am writing to you only a matter of days after attending the excellent Posidonia event in Athens, Greece. It was good to see so many people coming together in one place after so long, and also heartening to see that shipping and ship supply are definitely up and running and raring to go following the pandemic.

The overriding message from Posidonia was one of optimism and enthusiasm for the future and while society is facing a number of major difficulties in rising energy costs and general inflation, all the shipping markets are performing at very high levels, a phenomenon not normally seen across the board. This should translate into increased business for our members in the ports they serve. ISSA always stands for quality ship supply.

Posidonia also gave a number of the ISSA members an opportunity to exhibit their goods and services to the global shipping industry and it was great to see our friends from Turkey, Greece, Brazil, the UK and Vietnam, among others, there in force.

The ISSA Executive Board also used the opportunity of Posidonia to hold its first in-person Executive Board meeting in over two years and I would like to thank my fellow Executive Board members for the time and energy they put into the two days of meetings. Apart from being able to reconnect on a personal level, it was very useful to be able to debate issues at close hand and a lot of good progress was made. We look forward to similar meetings in the future.

In the meantime, may I wish you all a very successful summer and I look forward to continued dialogue with the ISSA membership moving forward.

You can keep up to date with the latest news on the ISSA website at www.shipsupply.org and send in your comments and views to the ISSA Secretariat either by phone on +44 (0)20 7626 6236; Fax +44 (0)20 7626 6234 or alternatively email secretariat@shipsupply.org

Happy reading. u

Saeed Al Malik ISSA President

he United Arab Emirates is now one of the top five countries for ship supply and bunkering operations. So reports Jason Georgiou, Vice-President of the United Arab Emirates National Ship Suppliers Association (UNSSA).

Turn-over in the sector now runs to $350m. This figure includes bunkering as well as ship supply.

With a membership of more than 40, UNSSA is a major player contributing to operations and deliveries within the ports of the UAE.

There are 12 ports within the UAE and cargo volume now approaches almost 100m tons. Biggest of these ports is Jebel Ali. Sharjah and Fujairah are also significant players.

UNSSA, a proud member of ISSA, has contributed its

suggestions and proposals in a bid to overcome the problems experienced in delivering to ships in all UAE ports.

The Association has been in dialogue with port authorities to ease delivery problems experienced.

ISSA President Mr Saeed al Malik, founder of UNSSA said: “ISSA has been meeting with IMO and Shipowners for the delivery of Hazardous Materials on board ships as well as for the replacement of plastic packaging within ship supplies.”

UNSSA is following the subject and most of the UAE ship suppliers are already in the process of using recycled plastic packaging and taking actions to protect the environment.

For the UAE, UNSSA is in discussion with Port authorities for clarification about Hazard materials deliveries like Chemicals and Gases. u

SISSA Senior Executive Vice-President, Abdul Hajah, explains where Indian ship supply is positioned and how it is supportive of the country’s investment programme

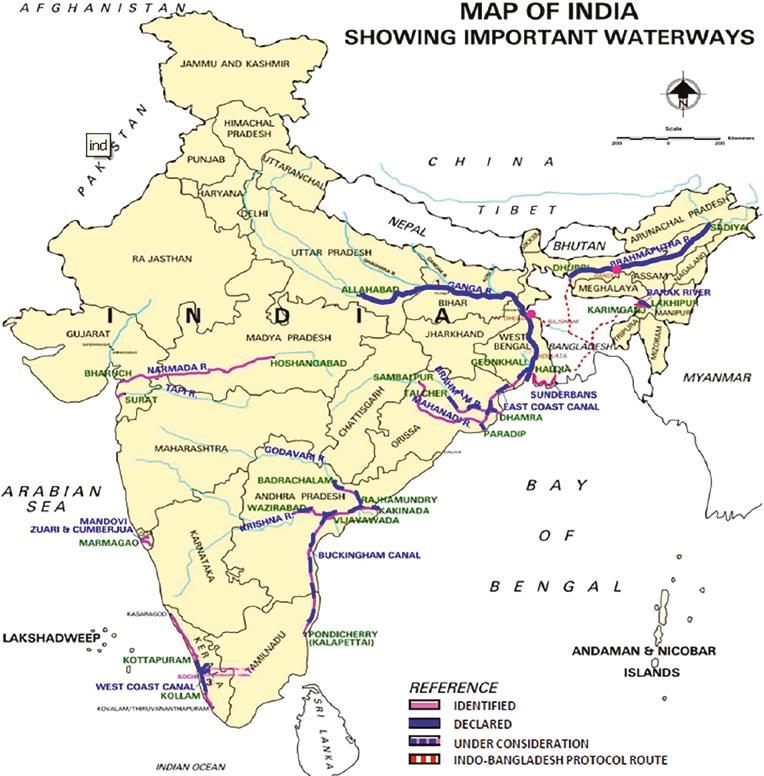

urrounded on three sides by water and with a coastline of more than 7,500km, sea ports remain crucial to India, the world’s 16th largest maritime country.

The government of India recognises the importance of the maritime industry and, as such, has made heavy investments in developing the ports to handle larger volumes and provide more efficient services.

There are projects being discussed for further developing major government-owned ports such as Mumbai and Chennai and this is in line with its aim to make India one of the biggest maritime hubs in the world.

The good work of the government is further complemented by associations such as the Indian Port

Association (IPA), which serves as a “think tank” for the major ports in India, with the aim of raising the standard of port facilities to international levels across the country.

With more than 100 associate members from India, Indian ship suppliers have always formed an important part of ISSA’s global outreach programme.

Over the years they have embraced the wave of globalisation and kept up with the demands of shipowners by increasing coverage at various ports within the country and providing a wide range of products and services.

With new companies continuously entering the industry, the Indian market is growing and this bodes well for shipowners and ship managers who require services in the Indian sub-continent. u

So say Noorul Ameen and Mohamed Yusuf, Directors of long established ship suppliers Admiral Marine Services Pvt. Ltd, who are headquartered in Chennai on India’s east coast.

Vessel agents now have added authority to undertake approvals from port authorities while liaising with suppliers who still have the onus of completing the port formalities.

While this was earlier seen as a welcome move, the lack of direct interaction with port authorities has made it challenging to plan a supply schedule due to delayed approvals.

Expectations for additional remunerations from vessel agents have also led to an increase in supply costs.

The Directors: “Palletized supply is our preference but the ground reality in most ports does not make it feasible due to complexities in arranging a forklift and

the unexpected delays in having to wait for it.

“With individual delivery of boxes, direct interaction between the boarding team and the crew has always been helpful especially in locating all the items.

“However, with communications being restricted, we have become more efficient with our packing and packing lists in ensuring traceability.”

It’s not all gloom and doom however. Safety measures adopted during the global pandemic have continued to be adopted and improved safety and well-being as a result.

“These safety measures have now become a regular practice across all our 13 branch offices where our own teams serve vessels calling in over 23 Indian ports.

“Our frequent interaction with the Port Health Offices, has made us pro-active in doing more than required by ensuring additional certifications and vaccinations

for our food delivery teams in addition the COVID doses,” the Directors said.

One nearby situation has resulted in mixed emotions. The unfortunate economic collapse in the neighbouring Sri Lankan economy, has increased the number of vessels that were earlier calling Colombo and other ports. This has created further opportunities for Indian ship suppliers although it is doubtful such misfortune in one area is universally welcomed in Admiral’s operational area.

The Directors concluded: “This pandemic/post-pandemic era has ensured that healthy collaboration within our supply ecosystem is the need of the hour.

“All active players (ship chandlers, vessel owners/managers, crew, vessel agents and port authorities) share this realization which is very promising as we move forward towards a sustainable, safe, delightful, and efficient supply to ships calling Indian ports.” u

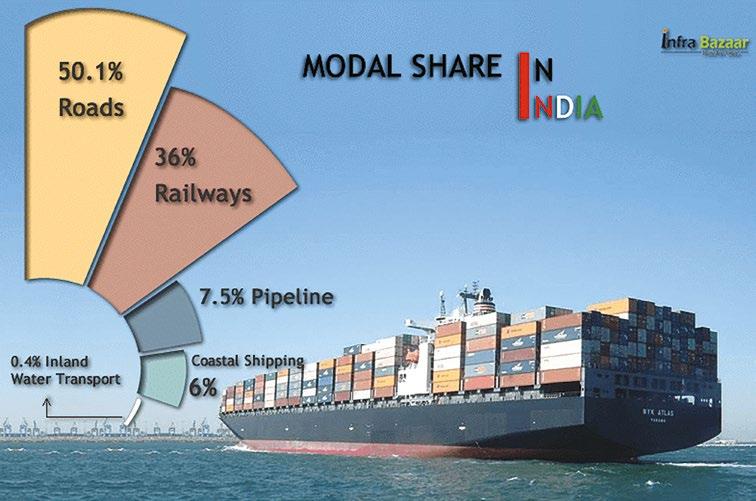

India has a long coastline of 7517 km, with over 200 ports. Most cargo ships that sail between East Asia and America, Europe and Africa pass through Indian territorial waters. India has 12 major and 205 notified minor and intermediate ports.

Under the National Perspective Plan for Sagarmala (Water Way transportation network), six new mega ports will be developed in the country. By next year, these ports in India will be implementing seven projects worth about US$300 Million on a public-private partnership basis. This will accelerate the development of water transportation and movement of goods by sea as well.

