https://ebookmass.com/product/waste-biorefinery-integrating-

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Waste Valorisation: Waste Streams in a Circular Economy

Carol Sze Ki Lin

https://ebookmass.com/product/waste-valorisation-waste-streams-in-acircular-economy-carol-sze-ki-lin/

ebookmass.com

Advanced Materials from Recycled Waste Sarika Verma

https://ebookmass.com/product/advanced-materials-from-recycled-wastesarika-verma/

ebookmass.com

Zero Waste Cooking For Dummies 1st Edition Rosanne Rust

https://ebookmass.com/product/zero-waste-cooking-for-dummies-1stedition-rosanne-rust/

ebookmass.com

Unheard Voices: Women, Work and Political Economy of Global Production 1st ed. Edition Farah Naz

https://ebookmass.com/product/unheard-voices-women-work-and-politicaleconomy-of-global-production-1st-ed-edition-farah-naz/

ebookmass.com

Anti-Proverbs in Five Languages: Structural Features and Verbal Humor Devices Anna T. Litovkina

https://ebookmass.com/product/anti-proverbs-in-five-languagesstructural-features-and-verbal-humor-devices-anna-t-litovkina/

ebookmass.com

The Honorable Warrior: Navy SEAL Romance Krey

https://ebookmass.com/product/the-honorable-warrior-navy-seal-romancekrey/

ebookmass.com

Halloween is Coming! Cal Everett

https://ebookmass.com/product/halloween-is-coming-cal-everett/

ebookmass.com

Pharis' Pickle in Seagull Bay: A heartwarming & uplifting new coastal town series Hill

https://ebookmass.com/product/pharis-pickle-in-seagull-bay-aheartwarming-uplifting-new-coastal-town-series-hill/

ebookmass.com

Islands and the British Empire in the Age of Sail Douglas Hamilton (Editor)

https://ebookmass.com/product/islands-and-the-british-empire-in-theage-of-sail-douglas-hamilton-editor/

ebookmass.com

https://ebookmass.com/product/shrm-cp-shrm-scp-certification-all-inone-exam-guide-2nd-edition-beverly-dance/

ebookmass.com

Editedby ThalladaBhaskar BiomassConversionArea, MaterialResourceEfficiencyDivision,

CSIR-IndianInstituteofPetroleum,Dehradun,India

AshokPandey CentreforInnovationandTranslationalResearch,

CSIR-IndianInstituteofToxicologyResearch,Lucknow,India

EldonR.Rene

IHEDelftInstituteforWaterEducation,Delft,TheNetherlands

DanielC.W.Tsang DepartmentofCivilandEnvironmentalEngineering, TheHongKongPolytechnicUniversity,HongKong

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright © 2020ElsevierB.V.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicor mechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem,without permissioninwritingfromthepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthe Publisher’spermissionspoliciesandourarrangementswithorganizationssuchastheCopyrightClearance CenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher (otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthis fieldareconstantlychanging.Asnewresearchandexperiencebroaden ourunderstanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecome necessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusing anyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationor methodstheyshouldbemindfuloftheirownsafetyandthesafetyofothers,includingpartiesforwhomthey haveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeany liabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceor otherwise,orfromanyuseoroperationofanymethods,products,instructions,orideascontainedinthe materialherein.

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

ISBN:978-0-12-818228-4

ForinformationonallElsevierpublicationsvisitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: SusanDennis

AcquisitionsEditor: KostasKIMarinakis

EditorialProjectManager: EmeraldLi

ProductionProjectManager: SelvarajRaviraj

CoverDesigner: MilesHitchen

TypesetbyTNQTechnologies

Contributors

RabiaAbad SchoolofAppliedSciences,TheUniversityofHuddersfield,Huddersfield,United Kingdom

AbdelrahimAbusafa ChemicalEngineeringDepartment,An-NajahNationalUniversity,Nablus, Palestine

MortazaAghbashlo DepartmentofMechanicalEngineeringofAgriculturalMachinery,Faculty ofAgriculturalEngineeringandTechnology,CollegeofAgricultureandNaturalResources, UniversityofTehran,Karaj,Alborz,Iran

AsamAhmed DivisionofSystems,Power&Energy,JamesWattSchoolofEngineering, UniversityofGlasgow,Glasgow,UnitedKingdom

MaherAl-Jabari RenewableEnergyandEnvironmentResearchUnit,MechanicalEngineering Department,PalestinePolytechnicUniversity,Hebron,Palestine

MariaAlexandri LeibnizInstituteforAgriculturalEngineeringandBioeconomyPotsdam, Potsdam,Germany

A.K.M.KaziAurnob DepartmentofChemicalEngineering,BangladeshUniversityofEngineeringandTechnology,Dhaka,Bangladesh

AyanBanerjee MaterialResourceEfficiencyDivision,CSIR-IndianInstituteofPetroleum, Dehradun,Uttarakhand,India;AcademyofScientificandInnovativeResearch(AcSIR),New Delhi,India

ShishirKumarBehera IndustrialEcologyResearchGroup,SchoolofChemicalEngineering, VelloreInstituteofTechnology,Vellore,TamilNadu,India

LaurentBelard NaturePlast,Ifs,France

StellaBezergianni ChemicalProcess&EnergyResourcesInstitute-CPERI,CentreforResearch &TechnologyHellasCERTH,Thessaloniki,Greece

