WoolFiberReinforced PolymerComposites

Editedby SabuThomas

SchoolofEnergyMaterials,Mahatma GandhiUniversity,Kottayam,Kerala,India

SeikoJose

SchoolofChemicalScience,Mahatma GandhiUniversity,Kottayam,Kerala,India; ICAR–CentralSheepandWoolResearch Institute,Avikanagar,Rajasthan,India

TheTextileInstituteBookSeries

IncorporatedbyRoyalCharterin1925,TheTextileInstitutewasestablishedastheprofessional bodyforthetextileindustrytoprovidesupporttobusinesses,practitioners,andacademics involvedwithtextilesandtoprovideroutestoprofessionalqualificationsthroughwhichInstitute Memberscandemonstratetheirprofessionalcompetence.TheInstitute’saimistoencourage learning,recognizeachievement,rewardexcellence,anddisseminateinformationaboutthe textiles,clothingandfootwearindustriesandtheassociatedscience,designandtechnology;it hasaglobalreachwithindividualandcorporatemembersinover80countries.

TheTextileInstituteBookSeriessupersedestheformer“WoodheadPublishingSeriesinTextiles” andrepresentsacollaborationbetweenTheTextileInstituteandElsevieraimedatensuringthat InstituteMembersandthetextileindustrycontinuetohaveaccesstohighcalibertitlesontextile scienceandtechnology.

BookspublishedinTheTextileInstituteBookSeriesareofferedontheElsevierwebsiteat: store.elsevier.com andareavailabletoTextileInstituteMembersatasubstantialdiscount. TextileInstitutebooksstillinprintarealsoavailabledirectlyfromtheInstitute’swebsiteat: www.textileinstitute.org

Toplaceanorder,orifyouareinterestedinwritingabookforthisseries,pleasecontactMatthew Deans,SeniorPublisher: m.deans@elsevier.com

RecentlyPublishedandUpcomingTitlesintheTextileInstitute BookSeries:

HandbookofNaturalFibres:Volume1:Types,PropertiesandFactorsAffectingBreedingand Cultivation,2ndEdition,RyszardKozlowskiMariaMackiewicz-Talarczyk,978-0-12-818398-4 HandbookofNaturalFibres:Volume2:ProcessingandApplications,2ndEdition,Ryszard KozlowskiMariaMackiewicz-Talarczyk,978-0-12-818782-1

AdvancesinTextileBiotechnology,ArturCavaco-Paulo,978-0-08-102632-8

WovenTextiles:Principles,TechnologiesandApplications,2ndEdition,KimGandhi,978-0-08102497-3

AuxeticTextiles,HongHu,978-0-08-102211-5

CarbonNanotubeFibresandYarns:Production,PropertiesandApplicationsinSmartTextiles, MengheMiao,978-0-08-102722-6

SustainableTechnologiesforFashionandTextiles,RajkishoreNayak,978-0-08-102867-4 StructureandMechanicsofTextileFibreAssemblies,PeterSchwartz,978-0-08-102619-9 Silk:Materials,Processes,andApplications,NarendraReddy,978-0-12-818495-0 Anthropometry,ApparelSizingandDesign,2ndEdition,NorsaadahZakaria,978-0-08-102604-5 EngineeringTextiles:IntegratingtheDesignandManufactureofTextileProducts,2ndEdition, YehiaElmogahzy,978-0-08-102488-1

NewTrendsinNaturalDyesforTextiles,PadmaVankarDharaShukla,978-0-08-102686-1 SmartTextileCoatingsandLaminates,2ndEdition,WilliamC.Smith,978-0-08-102428-7 AdvancedTextilesforWoundCare,2ndEdition,S.Rajendran,978-0-08-102192-7

ManikinsforTextileEvaluation,RajkishoreNayakRajivPadhye,978-0-08-100909-3

AutomationinGarmentManufacturing,RajkishoreNayakandRajivPadhye,978-0-08-101211-6

SustainableFibresandTextiles,SubramanianSenthilkannanMuthu,978-0-08-102041-8

SustainabilityinDenim,SubramanianSenthilkannanMuthu,978-0-08-102043-2

CircularEconomyinTextilesandApparel,SubramanianSenthilkannanMuthu,978-0-08102630-4

NanofinishingofTextileMaterials,MajidMontazerTinaHarifi,978-0-08-101214-7

NanotechnologyinTextiles,RajeshMishraJiriMilitky,978-0-08-102609-0

InorganicandCompositeFibers,BorisMahltigYordanKyosev,978-0-08-102228-3

SmartTextilesforInSituMonitoringofComposites,VladanKoncar,978-0-08-102308-2

HandbookofPropertiesofTextileandTechnicalFibres,2ndEdition,A.R.Bunsell,978-0-08101272-7

Silk,2ndEdition,K.MurugeshBabu,978-0-08-102540-6

WoodheadPublishingisanimprintofElsevier

50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates TheBoulevard,LangfordLane,Kidlington,OX51GB,UnitedKingdom

Copyright©2022ElsevierLtd.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans, electronicormechanical,includingphotocopying,recording,oranyinformationstorageand retrievalsystem,withoutpermissioninwritingfromthepublisher.Detailsonhowtoseek permission,furtherinformationaboutthePublisher’spermissionspoliciesandour arrangementswithorganizationssuchastheCopyrightClearanceCenterandtheCopyright LicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions

Thisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythe Publisher(otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchand experiencebroadenourunderstanding,changesinresearchmethods,professionalpractices,or medicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgein evaluatingandusinganyinformation,methods,compounds,orexperimentsdescribedherein. Inusingsuchinformationormethodstheyshouldbemindfuloftheirownsafetyandthesafety ofothers,includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors, assumeanyliabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterof productsliability,negligenceorotherwise,orfromanyuseoroperationofanymethods, products,instructions,orideascontainedinthematerialherein.

