WASTEANDBIODIESEL

FeedstocksandPrecursors forCatalysts

Editedby BHASKARSINGH

DepartmentofEnvironmentalSciences,CentralUniversityof Jharkhand,Ranchi,India

ABHISHEKGULDHE

AmityInstituteofBiotechnology,AmityUniversityMaharashtra, Mumbai,India

Radarweg29,POBox211,1000AEAmsterdam,Netherlands TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2022ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicor mechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem,without permissioninwritingfromthepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthe Publisher’spermissionspoliciesandourarrangementswithorganizationssuchastheCopyrightClearance CenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions.

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher (otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroaden ourunderstanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecome necessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingand usinganyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformation ormethodstheyshouldbemindfuloftheirownsafetyandthesafetyofothers,includingpartiesforwhom theyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeany liabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceor otherwise,orfromanyuseoroperationofanymethods,products,instructions,orideascontainedinthe materialherein.

ISBN:978-0-12-823958-2

ForInformationonallElsevierpublicationsvisitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: CharlotteCockle

AcquisitionsEditor: PeterAdamson

EditorialProjectManager: AleksandraPackowska

ProductionProjectManager: SojanP.Pazhayattil

CoverDesigner: VictoriaPearsonEsser

TypesetbyAptara,NewDelhi,India

Foreword

Therecentlyheldclimateconference(COP26)atGlasgow,andthepledgestaken bymostparticipatingcountriestoshift100%torenewablesassoonaspossible,hasonce againhighlightedtheimportanceofrenewablefuels,especiallybiodiesel.Averyattractive featureofbiodieselisthatits“neat”form(B100)canbeblendedtotheextentofupto 20%withmineraldieselandtheblendcanbeusedtorunexistingengineswithlittleor nomodifications.

Butthereareseveralchallengesassociatedwiththelarge-scaledeploymentof biodiesel.Therawmaterialsneededforit—vegetableoilsandanimalfats—notonly havestronglycompetitiveusesasfood,feed,andindustrialrawmaterialsbutalsoneed largeareasofarablelandandlargevolumesofirrigationqualitywaterwhichbothare becomingincreasinglyprecious.Thesefactorsmakebiodieselprohibitivelycostlyaswell.

TogetroundthesehurdlesstrongR&Dthrustsarebeingmadeacrosstheworldto utilizewastematerialsasfeedstocksinbiodieselgeneration.Thepresentbookistheresult ofthecompilation,collation,andsynthesesofallexistingknowledgeinthisexceedingly importantareaofenergytechnology.Inthefirstfivechapterstheentiregamutofbiodiesel productionfromdifferentformsofwastehasbeencovered,encompassingwasteanimal fats,municipalwastelipids,microalgae,fungi,bacteria,andyeast.Inthenextfourchapters, therolesofallpossiblewaste-derivedcatalystshavebeendocumentedinspeedingupand enhancingofbiodieselgeneration.Thepenultimatechapterexpressesthestate-of-the-art oftheintegrationoffluegasbiomitigationwithbiodieselproduction.Theconcluding chapteraddressesthecrucial,butrarelycovered,aspectoftheenvironmentalimpacts associatedwithbiodieselandthelegallimitsprescribedinthatcontext.

TheeditorsDr.BhaskarSinghandDr.AbhishekGuldhehavebothhadahighly meritoriousresearchcareer,distinguishedbytheircopiousoutputofsustainedexcellence. Withcloseto10,000citationsbetweenthem,thewriterduoisnowamongtheforemost scientistsinthisfield.Theirwealthofexpertiseisreflectedinthemeticulousplanning ofthebook,selectionofthemostappropriateofthecontributions,andensuringthatall chaptersmeetthehigheststandardsofcomprehensiveness,cogency,andclarity.

Iamsurethisbookwillblazeatrial.KudostoElsevierforundertakingthisprojectat therighttimeandtotheauthorfortheirimpeccabletranscreationoftheconceptinto reality.

S.A.Abbasi INSAEmeritusProfessor PondicherryUniversity India https://vidwan.inflibnet.ac.in/profile/61966

Preface

Biodieselhasemergedasapromisingalternativerenewablefuel.Severalfeedstocks andprocessingtechniqueshavebeenstudiedanddevelopedbyresearchersacrossthe globe.Despitethesustainabilityandenvironmentalbenefitsattributedtobiodiesel,ahigh productioncostisthemajorbottleneckforcommercializationofbiodiesel.Themajor contributorstowardstheproductioncostarefeedstockprocurement,oilextractionand oiltobiodieselconversionprocess.Researchersandpolicymakersofnationsworldwide haverecentlyadvocatedtowardsincorporatewastematerialsinthebiodieselproduction processtoreducetheproductioncost.Wastematerialscanbeusedasfeedstockorin otherprocessingstepssuchassynthesisofcatalystsforconversionofoiltobiodiesel.In otherapproach,wastematerialcanbeusedasresourcetodeveloppotentialfeedstock orcatalysts.Thisbook,WasteandBiodiesel:FeedstocksandPrecursorsforCatalystsaim tocriticallyevaluatetheemergingtrendsofutilizingwasteinvariousstagesofbiodiesel productionprocess.

Chaptersinthebookincludeoverviewofwasteutilizationinbiodieselproduction process,criticalevaluationofwasteanimalfats,municipalwastederivedlipidsand biowastesasbiodieselfeedstock,biodieselproductionfrommicroalgae,oleaginousfungi, yeastandbacteriabiomassproducedbyusingwastesubstratesasnutrientmedium. Chaptersalsoincluderecenttrendsandadvancementsinsynthesizingcatalystsusedfor biodieselproductionfromwastederivedfromorganicorigin,suchaswasteshell,fishand animalwaste,andinorganicmaterials.Achapterdealswithwholecellenzymecatalyst forproductionofbiodiesel.Achapteralsodiscussesintegrationoffluegasmitigation inbiodieselproductionprocess.Integrationofwasteinbiodieselproductionprocess provideseconomicalaswellasenvironmentalbenefitsandleadstowardsthesustainable productionofbiodiesel.

BhaskarSingh AbhishekGuldhe

Contributors

MaiO.Abdelmigeed

ChemicalEngineeringDepartment,CairoUniversity,Giza,Egypt

OmarM.Abdeldayem

EnvironmentalEngineeringProgram,ZewailCityofScienceandTechnology,Giza,Egypt

WiuryC.Abreu

FederalInstituteofMaranhão,Buriticupu,MA,Brazil

AdewaleAdewuyi

DepartmentofChemicalSciences,FacultyofNaturalSciences,Redeemer’sUniversity,EDE, OsunState,Nigeria

ShahrukhN.Alam

DepartmentofEnvironmentalSciences,CentralUniversityofJharkhand,Ranchi,India

T.CAniokete

DepartmentofChemicalEngineering,FacultyofEngineering,EnuguStateUniversityof ScienceandTechnology,Enugu,Nigeria

NaveenK.Arora

DepartmentofEnvironmentalSciences,BabashahebBhimraoAmbedkarUniversity,Lucknow, India