ThalladaBhaskar MaterialResourceEfficiencyDivision,CSIR-IndianInstituteofPetroleum, Dehradun,Uttarakhand,India;AcademyofScientificandInnovativeResearch(AcSIR),New Delhi,India

NilutpalBhuyan DepartmentofEnergy,TezpurUniversity,Tezpur,Assam,India

HanifA.Choudhury DepartmentofChemicalEngineering,TexasA&MUniversityatQatar, Doha,Qatar

LoukiaP.Chrysikou ChemicalProcess&EnergyResourcesInstitute-CPERI,Centrefor Research&TechnologyHellasCERTH,Thessaloniki,Greece

CaterinaCollLozano ImecalS.A.,La ´ lcudia,Valencia,Spain

SutapaDas DepartmentofChemicalEngineering,IndianInstituteofTechnologyGuwahati, Guwahati,Assam,India

AntonioDavid-Moreno CIEMAT,Madrid,Spain

FrancescaDemichelis DIATI,PolitecnicodiTorino,Torino,Italy

ChenyuDu SchoolofAppliedSciences,TheUniversityofHuddersfield,Huddersfield,United Kingdom

CapucineDupont DepartmentofEnvironmentalEngineeringandWaterTechnology,IHEDelft InstituteforWaterEducation,Delft,TheNetherlands

AmerElhamouz ChemicalEngineeringDepartment,An-NajahNationalUniversity,Nablus, Palestine

SilviaFiore DIATI,PolitecnicodiTorino,Torino,Italy

Marı´aGarcı´aTorreiro AINIA-Centrotecnolo ´ gico,Paterna,Valencia,Spain

DebashishGhosh MaterialResourceEfficiencyDivision,CSIR-IndianInstituteofPetroleum, Dehradun,Uttarakhand,India;AcademyofScientificandInnovativeResearch(AcSIR),New Delhi,India

InmaculadaGonza ´ lezGranados BiomasaPeninsularS.A.,Madrid,Spain

VaibhavV.Goud DepartmentofChemicalEngineering,IndianInstituteofTechnologyGuwahati, Guwahati,Assam,India

JasneetGrewal EnzymeandMicrobialBiochemistryLaboratory,DepartmentofChemistry, IndianInstituteofTechnologyDelhi,HauzKhas,NewDelhi,India

NataliaHerreroGarcı ´ a BiomasaPeninsularS.A.,Madrid,Spain

HomaHosseinzadeh-Bandbafha DepartmentofMechanicalEngineeringofAgriculturalMachinery,FacultyofAgriculturalEngineeringandTechnology,CollegeofAgricultureandNaturalResources,UniversityofTehran,Karaj,Alborz,Iran

Shu-ChienHsu DepartmentofCivilandEnvironmentalEngineering,TheHongKongPolytechnicUniversity,Kowloon,HongKong,China

KaziBayzidKabir DepartmentofChemicalEngineering,BangladeshUniversityofEngineering andTechnology,Dhaka,Bangladesh

RupamKataki DepartmentofEnergy,TezpurUniversity,Tezpur,Assam,India

RavneetKaur Dr.B.R.AmbedkarNationalInstituteofTechnology,Jalandhar,Punjab, India;MaterialResourceEfficiencyDivision,CSIR-IndianInstituteofPetroleum,Dehradun,Uttarakhand,India

S.K.Khare EnzymeandMicrobialBiochemistryLaboratory,DepartmentofChemistry,Indian InstituteofTechnologyDelhi,HauzKhas,NewDelhi,India

KawnishKirtania DepartmentofChemicalEngineering,BangladeshUniversityofEngineering andTechnology,Dhaka,Bangladesh

Chor-ManLam DepartmentofCivilandEnvironmentalEngineering,TheHongKong PolytechnicUniversity,Kowloon,HongKong,China

MarcosLatorre-Sa ´ nchez ImecalS.A.,L’alcudia,Valencia,Spain

RaquelLebrero InstituteofSustainableProcesses,UniversityofValladolid,Valladolid, Spain;DepartmentofChemicalandEnvironmentalEngineering,UniversityofValladolid, Valladolid,Spain

YizeLi DivisionofSystems,Power&Energy,JamesWattSchoolofEngineering,Universityof Glasgow,Glasgow,UnitedKingdom

DiannanLu DepartmentofChemicalEngineering,TsinghuaUniversity,Beijing,China

MetteLu ¨ beck DepartmentofChemistryandBioscience-SectionforSustainableBiotechnology, Denmark

TiffanyM.W.Mak DepartmentofCivilandEnvironmentalEngineering,TheHongKong PolytechnicUniversity,Kowloon,HongKong,China

RiteshS.Malani CentreforEnergy,IndianInstituteofTechnology,Guwahati,Guwahati,Assam, India

N.ArulManikandan DepartmentofChemicalEngineering,IndianInstituteofTechnology Guwahati,Guwahati,Assam,India

VijayanandS.Moholkar CentreforEnergy,IndianInstituteofTechnology,Guwahati,Guwahati, Assam,India;DepartmentofChemicalEngineering,IndianInstituteofTechnology,Guwahati, Guwahati,Assam,India

HamidrezaMojab DepartmentofWaterResourceManagement,FacultyofCivilEngineeringand Geoscience,TechnicalUniversityofDelft,Delft,TheNetherlands

