More than Motors

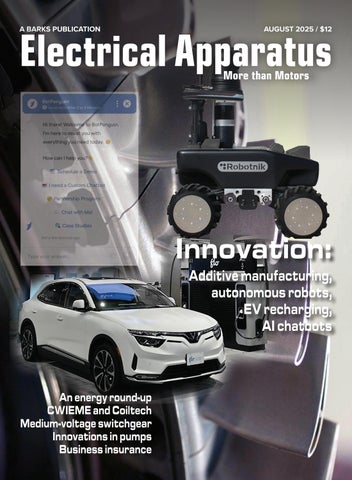

Electrical Apparatus Innovation:

Additive manufacturing, autonomous robots, EV recharging, AI chatbots

An energy round-up

CWIEME and Coiltech

Medium-voltage switchgear

Innovations in pumps

Business insurance

Electrical Manager

14 Chatterboxes

AI chatbots are suddenly everywhere. How best to tame and use them?

By Bill O’Leary, EA Contributing Writer Electric Avenue

18 Dealer’s choice

Having EV chargers on site at auto dealerships demonstrates that the dealers stand behind the EVs they sell

By Maura Keller, EA Contributing Writer Energy

21 Energy round-up

What’s new in the energy industry as summer draws to a close

By Charlie Barks, EA Managing Editor

Conventions & Trade Shows

22 A North American debut

Coiltech North America’s premiere performance offered a glimpse of electrification’s future

By Charlie Barks, EA Managing Editor

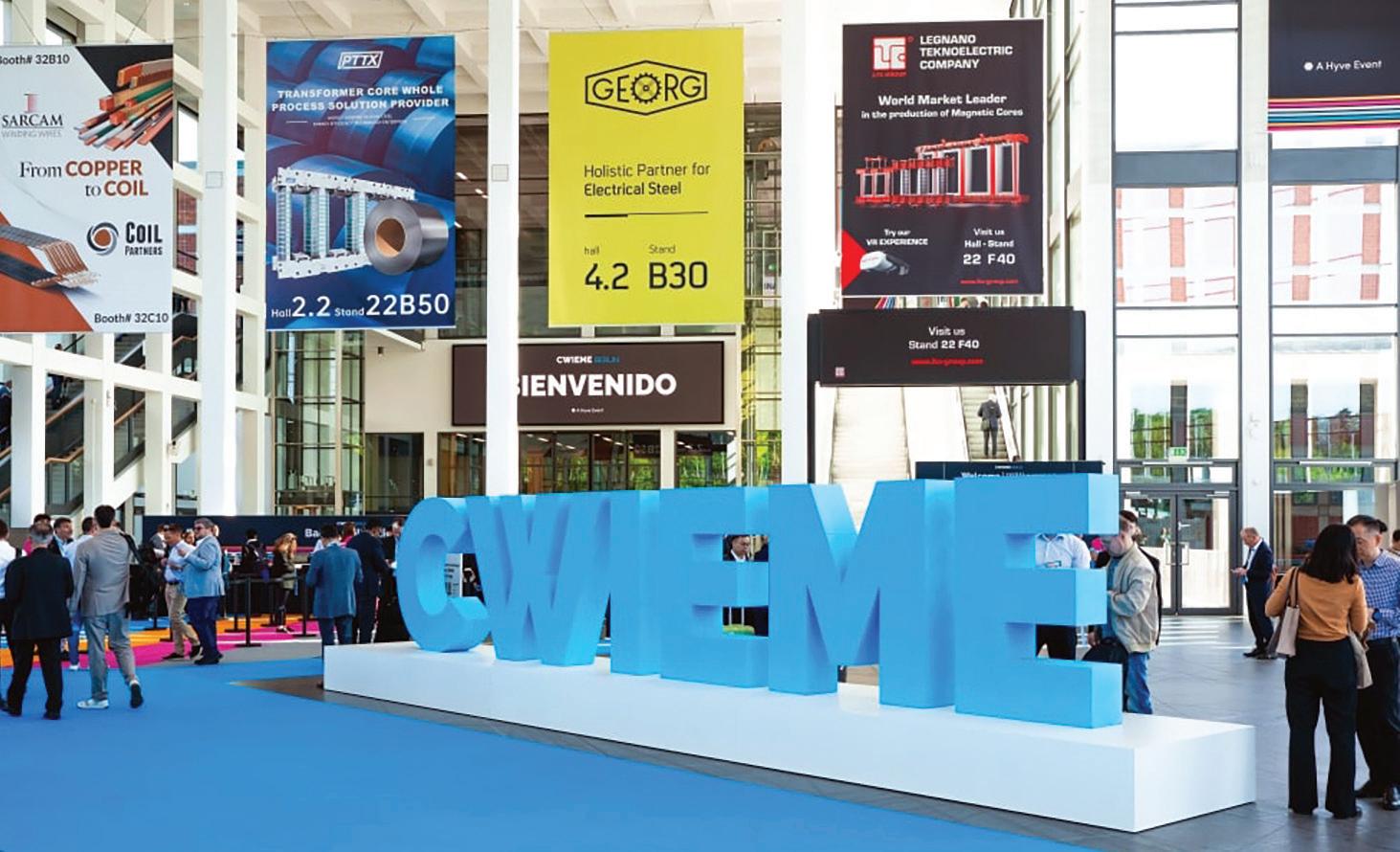

26 Transformative talks

Presentations on transformers and motors figured prominently at CWIEME Berlin June 3-5

By Kevin Jones, EA Senior Editor

EA Reader Profile

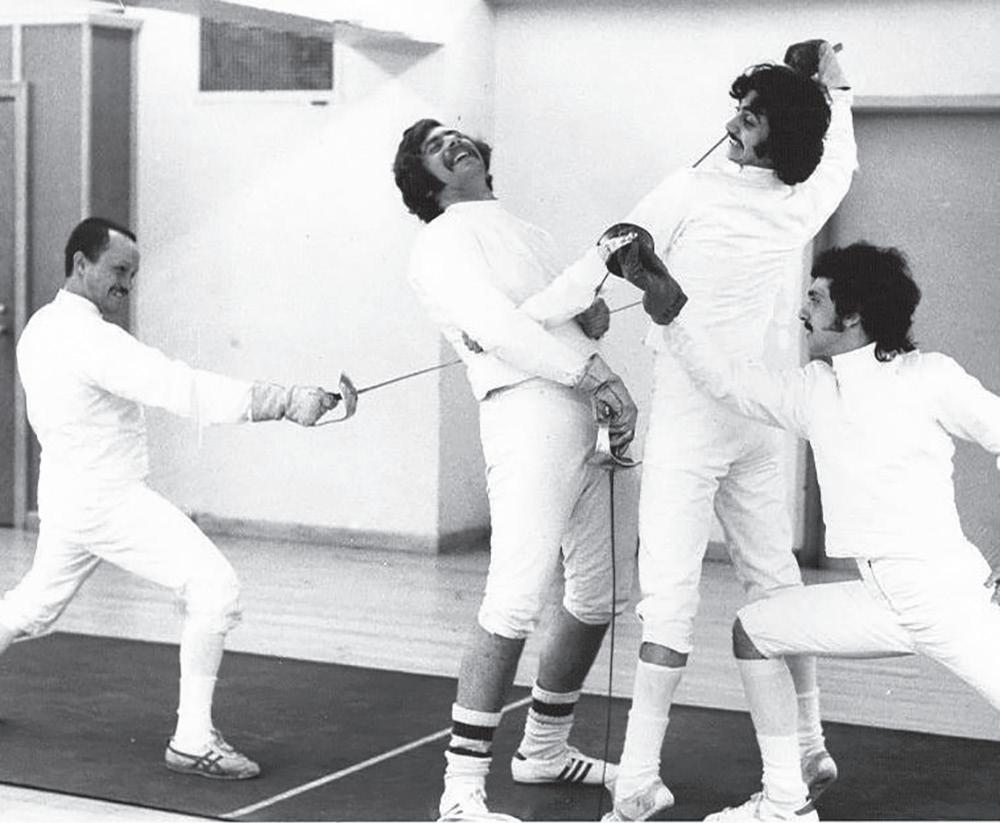

29 En garde, prêts, allez . . . ‘Ready, set, go!’ is fencer Anthony Cuschieri’s approach to running his polyester film company

By Colin Gregory-Moores, EA Contributing Writer

Training & Education

31 Amazon U.

Bakersfield College is partnering with Amazon for educational programs that offer employees a plethora of opportunities