The growing shipping industry in India is giving a big boost to the ship chandling business.

Previously ship owners and management preferred to get ship stores from the Middle East but now the scenario has changed and they are considering Indian ports to store their vessels.

Hopefully, this will lead to a huge growth for ship stores and spare parts supply and maintenance in the future.

The widespread port networks in India shed light on the future ship supply industry. The current industrial friendly atmosphere

in India gives new hopes to the ship chandling business. The government policies and tremendous growth in infrastructure also leads the business to new heights.

Availability of all kinds of products and services are the main advantages about ship suppliers in India.

It is a great relief for shipping companies to have all the provisions and technical stores in a country with such a vast port network as India.

All this bodes well for the future of Indian ship supply. u

Recently we heard and saw in the news that Qatar has awarded EPIC contracts to some famous international contractors.

Obviously these contracts will have a positive impact on marine services, which will whet the appetite of international companies to serve the main contractors offshore.

One of these services is, of course, ship supply. The State of Qatar has a proven history of ship supply which has developed in parallel with the development of the state and accompanying regulations.

With gas and oil booming, ship supply will continue to expand in Qatar especially when the new Hamad port becomes operational along with the expansion of Ras Laffan port.

Ship supply in Qatar is based on a clear vison of Qatar 2030, and equal competition. The infrastructure that the State

of Qatar has invested during the last decade has allowed the operating companies to serve different ports and to supply provisions to vessels to an excellent quality standard.

The State of Qatar has invested in logistics infrastructure and zones to manage the delivery of provisions in containers (either dry or frozen).

The role of the supplier in this ecosystem is very important to secure supplies. Food control is strict to maintain the health of the consumer.

The ship supply sector is an active business that contributes to the development of the full range of marine activities, and the State of Qatar is keen to continue the development of this vital sector. u

www.akd-qatar.com

The Singapore-based Global Centre for Maritime Decarbonisation (GCMD) has announced three new partnerships.

The new partners are: International Bunker Industry Association (IBIA), the International Windship Association (IWSA) and the commodity markets data and analytics provider Kpler.

Since its formation in August last year, the Centre has established partnerships with key stakeholders in the maritime industry and it says that the new partnerships will enable it to extend collaboration beyond the immediate supply chain to the broader ecosystem and will be ‘crucial to the pilots and studies in the Centre’s 5-year projects outlook.’

Professor Lynn Loo, CEO of GCMD, commented: ‘Working together with our new partners, we look forward to collectively unlocking the full potential of each organisation to amplify the impact for our decarbonisation efforts.

“With IBIA, we look to increasing outreach to the bunkering sector, a key stakeholder group especially when we begin preparations for pilots with alternative fuels.

“GCMD is already working closely with IWSA to gain perspectives and insights relating to wind-assisted propulsion as a near-term retrofit solution.

“Through Kpler, we will also have access to market data that can help us better understand trade flows which can support us in shaping our pilots and studies.”

IBIA’s Director, Unni Einemo, said: ‘We saw the importance of cross-industry co-operation and knowledgesharing to navigate successfully IMO 2020, which IBIA was actively involved in.

“As we grapple with the much bigger challenges to reach carbon-neutral shipping, collaboration and effective information gathering and sharing is even more important to ensure efforts are aligned.

“IBIA’s members are increasingly engaged in the supply and use of alternative fuels, or making plans to do so. We look forward to working with our fellow partners in GCMD to untangle the complexities of the energy transition.”

“The challenge of decarbonising the shipping industry requires a fundamental shift towards a hybrid approach, utilising all of the tools we have over the coming decade to make shipping cleaner, more efficient, profitable and fit for purpose in a carbon constrained world,” said Gavin Allwright, Secretary General of the International Windship Association (IWSA).

“GCMD brings together a wealth of expertise and experience and is positioned at the very centre of this transition.

“We are looking forward to working together to help drive innovation and further integrate wind propulsion, so as to meet our shared goals of delivering deep and urgent decarbonisation in the maritime sector.” u

Ballast Water Treatment Systems’ installation costs as well as system footprint are causing increasing concern to ship owners. BIO-SEA aims to address these issues

Significant BWTS developer BIO-UV Group have pledged to address ship owners’ concerns by developing a more compact and competitive range of their BIO-SEA ballast water treatment system.

The BIO-SEA “M” Range is a multi-lamp reactor designed specifically for flow rates of up to more than 2100m3/h.

The M range also reduces unit height making installation easier than other comparable systems in the market.

“Prior to this development we primarily focused on the low and medium flow rate requirements,” says Florian Cortes, Technical Director for BIO-SEA.

The development follows a steep rise in retrofit activities this year, which the French UV water treatment expert expects to peak in the last quarter.

The company has signed several fleet retrofit agreements with northern European shipowners, with most requiring flow rates of up to 2000m3.

There has also been a number of new orders for its tworeactor B02 300 BIO-Sea system, mainly from the offshore vessel and general cargo sectors.

“We are also proud to announce that BIO-SEA has recently been selected for the BWTS development program

for the US Navy and signed another substantial naval contract in Europe, with the system selected for several projects in coming years.

“We are also seeing an increase in orders from the superand mega-yacht segments for which our range of product is ideal and will be strengthening our position in the low to medium flow rate market across the yachting sectors.

“Our Low Flow range has the lowest footprint among UV systems for requirement below 100 m3h”, said Mr Cortes.

BIO-UV Group’s market share in the OSV segment has increased, with dozens of successful deliveries.

Quite often, retrofits occurred under time pressure for delivery, as vessels were going out from layup for new missions. BIO-SEA’s short delivery time - one of its key strengths - has been a major factor.

“We have also secured several fleet agreements, mostly in North Europe.

“These include the full front-end engineering, design supply and commissioning of units for cargo ships and reefer vessels ranging from 3,000 to 15,000dwt,” said Maxime Dedeurwaerder, Business Development Manager, BIO-SEA by BIO UV Group.

The company’s current range of BIO-SEA systems is up to date with all the regulatory requirements, including IMO, USCG, IACS. Its new BIO-SEA M range has also been approved for G8 and is now USCG certified.

“We also have the IMO certification for the latest version of the BIO-SEA control system and we are currently in the process of updating all our certifications in order to include the latest versions of BIO-Sea, which will be compatible with GPS data acquisition.

“This is a new feature we are providing in order to anticipate possible future regulatory requirement for that respect,” said Mr Cortes.

The GPS Data is simply the registration in the log of the system of the vessel’s GPS position when a ballasting operation is performed. By cross referencing with all other input data, various analyses will be possible, although at first this addition aims to anticipate a possible IMO regulation update: localisation and tracking of ballasting operations.

With many ships now using the BWTS they installed in previous years, it is apparent that Filter + UV-based treatment technology is the more operationally and financially efficient technology at certain flow rates than any other ballast water treatment technology.

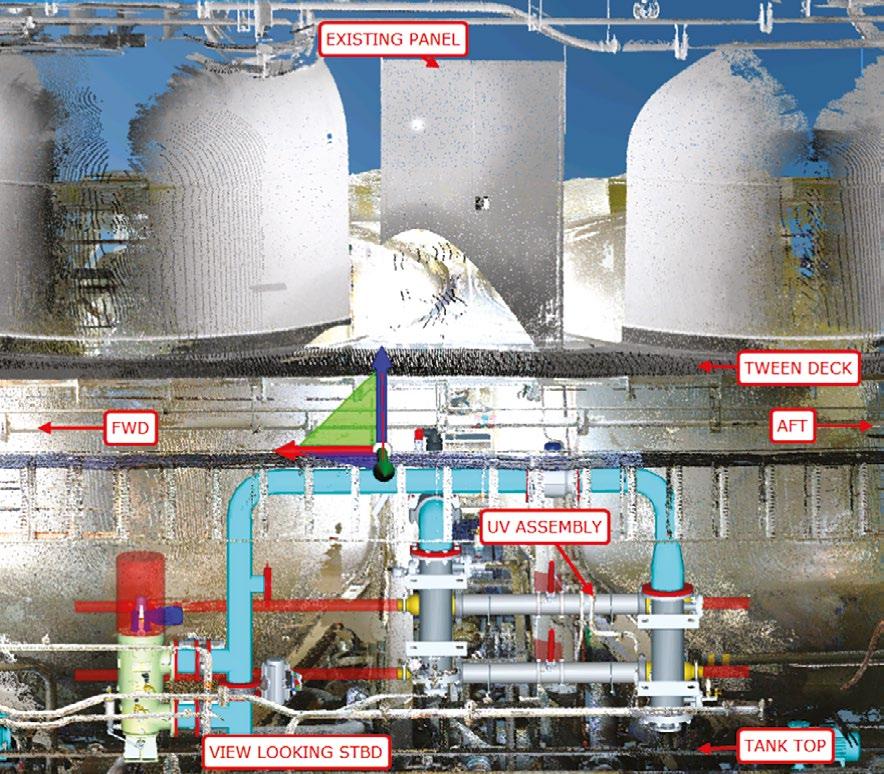

“We introduced the new BIO-SEA M-Series as shipowners have specific requirements in terms of size, capacity and installation simplicity.

