be a barrier to many in buying an EV, especially for consumers who plan to own only one car and need a vehicle for long road trips where charging might not be available and for short commuting. “The automotive and battery industry continues to innovate and develop longer-range, faster-charging batteries,” Christensen says. “Very soon, range anxiety should be a thing of the past.” EA

GLOBAL SOURCING

UL CERTIFIED TO SLIT 3M TAPES

MANUFACTURING

RES-I-LAM - NMN, DMD 180, NKN LAMINATES

| RES-I-GLAS & POLYGLAS BANDING TAPE

| RES-I-STRAINT EDGING TAPE | RES-I-FLEX

ARMOR TAPE | B-STAGE SURGE ROPE & FELT | RES-I-BAND BANDING FILM

CONVERTING

THERMAVOLT / TUFQUIN / CEQUIN INSULATING PAPERS | ELANTAS HT180 FILM | DIAMONDDOT& PRE-PREG PAPERS |ARAMID, POLYESTER,POLYIMIDE, POLYAMIDE,& PEEK PRODUCTS BYDUPONT, 3M, & ST. GOBAIN DISTRIBUTING

LENNI, VARFLEX, 3M, KANEKA, IPG, IDP, ATKINS & PIERCE, KREMPEL, ISOVOLTA, HESGON, ST. GOBAIN, DUNBAR, DELFINGEN MANUFACTURING lCONVERTING l DISTRIBUTING THE RIGHT SOURCE, RIGHT ON TIME. SALES@PEIPITTSBURGH.COM ESPANOL@PEIPITTSBURGH.COM (412)462-6300 (EN) | (956) 554-3690 (ES) WWW.PEIPITTSBURGH.COM CALL US FOR A QUOTE TODAY. 800.462.4734 ELECTRICAL APPARATUS | JUNE 2024 27

On display in Vegas

Highlights of the products and services to be showcased at this month’s convention of the Electrical Apparatus Service Association

By the Electrical Apparatus sta

If it’s June, it must be EASA. This annual rite of summer, familiar to many EA readers, will get fully underway June 24-26 when members of the Electrical Apparatus Service Association convene at Caesars Forum and Harrah’s Las Vegas.

Equal parts trade show, educational conference, networking event, and reunion, the EASA Convention brings together vendors and customers to share their knowledge, have a few laughs, and perhaps close a deal or two. Las Vegas offers many side attractions, many of them covered last month in the article “Vegas’s special powers” by Managing Editor Charlie Barks.

On this and 17 pages following we bring you previews of many of the products and services that exhibitors have told us they plan to feature at the EASA Solutions Expo. Our hope is that even readers who don’t plan to attend the convention will nd value in these summaries of what’s new in the electromecnanical service and sales industry.

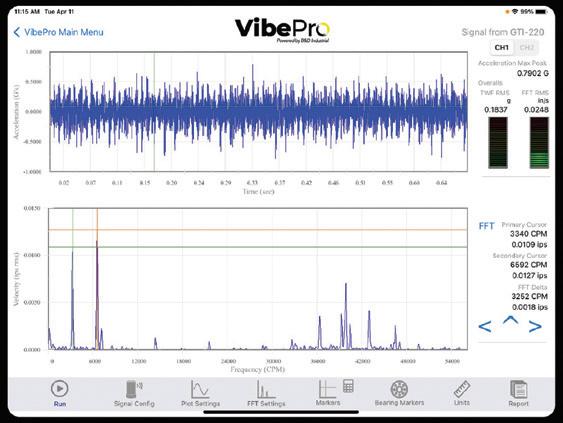

Motor tester and winding analyzer

This year at the EASA Solutions Expo, Electrom Instruments will demonstrate how it continues to miniaturize the iTIG motor tester and winding analyzer. The company will be showcasing its new 6-12 kV and 15 kV motor tester, “now smaller than ever with a significant reduction in size and weight from previous generations,” according to Electrom. The company says the tester is suitable for both inshop use and field testing. The entire iTIG product line will be on display in the Electrom booth. “Expo visitors are encouraged to stop by to see just how small these new testers really are,” Electrom says.

Electrom Instruments now has a motor tester and winding analyzer that’s smaller than ever and easily transportable into the field.

STOP BEARING FAILURE

Premature bearing failure is a major cause of motor downtime and costly repairs. Helwig Carbon uses proven silver graphite technology in a variety of bearing protection kits (BPK) for motor shaft grounding. They effectively divert electrical currents away from the bearings, protecting them from damage.

For more info, visit www.helwigcarbon.com

Feature | 2024 EASA Convention Exhibitors

CAUSED BY VFD-INDUCED CURRENTS BPK WITH HELWIG’S INDUSTRY LEADING SHAFT GROUNDING SOLUTION

28 ELECTRICAL APPARATUS | JUNE 2024

Distributor of motors and drives

ESR Motor Systems, Inc., a distributor of new motors and drives for commercial and industrial clients, is set to showcase its diverse product line. The company prides itself in maintaining a comprehensive inventory of top-tier brands and essential tools for basic modifications across all its warehouses. In the past year, ESR Motor Systems has expanded and enhanced its operations across its six locations. Notable changes include the introduction of innovative motor storage and the acquisition of tools for basic motor modifications. ESR Motor Systems’ president, national sales manager, a national inside sales member, and the e-commerce product manager will all be present during the Solutions Expo.

Coils, poles, magnet wire, and more

Coral Coil, part of the Coral Group of companies, has stateof-the-art capabilities at three manufacturing facilities and two repair shops. The company calls itself “a one-stop solution provider for all your rotating electrical machine needs.” Having grown “quite substantially in the last years,” Coral Coil plans to highlight several products and services at Booth 738, including diamond coils 400 V up to 16 kV, bars from 11 kV up to 22 kV for air- and water-cooled systems, plus rotor coils, poles, and magnet wire. On the service side, Coral Coil offers reverse engineering, power increase, and on-site rewinding of power and hydro generators. The company says it has more than 150 rewinders.

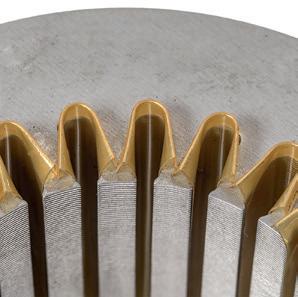

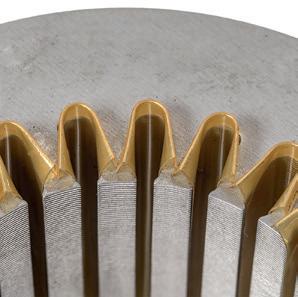

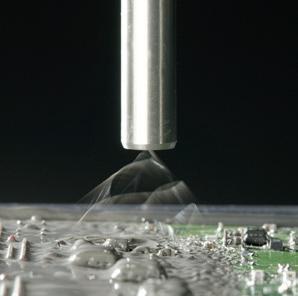

Laser machine for high-end laminations

Benefitting from many years of experience in developing and manufacturing laser cutting machines, Stiefelmayer has developed a line of application-specific machines to ensure the highest precision and dynamics standards for stator and rotor laminations. Modern technology in laser, carbon construction, and dynamic motors creates a laser machine capable of high-end motor laminations, setting new industry standards.

At the EASA Solutions Expo, the company plans to have these machines on full display. The Stiefelmayer laser machine is particularly well adapted to cutting precision shapes in thin substrates, including electro-steel, stainless, copper, and brass, according to the company. Motor laminations are a specialty, and this fact, the company says, matches the drive for EVs in the U.S. auto industry.