https://ebookmass.com/product/wire-technology-secondedition-process-engineering-and-metallurgy-roger-n-wright/

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Biofuels engineering process technology 2nd Edition Caye M. Drapcho

https://ebookmass.com/product/biofuels-engineering-processtechnology-2nd-edition-caye-m-drapcho/

ebookmass.com

Biscuit Baking Technology, Second Edition : Processing and Engineering Manual Iain Davidson

https://ebookmass.com/product/biscuit-baking-technology-secondedition-processing-and-engineering-manual-iain-davidson/

ebookmass.com

Chemical Engineering Process Simulation 1st Edition Nishanth G. Chemmangattuvalappil

https://ebookmass.com/product/chemical-engineering-processsimulation-1st-edition-nishanth-g-chemmangattuvalappil/

ebookmass.com

Macroeconomics 13th Edition Roger A. Arnold

https://ebookmass.com/product/macroeconomics-13th-edition-roger-aarnold/

ebookmass.com

WIRE TECHNOLOGY ProcessEngineeringand Metallurgy

SecondEdition

By ROGERN.WRIGHT

AMSTERDAM • BOSTON • HEIDELBERG • LONDON

NEW YORK • OXFORD • PARIS • SAN DIEGO

SAN FRANCISCO • SINGAPORE • SYDNEY • TOKYO

Butterworth-Heinemann is an imprint of Elsevier

10.ShapedDiesandRollerDies115

10.1 DrawingShapeswithOne-PieceDies115

10.2 DrawingwithUnpoweredRollerDieSystems120

10.3 “Drawing” withPoweredRollerDieSystems123

10.4 RollGapIssues125

10.5 QuestionsandProblems126

11.MechanicalPropertiesofWireandRelatedTesting129

11.1 TheFlowStressoftheWire130

11.2 TheTensileTest132

11.3 TheCrystalPlasticityBasisfortheFlowCurve140

11.4 OtherMechanicalTests146

11.5 HardnessTests146

11.6 CompressionTests148

11.7 BendingTests150

11.8 TorsionTests152

11.9 CreepTesting153

11.10 FatigueTesting154

11.11 SpringbackTesting155

11.12 EvaluatingResidualStress156

11.13 QuestionsandProblems157

12.DrawabilityandBreaks159

12.1 PracticalDefinitions159

12.2 MeasuringandEstimatingDrawability160

12.3 CategorizingDrawingBreaks166

12.4 MechanicsofDrawingBreaks168

12.5 TheGenerationof “Fines” 173

12.6 QuestionsandProblems175

13.RelevantAspectsofCopperandCopperAlloyMetallurgy177

13.1 ImportantPropertiesofCopper178

13.2 PrimaryProcessing178

13.3 CrystalStructure,Grains,Texture,Anisotropy,andSpringback181

13.4 FlowStress,ColdWorking,andAnnealing184

13.5 SolidSolutionsandPhases188

13.6 FactorsAffectingConductivity/Resistivity190

13.7 DiluteCopperAlloys192

13.8 High-AlloySystems194

PREFACE

Beinginafamilywithseveralgenerationsofprofessionalpractitionersin metalsprocessingandtheteachingthereof,Isupposemywritingofthis bookwasinevitable.Evenso,Imustclearlyacknowledgetwostronginfluencesoutsideofthefamilysphere.ThefirstwasthelateWalterA.(Al)Backofen,professorofmetallurgyandmaterialsscienceatMITahalfcenturyor soago.WhileIreceivedthebenefitofsomeofhislectures,hismajorimpact wasbythewayofhisbook DeformationProcessing,Addison-Wesley,1972. ThisbookwasthefirstthatIamawareoftoteachdeformationprocessing withmajoremphasison Δ,theshapeofthedeformationzone.Tobesure, Δ oritsequivalentwasutilizedinsomeofthemoreenlightenedmid-twentieth centurywiredrawingresearch(mostnotablythatofJ.G.Wistreich)andcitationsoftheimportanceofdeformationzonegeometrycanbefoundinthe literatureofthe1920s.However,Backofenpowerfullyemployeditasa teachingtool,bringingtogetheraconsiderablearrayofmechanicalanalyses, processdesigns,andmechanicalmetallurgicalphenomenology.Asayoung metallurgist,Iassumedthatjustabouteverybodyused Δ,onlytofindout thatitswork-a-dayindustrialapplicationshadbeenminimal.Inthiscontext, Iappliedit(arguablyevenoverappliedit)everychancethatIhad,andinthe wireindustryIbelieveithasbeenofsignificantvalue.Inanycase,itiscentral tomuchofthisbook,andIhaveProfessorBackofentothank.