“There has been a number of issues relating to the height of other units in the market. BIO-SEA M is also a manifold-free design which allows shipowners to optimise installation time and costs dramatically, whilst keeping the number of reactors required to an absolute minimum: only one or two depending on the required flowrate.

“We anticipate an increase in orders throughout 2022, which will be an important year for the market in terms of retrofits. We also notice that the yacht and the OSV segments, two types of ships for which we have specially developed BIO-Sea solutions, are now looking at the options available more thoroughly.

“Another noticeable trend is the requirement from shipowners to work with a limited number of business partners during a retrofit project, and to be fully supported throughout the process.

“We addressed this need by developing turn-key offers. Today, we provide a full ballast water retrofit package that includes everything from 3D Scanning and detailed engineering to commissioning and training globally.

“By strengthening our in-house capabilities in this way, we better address containerised options or turn-key with a complete BIO-SEA front end engineering and design (FEED) capability,” Mr Dedeurwaerder explains.

3D scanning allows for the scanning of the entire ship to find the optimum site/space for a BIO-SEA installation. BIO-UV Group provides basic and detailed drawings for class approvals to ensure shipowners only need deal with a single supplier. u

www.bio-uv.com/en

Maxime Dedeurwaerder BIO-SEA Business Unit DirectorCompact, high-performance and easy-tomaintain MANTA filters, created in response to market-feedback, also receive equivalent series type approval

Filtersafe, a world leader in automatic seawater filtration, has launched its new ‘MANTA’ filter series. The system was shown to the market at Posidonia recently in June.

The company’s latest high-performance filter is able to maintain impressive removal rates – 99.6% of organisms over 50 μm – all in a cost-effective package with a small footprint, specifically engineered for UV based ballast water management systems (BWMS).

These organism removal rates ensure that ship owners and operators will be compliant with the International Maritime Organization’s D-2 standard for the implementation of the ballast water management convention, which must be adhered to by 08 September 2024, as well as the U.S. Coast Guard’s (USCG) existing ‘Final Rule for Ballast Water Treatment’.

Filtersafe has received an equivalent series type approval from Det Norske Veritas (DNV) and the USCG. As one of the first complete filter redesigns to be approved under the USCG’s Policy Letter (CG-OES 03-20) Guidance on Testing Alternate Components for a Type Approved BWMS, the MANTA reflects one of the first true evolutions in ballast water filtration since the

complex and costly testing regimes were mandated. Gaining approval under this policy ensures that customers of the performance-leading BallastSafe filter now have a new, more compact option to add to their BWMS portfolio.

The MANTA features Filtersafe’s new one-motion scanner. This new design removes lateral motion of the scanner, reducing cost and eliminating parts. It features a larger proximity nozzle which is able to clean the filter screen in one continuous motion. When combined with the filter’s unpleated screen, the MANTA has improved cleaning coverage that reaches 100% of the screen.

A high-performing filter with scalable automatic self-cleaning technology is particularly important for BWMS operations in challenging water conditions, which is a priority for regulators and ship operators alike.

Automatic filter cleaning can be increased when ballasting in sediment-rich waters, including those found in the port of Shanghai, to ensure a consistent flow rate and to avoid costly operational issues such as clogging.

Despite being tested with a finer mesh filter, the MANTA outperformed the original BallastSafe design in independent testing of the cleaning, removal rate, and throughput efficiency of the filters.

Corrosion prevention remains another key industry pain point. Filtersafe introduced 904L stainless steel across its filter screen supply chain last year and this superior steel is also used in the MANTA series’ sintered screens.

In addition, and in order to combat the steady-rising cost of alloy material, Filtersafe, together with its partners, has adopted a new SuperQuenching procedure, borrowed from the space industry, to overcome the material degradation of 316L due to the weaving, sintering, and fabrication process. This allows it also to offer a viable 316L screen option at a lower cost. Improved longevity and superior cleaning reduces maintenance costs and, even when maintenance is required, MANTA is thoughtfully designed to ensure it can safely and efficiently be maintained by one person.

Mark Riggio, Head of Marine at Filtersafe, commented: “As requested by leading BWMS manufacturers, we’re pleased to offer Filtersafe performance in a smaller package, designed specifically for UV systems.

“Having equivalent series type approval already completed makes adopting a MANTA filter a no brainer for our current customers. The rising challenges posed by sediment-rich water conditions are not going away – and now we have the filter that anyone can use to meet them.

Ballast water management is one of the toughest water treatment challenges in the world and demands the best technical solutions. There is sufficient technology and innovative equipment available on the market today to overcome operational challenges and ensure seamless, costeffective regulatory compliance. u

https://filtersafe.net/

• As Industry Pushes to Expand the Definition of “Challenging Waters” Will There Ever be a Value to Compliance with IMO’s D2 Standard?

• As Contemaporary BWTS, and Their Limitations, Become Entrenched, Is There Room for Innovation in the BWT Market?

The IMO’s 2004 Ballast Water Convention is intended to limit aquatic invasive species from being spread globally via ballast water transported in commercial vessels. The Convention uses a biological discharge standard “D2” as the primary control mechanism to achieve the aim of The Convention. D2 is a stringent standard e.g., ten zooplankton per cubic meter, where ambient waters can often carry hundreds of thousands or more critters per cubic meter.

About half-way into the five-year Ballast Water Management System (BWMS) retrofit schedule, with many thousand BWMS fitted, D2 is still an aside, rarely considered during system selection, almost never measured, and so far not enforced.

The IMO’s Ballast Water (BW) Experience Building Phase (EBP) is coming to an end. The EBP is intended to inform IMO of stake holders experiences with BWMS and The Convention. A major part is experience with the BWT hardware. Available information will be collated and submitted to MEPC 78 by the World Maritime University. A primary product of the EBP should be guidance from IMO on enforcement of The Convention and finally, its raison d’etre, D2 compliance will become a consideration.

The very small amount of publicly available data indicates relatively high (20-30%) failure rates for both biological and technical (generally Chlorine) discharges of treated ballast. This is at least indicative of operational shortcomings for some BWMS. Also at MEPC 78, IMO will consider input on what has become an effort to gain leniency for vessels in the event “challenging waters”

are encountered. The spectrum of water qualities encountered by commercial vessels in 2022 is little different to 2004. Achieving D2 can be hard work, particularly with a more fragile BWMS. This shipping industry push is again indicative of operational shortcomings of at least some BWTS.

So, with enforcement guidance a year or more away and industry pushing for increasing exceptions to The Convention, can there be value for an owner who takes the time to consider the fundamentals of water treatment in the light of their vessel operations and trading routes? The cheapest route to paper compliance (selection of the cheapest BWTS) has proven a viable path over the last several years – though it is important to stress this route has not been taken by all, many owners have shown a high commitment to investing in and learning about BW compliance. Others have installed systems with little hope of compliance in their trading patterns. Earlier this year I sat across the table from an owner convinced his dozen plus installed systems, though economically attractive, would not provide compliance. He repeated this quite emphatically. Given the fundamentals of water treatment and the range of waters encountered, he is probably right. He remained comfortable with the decision in the light of the enforcement environment, while acknowledging the attractiveness of the in-tank BWTS I was presenting.

In the future there will be value in investing in a robust system which will provide compliance. Working with the InTank BWTS, we have encountered several installations where original BWTS

are being replaced. Both operational shortcomings of existing systems and owners’ increasing realization that D2 compliance will not be practical are forcing owners to reconsider their selection of treatment systems. The expectation of enforced D2 compliance, even if it is more than a year away, is revealing the value of BWTS which will work sympathetically with a vessel’s operations, and is robust enough from a fundamental water treatment point of view, to give the vessel active control over compliance.

The understanding that not all Type Approved BWMS are equal is growing. Moreover, stakeholders are beginning to recognize that IMO’s untreated testing standards e.g., 100,000 zooplankton per cubic meter, can be far exceeded in many ambient waters. Finally, it is perhaps optimistic to expect 50um or smaller filters to operate perfectly at up to 25,000 gallons a minute during every single ballasting event. But still, the notion of a BWTS operating in the ballast line during ballasting/cargo/ port operations has become so much the norm that few are aware when a true innovation enters the market.

Yards have established makers lists, owners have completed their extensive BWT studies, supply agreements (some bundled) are in place, and crews are getting used to conventional in line systems – how to work with them, and around them. Innovation, particularly without enforcement, is not an easy path, even with

Type Approval. However, D2 enforcement will come and innovation in BWT will help. Nations receiving ballast discharges -- as well as owners -- understand D2 enforcement is on the horizon. IMO is making protocols for the verification of Compliance Monitoring Devices (CMD’s) and will publish Guidelines for D2 sampling and enforcement of other aspects of The Convention. The operational issues caused by regular operation of BWTS are becoming clearer and less easy to avoid. This is causing some to look again for alternatives in the BWT market.

Ballast Water Treatment is simply, water treatment, albeit in a tough maritime environment. The fundamentals of water treatment were established long before BWT was even thought of. The future potential of LED UV aside, most of the low hanging fruit in the development of treatment techniques has been discovered and developed, which means that improvements from here on will be incremental rather than game-changing. The largest remaining area for innovation in BWT is in how the treatment is integrated with the vessel and its operations in the tough maritime environment. All contemporary BWTS systems treat in-line, on the way to and/or from the ballast tank. Almost all use a filter. The in-line treatment arrangement places operational burdens on a vessel, particularly if clear Caribbean water is not being ballasted, and makes real-time compliance a must – a failure of treatment/neutralization/recording during discharge means a non-compliant discharge is recorded. It also fixes the size of the equipment to the size of the ballast pump(s) as opposed to the length of the voyage.