JoseL.MoltoMarin ExergyLtd.,Coventry,UnitedKingdom

SidraMunir SchoolofAppliedSciences,TheUniversityofHuddersfield,Huddersfield,United Kingdom

RaulMun ˜ oz InstituteofSustainableProcesses,UniversityofValladolid,Valladolid, Spain;DepartmentofChemicalandEnvironmentalEngineering,UniversityofValladolid, Valladolid,Spain

HanaMusinovic NATRUE,Brussels,Belgium

AhaduzzamanNahid DepartmentofChemicalEngineering,BangladeshUniversityofEngineeringandTechnology,Dhaka,Bangladesh

M.M.TejasNamboodiri DepartmentofBiosciencesandBioengineering,IndianInstituteTechnologyGuwahati,Guwahati,Assam,India

Abdul-SattarNizami CenterofExcellenceinEnvironmentalStudies(CEES),KingAbdulaziz University,Jeddah,MakkahProvince,SaudiArabia

JoseMiguelOliva-Dominguez CIEMAT,Madrid,Spain

DavidOvejero-Roncero ExergyLtd.,Coventry,UnitedKingdom

SantiagoPacheco-Ruiz VeoliaWaterTechnologiesTechnoCenterNetherlandsB.V./Biothane, Delft,TheNetherlands

KannanPakshirajan DepartmentofBiosciencesandBioengineering,IndianInstituteofTechnologyGuwahati,Guwahati,Assam,India

Hung-SuckPark DepartmentofCivilandEnvironmentalEngineering,UniversityofUlsan, Ulsan,RepublicofKorea

CeliaPascual InstituteofSustainableProcesses,UniversityofValladolid,Valladolid, Spain;DepartmentofChemicalandEnvironmentalEngineering,UniversityofValladolid, Valladolid,Spain

Andre ´ sPascual AINIA-Centrotecnolo ´ gico,Paterna,Valencia,Spain

Vı´ctorPe ´ rez InstituteofSustainableProcesses,UniversityofValladolid,Valladolid, Spain;DepartmentofChemicalandEnvironmentalEngineering,UniversityofValladolid, Valladolid,Spain

GregPerkins MartinParryTechnology,Brisbane,QLD,Australia;SchoolofChemical Engineering,UniversityofQueensland,Brisbane,QLD,Australia

DanielPleissner SustainableChemistry(ResourceEfficiency),InstituteofSustainableand EnvironmentalChemistry,LeuphanaUniversityofLu ¨ neburg,Lu ¨ neburg,Germany

G.Pugazhenthi DepartmentofChemicalEngineering,IndianInstituteofTechnologyGuwahati, Guwahati,Assam,India

Ame ´ lieRaingue ´ UrbaserS.A.,R&DandInnovationDepartment,Madrid,Spain

EldonRaj DepartmentofEnvironmentalandWaterTechnology,IHEDelftInstituteforWater Education,Delft,TheNetherlands

MohammadRehan CenterofExcellenceinEnvironmentalStudies(CEES),KingAbdulaziz University,Jeddah,MakkahProvince,SaudiArabia

EldonR.Rene DepartmentofEnvironmentalEngineeringandWaterTechnology,IHEDelftInstituteforWaterEducation,Delft,TheNetherlands

AliS.Reshad DepartmentofChemicalEngineering,IndianInstituteofTechnologyGuwahati, Guwahati,Assam,India

AlfredoRodrigo AINIA-Centrotecnolo ´ gico,Paterna,Valencia,Spain

RocioRoldan-Aguayo ExergyLtd.,Coventry,UnitedKingdom

AyeshaSadaf EnzymeandMicrobialBiochemistryLaboratory,DepartmentofChemistry,Indian InstituteofTechnologyDelhi,HauzKhas,NewDelhi,India

MeghaSailwal MaterialResourceEfficiencyDivision,CSIR-IndianInstituteofPetroleum, Dehradun,Uttarakhand,India;AcademyofScientificandInnovativeResearch(AcSIR),New Delhi,India

HassanSawalha RenewableEnergyandEnvironmentResearchUnit,MechanicalEngineering Department,PalestinePolytechnicUniversity,Hebron,Palestine AlbaSerna-Maza UrbaserS.A.,R&DandInnovationDepartment,Madrid,Spain

IzharHussainShah DepartmentofCivilandEnvironmentalEngineering,UniversityofUlsan, Ulsan,RepublicofKorea;InstituteofEnvironmentalSciencesandEngineering,SchoolofCivil andEnvironmentalEngineering,NationalUniversityofSciencesandTechnology,Islamabad, Pakistan

ShailendraKumarShukla CentreforEnergyandResourcesDevelopment,Departmentof MechanicalEngineering,IndianInstituteofTechnology(BHU),Varanasi,UttarPradesh,India

PushpendraKumarSinghRathore CentreforEnergyandResourcesDevelopment,Department ofMechanicalEngineering,IndianInstituteofTechnology(BHU),Varanasi,UttarPradesh,India

MarkSmith NATRUE,Brussels,Belgium

DebashisSut DepartmentofEnergy,TezpurUniversity,Tezpur,Assam,India

MeisamTabatabaei FacultyofPlantationandAgrotechnology,UniversitiTeknologiMARA (UiTM),ShahAlam,Selangor,Malaysia;MicrobialBiotechnologyDepartment,Agricultural BiotechnologyResearchInstituteofIran(ABRII),AgriculturalResearch,Education,andExtension Organization(AREEO),Karaj,Alborz,Iran;BiofuelResearchTeam(BRTeam),Karaj,Alborz, Iran;FacultyofMechanicalEngineering,HoChiMinhCityUniversityofTransport,HoChiMinh City,Vietnam