By Avery Heeringa, EA Contributing Writer

Manufacturing

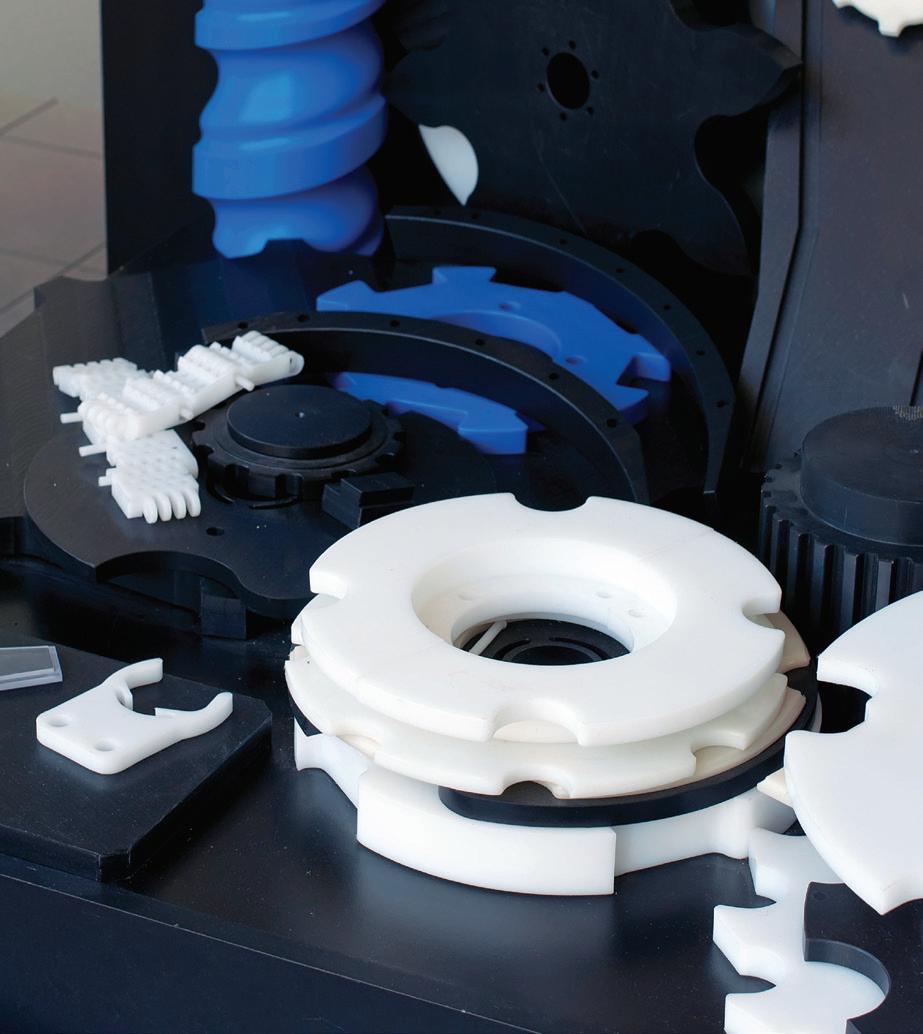

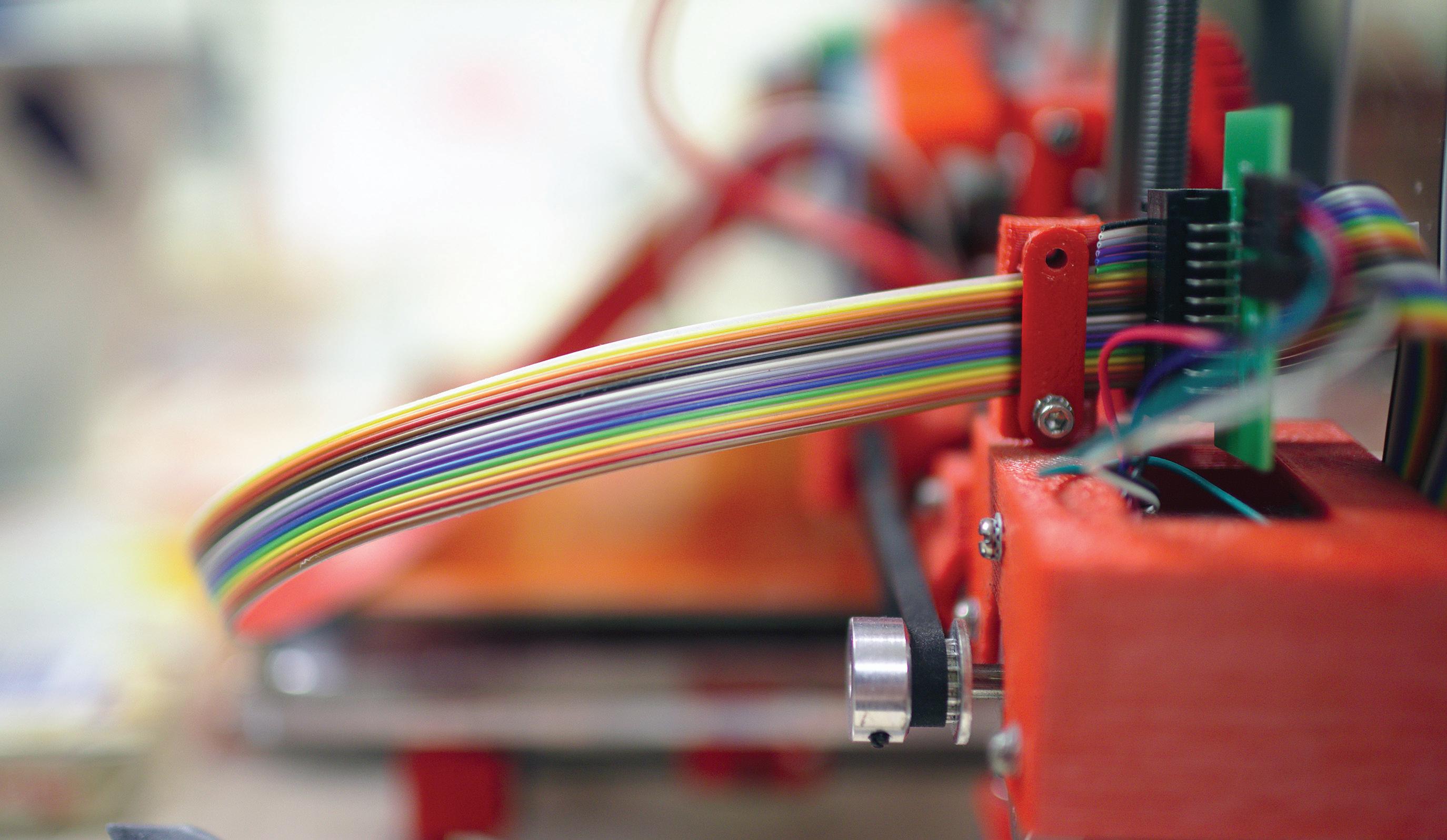

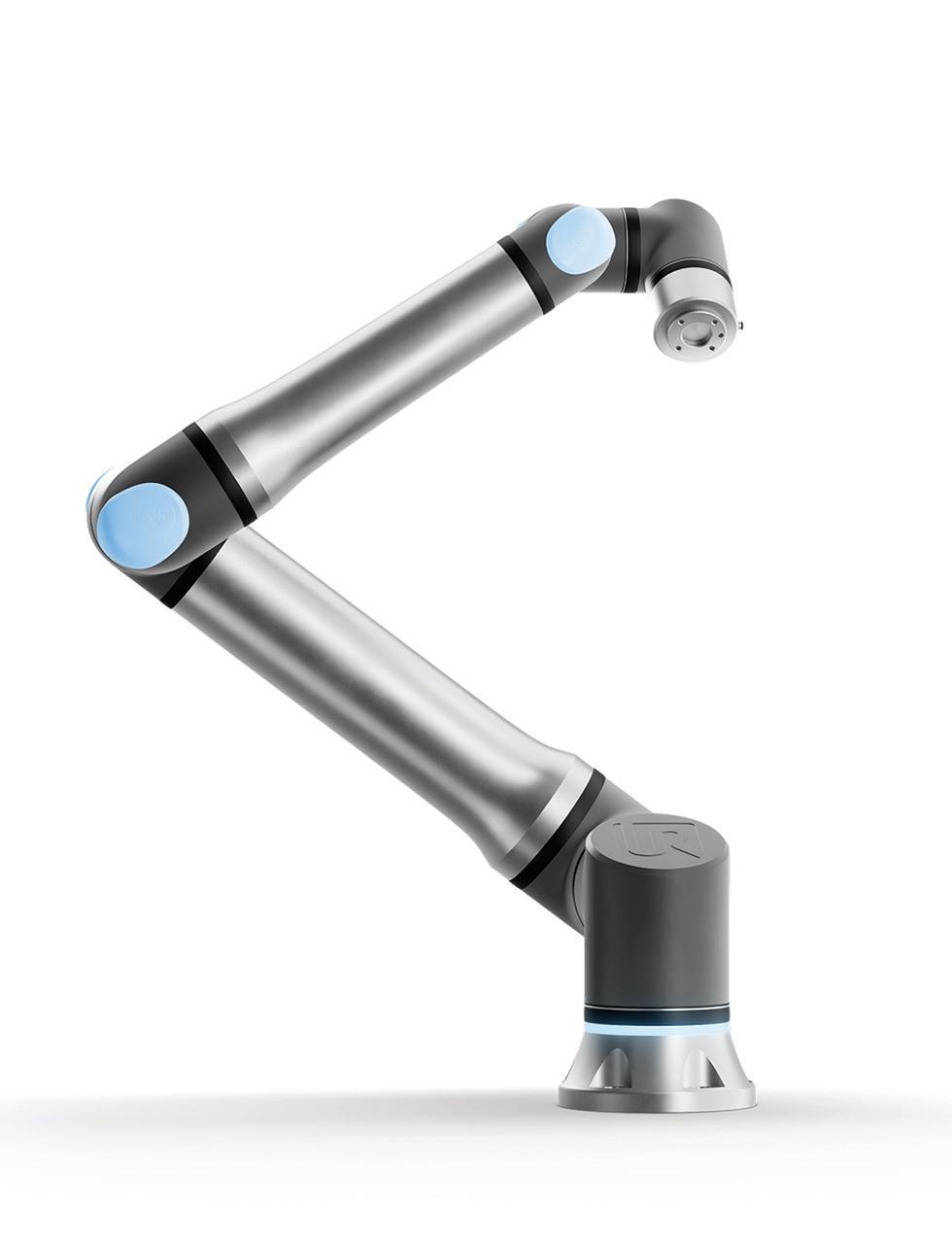

33 3D printing comes of age

How 3D printing — once a novel manufacturing technology — has become firmly established in the industrial workplace

By Bill O’Leary, EA Contributing Writer

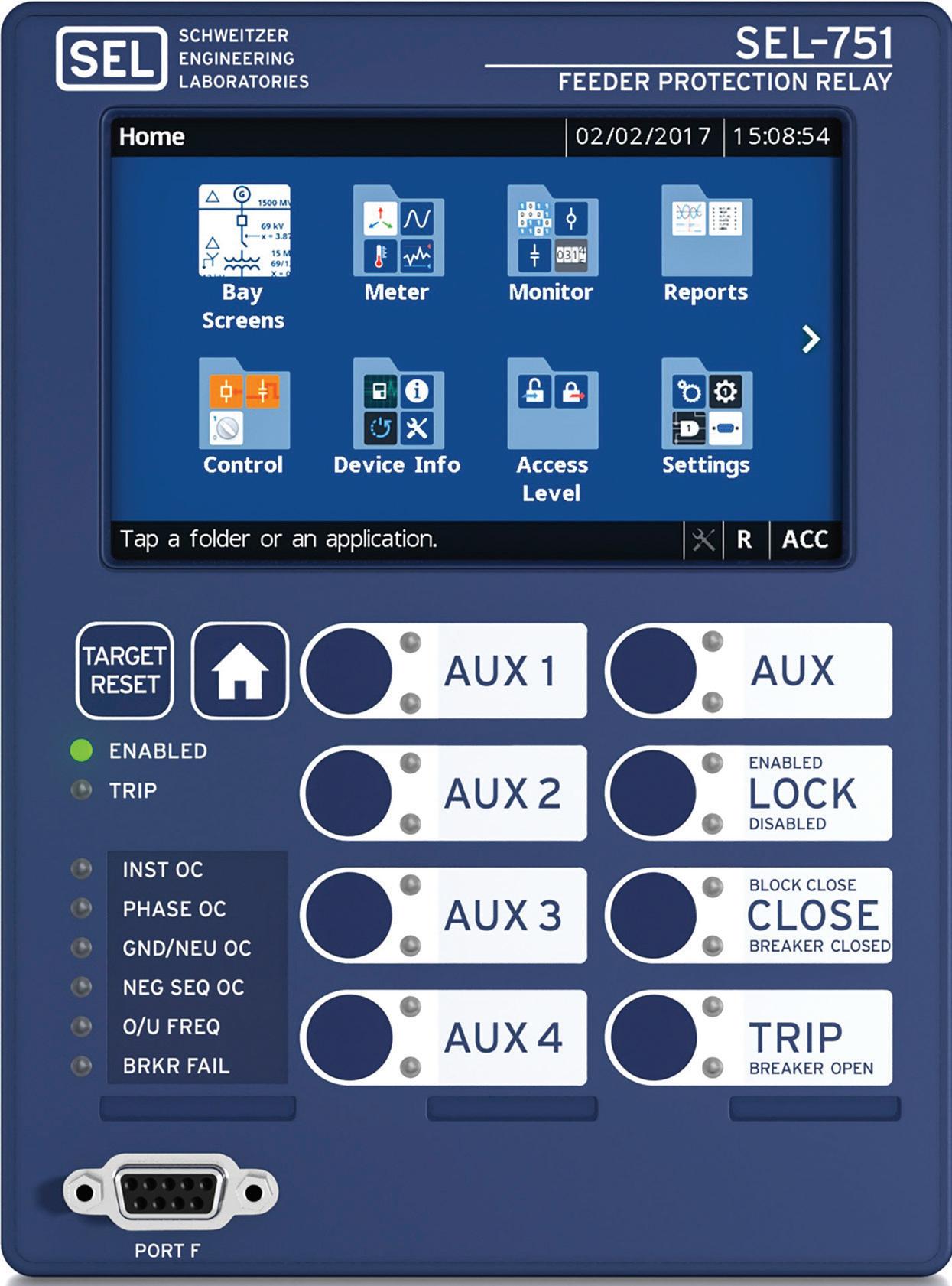

Power Transmission & Distribution

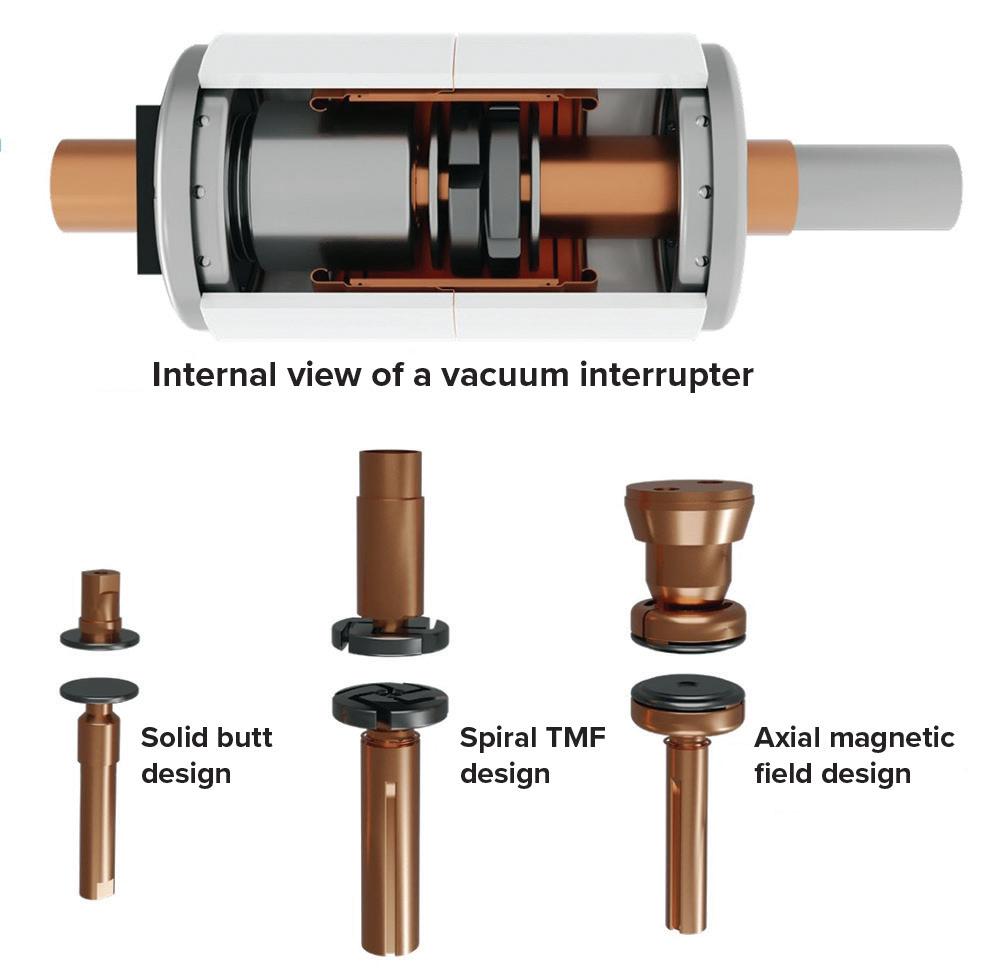

39 Breaker breakout

Given the proliferation of massive data centers, demand for medium-voltage breaker switchgear appears boundless

By David Bredhold, EA Contributing Writer

Finance & The Workplace

44 ‘Insuring’ your business continues Covering both property and people can be well worth the cost

By William H. Wiersema, EA Finance Editor

Pump It Up

48 Innovations in pump design and application

Improvements in materials and design are helping to push the limits of performance