If the vessel’s operation can accommodate treatment during the voyage, the innovation of in-tank treatment while underway can be applied. A new, fundamentally different approach, moving treatment from port to voyage can be introduced: Automatically adjusting treatment intensity to specific water quality. Such an approach allows for re-checking treatment and neutralization before discharge. This approach removes filtration. It allows an issue to be fixed during the voyage; accommodates gravity ballast/deballast; allows in-place ballast/deballast without treatment (semi-subs); puts the vessel in control of timing of treatment (regrowth) and neutralization – in control of compliance. And finally, it allows normal port operations. All these fundamental innovations can be introduced to BWT. This fundamentally different approach reduces the operational burden and increases control over BW compliance for a commercial vessel.

The InTank BWMS brings all these innovations, while bringing the value of compliance to the vessel – however challenging the ballast water is.

The system is already installed from MR to VLCC, Handy to Cape, Semi-sub HLs and Rigs. With InTank FITT, the footprint is from 0.5m2 -- yes, half a square meter -- and upwards.

Ask your questions and find out how this innovation could work for your vessels. u

www.intankballast.com

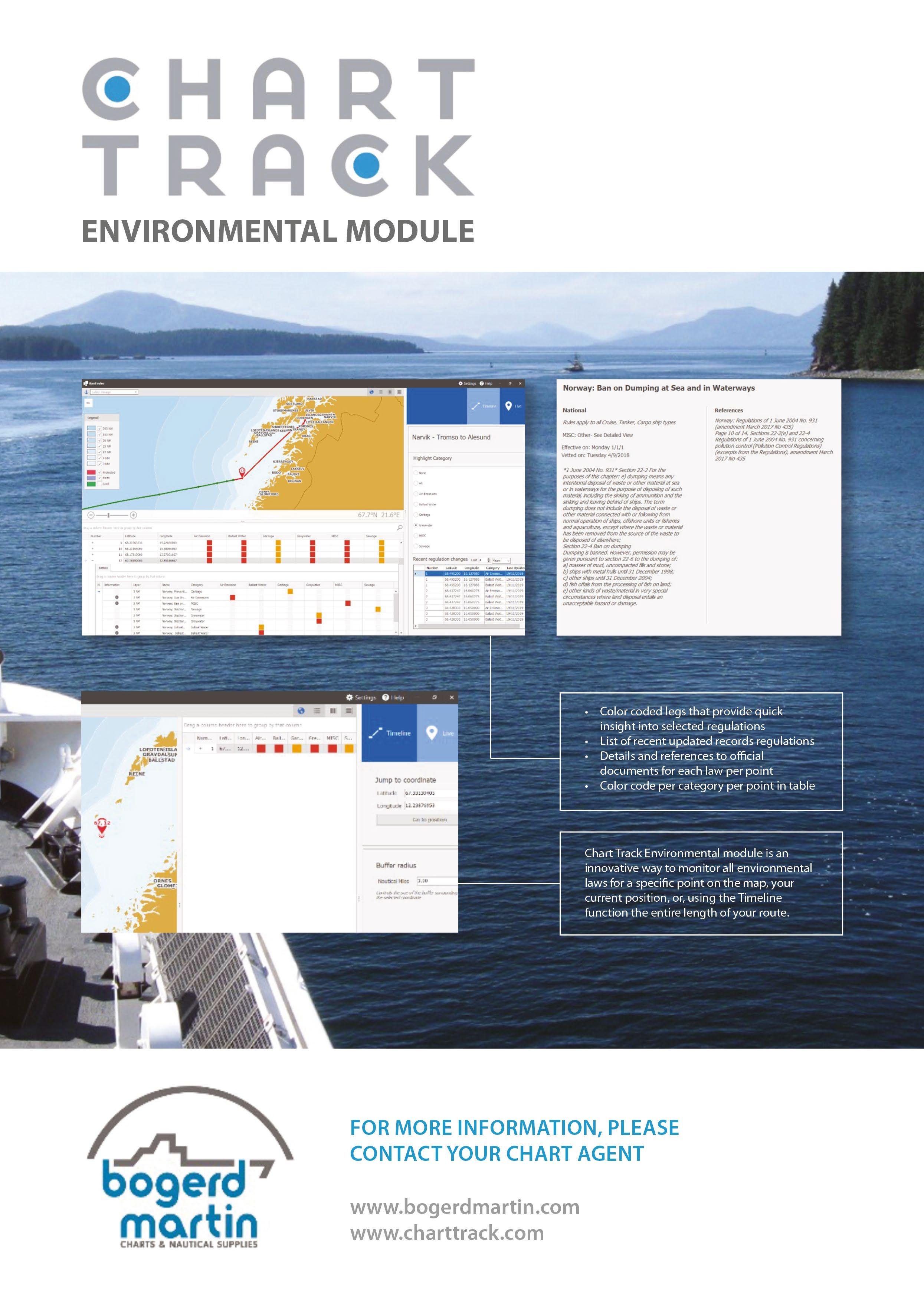

The landscape for maritime supplies and solutions providers is undergoing serious changes. And they impact all of us. In the fast evolving and ever digitising world of maritime navigation, suppliers of nautical charts, publications and software solutions are seeing an increasing number of alliances and collaborations form that have a significant impact on their businesses. Nelson Morais from Bogerd Martin sheds light on today’s navigation supplies reality

Ship owners and shipping companies have a barrage of offers and deals to consider on a daily basis. From everything that is in their direct line of business to equipment and services used on board of their vessels.

For that reason, it’s understandable that they would be swayed to go with an offer that consolidates several challenges for them, and hits perhaps 6 birds with one stone.

However, an all-in-one solution often lacks excellence in any one specific area.

“Those who aspire to be good at everything will find difficulty in being great at anything”.

Chart agents are a breed of organisations that have a very specific set of talents and properties. They’ve been around for as long as nautical charts and publications have been on the market.

Now that maritime navigation is undergoing the enormous transition into the digital era, another group of companies is treading into their field of expertise.

OEMs are not only offering their technologies in the form of hard and software to execute navigational tasks, they’ve also begun taking on the role of being a chart agent.

This is very new to them. And in the light of simplicity, they offer their customers package deals which include everything from ECDIS systems to charts, publications, etc.

That sounds pretty neat right?

While it’s true that doing business this way may relieve part of the costs of purchase, customers can end up in a worse situation, exactly because of them, inversely leading to higher costs than anticipated.

Considering the vast experience that chart agents have built up over the many decades they’ve been doing what they do, it’s almost utopic to think that OEMs will deliver a service that is on par with what your trusted chart agent throws on the table.

Many chart agents are facing increasing difficulty staying afloat. And this happens largely because of business practices that have a “monopolising air” over them.

“When money, rather than innovation or value, is your competitive advantage, that’s when things get boring and stagnant, and monopolies take root”

Hank Green

At Bogerd Martin, we take great pride in being able to offer our customers exactly what they need. We don’t like being tied to bureaucratic restrictions and believe that our customers are the only right team members to drive our creativity.

Being a heavily customer centric service provider, it is true to state that we actually care about our customers. Our dedicated teams are on standby 24/7/365 and a quarter and realize that when they’re called, they’re needed.

N. Morais – Bogerd Martin

It’s important for shipping companies and owners to keep a keen eye on why they choose a certain party to invest their resources in.

“How much” should be secondary (to the quality of solutions), no matter how attractive a deal may look financially.

To stay relevant, it’s becoming increasingly important for chart agents to innovate and act as knowledgeable development partners in all aspects of navigation.

Chart agents are no longer just chart agents. They must be trusted advisors to their customers. With proven technical talent and the will to research into new regulations imposed on shipping companies.

And while these trusted advisors work hard at trying to simplify tasks for ship crews, the transition into this new digital reality brings along its own set of complexities.

It is for that exact reason that shipping companies need partners who provide excellent supportive services. Not just good. Excellent.

So even with business crippling alliances, the importance of having a solid partnership with a well-founded chart agent emerges like the sun over the horizon.

“High end voyage planning tools, CII, weather routing optimization, cost reducing smart catalogues, cargo operations monitoring, e-logbooks,…

These are just a handful of new innovations we’ve invested in over the course of the past two years.

And with increasing demands for new technology to keep a competitive edge in the market, there are many more projects on the table”, Céline Mortier – CEO of Bogerd Martin says.

So where can you find the added value when deciding who to partner with, you might ask.

The key is to develop a synergetic relationship with a flexible partner. One that truly wishes to understand your requirements.

There are many solid products available to shipping companies and ship crews. And you’ll find pros and cons in each one of them. In most cases, you’ll be paying for the good, the bad and the ugly.

What you see is what you get… or is it?

Caveat Emptor – so the saying goes.

The closest we can get to a scenario in which it’s all good, is to be in a business relationship with a partner that is willing to budge.

Sure, some things look really shiny. But do they do what you’d hoped they would?

The maritime industry looks for solutions to their challenges everywhere. And what ship owners cannot develop themselves, others must.

That’s where your experienced modern day chart agent comes in.

