https://ebookmass.com/product/valorization-of-fruit-

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Handbook of Grape Processing By-Products: Sustainable Solutions 1st Edition Galanakis

https://ebookmass.com/product/handbook-of-grape-processing-byproducts-sustainable-solutions-1st-edition-galanakis/

ebookmass.com

The Role of Alternative and Innovative Food Ingredients and Products in Consumer Wellness Charis M. Galanakis

https://ebookmass.com/product/the-role-of-alternative-and-innovativefood-ingredients-and-products-in-consumer-wellness-charis-m-galanakis/

ebookmass.com

Food Waste Recovery: Processing Technologies, Industrial Techniques, and Applications 2nd Edition Charis M. Galanakis

https://ebookmass.com/product/food-waste-recovery-processingtechnologies-industrial-techniques-and-applications-2nd-editioncharis-m-galanakis/

ebookmass.com

Pluralism

and World Order: Theoretical Perspectives and Policy Challenges Feng Zhang

https://ebookmass.com/product/pluralism-and-world-order-theoreticalperspectives-and-policy-challenges-feng-zhang/

ebookmass.com

The Science of Religion, Spirituality, and Existentialism

Kenneth E. Vail Iii

https://ebookmass.com/product/the-science-of-religion-spiritualityand-existentialism-kenneth-e-vail-iii/

ebookmass.com

High Growth Enterprises: The Role of Founder Characteristics and Venture Policies 1st Edition Mathew J Manimala

https://ebookmass.com/product/high-growth-enterprises-the-role-offounder-characteristics-and-venture-policies-1st-edition-mathew-jmanimala/

ebookmass.com

Hasta que la curiosidad nos vuelva gatos 1ª Edition Anaid Liddell

https://ebookmass.com/product/hasta-que-la-curiosidad-nos-vuelvagatos-1a-edition-anaid-liddell/

ebookmass.com

Wreckless

Katie Golding

https://ebookmass.com/product/wreckless-katie-golding-4/

ebookmass.com

Close Ties in European Local Governance: Linking Local State and Society 1st ed. Edition Filipe Teles

https://ebookmass.com/product/close-ties-in-european-local-governancelinking-local-state-and-society-1st-ed-edition-filipe-teles/

ebookmass.com

First Aid for the Basic Sciences. General Principles 3rd Edition Tao Le

https://ebookmass.com/product/first-aid-for-the-basic-sciencesgeneral-principles-3rd-edition-tao-le/

ebookmass.com

ValorizationofFruitProcessingBy-products

Thispageintentionallyleftblank

ValorizationofFruit ProcessingBy-products

Editedby CharisM.Galanakis

Research&InnovationDepartment,GalanakisLaboratories,Chania,Greece FoodWasteRecoveryGroup,ISEKIFoodAssociation,Vienna,Austria

AcademicPressisanimprintofElsevier 125LondonWall,LondonEC2Y5AS,UnitedKingdom 525BStreet,Suite1650,SanDiego,CA92101,UnitedStates 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom

Copyright©2020ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicormechanical,including photocopying,recording,oranyinformationstorageandretrievalsystem,withoutpermissioninwritingfromthepublisher. Detailsonhowtoseekpermission,furtherinformationaboutthePublisher’spermissionspoliciesandourarrangements withorganizationssuchastheCopyrightClearanceCenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions .

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher(otherthanasmaybe notedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroadenourunderstanding, changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusinganyinformation, methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationormethodstheyshouldbemindfuloftheir ownsafetyandthesafetyofothers,includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeanyliabilityforanyinjury and/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceorotherwise,orfromanyuseoroperationof anymethods,products,instructions,orideascontainedinthematerialherein.

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

ISBN:978-0-12-817106-6

ForInformationonallAcademicPresspublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: CharlotteCockle

AcquisitionEditor: NinaRosadeAraujoBandeira

EditorialProjectManager: KaterinaZaliva

ProductionProjectManager: NileshKumarShah

CoverDesigner: MarkRogers

TypesetbyMPSLimited,Chennai,India

1.Fruitprocessingby-productsas foodingredients1

SusanneStruckandHaraldRohm

1.1Introduction1

1.2Processingoffruitby-products2

1.2.1Pomaceprocessingconditions2

1.2.2Influenceofprocessingonpomace composition3

1.3Technofunctionalandphysical propertiesofprocessedfruitpomace4

1.3.1Pomaceasasourceofdietary fiberandbioactivecompounds4

1.3.2Roleofdietaryfiberinthehuman nutrition4

1.3.3Physicalpropertiesofprocessedfruit pomace5

1.4Applicationoffruitpomaceinbaked products6

1.5Pasta9

1.6Meatproducts10

1.7Conclusion12 References12

2.Apple17

SenkaVidovi ´ c,AleksandraTepi ´ cHorecki, JelenaVladi ´ c,Zdravko ˇ Sumi ´ c, AleksandraGavari ´ candAnitaVakula

2.1Apple17

2.2Applefruitprocessing18

2.2.1Applefruitjuiceproduction18

2.2.2Concentratedfruitjuiceproduction25

2.2.3By-productsofapplefruitjuice production26

2.2.4Otherappleprocessing—applecontainingfruitfiltertea productionandby-product remaining27

2.3Possibilitiesofapplicationofapple processingby-products28

2.3.1Pectin29

2.3.2Valorizationofappleby-products throughantioxidantsextraction32

2.4Conclusion37 References37 Furtherreading42

3.Apricot43

Estefanı´aGonza ´ lez-Garcı´a,Marı´aLuisaMarina andMarı´aConcepcio´nGarcı ´ a

3.1Introduction43

3.2Apricotkernel44

3.2.1Kerneloil44

3.2.2Kernel:skinandpresscake52

3.2.3Essentialoil55

3.3Otherapricotby-products56

3.3.1Pomace56

3.3.2Thinnedapricots58

3.3.3Blanchingwaterconcentrateand debitteringwaterconcentrate58

3.4Applicationofapricotby-products58

3.5Conclusionsandfuturetrends61 Acknowledgments61 References61

4.Avocado67

HueyShiLye,MeiKyingOng,LaiKuanTeh, ChewCheenChangandLooKeatWei

4.1Introduction67

4.2Nutritionalcomposition70

4.3Extractionofphytochemicals72

4.4Healthbenefits74

4.4.1Antioxidanteffect74

4.4.2Anticancer78

4.4.3Antidiabetic80

4.4.4Antiatherogenic81

4.4.5Antimicrobialeffect84

4.4.6Antiinflammatoryeffect86

4.5Industrialapplications88

4.6Conclusion89 References89 Furtherreading93

5.Berries95

PetrasRimantasVenskutonis

Abbreviations95

5.1Introduction96

5.2Compositionofberrypomace97

5.2.1Cellwallpolysaccharides, proteins,andminerals97

5.2.2Berrypomaceandseedoil99

5.2.3Phytochemicalcompositionand bioactivitiesofpomace102

5.3Processingofberrypomace108

5.3.1Postpressingpreparationofberry pomaceforprocessing108

5.3.2Extractionofvariousconstituents fromberrypomace109

5.4Applicationofberrypomaceproducts116

5.4.1Applicationsofdried berrypomace117

5.4.2Applicationsofberrypomace extracts118

5.4.3Encapsulationofpomace ingredients119

5.5Conclusion120 Acknowledgments120 References120 Furtherreading125

6.Chestnut127

DianaPinto,NairBraga,AnaMargaridaSilva, PauloCosta,CristinaDelerue-Matos andFranciscaRodrigues

Abbreviations127

6.1Introduction128

6.2 Castaneasativa by-products128

6.2.1Leaves129

6.2.2Flowers133

6.2.3Shells135

6.2.4Burs137

6.3Futureperspectives140

6.4Conclusion140 Acknowledgments141 References141

7.Citrusfruits145

DebajyotiKundu,MohanDas,ReddhyMahle, PrithaBiswas,SandipanKarmakarandRintu Banerjee

7.1Introduction145

7.2Citrusfruitwastegenerationand management146

7.3Valorizationofcitruswaste148

7.3.1Recoveryof phytochemicals/bioactive compounds148

7.3.2Recoveryofessentialoil151

7.3.3Recoveryofenergy152

7.4Othervalue-addedproducts157

7.4.1Productionofenzymes157

7.4.2Organicacidproduction159

7.4.3Dietaryfibersproduction159

7.4.4Productionofsinglecellprotein160

7.4.5Candypreparation160

7.5Bioeconomyconceptincitruswaste valorization161

7.6Futurescope162

7.7Conclusion162 References162 Furtherreading166

8.Mango167

C.H.Okino-Delgado,D.Z.Prado, MileneStefaniPereira,DafneAngelaCamargo, MelianeAkemiKoikeand LucianaFranciscoFleuri

8.1Introduction167

8.2Mangowaste169

8.3Mangopeel170

8.4Mangoseed172

8.5Mangowasteassubstrate174

8.6Prospectsandconclusion177 References177 Furtherreading181

9.Passionfruit183

PramoteKhuwijitjaru andKhwanjaiKlinchongkon

9.1Introduction183

9.2Passionfruitproduction184

9.3Pulpandjuiceprocessing185

9.4Animalfeeding185

9.5Valuablecomponentsfrompeel185

9.5.1Dryingofpeel185

9.5.2Pectinandpecticoligosaccharides186

9.5.3Dietaryfiber189

9.5.4Passionfruitpeelflour190

9.5.5Passionfruitpeelextract190

9.6Valuablecomponentsfromseed191

9.6.1Dryingofseed191

9.6.2Seedoil191

9.6.3PiceatannolandscirpusinB195

9.6.4Otherphenoliccompoundsand antioxidantactivities196

9.6.5Seedprotein196

9.6.6Antifungalprotein196

9.6.7Seedfiber197

9.7Conclusion197 References197

10.Pineapple203

TodorVasiljevic

10.1Introduction203

10.2Pineapplewasteutilization204

10.3Proteinutilizationfrompineapple waste—bromelainenzyme204

10.4Bromelainextractionstrategies209

10.5Membranefiltrationprocessfor bromelainextraction209

10.6Applicationofmembranetechnology inbromelainpurification213

10.7Configurationalconsiderations213

10.8Processingparametersconsiderations216

10.9Bromelainpurity217

10.10Valorizationofcarbohydrates218

10.10.1Insolublefibers—cellulose andhemicellulose218

10.11Solublefibers—pectinandgums218

10.12Simplesugars—productionof organicacids219

10.13Othervalue-addedproducts obtainedfrompineapplewaste219

10.14Conclusion220 References221 Furtherreading225

11.Pinkguava227

YingPingChang,KwanKitWoo andCharlesGnanaraj

11.1Introduction227

11.1.1Aboutpinkguava227

11.1.2Pinkguavaby-products228

11.2Functionalpropertiesand health-promotingeffectsofpinkguava phytochemicalconstituents229

11.3Possibleroutestoupgradepink guavaby-productscommercialization values231

11.3.1Phytochemicalextraction233 11.3.2Prebioticsingredients240 11.3.3Substrateforfermentation241