TheotherinfluencethatIwouldliketocitewasDr.AlanT.Male,my managerduringtheyearsthatIspentatWestinghouseResearchLaboratories.Alanwas,ofcourse,renownforhisdevelopmentoftheringcompressiontestthatquantifiesfrictioninforging(abrilliantapplicationof deformationzonegeometry,incidentally).Moreover,hehadbeenafaculty memberatTheUniversityofBirminghamandhadaninstinctiveandsynergisticapproachtoapplyingrigorousresearchtechniqueandperspectiveto industrialprocessingsystems.He,earlyon,directedmyinvolvementina widevarietyofsophisticatedwireprocessingstudies,aswellasinthesupervisionofindustrialsocietyseminarsandshortcourses.WhenIleftWestinghousetojointhefacultyatRensselaerPolytechnicInstitutein1974,Ihad beengivenathorougheducationinwireprocessing,togowithmybroader backgroundsinmetallurgyandmetalsprocessing.

Addressingthesubjectathand,Ihavewrittenthisbookinthestyleofan upper-levelundergraduate,orpossiblygraduate-leveltext,acknowledging

thatoneisnotlikelytofindsuchacourseonwireprocessing,exceptperhaps inEasternEurope.Thisapproachhasallowedmetousedirectlymuchofmy experienceintechnology-focusedshortcourses,aswellasmyexperiencein teachingundergraduatesandgraduatestudentsatRensselaer.Ihavewritten itwiththehopethatitwillbeusefulforself-studyandcontinuingeducation offerings,aswellasservingasadeskreference.Atthispointintime,Ibelieve thatitoccupiesauniquepositionintheengineeringliterature.

Thissecondeditiondiffersfromitspredecessorprimarilyinitssummary andcitationofrelevantresearchofthe2009-2015timeframe.

Finally,IwouldliketothankthemosthelpfulstaffatElsevierInc.,particularlyJeffreyFreeland,fortheirpatienthandlingofthissecondeditionof mybook.

ABOUTTHEAUTHOR

RogerN.Wright,professoremeritus,School ofEngineering,RensselaerPolytechnic Institute,hascontributedbroadlytotheliteratureintheareasofmetallurgyandmetals processingandisactiveasashort-course lecturerandconsultant.Priortojoining Rensselaer,hewasaseniorstaffmemberat WestinghouseResearchLaboratoriesandat AlleghenyLudlumSteelCorporation.He holdsB.S.andSc.D.degreesinmetallurgy fromMassachusettsInstituteofTechnology. Heisaregisteredprofessionalengineeranda fellowofASMInternationalandoftheSocietyofManufacturingEngineers.

stretching,allfurtherelongationwillbeconcentratedatasinglelocation (aneck),whichwillrapidlythinandbreak.Thisoccursbecausethedecrease incross-sectionalareaeventuallyweakensthewiremorethananystrengtheningthatoccursbyworkhardening.Heavilydrawnwirewillhavelittleor nowork-hardeningcapabilityandwillneckalmostatonceifsubjectedto simplestretching.Althoughsomecomplex“dieless”drawingsystemshave beeninvented,simplestretchinghasonlylimitedapplicationbecauseofits vulnerabilitytonecking.