Profoundly understanding what drives your business, what frustrates you and what needs to be done to address that, is what’s required to develop and introduce innovations to the market. u

www.bogerdmartin.com

When supplying a ship, sellers are frequently providing credit to purchasers who they know little about.

It is crucial that the seller understands (i) who is the purchaser; and (ii) what is the purchaser’s relationship to the ship supplied. Never make assumptions about these important matters.

Commonly, you will be approached by the “technical manager”. This might be the “in-house” manager, often the name understood by the market as the true owner.

In reality (and in law) the vessels are each owned by single-ship owning companies and the manager is simply acting on behalf of the legal owner. This arrangement is often described as the “Greek structure”, though now replicated around the world.

Alternatively, the technical manager may be a professional third-party manager, who has no ownership interest in the vessel and is simply employed to manage the ship - V-Ships would be an obvious example.

The third-party manager will depend upon funding from the owner, which will be provided according to the terms of the relevant management agreement on a vessel-by-vessel basis.

The funding arrangements between an in-house manager and its owner will be rather looser, with the financial affairs of the respective vessels/owners often appearing to merge into one.

In both cases, the manager will typically contract as agent for the respective owner, usually (but not always) making that clear when placing an order. In such cases, the seller’s contract is with the owner of the ship, and not the manager. If the seller is unpaid, a claim would lie against the owner, and importantly against the ship.

It is important to distinguish between a manager who is acting as an agent for the owner/vessel, and a purchaser who is purchasing in its own name and for its own account. In the latter cases, it may be much more difficult to argue that the owner (or importantly the vessel) is liable, and this could, for example, prevent the seller being able to arrest the vessel.

In some cases, we see that shipping groups create a purchasing company, who will purport to purchase in its own name and not as an agent for the owner. Whilst there may be legitimate reasons for creating such a purchasing company, it creates real danger for a seller and is often a structure created by less honest buyers and intended to shelter ships from the risk of arrest when bills go unpaid. It creates a buffer between the seller and the ship, and often means that a ship cannot be arrested for unpaid bills.

You may also be asked to supply by another ship supplier. Typically, that supplier will be your buyer, and the party liable to pay you. If they do not pay, you cannot turn to the owner and demand payment from them.

This does, however, depend upon how the transaction has been structured. In essentially the same way, a catering company will purchase on their own behalf, and not as agent for the owner. The seller’s claim lies against the caterer, not the owner.

There may be occasions when you receive a request to supply from a charterer, or from the local port agent acting on behalf of a charterer. In neither case will it be likely that the owner (or the vessel) will be liable to pay for supplies, if the agent/charterer fails to do so.

It is crucial to be careful to understand the relationship between the party who approaches you and the vessel. If it is not clear, ask the question. Once you have the answer you are then in a better position to assess and address your risk. Do not rely on the notion that if you don’t get paid you can always arrest the ship, as this may not always be possible. u

www.salvuslaw.com

Vessel owners are placing more emphasis on Maritime Decarbonisation and Sustainable Shipping while investments towards improved energy efficiency have become increasingly relevant in the current economic and environmental situations.

International Energy Agency (IEA) foresees global energy investment to increase by 8% in 2022 to reach USD 2.4 trillion. Global benchmarking of energy efficiency has provided vessel owners with goals to work towards. Such benchmarking also identifies areas for improvement and promotes the sharing of best practices internationally.

There are various measures individuals and corporations can partake in energyefficiency schemes and one possible venture for energy savings is to retrofit conventional lighting with LED Lights.

But why LED?

LED optimises energy consumption as compared to conventional lighting, reduces maintenance through improved durability, and allows great savings to one’s electricity consumption. SOPEX Innovations Ltd (“SOPEX”) pledges to deliver the highest-quality range of reliable LED lighting, allowing you to maximise your investment in operations and reduce your maintenance needed.

With over a decade of experience and technical know-how, SOPEX emphasises the design and development of ideal LED solutions. Missioned to ‘Save Our Plant’, SOPEX and SOP, a product line catered to hazardous and non-hazardous environments, provides reliable and innovative energy-efficient technologies, while meeting the demands of harsh marine environments.

Developed and manufactured by General Luminaire Holdings (“GLH”), SOPEX and SOP are dedicated to use their technical knowhow to drive lighting

technologies and innovations toward decarbonisation. Their Green Initiatives plan involves working with vessel owners to retrofit conventional lighting to LED lights with maximum luminosity and the shortest Return-on-Investment.

GLH prides itself on having one of the best and up-to-date luminaire plants in Asia, the manufacturing facilities in Kunshan, China currently occupies 22,000m2, consisting of a mechanical and electronics plant, which have the capacity to produce more than 200,000 luminaires and 3,000,000 LED light engines annually. This advanced facility comprises 5 fully automatic Surface Mount Technology (SMT) lines, clouds enabled electronics manufacturing setup, advanced powder coating line, and CNC/laser/plastic injection/cold-forged/aerospace welding. The company has been awarded best in class for ISO90001/14000/45001.

It is operated by a highly qualified international team of quality engineering, productions, and operations staff, and includes an on-site R&D which churns out patented products for notable brands. GLH employs a vertical integration approach, enabling them to oversee the extensive and crucial process of luminaire production.

A recent case study is the replacement of Ex-proof lightings on the Deck of Singapore-registered Liquid Bulk Carrier DENKO BRIGHT 9709362 managed by Norstar Ship Management. SOP supplied 2 units of Ex-proof

Floodlight for immediate replacement to avoid any discrepancies during her Class Survey. The crew were very satisfied with the performance and coverage of the Marine IEC 60533 Certified outdoor LED Floodlights, not forgetting the more than 88% substantial energy savings and being able to do without monthly consumables replacement.

Be it a new vessel or a retrofit, “Going Green” is one of the ways you can amortise your investment within 1-2 years.

Selecting the right LED lighting for your vessel applications remains a challenge for many owners, vessel managers, or buyers. Most consumers are used to traditional fluorescent lamps, incandescent bulbs or even High-Intensity Discharge (HID) lamps, available in fixed wattage with similar lumen output, similar lamp service life, standard lamp bases and similar conventional housing. SOPEX pledges to only deliver the highest-quality range of reliable LED lighting, allowing users to maximise their investment in operations and reduce their maintenance needed. We are committed in our mission to help you find the ideal lighting for your vessel or yacht.

This approach is proven, costeffective and can be achieved within 12 to 24 months. Let us work collaboratively to do something real, measurable and impactful. u

Write to us at info@sop-led.com and we will be glad to provide you with a workable solution.

– so says Mombasa, Kenya based ship supplier All Supply Mombasa Shipchandlers Ltd. The Ship Supplier reports on ardent fans of the Green ISSA Programme

This succinct phrase highlights the company’s deep commitment to ISSA’s own green initiative.

You won’t find yards of plastic wrapping pallets of cardboard boxes destined for the many vessels visiting Mombasa Port and supplied by the firm.

Company boss Mohammed Muses explained: “What we want to get across is that sustainable or environmentally friendly options actually save costs!”

“This policy is a win-win for the environment, our customers and our company.”

For All Supply the solution to replacing plastic in all its many forms - often seen dockside and on board - is the use of reusable plastic crates.

Ever conscious of hygiene standards the company was recently awarded Gold Standard following an in-depth audit of operations by NSF International.

Only in exceptional circumstances are pallets wrapped in yards of plastic. The use of re-usable plastic bottles is actively encouraged and three lines that regularly call at Mombasa and are supplied by the business have embraced this simple behavioural change.

Mr Muses commented: “We encourage vessels to instal, relatively

cheaply, water filling stations on board. Crew can fill re-usable bottles and this simple change again reduces single use plastic bottles.”

The use of reusable plastic crates has proved to be an excellent choice, reducing by 75% the amount of cardboard previously employed in deliveries to vessels.

Mr Muses said: “We did encounter some initial resistance to this change but we persevered and won over our customers. We save money and each ship saves money as there is less waste to dispose of.

“A further advantage in this clean method of delivery container is that the products are very visible. What’s not to like?!”

All Supply with more than a 40-year distinguished history, is the only dedicated shipchandler with ISSA Member in Kenya enjoying ISSA Quality status, allied to the Green ISSA initiative which includes tackling packaging waste.

Alert to the geo-political climate, Mr Muses confirmed that peering into the future led him and his team to move away from buying from local wholesalers to importing staple products directly.

Now some 70% of fast-moving consumer goods are imported directly by the company resulting in significant cost savings.

The firm’s supply chain has really been stream-lined following this major buying decision. As a result the inflationary pressure on customers is somewhat eased by this clever initiative.