ISBN:978-0-12-824056-4

ForInformationonallWoodheadPublishingpublicationsvisit ourwebsiteat https://www.elsevier.com/books-and-journals

Publisher/AcquisitionsEditor: MatthewDeans

EditorialProjectManager: RafaelGuilhermeTrombaco

ProductionProjectManager: AnithaSivaraj

CoverDesigner: MatthewLimbert

TypesetbyAptara,NewDelhi,India

Contributors

RavindraV.Adivarekar,DepartmentofFibersandTextileProcessingTechnology, InstituteofChemicalTechnology,Mumbai,Maharashtra,India

GregorioGCarbajalArizaga,UniversidaddeGuadalajara–UDG,Jalisco,México

M.Arous,DepartmentofPhysics,LaMaCoP,FacultyofSciencesofSfax,University ofSfax,Sfax,BP,Tunisia

D.Balaji,DepartmentofMechanicalEngineering,KPRInstituteofEngineeringand Technology,Coimbatore,TamilNadu,India

SimonCurling,BioCompositesCentre,BangorUniversity,Bangor,Gwynedd,United Kingdom

DebasishDas,DepartmentofJuteandFiberTechnology,UniversityofCalcutta, Calcutta,Kolkata,India

SrijanDas,GovernmentCollegeofEngineeringandTextileTechnology,Serampore, Hoogly,WestBengal,India

SayandeepDebnath,NationalInstituteofFashionTechnology,NaviMumbai,Maharashtra,India

FábioA.O.Fernandes,CentreforMechanicalTechnologyandAutomation(TEMA), DepartmentofMechanicalEngineering,UniversityofAveiro,Aveiro,Portugal

ThaisFlores-Sahagun,FederalUniversityofParaná–UFPR,Curitiba,PR,Brazil

TalitaSzlapakFranco,FederalUniversityofParaná–UFPR,Curitiba,PR,Brazil

DalilaHammiche,LaboratoiredesMatériauxPolymèresAvancés,FacultédeTechnologie,UniversitédeBejaia,Algérie

MedBenHassen,CollegeofEngineering,IndustrialEngineeringDepartment,Taiba University,Taiba,SaudiArabia;LaboratoiredeGenieTextile,DepartementdeGenie Textile,UniversitedeMonastir,ISETKsarHellal,Tunisia

SeikoJose,SchoolofChemicalScience,MahatmaGandhiUniversity,Kottayam, Kerala,India;TextileManufacturingandTextileChemistryDivision,ICAR-Central SheepandWoolResearchInstitute,Avikanagar,Rajasthan,India

VinodKadam,TextileManufacturing&TextileChemistryDivision,ICAR-Central SheepandWoolResearchInstitute,Avikanagar,Rajasthan,India

AmmayappanLakshmanan,ChemicalandBiochemicalProcessingDivision,ICARNationalInstituteofNaturalFiberEngineeringandTechnology(ErstwhileICARNIRJAFT),Kolkata,WestBengal,India

SaptarshiMaiti,DepartmentofFibersandTextileProcessingTechnology,Instituteof ChemicalTechnology,Mumbai,Maharashtra,India

SubhankarMaity,DepartmentofTextileTechnology,UttarPradeshTextileTechnologyInstitute,Kanpur,UttarPradesh,India

J.Manivannan,MachineDynamicsandConditionMonitoringLaboratory, KalasalingamAcademyofResearchandEducation,AnandNagar,TamilNadu, India

K.Mayandi,DepartmentofMechanicalEngineering,KalasalingamAcademyof ResearchandEducation,AnandNagar,TamilNadu,India

JörgMüssig,HSB,HochschuleBremen/CityUniversityofAppliedSciences,DepartmentofBiomimetics–TheBiologicalMaterialsGroup,Bremen,Germany

Tri-DungNgo,InnoTechAlberta,Edmonton,AB,Canada

Tri-Dung(T.-D.)Ngo,BioIndustrialsResearchandDevelopment,InnoTechAlberta (FormerlyAlbertaResearchCouncil(1921-2010)andAlbertaInnovatesTechnology Futures(2010-2016)),Edmonton,Alberta,Canada

DangMaoNguyen,LaboratoireInnovationMatériauBoisHabitatApprentissage(LIMBHA),EcoleSupérieureduBois,Nantes,France

MedAminOmri,DepartmentofPhysics,LaMaCoP,FacultyofSciencesofSfax, UniversityofSfax,Sfax,BP,Tunisia

GrahamOrmondroyd,BioCompositesCentre,BangorUniversity,Bangor, Gwynedd,UnitedKingdom

PintuPandit,DepartmentofTextileDesign,NationalInstituteofFashionTechnology, Patna,Bihar,India

PatrickPerré,LaboratoireInnovationMatériauBoisHabitatApprentissage (LIMBHA),EcoleSupérieureduBois,Nantes,France

ThanhKhoaPhung,DepartmentofChemicalEngineering,SchoolofBiotechnology, InternationalUniversity,HoChiMinhCity,Vietnam;VietnamNationalUniversity, HoChiMinhCity,Vietnam

S.Rajesh,MachineDynamicsandConditionMonitoringLaboratory,Kalasalingam AcademyofResearchandEducation,AnandNagar,TamilNadu,India

L.Rajeshkumar,DepartmentofMechanicalEngineering,KPRInstituteofEngineeringandTechnology,Coimbatore,TamilNadu,India

GovindarajuRajkumar,KumaraguruCollegeofTechnology,DepartmentofFashion Technology,Coimbatore,India

M.Ramesh,DepartmentofMechanicalEngineering,KIT-KalaignarkarunanidhiInstituteofTechnology,Coimbatore,TamilNadu,India

VincentRöhl,HSB,HochschuleBremen/CityUniversityofAppliedSciences,DepartmentofBiomimetics–TheBiologicalMaterialsGroup,Bremen,Germany

I.Sankar,DepartmentofMechanicalEngineering,NationalEngineeringCollege, Kovilpatti,TamilNadu,India

KesturGundappaSatyanarayana,RRL-Triv.CSIR-India,UFPR,Curitiba& EMBRAPA,Colombo(PR-Brazil)andPoornaprajnaScientificResearchInstitute (PPISR),Poornaprajnapura,Devanahalli,Bangalore,Karnataka,India

KunalSingha,DepartmentofTextileDesign,NationalInstituteofFashionTechnology,Kolkata,WestBengal,India;DepartmentofTextileDesign,NationalInstituteof FashionTechnology,Patna,Bihar,India

I.Siva,CentreforCompositeMaterials,KalasalingamAcademyofResearchand Education,AnandNagar,TamilNadu,India

S.Sivalingam,DepartmentofMechanicalEngineering,CoimbatoreInstituteofTechnology,Coimbatore,TamilNadu,India.