EslamG.Al-Sakkari

ChemicalEngineeringDepartment,CairoUniversity,Giza,Egypt

RifatAzam

DepartmentofEnvironmentalSciences,BabashahebBhimraoAmbedkarUniversity,Lucknow, India

RachaelJBarla

DepartmentofChemicalEngineering,BirlaInstituteofTechnologyandScience(BITS)Pilani, Rajasthan,India

DeovratN.Begde

DepartmentofBiochemistry&Biotechnology,Dr.AmbedkarCollege,Deekshabhoomi, Nagpur,Maharashtra,India

DariaC.Boffito

ChemicalEngineeringDepartment,PolytechniqueMontreal,Montreal,Canada

JeanC.S.Costa

FederalUniversityofPiaui,Teresina,PI,Brazil

M.O.Daramola

DepartmentofChemicalEngineering,FacultyofEngineering,BuiltEnvironmentand InformationTechnology,UniversityofPretoria,Pretoria,SouthAfrica

SumitH.Dhawane

DepartmentofChemicalEngineering,MaulanaAzadNationalInstituteofTechnology,Bhopal, India

AlaaeldinA.Elozeiri

EnvironmentalEngineeringProgram,ZewailCityofScienceandTechnology,Giza,Egypt

AyodejiJFatehinse

DepartmentofChemicalSciences,FacultyofNaturalSciences,Redeemer’sUniversity,EDE, OsunState,Nigeria

KajolGoria

DepartmentofEnvironmentalSciences,CentralUniversityofJammu,Jammu,Jammuand Kashmir,India

AbhishekGuldhe

AmityInstituteofBiotechnology,AmityUniversityMaharashtra,Mumbai,India

SureshGupta

DepartmentofChemicalEngineering,BirlaInstituteofTechnologyandScience(BITS)Pilani, Rajasthan,India

ZairaKhalid

DepartmentofEnvironmentalSciences,CentralUniversityofJharkhand,Ranchi,India

RichaKothari

DepartmentofEnvironmentalSciences,CentralUniversityofJammu,Jammu,Jammuand Kashmir,India

BlazLikozar

DepartmentofCatalysisandChemicalReactionEngineering,NationalInstituteofChemistry, Ljubljana,Slovenia

KhushalMehta

DepartmentofBiology,SRMUniversity-AP,AndhraPradesh,India

CarlaV.R.Moura

FederalUniversityofPiaui,Teresina,PI,Brazil

EdmilsonM.Moura

FederalUniversityofPiaui,Teresina,PI,Brazil

MarwaM.Naeem

ChemicalEngineeringDepartment,BritishUniversityinEgypt,Cairo,Egypt

MahmoudNasr

EnvironmentalEngineeringDepartment,Egypt-JapanUniversityofScienceandTechnology (E-JUST),P.O.Box179,NewBorgEl-ArabCity,Alexandria21934,Egypt;Sanitary EngineeringDepartment,FacultyofEngineering,AlexandriaUniversity,P.O.Box21544, Alexandria21526,Egypt

ImranPancha DepartmentofBiology,SRMUniversity-AP,AndhraPradesh,India

SmitaRaghuvanshi

DepartmentofChemicalEngineering,BirlaInstituteofTechnologyandScience(BITS)Pilani, Rajasthan,India

ShubhamRaina

DepartmentofEnvironmentalSciences,CentralUniversityofJammu,Jammu,Jammuand Kashmir,India

O.OSadare

DepartmentofChemicalEngineering,FacultyofEngineering,BuiltEnvironmentand InformationTechnology,UniversityofPretoria,Pretoria,SouthAfrica

AnjaliSingh InstituteofMicrobiology,AlgatechCentrum,CzechAcademyofScience,Trebon,Czech Republic

BhaskarSingh

DepartmentofEnvironmentalSciences,CentralUniversityofJharkhand,Ranchi,India

HarMohanSingh

SchoolofEnergyManagement,ShriMataVaishnoDeviUniversity,Jammu,Jammuand Kashmir,India

PoonamSingh

InstituteofPlantMolecularBiology,BiologyCentre,CzechAcademyofScience,Czech Republic

KiranToppo

CSIR-NationalBotanicalResearchInstitute,Lucknow,UttarPradesh,India

V.V.Tyagi

SchoolofEnergyManagement,ShriMataVaishnoDeviUniversity,Jammu,Jammuand Kashmir,India

Contributors ix

Foreword xiii

Preface xv

Acknowledgments xvii

1.Biodieselandanoverviewofwasteutilizationatthevariousproductionstages1 ShahrukhN.Alam,ZairaKhalid,AbhishekGuldheandBhaskarSingh

1.1 Introduction 1

1.2 Biodieselproductionprocess2

1.3 Integrationofwasteintobiodieselproductionprocess3

1.4 Wastematerialasfeedstock4

1.5 Feedstocksgeneratedusingwastematerial9

1.6 Challengesandfutureprospects11

References 11

2.Prospectsofbiodieselproductionfromwasteanimalfats17 T.CAniokete,O.OSadareandM.O.Daramola

2.1 Introduction17

2.2 Biodieselproductionfromwasteanimalfats21

2.3 Transesterificationofwasteanimalfattobiodiesel32

2.4 Technoeconomicfeasibilityofbiodieselproductionfromwasteanimalfats38

2.5 Challenges/recentstudiesforlarge-scaleproductionofbiodieselfromwasteanimal fatsviatransesterification38

Conclusionsandoutlook39

References 40

3.Efficacyofmunicipalwastederivedlipidsinproductionofbiodiesel45 MahmoudNasr

3.1 Introduction45

3.2 Overviewoflipids/biodieselproductionfrommunicipalsolidwastereportedinliterature47

3.3 Typesofmunicipalsolidwasteavailableforbiodieselproduction51

3.4 Waste-to-energyconversiontechniques54

Conclusions 55

Acknowledgements55 References 55 v

4.Wastewatergrownmicroalgaefeedstockforbiodieselproduction59

PoonamSingh,ImranPancha,AnjaliSingh,KhushalMehtaandKiranToppo

4.1 Introduction59

4.2 Assimilationmechanismofnutrientsbymicroalgae60

4.3 Feasibilityandpotentialofwastewaterbasedmicroalgalcultivation61

4.4 Challengesforbiodieselproduction63

4.5 Biorefineryapproachforbiodieselproductionfromwastewatergrownmicroalgae66

69

5.Biodieselfromoleaginousfungi,bacteria,andyeastproducedusingwaste substrates73

HarMohanSingh,KajolGoria,ShubhamRaina,RifatAzam,RichaKothari, NaveenK.AroraandV.V.Tyagi

5.1 Introduction73

5.2 Oleaginousmicroorganisms74

5.3 Technologiesinvolvedinbiodiesel80

5.4 Challengesandperspectives83

6.CaOderivedfromwasteshellmaterialsascatalystsinsynthesisofbiodiesel91

CarlaV.R.Moura,WiuryC.Abreu,EdmilsonM.MouraandJeanC.S.Costa

6.1 Introduction91

6.2 CaOderivedfromplantresidues92

6.3 CaOderivedfromanimalwaste102

6.4 CaOderivedfrommineralwaste106 Conclusion 113

7.Fishandanimalwasteascatalystsforbiodieselsynthesis119

EslamG.Al-Sakkari,AlaaeldinA.Elozeiri,OmarM.Abdeldayem,BlazLikozar andDariaC.Bofitto