In a final word Mr Muses commented: “Our business is, under the current economic climate, extremely elastic and, ultimately, it all comes down to price. We have weathered the Coronavirus storm and are in the middle of local elections that are impacting us. However, by embracing this green initiative wholeheartedly we have placed ourselves at a significant advantage as well as helped our customers.” u

www.msaship.com

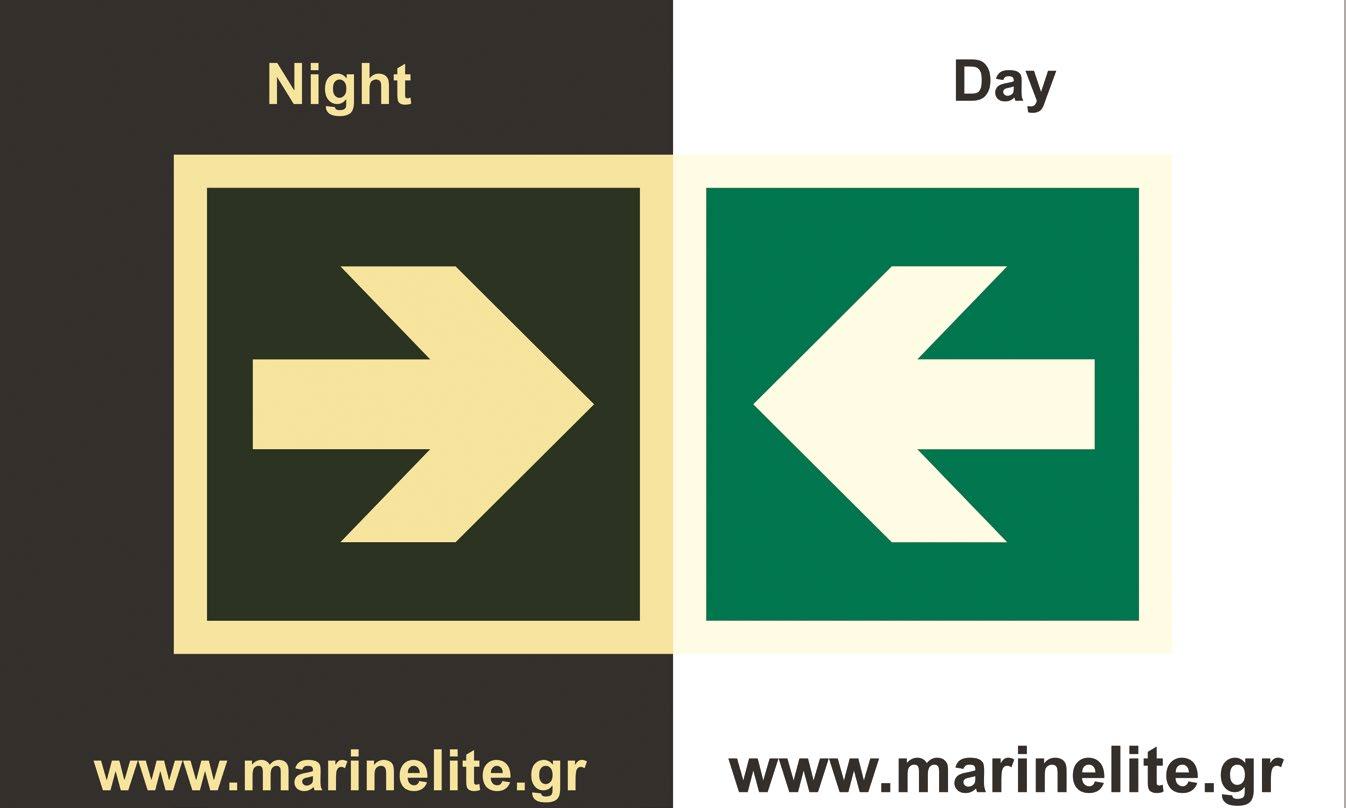

Tracey Montgomery of Greek signage manufacturers

Marinelite pulls no punches when it comes to the importance of emergency signage

The Maritime industry’s most important concerns are for the safety of personnel, passengers and the prevention of marine pollution.

To achieve this, the International Maritime Organisation (IMO) relies on two very important pillars: SOLAS (Safety Of Life At Sea) and MARPOL (International Convention for the Prevention of Pollution from Ships). Signage & Posters throughout the ships are one of the utmost important features to insure this happens.

Marine Lite Printing SA is the largest Greek manufacturer of Marine Safety signs with over 17 years of manufacturing high quality compliant signage

to the latest regulations and for a number of years also a Lloyds Approved Supplier for photoluminescent Low Location Lighting (LLL) Systems. Our team of highly trained technicians travel internationally to check the luminance on board, according to IMO resolution A. 752(18).

The correct signage in the correct position on a vessel could mean the difference between life and death. During a blackout on a vessel, without the guidance of a quality photoluminescent sign placed at the location of firefighting or safety equipment could cause response times to be detrimental to life on board.

Over the last few years, regulations concerning sign quality, placement and design have significantly changed to be more internationally standardised.

SOLAS Chapter III Regulation 20.10 requires signs to be in place to identify lifesaving systems and appliance signs. As does SOLAS Chapter III Regulation 13.1.13 and 13.3.2.5.1. All escape routes and fire equipment must have signage to mark their positions.

The latest IMO Resolution A. 1116(30) has adopted the escape route and equipment location markings from the 2016 MSC. 1/Cir. 1553 which invited contracting governments to start implementing safety signs as per ISO 24409-2:2014 on a voluntary basis.

The adoption of the ISO symbols is the well timed and greatly needed standardization of the international symbols that indicate the location of emergency equipment for those seafarers and passengers who travel and work on ships and on other maritime installations.

IMO Resolution A. 1116(30), was adopted on 5 December 2017. The signage for the escape routes and equipment location is effective for ships constructed on or

after 1 January 2019 and for ships which undergo repairs, alterations, modifications and outfitting on or after that date.

Some samples of the changes on safety signs that the IMO Resolution A. 1116(30) adopted can be seen below:

Signage adopted by IMO Resolution A. 1116(30) and can be found in the Marine Lite Printing Catalogue.

Signs in this standard are categorized according to their function as follows:

a. MES – Means of escape signs are safe condition signs used to indicate location within the ship and to provide directional guidance from any area within the ship to a designated assembly station and/or to exits and embarkation stations.

b. EES – Emergency equipment signs are safe condition signs that are used to indicate the exact location of first aid facilities, first aid equipment, or portable safety equipment, the type of facility or equipment and any instructions for its use.

c. LSS – Lifesaving systems and appliances signs are safe condition signs that are used to indicate the exact location or storage of the life-saving equipment, the type of equipment, the identification number and any instructions for its correct use.

d. FES – Fire-fighting equipment signs are used to indicate the exact location of the fire-

fighting equipment, the type of equipment and any instructions for its effective and safe use.

e. PSS – Prohibition signs are used to restrict or prohibit the movement and actions of persons.

f. WSS – Hazard warning signs are used to warn people of possible dangerous conditions and hazards and risks that exist on board a ship.

g. MSS – Mandatory action signs are used to instruct persons of a specific course of action that shall be followed.

h. SIS – Safety and operating instructions for qualified personnel are for the use of specialised safety and fire protection equipment and life-saving appliances on board ship. u

www.marinelite.gr

Reliable and cost-effective solution for end-toend cargo shipments throughout Europe is now available.

Asset tracking and telematics expert, Tracker Network (U.K.) Ltd, is offering to pan-European transportation and logistics operators a reliable and cost-effective solution for end-to-end cargo tracking of shipments.

Developed and implemented by its USA parent company CalAmp, a connected intelligence company helping people and organisations improve operational performance with a data-driven solutions ecosystem, the new service will particularly benefit multinational businesses in the pharmaceutical, electronics, biotech, food and consumer goods industries looking to secure high-value, high-risk shipments in transit, while also improving supply chain efficiency and offering essential documentation for regulatory compliance purposes.

Ship suppliers in Europe may well be interested in this innovative service where security of vital shipments (e.g. spare parts urgently required) is vital.

Tracker’s Supply Chain Visibility solution is enabled by a portfolio of wireless sensors and oth er reusable and single-use devices that can be affixed to assets to track and collect critical data, such as temperature, light, shock, vibration and location.

The solution enables operators to monitor cargo throughout the shipment journey from a manufacturer through land, sea and air touchpoints to the final destination.

Upon arrival, the sensors automatically synchronise with fixed and mobile hubs to support chain of custody documentation and environmental reporting. Sensor data sent through the CalAmp Telematics Cloud can be directly integrated into warehouse, fleet and logistics management systems via Application Programming Interfaces (APIs).

Mark Rose, managing director for Tracker explained: “The pandemic brought to light many challenges within the global supply chain, from port and border closures to product shortages and COVID-19 vaccine shipments.

“Manually tracking goods in transit exposes cargo to human error and theft, and limits visibility into any environmental damage. “Sensor- and API-enabled smarter logistics systems like our Supply Chain Visibility solution prove invaluable in reducing freight spoilage, optimising supply chain performance, documenting chain of custody and protecting brand integrity.”

The Tracker Supply Chain Visibility solution provides:

• Reporting and data analytics: Logging of data to help document chain of custody in compliance with Food Safety Modernisation Act (FSMA) and Good Distribution Practice (GDP) requirements

• Critical alerts and notifications: Immediate web-based and mobile alerts when a shipment exceeds a predetermined temperature range or goes out of the authorised shipping zone, enabling supply chain operators to take corrective action to minimise spoilage and loss

• Near real-time location tracking: Smart sensors and disposable devices utilise GPS tracking to provide near real-time delivery estimates, current location and progress reports even when cargo is in the hands of a third-party provider

• Geofencing and route fencing: Alerts notify users if the cargo deviates from the planned route or strays from authorised waypoints

• Stationary and movement detection: Detection of when a shipment is moving or stalled, which is especially important when

navigating high risk areas in route between waypoints

• API integration: CalAmp integrates with Electronic Data Interchange (EDI) or Enterprise Resource Planning (ERP) systems to facilitate information sharing, collaboration and transparency along the entire supply chain

• External sharing of critical sensor readings and history: A device’s sensory reading, location and historical data can be shared with other stakeholders including third-party logistics providers (3PLs), private fleet operators, warehouses and distribution centers.