FaisalAmriTanjung,FacultyofScienceandTechnology,UniversitasMedanArea, Medan,Indonesia

ValcineidedeAndradeTanobe,FederalUniversityofParaná–UFPR,Curitiba,PR, Brazil

SabuThomas,SchoolofEnergyMaterials,MahatmaGandhiUniversity,Kottayam, Kerala,India

VyAnhTran,DepartmentofChemicalandBiochemicalEngineering,GachonUniversity,Bokjeong-Dong,Sujeong-Gu,SeongnamCity,SouthKorea

A.Triki,DepartmentofPhysics,LaMaCoP,FacultyofSciencesofSfax,Universityof Sfax,Sfax,BP,Tunisia

NikNorimanZulkepli, FacultyofChemicalEngineeringTechnology,Universiti MalaysiaPerlis,Jejawi,Malaysia

Contributorsxi

1Introductiontonaturalfibercomposites1

FábioA.O.Fernandes,SeikoJoseandSabuThomas

1.1Introduction1

1.2Naturalfibercomposites1

1.3Naturalfibercompositesandtheroleofnaturalfibers asreinforcement4

1.4Woolincomposites5

1.5Casestudies6

1.6Currenttrendsandfuturedirections9

Funding&Acknowledgments10 References10

2Woolstructureandmorphology13

DebasishDasandSrijanDas

2.1Introduction13

2.2Chemicalcomposition14

2.3Woolfibermorphology20

2.4Two-componentandthree-componentmodelsofwoolfiber27 References29

3Microscopyandspectroscopyofwoolfiber33

VinodKadamandAmmayappanLakshmanan

3.1Introduction33

3.2Microscopytechniques33

3.3Spectroscopytechniques38

3.4Conclusion45 References45

4Physicalandchemicalpropertiesofwoolfibers49 AmmayappanLakshmanan

4.1Introduction49

4.2Classificationofwoolfibers52

4.3Physicalpropertiesofwoolfiber53

4.4Chemicalpropertiesofwoolfiber56

4.5Roleofwoolfiberpropertiesforreinforcement65

4.6Conclusion67 References68

5Surfacemodificationtreatmentmethodsofwool71 KesturGundappaSatyanarayana,ThaisFlores-Sahagun, GregorioGCarbajalArizaga,TalitaSzlapakFrancoand ValcineideOliveiradeAndradeTanobe

5.1Introduction71

5.2Characteristicsandpropertiesofwool72

5.3Surfacemodificationofwool—Physical,chemical,andenzymatic methods75

5.4Conclusion95 Acknowledgments96 References96

6Compositepreparationtechniques105 Tri-DungNgo

6.1Introduction105

6.2Matrixandreinforcements106

6.3Advantagesofcomposites107

6.4Preparationtechniques108

6.5Summary115 References116

7Biofillersforbiocomposites121 DalilaHammiche

7.1Introduction121

7.2Commonnaturalfibersfromby-product123

7.3Endoflifeofnaturalfiber-reinforcedbiocomposites131

7.4Conclusions133 Acknowledgment134 References134

8Nanotechnologicalinterventioninthewoolcomposites141 Tri-Dung(T.-D.)Ngo

8.1Introduction141

8.2Woolfiberandadvantages141

8.3Woolclassification143

8.4Classificationbysheep143

8.5Classificationbyfleece143

8.6Processingwool143

8.7Advantagesofwool144

8.8Nanotechnologicalapproachesonwool146

8.9Woolbio-andnanocomposites147

8.10Summary149 References150

9Thermoplasticpolymer/woolcomposites155 FaisalAmriTanjungandNikNorimanZulkepli 9.1Introduction155 9.2Thermoplasticpolymers156 9.3Conclusionandfuturetrends171 References172

10Generaltestingofwoolcomposites179 SayandeepDebnath,SaptarshiMaitiandRavindraV.Adivarekar 10.1Introduction179

10.2Generaltestingofwoolcomposites180 10.3Conclusion192 References192

11Advancedtechniquesfortestingandcharacterizationofwool composites197

DangMaoNguyen,PatrickPerré,ThanhKhoaPhungandVyAnhTran 11.1Introduction197

11.2Woolcompositesmanufactures198 11.3Characterizationapproaches199 11.4Morphologicalanalysis199 11.5Mechanicalproperties202 11.6Thermalanalysis207 11.7Flame-retardantproperties216 11.8Conclusions220 Acknowledgments220 References220

12Developmentofwoolfiberincorporatedpolymercomposites227 KesturGundappaSatyanarayana,ThaisFlores-Sahagun, GregorioGCarbajalArizaga,TalitaSzlapakFrancoand ValcineidedeAndradeTanobe

12.1Introduction227

12.2Compositescontainingwool:Reinforcement,matrix,processing, andproperties230

12.3Perspectives/futuretrendsinwool-containingpolymercomposites243 12.4Conclusion246 Acknowledgments247 References247

13Scopeofblendingofwoolwithothersynthetic/naturalfibersfor composites255

A.Triki,MedAminOmri,MedBenHassenandM.Arous 13.1Introduction255 13.2Experimental256

13.3Resultsanddiscussion258 13.4Conclusion268 References270

14Silkandwoolhybridfiber-reinforcedpolypropylenecomposites273 GovindarajuRajkumar 14.1Introduction273

14.2Materialsandmethods274

14.3Resultsanddiscussion277 Conclusion294 References295

15Mechanicalandviscoelasticpropertiesofwoolcomposites299

M.Ramesh,L.Rajeshkumar,D.BalajiandS.Sivalingam 15.1Introduction299

15.2Mechanicalandthermalpropertiesofwoolfibers300

15.3Mechanicalpropertiesofwoolcomposites303

15.4Mechanicalpropertiesofwoolsandwichcomposites306

15.5Viscoelasticpropertiesofwoolcomposites307

15.6Characterizationofwoolcomposites312

15.7Conclusion313 References314

16Moistureinteractionsofwoolandwool-basedcomposites319

SimonCurlingandGrahamOrmondroyd

16.1Introduction319

16.2Watersorptionbywool319

16.3Effectsofmoistureonwoolfiberproperties324

16.4Woolcompositesandmoisture327

16.5Conclusions330 References330

17Abrasivewaterjetcuttinganditsoptimizationmodelformachining thesheepwool/polyestercomposites327

J.Manivannan,S.Rajesh,K.Mayandi,I.Siva,I.Sankarand KesturGundappaSatyanarayana

17.1Introduction327

17.2Materialsandmethods328

17.3Resultsanddiscussions342 17.4Conclusion347

Acknowledgment347 References348

18Woolfiber-reinforcedthermoplasticpolymersforinjectionmolding and3D-printing351

VincentRöhlandJörgMüssig 18.1Introduction351

18.2Woolandotherkeratinouscompositematerials352 18.3Mechanicalpropertiesofkeratinouscompositematerials355 18.4Woolfiber-reinforcedthermoplasticcomposites355 18.5Processing&applicationofwoolfiber-reinforcedthermoplastics372 18.6Specificfeatureswhenprocessingwoolfiber-reinforcedPLA intheFDMprocess373

18.7Specificfeatureswhenprocessingwoolfiber-reinforcedPLA intheinjectionmoldingprocess374 18.8Applicationsofwoolfiber-reinforcedcomposites375 18.9Conclusionandoutlook379 Acknowledgments379 References380