11.4Processingmethodtominimize thewasteafterextraction242

11.5Constraintsandchallengesin reutilizingpinkguavaby-products245 11.6Furtherresearchtofillthe knowledgegap247 References248

12.Pomegranate253

ShohrehSaffarzadeh-Matin

12.1Introduction253

12.1.1Polyphenolextractionof pomegranatewaste254

12.1.2Assessmentofextraction methodefficiency265

12.1.3Purificationandfractionation268

12.1.4Healthbenefits,safety assessment,andstabilityof pomegranatefruitextract270

12.1.5Concludingremarks272 References273

13.Strawberry281

IsidoroGarcı´a-Garcı´a, M.CarmenGarcı´a-Parrilla, InesM.Santos-Duenas,AlbertMas andAnaM.Canete-Rodrı ´ guez

13.1Introduction281

13.2Developmentofnewproducts285

13.3Usingstrawberriestoobtain fermentedproducts287

13.3.1Processdevelopmentand qualitycontrol287

13.3.2Biotransformationofstrawberry pure ´ eintowineandvinegar288

13.4Conclusions296 Acknowledgments296 References297 Furtherreading300 Index301

Thispageintentionallyleftblank

ListofContributors

RintuBanerjee DepartmentofAgriculturalandFood Engineering,IndianInstituteofTechnology Kharagpur,Kharagpur,India

PrithaBiswas SchoolofMedicalScienceandTechnology, IndianInstituteofTechnologyKharagpur,Kharagpur, India

NairBraga REQUIMTE/LAQV,InstitutoSuperiorde EngenhariadoPorto,InstitutoPolite ´ cnicodoPorto, Porto,Portugal

DafneAngelaCamargo Sa ˜ oPauloState University(UNESP),InstituteofBiosciences, Botucatu,Brazil

AnaM.Canete-Rodrı´guez DepartamentodeQuı´mica Inorga ´ nicaeIngenierı´aQuı´mica,Facultadde Ciencias,UniversidaddeCo ´ rdoba,Co ´ rdoba,Espana

ChewCheenChang DepartmentofChemicalScience, FacultyofScience,UniversitiTunkuAbdulRahman, Kampar,Malaysia

YingPingChang FacultyofScience,Departmentof ChemicalScience,UniversitiTunkuAbdulRahman, NegeriPerak,Malaysia

PauloCosta REQUIMTE/UCIBIO,DepartmentofDrug Sciences,FacultyofPharmacy,UniversityofPorto, Porto,Portugal

MohanDas DepartmentofAgriculturalandFood Engineering,IndianInstituteofTechnology Kharagpur,Kharagpur,India

CristinaDelerue-Matos REQUIMTE/UCIBIO, DepartmentofDrugSciences,FacultyofPharmacy, UniversityofPorto,Porto,Portugal

LucianaFranciscoFleuri SaoPauloStateUniversity (UNESP),InstituteofBiosciences,Botucatu,Brazil

Marı´aConcepcio ´ nGarcı ´ a DepartmentofAnalytical Chemistry,PhysicalChemistryandChemical Engineering,FacultyofScience,ChemicalResearch Institute“Andre ´ sM.delRı´o”(IQAR),Universityof Alcala ´ ,Madrid,Spain

IsidoroGarcı´a-Garcı´a DepartamentodeQuı´mica Inorga ´ nicaeIngenierı´aQuı´mica,Facultadde Ciencias,UniversidaddeCo ´ rdoba,Co ´ rdoba,Espan ˜ a

M.CarmenGarcı´a-Parrilla DepartamentodeNutricio ´ n yBromatologı´a,Toxicologı´ayMedicinaLegal, FacultaddeFarmacia,UniversidaddeSevilla,Sevilla, Spain

AleksandraGavari ´ c FacultyofTechnologyNoviSad, UniversityofNoviSad,NoviSad,Serbia

CharlesGnanaraj FacultyofScience,Departmentof ChemicalScience,UniversitiTunkuAbdulRahman, NegeriPerak,Malaysia

Estefanı´aGonza ´ lez-Garcı´a DepartmentofAnalytical Chemistry,PhysicalChemistryandChemical Engineering,FacultyofScience,ChemicalResearch Institute“Andre ´ sM.delRı´o”(IQAR),Universityof Alcala ´ ,Madrid,Spain

SandipanKarmakar XavierInstituteofManagement, XavierUniversity,Bhubaneswar,India

PramoteKhuwijitjaru DepartmentofFood Technology,FacultyofEngineeringandIndustrial Technology,SilpakornUniversity,NakhonPathom, Thailand

KhwanjaiKlinchongkon DepartmentofInnovation inFoodTechnology,CollegeofHealthSciences, ChristianUniversityofThailand,NakhonPathom, Thailand

MelianeAkemiKoike SaoPauloStateUniversity (UNESP),InstituteofBiosciences,Botucatu,Brazil

DebajyotiKundu DepartmentofAgriculturalandFood Engineering,IndianInstituteofTechnology Kharagpur,Kharagpur,India

HueyShiLye DepartmentofAgriculturalandFood Science,FacultyofScience,UniversitiTunkuAbdul Rahman,Kampar,Malaysia

ReddhyMahle DepartmentofAgriculturalandFood Engineering,IndianInstituteofTechnology Kharagpur,Kharagpur,India

Marı´aLuisaMarina DepartmentofAnalytical Chemistry,PhysicalChemistryandChemical Engineering,FacultyofScience,ChemicalResearch Institute“Andre ´ sM.delRı´o”(IQAR),Universityof Alcala ´ ,Madrid,Spain

AlbertMas DepartamentodeBioquı´micai Biotecnologı´a,FacultaddeEnologı´a,Universitat RoviraiVirgili,Tarragona,Espana

C.H.Okino-Delgado AgronomicEngineering,University CenterofRioPreto,Sa ˜ oJose ´ doRioPreto,Brazil

MeiKyingOng DepartmentofAgriculturalandFood Science,FacultyofScience,UniversitiTunkuAbdul Rahman,Kampar,Malaysia

MileneStefaniPereira SaoPauloStateUniversity (UNESP),InstituteofBiosciences,Botucatu,Brazil

DianaPinto REQUIMTE/LAQV,InstitutoSuperiorde EngenhariadoPorto,InstitutoPolite ´ cnicodoPorto, Porto,Portugal

D.Z.Prado Sa ˜ oPauloStateUniversity(UNESP), InstituteofBiosciences,Botucatu,Brazil

FranciscaRodrigues REQUIMTE/LAQV,Instituto SuperiordeEngenhariadoPorto,InstitutoPolite ´ cnico doPorto,Porto,Portugal

HaraldRohm ChairofFoodEngineering,Insituteof NaturalMaterialsTechnology,TechnischeUniversitat Dresden,Dresden,Germany

ShohrehSaffarzadeh-Matin DepartmentofChemical Technologies,IranianResearchOrganizationfor ScienceandTechnology(IROST),Tehran,Iran

InesM.Santos-Duen ˜ as DepartamentodeQuı´mica Inorga ´ nicaeIngenierı´aQuı´mica,Facultadde Ciencias,UniversidaddeCo ´ rdoba,Co ´ rdoba,Espana

AnaMargaridaSilva REQUIMTE/LAQV,Instituto SuperiordeEngenhariadoPorto,InstitutoPolite ´ cnico doPorto,Porto,Portugal

SusanneStruck ChairofFoodEngineering,Insituteof NaturalMaterialsTechnology,TechnischeUniversitat Dresden,Dresden,Germany

Zdravko ˇ Sumi ´ c FacultyofTechnologyNoviSad, UniversityofNoviSad,NoviSad,Serbia

LaiKuanTeh DepartmentofBiomedicalScience, FacultyofScience,UniversitiTunkuAbdulRahman, Kampar,Malaysia

AleksandraTepi ´ cHorecki FacultyofTechnologyNovi Sad,UniversityofNoviSad,NoviSad,Serbia

AnitaVakula FacultyofTechnologyNoviSad, UniversityofNoviSad,NoviSad,Serbia

TodorVasiljevic InstituteforSustainableIndustriesand LiveableCities,VictoriaUniversity,Melbourne,VIC, Australia

PetrasRimantasVenskutonis DepartmentofFood ScienceandTechnology,KaunasUniversityof Technology,Kaunas,Lithuania

SenkaVidovi ´ c FacultyofTechnologyNoviSad, UniversityofNoviSad,NoviSad,Serbia

JelenaVladi ´ c FacultyofTechnologyNoviSad, UniversityofNoviSad,NoviSad,Serbia

LooKeatWei DepartmentofBiologicalScience,Faculty ofScience,UniversitiTunkuAbdulRahman,Kampar, Malaysia

KwanKitWoo LeeKongChianFacultyofEngineering andScience,DepartmentofChemicalEngineering, UniversitiTunkuAbdulRahman,NegeriPerak, Malaysia

Preface

Theglobalfruitprocessingindustryhasbeengrowingsteadilyoverthelastfewyearsduetopopulationgrowth,consumers’eatingpatternstargetinghealthierproducts,andfinallyadvancesinsupplychainmanagementandproduction processes.Atthesametime,fruitprocessingresultsinsignificantamountsofby-productsthataretypicallygivenas animalfeedordischargedintotheenvironment.Thispracticecannotbecontinuedwithinthebioeconomyframework ofourtimes.Inparticular,theurgentneedforsustainabilitywithinthefruitindustryhasturnedtheinterestsofresearch towardinvestigatingthehandlingoftheseby-productsfromanotherperspective,forexample,byadaptingmore profitableoptions,utilizingcontainedantioxidants,etc.Subsequentlythereisaneedforanewguidecoveringthelatest advancesinthisdirection.

FoodWasteRecoveryGroup(www.foodwasterecovery.group ofISEKIFoodAssociation)hasorganizeddifferent traininganddevelopmentactionsinthefieldoffoodandenvironmentalscienceandtechnology,includingteaching activities(e-course,referencemodule,trainingworkshops,andwebinars),literaturematerials,experts’database,several newschannelsfordisseminationofknowledge,andanopeninnovationnetwork,withtheaimtobridgethegap betweenacademiaandthefoodindustry.Inaddition,thegrouphaspublishedbooksdealingwithfoodwasterecovery technologies,differentfoodprocessingby-products’valorization(e.g.,fromolive,grape,cereals,coffee,meat,etc.), sustainablefoodsystemsandsavingfood,sustainablewaterandwastewaterprocessing,innovationsinthefoodindustry andtraditionalfoods,nutraceuticalsandnaturalproductpharmaceuticals,andnonthermalprocessing,aswellasthetargetingoffunctionalcompoundssuchaspolyphenols,proteins,dietaryfiber,andcarotenoids.

Followingonfromtheseefforts,thecurrentbookaimstoindicatethealternativesolutionsfortheupgradingofprocessingby-productsofdifferentfruits,aswellasdenotingtheirindustrialpotentialasasourcefortherecoveryofbioactivecompoundsandtheirreutilizationindifferentsectors(e.g.,food,beverage,nutraceutical,andcosmetic industries).Theultimategoalistosupportthescientificcommunity,professionals,andenterprisesthataspireto developreal,high-scaleindustrialapplications.Itfocusesonthemostrecentadvancesinthefield,whilealsoanalyzing thepotentialofalreadycommercializedprocessesandproducts.Thebookfillstheexistinggapinthecurrentliterature byprovidingaguideforalltheinvolvedstakeholders,professionals,andtechnologistswhoareactiveinthefieldand aretryingtooptimizetheperformanceoffruitprocessingindustriesandreducetheirenvironmentalimpact.