By Kevin Jones, EA Senior Editor

word search puzzle based on this month’s “Finance” article

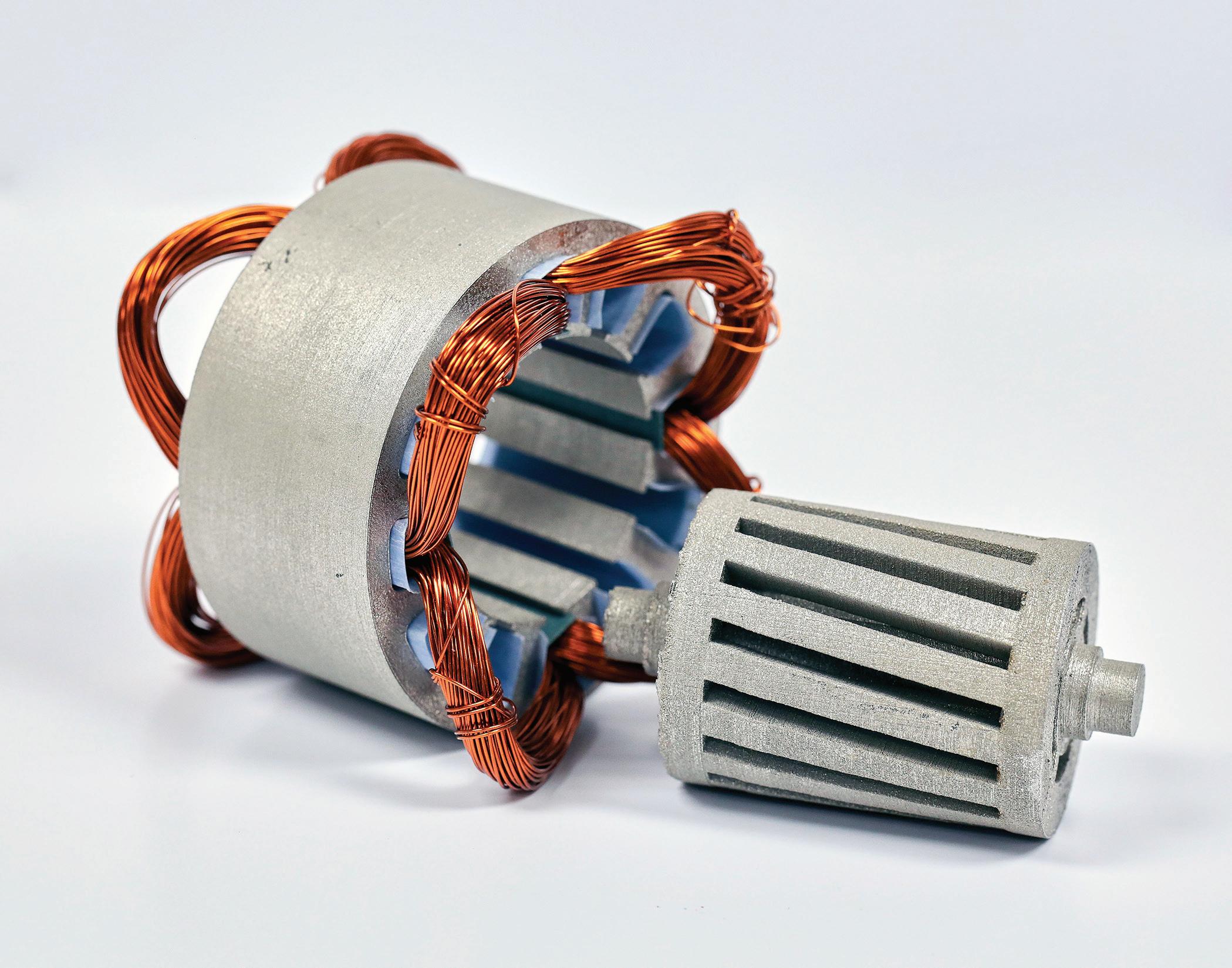

At Toshiba, we don’t test one motor per batch—we test every low voltage motor we manufacture. Whether it’s 0.5 HP or 500 HP, each motor undergoes full testing before it leaves our facility. Because when performance powers critical operations, only proven reliability will do. Built with integrity. Tested for trust.

The Editor’s Comment

What’s new in innovation

Innovation is so common in technological applications, it’s become difficult to distinguish the useful from the unnecessary. Claims of innovation are around every corner, every year, as we’ve covered at length in this publication both in general and in the issues with this theme over the years. We’ve even covered failed innovations and aimed to identify which advancements and new products are truly most applicable to the readers in the many industries we cover.

Look no further than this issue of EA to witness that breadth of variety, starting with this month’s cover story by Bill O’Leary, which covers additive manufacturing (page 33).

Additive manufacturing, which in its early stages was usually referred to as “3D printing,” has come a long way in its 40 years of existence. Bill’s research brought up an intriguing range of questions related to innovation, with 3D printing as a prime example:

Electrical Apparatus

17 N. State St., Suite 435 Chicago, Illinois 60602-3598

(312) 321-9440; fax (866) 228-7274

E-mail: EAMagazine@barks.com www.barks.com

Founded 1948 as Volt/Age

Horace B. Barks, Founding Publisher

Elsie Dickson, Founding Publisher

STAFF

Elizabeth Van Ness, Publisher

Kevin N. Jones, Senior Editor

Charlie Barks, Managing Editor

FINANCE EDITOR

William H. Wiersema

CONTRIBUTING WRITERS

David Bredhold, Chase Fell, Colin Gregory-Moores, Avery Heeringa, Maura Keller, John Malinowski, Michael Mitten, Bill O’Leary, Kristine Weller

SPECIAL PROJECTS

Barbara Goetz Barks

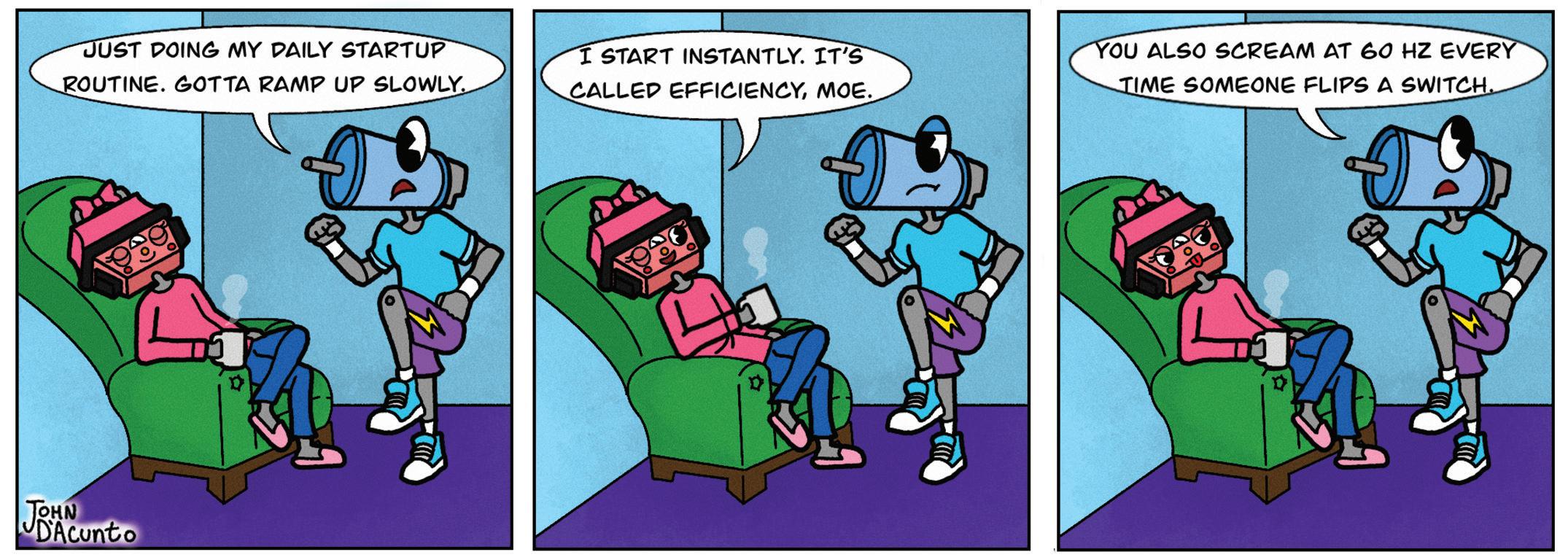

CARTOONS AND PUZZLES

John D’Acunto, Myles Mellor, Tim Oliphant

Coming next month in Electrical

Apparatus:

Sidewinders LLC of Magna, Utah; EASA Show report; Battery Show preview; Testing electrical steel for lamination performance; The new tax law.

“What makes an innovative technology sustainable? How does the new become old but not forgotten? The realm of innovative technology is riddled with one-hit wonders — something that was supposed to revolutionize some industry or task but quickly went the way of the dinosaur. Smart glasses, e-ink color tablets, soft exoskeletons for industrial use, hydrogen internal-combustion engines. But the jury is still out on a host of other technological innovations. One gleaming example: the 3D printer.”

Elsewhere in this edition of EA are reports from one realm where innovation is seemingly always visible: the trade show. We have two trade show reports in this issue: CWIEME Berlin 2025 (page 26) and Coiltech North America 2025 (page 22). Both shows featured tons of new ideas and companies putting their stamp on innovative advancements.

ElectroMechanical Bench Reference Supplement mailed with the December issue

Elizabeth Van Ness, Editor & Publisher

ADVERTISING

Barbara Wachter, Advertising Director

CIRCULATION

Circulation@barks.com

Read Electrical Apparatus online

The entire contents of this issue are available online. Scan the QR code below:

The CWIEME show, which EA has attended multiple times in the past both in America and abroad, is well-established as a haven for the latest lines of thinking in the coil and transformer industries. Meanwhile, Coiltech was debuting its first North American edition, and the early feedback indicates a successful venture that focused on cross-industry networking.

To round out the issue, we have a technical article from David Bredhold on medium-voltage breaker switchgear (page 39), an accounting piece from Bill Wiersema entitled “‘Insuring’ your business continues” (page 44), and the interesting consideration of adding EV chargers to auto dealerships in Maura Keller’s “Electric Avenue” column (page 18).

As always, thanks to our advertisers, readers, and contributors for a great issue!

Electrical Apparatus (ISSN 0190-1370), Vol. 78, No. 8, is published monthly by Barks Publications, Inc., 17 N. State St., Suite 435, Chicago, Ill. 60602-3598; (312) 321-9440; fax (866) 228-7274. www.barks.com. Periodicals postage paid at Chicago, Ill., and at additional mailing offices. Postmaster: Send address changes to Electrical Apparatus, c/o Barks Publications, Inc., 17 N. State St., Suite 435, Chicago, Ill. 60602-3598. PM #40830553

U.S. subscriptions: 2 years—$120; 1 year— $65. Foreign airmail: 2 years—$275; 1 year—$150. Subscriptions also include an annual directory supplement, the ElectroMechanical Bench Reference. Single copies: $12 each plus postage; December issue, $30 with the supplement ElectroMechanical Bench Reference.

Copyright 2025 Barks Publications, Inc.

Reproduction of any part, by any means, including photocopy machines and computer networks, without the written permission of Barks Publications, Inc., is prohibited. Electrical Apparatus and ElectroMechanical Bench Reference are trademarks registered with the U.S. Patent Office.

Or enter the URL directly: https://bit.ly/aug 25woww

See page 54 for links to upcoming issues that you can bookmark.

A note from the publisher

An item in our July EASA Convention exhibitors’ section misstated the ownership of the Marathon brand of electric motors. The Marathon motor brand was acquired by WEG S.A. from Regal Rexnord Corp. in September 2023. Electrical Apparatus regrets the error.

Copies of articles in print or PDF format may be ordered from our Marketing Department (312) 321-9440. Prices available on request. Libraries and companies registered with Copyright Clearance Center, 222 Rosewood Dr., Danvers, Mass. 01923, should send 75¢ per page copied direct to CCC.

Material also available in microform and CD-ROM from Pro Quest information service, (800) 521-0600 ext. 2888 (US) or 01734-761-4700 (International); https://www. proquest.com/.

Printed in the U.S.A.

Let’s Solve Your Problem

Have you been stumped recently by an electromechanical application or repair problem? Send your question to this department, at editor@barks.com, and we’ll see if we can give you an answer.