19Woolcompositesforhygienic/medicalapplications387

KunalSingha,PintuPanditandSubhankarMaity 19.1Introduction387

19.2Woolkeratin:Asignificantbiomoleculeforthemanufacture ofmedicinaltextiles,biopolymers,andmedicines388 19.3Importanceofcuticleandcortexofwoolfiber389 19.4Keratinextractionfromwoolfiber390 19.5Commerciallyavailablewool-basedMedtexproducts391 19.6Scaffoldfromwool393 19.7Keratininbiomedicalapplications393 19.8Applicationofwoolinmedicaltextiles396 19.9Revenuegenerationofwool/polymericproductsinsidetechnical textilemarket400 19.10Companyacrosstheglobeinmedicaltextilebusiness401 19.11Conclusions402 References402

20Applicationsofwoolcompositesforconstruction407 KunalSingha,SubhankarMaityandPintuPandit 20.1Introduction407

20.2Typesofreinforcementmechanismofwool–polymer reinforcementcomposite409 20.3Materialsusedinwool–polymerreinforcementcomposites:Fibers412 20.4Innovative/recentmaterialsusedinwool–polymerreinforcement composites:Reversiblecovalentbondsusedinwoolcomposites414 20.5Significanceofinnovativeofwoolcompositepolymerblends416 20.6Conclusion419 References420

21Conductivepolymer-coatedwoolcompositesfornovelapplications423 SubhankarMaity,KunalSinghaandPintuPandit

21.1Introduction423

21.2Conductivepolymers424

21.3Thereasonofelectricalconductivityinconductingpolymers426

21.4Methodsofpreparationsofconductivepolymer-coatedwoolfibers427

21.5Polypyrrole-coatedwoolfibers431

21.6Polyaniline-coatedwoolfiber433

21.7Colorationofwoolbycoatingwithconductivepolymers434

21.8Fouriertransforminfraredspectroscopy(FTIR)analysis ofPPy-coatedwool435

21.9Interactionofwoolfiberandconductivepolymersattheinterface436

21.10Thermalstabilityanddurabilitypropertyofthewool/conductive polymer-coatedwool437

21.11Heattransferbehaviorandthermalconductivityofconductive polymer-coatedwool437

21.12Conductivepolymer-basedwoolcompositesforelectromagnetic shielding438

21.13Conductivepolymer-basedwoolcompositesforpHsensor439

21.14Conductivepolymer-basedwoolcompositesasbendingstrainsensor440

21.15Conductivepolymer-basedwoolcompositesashumiditysensor441

21.16Antimicrobialeffectofconductivepolymer-coatedwoolcomposites441

21.17Conclusionsandfutureperspective443 References444 Index447

1.3Naturalfibercompositesandtheroleofnatural fibersasreinforcement

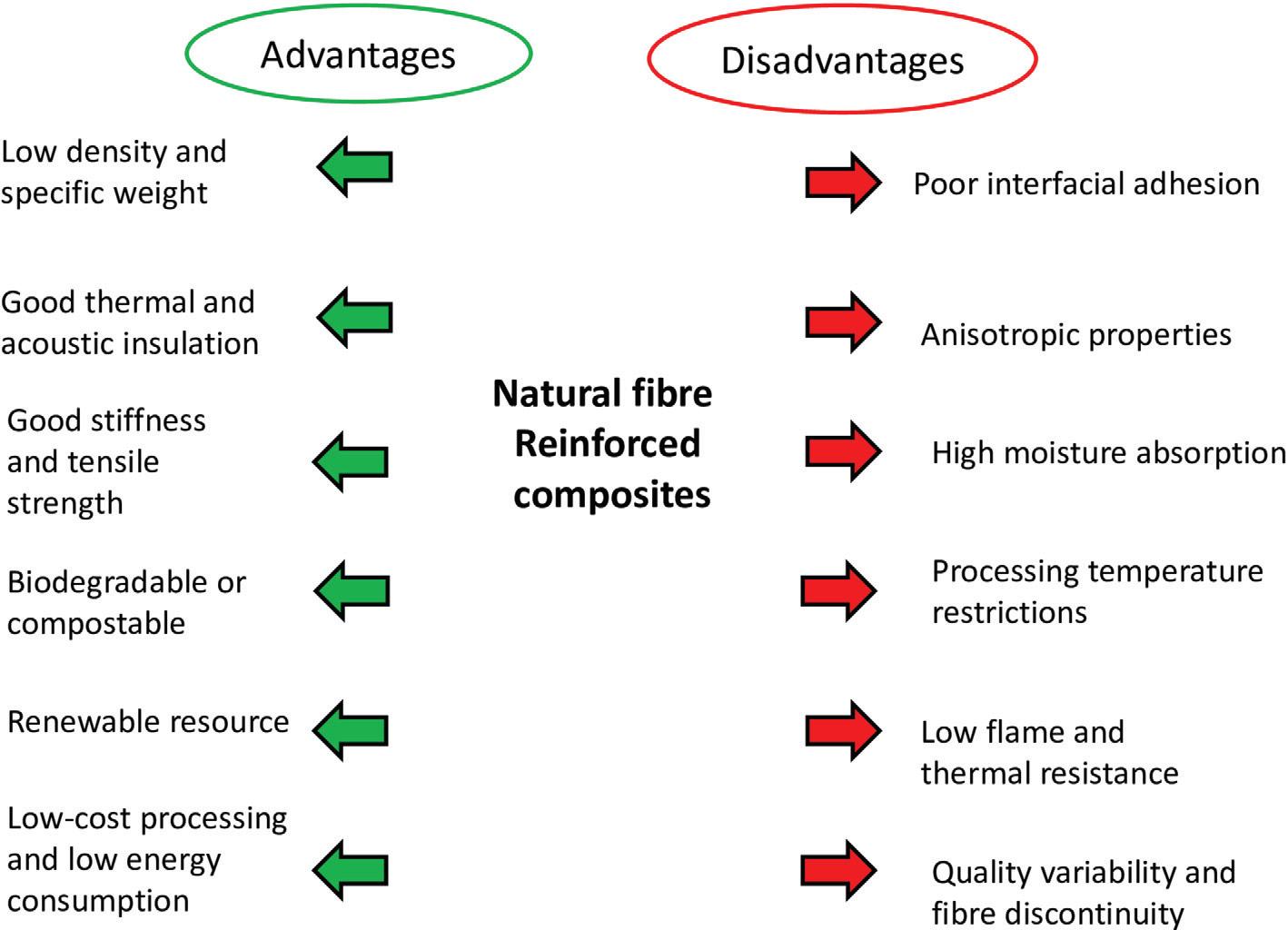

Recently,theindustryhasdemonstratedaclearinterestinsustainableandenvironmentallyfriendlymanufacturingprocesses,withsignificantinvestmentsinsustainable productsandprocessesforapplicationsinvarioussegmentssuchasautomotive, textile,naval,andaerospace.Regardingfiber-reinforcedcomposites,thishasbeen demonstratedbyreducingorreplacingsyntheticfiberswithnaturalfibers.Themain principlebehindthisinvestmentandstrategychangetowardnaturalfibersisjustified bytherenewabilityofthesenaturalsourcesandthehighCO2 emissionsandenergy consumptionusuallyassociatedwiththemanufacturingofsyntheticfibers(Becker, Kleinschmidt,Balzer,&Soldi,2011).Naturalfibersofvegetableoranimalorigincan befarmedandprocessed,inadditiontotheotherclearadvantagesoftheserenewable materials.