Thebookconsistsof13chapters. Chapter1,Fruitprocessingby-productsasfoodingredients,introducesthesubject ofthebookbyprovidingashortoverviewontheprocessingandcompositionoffruits’pomace.Byhighlightingthe importanceofpomaceasanutritionallyvaluablematerial,thechapterreviewstheincorporationoffruitpomacein selectedfoods.Emphasisisespeciallygiventobakeryproducts,extrudedcerealproducts,pasta,andmeatproducts. Theremainingchaptersofthebookdealwithdifferentfruitprocessingby-productsinchaptersplacedin alphabeticorder.

Chapter2 dealswithapples.Applejuiceproductiongeneratesapproximately25%ofby-productsincludingpomace, peel,andseeds.Traditionalapplicationsofappleprocessingby-productstypicallyconcerncompostingorcrudefeed. Nevertheless,owingtoitshighcarbohydratecontent,applepomacecanbeusedasasubstratefortheproductionofvariousvalue-addedproductssuchasorganicacids,enzymes,andethanol.Theapplicationofapplepomaceintheproductionofbiscuitsandrelatedproductsduetoitshighpectincontentisalsoreported.

Chapter3discussestheby-products(mainlystone)ofapricotprocessing.Theapricotisastonefruitbelongingto the Prunus genushighlyconsumedworldwide.Theapricotkernelisagreatsourceofoil,mainlycomposedoffatty acids,especiallyunsaturatedfattyacid s.Thisoilalsopresentshighconcentrati onsoftriterpenoids,carotenoids,vitaminEactivecompounds,phytosterols,andpolyphenols.Apricotkernelsarealsoasourceofproteins,peptides,and essentialoil.

Chapter4 dealswiththenutritionalprofiles,theextractionofphytochemicals,andtheindustrialapplicationsofavocadoanditsby-products(seed,pulp,andpeel).Avocadohasbeenrecognizedasanutritionallyvaluabletropicalfruit thathasavarietyofhealth-promotingeffectsandnutrients.Paststudieshaverevealedthatavocadopossesses

antioxidant,anticancer,antidiabetic,antiatherogenic,antihypertensive,antiinflammatory,andantimicrobialeffects. Wholeavocadoanditsderivativeshavebeenusedinvariousindustriesasamainingredientandhavebeenprocessed intoanumberoffoodproductsandskincareproducts,whileavocado’sprocessingby-productshavenotbeenmuch investigatedyet.

Chapter5reviewstheresultsofinvestigationsconcerningpomacefromberries.Berriesareamongtherichest sourcesofhealth-beneficialphytochemicals,andtheircultivationandconsumptionaresteadilyincreasing.Juiceproductionfromberriesgenerateslargeamountsofpresscake(pomace),aby-productofberryprocessing,whichretains largefractionsofvariousberrycomponents,includingvaluablephenoliccompounds,seedoils,dietaryfiber,minerals, andothers.Currently,considerablequantitiesofpomacearediscardedaswaste,causingboththelossofvaluablenutrientsandenvironmentalpollution.Itisevidentthatberrypomaceshouldbeusedmoreefficiently,forexample,forthe recoveryofvaluableconstituentsandthedevelopmentofingredientsforhumannutritionandotherapplications.

Duringchestnutprocessing,alargeamountofwastematerialisgenerated. Chapter6 providesknowledgeonthe typesofchestnutby-productsproduced(e.g.,leaves,flowers,shellsandburs),theirchemicalcompositions,andbiologicalactivities,priortodiscussingtheirpossibleapplicationsinthepharmaceutical,food,orcosmeticssectors.

Wastefromthecitrusprocessingindustry,generatedafterjuiceextraction,comprisesabout50%ofthewetmassof citrusfruits,ofwhichabout50%ispeelwaste.Withtheincreasingsizeofthecitrusindustry,colossalvolumesof wastearebeingreleasedconstantlyintotheenvironment. Chapter7 highlightsthevalorizationofcitruswastethrough value-addedproductrecoveryandenergyproduction,whichisgainingmoreimpetusundertheumbrellaofthebiobased economy.

Chapter8 dealswiththemango,whichisamongthemostconsumedfruitsworldwide.Indeedtheconsumptionof processedmangoproductshasgrown,andconsequentlythegenerationofmangowastehasalsogrown,sincethepulp (themainproduct)correspondstoapproximatelyhalfofthefruitmass.Mangoby-productscanbeusedbythefinal consumerorasfoodingredientsindiversesegmentssuchasfoods,pharmaceuticals,finechemicals,cosmetics,cleaning products,andpersonalhygieneproducts.

Chapter9 discussesthevalorizationofpassionfruitby-products,whichhaveattractedmanufacturersandresearchers worldwideduetothefactthattheycontainvaluableandhealth-beneficialcomponents.Currentby-productvalorizing schemesthathavebeenalreadycommercializedincludetheextractionofseedoilandthefurtherfractionationofunsaponifiablefractionforcosmeticpurposes.Inaddition,seedextractscontainingfunctionalphenoliccompounds,piceatannol,andscirpusinBarealsointhemarket.Atthesametimeanumberofresearchworksonthepeelhaverevealed variouspossibilitiesfortheextractionofpectinandotherbioactivecompounds.

Chapter10 focusesontheextractionofvaluablecompoundsfrompineappleon-farmandfromprocessingwastefor foodandtherapeuticsapplications.Anemphasisisgiventomoreenvironment-friendlyandcommerciallyviabletechnologies—mainlymembrane-basedextractiontechniques.Thehighcarbohydratecontent(55%)andpresenceofa highlyvaluableenzyme,bromelain,inpineapplewastemakesitanappropriatesubstrateforasimpleextractionofthese valuablecompoundsorfeasiblebioconversionsintoxylitol,xylooligosaccharides,lacticacid,succinicacid,andothers, whichallhavepotentialapplicationsinthefoodindustry.

Guavaisapopulartropicalfruiteateneitherfreshorinapreservedorprocessedformanditisalsoagoodsource ofdietaryfiberandnaturalantioxidantcompounds.Thefleshyedibleportionofguavafruitonlyconstitutesabout50% ofthewholefruit,whilethepeel(20%)andseedcore(30%)aretakentoalandfillsiteaswaste. Chapter11 discusses possibleroutestoupgradethecommercialvaluesofpinkguavaby-productsbyapplyingdifferentextractiontechniques torecovervaluablephytochemicals.Themanufacturersofprocessedguavamayincludeby-productsprocessinginone oftheirproductionlinesinordertogeneratediverseproductsoringredientswithina“zero-waste”conceptandto achieveamoresustainableapproach.

Chapter12 providesanupdatedoverviewofthepolyphenolicextractionofpomegranatewaste,includingvarious extractionprocessvariables,conventionalandnonconventionalextractionmethods,andextractionprocessoptimization. Additionally,thepurificationandfractionationofpolyphenolicextracts,includingsmall-scaleisolation,selective adsorption desorption,andmembranefiltrationprocessarecovered,too.Furthermore,thehealthbenefits,safety assessments,andimprovementsinstabilityoftheextractsarereviewed.

Thestrawberry’sinstabilityinseasonalmarkets,highperishability,andstringentqualitycriteriacanleadtosubstantialsurpluseswithhighlyadverseimpactsonsocialandeconomicconditionsintheproductionareas,andalsoonthe environmentbytheeffectofsuchsurplusesconstitutinghighlypollutingwaste.Chapter13discussestheproductionof newbeveragesandcondimentsbymixingtwoessentialingredientsobtainedinparallelbythebiotransformationof strawberrypure ´ e.Pure ´ ecanbeusedtoobtainstrawberryvinegarthroughalcoholicfermentationandsubsequent

Preface xiii

acetification,aswellasgluconicacidbytheselectivebioconversionofglucosewhilepreservingthefructosecontentof thesubstrate.

Inconclusion,thisbookaddressesresearchers,consultants,andnewproductdevelopersworkinginthefoodand fruitprocessingindustry.ItcouldbeutilizedbyUniversitylibraries,Institutes,andAgenciesworldwideasatextbook andancillaryreadinginundergraduateandpostgraduatelevelmultidisciplinecoursesdealingwithagriculture,bioresourcetechnology,andfoodscience.Atthispoint,Iwouldliketothankalltheauthorsforacceptingmyinvitationto contributetothisbook.Theiradaptiontoeditorialguidelinesandproject’stimelinearehighlyappreciated.InfactI considermyselffortunatetohavehadtheopportunitytocollaboratewithdifferentinternationalexpertsfromAustralia, Brazil,India,Iran,Lithuania,Malaysia,German,Portugal,Spain,andThailand.IwouldalsoliketothanktheacquisitioneditorsNinaBandeiraandNancyMaragioglio,thebookmanagerKaterinaZaliva,aswellasElsevier’sproduction teamfortheirassistanceduringeditingandthepublicationprocess.Finally,Ihaveamessageforallofyou,thereaders. Collaborativebookprojectscontainhundredsofthousandsofwordsandthereforetheymaycontainerrorsorgaps.I willwaitforyourinstructivecommentsorevencriticism,sopleasedonothesitatetocontactmeinordertodiscuss anyissuesregardingthevalorizationoffruitprocessingby-products.

CharisM.Galanakis1,2

1Research&InnovationDepartment,GalanakisLaboratories,Chania,Greece, 2FoodWasteRecoveryGroup, ISEKIFoodAssociation,Vienna,Austria

Thispageintentionallyleftblank

Chapter1

Fruitprocessingby-productsasfood ingredients

SusanneStruckandHaraldRohm ChairofFoodEngineering,InsituteofNaturalMaterialsTechnology,TechnischeUniversitatDresden,Dresden,Germany

ChapterOutline

1.1 Introduction1

1.2 Processingoffruitby-products2

1.2.1Pomaceprocessingconditions2

1.2.2Influenceofprocessingonpomacecomposition3

1.3 Technofunctionalandphysicalpropertiesofprocessed fruitpomace4

1.3.1Pomaceasasourceofdietaryfiberandbioactive compounds4

1.1Introduction

1.3.2Roleofdietaryfiberinthehumannutrition4

1.3.3Physicalpropertiesofprocessedfruitpomace5

1.4 Applicationoffruitpomaceinbakedproducts6

1.5 Pasta9 1.6 Meatproducts10 1.7 Conclusion12 References12

Inmanycases,anddependingonthetargetcommodity,theprocessingoffruitsresultsincertainamountsof by-products.Therespectivequantitiesareclosetozerowhen,forexample,berriesareprocessedtojam,butmaybe around5% 10%whenitcomestopeelsofapplesorpearsthatareusedfortheproductionoffruitsauces,and 20% 30%whenjuiceisextractedfromtherawmaterial.Sustainableandintegratedvaluechainmanagementcallsfor afurtheruseoftheseby-products,commonlydenotedaspomace,toavoidtheirloss.Potentialbutuninspiredusesare assoilfertilizer,asanimalfeed,orassubstrateforbioenergygeneration.Evenforthesetypesofutilization,limitations havetobeconsideredbecauseofthehighacidityofthepomace,itshighcontentofphytochemicals,andthelow amountofdigestibleenergy.Recyclingmethodsthataddvaluetofruitprocessingresiduesarethereforeofgreatinterest,anditcanbeexpectedthattheoverallprofitfromfruitprocessingwillbeincreasedbyanefficientandsustainable wastestreammanagement.Innovativeutilizationmethodsmustthereforeaddresstheusabilityoffruitprocessingresiduesasvalue-addingfoodingredients,eitherasawholeoraftertheextractionofhigh-valuecompounds.