7.1 Introduction119

7.2 Sourcesoffishandanimalwaste-basedcatalyst120

7.3 Preparationoffishandanimalwaste-basedcatalyst121

7.4 Transesterificationkineticsoverwaste-derivedheterogeneouscatalysts124

7.5 Currentstatusoffishandanimalwaste-basedcatalyst126

7.6 Remarksonprocessfeasibilityandgreenness130

7.7 Scaling-up:opportunitiesandlimitations131

8.Inorganicwastesasheterogeneouscatalystsforbiodieselproduction137

EslamG.Al-Sakkari,MaiO.Abdelmigeed,MarwaM.NaeemandSumitH.Dhawane

8.1 Introduction137

8.2 Inorganicwastes144

Conclusionsandfutureperspectives156

References 156

9.Wholecellenzymecatalystproductionusingwastesubstrateforapplication inproductionofbiodiesel163

DeovratN.Begde

9.1 Introduction163

9.2 Transesterification-conventionalandemergentstrategies164

9.3 Whole-cellbiocatalysts-advantagesandlimitations165

9.4 Organismsaswhole-cellbiocatalyst167

9.5 Industrialwasteaspotentialfeedstock/nutrientmediumforwhole-cellenzyme catalystsproduction172

9.6 Otherpotentialsourcesforwhole-cellbiocatalystproduction177

9.7 Stabilizationandoptimizationofwhole-cellbiocatalystforbiodieselproduction177

9.8 Geneticandmetabolicengineeringofwhole-cellbiocatalystforbiodieselproduction178

Concludingremarksandfutureprospects179

References 180

10.Processintegrationforthebiodieselproductionfrombiomitigation offluegases191

RachaelJBarla,SmitaRaghuvanshiandSureshGupta

10.1 Introduction191

10.2 Fluegasmitigationbymicrobialspecies193

10.3 Processintensificationstudyforbiodieselproduction200 Conclusionandfutureprospects209

References 209

11.Bio-wasteasanalternativefeedstockforbiodieselproduction:Currentstatus andlegalenvironmentalimpacts215

AdewaleAdewuyiandAyodejiJFatehinse

11.1 Introduction215

Reference 241 Index 247

Biodieselandanoverviewofwaste utilizationatthevariousproduction stages

ShahrukhN.Alam a,ZairaKhalid a,AbhishekGuldhe b andBhaskarSingh a

a DepartmentofEnvironmentalSciences,CentralUniversityofJharkhand,Ranchi,India

b AmityInstituteofBiotechnology,AmityUniversityMaharashtra,Mumbai,India

1.1Introduction

Fossilfuelreservesthroughouttheworldaredecliningatanexponentialratemainly attributedtopopulationexplosion.Aboveall,theextensiveburningoffossilfuelsfor transportation,energy,industrialapplicationcreatesnegativeenvironmentalissues,such asglobalwarming,continuousCO2 emission,andgreenhousegasemission.Global energyconsumptionhasalreadydoubledbetween1971and2001anditisestimatedthat energydemandby2030istobecalledforadditionalincreaseby53%.Since,thefossil fuelsarenonrenewableandasperBritishPetroleum’s(BP)annualreport,2013itwillget exhaustedinaround50yearsifthecurrentpacecontinues.Consequently,sustainable fuelalternativesarebecomingahighpriorityformanycountriesandareboundto playamajorroleinthefuelindustryintheimmediatefuture.Liquidbiofuelsarebeing advocatedasoneofthemostsustainablealternativestodealwithever-increasingdemand andtotackleenvironmentalconcerns,includingdiminishingfossilfuelreservesand globalwarming.Biodieselhasbeenidentifiedasoneofthebestalternativenonpetroleum basedsustainablefuelconsistingofalkylestersderivedfromeitherthetheesterificationof freefattyacids(FFAs)ortransesterificationoftriglycerides(TGs)orwithshort-chained alcohols.Productionofbiodieselfrombiologicalrenewablesources,suchasvegetableoils, animalfats,wasteoilsandrecentlylignocellulosicmaterialsarebeingreviewedwidely. Manyadvantagesofbiodieseloverconventionalpetroleumdieselare:ithaslowemissions andhencesafer,renewable,biodegradable,betterlubricity,nontoxic,itcontainsnosulfur andbiodegradable.Biodieselistheonlyalternativefueltocompletethehealtheffects testrequirementsoftheCleanAirActAmendments1990.Currently,itisnotamongthe popularalternativefuelgloballymainlybecauseofitshighercostwhencomparedwith conventionalpetroleumdiesel.Themajorprobleminthewidespreadcommercialization ofbiodieselistheavailabilityofthefeedstock,whichmakesthecostofproductionabit high,therebyraisingtheoverallprice.However,therecentadvancementsinusingthe

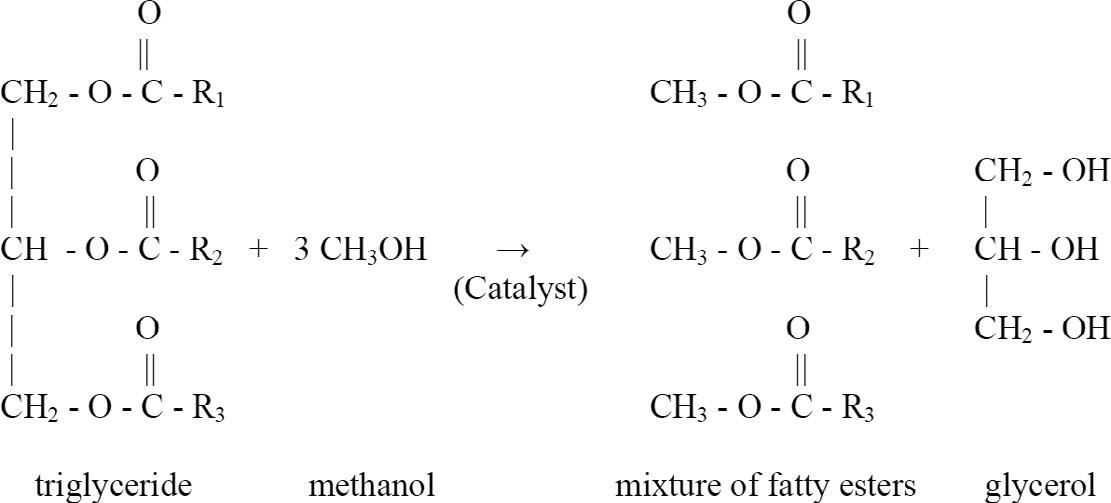

Figure1.1 Transesterificationreversiblereaction.

cheaprawmaterialinsteadofpricyrefinedvegetableoilandfatisshowingpromising resultsinmakingbiodieselmoreeconomical.

Thischapteraddressesanoverviewofutilizationofvariouswastematerials,suchas wastecookingoil,wasteanimalfats,agriculturalwastes,wastecoffeegrounds,etc.,and thechallengesandotherprospectsofusingthesewastesmaterial.