PankajTiwari DepartmentofChemicalEngineering,IndianInstituteofTechnologyGuwahati, Guwahati,Assam,India

Khanh-QuangTran Departmentofenergyandprocessengineering,NorwegianUniversityof ScienceandTechnology,Trondheim,Norway

DanielC.W.Tsang DepartmentofCivilandEnvironmentalEngineering,TheHongKongPolytechnicUniversity,Kowloon,HongKong,China

JackVandeVossenberg DepartmentofEnvironmentalEngineeringandWaterTechnology,IHE DelftInstituteforWaterEducation,Delft,TheNetherlands

EricD.vanHullebusch DepartmentofEnvironmentalEngineeringandWaterTechnology, IHEDelftInstituteforWaterEducation,Delft,TheNetherlands

CarolW.Wambugu DepartmentofEnvironmentalEngineeringandWaterTechnology,IHEDelft InstituteforWaterEducation,Delft,TheNetherlands

LeiWang DepartmentofCivilandEnvironmentalEngineering,TheHongKongPolytechnic University,Kowloon,HongKong,China;DepartmentofMaterialsScienceandEngineering,The UniversityofSheffield,Sheffield,UnitedKingdom

IanWatson DivisionofSystems,Power&Energy,JamesWattSchoolofEngineering,University ofGlasgow,Glasgow,UnitedKingdom

NeerjaYadav EnzymeandMicrobialBiochemistryLaboratory,DepartmentofChemistry,Indian InstituteofTechnologyDelhi,HauzKhas,NewDelhi,India

SimingYou DivisionofSystems,Power&Energy,JamesWattSchoolofEngineering,University ofGlasgow,Glasgow,UnitedKingdom

IrisK.M.Yu DepartmentofCivilandEnvironmentalEngineering,TheHongKongPolytechnic University,Kowloon,HongKong,China;GreenChemistryCentreofExcellence,Departmentof Chemistry,UniversityofYork,York,UnitedKingdom

Preface

Wherethereisrighteousnessintheheart,thereisbeautyinthecharacter.Whenthereis beautyinthecharacter,thereisharmonyinthehome.Whenthereisharmonyinthe home,thereisorderinthenation.Whenthereisorderinthenation,thereispeacein theworld.

A.P.J.AbdulKalam(1931 2015,AerospaceScientistandthe11thPresidentofIndia)