“The need for real-time, end-to-end cargo visibility has never been greater than in today’s complex, just-in-time global supply chain,” said Jeff Clark, chief product officer, CalAmp.

“Manufacturers, logistics operators, consumers and regulators all want to ensure their shipments in transit adhere to strict safety and compliance requirements and will arrive quickly and as expected.

“We’re excited to provide this level of visibility and intelligence to the European market through our Supply Chain Visibility solution.

“For our customers shipping goods across pan-European regions, these location and environmental insights will strengthen the reliability, security and efficiency of their operations to benefit all stakeholders in the supply chain.” u

www.tracker.co.uk

MEric Bezemer, Commercial Director of NeKo, believes a “perfect storm” of events has significantly impacted basic commodities’ prices

ajor Dutch ship supplier and long-time ISSA Member, NeKo Ship Supply B.V., is keen to flag up the significant price increases in basic commodities.

Commercial Director Eric Bezemer –who recently joined the Board of the Dutch Ship Suppliers Association - believes it is high time to give a clarion call to the ship supply industry and would welcome input from ISSA Members also suffering from the pricing hit to their bottom lines.

The Ship Supplier caught up with Mr Bezemer and asked him what were the key factors that have caused this massive hike in prices of basic commodities.

“We have, if you like, a perfect storm here. Five key factors have impacted the rise in prices:

• Significant increase in freight rates (particularly from the Far East and Middle East to Europe)

• The lingering impact of Covid-19 where it is often the case we can still not visit ships

• The wider geo-political realities now prevalent

• An inflation figure now higher than at any time since World War 2

• And the environment

“All these factors have led to the significantly higher cost of importing these basic commodities. Add to the mix the increase in interest rates and because of the business model of big contracts at fixed prices, ship suppliers will soon find their operations unsustainable.”

To give an idea of just how dramatic the price rises have been – and seem set to continue to be – Mr Bezemer cited the UN’s Food & Agriculture World Food Situation Report.

Covering meat, dairy, cereals, vegetable oils and sugar the extrapolated figures produce the latest Food Price

Index that shows a steady increase in the Index from 122.1 in April 2021 to 158.5 in April 2022. There was a broader spike in prices of these basic commodities in March and April 2021.

Mr Bezemer believes this upward trend will continue.

Whilst his focus is on the basic commodities detailed earlier he also counsels caution when it comes to “fresh steel” products and recommends ship suppliers maintain vigilance of the spot steel market – particularly in Asia.

Other contributory factors to this “perfect storm” of escalating prices world-wide include port disruption –particularly in Asia – leading to a scarcity of products and the recent phenomenon of labour problems.

Turning to this latest blow to the industry, Mr Bezemer highlighted his own experience of the labour market in the Netherlands where there are for every 100,000 unemployed workers 130,000 vacancies. In addition sub-contractors are presently operating a three days delivery service for items that need to be specially made instead of one day.

The economic impact of this aspect of the crisis – for crisis it is – will include higher wages and “signing bonuses” to attract the necessary staff to operate the business.

Mr Bezemer: “We ourselves operate in a hugely competitive market here in Rotterdam. The port is and always has been competitive. At NeKo we rise to the challenge and I am glad to report that after more than 20 years we continue to flourish and prosper and are stronger than ever.

“However I want to issue this call to industry colleagues: let us together try and work out a mutually acceptable way to cope with this major problem and its constituent parts to the benefit of ourselves and our customers alike.”

The word on the street is that with many ship owners benefiting from unprecedented levels of freight rates there is room for negotiation to soften the blow of these massive hikes in commodities prices along with the other contributory factors worrying ship suppliers at the moment.

When asked about his fears for the future, Mr Bezemer countered: “Fear of the future is not helpful. That is why I believe we can overcome this economic perfect storm as I call it if colleagues come together and tackle the problems with the support and understanding of our customers.” u www.nekoship.nl

The German Ship Suppliers Association (Verband Deutscher Schiffsausrüster E.V.) celebrated 75 years of service to the ship supply industry under the VDS name.

VDS Chairman Jens Pfeiffer emphasised the importance of the Association’s active participation within the international platforms it enjoys membership of and confirmed it was VDS’s intention to continue the engagement.

Some 60 guests gathered at the Hafen-Klub in Hamburg on 17th May 2022 to mark this great milestone. In addition to Association members and other participants, top representatives from the German maritime cluster were present at the celebration.

The Reception was preceded internally by the VDS General Assembly.

Congratulations and best wishes for the coming decades were provided by Hamburg’s Senator for Economics and Innovation, Michael Westhagemann (Independent) and the Federal Government’s Co-ordinator for the Maritime Industry and Tourism, Claudia Müller (Green Party “Bündnis 90/Die Grünen”) – each with their own video greetings.

Afterwards Dr Gaby Bornheim, the new President of the Association of German Shipowners (VDR), spoke directly to Association Members and Guests emphasising the historically close relationship between VDR and VDS.

Association Chairman Jens Pfeiffer then reminded everyone of the past financial year and looked forward to the rest of the current financial year and mid-term future.

“Presently the shipping industry continues to find itself in an extremely challenging situation,” he said.

“Delays in the supply chain and sharp price rises compound the difficulties,” he continued.

Significant changes in the profitability of cargo ship companies together with the return of the cruise industry mean German ship suppliers have begun to feel more favourable winds at their backs.

VDS now boasts 100 members and the Board and Management of the Association are working on a transition project to build an even stronger foundation for the Association’s future.

Mr Pfeiffer said, for him, one of the most important steps in this direction was the decision made at the September 2021 General Assembly in Hamburg to join the Wholesale and Foreign Trade Association (WGA).

Mr Pfeiffer: “For VDS this is a classic win-win situation for both organisations. “VDS will remain a fully independent organisation whilst benefiting from synergies and additional services offered by the WGA.” July 1st is the planned date for this significant move.

Chairman Pfeiffer: “In my opinion VDS will in any case have a successful future as a fundamentally important part of the maritime supply chain.”

The Maritime Co-ordinator, Claudia Müller, and Hamburg’s Economics Senator Westhagemann agreed.

Ms Müller: “The ship suppliers ensure smooth processes in the German Ports with their 24/7/365 services.”

She concluded that VDS companies will also have to deal – and already deal intensively – with the major topic of “sustainability in shipping” in the future.

VDR President Dr Gaby Bornheim highlighted important milestones in shipping in general and the special relationship enjoyed with the German Ship Supply industry in particular.

“Without you, and the services of your members we, as shipowners, would sometimes be stuck in port.

“With a lot of flexibility, characterised by the will to provide the best service, you make it possible for our ships to go on great voyages with excellent equipment and your specialists’ services.”

Dr Bornheim concluded that there was a special relationship between the shipping companies and ship suppliers due to the cooperation between each sector.

Finally it was confirmed that the 2022/23 Edition (the 50th) of the German Ship Suppliers Register has once again been published.

Featuring 112 members in 29 German cities, the Register provides full details of goods and services provided by this flurishing national association.

A number of dynamic features are included in the Register. The print run for the booklet runs to 3,000 copies and digital features may be harnessed from the VDS web site: www.shipsuppliers.de

Further information on VDS may be had from the Association’s Office at Colonnaden 46, 20354 Hamburg. Tel: +49 40 32 40 82; e-mail: vds@shipsuppliers.de u

Lennart Clasen, HOLGER CLASEN GmbH & Co. KG, Board

The International Shipsuppliers & Services Association (ISSA), the trade association for the world’s ship supply industry, has signed an agreement with World Maritime Academy (WMA) to deliver high quality online training to the global ship supply and procurement sectors.

The ISSA Education Programme brings together the industry expertise and knowledge of ISSA and its member companies with the maritime education and training capabilities of WMA, to produce some of the highest quality ship supply and procurement courses for ISSA members and non-ISSA members.

Welcoming the agreement, Saeed Al Malik, ISSA President, said the drive for higher standards within quality ship supply coupled with the increased focus of the industry on the environment and the powers of digitalisation, created the perfect backdrop for the launch of an industry-wide education programme dedicated to preserving quality ship supply and procurement well into the future.

“Shipping is changing, and success is as much about knowledge and learning as it is about innovation and cooperation. The ISSA Education Programme will be an important element of ISSA’s work in creating a supply industry that is as attractive to the young and talented today as it will be in the future. Its launch today, echoes the hard work that ISSA is doing through its Green ISSA and ISSA Quality initiatives and will form a strong foundation for training standards in this sector for years to come,” he said.

Dr Katerina Konsta, CEO of WMA, added: “The maritime industry goes through a period of time defined by the acceleration of change, enabled by a growing technology and considerable geopolitical abnormalities and market fluctuations.

“Our collaboration with ISSA goes beyond innovation. Joining powers and capabilities we enhance learning and we provide utmost quality, core ship supply knowledge and skill to ISSA members, as well as non-members.”

She added: “We are delighted to be working with an association as important and global as ISSA and look forward to bringing the high quality of training we employ here at the WMA to the fore in preserving a global ship supply and procurement industry of the highest quality.” u

2021 was a good year for ISSA Member Wrist Ship Supply.