1.2Biodieselproductionprocess

Thedirectuseofanykindofvegetableoilorfatoritsblendforthepurposeof runninganenginehasbeendeemedimpractical,mainlyduetoitscharacteristicslike highviscosity,freefattyacidcontentandacidcompositionofsuchoils.Thesetypes ofoilsandfatsalsohavetheproblemofgumformationbecauseofpolymerization andoxidationwhilestoringandcombusting.Additionally,thickeningofunprocessed oilwithtimeanddepositionofcarbonaretwomoreissueswhichmakeitunfitfor directapplication(Fukudaetal.,2001).Keepinginview,theproblemsmentionedthe oilsandfatsneedstoundergoconversionprocessestomakeorconvertthemintoviable biodieselformsuitableforconventionaldieselengine.Transesterificationofvegetable oilsorfatswithalcohol(withonetoeightcarbonatoms)isthemostwidelyadapted andpreferredmethodforbiodieselproduction.Basically,therearetwotransesterification methods,oneisperformedwithcatalystandtheotherisperformedanywithoutcatalyst. Theutilizationandselectionoftypeofcatalystisdependedontypeofthefeedstock. Generallytheuseofcatalystsimprovestherateandyieldofbiodieselandispreferred overtheotherdependingonthefeedstockbeingusedforproducingbiodiesel.According to Otera(1993) transesterificationreactioncanbedefinedbythreereversiblereactions whereexcessalcoholshiftsthewholeequilibriumtotheproductsideasdepictedin Fig.1.1.

Firststepinvolvesthereversiblereactionofchangingoftriglyceridestodiglycerides, thenthesecondreactionischangingofdiglyceridestomonoglycerides,similarlyfollowedbyconversionofmonoglyceridestoglycerol.Allthereactionsyieldonemolecule ofmethylesterpermoleofglycerideateverystep(Noureddinietal.,1998).Sometimes,

Figure1.2 Transesterificationprocessdepictingmethanolysisoftriglyceride.

esterificationpriortothetransesterificationprocessisthemostcommonmethodfor reducingthefeedstock’sfreefattyacid(FFA)content.

Thecompletereactioninvolvedintransesterificationprocessis:

Asdepictedin Fig.1.2,R1,R2,andR3arelongchainsofhydrocarbonsandcarbon atomscalledfattyacidchains,whichmaybesameordifferentwithCH3 andC2 H5 attached.Thetransesterificationreactionisbasedononemoleoftriglyceridereacting withthreemolesofmethanoltoproducethreemolesmethylester(biodiesel)andone moleglycerol.

Severalkindsofalcoholscanbeincorporatedinthisreaction,suchasethanol,butanol, propanol,ormethanol.However,methanolismostcommonlyusedbasedonthelowcost,severalphysicochemicalbenefits(highpolarityandshortestalcoholchain(Maand Hanna,1999).

Thetransesterificationreactioninvolvesfewimportantparameterswhichsignificantly impactsthefinalyield.Someofthemostimportantvariablesare:reactiontime,freefatty acidcontentintheoil,reactiontemperature,watercontentintheoil,typeandamount ofcatalyst,molarratioofalcoholtooil,useofcosolventandmixingintensity.

1.3Integrationofwasteintobiodieselproductionprocess

Currentbiodieselindustrymostlyemploysedibleoilseedasfeedstockandstrongbase andacidbasedhomogenouscatalystmainlyduetohighconversionrates.However,high costsofthesetypeoffeedstocks,catalyst,andotherexpensiveprocess,suchaspurification offinalproductorseparationofcatalystmakesthewholecostofbiodieselexpensive andimpractical(Santosaetal.,2019).Inordertoreducetheproductioncost,research involvingtheincorporationofwastematerialsinseveralbiodieselproductionstagesis beingfavored.Therearevariousadvantagesinutilizingorreusingthewastematerials withdisposalandrecycleissues.Insteadofjustthrowingawaythewastematerialswhereit maydamagetheenvironment,utilizingitinbiodieselsolvesmultipleproblemsincluding

employmentgenerationforalargenumberpeopleinwasterecoveryandproduction stages.

Wastematerialshavebeenincorporatedinvariousbiodieselproductionstages viz. asfeedstockforbiodieselproductionorusingheterogeneouscatalystderivedfrom severalwastematerialsinsteadofhomogenouscatalyst.Theheterogeneouscatalysthave severaleconomicalandenvironmentaladvantagesinadditiontolowproductioncost, suchasitcanbeeasilyseparatedattheendofthebiodieselproductionprocessesby centrifugationorfiltrationandalsotheycanbereusedseveraltimes(Gotchtetal.,2009). Theseheterogeneouscatalystsaremuchsafertohandle,lesscorrosive,andmoreecofriendly(Lametal.,2010).Recentstudiesshowseveralkindsofwastesrangingfrom lignocellulosicwastes,shellwastes,andothershavebeensuccessfullyusedascatalystfor biodieselproduction.IncludingvarioustypesofCaCO3 basedwastesascatalyst,suchas wasteeggshell(Bhartietal.,2020),wasteshell(Yulianaetal.,2020),wastefishscales (Chakrabortyetal.,2011),wasteanimalbones(Farooqetal.,2015),wastecoralfragment (Roschatetal.,2012),andothers.Similarlyvariouslignocellulosicbiomasshasalsobeen investigatedforlowcostcatalystsuchassugarcanebaggase(Akinfalabietal.,2020),rice huskash(Hindryawatietal.,2014),bamboo(Zhouetal.,2016),palmshell(Baroutian etal.,2010),etc.

Severalwastesutilizedasbiodieselfeedstocklikewasteoil,animalfat,agricultural waste,municipalwaste,lignocellulosicwaste,etc.,havebeendiscussedindetailbelow.

1.4Wastematerialasfeedstock

Theincreasedenergydemand,growingconcernfortheenvironmentandthepossible shortageofpetroleumfuelsinfuturehaveincentivizedtheresearchtowardfinding alternativesustainablefuel(Paglianoetal.,2017).Biodieselhascomeforwardasa promisingalternativetopetroleumfuelwithsimilarphysicochemicalpropertiesasdiesel thatcanbeusedasitssubstituteindieselengineswithoutanyneedformodification (Mardhiahetal.,2017).Biodieselismostcommonlysynthesizedfromoilseedswhich stronglyinfluencetheglobalfoodsecuritywhileincreasingthepriceofedibleoils therebyshiftingthefocustowardsnon-edibleaswellaswastecookingoil(Patiletal., 2011).Theincorporationofmunicipal,domestic,andagroindustrialwastefeedstockfor biodieselproductionmakestheprocesssustainableandeco-friendly(Aboelazayemetal., 2018).

1.4.1Wasteoil

Biodieselareethylormethylestersextractedfromdifferentfeedstocksthroughthe processoftransesterification(Sharmaetal.,2013).Theavailabilityofwastefeedstock createsanattractiveoptionofovercomingtheenergycrisisbyconversionofthese feedstockstobiofuel.Wastecookingoil(WCO)presentsitselfasapromisingbiofuel

Table1.1 Fameyieldofwastecookingoil(WCO)underdifferentcatalysts.