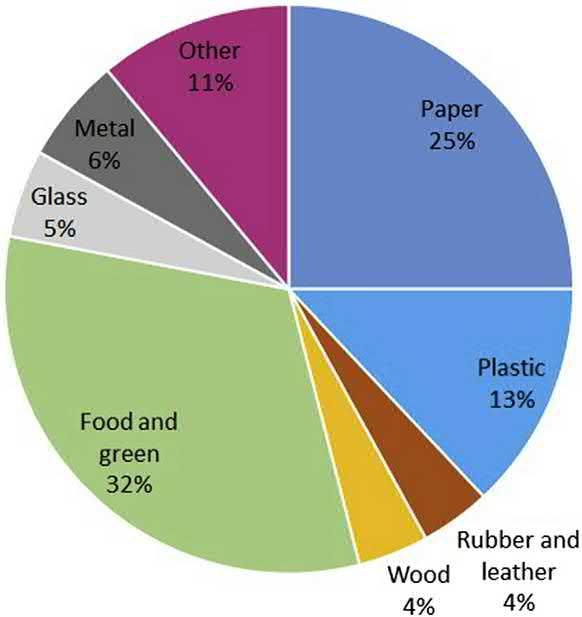

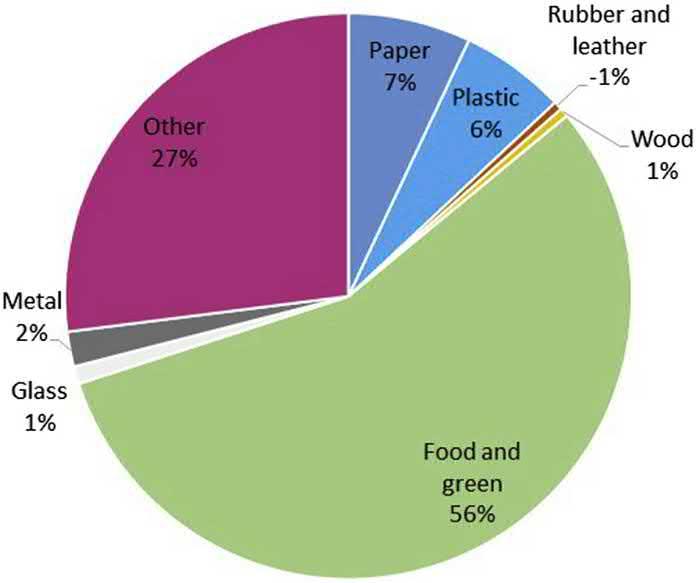

Rapidindustrialization,populationgrowth,unplannedexpansionofurbanzonesandinfrastructures,andinadequatepolicieshaveledtothemismanagementofsolidwasteindevelopednationsaswellaspoorercountriesinthedevelopingworld.Solidandliquidwaste,both thegenerationanddisposal,isatopicofmajorpublichealthandenvironmentalconcern. Moreoften,theseissuesareengenderedduetopoorwastecollectionsystems,lackofgovernmentalormunicipalservices,limitedbudget,weakmanagementpolicies,andlackofanefficientorganizationalinfrastructure,amongothers.Therefore,solidwastepilesupinstreets, backyards,alleys,andillegaldumpsites;peoplescavengethemtoearnaliving.Inmany countries,thesenonsanitarylandfillshavecausedaustereproblems,includingair,water,and soilpollution,andhasinducedthespreadofdisease-causingvectors.However,froma resourcerecoveryviewpoint,solidwastecanbeconsideredatreasurehouseofenormous wealth,whereinelectricitycanbeproducedbycombustion/incinerationofthesolidwaste foundinlandfills.Withtheadventofadvancedequipment,newprocesses,andbetterunderstandingofthemechanismsinvolvedinbiologicalandengineeringsciences,solidwastecan beefficientlytransformedintoenergy,fuels,andvalue-addedproducts.Thesolidwastes includeamixtureofbiological,combustible,andnoncombustiblematerialssuchasbiomass, grassclippings,wood,leaves,foodwaste,paper,cardboard,leatherproducts,plastics, beddingmaterials,resins,metals,glass,etc.

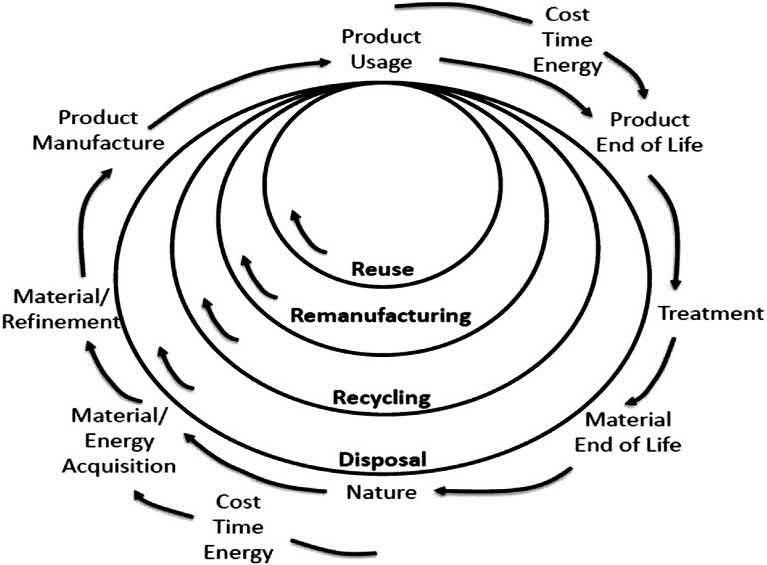

Byapplyingtheconceptsofpollutionprevention,resourcerecovery,andcleanerproduction, abiorefinerycanbedefinedasafacilitythatintegratesdifferentbiomassconversionprocess andequipmenttoproduceawiderangeofbiobasedproductssuchasbiofuels,power,heat, andplatformchemicals.Abiorefinerycanalsobeusedtorepresentastand-aloneprocess,a plantoragroupofsynergisticallylinkedfacilities,e.g.,ecoindustrialparks.Themainaimof

allthesefacilitiesaretointegrateandapplythebestengineering,biological,andmanagementpracticestominimizetheimpactonsolid,liquid,andgaseouswastesonhumanhealth andtheenvironment,convertwasteintoseveralvalue-addedproductstreams,andsustainably managetheexistingresources.Thus,theconceptofabiorefineryhasbeenconstantly evolving,andasystematictransformationofthefacilitieshasbeenenvisionedinrecent years.Forexample,theconventionalbiorefinery(first-gen)usesagriculturalbiomasstoproducebioethanolorbiodiesel,whereasthesecondandthirdGenbiorefineriesusesadvanced processesusinglignocellulosicbiomass,cereals,forestrybiomass,algalbiomass,waste gases,industrialsludges,oilresidues,foodwaste,andhigh-strengthwastewaterstreamsto producechemicalsandenergy.Dependingonthesourceandcharacteristicsoftherawmaterials,theprocessescanbeeitherchemical,biological,thermochemical,andmechanical,ora combinationoftheseprocesses.

Therefore,ascitizens,wehavetochangeourperspectivetoseehowwastecanbeusedasa secondaryresourcefortheproductionofenergyandothermaterials.Inordertomeetthe growingdemandoffuels,biofuelsareemergingasanalternativecleanfueltoreplacethe conventionalfossilfuels.AccordingtotheEuropeanUnion(EU)EnergyCommission,by theyear2020,theEUaimstohave10%ofthetransportfuelofeveryEUcountrycomefrom renewablesourcessuchasbiofuels.ThefuelsuppliersarealsorequiredtoreducethegreenhousegasintensityoftheEUfuelmixby6%by2020incomparisonto2010.Anew,dueto therisingenergydemandinthemarket,novelresearchareashavestartedtofocuson resourcerecovery,andagalaxyofnewtechnologieshavebeensuccessfullytested,bothat thelabandpilot-scale.Althoughallbiorefinery-basedprocessesareexpectedtoproduce feweremissionsandsupportsustainablelocalbioeconomy,theoverallenvironmentalimplicationsandlife-cycleimpactanalysisarestillbeingstudied.Inthislineofprogressive research,thereisstillalottobedone,andinterestingly,standardizationofprotocolsand methodsshouldbedocumentedclearly.Althoughregulationsarewell-establishedandimplementedforbiomethaneandnaturalgas,thefuels,lubricants,andhydraulicfluidsproduced frommineraloilorbiomassoriginstilldoesnothavestandardizedmethodsofsampling, analysis,andtesting,terminology,andspecificationsforapplicationinthetransportation,industrial,anddomesticsectors.