1.2.2ASimpleExplanationoftheDrawingProcess

Inthedrawingprocess,a pullingforce anda pressureforce,fromthedie, combine tocausethewiretoextendandreduceincross-sectionalarea, whilepassingthroughthedie,asschematicallyillustratedin Figure1.1. Becauseofthiscombinedeffect,thepullingforceor drawingforce can belessthantheforcethatwouldcausethewiretostretch,neck,andbreak downstreamfromthedie.Ontheotherhand,ifareductiontoolargein cross-sectionalareaisattemptedatthedie,thedrawingforcemaybreak thewire.Incommercialpractice,engineeredpullingloadsarerarelyabove 60%oftheas-drawnstrength,andtheareareductioninasingledrawingpass israrelyabove30%or35%andisoftenmuchlower.Aparticularlycommon reductioninnonferrousdrawingisthe AmericanWireGage(AWG) numberorabout20.7%.Manydrawingpassesareneededtoachievelarge overallreductions.

Figure1.1 Schematicillustrationofforcesindrawing.

1.3QUESTIONSANDPROBLEMS

1.3.1. Oneoftheprocessesschematicallyillustratedin Figure1.2 isparticularlywellsuitedtoverylongworkpiecelengths,asisdrawing.Whichprocessisthis?Whyaretheothertwoillustratedprocessesnotaswellsuited?

Answer:Rollingisparticularlywellsuitedtoverylongworkpiece lengths,suchascoils,becauseitisacontinuousprocess.Forginginvolves alimitedworkpiece,whichisconstantlychangingshape.Extrusionusually involvesalimitedworkpiece,aswell,althoughsome“continuous”extrusiontechnologieshavebeendevelopedinvolvingbillet-to-billetjuxtapositionsorfrictionalbilletpressurizationwithbeltorchainsystems.

1.3.2. Listsomewaysbywhichwire,rod,andbarcanbepointed.Donotbe afraidtouseyourimagination.

Answer:Thesewaysincluderotaryswaging(see Section18.6.3), rolling,machining,stretching,andchemicalattack.

1.3.3. Whyiscross-sectionaldimensionalcontrolmuchbetterindrawing thaninrolling?

Answer:Thedieisonepieceindrawing,withweartheonlycommon sourceofcross-sectionaldimensionchange.Rollingforcescausechangesin therollgap,andbarrollinginvolvescomplexshapechanges.

1.3.4. Wirebreakageduringdrawingcansignificantlyimpacttheprofitabilityofaproductionfacility.Citeatleasttwocostlyaspectsofawirebreak.

Answer:Productiontimeislostrestringingthemachine;wirelengths tooshortforcontinueddrawingmayhavetobescrapped;andwirebreakage mayindicatethatlargenumbersofflawsaregenerated,implyingpossible rejectionofthedrawn-wireproduct,andmandatingincreasedquality controlandprocesstroubleshooting.

CHAPTER2

ABriefHistoryofTechnology

2.1ANCIENTANDEARLYTECHNOLOGY

Rodandwiretechnologiesareofancientorigin,althoughsomedistinctionmust bemadebetweenwiremakingandwiredrawing.Goldwirewasincorporated intotheadornmentsofthepharaohsbyEgyptiansasearlyas3000BC,andtechniquedevelopmentprobablypredatesthisera.Itislikelythattheancientscut stripsfromhammeredfoilandthendrewfoldedstripsthroughstonediesas theinitialstepinwiremaking.Cross-sectionalconsistenciesindicatethatdrawingdieswereavailabletosuchcraftsmen.Itisthoughtthatholeswereboredin naturalstonewiththeaidofpointedsticksandsand/tallowabrasivemedia.