S.No. Feedstock

Catalystused Reference

1. WCO 79.7% Sr/ZrO2 OmarandAmin,2011

2. WCO 81.0% ZS/Si Jacobsonetal.,2008

3. WCO 83.08% CaO/KI/ᵞ-Al2 O3 Asrietal.,2015

4. WCO 88% Lipase Saifuddinetal.,2009

5. WCO 90% Novozyme435 Haighetal.,2012

6. WCO 90% H2 SO4 Wangetal.,2006

7. WCO 91.7% KOH/Al2 O3 Noirojetal.,2009

8. WCO 94% PuroliteD5081 Haighetal.,2012

9. WCO 97.8% Acid-basedcatalyst OuachabandTsoutsos,2013

feedstocksinceitisawastethatisreadilyavailablefromhouseholdkitchens,restaurants, andcafeterias.Theutilizationofwastematerialsforbiodieselproductionwillbehelpful inmitigationofpollution.WCOwhichisgenerallydisposedoffaswastecanbeexploited asafeedstockmakingthewholeprocesseconomical(Arshadetal.,2018; Tangyet al.,2016).TheproductionofbiodieselfromWCOisdeemedtobecosteffective, technicallyviableandenvironmentallybenign(Farooqetal.,2013).Itisestimatedthat UnitedStatesofAmerica,Japan,China,Europe,andMalaysiatogetheraccountsfor 15milliontonnesofWCOgenerationperyearonanaverage.Indiaisoneofthe largestproducersofWCOwithanestimateof9.2milliontonsperannum(Bharti etal.,2020; Kolheetal.,2017). Cheetal.,(2012) usedolivepomaceoilfortheproduction offattyacidmethylester(FAME)viaacidesterificationprocesswithsulfuricacidas catalyst.Reductioninfreefattyacid(FFA)by50%atlowmethanoltooilratiowhile forhighmethanoltooilratioover80%reductionwasobserved.Furthermore, Ouachab andTsoutsos(2013) alsousedolivepomaceoilfortheproductionofFAMEthrough esterificationprocessachievingayieldof97.8%(Table1.1).

Theprocessoftransesterificationhaseliminateddurabilityandoperationalproblems whilereducingtheviscosityofvegetableoil.BiodieselblendofWCOinperformance characteristicsareclosetodieselfuel(Abedetal.,2018). Mohodetal.(2013) intheirstudy comparedB5andB10blendsofWCObiodieselwithdieselfuelbyusingitinasingle cylinderdieselengine.Thebiodieselblendresultedinreductionofthermalefficiency by2.8%andincreaseinspecificfuelconsumptionby4%. MuralidharanandVasudevan (2011) testedfourblendsofdiesel-WCObiodiesel;dieselfuel,B5,B20,andB30indiesel engineandfoundhigherfuelconsumptionloadinbiodieselblendssinceheatingvalueof biodieselislowerwhencomparedwithdieselfuel.TheWCObiodieselfuelsynthesized bytransesterificationprocessissimilartodieselfuelinitsphysicalandchemicalproperties. TheongoingstudiesfocusonthefunctioningofbiodieselblendofWCOwithdiesel fuelintheoperationofdieselenginewithoutanyalterationinhardware(Abedetal., 2018).

1.4.2Wasteanimalfats

Meatprocessingfacilitiesproduceanimalfatsasaby-product.Recentlyalotofattention ispaidontheeconomicallysustainablefeedstock,animalfatwaste(AFW)beingone ofthem(Habibetal.,2020).Theanimalfatderivedfromthemeatprocessingfacility mainlyincludewhitegreaseandlardfrompork,tallowsfromcattle,poultryfatfrom turkey,chickens,ducks,andotherbirds.Oilsandfatsderivedfromleatherindustry wasteandfishprocessingplantsarealsodeemedtobeaviablefeedstockforbiodiesel (Alptekinetal.,2012).Currently,animalfatforthemostpartisusedasrawmaterialin soapandcosmeticsindustriesmakingthemarketdemandforAFWverylimited.AFW offersenvironmental,economicaswellasfoodsecuritybenefitovertheconventional ediblevegetableoilswhenusedasafeedstockforbiodiesel.Additionally,thecostfor transesterificationofAFWi.e.,$0.4-0.5/literischeaperthanthetransesterificationcost ofvegetableoilwhichis$0.6–0.8/liter(Bankovi ´ c-Ili ´ cetal.,2014).SomeAFW,such aschicken,tallow,lardfatsarealreadyinuseforbiodieselproductionatindustrialscale (Bender,1999; SchörkenandKempers,2009).AFWsrequirecomplextechniquesfor biodieselproductionsincetheycontainhighlevelsoffreefattyacids(FFA)andsaturated fattyacidswhichresultsinlowerchemicalandphysicalqualityofbiodiesel.Despitethat, AFW’slowunsaturationoffattyacidshasnumerousadvantages,suchashighcetane number,highcalorificvalue,andhighoxidationstability(Alptekinetal.,2012).Since, AFWcontainshighquantityofFFAandwaterresultinginreducedyieldofbiodieselas wellasincreasedproductioncost,pretreatmentisessentialwhichalleviatestheproblem ofseparationandpurification(GebremariamandMarchetti,2018).Theproductionof biodieseltakesplacethroughtheprocessoftransesterificationwhichinvolvesreaction offatinthepresenceofacatalystwithshortchainalcohol.Therearemanycatalysts availableforuseintheproductionofbiodiesel(Toldrá-Reigetal.,2020).Catalysts,suchas potassiumhydroxide,potassiumamide,potassiummethoxide,potassiumhydride,sodium hydroxide,sodiumamide,sodiummethoxide,sodiumhydride,sulfuricacid,phosphoric acid,hydrochloricacid,organicsulfonicacid,lipase,zirconias,silicates,andnanocatalysts, aresomeofthemostwidelyusedalkali,acidic,generous,andcomplexcatalystsused intransesterificationreaction(MaandHanna,1999).TheuseofalkalicatalystinAFW transesterificationresultsinafasterreactionrate(4000timesfaster)incomparisonwith acidcatalysts.Theotherbenefitofusingalkalicatalystsisthatitisreadilyavailableand lessexpensive.VariousstudieshavebeenconductedusingAFWfortheproductionof biodiesel,fewofwhicharementionedin Table1.2

1.4.3Agriculturalwaste

Agriculturalcropresiduesoragriculturalwastescanbebroadlyclassifiedintotwotypes: 1. Fieldresidues:Materialswhichareleftinplantationareasoragriculturallandafter harvesting.Fieldresiduesgenerallyincludestalks,ricebran,stems,seedpods,etc.

Table1.2 Biodieselproductionfromdifferentanimalfatfeedstock.