Dependingontherawmaterial,residuesfromfruitprocessingmaycontainhighamountsofbioactivecompounds, includingdietaryfiber,whichthereforemakestheseresiduesanattractivesourceofnutrients.Dietaryfiberrefersto polymericcarbohydrateswithatleast10monomericunitswhicharenotdigestedinthehumansmallintestine.They eitherdissolveinwater(solubledietaryfiber)andaremetabolizedinthelargeintestine,ortheyareinsolubleand thereforemainlyexcreted(Viebkeetal.,2014).Incomparisontofiberfromcereals,theamountofsolubledietaryfiber infruitpomaceissignificantlyhigher(Sudha,2011).Manyhealth-promotingeffectshavebeenattributedtothese bioactivecompounds.Someofthesethathavealreadybeenreportedarethereductionofriskofcardiovasculardiseases andcancerthroughtheirantioxidantandantiinflammatoryactivitiesthat,inturn,reduceoxidativestress(Basuetal., 2010;Mazzonietal.,2016;Rodriguez-Mateosetal.,2013),andthemodulationofintestinalmicrobiota(Vendrame etal.,2011). Koutsosetal.(2015) summarizedinvitro,animal,andhumaninterventionstudiesthatanalyzedtheinfluenceofapplecompoundsongutmicrobiotaandontherisksofcardiovasculardiseases.Theyconcludedthatsignificant effectsareevidentwithrespecttolipidmetabolism(i.e.,reductionintotalcholesterol),andwithrespecttometabolites producedinthegut. Teixeiraetal.(2014) focusedonwinemakingby-productsandreviewedthebiologicalactivityof

ValorizationofFruitProcessingBy-products.DOI: https://doi.org/10.1016/B978-0-12-817106-6.00001-0 © 2020ElsevierInc.Allrightsreserved.

functionalcompoundssuchasphenolicacids,flavonoids,andstilbenes.Asmanyphenoliccompoundsarelocatedin theskinandseedfractionsoffruits,therespectiveby-productsarerichinstilbenesandflavonoids.Someofthelatter, namelytheanthocyanins,areresponsibleforthecoloroffruitsandtheirhighantioxidantcapacity(Larozeetal.,2010). Consequently,theincorporationofbioactivecompoundsfromfruitprocessingresiduesinfoodsincreasesthesupplyof valuablenutrients.Forthatthedevelopmentofattractiveproductsisnecessary,asisthecommunicationoftheproposed effectstotheconsumer.

1.2Processingoffruitby-products

1.2.1Pomaceprocessingconditions

Theconventionalprocedurefortheproductionoffruitjuicefrom,forinstance,apples,pears,ordifferentberryvarieties usuallystartsbywashingtherawmaterialsandremovingforeignbodies.Itthencomprisesthecrushingoffreshor frozenfruitstomash,heatingthemashto40 C 50 Cand,inmanycases,treatingthemashwithdepectinizing enzymes(pectinesterases,polygalacturonases,and/orpectinlyases)foraperiodofapproximately1 3h.Thishelpsto breakdowncellwallstructuresandtodisruptthehighlyviscouspectingelthatformsduringmashing(Hilzetal., 2005),sothatjuiceyieldduringsubsequentpressingisenhancedby1% 3%.Additionally,morepolyphenolsare extractedwiththejuicewhich,especiallyinthecaseofdarkfruits,leadtoamoreintensecolorthatisfrequentlyassociatedwithahigherjuicequalitybytheconsumer.Thenextstepisseparatingthejuicefromthesolidcellmaterialsby usingbeltpresses,basketpresses,orBucherhorizontalpresses,theselectionofwhichlargelydependsontherequired capacity.Forinstance,beltpressesaremoreversatilebutasevereriskofjuiceoxidationmustbeconsidered. Subsequentlythejuiceisdecloudedbydiskstackordecantercentrifugesandfinallypasteurizedtoassureanappropriateshelflife.Inthecaseofcitrusprocessing,thetechnologicalschemeissomewhatdifferent:themostimportantstep istherecoveryofthejuicefromthewholefruit,realizedbyextractorswithdifferentworkingprinciples.Remnants fromtheprocessingofdifferenttypesofcitrusfruits—thesearemainlyusedfortheproductionofcitruspectin(Wang etal.,2015)—willnotbeconsideredfurtherinthischapter.

Thepressingresiduesthatremainafterfruitextractioncontain50% 80%moisture,andareconsequentlyhighly susceptibletowardmicrobialspoilage,especiallybyyeastsandmolds.Factorsthatcontributetotheresidualmoisture contentofthepomaceare,amongothers,thefruitvarietyitself,anydepectinizationofthemash,andtheprocessing conditionsduringpressing(method,pressure).Inthecaseswheretheremainingpomaceisconsideredforfurtherusein humannutrition,immediateprocessingtoreducepomacemoistureisessential.Recentreviewsrelatedtopomace utilizationcoveradvancesinpectinproduction(Adetunjietal.,2017;Grassinoetal.,2018),theuseoffruitbyproductsasediblefilms(Otonietal.,2017),theuseoftheseby-productsasnovelfunctionalingredientsforfoodsand nutraceuticals(Laietal.,2017;Quilesetal.,2017;Schieber,2017;Sharmaetal.,2016),theextractionandanalysisof thepolyphenols(Strucketal.,2016c),butalsotheapplicationasheavymetalchelatingagentsforwastewatertreatment (Renuetal.,2017).Becauseofitscontentofapproximately15%,thetraditionalutilizationofapplepomaceisforthe productionofrawpectin.Inbrief,hotacidicextractionofsolublematerialsisfollowedbytheirconcentrationandthe subsequentpectinprecipitationandpurification.

Thecompositionofberrypomacelargelydependsontheberrycultivar.Inblueberries,themassfractionsforskin andseedsare19%and1.5%,respectively(LeeandWrolstad,2006).Afterjuiceextraction,thepomacealsocontains residualstems,andsomewoodenpartsandleaffragmentsremainingfromharvesting.Forblackcurrantpomace,these constituentsaccountforapproximately6%ofthefreshmass,whereasseedswerereportedtocomprisethemain fraction(i.e.,55%)ofthedriedpomace(Hilzetal.,2005;SojkaandKrol,2008).Fortheproductionofanonperishable berrypowderintendedtobebroughtbackintothefoodvaluechain,themostimportantprocessingstepisimmediate dryingafterjuicepressing,followedbymillingandfractionation.Potentialmethodsforpomacedryingincludeconventionalhot-airconvectiondrying,low-temperaturevacuumdrying,freeze-drying,infrareddrying,andmicrowavedrying (thelattertwoareoftencombinedwithconvectiondryingundervacuum).Convectiondryingoffruitpomaceisusually performedinatemperaturerangeof50 C 80 Catambientpressure,oratreducedtemperatureandpressure(e.g., Requeetal.,2014; Sojkaetal.,2013).Processingconditionsduringdryingexhibitasignificantinfluenceonproduct characteristicssuchasappearance,color,andporosity,andalsoonthecontentofbioactivecompounds. Garauetal. (2007) observedadecreasedwaterretentioncapacity,andreducedfatadsorptionandsolubilitywithincreasingdrying temperatureofby-productsfromorangeprocessing.IntheproductionofAroniapowderfromjuice,convectiondrying resultedinamoreintenseanddarkercolorofthepowderthanfreeze-dryingorspray-drying(Horszwaldetal.,2013). ZielinskaandMichalska(2018) comparedmoisturediffusioncoefficientsobtainedbythementionedtechniques,and

reportedthelowestdegradationofbioactiveconstituentswhenmicrowave-assisteddryingwasapplied.Microwave radiationinducesthedevelopmentofthinporesinthesample,sothatmoisturereleaseisfacilitated,dryingtimeis decreased,andproducttextureisaltered(Bohmetal.,2006).Dependingonthecompositionandonfurtherrequirements,thedriedmaterialistheneithersubjectedtomilling—inthiscase,theseedsremaininthematerial—oritisseparatedbysievingpriortothemillingstep.Thisaffectsthefatcontentofthepomace;millingwithseedsishelpfulin increasingthebeneficialpropertiesofberrypowderastheseeds’breakdownliberateshealth-promotingcompounds (thatarenormallyexcretedundigestedinsidethehardseeds; Helbigetal.,2008),butalsoforitspotentialfieldof application(Reissneretal.,2019).Bymeansofmicromilling Mayer-Miebachetal.(2012) demonstratedanenhanced extractabilityofphenoliccompoundsfromchokeberrypomaceandanimprovedantioxidantcapacityoftheresulting nanosizedmaterial.Theparticlesizeofdietaryfiberpowderisalsoknowntoinfluenceitshydrationproperties,asa decreasedparticlesizeisusuallylinkedtoalowerwater-bindingcapacity;however,dependingontheresulting particlesizedistribution,contraryeffectshavealsobeenobserved.Afinalprocessingstepcouldthereforebefractionation,ortheseparationoftheseedswiththeaimofusingthemforthesubsequentextractionofseedoil(Abrahamsson etal.,2015).

1.2.2Influenceofprocessingonpomacecomposition

Methodsandconditionsappliedduringfruitprocessingsignificantlyinfluencethecompositionoftheremainingpomace anditsfunctionalandtechnofunctionalproperties.Ithasalreadybeenshownthatprocessingusuallydoesnotchange thecontentbutmayaffectthephysiologicalfunctionalityofthefiberinthesmallorlargeintestine.Theunderlying changesindietaryfibercompositioncanbeinducedbyhydrolyticenzymesorbychemicaldegradationthatis,for example,triggeredbythethermalimpact.Amolecularmassreductionofdietaryfibercomponentsbychemical degradationisresponsibleforaviscositydecreaseandareducedhydrationcapacity,andchangestheirmetaboliceffects (Nyman,2003).Theinfluenceofthermalenergyoncellwallmaterialmayinducelignindepolymerizationand thereforetheformationoffreehydroxylandcarbonylgroups(Waweretal.,2006).Enzymaticmashtreatmenthasbeen showntoincreasetheswellingcapacitybuttodecreasethewater-bindingcapacityofmilledpomace(Albaetal.,2017; Kosmalaetal.,2010).Thiswasattributedtothefactthatdepectinizingenzymesdegradepartsofthecellwallfragmentsandhenceloosentheirstructure.Phenoliccompoundsarealsoinfluencedbyprocessingconditions,either becausetheydecomposeathighertemperature( . 90 C),orbecausetheybecomemoreeasilyextractableafterenzymatictreatment(Holtungetal.,2011;Koponenetal.,2008).