Toaddresssomeofthepracticalissuesdiscussedaboveandtoprovideageneralperspective ofthedifferenttypesofbiorefineries,thefirstvolumeofthebookentitled“Wastebiorefinery: Potentialandperspectives”waspublishedintheyear2018.Thebookexploredsomeofthe recentdevelopmentsinbiochemicalandthermochemicalmethodsofwaste-to-energyconversionandthepotentialgeneratedbydifferentkindsofbiomassinmoredecentralized biorefineries.Toaddressthemostrecentadvancementsmadeinthefieldofbiorefineries,the secondvolumeofthisbookseriesentitled Wastebiorefinery:Integratingbiorefineryforwaste valorization hasbeencompiled.Thisvolumepresentsrecentupdatesonthedifferenttypesof biorefineries(e.g.,solidwaste,ligninresidue,agroindustrialwaste,lignocellulosicwastes, foodwaste,andnonedibleoils),theapplicationofmultiscalemodelingstrategies,systems

approach,life-cycleanalysis(LCA),andcarbonfootprintestimationtools,anditpresents differentcasestudiesrelatedtotheintegrationofbiorefineriesforwaste-to-energyandfuels production.Thevolumecomprisesoftwenty-fivechapters,dividedamongthefollowingeight thematicsections:

SessionA:Municipalsolidwaste basedbiorefineries

SectionB:Lignocellulosicbiomass-basedbiorefinery

SectionC:Foodwasteandchitin-basedbiorefinery

SectionD:Nonedibleoils basedbiorefineryandapplications

SectionE:Sewagesludgebiorefinery

SectionF:Modelingandlife-cycleanalysisstudies

SectionG:Systemdynamicsandcarbonfootprints

SectionH:Country-specificcasestudies

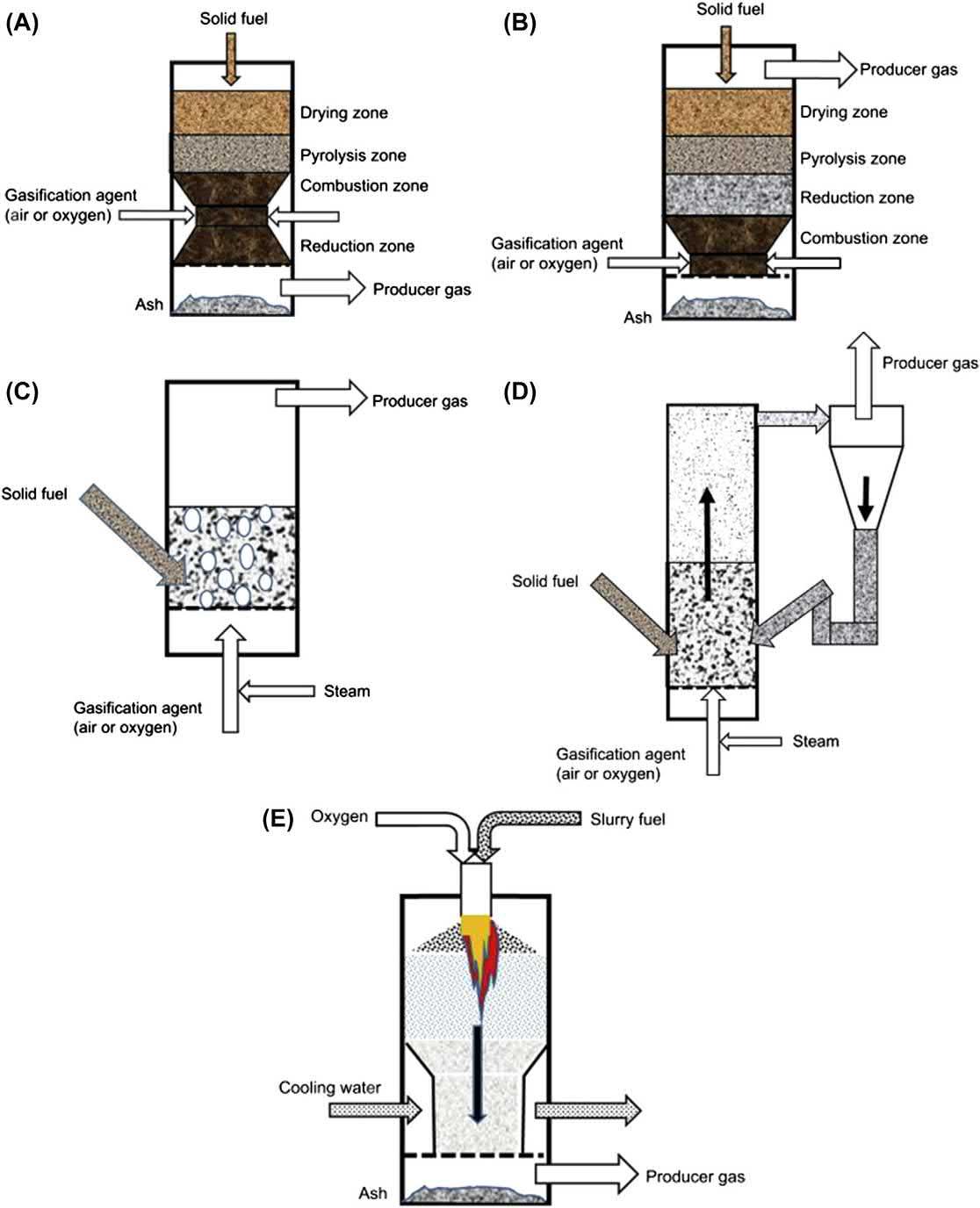

InSectionA,thechallengesandopportunitiesofapplyinggasificationtomunicipalsolid waste,itsperformancefortheproductionofelectricityandchemicals,economicconsiderations,andopportunitiesforthefuturedevelopmentispresentedinChapter1.The URBIOFINdemo-scaleprojectpresentedinChapter2exploresthepotentialoftheorganic fractionofmunicipalsolidwaste(OFMSW)toproducebioblocks(bioethanol,volatilefatty acids(VFA),andbiogas),biopolymers(shortchain[scl-PHA]),mediumchainpolyhydroxyalkanoates(mcl-PHA),andadditives(bioethyleneandbiofertilizers)usingabattery ofinnovativeandintegratedphysical,chemical,andbiologicalprocesses.

InSectionB,Chapter3highlightstheworkingprincipleandconceptofanozzlereactorwith countercurrentmixingfortheupscalingoffasthydrothermalliquefaction(HTL)ofsolid biomassresiduesandwastes.Chapter4presentstheadvantages,limitations,andpracticalapplicationsofanup-flowanaerobicsludgeblanket(UASB)andexpandedgranularsludgebed (EGSB)forenhancedresourcerecovery(mainlybiomethane)duringwastewatertreatment. TwocasestudiesrelatedtotheapplicationofUASBandEGSBsystemsinoliveoilandthe