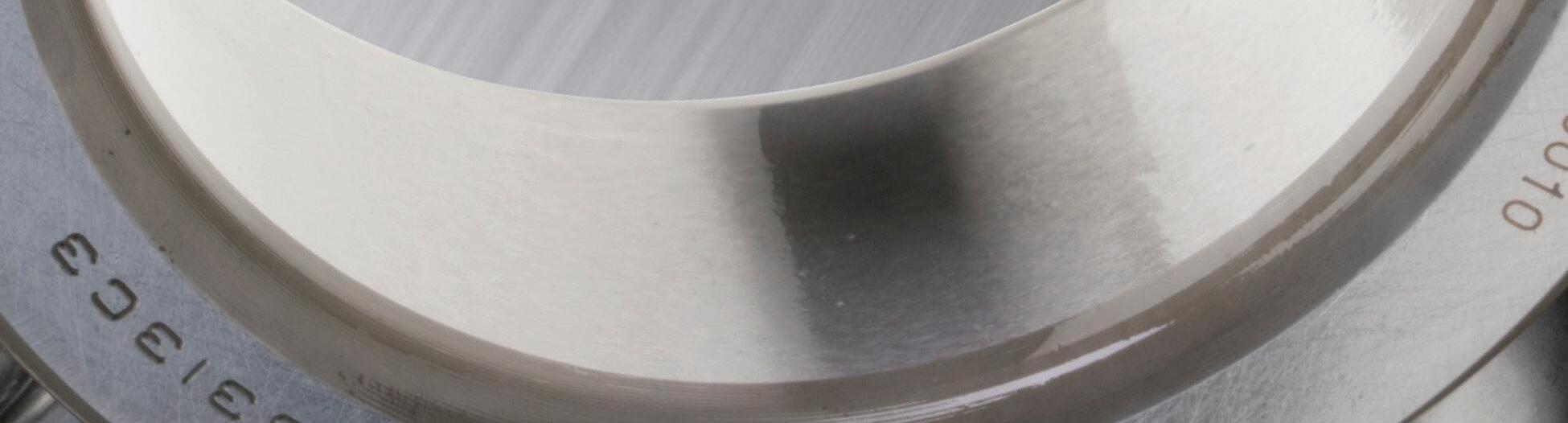

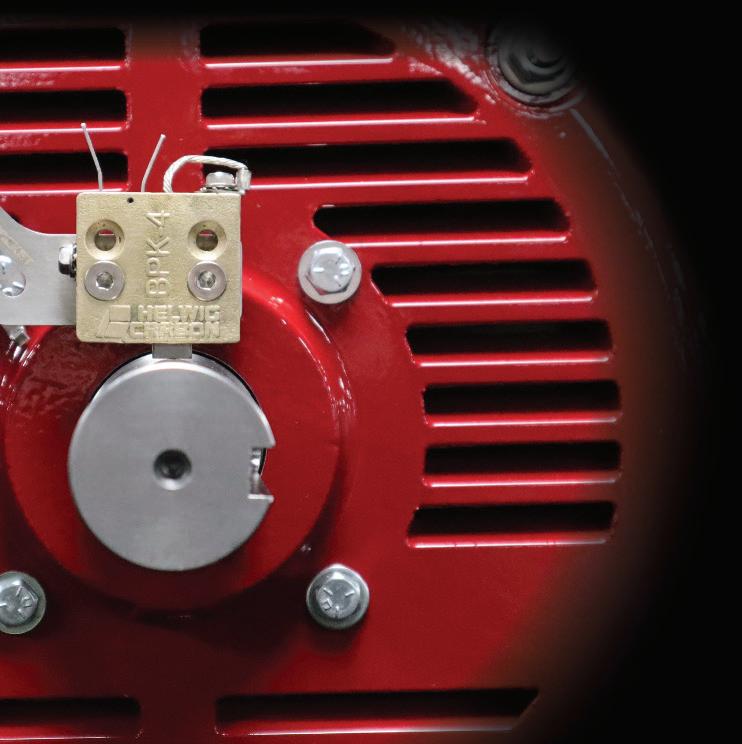

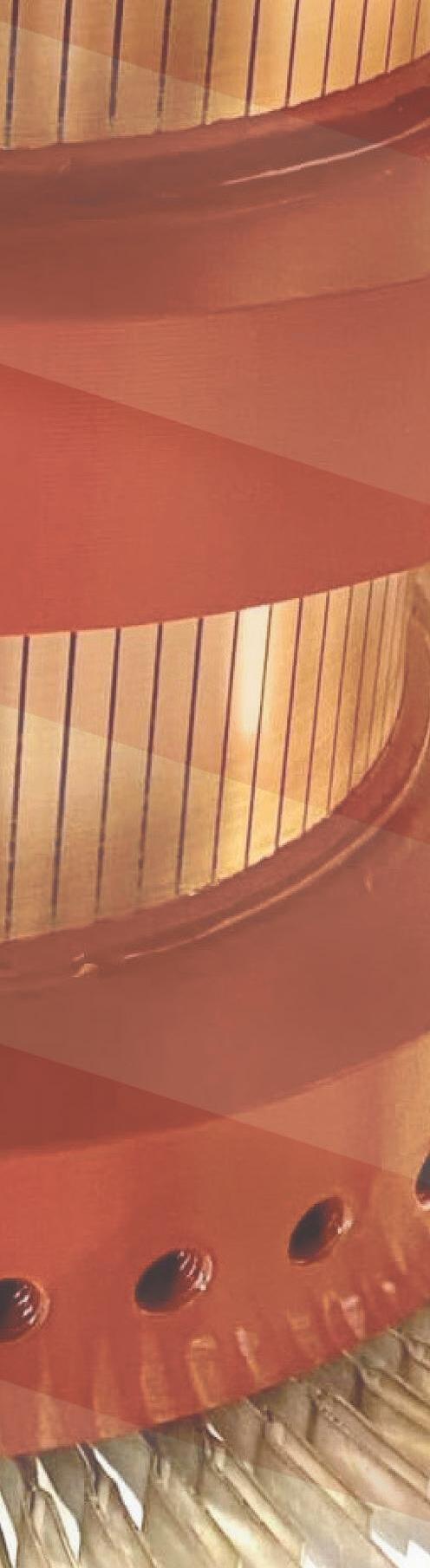

Can we maintain this commutator in the field?

We use d-c motors for variable-speed and reversing processes in our mill. The operator’s manual for these motors recommends turning and undercutting of the commutator. Can we do this in the plant? If so, what are the steps involved in this service?

The commutator is the copper segmented cylindrical component that serves to connect the armature winding to the d-c power supply through your carbon brushes. The brush contact surface of the commutator should be smooth and clean with runout at 0.003-inch or lower. The insulating mica between the segments should always be approximately 1/16 inch below the bar contact surface.

After finishing the commutator surface and cutting the mica, all slots should be thoroughly re-cleaned and bar edges beveled. A final polish should be performed after the cleaning and beveling. Unless you have access to very special knowledge and equipment, this work should be done in a shop by qualified technicians.

Squirrel-cage a-c motor as a generator?

I have a standard NEMA-frame a-c four-pole 10 hp motor. Can I make this motor run as a generator by rotating the shaft by way of an external source?

Well, maybe. A standard three-phase squirrel-cage induction motor can be used as a generator, but with some important caveats. When you spin the shaft of an

induction motor faster than its synchronous speed, it begins acting as an induction generator. The rotor cuts through the stator’s rotating magnetic field in reverse. This induces current.

However, unlike synchronous generators, an induction generator needs an existing magnetic field to operate. It cannot self-excite unless specific conditions are met. The most common excitation method involves connecting the motor to a live three-phase grid. Once the motor is connected to the grid, spin the motor shaft at a speed faster than synchronous speed. The grid provides magnetizing current (reactive power), and the motor feeds real power back into the grid.

A less common excitation option is the off-grid self-excited induction generator. This is possible if you connect capacitors across the stator terminals to supply the necessary reactive power to generate.

The capacitor solution is more complex and harder to regulate when compared to the grid. Frequency and voltage regulation may be a problem. And you will need switchgear and circuit protection, of course.

Resistance imbalance: What is acceptable?

I measured a 3% resistance imbalance between the three phases of a 100 hp, 480 V electric motor winding in our container board plant.

Is this acceptable? What could cause this imbalance? If it is not acceptable, what should it be, and what is the recommended fix?

A resistance imbalance of 3% in a threephase a-c winding is generally considered too high, according to standards like IEEE 112 or NEMA MG-1, which recommend a resistance imbalance not exceeding 1%. Causes of such imbalance may include

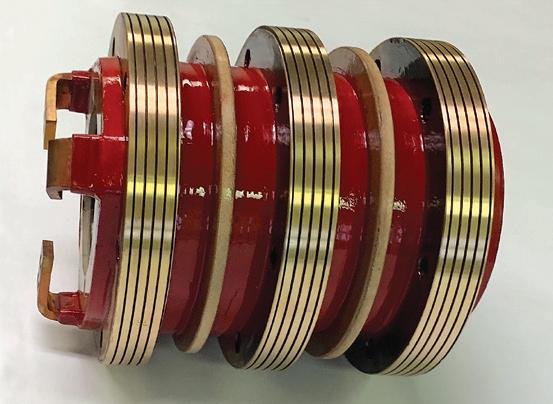

Synchronous Motor Rotating Rectifier Assemblies

•Reverse

•Parts

•Testing

•Repair

uneven wear or damage to the winding insulation, loose or corroded connections, or manufacturing defects.

To resolve this issue, inspect and tighten all connections, ensure there is no corrosion or contamination, and test the winding insulation for damage. If the imbalance persists, consider reconditioning the motor or replacing the affected windings to restore proper operation. If the winding has a shorted turn, it won’t likely run very long.

Running a d-c motor with armature circuit grounded

I’ve been told that it’s possible to run a d-c motor with the armature circuit grounded. Is this true?

Yes, it’s technically possible, but only under specific conditions. It depends on the motor design and the wiring scheme. When people say the armature is grounded, they typically mean that one side of the armature winding is connected to chassis ground. In some older systems, especially vehicle or industrial applications, this is intentional. But it can also be undesirable if it’s an accidental ground fault.

In older automotive or railway d-c systems, it was common to ground one side of the power supply, and sometimes the armature return path was through the chassis. In this case, grounding one side of the armature was by design.

In some cases, one terminal of the motor (either armature or field) is grounded intentionally as part of the control strategy. This is safe, as the power supply return is referenced to ground at the same point and no potential difference builds up. That could cause circulating currents. If a normally isolated armature winding becomes grounded due to insulation failure - this is a fault. It may run for a while, but it’s not right. — Edited by the EA staff EA

Update your calendar with these upcoming trade shows, conferences, and other events. Do you know of an event that you think we should bring to the attention of Electrical Apparatus readers? E-mail us about it at edi tor@barks.com.

• August 6-8, 2025 — NSPECon, InterContinental Kansas City at The Plaza, Kansas City, Mo. National Society of Professional Engineers, www.nspecon.org.

• September 4, 2025 — Golf Day 2025, Belton Woods Golf & Spa Resort, Lincolnshire, U.K. British Pump Manufacturers’ Association, www.bpma.org.uk/ news-article/67ec00e3dc878/BPMAGolf Day2025.

• September 8-11, 2025 — Fabtech 2025, McCormick Place, Chicago, Ill. Fabtech Event Partners, www.fabtechexpo.com.

• September 12-15, 2025 — NECA 2025 Convention and Trade Show, McCormick Place, Chicago, Ill. National Electrical Contractors Association, http:// bit.ly/4f9BWoN.

• September 17-19, 2025 — AEE World Energy Conference & Expo, Georgia World Congress Center, Atlanta, Ga. Association of Energy Engineers, https:// aeeworld.org/conference.

• September 18, 2025 — AEMT 80th Anniversary Conference, British Motor Museum, Gaydon, Warwickshire, U.K. Association of Electrical and Mechanical Trades, www.theaemt.com/ems-event-cal endar/aemt-conference.html.

• September 29-October 2, 2025 — Canadian Manufacturing Technology Show, Toronto Congress Centre, Toronto, Ontario, Canada. Society of Manufacturing Engineers, www.cmts.ca.

Upcoming events

• October 5-7, 2025 — EGSA Fall Conference, Royal Pacific Resort, Orlando, Fla. Electrical Generating Systems Association, https://egsa.org/Events/Fall-2025-Confer ence.

• October 13-16, 2025 — Hydraulic Institute Fall Conference, Kansas City Marriott Country Club Plaza, Kansas City, Mo. Hydraulic Institute, www.pumps.org/ event/2025-fall-conference.

• October 23, 2025 — The 2025 U.S. Celebration of World Standards Day, Bethesda North Marriott Hotel and Conference Center, Rockville, Md. American National Standards Institute, www.ansi.org/events/ standards-events/world-standards-day.

• November 16-20, 2025 — International Mechanical Engineering Congress & Exposition, Renasant Convention Center, Memphis, Tenn. American Society of Mechanical Engineers, https://event.asme. org/IMECE.

• January 31-February 4, 2026 — 2026 ASHRAE Winter Conference, Caesars Palace, Las Vegas, Nev. American Society of Heating, Refrigerating, and AirConditioning Engineers, www.ashrae.org/ conferences/2026-winter-conference.

• February 2-4, 2026 — AHR Expo 2026, Las Vegas Convention Center, Las

Vegas, Nev. The Air-Conditioning, Heating, and Refrigeration Institute, www.ahrexpo. com/sales-floor-plan-2026.

• February 8-11, 2026 — NEMRA 2026: Power Tomorrow, Today, Orlando World Center Marriott, Orlando, Fla. National Electrical Manufacturers Representatives Association, www.nemra.org/save-the-datenemra26-returns-to-the-sunshine-state.

• February 22-26, 2026 — Hydraulic Institute 2026 Annual Conference, Sawgrass Marriott Golf Resort & Spa, Ponte Vedra Beach, Fla. Hydraulic Institute, www. pumps.org/event/2026-annual-conference.

• March 2-6, 2026 — PowerTest 2026, Gaylord Opryland Resort & Convention Center, Nashville, Tenn. InterNational Electrical Testing Association, https://bit.ly/ 4cMrfZ5.

• June 1-4, 2026 — CleanPower 2026, George R. Brown Convention Center, Houston, Tex. American Clean Power Association, https://cleanpower.org/expo.

• June 13-16, 2026 — Electrical Apparatus Service Association Solutions Expo, Rosen Shingle Creek, Orlando, Fla. Electrical Apparatus Service Association, https://easa. com/convention/future-easa-conventions.

• September 14-19, 2026 — International Manufacturing Technology Show, McCormick Place, Chicago. Association for Manufacturing Technology, www.imts.com/ index.cfm.

• June 11-14, 2027 — Electrical Apparatus Service Association Solutions Expo, Ernest N. Morial Convention Center & Hilton Riverside, New Orleans, La. Electrical Apparatus Service Association, https://easa. com/convention/future-easa-conventions. Edited by Kevin Jones EA

Plant Happenings

Limbo number five

Production was suspended last spring at the Denka Performance Elastomer plant in St. John the Baptist Parish, Louisiana. The inde nite suspension of Denka’s synthetic rubber production comes after disappointing nancial results were reported by the company. Rising costs, declining production volumes, and expensive anti-

emissions technology were cited by the company as contributing factors.