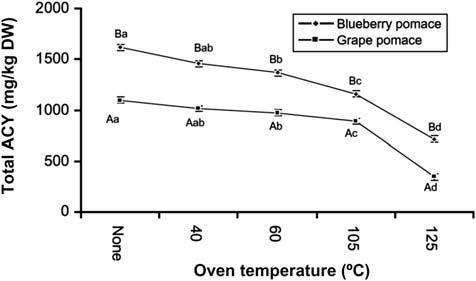

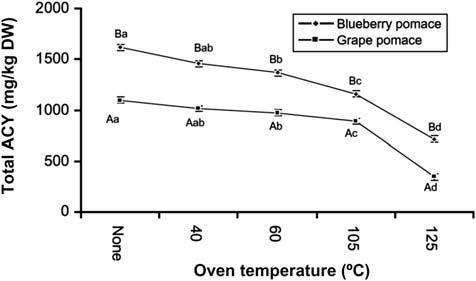

Usingblueberryandgrapepomaceasdemonstrationobjects, Khanaletal.(2010) analyzedtheinfluencesofdrying temperatureandtimeandshowedthatprocyanidinandanthocyanincontentsdidnotchangewhenthepomacewas warmedto40 C,butheatingtoabove60 Creducedtherespectivecontents;thehighestlossofanthocyanins(52%) wasobservedaftersubjectingthepomaceto125 Cinaforced-convectionoven(Fig.1.1).Heatingofchokeberrypure ´ e upto100 Cfor15minhadnosignificantinfluenceonitsprocyanidincontent;itseemsthatmoisturecontentand dryingmethodandtimearetheprominentfactorsthatinfluencepolyphenoldegradationbuttheextractabilityof

FIGURE1.1 Effectofheatingtemperatureinaforced-airovenontotalanthocyanincontent(mgcyanidin3-glucosideequiv./kgdrymatter)of blueberryandgrapepomace.Eachdatapointindicatesmeans 6 SEM.Datapointswithdifferentuppercaselettersindicatesignificantdifferences (P , .05)betweengrapeandblueberrypomace,whilethosewithdifferentlowercaselettersindicatethedifferences(P , .05)causedbydifferent heatingconditionswithineachpomacetype. FromKhanal,R.C.,Howard,L.R.,Prior,R.L.,2010.Effectofheatingonthestabilityofgrapeand blueberrypomaceprocyanidinsandtotalanthocyanins.FoodRes.Int.43,1464 1469,withpermissionfromElsevier.

polyphenoliccompoundsalsohasaninfluence(Mayer-Miebachetal.,2012;Whiteetal.,2011).Extrusionwasalso reportedtoaffectthepolyphenolscontentofpomace. Khanaletal.(2009) showedareductionofthetotalamountof anthocyaninsinblueberrypomaceof33% 42%,andanincreaseofmonomericanddimericprocyanidinswhichare moreeasilyabsorbedinthehumanintestineandthereforeexhibithigherbioactivity.Accordingto Whiteetal.(2010), theeffectsofextrusiontemperaturedependonthechemicalcharacteristicsoftherespectivecompounds:chemical degradationisanissuebut,inthecaseofmoreheat-stablecompounds,suchasflavonols,thedisruptionofthepomace matrixthatfacilitatestheimprovedextractabilityofthemoleculesshouldalsobetakenintoaccount.

Anotherfactorthatmayaffectthecontentofbioactivecompoundsinpomaceisenzymaticdegradationthatmay occurafterpressingbyendogenousenzymessuchaspolyphenoloxidaseandglucosidase.Polyphenoloxidaseismainly responsibleforcolorchangescausedbythedegradationofphenoliccompounds,butactivityoftheseenzymesvaries considerablybetweendifferentfruits.Additionally,flavonolshavebeenreportedtobelesssusceptibletoenzymatic degradationthananthocyanins(Skredeetal.,2000).Blanchingmaybeconsideredfortheinactivationofendogenous enzymes;however, Whiteetal.(2011) statedthatinthecaseofcranberriesblanchingresultedinasignificantlossof anthocyanins.

1.3Technofunctionalandphysicalpropertiesofprocessedfruitpomace

1.3.1Pomaceasasourceofdietaryfiberandbioactivecompounds

Theresiduesfromfruitjuiceprocessingcontainhighamountsofdietaryfiberandbioactivecompounds.Dietaryfiber referstoplantcellwallsconsistingofcomplexpolysaccharides,mainlycellulose,hemicellulose,andpecticsubstances thatareresistanttopancreaticenzymes.Asalreadymentioned,bioactivecompoundshavebeenlinkedtoanumberof health-promotingeffects.Forinstance,ariskreductionwithregardstocardiovasculardiseasesandcancerviatheir antioxidantandantiinflammatoryactivitythat,inturn,reducesoxidativestresshasbeenaddressed(ChuandLiu,2005; Mazzonietal.,2016). Khanaletal.(2009) pointedoutthat25% 50%ofblueberryprocyanidinsremaininthepomace afterjuiceextraction,indicatingalossofvaluablenutritionalcompoundswhenpomaceleavesthefoodchain. Additionally,manyphenoliccompoundslocatedintheskinsandseedsareretainedinthepomace(Whiteetal.,2010). Pomacesfromdifferentfruitvarietiesweresuggestedaspossiblesourcesofdietaryfiberforhumannutrition.For instance,applepomacehasawell-balancedproportionofsolubleandinsolubledietaryfiberandcontainsbioactive compoundssuchaspolyphenols,flavonoids,andcarotenes.Dependingontheapplevariety,thefibercontentofthe pomacevariesfrom35.5g/100gdrymatterforGoldenDelicioustoashighas89.9g/100gforLiberty(Figuerola etal.,2005;Sudha,2011).By-productsfromcitrusjuiceproductionalsohaveahighpotentialasfoodingredientssince theyarerichinpectin,afoodadditiveofinterestbecauseofitsspecificgellingproperties.Someorangevarieties suchasValenciahavesubstantialdietaryfibercontent(64.3g/100gdrymatter),whileotherssuchasNavelor Salustianahavelowerdietaryfibercontent(35.4 36.9g/100g; Figuerolaetal.,2005; Grigelmo-MiguelandMartı ´ nBelloso,1999).

Grapepomaceisarichsourceofbioactivecompoundssuchasphenoliccompoundsandfattyacids.Thefiber compositionofgrapepomacemaybeinfluencedbyvariety,culturecharacteristics,andwineprocessingprocedures (Ioraetal.,2015).Theusualrangeofdietaryfiberingrapepomaceis50 75g/100gdrymatter.Pomacesofpeach (Grigelmo-MiguelandMartı´n-Belloso,1999),plum(Milalaetal.,2013),grapefruit(Wangetal.,2015),guava(Matias etal.,2005),kiwi,andpear(Martin-Cabrejasetal.,1995)werealsosubjectofscientificstudies.

1.3.2Roleofdietaryfiberinthehumannutrition

Althoughfiberisnothydrolyzedinthehumansmallintestine,aprotectiveeffectofdietaryfiberagainstthediseases thatarepredominantinWesterndevelopedcountriesiswellknown,forinstanceinconnectionwithcolorectalcancer, coronaryheartdisease,obesity,anddiverticulardisease.Fiberconsumptionisassociatedwithareductionintotalserum cholesterolandlow-densitylipoproteincholesterollevels,andthemodificationofglycemicandinsulinemicresponses (Blackwoodetal.,2000).Accordingtothephysical,functional,andchemicalproperties,dietaryfibercanbeclassified assolubleorinsolubledietaryfiber.Solubledietaryfiber,suchaspectins,gums,inulin-typefructans,andsomehemicelluloses,formsviscousgelsinwaterandcanbefermentedbymicrobiotainthelargeintestine.Insolubledietaryfiber thatleavestheintestineinanalmostunchangedformcompriseslignin,cellulose,andsomehemicelluloses(Lattimer andHaub,2010).

Somephysicochemicalpropertiesofdietaryfiberarelinkedtotheirgastrointestinalfunction.Theseproperties includeviscosity,water-andfat-bindingcapacities,gelformation,swelling,thebindingoforganicmolecules,and fermentation(Viuda-Martosetal.,2010).Anincreaseofviscosityinthegastrointestinaltracttriggeredbydietaryfiber consumptionslowsthetransitvelocitythroughthesmallintestineandthereforeprolongsgastricpassage.Dietaryfiber hastheabilitytoretainwaterduetoitshydrophilicnature.Thereforestoolbulkingisincreasedandsubsequentlythe volumeoftheintestinalcontentsisincreasedaswell.Thiswilllowertheconcentrationofnutrientsintheaqueous phaseandslowdowntheirabsorption.Bindingofbileacidsbydietaryfiberisthemechanismmostprobablyresponsiblefortheirhypocholesteremiceffect(Blackwoodetal.,2000;Schneeman,2001).

Concerningcarbohydratemetabolism,dietaryfiberaffectstherateandextentofstarchdegradationandglucose absorption.Theeffectofdietaryfiberinthatcontextmightresultfromthealterationofviscosityinthesmallintestine, thusleadingtoareducedaccessibilityofstarchgranulesbyamylases(Brennan,2005).Invitrodigestionmethodsthat mimictheoral,gastric,andsmallintestinalphaseshelpinthestudyofgastrointestinalbehavioroffoods.Bydoingso, theinfluenceofdietaryfiberontheglycemicindexoffoodscanbeanalyzed(Minekusetal.,2014).

Therecommendedfiberintakeforadultsis25g/dayfora2000kcaldiet,whereastheaveragedietaryfiberintake foradultsvariesfrom16to29g/dayforcountriesoftheEuropeanUnion(EFSA,2010).Manycommonlyconsumed foodsarelowindietaryfiber;higherfibercontentscanbefoundinfoodssuchaswholegraincereals,legumes,and driedfruits(Slavin,2013).Inthiscontexttheadditionofprocessedfruitpomacetofoodformulationsseemspromising toaidinincreasingthedietaryfibercontentoffoodsandthusprovideadditionalhealthbenefits(Rohmetal.,2015).

1.3.3Physicalpropertiesofprocessedfruitpomace

Thewater-bindingcapacityofdietaryfiberisofconsiderableimportanceforfoodapplicationsbecauseitimpactsnot onlythephysiologicalfunctionalityofthefood,butalsotheproductyield,ingredientfunctionality,andshelflife (Roselletal.,2009).Asregardsphysiologicalfunctionality,thewater-bindingcapacitymaybeusedtopredictthe abilityoffibertoincreasestoolweightandtheinductionofcolonicfermentation(Auffretetal.,1994).Inaddition,the quantificationofrespectivepropertiesallowsdrawingofconclusionswithrespecttopossiblefoodapplications.For example,fiberwithahighfat-bindingcapacitymightbebestappliedtostabilizefatinemulsion-basedproducts, whereasahighwater-bindingcapacitycanbelinkedtodecreasingsyneresisinhydrogels,oralteringfoodviscosityand texture(Eimetal.,2008;McKeeandLatner,2000).