Turn-over and operating profit were both up. The Company says its strategic transition and substantial investments in customised digital solutions were the drivers of the pleasing increases.

The year saw several major, global customer agreements expanded and new ones inked – all in the face of challenging marketing conditions. Food and steel price inflation, global supply chain challenges and historically high ocean freight rates led to general cost increases and volatility.

Jens Holger Nielsen, Group CEO of Wrist Group said: “During 2021 we continued to explore new opportunities for growth and acquisitions and in February we concluded the acquisition of Centralam Panama, a key ship supplier based at the Panama Canal.”

Last year saw Wrist generate DKK4.5bn, up 3.6% over 2020. However gross profit declined slightly to DKK 1,166m from DKK 1,182m in 2020. This decline translated to 26.1% compared to 27.1% in 2020.

Operating profit (EBITA) was DKK 155.5m for 2021 compared to DKK 142.2m in 2020. This showed an increase of 9.4% (DKK 13m).

The Group’s equity stood at DKK 932m at the end of last year – up DKK 104m compared to 2020.

In a fresh development Wrist announced the founding and funding of a new digital marketplace – Source2Sea.

This multi-supplier marketplace facilitates marine procurement and supply between maritime buyers and suppliers.

The marketplace operates independently of the Wrist Group with Wrist Ship Supply as a major supplier of provisions and stores as well as last-mile logistics.

In other news: investments were made a priority in 2021 to strengthen operational capabilities and infrastructure in the remaining business.

An online customer portal was launched within Wrist’s Marine Logistics operations. Innovation within Garrets, the Provisions and Stores Management business area of Wrist, continued.

In addition, in 2021, Wrist launched is first environmentally friendly product line – Aware – to meet customers’ increasing demand for responsible stores and provisions.

The green agenda is a key focus for the firm. Mr Nielsen commented: “Expectations to the green transition within the maritime and offshore industries are higher than ever.

“With thousands of different products and solutions delivered to seafarers around the world, we are aware of our contribution to the climate footprint.” u

www.wrist.com

GET STC, based in Piraeus, Greece, is a specialist trading all types of internal combustion engines, mechanical and deck equipment for ships, boats, factories and power plants. They also have a skilled team of technical advisors and project managers for any kind of repair/ maintenance within the marine and industrial sector.

https://get.com.gr

Turbo General specialises in turbocharger spares and repairs for marine, industrial, locomotive and automotive applications in main engine and auxiliary engines. They operate from their headquarters in the Port of Piraeus, Greece and enjoy an illustrious 45-year history of service.

https://turbogeneral.com

Chandrinos K & Sons Co based in Igoumenitsa, Greece, specialise in provisions and bonded stores for the marine and hotel sectors. They are also general ship suppliers and their operation spans the ports of Corfu, Patras, Piraeus, Thessaloniki. www.chandrinos.com

Gulf Shipchandler Est operates from the Port of Aqaba in Jordan. They are ISSA Quality Certified and are General Ship Suppliers with a speciality for additional marine services. As well as their main operations in Aqaba, the firm also serves the ports of Haifa and Ashdod. www.gulfchandler.com

For the second time in three years Coltraco Ultrasonics are winners of the Queen’s Award.

This time they are delighted to have been honoured with the Queen’s Award for Enterprise 2022.

High-exporting advanced manufacturer Coltraco Ultrasonics won the Queen’s Award for International Trade in 2019 and are thrilled to win it again in 2022 for Outstanding Growth in international trade over the last three years.

The Queen’s Award for Enterprise is the UK’s most prestigious business award and is a globally recognised Royal seal of approval for UK companies.

In its 56th year, the 2022 Queen’s Awards for Enterprise comes in this special year of Her Majesty the Queen’s Platinum Jubilee.

The company exports over:

• 90% of its output

• to 120 countries

• with 150+ distributors in 80.

Chairman of Coltraco Ultrasonics, Dr Carl Stephen Patrick Hunter OBE: “Since 1965 an average of 122 British companies have been annually awarded the United Kingdom’s highest Queen’s Award for Enterprise.

“In 2019 we were fortunate to be one of them, in the International Trade category. To receive this latest award is a great privilege for us. It reflects the extraordinary endeavour and resilience of the company team during COVID19, a period in which we lost 50% of our global markets but which we responded to by the formulation and implementation of our new ResilienceDiversification-Growth strategy.

“It has seen our company deliver outstanding growth and scientific advance during COVID19 and in its Economic Recovery phase.

“Indeed it also resulted in the establishment of our new Durham Institute of Research, Development & Invention at Durham University and a completely new Global Distributor Network across 80 countries.

During the challenging 24 months of the pandemic

Coltraco Ultrasonics developed their high-exporting advanced manufacturing tradition and created a new science-led organisation that comprises the Company, their Institute (DIRDI) and its Centre (CUAA).

Coltraco have continued with 3 years of outstanding growth despite COVID19 because of their Resilience-DiversificationGrowth Strategy created during it. The company never went into furlough despite losing 50% of its global markets during COVID19 and have built new company export and scientific success since.

Their changed strategy made them less dependent on a few “primary” market sectors and brought them together into a “Multi-Sectoral” whole with a Global Distribution Network to fulfil them.

With the change of the company since COVID19, they have now become a “multi-sectoral” company which their Research & Development Plan and Global Distribution Strategy are designed for, increasing exports and international trade. u

AkzoNobel Marine Coatings is supporting the industry on its carbon-neutral journey by appointing its first ever Global HullCare Manager.

Company veteran of 23 years, Colin expressed excitement at taking on this new role at such a significant time for the marine industry.

For much of his career with the Company he has been delivering sustainability goals across multiple AkzoNobel business units.

IFor the past four years he has been Marine Business Manager for the Middle East championing environmental sustainability there.

Colin commented: “I am absolutely delighted to take on this hugely important role within the AkzoNobel Marine Coatings team at a time of such significant change within the industry.

“As a business, we are committed to being at the absolute forefront of developing the products and solutions that enable our owner partners

to reach their sustainability and performance goals.

“The majority of my career within AkzoNobel has been spent within the marine segment, which has provided me with an extensive understanding of our customers’ requirements.

“As the industry faces an ever more stringent regulatory environment our ambition is to provide our owner partners with stand-out, end-to-end support.” u https://www.international-marine. com/in-focus/intertrac-hullcare

SSA Member CMA D. Argoudelis & Co S.A. has established a new subsidiary outside Greece in Cyprus.

CMA Group is one of the largest automation groups in Greece and Cyprus and was established in 1987. The firm is a Member of Hellenic Ship Suppliers & Exporters Association (the national association of ship suppliers of Greece).

Based in Nicosia at Themistokli Dervi 41, Hawaii Nicosia Tower, the aim of the new operation is to provide the Cypriot market with all the solutions, products and services – tailored for local needs – that the company has in Greece.

For customers operating in both countries, CMA Group has the ability to cover their needs with a unified sales and technical support operation.

D. Argoudelis & Co. Ltd., partners with the world’s largest manufacturers including Bosch Rexroth, Emerson Aventics, Danfoss, SEIF, FESTO, PR Electronics, Siemens, Klay Instruments, Brannstrom and Lumel to name but a few, thus offering a wide range of solutions for the majority of companies in the Cypriot market. u www.cmagreece.com

Boston-based Sea Machines Robotics, a leading developer of autonomous command and advanced perception systems, has gained type approval from Bureau Veritas (BV) for the company’s commercial wireless remote-control helm system.

Type Approval from Bureau Veritas means that the wireless control technology embedded in both Sea Machines’ SM200 and SM300 systems has undergone rigorous thirdparty testing and certification to meet the stringent demands of Classification and Flag State requirements for critical equipment on board marine vessels.

Sea Machines’ wireless remote-control helm technology offers flexible control for mariners, eliminating the need for the vessel operator to be bound to a fixed control station.

This system enables line-of-sight wireless helm and propulsion control with up to 1,000-meter range, as well as remote control of auxiliaries and payload equipment via a wearable belt-pack device, freeing mariners from the wheelhouse to conduct operations from any location that offers the greatest advantage, visibility, and safety.

“Bureau Veritas’ Type Approval provides a user with confidence that an approved technology or piece of equipment meets stringent international standards. It brings a substantial assurance of quality,” said Daniel Holmes, business development manager, BV Marine & Offshore.

“Sea Machines is the first company to receive BV’s Type Approval certification for this specific form of technology.”

Laurent Leblanc, senior vice president technical & operations at Bureau Veritas Marine & Offshore said:

“Being by our clients’ side to help them develop their new technologies is central at BV.

“Congratulations to Sea Machines for this first Type Approval. We are looking forward to further collaborating with Sea Machines.”

“This inaugural certification is further proof that Sea Machines is leading the development of advanced vessel control technologies. We appreciate the lengthy laboratory testing and exhaustive reviews that BV conducted to objectively validate our wireless remote-control helm system,” said Captain Artie Seaman, product manager, government and compliance.

“Looking ahead, our key area of focus is to work with BV and other agencies to define the regulations and approval requirements for autonomous and advanced perception products. Together we are developing the framework needed to propel our industries towards acceptance and use of advanced emerging technologies – like those of Sea Machines’ – that improve operations, efficiency and safety.”