Going on the rails

A new advanced manufacturing plant is opening in Hornell, N.Y., as an expansion of the current Alstom production, bringing 258 new jobs and re-

duce stainless-steel rail car body shells, according to the company.

Sausage plant closed suddenly

jobs. The facility, named Plant 4, will pro-

The Industry’s

Quietest Bearings

Utilizing our precision manufacturing process to create improved raceway finishes and tighter dimensional tolerances, NTN pairs high-quality components and a special polyureabased grease designed for the electric motor industry to provide the needed quietness and a high-temperature performance you expect in your applications.

The small Illinois community of Momence was rocked by the sudden closure of the Momence Packing Co. plant, owned since 1995 by Johnsonville Foods. The facility has employed local residents since its opening in 1962, but the June closure displaces 274 employees. Production will be picked up by three plants in Wisconsin and Kansas.

New meaning for new Coke

While New Coke did not garner much support in the 1980s, a new Coke plant has found favorable opinions in Olathe, Kan. The recently opened Heartland Coca-Cola bottling plant is a 700,000-squarefoot facility that includes four production lines, two for aluminum cans and two for PET bottles. Heartland Coca-Cola was founded in 2017 and is an anchor bottler serving the Midwest.

DOE orders change of plans

A soon-to-close power plant outside of Philadelphia had a reversal of fortune U.S. Dept. of Energy ordered the plant’s owner to ensure operations continue through Aug. 28.

Eddystone Generating Station’s owner had planned to retire the plant in May, but forecasts for increased energy demand related to large data centers and transportation electri cation caused the change in plans.

Chips fall where they may

PepsiCo recently announced the closure of its Frito-Lay manufacturing plant in Rancho Cucamonga, Calif., due to decreasing snack sales. The number of employees a ected was not released by PepsiCo. Some of the facility’s employees will remain, as the distribution, warehouse, and transportation divisions will not close. — Kristine Weller EA

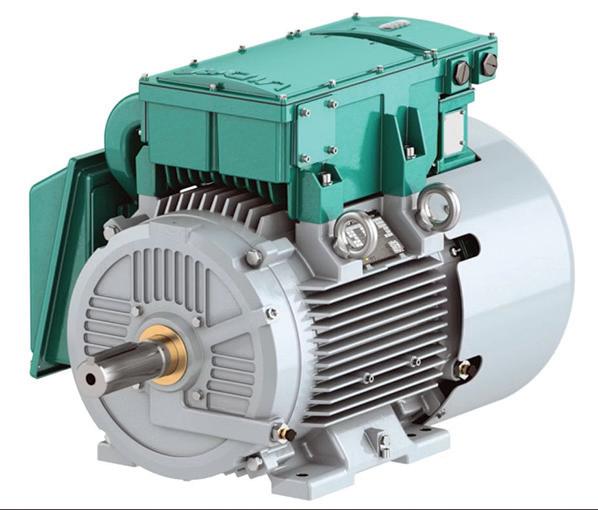

Leading the way in energy efficiency yet again, ABB Baldor-Reliance SP4 motors give you a shortcut in energy savings, lower operating costs and total cost of ownership. SP4 motors achieve NEMA Super Premium efficiency across-the-line, independently of a drive. Whether DOL or inverter duty, these motors run cooler, longer and quieter – now with a 48-month warranty. new.abb.com/motors-generators/sp4

IE6 motors and the path to further e ciency gains

It wasn’t long ago that IE4 and then IE5 motors were pushing what seemed the practical limits of e ciency. Now, for the past year, even though the International Electrotechnical Commission has yet to codify IE6 as a motor classi cation, several manufacturers have been marketing motors promoted as such.

The manufacturers o ering IE6 motors include ABB, Lafert, WEG, and Innomotics. Price lists for these motors are typically not available publicly, as these are high-performance, often customized industrial machines whose prices vary based on horsepower, RPM, voltage, features, and application requirements. It’s a virtual given, though, that the up-front cost of an IE6 motor will be notably higher than the price of a motor with a lower e ciency rating.

Does the greater e ciency justify the higher price? Manufacturers can be counted on to assure customers that it often does — that the increased expense is more than covered by the substantial energy savings and rapid return on investment such motors are promised to yield. To the purely economic rationale for buying an IE6 motor can be added the purported environmental bene ts of doing so — at least in those jurisdictions where e orts to cap emissions of carbon dioxide are still enthusiastically embraced. (In the U.S., federal support of energy-e ciency e orts seems to be fading by the day.)

The W23 Sync+Ultra motor from WEG is among motors being marketed these days as IE6. Motors with this classification — which hasn’t yet been codified by the International Electrotechnical Commission with o cial benchmark standards — generally deliver 20% greater e ciency than IE5 motors. — WEG photo

A white paper released in June by ABB, titled “Achieving the COP28 UAE Consensus,” details what ABB characterizes as the vital role high-e ciency motors and drives are playing in meeting global energy objectives. It argues that investing in these technologies o ers rapid and substantial nancial returns for businesses.

Please turn to page 12

Global energy demand is increasing rapidly, the paper points out, with worldwide energy demand in 2024 growing by 2.2%, a rate exceeding the average of the previous decade. Electricity use, driven by factors such as electrification, record temperatures, and increasing digitalization, rose by nearly 1,000 terawatt-hours in 2024.

The financial benefits of improved energy efficiency are considerable, according to ABB. Investment in this area has grown by almost 50% since 2019. Variable-speed drives and high-efficiency motors sometimes pay for themselves within months rather than over several years.

A 2023 report from the Swiss Energy Efficiency Movement Association titled “The Case for Industrial Energy Efficiency” outlines 10 actions that could help bring about significant carbon reductions and financial benefits. According to the report, four of these actions alone could prevent the release of 2.53 gigatonnes of carbon dioxide emissions annually by 2030, which is equivalent to the output of about 600 coal-fired power plants. These actions are also financially attractive, with potential gross financial benefits for industry estimated at $4.1 trillion in savings by 2030.

Energy efficiency offers several benefits for customers, including energy and material savings, enhanced reliability, optimal equipment lifetime, and reduced emissions. For example, ABB’s joint research with the European Laboratory for Particle Physics between 2022 and 2023 identified a 17.4% energy-saving opportunity in cooling and ventilation motors. This represents potential annual savings of 31 gigawatt-hours.

Governments are playing a pivotal role in all of this by setting ambitious standards, providing incentives such as subsidies and tax breaks, and prioritizing energy efficiency in public procurement. India, for example, has included industrial energy efficiency as an eligible offset in its new carbon market guidance. In China, ABB’s installed base of more than 11 million high-efficiency motors and drives has resulted in energy savings estimated to have exceeded 510 billion kilowatt-hours.

A considerable challenge, according to the ABB white paper, is that many motors currently in operation do not meet modern efficiency standards. Straightforward steps, such as correctly sizing industrial electric motors for their applications, can go a long way toward compensating for this shortcoming.

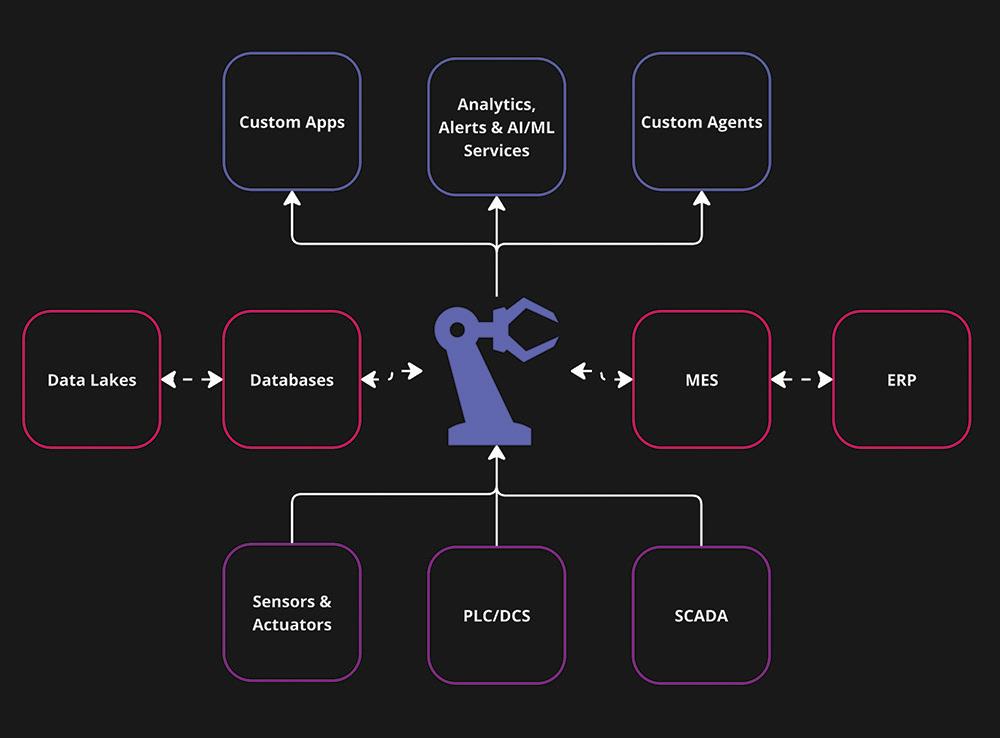

The paper also describes the value of energy audits, which can help identify and quantify potential energysaving opportunities. Digitalization and connectivity are fundamental tools in the quest for greater efficiency because, as the paper says, “You can’t manage what you can’t measure.”

Digital tools provide the basis for the energy monitoring and controls necessary for improving energy efficiency. ABB’s Top Industrial Efficiency Initiative, for instance, can help businesses exceed existing efficiency standards by collaboratively developing and deploying innovative systems, from pilot projects to widespread implementation of power systems.

The technology required for significantly improving energy efficiency, ABB’s white paper concludes, is both proven and readily available. Accelerating the adoption of high-efficiency motors and drives could substantially contribute to global energy savings and economic growth. Doubling the current annual rate of energy efficiency improvements from 2% to 4% until 2030 could avoid a third of the total emissions reductions required to achieve net zero.

And that slick new IE6 motor — the one that hasn’t yet been blessed with official IEC recognition — could play a significant role in making it all happen. — Kevin Jones EA

Chatterboxes

AI chatbots are suddenly everywhere. How best to tame and use them?

By Bill O’Leary, EA Contributing Writer

Sure, everybody is talking about ChatGPT, but have you heard about Eddy? Because Eddy wants to talk to you.

Chatbots have become a mainstay on many business and trade association websites, and the Electrical Apparatus Service Association is no different. Eddy, its artificial-intelligence-powered “assistant,” fields questions and helps members navigate not only the association’s website (www.easa.com) but also the various technical resources, articles, convention papers, and industry reports that fill its vast database.

Eddy is a large language model (LLM) machine, a type of artificial intelligence program that harnesses machine learning to process, understand, and deliver text. LLMs are trained on colossal data sets, allowing them to learn patterns and relationships in language.

They are also trained to sound like humans, producing an experience more akin to a conversation with a knowledgeable friend than combing through an encyclopedia.

Hence, Eddy - and Alexa and Siri before him. This personalization also serves another function. Eddy gets his name from “eddy” currents, which are electric current loops created within conductors by a shifting magnetic field. The currents are common in electric motors and transformers.

Visitors to Eddy’s home, www.easa.com/eddy, are offered a prompt box into which they can type queries, and a couple of preset questions to get a user started, with industry-specific asks such as “What is the EASA ERT Certificate Program all about and how much does it cost?” or relevant technical questions like “What is the minimum insulation resistance of a random wound stator?”

And it’s this level of targeted specificity that conceivably sets Eddy apart from other LLMs. ChatGPT and its digital ilk comb the internet writ large to construct their responses. You’re getting everything, but packaged and ultimately curated based on algorithmic thought and patterns.

That can often lead to irrelevant information or “hallucinations,” which are completely inaccurate responses delivered as fact.

With Eddy, you know what you’re getting, and it’s coming from EASA. The model has been trained on just some of the following:

> The EASA Technical Manual.

> EASA’s AR200-2021: Guide for the Repair of Dry-Type Transformers.

> EASA’s seminar manuals, such as Principles of Medium & Large A-C Motors (NEMA & IEC) and Mechanical Repair Fundamentals of Electric Motors.

> All issues of its newsletter EASA Currents, dating back to September 1998.

> EASA’s website content and resource library, which includes articles on technical subjects, management, sales and marketing.

> Convention papers authored by EASA staff, dating back to 2006.

Swimming in a smaller pond of relevant and authoritative content should help provide a level of validity to Eddy that isn’t often apparent in other chatbots.

There are a variety of business benefits for using website chatbots, which is why they have been digital mainstays for many years, with the recent evolutions in artificial intelligence only further fueling their strength.

Of course, these resources operate around the clock and can accommodate audiences from any time zone. You don’t need to wait for the technician expert or subject matter expert to e-mail you. Their intimidating processing power allows them to handle unlimited conversations at the same time, which reduces wait times and allows human agents to devote their time to more complex issues.

Chatbots also can be used to reduce the need for a larger contact support staff or expensive infrastructure. Whether that should be tagged as a “benefit” is debatable for many, but what is not debatable is that these large language models allow companies to scale customer support strength without a commensurate scale in head count.

Like Eddy, modern chatbots are multilingual, supporting multiple languages using language translation models. This expands customer service to a wide array of new audiences and increases accessibility for non-English speakers. It also cuts down any misunderstandings that are commonplace in verbal communication.