Sl.No. Feedstock Catalyst Yield(%) Reference

1. Chickenfat

H2 SO4 99.01 Bhattietal.,2008

NaOMe 88.5 AlptekinandCanakci,2010

NanoCaO 88.5 Keihanietal.,2018

AC/CuFe2 O4 encapsulatedwith CaO 95.6 Seffatietal.,2019

CaO/CuFe2 O4 94.5 Seffatietal.,2020

Compositemembrane& NaOMe 98.1 Shietal.,2013

KOH 82.0 Chavanetal.,2017

2. Lard KOH 91.4 Mataetal.,2014 KOH 98.0 Heetal.,2020

35%CaO/zeolite 90.9 Lawanetal.,2020

Supercriticalmethanol 89.9 Shinetal.,2012

Immobilizedlipasefrom Candidaantartica 96.8 Adewaleetal.,2016

LipasefromCandidasp. 87.4 Luetal.,2007

LipasefromCandida antartica 74 Leeetal.,2002

LipasefromCandida antartica 97.2 Huangetal.,2010

3. Beeftallow KOH 90.8 Mataetal.,2014

Immobilizedlipasefrom Burkholderiacepacia 89.7 DaRósetal.,2010

Surfonatedpolystyrene 75 Soldietal.,2009 KOH 95 Moraesetal.,2008

4. Mutton tallow MgO-KOH 98.00 Liuetal.,2007

Bhattietal.,2008

2. Processresidues:Theleftovermaterialsafterthecropisprocessedtosomeusable resourcearecalledprocessresidues.Theseprocessresiduesmayincludehusks,roots, bagasse,seeds,anddeoiledcakesofedibleandnonedibleoilseeds. Ofwhichcornstover,rice,andwheatstalksandmostlydeoiledcakesofedibleand nonedibleoilseedshavebeenstudiedaspotentialfeedstocksforproducingbiodiesel mainlybecauseoftheremainingoilcontentafterprocessinginthem.Globalestimation showsthat38.5millionmetrictonsofricebranfrom482millionmetrictonsofrice isproducedannually(Pattanaiketal.,2019).Roughlythisricebrancontainsaround 17.5%oilandunrefinedricebranoilwith8%FFAcontentshowsgreatpotentialforthe productionofbiodiesel.SincethericebranhashighFFAcontent,itrequirescertainlevel ofpretreatment. Kattimanietal.,(2014) intheirstudyshowedbiodieselproductionin therangeof60%–80%afteracidcatalyzedesterificationwithsulfuricacidfollowedby

transesterification.Similarly, Zhangetal.(2013) conductedsimultaneousesterification andtransesterificationreactionfromricebranoilwith40%FFAtoobtainbiodiesel yieldof92%usingchlorosulfonicacidmodifiedzirconiaascatalyst.Whereas, Jitputti etal.(2006) performedtransesterificationofricebranoilwithsolidacidcatalystand statedthatsolidacidcatalystcanperformbetterthanmineralacidmainlyattributedto itsreproducibilityandheterogeneouscharacteristics.

Deoiledcakesofedibleandnonedibleoilseedslikeolivedeoiledcakehaverecently gainedmuchattentionduetotheirpotentialforbiodieselproduction.Theolivedeoiled cakeinaveragecontains19.75%oilcontentandhencehasbeenusedintwostep processestoproducebiodiesel.Theolivedeoiledcakeprimarilycontains24.5%FFA whichneedsesterificationreactiontoreducetheFFAcontenttoaround.52%followed bytransesterificationtoyieldbiodieselintherangeif40to65%(Al-Hamamre,2011).

1.4.4Wastewaterasbiodieselfeedstock

Wastewatercontainsnumerousmicroorganismsthatexploittheinorganicandorganic compoundspresentinthewastewaterforcarbon,nutrientsandenergy(Dufreche etal.,2007).Itisanobviousfactthattheproductionofwastewatersludgeisinlarge quantity.Ithasbeenreportedthatdrysludgeobtainedfromthewastewatercontains 5%–20%lipidw/wwhichisasgoodasplantseeds(Wangetal.,2016).Ithasbeen estimatedthatbecauseoftheuseofsludgeasalipidsourcethebiodieselproduction costwillbereducesimmenselysincesludgeisafreematerial.Sincewastewatersludge isrichinnitrogen,phosphorus,andcarbon,itcanbeusedasamediumforcultivation ofmicroorganisms.Microorganismsuchas Lipomycesstarkeyi,Rhodosporiumtoruloides, and Trichosporonoleaginosus havebeenrecognizedfortheircapabilityofassimilatingwaste forproductionoflipid(Xavieretal.,2017). Dufrecheetal.,(2007) throughinsitu transesterificationprocessfoundtheyieldofthedrysludgetobe6.23%. Sharmaetal., (2020) investigatedtwomicroalgalconsortiagrowninsewagewaterandfoundthelipid contentofonetobeincreasedby31.3%overtheotheraswellasdesirablefattyacids fortheproductionofbiodieselwerealsoobserved. Aroraetal.,(2020) observedhigh microalgalbiomassinwastewateraswellasenhancedlipidcontentofabout31%drycell weight.

1.4.5Wastecoffeegroundresidue

Coffeeisoneofthemostextensivelyconsumedbeveragesthroughouttheworldand hasbeensince1000years.Theconsumptionofcoffeeworldwidearound2015–1016was morethan9milliontonsaccordingtotheInternationalCoffeeOrganization(ICO,2016). CoffeaArabicaandCanephora/Robustaaretwospeciesofcoffeewithgreateconomic importance(Blinováetal.,2017).Worldwidetherearetoptenproducersofcoffee beans,withVietnamandBrazilbeingaccountableforalmosthalfofthetotalproduction

(DangandNguyen,2019).Spentcoffeeground(SCG)isawasteresiduethathasgained interestasapotentialbiodieselfeedstockaswellasasustainablewastereduction.The extractionofcoffeeoilfromdefectivecoffeebeansandcoffeegroundswasfoundtobe costeffectiveaswellasofhighqualityforbiodieselproduction.TheSCGfeedstockdue toitshighcontentofantioxidantexhibithigherstabilityislessexpensiveandpleasant smelling(Haile,2014).TheproductionofbiodieselfromSCGinvolvescollectionofthe coffeegroundanditstransportation,drying,extractionresultinginbiodieselproduction. Thecontentofoilvariesbasedonthecoffeesourcefrom11–20wt%.Theoilyield fromdefectivecoffeebeanrangesfrom10-12wt%onthebasisofdryweightwhileSCG produce10–15wt%(Al-Hamamreetal.,2012).

1.5Feedstocksgeneratedusingwastematerial

Utilizationofwastematerialfortheproductionofmicrobiallipidsforthebiodiesel synthesis,suchasnutrient-richwastewater,canprovidelowcostmediumforthe productionofvaluablefeedstocks.Microbiallipidsproducedinwastewateralsohelps inremovalofexcessnutrients(suchasphosphorusandnitrogen),avoidingdisposalof wastewaterintowaterbodiesbecausephosphorusandnitrogencauseeutrophicationof riversandlakestherebyalsohelpinginprotectingenvironment.