Fiberspresentsignificantadvantagesasreinforcementmaterial.Generally,fibers havehightensilestrength,makingitpossibletousesomematerials(typicallyweak totensileloadingifsolelyemployed)asthematrix.Typically,compositesarecharacterizedbybeinglightweightandhavinghighstrength.Thisisthemainreason whycompositesaresodesirableforapplicationsuchastransportation.Parameters suchasthefiberslengthandtheirorientationandconcentrationinthecompositeare determinantinthemechanicalpropertiesoffiber-reinforcedcomposites,andthus, theseparametersinfluencethecompositeperformance.Forinstance,fiberlength affectshowtheloadisdistributed.Fiberorientationandconcentrationalsosignificantly impactthemechanicalperformanceofthecomposite,beingacriticalfactortoconsider duringdesign(e.g.,loadtype,cost,etc.)(Ashby&Jones,2005; Callister&Rethwisch, 2007).

Overall,fibersmakeitpossibletodevelophigh-performancecompositesfordemandingapplications,throughthecombinationofexcellentproperties,suchasrelativelylowdensity,hightenacity,andhighmechanicalstrength.Dependingonthe combination,otherexcellentpropertiesmaybeachievedsuchasgoodresistanceto friction,goodthermalresistance,resistancetocorrosion,andevenrecyclabilityand biodegradabilityinsomeparticularcases.

Syntheticfibershaveavastrangeofapplications,especiallythosethatdemand high-performancematerialsorrequirelow-weightandhighmechanicalperformance (Ashby,2005; Scheirs,2001).Despiteconstantusebymanthroughouthistory,compositesreinforcedwithnaturalfibersareofrecentindustrialimportance,beingincreasinglyemployedasaviablesolutioninsomeapplications.Thisinterestwasstrengthenedbythedevelopmentofnewtechniques,improvementofmaterials,reductionof costsandalsobytheincreasingmotivationgeneratedbyenvironmentalissues,and morerecentlyenforcedbypoliciesandregulationsaddressingtheuseofrenewable andrecyclablematerials,inrelevantindustriessuchastheautomotiveandaerospace onesandtheconstructionsector.

Theuseofcompositematerialsbasedonpolymericmatrixesandnaturalfibers isoneofthesolutionsfoundbycarmanufacturersinEuropetomeettheregulation

requirements.TheEuropeanUnionhasforcedtheautomotivesectortoimplement sustainablepoliciessuchastheend-of-lifevehicles,resultingininvestmentsinnaturalmaterialstoreplacesyntheticmaterials,reducingtheenvironmentalimpactat theendofthelifecycle.Thedirective2000/53/EConend-of-lifevehiclespushed manufacturertosearchforalternativestocomplywithaseriesofstandardssuch asrecycling85%ofthetotalweightofend-of-lifeautomotivecomponentsanda minimumrecovery/reusabilityof95%(EuropeanParliament,CounciloftheEuropean Union,2000).Carmanufacturersmakeuseoftheadvantagesofthesematerialsusing varioustechnologiessuchaslow-pressurecompressionmoldingtoproducepartsand componentsthatcanbesimultaneouslycoatedwithothermaterials.Forinstance,in nonstructuralinteriorcomponentsorsemistructuralcomponents,reducingitsweight, andtherefore,ofthevehicle.Asanexample,inMercedes-BenzE-classandS-Class, thereareseveralcomponentsmanufacturedwithnaturalfiberssuchaswool,hemp, flax,sisal,andwoodfibers:luggagecompartmentlinings,sectionsofinternaldoor panels,driver’sseatbackrest,amongothers.Asreportedby(Akampumuza,Wambua, Ahmed,Li,&Qin,2017),savingsupto45%wereachievedonthedoorpanel carrierweightoftheMercedes-BenzS-Class.Intheautomobileindustryandother vehiclemanufacturers,thereisalreadyawidevarietyofproductsmanufacturedusing composites,addingtoothergoodexamplesofdevelopinghigh-valueapplicationsfor compositesreinforcedwithnaturalfibers(Müssig&Stevens,2010).

Civilconstruction,alongsidetheautomotiveindustry,alsorepresentsarelevant areaofbiocompositeapplication.Itiscommontousethesematerialsonfloors, decks,structuralreinforcements,façadepanels,fillers,andinsulation(e.g.,floorpanels reinforcedwithshortflaxfibers,façadepanelsreinforcedwithhempfibers,etc.)(Dahy, 2017).Currently,itisincreasinglyeasiertofindproductsthatincorporatecomposites reinforcedwithnaturalfibers.Inadditiontothemainapplications,thesematerialsalso satisfyseveralnicheapplicationssuchasofficeitems,furnitureitems,householditems, boxesandcontainers,varioussportsproducts,andleisureproducts.Itshouldalsobe notedthatmanymusicalinstrumentmanufacturerstodayproducemusicalinstruments withgoodpropertiesacousticsfromcompositeswithnaturalreinforcements.Flaxand hempfiberspossessahighvibrationdampingcapacity,makingthemexcellentforthis applicationandotherssuchassportingproducts(Pil,Bensadoun,Pariset,&Verpoest, 2016).

1.4Woolincomposites

Woolisoneofthemostpreferrednaturalfiberstomankindandisoneoftheoldest fibersusedincivilization.Australia,China,theUnitedStates,andNewZealandarethe world’sleadingproducersofwool.Thefiberfinenessofthewoolgreatlydependsupon sheepbreed,climaticcondition,etc.(Kumar,Prince,&Jose,2017).Thewoolfiber canbeclassifiedintothreecategoriesbasedupondiameter:fine(20–24μm),mediumcoarsewool(24–30μm),andverycoarse(above35μm).Thefineandmedium-coarse woolisutilizedinthegarmentsandcarpetindustries.However,theverycoarsewool couldfindverylimitedapplicationsinproductdevelopmentduetoahighdiameter,