Hydrationpropertiesareusuallycharacterizedeitherbythewater-bindingcapacitywhichisdeterminedbyapplying externalstress(centrifugation,compression,suctionpressure),thewater-holdingcapacitywhichisdefinedaswater uptakeatagivenexternalchemicalpotentialofwaterwithoutapplicationofexternalstress(sorptionisotherms, Baumannapparatus,freezingpointmethod),ortheswellingcapacity,definedasthevolumeoccupiedbyadefined amountofhydratedfiber.

Waterinafoodmatrixisretainedbycapillaryforces,orbyhydrogenbondstootherfoodmolecules.Thereforethe foodmatrixandthephysicochemicalpropertiesofthefiberwillstronglyinfluencewaterbinding.Differencesinwater bindingbetweendifferentfibersourcesareratherinfluencedbyfiberstructureandshapebut,toacertainextent,also bychemicalcomposition(Lo ´ pezetal.,1996;Roselletal.,2009).Fiberwithahighamountofpectin-containing primarycellwallsandaloosenetworkofpolysaccharideshasenhancedhydrophilicandelasticproperties;thisis,for instance,trueforsugarbeetorcitrusfiber.Conversely,fiberwithahighnumberofsecondarycellwallsrichincrystallinecellulosehaspoorhygroscopicpropertiesduetotheirrigidstructure(e.g.,wheatbranandpeahulls; Auffretetal., 1994).Fordifferenttypesofdriedandmilledberrypomace, Reissneretal.(2019) showedthatwater-bindingand swellingcapacitiesdiffersignificantlybutareatleastpartiallyrelatedtothecontentofsolubledietaryfiber(Fig.1.2).

Themethodofpreparationofthefiberalsoplaysanimportantrole.Forinstance,fiberdriedundermoresevere conditionsisknowntohavealowerwater-bindingcapacity. Akteretal.(2010) showedthatthepretreatmentoffruit by-productsby,forexample,washingwithhotandcoldwaterincreasesthehydrationpropertiesofprocessedpowders frompersimmonpeels.Fiberstructureandconsequentlyhydrationpropertiesmaybealteredbycookingorautoclaving, extrusioncooking,highhydrostaticpressure,drying,microwave-assisteddrying,vacuumdrying,andchemicaltreatment(e.g., ˇ Soronja-Simovi ´ cetal.,2016; Talensetal.,2017; Tejada-Ortigozaetal.,2017).

Water-bindingandswellingcapacitiesoffruitfiberusuallydecreasewithdecreasingparticlesize,mainlybecause grindingcausesthematrixtocollapseandreducesthespaceavailableforfreewater.Apartfromparticlesize,grinding alsochangesthephysicalstructureofthematrixthataffectswaterbinding(Auffretetal.,1994).Theinfluenceof particlesizeonwater-holdingcapacityisnotthatstrictsince,apartfrommatrixcollapse,othereffectsmaybecome prominent.Fiberwithahighcontentofmicrocrystallinecellulosehasahighermechanicalresistancesothatgrinding

FIGURE1.2 Water-bindingcapacity(g/g,blackbars),swellingcapacity(mL/g,graybars),andfat-absorptioncapacity(g/g,whitebars)of fiveberrypomacevarietiesdriedat60 Cfor24h,andsubsequently milledto x50 , 120 μm. DataredrawnfromReissner,A.-M.,AlHamimi,S.,Quiles,A.,Schmidt,C.,Struck,S.,Hernando,I.,etal., 2019.Compositionandphysicochemicalpropertiesofdriedberrypomace.J.Sci.FoodAgric.99,1284 1293,withpermissionfromWiley.

leadstoanincreaseinthetotalporevolumethatisaccessibletowaterand,subsequently,toahigherwateruptake (Auffretetal.,1994;Lo ´ pezetal.,1996).Forcoconutresiduefibertheparticlesizewithmaximumhydrationproperty wasfoundtobe550 μm;smallerorlargerparticlesreducedhydration(Raghavendraetal.,2004).Whenselectingfiber forspecificapplications,theprocessinghistoryshouldthereforebeconsidered(Robertsonetal.,2000).Asregards chemicaleffectsitismainlythefatcontentofthefiberandtheionicstrengthofthesolubilizationmediumthatnegativelyaffectwater-bindingandswellingcapacities.

1.4Applicationoffruitpomaceinbakedproducts

Bakedbutalsoextrudedfoodsbasedoncerealscanbeconsideredasthemostimportanttargetproductsforpomaceutilization.Whenitcomestoincludingpomaceintheformulation,itisclearlynecessarytodistinguishbetweensweetand softcakes,brittlecookiesandbiscuits,breadandextrudedproducts.Thepartialsubstitutionofthemainingredients— theseare,dependingonthecommodity,(wheat)flourbutalsosugarand/orfat—resultsinchangesofthedoughsorbattersthatmustbetakenintoaccountduringsubsequentprocessing,andinmodifiedproductproperties.

Therearenumerousstudiesinwhichfruitpomacehasbeenusedtoreplacethementionedcompoundsinsoftbakery products(forinstance, Mildner-Szkudlarzetal.,2015; Quilesetal.,2018; Strucketal.,2016a).Theimpactofeachof theingredientsoncakebatterpropertieshastobeconsideredwhenintroducingfruitpomaceintothesystem.Thefiber significantlyhampersthecreationofanaeratedstructureand,becauseofitshighaffinityforwater,increasesthe viscosityofthebatter.Theconsequenceofthesechangesislimitedvolumeexpansionduringbaking,resultinginan increasedcrumbdensityandinafirmer,moregummyandlesscohesivetextureofthefinalproducts(Foschiaetal., 2013).Ameta-analysisonsensoryconsumeracceptancerevealedthatfiber-enrichedcerealsfoodsareusuallydowngraded,especiallywhentheacceptanceofthereferencefoodishigh(Grigoretal.,2016).Anapproachtoovercomethe problemsrelatedtothehighwater-bindingcapacityofthefruitfiberwaspresentedby Strucketal.(2016a) whomodifiedtherespectiveformulationssothatreferenceandtestbatterswereisoviscous.

Withthegeneralobjectivetoincreasethefibercontentofcakes,driedpomaceofdifferentoriginswasincorporated informulations,eitherasanadditionalcompoundorbypartiallyreplacingflour(e.g., Mildner-Szkudlarzetal.,2015; Romero-Lopezetal.,2011; Rupasingheetal.,2008; Walkeretal.,2014).Acomparisonoftheoutcomesofsuchstudies isdifficultasstudydesignandexperimentalmethodsdiffertoalargeextent.Forallthisworkitisvalidtostatethat theadditionoffruitby-productsincreasedthefibercontentandthecontentoftheaccompaniedbioactivecompounds, andreducedtheenergydensityofthefinalproducts.However,itremainsopenastowhethertheseproducts,despite theobservedeffectsoncrumbpropertiesandsensorycharacteristics,havebeenfinallyacceptedbytheconsumer.

Whenintendingtopartiallyreplacefatwithdriedfruitby-products,themanifoldfunctionalitiesofthisbasicingredientmustbetakenintoaccount.Fathelpstoincorporateairbubblesinthecakebatterandcontributestoemulsification duringmixing,anditalsohelpsinleaveningduringbakingandinstabilizingcrustandcrumb(Rodriguez-Garciaetal., 2014a,b;Zahnetal.,2010).Thefunctionalitiesmustalsobetakenintoaccountifdriedfruitby-productsareintended toreplacepartofthesugarintheformulation.Thetechnologicalfunctionalityofsugarinsweetbakedfoodshas recentlybeensummarizedby Strucketal.(2016b).Inbrief,sugarhasatenderizingeffectoncrumbtexturefrom restrictingglutennetworkformationandtheincreaseinstarchgelatinizationandeggproteindenaturationtemperatures, butalsoitcontributestocrustcolorformationduringbakingthroughcaramelization.Sugarfurthermoreassistsinthe

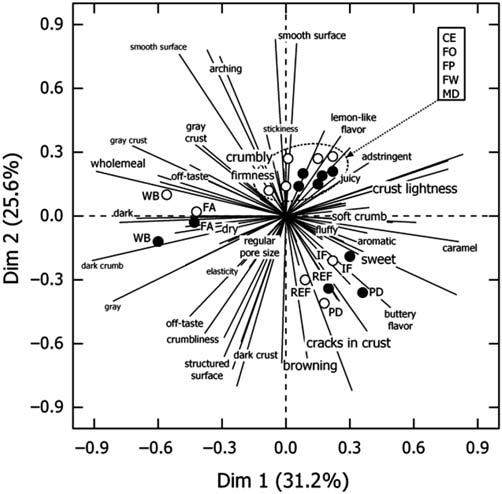

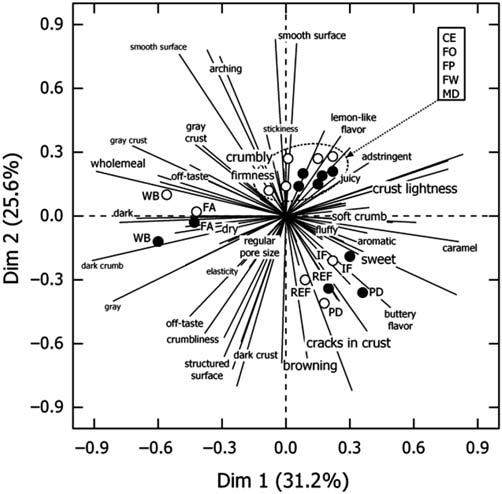

FIGURE1.3 GroupaverageplotsformuffindescriptorsobtainedbyGeneralProcrustesAnalysis.Muffinsamplesintheconsensusspaceare displayedforreplicatesession1(opencircles)and2(closedcircles).Formultipleoccurrencesofdescriptorsatasimilarpositionintheplot,character sizeisproportionaltothenumberofassessorswhousedthem. CE,Cellulose; FA,applefiber; FO,oatfiber; FP,peafiber; FW,wheatfiber; IF, inulin; MD,maltodextrin; PD,polydextrose; REF,reference; WB,wheatbran. FromZahn,S.,Forker,A.,Krugel,L.,Rohm,H.,2013.Combineduse ofrebaudiosideAandfibersforpartialsucrosereplacementinmuffins.LWT—FoodSci.Technol.50,695 701,withpermissionfromElsevier.

formationofcrystallineagglomerationsoffat,thusimprovingairentrapmentandairbubblestabilityduringbaking, resultinginmoreporousandspongyproducts.Inaddition,itisofstrategicimportancewhetherareducedsweetnessas thesecondmaineffectshouldbepassedontotheconsumer,oristhesubjectofsubstitutionthroughartificialornatural high-intensitysweeteners.Usingdifferentfibersforpartialsugarreplacementandsteviolglycosidesforsweetening purposes, Zahnetal.(2013) demonstratedthatthetypeofthefibersignificantlyaffectsthephysicalpropertiesofthe respectivecakes,andthatfiberpropertiesalsodeterminethesensorycharacteristicsoftheproducts(Fig.1.3).