1.5.1Microalgaecultivationusingwastewater

Currently,microalgaeisconsideredoneofthepromisingalternatefeedstockforproducingbiodieselmainlyduetorapidgrowthrate,highlipidconcentrationandhighGHG fixingcapacity(Alametal.,2012).Cultivationofmicroalgaerequireslargeamountof nutritionwhichmakesitafairlyenergyextensiveandexpensiveprocessandtherefore researchersarestudyingvariousmethodstoreducetheproductioncost.Oneofthemost prominentbeingmicroalgaecultivationusingwastewaterwhichincorporatesproduction ofmicroalgaeandremovalofnutrientsfromwastewatersimultaneously.Thismethod servesmultiplepurposeofsavinglargeamountofwaterrequirementformicroalgae cultivationandnutrientsfromgoingtowastebyconvertingthenutrientavailable inwastewater(particularlynitrogenandphosphate)intomicroalgalbiomassthereby sequesteringlargeamountofcarbondioxideaswell(delaNoüeetal.,1992).Mostofthe microalgaespecieshavetheabilitytogrowfairlywellundernutrientrichwastewaterby absorbingthenutrientandmetalfromthewastewater.Severalspeciesofgreenmicroalgae havebeenusedinexistingwastewatertreatmentpondsfortreatingthewastewatersof industrial,agricultural,andmunicipalsourcesmakingthemanappealingmeansoflowcostandsustainablewastewatertreatmentalternative.Therefore,thegreenmicroalgaeare consideredasideallysuitedfordualroleofbiomassproductionandphytoremediation byconvertingnutrientspresentinwastewatertocarbohydrateandlipids(Rawatetal., 2011).

Table1.3 Biomassproductivityofmicroalgaecultivatedindifferenttypesofwastewater.

Sr.No. Microalgaespecie Wastewatertype Biomass productivity/day Reference

1. Chlorellavulgaris Aquaculture wastewater 42.6mgL-1 Gaoetal.,2016

2. Scenedesmussp. Industrial wastewater 900mgL-1 Jebalietal.,2015

3. Chlorellavulgaris Poultrylitter wastewater 127mgL-1 Markou,2015

4. Chlorellavulgaris Municipal wastewater 0.251gL-1 Gaoetal.,2014

5. Goniumsp. Textileeffluent 0.53gL-1 Boduro ˘ gluetal.,2014

6. Scenedesmusobliquus Urbanwastewater 380mgL-1 Ruizetal.,2013

7. Chlorellapyrenoidosa Piggery wastewater 0.3gL-1 Wangetal.,2012

8. C.pyrenoidosa Soybean processing wastewater 1070mgL-1 Hongyangetal.,2011

Severalkindsofwastewaterwhichhasbeeninvestigatedfortheproductionof microalgalbiomassaredepictedin Table1.3.

1.5.2Oleaginousfungigrownusingwastewater

Somefilamentousfungihavethepotentialtoaccumulatehighcontentoflipidsforthe productionofbiofuelsarecalledoleaginousfungi.Examplesofsomeoleaginousfungi include Mucorcircinelloides (Songetal.,2001), Cunninghamellaechinulate (Fakasetal.,2009), Mortierellaalpina (Wangetal.,2011), Umbelopsisisabellina (Hardeetal.,2016),etc.These oleaginousfungispeciesarecurrentlyattractingmuchattentionmainlybecauseofhigh concentrationoflong-chainpolyunsaturatedfattyacids(PUFAs).

Differentkindsofwastewatershavebeenincorporatedbyseveralresearchersforthe productionofoleaginousfungiadvantagebeingutilizationofwasteasnutrientsource forgrowingthefeedstock.Suchas Munirajetal.,(2015) showedthatpotatoprocessing wastewatercanbeeffectivelyusedforthecultivationoftwooleaginousfunginamely Aspergillusflavus and Mucorrouxii withhighlipidcontent.Similarly, Munirajetal., (2013) alsousedpotatoprocessingwastewaterfortheproductionofmicrobiallipidusing filamentousoleaginousfungusspecieAspergillusoryzae.Theresultshowedsubsequent amountoffattyacids,suchasoleicacid,palmitolicacid,palmiticacid,etc.Inadifferent study, SubhashandMohan,(2015) investigatedthepotentialoftwolignocellulosic wastewaterofcorncobwasteliquorandpapermilleffluentbyusingoleaginousfungi specie Aspergillusawamori. Resultsshowedthatavailabilityofsimplemonomericcarbon

compoundsintheselectedlignocellulosicwastewatergreatlyinfluencedbothlipid productivityandfungalgrowth.

1.6Challengesandfutureprospects

Currently,thebiodieselindustryismostlybasedontheavailabilityofoilseedforthe productionandtheutilizationofwasteindifferentstagesofbiodieselproductionreduces theassociatedcost.However,theproductionprocessmostofthetimesarenotasefficient asthatwithoilseed.Thereforealotofresearchisstillrequiredfirstlytosearchmore compatiblewastederivedfeedstockandoptimizetheoverallproductionprocessto competewiththeoilseedbiodieselproduction.Theprospectofutilizingawastematerial tosynthesizeheterogeneouscatalystssurelyisapromisingalternativetohomogenous catalystseliminatingvariousdisadvantagesofhomogenouscatalysts.Therefore,secondis explorationofmorewastederivedcatalystwhichcanreducetheoverallproductioncost andincreasetheproductionefficiency.Furthermore,alotofinvestigationofwastebased feedstockandwaste-derivedcatalystarenecessarytoimprovetheoverallperformance forbiodieselproductionincomparisontoconventionalfeedstockandcatalystaswellas otherchemicalprocessesinvolved.

References

Abed,K.A.,ElMorsi,A.K.,Sayed,M.M.,ElShaib,A.A.,Gad,M.S.,2018.Effectofwastecooking-oilbiodiesel onperformanceandexhaustemissionsofadieselengine.Egypt.J.Pet.27,985–989.

Aboelazayem,O.,Gadalla,M.,Saha,B.,2018.Biodieselproductionfromwastecookingoilviasupercritical methanol:optimisationandreactorsimulation.Renew.Energy124,144–154.

Adewale,P.,Dumont,M.-J.,Ngadi,M.,2016.Enzyme-catalyzedsynthesisandkineticsofultrasonicassisted methanolysisofwastelardforbiodieselproduction.Chem.Eng.J.284,158–165.

Akinfalabi,S.-I.,Rashid,U.,Ngamcharussrivichai,C.,Nehdi,I.A.,2020.Synthesisofreusablebiobasednanocatalystfromwastesugarcanebagasseforbiodieselproduction.Environ.Technol.Innov.18,100788.

Al-Hamamre,Z.,2011.BiodieselProductionfromOliveCakeOil.ChemicalEngineeringDepartment, FacultyofEngineeringandTechnology,UniversityofJordan,Amman11942,Jordan.

Al-Hamamre,Z.,Foerster,S.,Hartmann,F.,Kröger,M.,Kaltschmitt,M.,2012.Oilextractedfromspentcoffee groundsasarenewablesourceforfattyacidmethylestermanufacturing.Fuel96,70–76.

Alam,F.,Date,A.,Rasjidin,R.,Mobin,S.,Moria,H.,Baqui,A.,2012.Biofuelfromalgae-isitaviable alternative?ProcediaEng49,221–227.

Alptekin,E.,Canakci,M.,2010.Optimizationofpretreatmentreactionformethylesterproductionfrom chickenfat.Fuel89,4035–4039.