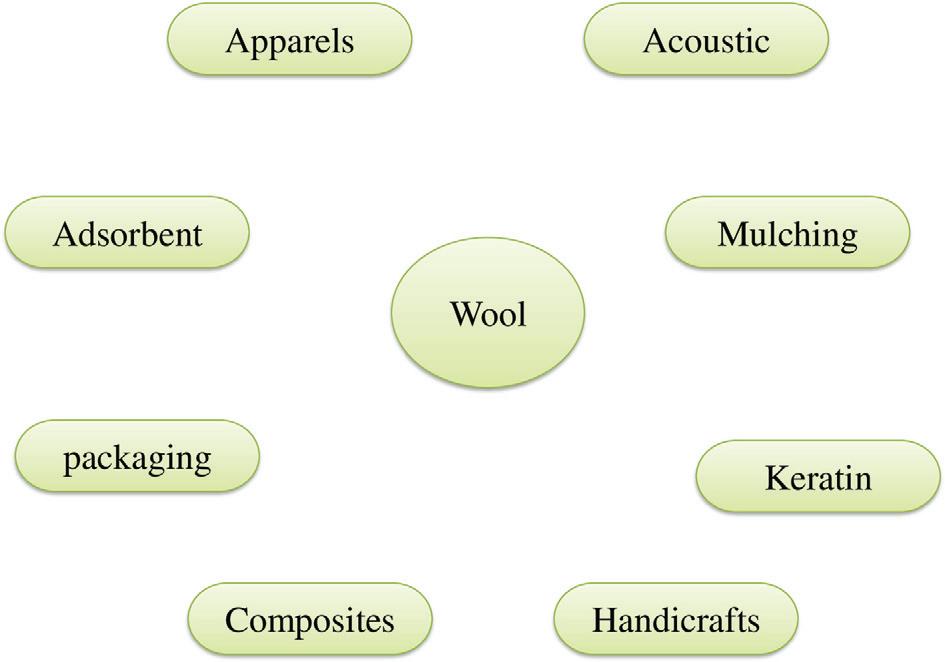

Figure1.2 Applicationsofwoolfiber.

medullation,andbrittlenature(Shakyawaretal.,2018).Becauseofthisreason,coarse woolisfetchingaverylowpriceinthemarket.Apartfromtextileandapparel, todaywoolisusedformanyapplications,whichincludecomposites,conductive polymers,thermalandacousticinsulation,mulching,packaging,keratinextraction, andhandicrafts(Fig.1.2).Inmostcountries,coarsewoolislocallyutilizedformaking handmadecarpetsorlow-gradeproducts(Lakshmanan,Jose,&Chakraborty,2016). Thus,itisaneedofthehourtodesignanddevelopnewalternativeproductswithcoarse wool.

Asmentionedearlier,bio/greencompositesaregainingattentiondaybyday. Currently,themajoritiesofthecompositesarebeingpreparedfromsyntheticorglass fiber,whichisnotbiodegradableandishavingamajorenvironmentalconcern.Inthis context,coarsewoolcanbeusedforthepreparationofcomposites,whichmayprovide bettervalueadditiontothewool.Incontrast,theuseofwoolinthecompositeapplicationisverylimitedsinceunlikeotherplantfibers,woolishavinglessfiberlengthand tensileproperties.Thehighmoistureabsorptionpropertyalsorestrictstheuseofwool fiberinthecomposite.Becauseoftheabove-saidreasons,averylimitedamountof worksisreportedonwoolfiberinthepreparationofbiocomposites.However,woolcan findpotentialapplicationsincomposites,wheremechanicalstrengthisnotcomingas animportantfactor.Theheat,thermal,soundinsulation,andflameresistanceproperties ofthewoolfibercanbeeffectivelyutilizedforthedevelopmentofthecomposites, wherethesepropertiesareessential(Fig.1.2).

1.5Casestudies

Finewoolfiberhavingadiameterof18micronintheformofsliverwasmixed withpolypropyleneandpolypropylenegraftedwithmaleicanhydridetoformthe biocomposites.Thewoolfiberwasmixedindifferentproportions(20%,40%,and

Introductiontonaturalfibercomposites7

60%)andthecompositeswerepreparedthroughthemeltblendingprocess.The SEMimagesshowedthatthefiber–matrixadhesionwasfoundtobepoorinPP woolcomposites,lateritwasenhancedinpresenceofcompatibilizer.Thethermal degradationstudiesshowedthatthecharyieldwasfoundhigherwhenwoolfiber wasmixedwithpolypropylenegraftedwithmaleicanhydrideincomparisonwithonly woolandPPcomposites.However,thetensilestrengthofthecompositeswasreduced withtheadditionofwoolincomparisonwithneatcomposites.Thereductionintensile strengthisdirectlyproportionaltotheincrementinthewoolpercentage(Conzattietal., 2013).

Asstatedearlier,woolishavingthehighestflameretardancyamongnaturalfibers. Thisuniquepropertyhasbeentakenadvantageofthecompositeapplication. Kim, Bhattacharyya,andLin(2013))makeuseofcoursewoolfiberhaving45micronfor thepreparationofwool–polypropylenecomposites.Afteradding15–30percentageof woolfiberinthepolypropylene(PP),theresearchersobservedasignificantenhancementinthefire-retardantbehaviorofthecompositeincomparisonwithneatPP.During thehorizontalburningtest,the30%woolloadedcompositeshownaflamepropagation timeof60mm/min,incomparisonwith140mm/minofneatPP.Interestingly,the tensilepropertiesofthewool-loadedcompositedidnotmarkanysignificantchanges, however;themodulusenhancedfrom1.68to2.14GPwiththeadditionof30%inthe PP.

Owingtothelowdensity,thewoolfibercanbeusedasfillerforbuildingapplications.Insuchastudy,low-gradewoolhasbeenattemptedasafillerintheconcrete mixertoproducelight-weightconcreteblocks(Štirmer,Milovanovi ´ c,&Sokol,2014). Differentconcentrationsoflow-gradewoolfiber(3.0%,5.0%,and9.0%)weremixed withconcreteinthemortarandtheresultedblockswereanalyzedfortheirstrength andotherrelatedproperties.Incomparisonwiththereferenceconcreteblock,the9% additionofthewoolfibercompositeblockresultedinareductionindensityfrom 1.49kg/dm3 to1.09kg/dm3 .Theaircontentalsoincreasedfrom27%to34%.Theadditionofthewoolmarginallyenhancedthethicknessofthecomposites.Whiletheweight oftheconcreteblocksgotreduced,theadditionofwoolcausesasignificantreduction inthecompressionandflexuralstrengthofthecompositeswiththeenhancement inthewoolcomponent.Theresearcherssuggestthatthedevelopedwoolcomposite couldfindpotentialapplicationsinfalseceilingsornonload–bearingwallpartition. Anothersuccessfulexamplewasreportedby(Fioreetal.,2019),byusingwoolfibersas reinforcementincompositesfortheconstructionindustry,wherethethermalproperties ofwoolexcel.Woolfiber-reinforcedcompositesshowedbetterthermalinsulationin comparisonwithothersolutions,regardlessofthefiberlengthandthiscapacitywas improvedbyincreasingthewoolfibercontent.