There are dual benefits and drawbacks as well, which shows the risks that confront managers and other business leaders when they implement this technology. Chatbots are designed to give immediate, detailed responses, which reduces the risk of human error or “emotionally heightened exchanges.” Eddy ain’t gonna hang up on you.

But it also ultimately lacks that human touch that some are actively seeking in their interactions. Static, uniform, and scripted responses may be relevant vessels for high-volume info dumps, but what about nuanced, personal discussions that evolve and grow off of subsequent responses? Can artificial intelligence ever capture that level of complexity, that level of specificity, that sheer level of uniqueness that defines the human experience?

There are other challenges that chatbots face. They can become confused by complex, ambiguous, or multi-part questions, which is why prompt generation has become one of the most indemand new skills today. Prompt generation is the process of writing instructions that you provide to the generative AI model to get a desired output. It requires using speci c words, crafting speci c sentences, and communicating speci c contexts to guide the AI.

Good prompts lead to better results and prompt generation is both art and science.

EASA provides a number of prompting tips to best utilize Eddy, such as clearly de ning what you want, including necessary background information, and avoiding complex language or jargon. Simple, direct language is best.

Other tips include the type and amount of questions. One question per prompt helps Eddy focus and provide a more precise response. Have more than one question? Fire it o in the next response. Follow-up questions actually help the large language model better understand the intent of the user since they have more information to go on.

EASA also recommends asking Eddy direct questions, and users can also customize responses by requesting equally direct answers or responses that are more detailed or in a bulleted format. Many a time, while using LLMs, I’ll type a follow-up prompt that says “more detail.” A prompt isn’t a one-anddone a air. Creating a back and forth allows for the model to better isolate the most relevant data, leading to a more pruned and targeted response.

Large language models require sizable processing power and complex setups that I won’t get into here, but the technical demands can lead to delays and crashes on your system. They are also sensitive to data security and privacy, speci cally if they are

built on third-party platforms without a robust security apparatus.

With that said, AI chatbots dominate business websites across all industries, and there doesn’t appear to be an end or even a peak in sight. A recent study by search engine optimization (SEO) analytics company Local Falcon analyzed 60,000 search results over 4,400 businesses in 20 countries and found that AI chatbots typically bypass traditional SEO metrics like page ranking or link volume. They instead rely on authority, prominence, and relevance.

What that essentially means is the old SEO trick of keyword and link stu ng for tra c is ceding ground to what is called “citable evidence of expertise,” which includes data, FAQs, testimonials, and other meatier resources.

Good news for Eddy, who is packed to the brim with industry-relevant data. Warts and all, chatbots are just another way of delivering information with the hope of providing that important answer at the exact time it’s needed. Is a digital assistant the better option? A good old-fashioned human? Well, it really depends on the situation and the preference.

You have a choice, even if you have to dig a little harder for the human option these days. (We’ve all been stuck in the automated message labyrinth constantly saying “speak to a person,” haven’t we?) But whether it’s Eddie at the motor shop in Spokane, Wash., or Eddy from EASA.com, an answer is waiting for you.

Variety. It’s supposed to be the spice of life.

Right? Huh. Just found my next prompt.

Know Your Industry

Advancing materials and industry at the same time

Society for Advanced Material and Process Engineering

Founded: 1944

Headquarters: 21680 Gateway Center Dr., Suite 300, Diamond Bar, Calif. 91765

Annual Dues: Varies by membership tier Website: www.sampe.org

How often does one stop to consider the materials used in aircraft parts? What about marine and automotive applications?

The average Joe may not consider whether these parts are made from composite materials, but the Society for Advanced Material and Process Engineering, or SAMPE, sure does.

Across aerospace, transportation and construction industries, composite materials are being implemented to improve function and e ciency. SAMPE is the global organization that’s been enabling growth and innovation for these industries for 81 years and aims to “educate and connect the global community of engineers and scientists working in advanced materials and manufacturing, fostering

innovation and knowledge exchange that drives the industry forward,” according to the organization.

Advanced composite materials, which are an integral aspect of the organization’s focus, are the fusion of two or more materials that, when combined, can replace traditional ones like metal and wood to improve a product or part’s durability and application. Composite materials vary in form and can be used in cases like vehicle parts, utility poles, and aircraft parts. Even things as common as tennis rac-

quets, hockey sticks, and bicycle parts can use composite materials. The bene ts of using these materials are often increased durability, reduced weight, and less maintenance.

With the increased popularity of these materials over the years, and as industries continue to evolve toward e ciency and innovation, SAMPE is the bridge that joins engineering professionals across industries together. There are three types of membership tiers with the organization, which include professional, student, and retired. With membership, one gains access to the bi-monthly SAMPE Journal — the “industry’s only technical journal dedicated to advanced materials and processes,” according to the organization — which includes both technical and feature articles and also accepts article submissions from members. In addition to accessing the SAMPE Journal, members obtain entry to thousands of digitized technical papers in the organization’s digital library, as well as an industry resource guide.

One of the main objectives of SAMPE is to connect members across elds, which is facilitated by over 20 North American chapters and more than 60 student chapters at colleges across the country. Abroad, SAMPE o ers a large number of international chapters — from Australia to Beijing, France to Shanghai. At these chapters, whether local, international, or student, networking opportunities and professional connections are facilitated. According to the organization, chapters host meetings and o er tours and workshops among other events. These chapters are governed by elected o cials, and many professional chapters work closely with student chapters.

Dr. German Reyes-Villanueva, who has served as SAMPE’s president for the last year, says, “We have a nice membership

of people associated with academia, with the industry, with government. We provide networking opportunities, we have technical committees, [and] we produce things like the State of Technology Industry report.”

Dr. Reyes-Villanueva’s involvement with the organization goes back more than two decades, to when he rst joined the Great Lakes chapter as a member in 2004. He worked his way through the organization, going from secretary to treasurer and beyond, ultimately leading to his current role as president. “It’s not just a society for composites or aerospace but actually involves advanced materials and process engineering for all the di erent industries,” he says.

Across the globe, SAMPE has more than 12,000 members, and Dr. Reyes-Villanueva oversees all operations for the North American region — which includes the U.S., Canada, and Mexico chapters — and manages the activities for professional committees, student programs, and more.

“When we work with advanced materials, we can look into di erent types of composites, multifunctional materials that involve not just the basic development of the materials, but also processing [on an] industrial scale, trying to make sure that the process follows all the requirements,” he says of the organization’s work. “It’s not just controlling the process parameters but controlling how the process parameters a ect the behavior of the materials, to ensure that they have the right performance.”

Members not only gain access to information on these process parameters and insider information, but they also earn access to the SAMPE career center and discounts on conferences, workshops, and seminars. “You get to know a lot of people — not just professionals. You get to go [further] than just a simple opportunity or experience, you get to know the individuals and get to help students and see students grow in their professional career,” Dr. Reyes-Villanueva says. “We also launched MentorMatch, which allows our new young professionals to connect with mentors in the industry, academia and government, to help them grow.”

A year since he stepped into the role of President, Dr. Reyes-Villanueva is condent that the best is yet to come for the organization. “SAMPE’s experiencing an exciting period of growth and innovation,” he says. “This has been a very productive year, and it’s not related to one person. It’s the whole team that is working hard to make sure that SAMPE is at the forefront of the industry.” — Avery Heeringa

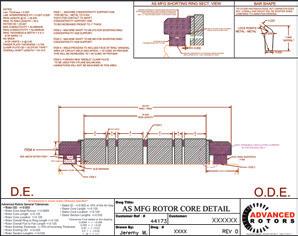

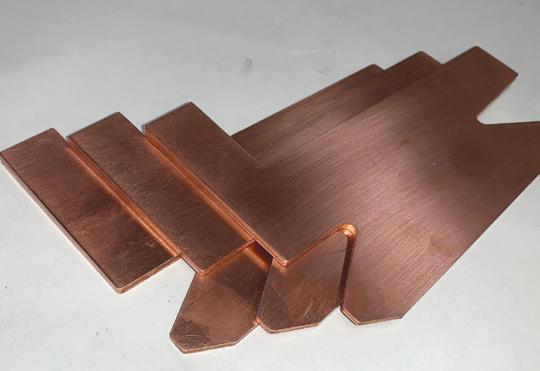

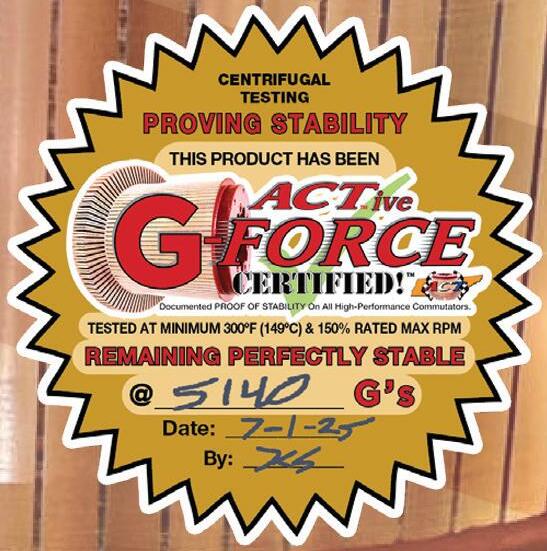

Marketing modified glassband commutators as properly manufactured steel shrink ring commutators (by simply applying forged steel rings over fiberglass tape) is NEVER a sound practice! Product quality ALWAYS tops advertising hype involving common industrial commutators. com • pli • ant adjective: compliant

Including ACTively MATCHED MATERIALS! ™ per OEM DESIGN PRINTS... Forged steel rings properly shrink fit directly onto precision machined hightemp mica maintaining stability exactly like the ORIGINAL SPECIFICATIONS for utmost stability & longevity.

ACT experts utilize engineering prowess to understand the technical/mathematic concepts involved in designing and properly manufacturing ACTually CERTIFIED COMPLIANT! ™ Ultra-High-Performance steel shrink ring type commutators of all makes and all sizes.

Whether it’s High-Performance, Ultra-HighPerformance, or Extreme Duty, COMPLIANCE is paramount in any application. There's truly a HUGE difference! WHEN YOU KNOW THE DIFFERENCE! ™

Dealer’s choice

Having EV chargers on site at auto dealerships demonstrates that the dealers stand behind the EVs they sell

By Maura Keller, EA Contributing Writer

As electric vehicles make up an increasingly larger segment of sales for auto dealers, it makes business sense for dealers to have EV chargers on site. Not only does it allow them to keep their on-lot EVs always charged, but it provides an opportunity to attract new customers and retain existing ones by offering free (or paid) charging.

David Kubick, vice president of business development at Maverick Corp., says installing EV chargers at auto dealerships is quickly shifting from a value-add to a necessity. For dealers, it’s all about future readiness. With automakers rapidly expanding their EV lineups, having the right charging infrastructure in place is essential for compliance, service, and customer satisfaction — whether they are “prospective” customers or “existing” customers.

ting to utility upgrades and final commissioning.

“What made this project successful was our ability to coordinate with the utility early and tailor the installation to meet both operational needs and branding standards,” Kubick says. “Now, Jack Madden Ford is fully equipped to support their growing EV lineup, and they’re better positioned to serve both sales and service customers in the EV space.”

“On-premise EV chargers allow dealerships to prep vehicles for test drives, deliveries, and inventory maintenance,” Kubick says. “They also enhance the customer experience by offering on-site charging during service appointments, which adds a layer of convenience and loyalty. From the driver’s perspective, visible EV charging infrastructure at a dealership builds confidence. It sends a strong message that the dealer is committed to supporting EVs long after the sale, which matters to today’s increasingly environmentally conscious buyer.”

Jason Powers, vice president, North America, ADSTEC Energy, says many dealers offer free charging to customers, so the on-site chargers make it attractive for buyers to return to the dealership, again and again, once they’ve purchased their vehicle. “And some dealers even make their on-site chargers available for public use,” Powers says.

Maverick Corp. worked with Jack Madden Ford, partnering with them to install EV chargers across multiple dealership locations. The project included both Level 2 and d-c fast chargers, and Maverick Corp. managed everything from design and permit-

According to Olga Haygood, CEO of S44 Energy, an EV charging software company that powers some of the country’s largest EV charging networks, for auto dealers, onsite EV chargers support key business functions: They enable test drives, pre-delivery inspections, and service operations for EVs.

“Chargers can also be used to attract public drivers or offer paid charging, creating potential new revenue streams,” Haygood says. “Strategically, it signals a dealership’s readiness for the EV transition and helps them meet manufacturer requirements.” For consumers, it’s about confidence and convenience.

“Chargers at the dealership demonstrate that the store is equipped to support EV ownership, from education and purchase through ongoing service,” Haygood says. “This can ease range anxiety and help build trust, particularly for first-time EV buyers.”

Embracing challenges

Vehicle manufacturers are making a push to an all-electric future, and dealerships continue to play a critical role in their delivery and service model. Auto dealerships are on the front line of electrification as they work directly with customers to find the best model and charging solutions for their needs. Most vehicle manufacturers have established strategies to ensure charging is available at their dealerships. As a result, many auto dealers are required to install charging infrastructure in order to receive their electric vehicle allotment from the manufacturer.

According to Michael Bresnahan, director of development at Chateau Energy Solutions in Atlanta, the challenge for these dealerships is that EV manufacturers are requiring a specified number of Level 2 and Level 3 EV chargers to be installed at the dealership by a specific year. However, these dealerships are owned by an individual or owner group and the manufacturers do not provide financial support to the dealers to deploy EV charging infrastructure and have charging capability.