pulpandpaperindustrieshavealsobeendiscussedinthischapter.Thevalorizationof agroindustrialwastesintoplatformchemicals(e.g.lacticacid,C3)anditsderivativesforapplicationsinpharmaceutical,food,animalfeed,dairy,detergent,andcosmeticindustriesis coveredinChapter5.Asimilarapproachhasbeendemonstratedtoconvertlignocellulosic biomassforpolyhydroxybutyrate(PHB)productioninChapter6.Laboratory-scaleandpilotscalestudiespertainingtothebioconversionoffoodwaste,municipalsolidwaste,food processingwaste,andagricultureresiduestobiofertilizers,includingthepracticalfieldapplications,hasbeenreviewedinChapter7.InChapter8,theimportantroleoftraceelements (e.g.,Fe,Ni,Co)inthemethanogenesisstepofanaerobicdigestionhasbeendiscussedfrom amechanismandmetabolicengineeringviewpoint.Theapplicationofbiocharforenhanced biogasproductionfromtheanaerobicdigestionoffoodwastehasbeenpresentedinthis chapterasacasestudy.

Chapter9ofSectionCintroducesthetheoryofplannedbehavior(TPB)thatprovidesatheoreticalframeworktoassistinourunderstandingofthefactorsinfluencingbehavioralchoices. Inthischapter,thecurrentimplementationofTPBtopredictfoodconsumptionpatternandto promotesafefoodhandlingandfood-wasterecyclinginhouseholdandcommercialsectors arediscussed.InChapter10,anoverviewofchitin,chitosan,itspropertiesandapplications, metabolicpathwayofchitinandchitosan,sourcesofchitinsuchascrustaceans,insects,and fungi,extractionmethodsandbioreactorconfigurationsforchitosanproductionhasbeen reviewed.

InSectionD,thesignificantapplicationsofcastorplant(Ricinuscommunis)fortheproductionofbiofuels(bioethanol,biomethanol)andbiochemicals(biophenolics)aswellastheproductionofderivativessuchassebacicacidandricinoleicacidfromcastoroilhasbeen demonstratedinChapter11.InChapter12,thefeasibilityofbiofuelproductionfromnonediblerubberseedoilhasbeenexplainedindetail.Theusefulpropertiesoftherubberseed oilmakeitsimilartowell-knownlinseedandsoybeanoil.Asthedemandforbiodieselis increasing,thebiorefineryapproachinthefieldfromrubberseedwouldbeofaddedadvantage.Inanotherapproach,thedifferentwastecarbonsourcesandrelatedcasestudiesforbiodieselproductionhasbeenpresentedinChapter13.Meanwhile,inChapter14,the productionandtheapplicationofbiodieselobtainedfromvariousplantspeciestoruntheengineandtheeffectofdifferentbiodieselblendsontheperformanceoftheenginehasbeen discussed.Additionally,thechapteralsocoversaspectsrelatedtothelifecycleandcostbenefitanalysisofbiodiesel.