Inanotherstudy,medium-coarsewoolfiberwasusedasreinforcementforepoxy polymermatrix(Bharath,Pasha,&Nizamuddin,2016).Twodifferentratiosofthe epoxyandwoolfiber(60:40and50:50)compositeswerepreparedandthephysicomechanicalpropertieswereevaluated.Thetensilestrength,bendingproperties,and waterabsorptionpropertiesofthe50:50compositewasfoundtobebetterthanthe 60:40composite.TheSEMimagesofthecompositesamplesshowedgooddistribution ofthewoolfiberinsidethepolymermatrix.Inanotherstudy,layeredfibercomposites

werepreparedusingwoolandglassfiber.Thewoolfiberwasconvertedintoawoven matandsandwichmodelcompositeswereprepared.Theresearchersfoundthattwo layersofwoolandglassfiberareproducingcompositehavingdesirableproperties (Pantoji&Pol,2018).

PowderedAustralianwool(30%)wasmixedwithglycerolandblendedwithPP andextrudedinascrewextruder.Then,thepelletsobtainedweresandwichedbetween twopiecesofPETfilmstoformathincompositethroughcompressionmolding.Up toFTIRanalysis,itisobservedthattheblendingdoesnotleadtotheformationof chemicalbondsofboththefiberandPP,andnonewsteadybondsareformedbysimple physicalblending.XRDpeaksregisteredamarginalreductioninthecaseofwool–PP blendedfilmincomparisonwithneatPPfilm.Theblendingofwooldidnotalterthe crystallinityandorientationofPPintheblendfilm,buttheadditionofwoolpowder enhancestheamorphousregioninthecomposites.Similarly,theTGAstudiesindicate thatthethermalstabilitydecreaseswiththeincrementinthewoolpowdercontentin theblendfilm.ThetensilestrengthoftheneatPPgotreducedafterblendingwithwool powder.Thismightbebecausetheadditionofthewoolpowderincreasesthenumberof holesintheblendfilmwhichdestructsthenaturalintegrityofPPandcausesareduction intensilestrength(Xuetal.,2007). Fig.1.3 showstheimageofwool–epoxyresin composites.

Compositeswereoftenpreparedusingtheblendingofdifferentfibers.Theblending processoftenovercomescertaininherentdisadvantagesofindividualfibers.These

Figure1.3 Wool–epoxycomposite.

blendedcompositesaresometimesreferredtoashybridcomposites.Astudyreportsthe developmentofwool–jutehybridcompositesusingapolypropylenematrix.Various concentrationsofblendedfiberviz., 5%,10%,and15%weremixedwithPPinaratio of1:1insideahotpressmachine.Theresultantcompositeswerecharacterizedfor theirphysico-mechanicalproperties.Unlikeotherstudies,theresearchersreporteda gradualelevationinthetensileandflexuralstrengthofthecompositestothefiber percentage.ItisobservedthatYoung’smodulusincreasedwithanincreaseinfiber loading,maybethebrittlenatureofthecompositegotincreasedwiththeincrease infibercontent.Thebestsetofpropertieswasobtainedfrom15%fiberloading withthejuteandwoolfiberratioof3:1;however,thestudyreportedpoorinterfacial adhesionoftheblendedfiberwiththepolymermatrix(Tusnim,Jenifar,&Hasan, 2018).

1.6Currenttrendsandfuturedirections

Fiber-reinforcedcompositesincorporatingnaturalresourcesarehighlyattractive.Both hybridandfullynaturalsolutionshavebeenproposedintheliterature.Although thegreencompositesaremoreattractiveregardingenvironmentalaspects,hybrid solutionsarestillmoresuccessful,consideringtheircost,durability,andperformance. Nevertheless,greencompositesaregainingmomentum,showingenormouspotential inseveralapplications.Forinstance,thedevelopmentoflightweightcomponents fortheautomotiveindustry.Oneofthechallengesisthecost-effectiveandsmart integrationofprocessingandmanufacturingtechnologiestosuccessfullyincorporate naturalfiberssuchaswoolintogreencompositestructuresthatpresentatleastthe samedegreeofperformanceasthecurrentsolutionsandatalowercost.Additionally, thegreatandfundamentalchallengeisthecompatibilitybetweenthesematerials. Thus,theimprovementoftheinterfacebetweenfiber–matrixingreencompositesisthemainchallengetoincreasethemechanicalperformanceofnaturalfiber composites.

Asoftoday,woolfiberisstillunderutilizedforcompositeapplications.Unlike othernaturalfibercomposites,veryfewattemptshavebeenreportedontheutilization ofwoolinthecompositessector.Woolcompositescanbeanexcellentmaterialfor buildings,automobiles,andotherstructuralapplications,wherelightweight,thermal insulation,andsoundinsulationaretheessentialneeds.Thepooradhesionproperties ofthewoolfiberwiththeresincanberesolvedbysurfacefunctionalizationbyphysical (radiationtreatment)orchemicals(enzymatictreatment,steamexplosion,andchlorite treatment)methods.Conventionally,thenonapparelandcarpetgradewoolisused domesticallyformakingmatsorhandicrafts.Thereisagooddemandforfinewool intheapparelindustry,however;coarsewoolisfetchingverylowcostinthemarket andthewoolcompositescanbevalue-additionforit.

Theresearchinvolvingnaturalfibercompositesisstillfocusedonimprovingits mechanicalpropertiesreflectingitsfiber–matrixinterfacialbond(e.g.,fibertreatment, compatibilizers/additives,etc.).Itisexpectedthatfutureresearchwilladdressthe influenceoffiberlengthandmatrixmodificationonthenaturalfibercomposites

10WoolFiberReinforcedPolymerComposites

propertiesashighlightedbyotherresearchers(Gholampour&Ozbakkaloglu,2020). Naturalfibercompositeshavebeenacceptedandfindingdiverseapplications,from theautomotiveindustrytotheconstructionsector,insportsandmedicalequipment, inpackaging,andintransportation.Futureresearchinthisfieldwillbenefitthe developmentofhigh-performancenaturalfibercompositesthatwillwidentheirapplicationandmanufacturedvolumes.Forinstance,naturalfibercompositeshavebeen reportedrecentlyinfields/applicationssuchaselectrical,electronics,andsporting segments(Girijappaetal.,2019).Althoughnaturalfibersarebiodegradableandcanbe incineratedtoproduceenergy,additionalresearchisnecessarytoaddressotherissues beyondperformanceandrelatedtocostsandsupplyoffiberformassproduction, consideringthesearealsofiniteresourcesandeventuallyrecyclabilityandreuseof naturalfibersresearchwillincrease.Itisexpectedthatfutureresearchwillexplore alternativemanufacturingmethods,forinstance,additivemanufacturing(Parandoush &Lin,2017),andthus,newstrategiesforrecyclabilitywillbenecessary.Finally,there areotherpotentialbenefitsatthesocio-economiclevelthatwillpushtheresearchof naturalfibercomposites,consideringthepotentialaddedvalueofresearchinvolving naturalfiberwaste,especiallywool.