Asregardscookiesandbiscuitstheintroductionoffruitpomaceinthesysteminfluencesthemechanicalaction neededduringdevelopmentofthedough,thebehaviorduringbaking,andproductproperties.Thehighaffinityofdried pomacetowardwatersignificantlyaffectsitsabsorptionsothatadditionalwatershouldbeadded;arelativeincreasein waterabsorptionofmorethan25%wasdeterminedinfarinographexperimentsafterpartialfloursubstitution(Ajila etal.,2008;Kohajdova ´ etal.,2013).Itismainlythehighpectincontentofpomacethatwasconsideredresponsiblefor theseeffects.Itneedshowevertobementionedthatanadversephenomenon,namelyreducedwaterbindingthrough theadditionofpomacewithahighlignincontent,wasalsoobserved(Mildner-Szkudlarzetal.,2013).Inaddition,a delayeddoughdevelopmentcausedbyfruitpomace,mainlythroughthepreventionofglutenhydration,mustbeconsidered(Kohajdova ´ etal.,2013;Srivastavaetal.,2014),anddoughstabilityisalsonegativelyaffected.Thefiberhinders theabilityofproteinstoformastableglutennetwork.However,insomecases,anincreaseindoughstability,which wasattributedtoenhancedinteractionsbetweenwater,fiber,andgluten,wasalsoreported(Kojahdovaetal.,2014).

Incontrasttosoftbakeryproductsbakedinmolds,whichincreasetheirvolumethroughchangesinheight,spreadingisadesiredtechnologicalpropertyduringbakingofcookiesandbiscuits.Areducedspreadingresultsinsmaller cookieswithhigherdensity,andwasobservedwhenmorethan10% 15%wheatflourwasreplacedbydriedfruit pomace(Ajilaetal.,2008;Kohajdova ´ etal.,2013).Asageneralconclusionfromstudiesdealingwiththissubject,the mainfactorinfluencingspreadingduringbakingispomacecomposition. Mildner-Szkudlarzetal.(2013) observeda higherflowabilityofthedoughforgrapepomacewithahighlignincontent.

Hardnessisoneofthemostimportantphysicalpropertiesofbakedcookiesandbiscuits.Addingmorewatertothe formulationtoachieveakneadabledoughmayleadtoanextensiveglutenstructurethatcausesasufficienthardening ofthefinalproducts(Ajilaetal.,2008;Larreaetal.,2005).Anotherimportantaspectisthat,inmostcases,fruitpomacecomeswithanindividualcolorandaflavorthatisalsoevidentintheproducts.Intheirworkonsavorycrackers, Schmidtetal.(2018) usedblackcurrantpomaceforpartialwheatfloursubstitution.Inthiscasethedarkercolorwas

associatedwithchocolatebytheconsumerswhichresultedinadecreasedacceptance.Thiswasovercomebyspreading sesameseedsontopofthebiscuitstoavoidtheunderlyingdark-sweetbias.

Incorporatingdietaryfiberinbreadisgenerallydetrimentaltotheformationofanaeratedstructure.Ittherefore diminishestheappealoffiber-fortifiedbreadandrestrictsthebenefitsthatcanbeobtainedthroughtheconsumptionof fiber(Campbelletal.,2008).Fruitpomaceisanalternatefibersourcetothefrequentlyusedcerealbran.Studiesthat haveappliedfruitby-productsinbreadusuallyconcludethatthesecanbeincorporatedatsomelimitedlevelwhile maintainingacceptablebreadquality.

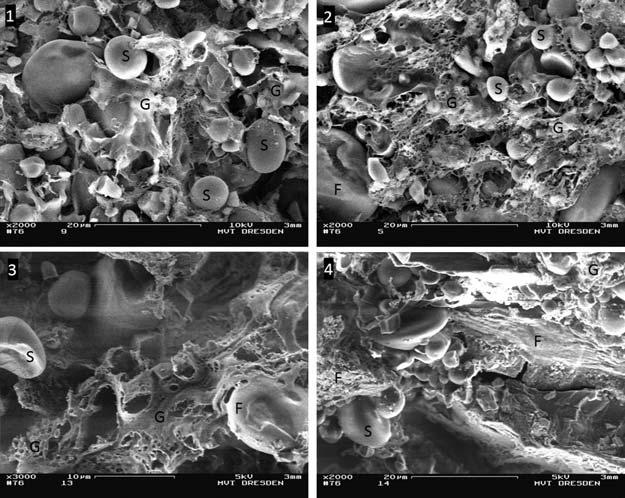

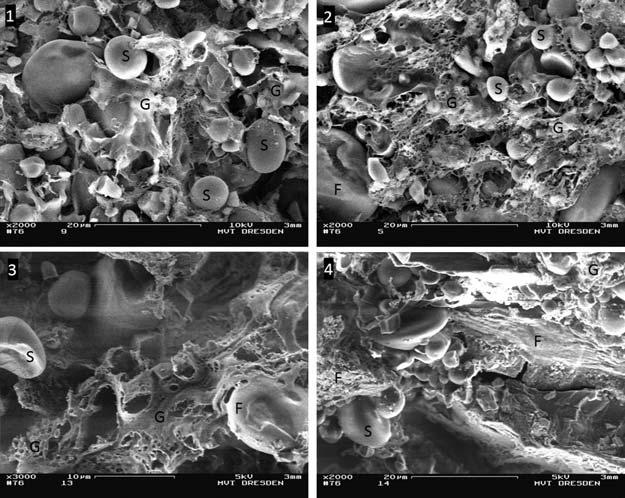

Cookedfruitby-products(apple,pear,anddatepomace)inwheatbreadformulationsexhibitedasignificantinfluenceondoughandproductproperties.Therewasincreasedwaterabsorption,anddoughstabilitywasalsoaffected. Extensibility,softening,breakdown,andsetbackofthedoughasmeasuredinafarinographusuallydecreasewithfiber addition.Thefinalbreadwithaslowas2%fibershowedaspecificvolumecomparabletothereferencebutamore aeratedcrumbstructure(Bchiretal.,2013).Areductioninbreadvolumewasobservedaftertheadditionofhazelnut (Anil,2007)orsugarbeetfiber(Filipovicetal.,2007). Sivametal.(2010) notedthattheeffectsofaddingnoncereal fibertowheatbreadgenerallyarereducedvolume,increasedcrumbfirmness,anddarkerappearance,andthatthenegativeeffectsderivemainlyfromthedilutionofglutenandtheinteractionsbetweenfiber,water,andgluten.Thewayin whichfiberindifferentamountscanbeincorporatedinwheatdoughhasrecentlybeenaddressedby Strucketal. (2018) (Fig.1.4).

O’Sheaetal.(2013) incorporatedorangepomaceingluten-freebreadandfoundthat,asregardswaterabsorption, thefibercompeteswithstarch.Thisreducesstarchgranuleswelling,anddecreasesbatterviscosityandgelatinization rate.Atalevelof5.5gpomaceper100g(riceflour 1 potatostarch),theorangepomacebreadwasconsideredsimilar insensoryacceptabilitytothecontrol,withaslightlylesspleasanttextureobservedduringchewing. RochaParraetal. (2015) incorporatedapplepomaceingluten-freebread,notingthathighfiberlevelsgavealesscohesiveandresilient crumbandalowerspecificvolume.Surpluswaterservedtocounteractthenegativeeffectsofpomacetosomeextent.

Manyexpandedsnackswithacrispytextureareproducedbyhigh-temperatureshort-timeextrusionthattakes advantageofthestructuralchangesofstarchinducedbytemperatureandpressure.Extrudedproductssuchasbreakfast cerealsorsavorysnacksarebasedonstarchandthereforearelowindietaryfiberandprotein.Anyincorporationof fruitpomaceintherespectiveformulationthereforeaffectsthebehaviorduringprocessingandtheresultingproduct properties,forexample,waterabsorptionandsolubility,expansion,texture,andstarchdigestibility.Whenstarchcontainingrawmaterial—inmostcases,corngrit—ispartlyreplacedbyfruitpomace(here,replacementlevelsofupto 50%wereevaluated,see Gumuletal.,2011,or Whiteetal.,2010)bothcompoundscompeteforwatersothatstarch gelatinizationissignificantlyaffected(Ma ¨ kila ¨ etal.,2014).Thehighwateraffinityoffruitpomaceisalsoresponsible fortheincreasedshearviscosityofthemeltwhichhinderstheflashingoffofsteamattheextruderdieandfurtherlimits

FIGURE1.4 Scanningelectronmicroscopyimages ofdoughsampleswithvaryingamountsofblack currantpomace(BCP).(1)Reference;(2)10%BCP; (3)20%BCP;(4)30%BCP. F,Fiberparticlesfrom BCP; G,proteinnetwork; S,starchgranules. From Struck,S.,Straube,D.,Zahn,S.,Rohm,H.,2018. Interactionofwheatmacromoleculesandberrypomaceinmodeldough:rheologyandmicrostructure.J. FoodEng.223,109 115,withpermissionfrom Elsevier.

FIGURE1.5 Expansionratioofextrudateswithdifferentmoisturecontent(MC)andapplepomace(AP). FromKarkle,E.L.,Alavi,S.,Dogan,H., 2012.Cellulararchitectureanditsrelationshipwithmechanicalpropertiesinexpandedextrudatescontainingapplepomace.FoodRes.Int.46, 10 21,withpermissionfromElsevier.

bubblegrowth.Fiberparticlescouldphysicallyrupturebubblecellwalls,henceleadingtoanearliercollapseofbubbles andthereforeareducedexpansion(Altanetal.,2008).Asregardstheeffectsoffruitpomaceontheamountofsoluble componentsinextrudatesthatislinkedtomoleculardegradationduringextrusion,reportsarecontroversial.Changesin solubilityarepresumablycausedbyareducedstarchdamageduringextrusion,orbyeffectsofdifferentratiosofsolubletoinsolublefiberinthepomacethatwasused(Altanetal.,2009;Karkleetal.,2012a;Selanietal.,2014).

Reducedstarchgelatinizationinlinewithalowergas-holdingcapacityandalsoeffectsrelatedtothegeometryof theusedfiberhavebeenconsideredresponsibleforthedecreaseinradialexpansionandtheincreaseindensityof pomace-containingextrudates(Karkleetal.,2012a,b; Fig.1.5).Alessporousstructurewithsmallergascellsisdirectly responsibleforalesscrispy,morefragiletexture(Strucketal.,2016b).Publisheddataleadhowevertotheconclusion thatthemagnitudeoftherespectiveeffectsislargelydeterminedbytypeandoriginofthepomaceand,withregardsto watersolubility,isdependentontheamountofsolubleandinsolublefiber(Selanietal.,2014;Karkleetal.,2012a).In addition,somelimitationsregardingapplicabilitycomefromeffectsoftheincorporatedpomaceontheflavorandtaste. Forexample, Gumuletal.(2011) reportedanamountof10%defattedblackcurrantseedsincornmealextrudatesas acceptablefromthesensorypointofview,whereasproductswithahigheramountofpomaceweresignificantly downgraded.