Alptekin,E.,Canakci,M.,Sanli,H.,2012.Evaluationofleatherindustrywastesasafeedstockforbiodiesel production.Fuel95,214–220.

Arora,N.,Jaiswal,K.K.,Kumar,V.,Vlaskin,M.S.,Nanda,M.,Pruthi,V.,Chauhan,P.K.,2020.Small-scale phyco-mitigationofrawurbanwastewaterintegratedwithbiodieselproductionanditsutilizationfor aquaculture.Bioresour.Technol.297,122489.

Arshad,M.,Bano,I.,Khan,N.,Shahzad,M.I.,Younus,M.,Abbas,M.,Iqbal,M.,2018.Electricitygeneration frombiogasofpoultrywaste:anassessmentofpotentialandfeasibilityinPakistan.Renew.Sustain.Energy Rev.81,1241–1246.

Asri,N.P.,Sari,D.A.P.,Poedjojono,B.,2015.Pre-treatmentofwastefryingoilsforbiodieselproduction.Mod. Appl.Sci.9,99–106.

Bankovi ´ c-Ili ´ c,I.B.,Stojkovi ´ c,I.J.,Stamenkovi ´ c,O.S.,Veljkovic,V.B.,Hung,Y.-T.,2014.Wasteanimalfatsas feedstocksforbiodieselproduction.Renew.Sustain.EnergyRev.32,238–254.

Baroutian,S.,Aroua,M.K.,Raman,A.A.A.,Sulaiman,N.M.N.,2010.Potassiumhydroxidecatalystsupported onpalmshellactivatedcarbonfortransesterificationofpalmoil.FuelProcess.Technol.91,1378–1385. Bender,M.,1999.Economicfeasibilityreviewforcommunity-scalefarmercooperativesforbiodiesel. Bioresour.Technol.70,81–87.

Bharti,R.,Guldhe,A.,Kumar,D.,Singh,B.,2020.Solarirradiationassistedsynthesisofbiodieselfromwaste cookingoilusingcalciumoxidederivedfromchickeneggshell.Fuel273,117778.

Bhatti,H.N.,Hanif,M.A.,Qasim,M.,2008.Biodieselproductionfromwastetallow.Fuel87,2961–2966.

Blinová,L.,Bartošová,A.,Sirotiak,M.,2017.Biodieselproductionfromspentcoffeegrounds.Ved.Práce Mater.Fak.Slov.Tech.UniverzityvBratislavesoSídlomvTrnave25,113.

Boduro ˘ glu,G.,Kılıç,N.K.,Dönmez,G.,2014.BioremovalofReactiveBlue220byGoniumsp.biomass. Environ.Technol.35,2410–2415.

Chakraborty,R.,Bepari,S.,Banerjee,A.,2011.Applicationofcalcinedwastefish(Labeorohita)scaleas low-costheterogeneouscatalystforbiodieselsynthesis.Bioresour.Technol.102,3610–3618.

Chavan,S.B.,Yadav,M.,Singh,R.,Singh,V.,Kumbhar,R.R.,Sharma,Y.C.,2017.Productionofbiodieselfrom threeindigenousfeedstock:Optimizationofprocessparametersandassessmentofvariousfuelproperties. Environ.Prog.Sustain.Energy36,788–795.

Che,F.,Sarantopoulos,I.,Tsoutsos,T.,Gekas,V.,2012.Exploringapromisingfeedstockforbiodiesel productioninMediterraneancountries:astudyonfreefattyacidesterificationofolivepomaceoil. BiomassBioenergy36,427–431.

DaRós,P.C.M.,Silva,G.A.M.,Mendes,A.A.,Santos,J.C.,deCastro,H.F.,2010.Evaluationofthecatalytic propertiesofBurkholderiacepacialipaseimmobilizedonnon-commercialmatricestobeusedin biodieselsynthesisfromdifferentfeedstocks.Bioresour.Technol.101,5508–5516.

Dang,C.-H.,Nguyen,T.-D.,2019.Physicochemicalcharacterizationofrobustaspentcoffeegroundoilfor biodieselmanufacturing.WasteBiomassValorization10,2703–2712.

delaNoüe,J.,Laliberté,G.,Proulx,D.,1992.Algaeandwastewater.J.Appl.Phycol.4,247–254.

Dufreche,S.,Hernandez,R.,French,T.,Sparks,D.,Zappi,M.,Alley,E.,2007.Extractionoflipidsfrom municipalwastewaterplantmicroorganismsforproductionofbiodiesel.J.Am.OilChem.Soc.84,181–187.

Fakas,S.,Papanikolaou,S.,Batsos,A.,Galiotou-Panayotou,M.,Mallouchos,A.,Aggelis,G.,2009.Evaluating renewablecarbonsourcesassubstratesforsinglecelloilproductionbyCunninghamellaechinulataand Mortierellaisabellina.BiomassBioenergy33,573–580.

Farooq,M.,Ramli,A.,Naeem,A.,2015.BiodieselproductionfromlowFFAwastecookingoilusing heterogeneouscatalystderivedfromchickenbones.Renew.Energy76,362–368.

Farooq,M.,Ramli,A.,Subbarao,D.,2013.Biodieselproductionfromwastecookingoilusingbifunctional heterogeneoussolidcatalysts.J.Clean.Prod.59,131–140.

Fukuda,H.,Kondo,A.,Noda,H.,2001.Biodieselfuelproductionbytransesterificationofoils.J.Biosci. Bioeng.92,405–416.

Gao,F.,Li,C.,Yang,Z.-H.,Zeng,G.-M.,Feng,L.-J.,Liu,J.,Liu,M.,Cai,H.,2016.Continuousmicroalgae cultivationinaquaculturewastewaterbyamembranephotobioreactorforbiomassproductionand nutrientsremoval.Ecol.Eng.92,55–61.

Gao,F.,Yang,Z.-H.,Li,C.,Wang,Y.,Jin,W.,Deng,Y.,2014.Concentratedmicroalgaecultivationintreated sewagebymembranephotobioreactoroperatedinbatchflowmode.Bioresour.Technol.167,441–446. Gebremariam,S.N.,Marchetti,J.M.,2018.Biodieselproductionthroughsulfuricacidcatalyzedtransesterificationofacidicoil:Technoeconomicfeasibilityofdifferentprocessalternatives.EnergyConvers.Manag. 174,639–648.

Gotcht,A.J.,Reeder,A.J.,McCormick,A.,2009.Studyofheterogeneousbasecatalystsforbiodiesel production.JUndergr.ChemRes8,22–26.

Habib,M.S.,Tayyab,M.,Zahoor,S.,Sarkar,B.,2020.Managementofanimalfat-basedbiodieselsupplychain undertheparadigmofsustainability.EnergyConvers.Manag.225,113345.

HaighK.F.,AbidinS.Z.,SahaB.,Vladisavljevi ´ cG.T.,2012.Pretreatmentofusedcookingoilforthe preparationofbiodieselusingheterogeneouscatalysis.In:StarovV.,GriffithsP.(eds.),UKColloids2011. ProgressinColloidandPolymerScience,vol.139.Springer,Berlin,Heidelberg.