Thereareinterestingreferencestowireinveryearlyliterature,particularly inHomer’s Odyssey (TheSongsoftheHarper)andinthe OldTestament (Exodus 28:14and39:3).ByfifthcenturyBC,thePersiansweredrawing0.55-mm bronzewirewithirondrawplates,implyingthattheymusthaveunderstood theconceptsofmultiplepassesandinterpassannealing.Interestingreferences todrawingtechnologyweremadebytheRomantribuneClaudiusClaudianus towardtheendoftheRomanEmpirecirca400AD.

MovingaheadtotheMiddleAges,themonkTheophilusPresbyterwrote aboutdrawingtechnologyaround1125,anditisclearthatcommercialpracticeswereemerging.AdocumentwritteninParisaround1270notesthat:

1. Thewiredrawermustthoroughlyunderstandhistradeandhavesufficientcapitalathiscommand.

2. Thewiredrawermayhaveasmanyapprenticesandservantsashewishes andmayworknightsasmuchashepleases.

WireTechnology Copyright © 2016ElsevierInc. http://dx.doi.org/10.1016/B978-0-12-802650-2.00002-9 Allrightsreserved.

Thedevelopmentoflubricantshasbeenavital,ifsubtle,aspectofthe historyofdrawing.Theearliestdrawingisthoughttohavedependedon animalfatortallow.Thiswasaugmentedbyparticulatematterintheform oflime,carbonblack,tars,powderedcoal,andgraphite.Reactivelubricant additionsthatmaintainedlubricantintegrityatelevatedtemperatureswere laterintroduced.Softmetalcoatingswereimplementedinsomecases. AparticularlyintriguingdevelopmentwasJohanGerdes’discoveryofthe “sullcoat”(actuallythinironoxide)around1632.Heallegedlyutilized thesuperiorlubricationresponseofwireexposedtohumanurine.Aspects ofGerdes’discoverywereemployedforthenexttwocenturies.

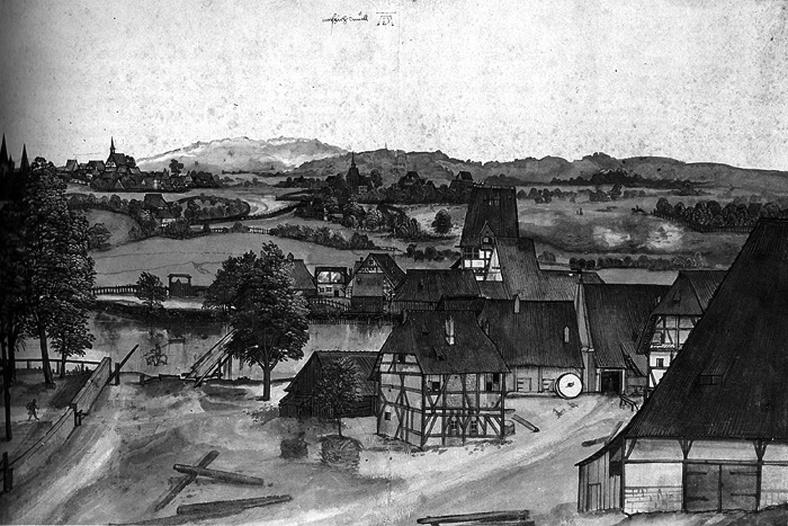

TheGermanartistAlbrechtDurerpainted TheWireDrawingMill in1489 withanapparentwaterpowersource,asshownin Figure2.2.Bythe fifteenthcenturynoneotherthanLeonardodaVinciwassketching drawingblocksandnotingthat“Withoutexperienceyoucannevertell therealstrengthwithwhichthedrawnironresiststhedrawingplate.”

2.2THENINETEENTHCENTURY

The“industrialrevolution”startedattheendoftheeighteenthcentury,and thenineteenthcenturyinvolvedrapidimprovementsinwiretechnology, particularlyinregardtoproductivity.BeginninginPortsmouth,England,