Recently, Hendrick Automotive Group selected Chateau Energy Solutions for deployment of the dealership’s EV charging infrastructure – specifically, a total of nine chargers were installed across Hendrick Automotive Group’s three dealership locations. Gwinnett Place Honda

was equipped with two d-c fast chargers and one Level 2 charger, as well as the capacity for two more d-c fast chargers. Newnan Honda received one d-c fast charger and two Level 2 chargers, while Mazda Mall received two Level 2 chargers and one dual-port Level 2 charger. Chateau Energy was responsible for the design, engineering, construction, procurement of electrical equipment, and commissioning of the project.

“Typically, the project developer buys and installs the equipment on behalf of the dealerships. Chateau Energy serves our customers in this capacity,” Bresnahan says. “We rst collaborate with our dealership customers to de ne their use case, then we set out to design, engineer, permit, procure, and build the EV charging infrastructure that suits their needs. Where utility upgrades are required, we run point on utility engagement. And in every case, we leverage available federal, state, and local incentive programs to reduce our customers’ out-of-pocket cost.”

Automotive dealers ideally need Level 3 (L3) fast chargers to ensure they can serve a steady stream of vehicles. However, installing L3 chargers typically requires extensive site upgrades and permits that can be both cost prohibitive and time consuming. As Powers explains, many dealers — especially those in city centers or remote areas with limited electrical grid access — are making do with slow L2 chargers, as a result.

“Technologies like battery-bu ered ultra-fast chargers provide an easier and less costly way for auto dealers to bring fast charging to their dealerships,” Powers says. “This category of L3 charger includes a built-in battery storage that enables fast charging on existing power-limited grids.”

In the case of ADS-TEC Energy, for example, the dealership will purchase the equipment and then choose a contractor for the infrastructure. Once that is in place, ADS-TEC Energy performs the installation and commissioning.

“Many auto brands provide nancial support for the project, and if the project is also used for public charging,

it may also qualify for utility or state make-ready funding,” Powers says.

Bresnahan says the biggest challenges and obstacles in deploying EV chargers at auto dealerships are cost and power capacity.

“Each dealership manages its own P&L, and the cost of upgrading their facility hits their bottom line. Deployment costs, including hardware, software, and construction, can be signi cant and don’t have a direct correlation to revenue generation,” Bresnahan says. “Where power is limited and utility upgrades are required, project timelines can balloon, further adding to project costs.”

Kubick agrees that one of the biggest challenges dealerships face when trying to install EV chargers is electrical capacity — as many sites simply weren’t built to support the kind of power needed for multiple Level 2 or d-c fast chargers, which can mean costly utility upgrades.

“Space is another issue. Most dealerships already have limited parking, so

placing chargers in a way that supports tra c ow without disrupting operations takes planning,” Kubick says. “On top of that, permitting requirements can vary widely by municipality, and applying for incentive programs can be time-consuming. And of course, we’re still seeing long lead times on some equipment and transformers, so early planning is critical to avoid project delays.”

Considerations to make

Once an on-site location for one or more chargers is determined, the biggest considerations for installing EV charging are electrical infrastructure and installation.

According to Powers, automotive dealers must consider existing electrical capacity, which must be able to handle the increased load of EV chargers. If upgrades are required, these may encompass new dedicated circuits, electricals, or even transformers. In addition, dealers must consider Please turn to next page

EV DEALERSHIP CHARGERS continued from previous page

installation costs, location, and proximity to power sources and permitting and compliance.

“A major consideration — which is often overlooked — are operating costs, especially electrical demand charges,” Powers says. “Utility companies often charge businesses based on their peak power demand. A single spike in power usage during a billing cycle — such as high use of an L3 EV charger — can result in high demand charges for the entire month. This is another benefit of battery-buffered EV chargers; the built-in batteries enable auto dealers to avoid exorbitant peak demand charges by allowing them to store power and then output when needed.”

Bresnahan adds that while cost and power capacity are the big considerations of making the decision on EV installation, the construction process is also a key consideration during the installation phase.

“Performing the construction activities while not affecting the dayto-day activities of the dealership, such as power outages to install electrical equipment, not impeding traffic flow while trenching, pouring concrete or installing asphalt, striping the charger area, and working around service mechanics in the service bay are just a few other considerations of the EV charger installation,” Bresnahan says.

State-run initiatives

Many states offer incentive programs for auto dealerships that install EV chargers. Efficiency Vermont has an EV Readiness incentive program that gives car dealerships monetary incentives for setting up equipment, tools, and training to sell and service EVs.

Efficiency Vermont’s EV Dealer program has two pillars: 1) the EV Readiness incentive that offers dealerships up to $25,000 for equipment, tools, and certifications needed to service and sell EVs (both new and used), and 2) the EV dealer sales incentives offering up to $600 per new or used EV sold or leased (up to 50 sales per dealer per year, up to $30,000). The program also includes free training on EVs, Ver-

mont incentives, and EV market trends, as well as dealer advertising support, promotional materials, featured promotion in Efficiency Vermont ad campaigns, and online listing via Efficiency Vermont’s “Find a Pro” tool.

“This program supports businesses selling EVs, giving Vermont car buyers more options for more affordable and lower-emission vehicles,” says Nicole Bourassa, Efficiency Vermont’s EV Dealer program manager. “Dealers are critical partners for the EV transition, and the majority of EVs on Vermont’s roads come through local, community dealerships. Many dealers are small businesses, and supporting new and used car dealers to take on and sell EVs supports these local businesses.”

The incentives of the EV dealer program reach dealers mostly through tools, training, professional certifications, and other support. For example, they can get incentives for installing chargers for EVs that customers are test-driving or that are being serviced. They can also purchase new tools and get additional training needed to service and maintain EVs, including their high-voltage batteries. The EV dealer program is specifically designed to help car dealers service and sell both new and used EVs by helping them get the equipment and training for the vehicles their customers are looking for. As more EVs become available, it’s especially important to support used car dealers to help them get the tools and training they need to sell and service used EVs.

“There are many state, federal and utility funding programs available to organizations transitioning to EV sales or offering public EV charging,” Powers says. “Part of our process in needs analysis for prospective customers is to assist them with navigating what funding options may be available.”

In California, for example, the California Energy Commission and utilities like PG&E provide strong support for EV infrastructure, including dealershipspecific incentives. New York, through NYSERDA, offers funding for charging stations and EV readiness tools. In Massachusetts, the MassEVIP program offers grants that dealerships can sometimes qualify for, especially for Level 2 workplace chargers. Connecticut is also very active — Eversource and United Illuminating have make-ready programs that reduce infrastructure costs. And in Colorado, the state energy office has a comprehensive EV readiness strategy that includes dealerships.

“Vermont’s EV Dealer program is implemented in close coordination with State of Vermont partners and Vermont’s electric utilities, which have direct customer incentives for EVs (including offers like purchase rebates and home charging equipment),” Powers says. “The EV dealer program strengthens the EV supply chain by engaging with vehicle dealers through outreach, trainings, and incentives.” EA

Energy round-up

What’s new in the energy industry as summer draws to a close

By Charlie Barks, EA Managing Editor

Solar numbers shine

Expounding on one of our “Direct & current” items from the June Electrical Apparatus (“It’s sometimes sunny,” page 64): The latest official numbers for the solar power industry are in. The U.S. solar industry installed nearly 50 GW d-c of capacity in 2024, according to an annual report from the Solar Energy Industries Association. The preeminent solar association in the country called this “remarkable,” as it represents a 21% increase from 2023. For perspective, it’s worth noting that renewable energy numbers tend to have annual increases, since they all began at very low percentages over the past few decades.

The solar industry accounted for 66% of all new generating capacity added to the grid in 2024. All solar segments set annual installation records except for residential solar, which experienced its lowest year of new capacity since 2021.

The factors driving installation growth in 2024 varied for each segment. Commercial solar installed 2,118 MW d-c in 2024, setting an annual record and growing by 8% year over year.

The community solar segment completed its largest-ever quarter in Q4, achieving an annual record of 1,745 MW d-c in 2024. This growth was primarily driven by record-breaking capacity additions in New York, Maine, and Illinois.

For the residential segment, a significant contraction in the California market and the impact of sustained high interest rates nationwide contributed to a 31% year-over-year decline in 2024, with 4.7 GW d-c of installed capacity.

Earth Day energy

Energy comes in many forms. It’s easy to forget the role of producing clean air performed by the very environment we’re trying to protect. And for that, we need plants.

In late April, the San Pedro, Calif.-based Sharefest Community Development and its longtime partner

Valero Energy Corp. came together once again to celebrate Earth Day with a beautification project at Banning High School in Wilmington, Calif. This year’s focus was the revitalization of a neglected on-campus parkette — now transformed into a vibrant outdoor space for studentled gardening and horticulture programs. The newly enhanced area features native shrubs, walking paths, revitalized planter beds, and a small orchard, creating a sustainable, hands-on learning environment for students.

“The 1-5 District spans from Watts to the waterfront, and here in the communities of Wilmington, Harbor City, and San Pedro, Valero has been a strong community partner,” said Los Angeles City Council member Tim McOsker, who spoke at the event about the power of cross-sector collaboration.

Wooden wind towers

The wood technology company Modvion, which designs, supplies, and installs wind turbine towers made of wood, is embarking on a new chapter. Maria-Lina Hedlund, previously chief financial officer at Modvion, will assume the role of CEO, the company said May 7. Succeeding the company’s co-founder Otto Lundman, she’ll focus on “product maturation” and strengthening partnerships.

The company, which built the tallest commercial wooden wind turbine in 2023, recently unveiled its newest model, engineered for the largest onshore wind turbines. The tower has been given third-party approval and will now be adapted for series production. The new tower is designed to support a V162 – 6.4MW turbine from the Vestas Enventus platform with a 35-year lifetime. The tower design has been evaluated by the independent certification body TÜV SÜD and received a design evaluation conformity statement. EA

Feature | Conventions & Trade Shows

A North American debut

Coiltech North America’s premiere performance offered a glimpse of electrification’s future

By Charlie Barks, EA Managing Editor

NOVI, MICH. — Coiltech, an international trade show with a growing presence, made its North American debut at the Suburban Collection Showplace in this Detroit suburb June 11-12 as a platform for the electric motor, generator, and transformer industry. The 2025 event’s workshop program also included the co-located Applied Electromagnetics Workshop and World Magnetic Conference.

Coiltech was a convention that involved people who are building the future of electrification. This meant traditional coil applications, like those for industrial electric motors, but also burgeoning areas such as the electric vehicle industry. The show featured a wide range of exhibitors whose products included insulation materials based on polymers, tools for technical maintenance in electrical wiring, and more.

Familiar faces

Electrical Apparatus was delighted to see familiar faces, such as those from Electrom Instruments and Rea Magnet Wire, at this year’s event. We also enjoyed meeting new folks from companies like BARplast and PPM.

At the Electrom booth, Jordan Testillo and Kris Torvik had plenty of takers for the company’s latest salvo: the iTIG IV+ winding analyzer. The new product is visually enhanced, with more screen real estate that workers in many different industries can benefit from.

On this series of machines, winding resistance can be measured down to 100 microohms with a resolution of 1 . IR leakage current

measurement resolution is 10 pA (0.00001 microamps), and measurements can be used for PI tests down to 500 pA. PI tests can be done accurately on motors with very low leakage current. Separate highprecision resistance and megohm meters are not needed when the iTIG is used for other tests such as surge and PD tests. Testillo told EA that the company found a number of great leads over the course of the two-day show.

There was plenty of traffic at the Rea booth nearby, too. Kudos to the Coiltech crew — at times it was “way more than what we thought we were going to get” for Rea’s section of the show, according to Nancy Black Hildebrand, a Rea customer experience representative. The long-respected Indiana magnet wire manufacturer found a payoff from bringing a group of employees to the event. Representatives of fellow Fort Wayne company Alliance Winding Equipment were out in force as well, showcasing the company’s trio-suite of products, which encompasses Alliance winding technology, Joyal fusing technology, and Newtech resin/varnish impregnation technology.

Event organizer QuickFairs focused on making the event optimal for face-to-face networking.

The Milan-based company had success with two earlier Coiltech shows in Europe. The core team of Coiltech North America consists of 31 permanent employees, whose main duties revolve around keeping in contact with the exhibitors.

The result was a trade show featuring the most relevant developments in electric motors, generators, and transformers, both on display and in discussion.

Bringing together people from R&D, production, purchasing, and maintenance, the fair delivered condensed, qualified insights in just two days, all while providing free admission, shuttles, parking, and food in what was an efficient expo.

“At Coiltech, ideas spark in the aisles,” said Sebastian Kuester of Coiltech. “You spot innovations before they become industry standard. You meet the supplier who solves the headache you didn’t know you’d have.”

Innovative products

While there was plenty of noise on the floor, it was apparent that the electric vehicle industry is pushing for less on the road. A Wednesday session at Coiltech, headed up by Enedym, covered switched-reluctance (SRM) motors featuring advanced acoustic noise control. This suggests that Enedym, based in Hamilton, Ontario, is working to mitigate the noise associated with SRMs in its products.

The SRMs at the center of Enedym’s approach can generate significant noise, particularly from radial electromagnetic forces. The company says its technology includes “advanced acoustic noise control” for its SRMs.

Methods for reducing electric motor noise generally involve design optimization, using sound-absorbent materials for enclosures (though this may not be economical and can affect thermal characteristics), and utilizing control strategies. Common sources of electric motor noise include worn bearings, misalignment, and issues with internal components.