1.5Pasta

Pastaisatraditionalfoodusuallybasedonrefinedorwholewheatflour.Itispopularworldwide,mainlybecauseofits lowcost,easeofproduction,versatility,sensoryattributes,andlongshelflife(Ajilaetal.,2010).Pastaisproducedby mixingandkneadingcerealflourorsemolinawithwater;theadditionofeggandsaltisoptionalanddependsonlocal productionhabits.Extrusionprocessingfacilitatesmixingandkneadingofdoughunderpressureandfrictionwhich enablesproteininteractionsthroughdisulfide,hydrogen,andhydrophobicbondsandthereforethedevelopmentofa cross-linkedglutenmatrix.Thepassagethroughthediewithrotatingbladesattheendoftheextruderbarrelgivesthe pastaitsfinalform(Bustosetal.,2015).Thesubstitutionofwheatflourordurumsemolinawithdietaryfiber-richraw materialssuchasfruitpomacesignificantlyalterstheproductcharacteristics,particularlycolor,waterabsorptionand swellingduringcooking,cookingtimeandcookingloss,textureandothersensoryattributes.

Cookinglossdescribestheamountofsolidsdiffusingfromtherawpastastructure(eitherfreshordried)intothe cookingwater.Thisparameterisusedtodescribethecookingperformanceofpasta,andavalueofapproximately8% isconsideredtobethelimitforgoodquality(Bustosetal.,2015).Thedietaryfiberinfruitprocessingby-products interfereswiththestarch/glutennetworkinpastadoughandcausesahigherlossofgelatinizedstarchandothernonstarchpolysaccharidesthanincontrolsamples.Thiseffecthasbeenobservedformangopeelpowder(Ajilaetal., 2010),orangeby-productfiber(Crizeletal.,2015),pomegranateseedpowder(Dibetal.,2018),carrotpomace(Gull etal.,2015),andgrapemarcpowder(Sant’Annaetal.,2014)thatwereusedforpastamaking.Thewateraffinityofthe

dietaryfiberisresponsibleforanunevendistributionofwaterwithinthepastamatrixandpreventsstarchswelling, therebyincreasingstarchleachingfromthematrixduringcooking(Tudorica ˇ etal.,2002).

Analyticalmeasurementsofpastatexturecaneitherbeperformedondrypastatodeterminefracturability,for instanceinrelationtopackagingortransportationissues,butalsotoassessthequalityofcookedpasta;here,noodle firmnessandadhesivenessarethemostrelevantproperties.Whenapplyingthetraditional(butnowsomewhat challenged)textureprofileanalysisthesampleiscompressedintwocycles,withtheoriginalaimtosimulatechewing. Whendoingso,themaximumforceduringthefirstcompressioncycleisdefinedasfirmness,andthenegativework betweenthetwocyclesreferstoadhesiveness. Ajilaetal.(2010) showedthattheadditionof7.5%mangopeelpowder toamacaroniformulationincreasedthefirmnessfrom0.44N(control)to0.73N.Insolubledietaryfibercausesa reductioninstarchswellingandthereforedecreaseswaterabsorptionofthepastaduringcooking,whichinturnresults inahigherfirmnessofthecookedpasta(Aravindetal.,2012).Pomegranateseedpowderontheotherhanddecreased thefirmnessofgluten-freepastawhenappliedatalevelabove5%.Thiseffectwasexplainedbythehighwaterholdingcapacityofthepomegranateseedpowder(Dibetal.,2018).

Sensoryevaluationofpastawithgrapemarcpowdershowedthatareplacementof2.5%ofwheatflourresultedin productswithasimilarflavorandadequateoverallacceptancecomparedtoacontrolsample.Athigherconcentrations thegrapemarcpowderpastawasrejectedinsensorytestingbecauseofanunexpectedaftertastewhichreducedoverall acceptability(Sant’Annaetal.,2014).Similarresultswereobservedforpomegranateseedpowder,whereanapplicationlevelalsoof2.5%gaveresultssimilartothatofacontrolformulation,buthigherlevels(10%and12.5%)resulted inalessacceptedpasta(Dibetal.,2018).Theadditionoforangeby-productstoapastaformulationledtothepresence ofabittertasteandthereforelessoverallacceptability.Accordingto Crizeletal.(2015),thisnegativeinfluenceon sensoryattributescouldbecounteractedbyapretreatmentoftherawmaterialtoreducetheamountsofthecompounds responsibleforbitterness.

Ingeneral,thereplacementofwheatflourwithfruitprocessingby-productsresultsinanincreasedpolyphenoland dietaryfibercontentwhichincreasesthenutritionalvalueofthefinalproduct.Thenegativeeffectsoncookingloss, texture,andsensoryattributeshavetobeanalyzedforeachpossiblefiber-enrichedproducttofindanoptimumreplacementlevel.

1.6Meatproducts

Oxidationreactionsareresponsibleforseveralchangesthatoccurduringmeatprocessingandthesubsequentstorageof theproduct,andwhichresultinoffflavorsfrom,forinstance,lipidoxidation,anddiscolorationfrommeatpigment oxidation.Withtheapplicationofantioxidantsitispossibletopreventthesenegativechangestoacertainextentandto increasetheshelflifeoftheproducts(Lorenzoetal.,2018).Asfruitby-productsarerichinphytochemicalsandthereforenaturalantioxidants,theymightserveaspromisingingredientstoinhibitoxidationreactionsandtheformationof rancidodors(Ahmadetal.,2015).Inmanycases,theextractionoffruitprocessingby-productsbeforeapplicationin meatproductsisrecommendedtogainahighconcentrationofphytochemicalsandtosimultaneouslyexcludeinterferingcompoundssuchasdietaryfiberorprotein.Thefractionationoffruitpomacecanberealizedbyalcoholicextraction,supercriticalcarbondioxideextraction,orhigh-pressureextractionwithethanolandwater(e.g., Garridoetal., 2011; Kry ˇ zevi ˇ cuteetal.,2017; Vaucheletal.,2015).Theresultingextractsfromraspberrypomacewereshownto prolongstoragetimeofbeefburgers(applicationlevelupto1%)andtoexhibitantimicrobialeffectswithoutchanging thesensoryprofileoftheproduct(Kry ˇ zevi ˇ cuteetal.,2017).Seasoningsproducedbydryingandmillingofwinepomaceincorporatedinrefrigeratedandfrozenbeefpattiesreducedthethiobarbituricacidreactivesubstances(TBARS) levelsduringstorageandthereforepreventedlipidoxidation.Incomparisonwithsulfite,anantioxidantthatiswidely usedinthemeatindustry,thewinepomaceseasoningwasmoreeffectiveindelayingtheformationofrancidodorsduringstorageoftheproducts.Withtheadditionofredwinepomace,noTBARSwereformedincookedbeefpatties;in rawpatties,areductionof60%comparedtoacontrolsamplewaspossible(Garcı´a-Lomilloetal.,2017; Fig.1.6).

Fruitby-productscanalsobeaddedtoanimalfeedtobenefitfromtheantioxidanteffectandtointroducethe compoundsintothemeat.Mangoseedextract,preparedbyethanolicextraction,wasaddedtoabroilerchickendietat alevelof400mg/kgandincreasedtheyellownessofthemeatat60daysofstorageandalsohelpedinmaintaining breastmeatcolorduringfrozenstorage(Freitasetal.,2015).Chokeberrypomaceshowedpromisingresultsasadietary supplementforbroilers,thoughtheoptimaldosageforantioxidantactivityrequiresfurtherinvestigation(Loetscher etal.,2013).

Aqueousextractsofpomegranateandgrapeby-productsaddedtorawlambpattiesresultedinlowermicrobial countsformesophilicandpsychrotrophicmicroorganismsafter7daysofrefrigeratedstoragethanforcontrolsamples.

FIGURE1.6 Thiobarbituricacidreactivesubstance(TBARS)levelsinrawandcookedbeefpattiesstoredinvacuumpackagingfor6monthsat 18 C. Pointsshowmeanvaluesandbarsindicatestandarddeviationsateachsamplingpoint(n 5 3).Greekletters(α,β,γ)showstatisticaldifferencesbetween samplesatthesamestoragetime.Latinletters(a,b,c)showstatisticalchanges(P-value , .05)duringstorage.Control:pattieswithoutanyantioxidant; sulfites:pattieswith300ppmofSO2;andSkRWPS:pattieswith2g/100gofseasoningobtainedskinfractionofredwinepomace. FromGarcı´a-Lomillo, J.,Gonzalez-SanJose,M.L.,DelPino-Garcı´a,R.,Ortega-Heras,M.,Muniz-Rodrı´guez,P.,2017.Antioxidanteffectofseasoningsderivedfromwine pomaceonlipidoxidationinrefrigeratedandfrozenbeefpatties.LWT—FoodSci.Technol.77,85 91,withpermissionfromElsevier.

Theantimicrobialeffectwashoweverlesspronouncedforenterobacteriaceaeandlacticacidbacteria.Theresultseven suggestedthatsodiumascorbatecouldbereplacedbygrapepomaceextractsasanantioxidantinmincedmeat(Andre ´ s etal.,2017).Additionally, Aquilanietal.(2018) reportedthatsodiumnitriteindryfermentedsausagescouldbe replacedbyanaturalantioxidantconsistingofgrapeseedextractandolivepomacehydroxytyrosolwithoutnegative effectsonthearomaprofile,oninstrumentalhardness,andonoverallacceptability.Insensoryanalyses,onlycolorrelatedattributes(rednessandcoloruniformity)wereevaluatedwithlowerscores.Anapplicationlevelof2.5%of cranberrypomaceextractreducedthebacterialcountofpathogenssufficientlywithoutnegativeeffectsonorganoleptic properties(StobnickaandGniewosz,2018).

Apartfromtheantioxidativeeffect,fruitpomacecanbeappliedtomeatproductstoenrichthedietaryfibercontent, ortoactasafatreplacer(Yadavetal.,2016;Ratheretal.,2015).Applepomacewasincorporatedinchickensausages, resultinginacceptabilityvaluesat3%applicationlevelthatwerecomparablewithacontrolsample.Higherapplication levels(6%and9%)resultedinsausagesthatwereperceivedaslessjuicythanthecontrol,whichmightbeattributedto thehighwater-bindingcapacityofthefiber.Instrumentaltextureanalysisshowedanincreasedhardnessforsausages withapplepomace(Yadavetal.,2016).DietaryfiberconcentratesofpineapplepomaceappliedtoVienna-type sausagesincreasedantioxidantpolyphenolandcarotenoidcontentsandwereconsideredaspotentialfunctionalingredients(Montalvo-Gonza ´ lezetal.,2018).

Sinceconsumerdemandstendtoshowapreferencefornaturalproducts,themeatindustryisseekingnatural solutionstoreducethenegativeeffectsofoxidationandmicrobialgrowththatcausechangesincolorandodorduring storage.Fruitby-productsareanaturalsourceofantioxidantsandcanbeappliedasapowderorasextractsinmeat products.Theymaybeconsideredtobeapromisingalternativeforconventionalsyntheticantioxidantswithagreat potentialforthemeatindustry.