InSectionE,Chapter15exploresthepossibleapplicationofsewagesludgeformaterialand energyrecoverythroughintegratedthermochemicalandbiochemicalconversionprocessesin asewagesludgebiorefinery.SectionFcoverschaptersrelatedtomodelingandLCA.Inthis section,Chapter16highlightstheapplicationofmultiscalemodelsthatrangefrom molecular-levelunderstandingofthebiorefinerytoasystem-scaleoptimizationofprocesses andproductdistribution.Anoverviewofthedifferentmodelingapproachesthatshapedthe currentstateofbiorefineries,theprocedureinvolvedinselectinganappropriatemodelthatis specifictotheapplication,andagenericguidelinehasbeenpresentedinthischapter.In Chapters17,18,and19,theapplicationofLCAasapracticalandmethodologicaltoolfor theenvironmentalcharacterizationofabiorefineryhasbeenpresented.Accordingly,biorefineriespresentafavorableenvironmentalprofileincomparisonwithfossil-basedreference systems,eventhoughtheresultsshowgreatvariabilityattributedmainlytothebiorefineries configurationandcomplexity.Specifically,Chapter18alsohighlightstheapplicationof LCA,conventionalmacroscalemanagementstrategies,andlaboratory-scalevalorizationtechniquesforafood-wastebiorefinery.InChapter19,asummaryofstudiesfocusingonthe LCAofwastebiorefineriesispresented.

InSectionG,Chapter20providesinformationontheapplicationofasystemsdynamics approachtounderstandtherelationshipbetweenthebehaviorofasystemovertimeandits underlyingstructure.Thechapteralsoaddressesthevariousenvironmentalissuesandpresentsacomprehensiveliteraturereviewonwoodandyardwastemanagementandtheimplementationofasystemsdynamicsapproachinthestreamofmunicipalsolidwasteand constructionanddemolitionwaste.InChapter21,theapplicationofLCAinevaluatingthe carbonfootprintsofwaste-to-biofuelsystemshasbeenexplainedindetail.Thegreenhouse gasemissionsassociatedwiththeprocessesarealsopresentedinthischapterwiththeidentificationofthecarbonemissionhotspots.

SectionHdealswithdifferentcasestudiesrelatedtobiorefineries.Chapter22presentscase studiesfromGermanythatarerelatedtothesimultaneousproductionoffoodandfeed,materials,andenergyinaccordancetoacascadinguseofbiogenicfeedstocksasrecommendedby theGermanBioeconomySociety.Apulp-andpaper-industrycasestudyfromIndiahasbeen discussedinChapter23,andthefeasibilityofintegratingbiochemicalandthermochemical processesinapaperandpulpwastebiorefinerytoproducevalue-addedchemicals,fuel,and energyhasbeendemonstrated.InChapter24,severalsuccessfulcasestudiessuchaslandfill gasrecoveryfromtheretrofittedlandfills,conversionoffoodwasteandsewagesludgeto biogas,andindustrialsymbiosisbetweenapapermillandzincsmelterhavebeendemonstratedaspathwaystowardintegratedbiorefineries.Finally,inChapter25,thecasestudyofa tanneryispresented,andthemostrecenttechnologiestotreatthewastewaterdischarged fromtanneriesisdiscussed.Optionsforresourcerecovery(e.g.,bycompostingofsolid wastes)andsubstitutionofchromiumandsodiumsulfidearealsopresentedascleanerproductionoptionsfortanneries.

Theindividualchaptersofthisbookfocusontheapplicationofdifferentbiorefineryconcepts inpractice(i.e.,atthelab,pilot,semiindustrial,andindustrialscales),provideoptionsfor enhancedresourcerecoveryfromwastes(solid,liquid,andgaseousforms),andanalyzethe supportingtoolsandtechniquesformonitoringtheperformanceofbiorefineries.Thisbook willserveasausefulresourceforchemicalengineers,environmentalengineers,biotechnologists,researchers,andstudentsstudyingbiomass,biorefineries,andbiofuels/products/processes,aswellaschemists,biochemicalengineers,andmicrobiologistsworkingin industriesandgovernmentagencies.Westronglyhopethatreadersenjoyreadingthisbook andfinditofimmenseuse.

Wewishtothankandexpressourappreciationtothemultidisciplinaryteamofauthorsfor discussionandcommunication aboveall,fortheirscientificcontributiontothisbook.We alsothankreviewerswhosesuggestionsgreatlyhelpedtoimprovethequalityofchapters. OursincerethanksareduetoElsevierteamcomprisingofDr.KostasMarinakis,Senior AcquisitionEditor;EmeraldLi,EditorialProjectManager;Mr.SelvarajRaviraj,Project Manager;andtheirproductionandtypesettingteamsforsupportingusconstantlyduringthe editorialprocess.Wefirmlybelievethattheinformationcontainedinthisbookwillenhance theinterdisciplinaryscientificskillsofreaderswhilealsodeepeningtheirfundamentalknowledgeonwastebiorefinery.

Editors

ThalladaBhaskar

CSIR-IndianInstituteofPetroleum,India

E-mail:thalladab@yahoo.com

AshokPandey

CSIR-IndianInstituteofToxicologyResearch,India

E-mail:ashokpandey1956@gmail.com

EldonR.Rene

IHEDelftInstituteforWaterEducation,Netherlands

E-mail:e.raj@un-ihe.org

DanielTsang

HongKongPolytechnicUniversity,HongKong

E-mail:dan.tsang@polyu.edu.hk