Another company showcasing innovative products was Delo, an adhesives manufacturer based in Windach, Germany. Adhesives play an important part in making electric drives smaller and more powerful while increasing their efficiency. For example, the installation space required for traditional production processes can be reduced thanks to narrow bonding gaps. Typical bonding applications for electric motors include the securing of buried or surface magnets, the stacking of segmented magnets, and the bonding of stators and housings.

Adhesives are also used for potting coils or for electrically insulating windings. Delo says suppliers can benefit from its extensive product portfolio. Specially developed for electric motors, the products offer maximum strength; they are temperature- and

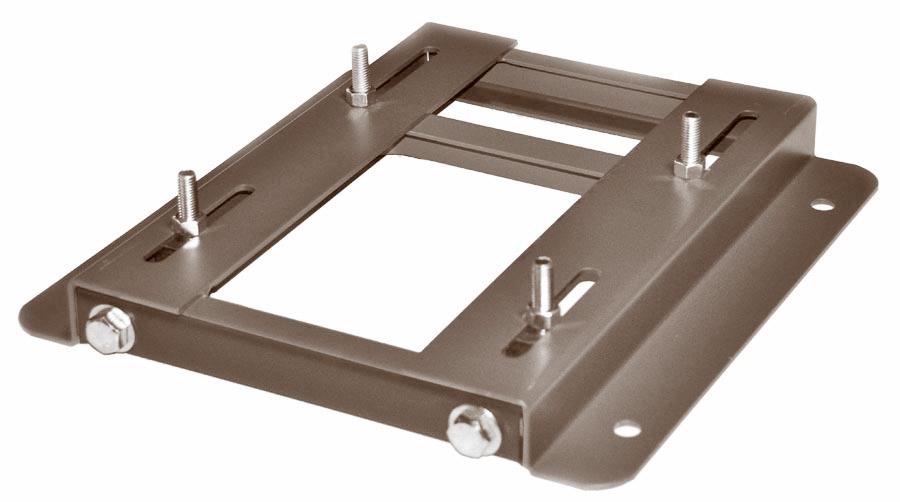

Adjustable Motor Base keeps

Our Adjustable Motor Base is continuously improving to be the most durable and longlasting motor base on the market. With the latest patent pending advancement, Overly Hautz motor bases now last 5 to 9.5 times longer than the competition. Decrease downtime and save money with extended motor base life cycles.

Read the verified factory test report at: www.overlyhautz.com

If you wish to continue receiving Electrical Apparatus, don’t forget that you need to renew your subscription periodically.

If renewing online, go to ea-renew.com and choose “Renew Subscription.” Then, fill out the form with your Subscriber ID or your e-mail address. Or, mail or fax your mailing label to . . .

Barks Publications, Inc. 17 N. State St., Suite 435, Chicago, Ill. 60602

Fax: (866) 228-7274

E-mail: EAMagazine@barks.com

media-resistant, gap-filling, impact-resistant, and tension-equalizing. Depending on the production process, curing is possible by heat, under the exclusion of air or, in the case of two-component products, at room temperature. If higher demands are placed on bonding accuracy, or if direct and fast further pro-

cessing is required, such final curing is often preceded by initial light fixation.

Show partners express satisfaction

For partner companies of the event, such as Haefely, Schleich, and Eurotranciatura, the debut American show seems to have made a favorable impression.

Eurotranciatura’s team called Coiltech “a dynamic event that offered quality networking opportunities and an engaging combination of exhibition and high-level conferences.” For Eurotranciatura, it was an important opportunity to strengthen its connection with the U.S. market, reaffirming the group’s longstanding presence in the region through its two strategic production facilities in the U.S. and Mexico and its commitment to working closely with local businesses.

The presence of the entire supply chain — from steel suppliers to OEMs, from component and systems manufacturers to research institutes — and the international representation from across Europe, Asia, Africa, and the Americas, made it a truly unique meeting point.

“We’re proud to have been among the most visited booths at the show, a reflection of the value we bring by combining expertise in e-mobility, industrial and infrastructure solutions, with a local presence and global impact,” said Giulia Polvara of EGLA.

Eurotranciatura also gave special thanks to Coiltech, the International Coil Winding Exhibition & Conference’s team, to Kuester for his contribution, vision, and organizational skills, and to Matteo Vezzini for supporting its overseas exhibition.

The next Coiltech North America is scheduled to be held June 10-11, 2026, again in Novi, Mich. There are two European Coiltechs scheduled as well: Coiltech Italia 2025, to be held Sept. 17-18 in Pordenone, Italy, and Coiltech Deutschland 2026, to be held March 25-26, 2026, in Augsburg, Germany. EA

Views from the Coiltech trade show floor

The operator’s side of a coil winding machine from Broomfield, of Leominster, Mass. The machine features multi-speed, large-capacity, high-torque winding capabilities.

| Conventions & Trade Shows

Transformative talks

Presentations on transformers and motors figured prominently at the Coil Winding, Insulation & Electrical Manufacturing Exhibition in Berlin June 3-5

By Kevin Jones, EA Senior Editor

The Berlin Coil Winding, Insulation & Electrical Manufacturing Exhibition — most people call it “Cwymee” — is many things: a marketplace of processes and materials used in electrical manufacturing, discussions about coil winding, tantalizing glimpses of new technology for electric vehicles, and ruminations about “sustainability” and the “energy transition.”

CWIEME Berlin typically pays particular attention to coil winding, electric motors, transformers, electrical conductors, and electrical insulation. The 2025 event, held June 3-5 at Messe Berlin, played true to form, showcasing innovations across the entire supply chain for these electrical manufacturing sectors.

This year, about 7,000 attendees gathered to explore new technologies, hobnob with industry professionals, and gain insights into global market trends. The exhibition featured about 750 manufacturers and suppliers from more than 85 countries. The conference program brought together more than 90 speakers.

The conference side of the event is so wide-ranging that one could hardly do it justice in just two pages. To narrow things down: This year’s edition of CWIEME Berlin contained enough about motors and transformers to give visitors a glimpse of where the industry’s priorities lie these days, at least on the European side of the Atlantic.

The latest in electric motors

The discussions about electric motors tended to consider motors in the context of “e-mobility,” but the principles under consideration could generally be applied to industrial motors as well. Ideas entertained by designers of motors for electric vehicles sometimes catch on with designers of industrial motors; see the way in which “power density,” once the purview solely of engineers in the e-mobility game, is now sometimes touted as a relevant characteristic of motors designed for manufacturing plants.

One session worth noting was an exploration of PMG technologies for e-motors, with a special focus on soft magnetic composite (SMC) components and e-axle secondary systems. This presentation delved into the ways in which SMC components can

CWIEME Berlin 2025 brought together some 7,000 attendees, 750 exhibitors, and 90 speakers. The state-owned Messe Berlin conceives, markets, and organizes hundreds of events each year.

enhance motor performance by reducing energy losses and improving magnetic properties. The speaker, Diego Castro Menéndez-Castañedo, director of engineering and R&D at PMG, explained how these technologies are helping to fulfill the growing demand for efficient motors, particularly in automotives.

Improving the performance of electric machines through additive manufacturing was the focus of a presentation by Drs. Anna Ermakova of the University of Bristol and Richard Pollock of Technelec Ltd. Their presentation showed how metal additive manufacturing can offer freedom for designers of electrical conductors, enabling new approaches to reduce a-c loss, improve thermal management, and provide alternative electrical insulation options.

“The Global Evolution of the Electric Motor Supply Chain and Technology Development: Evolving Landscape” was the title of a timely presentation by Michael Southcott of S&P Global Mobility. He explored the dynamic environment of the electric motor supply chain, looking particularly at the supply chain’s rapid growth and at technological advancements within the automotive industry.

The “circularity” of electric machine manufacturing came under scrutiny by Dr. Adriana Encinas-Oropesa of Cranfield University and Matthew Lamb of Turntide Technologies. Their presentation, titled “Circularity of Electrical Machines: A Case Study from the Automotive Industry,” was intended to show manufacturers of electric motors the way toward improved “circularity” practices. (The idea of circularity, in the sense in which European industrialists are fond of using the word, is to keep products, components, and materials in use for as long as possible, extracting their maximum value while in use, and then

recovering and regenerating products and materials at the end of their service lives.)

Continuous flow winding, or CFW, a manufacturing approach for electric motor stators, was described by Daniele Nocciolini of IMA Automation and Davide Bettoni of MAVEL. The technology behind CFW, the speakers explained, combines hairpin precision with inserted winding simplicity to enhance electric motor performance. In short, the purpose of CFW is to reduce rotor losses and provide superior thermal management through direct oil cooling within stator slots. Because it optimizes current density and streamlines the production of coils, this innovation, according to Nocciolini and Bettoni, can offer a compact, cost-effective, and scalable approach to designing and manufacturing motors.

The benefits of using composite materials in the manufacture of sleeved interior permanent magnet, or IPM, motors were outlined by Dr. David Hind of Drive System Design. (IPM motors are a type of permanent-magnet synchronous machine whose permanent magnets are embedded within the rotor core.) Hind explored the merits of using composite sleeves in IPM machines compared with conventional designs. Comparisons with a standard automotive traction market machine, he said, have shown that the optimized composite-sleeved motor design achieved a 0.6% increase in drive cycle efficiency alongside a 23% reduction in cost.

Carrying out the maintenance, repair, and end-of-life phases of electric motors — all with a view toward “sustainability” — was taken up by a trio of presenters from the International Copper Association Europe: Fernando Nuño, Tomas Jezdinsky, and Bruno de Wachter. Their discussion explored methods of extending motor life through innovative maintenance and repair strategies. They also examined current practices and potential improvements across various motor classes and sizes.

Transformer transformations

Transformers took center stage in several sessions, with sustainability, not surprisingly, a recurring theme.

Kirsi Seppäläinen, vice president of commercial planning and product management at Stora Enso Biomaterials, delivered a talk about building sustainable transformers. Her presentation covered innovations in materials and manufacturing processes that reduce environmental impact while maintaining performance. Seppäläinen emphasized the need for transformers that can handle the demands of modern power grids, which — as we have observed numerous times in Electrical Apparatus — are increasingly drawing on renewable energy sources.

In another session, Dr. Pawel Rozga of Lodz University of Technology discussed recent advances in transformer insulation, addressing nonstandard lightning impulse testing of dielectric liquids used in power transformers. His presentation detailed findings from experimental studies that tested the lightning performance of various dielectric liquids. Rozga highlighted new testing approaches aimed at verifying the dielectric properties of these insulating liquids, which are critical for transformer operation and safety.

A session titled “Supply-Demand Dynamics in the Transformer Market: Trends, Challenges, and Opportunities,” presented by Hassan Zaheer of PTR, Inc., explored the evolving supply-demand landscape of the transformer market. Subjects covered by Zaheer included global transformer market growth drivers, regional demand shifts, the impact

of supply chain disruptions and raw material shortages on transformer production, and technological innovations influencing transformer design and efficiency.

In a session with the provocative title “The Inconvenient Truth about Transformer Fires: Risks, Realities, and the Path to Safer Solutions,” Javiera McGuiggan of Cargill BioIndustrial addressed the often-overlooked risks of transformer fires. She confronted the frequency, impact, and data gaps surrounding such incidents and urged making fire safety a higher priority. McGuiggan’s discussion covered the operational, financial, and environmental consequences of transformer fires, and she presented several solutions — such as the use of FR3 natural ester fluid — as steps toward mitigating firerelated risks.

Mario Viarengo of Shell Lubricant Solutions, in a session titled “Energizing the Future: Sustainable Power for a Growing World,” spoke of the increasing demand for reliable, efficient, and sustainable energy. He explored the intersection of environmental regulations, renewable energy, and innovative technologies, emphasizing the impact these factors have on energy infrastructure.

Martin Stössl of Siemens Energy Austria GmbH and Sebastian Rehkopf of Maschinenfabrik Reinhausen GmbH, meanwhile, collaborated to present “Empowering the Energy Transition: The Role of OnLoad Tap-Changer-Equipped Transformers in Grid Sustainability.” The two spoke of the importance of decarbonizing the energy sector to meet climate targets, noting the contribution of renewable sources such as wind toward meeting this objective.

A session titled “Collaborative Decarbonization: Establishing Green Lead Markets for CO2-Reduced Electrical Steel in Energy Grids,” presented by Marcel Hilgers of thyssenkrupp Electrical Steel, examined collaborative efforts, particularly among producers of CO2-reduced steel, transformer manufacturers, and grid operators, to meet climate goals. (“CO2-reduced steel” refers to steel manufactured with processes that produce less carbon dioxide than conventional methods.) Hilgers also outlined strategies for maintaining the resilience of supply chains for grain-oriented electrical steel.

For people with an appetite for electric machines, materials, and electrical manufacturing methodologies, CWIEME is a movable feast. Those who missed the Berlin event — provided they could swing the time and the travel expenses — would have been able to catch CWIEME Shanghai at the Shanghai World Expo Exhibition & Convention Center June 25-27. The next CWIEME Berlin is scheduled to be held May 19-21, 2026. There used to be an annual CWIEME North America in Rosemont, Ill., but the most recent of those was held in 2019.

Associations

An association lays out an innovative energy plan

A March 10 call for opinions by the U.S. House of Representatives’ AI and Energy Working Group drew a response from the National Association of Manufacturers that lays out a plan for responding to increasing electricity demand. The response was signed by Charles Crain, the National Association of Manufacturers’ managing vice president of policy.

The Congressional working group, created and headed by Rep. Julie Fedorchak of North Dakota, had invited energy industry stakeholders to “examine how best to harness domestic energy resources, secure critical infrastructure, and tailor policies that not only meet today’s needs but also position the United States to outpace global competitors, particularly China, in the AI era.”