Funding&Acknowledgments

ThisworkwassupportedbytheprojectsUIDB/00481/2020andUIDP/00481/2020-FCTFundaçãoparaaCiênciaeaTecnologia;andCENTRO-01-0145-FEDER-022083-CentroPortugalRegionalOperationalProgramme(Centro2020),underthePORTUGAL2020Partnership Agreement,throughtheEuropeanRegionalDevelopmentFund.

References

Akampumuza,O.,Wambua,P.M.,Ahmed,A.,Li,W.,&Qin,X.H.(2017).Reviewofthe applicationsofbiocompositesintheautomotiveindustry. PolymerComposites,38,2553–2569.

Albinante,S.R.,Pacheco,E.,&Visconte,L.L.Y.(2013).Reviewofchemicaltreatmentsof naturalfiberforblendingwithpolyolefins. NewChemistry,36(1),114–122.

Alves,C.,Ferrão,P.M.C.,Silva,A.J.,Reis,L.G.,Freitas,M.,Rodrigues,L.B.,etal.(2010). Ecodesignofautomotivecomponentsmakinguseofnaturaljutefibercomposites. Journal ofCleanerProduction,18,313–327.

Ashby,M.(2005).Materialselectioninmechanicaldesign.(3rded.).Oxford,UK.ButterworthHeinemann.

Ashby,M.,&Jones,D.(2005).Engineeringmaterials2:Anintroductiontomicrostructures, processinganddesign.(3rdreviseded).Oxford,UK.PergamonPress. Azwa,Z.,&Yousif,B.(2013).Characteristicsofkenaffiber/epoxycompositessubjectedto thermaldegradation. PolymerDegradationandStability,98(12),2752–2759. Becker,D.,Kleinschmidt,A.C.,Balzer,P.S.,&Soldi,V.(2011).Influencefromthesequence forthemixtureofPP-MAonthepropertiesofPPandbananafibercomposite. Polímeros, 21(1),7–12.

Introductiontonaturalfibercomposites11

Bharath,K.N.,Pasha,M.,&Nizamuddin,B.A.(2016).Characterizationofnaturalfiber(sheep wool)-reinforcedpolymer-matrixcompositesatdifferentoperatingconditions. Journalof IndustrialTextiles,45(5),730–751.

Bledzki,A.K.,&Gassan,J.(1999).Compositesreinforcedwithcellulosebasedfibers. Progress inPolymerScience,24(2),221–274.

Callister,W.,&Rethwisch,D.(2007).Materialsscienceandengineering:Anintroduction.(7th ed.).NewYork,USA,JohnWiley&SonsInc.

Conzatti,L.,Giunco,F.,Stagnaro,P.,Patrucco,A.,Marano,C.,&Rink,M.(2013).Composites basedonpolypropyleneandshortwoolfibers. CompositesPartA:AppliedScienceand Manufacturing,47,165–171.

Dahy,H.(2017).Biocompositematerialsbasedonannualnaturalfibersandbiopolymers— Design,fabricationandcustomizedapplicationsinarchitectureConstruct. BuildingMaterials,147,212–220.

Dittenber,D.B.,&Gangarao,H.V.S.(2012).Criticalreviewofrecentpublicationsonuseof naturalcompositesininfrastructure. CompositesPartA:AppliedScienceandManufacturing,43(8),1419–1429.

EuropeanParliament,CounciloftheEuropeanUnion.(2000).Directive2000/53/ECofthe EuropeanParliamentandoftheCouncilof18September2000onend-oflifevehiclesCommissionStatements. OfficialJournalL,269,0034–004321/10/2000.

Faruk,O.,Bledzki,A.,Fink,H.,&Sain,M.(2012).Biocompositesreinforcedwithnaturalfibers: 2000-2010. ProgressinPolymerScience,37(11),1552–1596.

Fernandes,F.A.O.,Tavares,J.P.,AlvesdeSousa,R.J.,Pereira,A.B.,&Esteves,J.L.(2017). Manufacturingandtestingcompositesbasedonnaturalmaterials. ProcediaManufacturing, 13,227–234.

Fiore,V.,DiBella,G.,&Valenza,A.(2019).Effectofsheepwoolfibersonthermalinsulation andmechanicalpropertiesofcement-basedcomposites. JournalofNaturalFibers,17(10), 1532–1543.

George,J.,Sreekala,M.S.,&Thomas,S.(2001).Areviewoninterfacemodificationand characterizationofnaturalfiberreinforcedplasticcomposites. PolymerEngineering& Science,41(9),1471–1485.

John,M.J.,&Anandjiwala,R.D.(2008).Recentdevelopmentsinchemicalmodificationand characterizationofnaturalfiber-reinforcedcomposites. PolymerComposites,29(2),187–207.

Jose,S.,Thomas,S.,Jibin,K.P.,Sisanth,K.S.,Kadam,V.,&Shakaywar,D.B.(2022).Surface modificationofwoolfabricusingsodiumlignosulfonateandsubsequentimprovementin theinterfacialadhesionofnaturalrubberlatexinthewool/rubbercomposites. Industrial CropsandProducts.doi:doi.org/10.1016/j.indcrop.2021.114489

Jose,S.,Salim,R.,&Ammayappan,L.(2016).Anoverviewonproduction,properties,andvalue additionofpineappleleaffibers(PALF). JournalofNaturalFibers,13(3),362–373. Kalia,S.,Kaith,B.,&Kaur,I.(2009).Pretreatmentsofnaturalfibersandtheirapplicationas reinforcingmaterialinpolymercomposites—Areview. PolymerEngineering&Science, 49(7),1253–1272.

Kim,N.K.,Bhattacharyya,D.,&Lin,R.(2013).Multi-functionalpropertiesofwoolfiber composites, Advancedmaterialsresearch (747,pp.8–11).TransTechPublicationsLtd. https://doi.org/10.4028/www.scientific.net/AMR.747.8.

Kumar,A.,Prince,L.L.,&Jose,S.(2017).SustainablewoolproductioninIndia. Sustainable fibersandtextiles (pp.87–115).OxfordUK:WoodheadPublishing.

Lakshmanan,A.,Jose,S.,&Chakraborty,S.(2016).Luxuryhairfibersforfashionindustry. Sustainablefibersforfashionindustry (pp.1–38).Singapore:Springer.