https://ebookmass.com/product/unsaturated-polyester-resinsfundamentals-design-fabrication-and-applications-sabuthomas-editor/

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Fundamentals and Properties of Multifunctional Nanomaterials Sabu Thomas

https://ebookmass.com/product/fundamentals-and-properties-ofmultifunctional-nanomaterials-sabu-thomas/

ebookmass.com

Nano-Optics: Fundamentals, Experimental Methods, and Applications (Micro and Nano Technologies) 1st Edition Sabu Thomas (Editor)

https://ebookmass.com/product/nano-optics-fundamentals-experimentalmethods-and-applications-micro-and-nano-technologies-1st-edition-sabuthomas-editor/

ebookmass.com

Synthesis, Characterization, and Applications of Graphitic Carbon Nitride Sabu Thomas

https://ebookmass.com/product/synthesis-characterization-andapplications-of-graphitic-carbon-nitride-sabu-thomas/

ebookmass.com

The Future of Indian Banking 1st ed. 2022 Edition Vasant

Chintaman Joshi

https://ebookmass.com/product/the-future-of-indian-banking-1sted-2022-edition-vasant-chintaman-joshi/

ebookmass.com

Building With Ethereum: Products, Protocols, and Platforms

1st Edition Jamie Rumbelow

https://ebookmass.com/product/building-with-ethereum-productsprotocols-and-platforms-1st-edition-jamie-rumbelow-2/

ebookmass.com

Law 101: Everything You Need To Know About American Law, 5th edition Jay M. Feinman

https://ebookmass.com/product/law-101-everything-you-need-to-knowabout-american-law-5th-edition-jay-m-feinman/

ebookmass.com

Articles of Faith: Religion, Secularism, and the Indian Supreme Court Ronojoy Sen

https://ebookmass.com/product/articles-of-faith-religion-secularismand-the-indian-supreme-court-ronojoy-sen/

ebookmass.com

US Presidents and Cold War Nuclear Diplomacy Aiden Warren

https://ebookmass.com/product/us-presidents-and-cold-war-nucleardiplomacy-aiden-warren/

ebookmass.com

Merging Optimization and Control in Power Systems : Physical and Cyber Restrictions in Distributed Frequency Control and Beyond 1st Edition Feng Liu

https://ebookmass.com/product/merging-optimization-and-control-inpower-systems-physical-and-cyber-restrictions-in-distributedfrequency-control-and-beyond-1st-edition-feng-liu/

ebookmass.com

The Nightmare Thief Series, Book 1 Nicole Lesperance

https://ebookmass.com/product/the-nightmare-thief-seriesbook-1-nicole-lesperance/

ebookmass.com

UnsaturatedPolyester Resins

Fundamentals,Design, Fabrication,andApplications

UnsaturatedPolyester Resins

Fundamentals,Design, Fabrication,andApplications

Editedby SabuThomas

SchoolofChemicalSciences,MahatmaGandhiUniversity,Kottayam,India InternationalandInteruniversityCentreforNanoscienceandNanotechnology, MahatmaGandhiUniversity,Kottayam,India

MaheshHosur DepartmentofMaterialsScienceEngineering,TuskegeeUniversity,Tuskegee, AL,UnitedStates

CintilJoseChirayil DepartmentofChemistry,NewmanCollege,Thodupuzha,India

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2019ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicor mechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem,withoutpermission inwritingfromthepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthePublisher’ s permissionspoliciesandourarrangementswithorganizationssuchastheCopyrightClearanceCenterandthe CopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher (otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroadenour understanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusingany information,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationormethodsthey shouldbemindfuloftheirownsafetyandthesafetyofothers,includingpartiesforwhomtheyhaveaprofessional responsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeanyliability foranyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceorotherwise,or fromanyuseoroperationofanymethods,products,instructions,orideascontainedinthematerialherein.

BritishLibraryCataloguing-in-PublicationData AcataloguerecordforthisbookisavailablefromtheBritishLibrary

LibraryofCongressCataloging-in-PublicationData AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

ISBN:978-0-12-816129-6

ForInformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: MatthewDeans

AcquisitionEditor: EdwardPayne

EditorialProjectManager: FernandaA.Oliveira

ProductionProjectManager: R.VijayBharath

CoverDesigner: GregHarris

TypesetbyMPSLimited,Chennai,India

ListofContributors

BasimAbu-Jdayil

ChemicalandPetroleumEngineeringDepartment,UnitedArabEmiratesUniversity,AlAin, UnitedArabEmirates;EmiratesCenterforEnergyandEnvironmentResearch,UnitedArab EmiratesUniversityAlAin,AbuDhabi,UnitedArabEmirates

M.Alagar

CentreofExcellenceforAdvancedMaterials,Manufacturing,ProcessingandCharacterisation (CoExAMMPC),Vignan’sFoundationforScience,TechnologyandResearch(VFSTR), Vadlamudi,India

AndreaC.Alexander

CenterforPolymersandAdvancedComposites,AuburnUniversity,Auburn,AL,UnitedStates

NimaAlizadeh

CenterforPolymersandAdvancedComposites,AuburnUniversity,Auburn,AL,UnitedStates; DepartmentofChemicalEngineering,AuburnUniversity,Auburn,AL,UnitedStates

SandroC.Amico

Post-GraduationPrograminMechanicalEngineering,UFRGS,PortoAlegre,Brazil; Post-GraduationPrograminMining,MetallurgicalandMaterialsEngineering,UFRGS, PortoAlegre,Brazil

M.Arous

DepartmentofPhysics,LaMaCoP,FacultyofSciencesofSfax,UniversityofSfax,Tunisia

AnjaliA.Athawale

DepartmentofChemistry,SavitribaiPhulePuneUniversity,Pune,India

MariaL.Auad

CenterforPolymersandAdvancedComposites,AuburnUniversity,Auburn,AL,UnitedStates; DepartmentofChemicalEngineering,AuburnUniversity,Auburn,AL,UnitedStates

D.Bachtiar

StructuralMaterialsandDegradationFocusGroup,FacultyofMechanicalandManufacturing Engineering,UniversitiMalaysiaPahang,Pahang,Malaysia

NilRatanBandyopadhyay

Dr.M.N.DasturSchoolofMaterialsScienceandEngineering,IndianInstituteofEngineering ScienceandTechnology,Shibpur,Howrah,India

MattiaBartoli

DepartmentofAppliedScienceandTechnology(DISAT),PolitecnicodiTorino,Torino,Italy

DibakarBehera

SchoolofAppliedSciences(Chemistry),KIITUniversity,Bhubaneswar,India

SamanthaA.Bird

CenterforPolymersandAdvancedComposites,AuburnUniversity,Auburn,AL,UnitedStates

BhabatoshBiswas

Dr.M.N.DasturSchoolofMaterialsScienceandEngineering,IndianInstituteofEngineering ScienceandTechnology,Shibpur,Howrah,India

DanielH.Builes

ResearchandDevelopmentCenter-Andercol,AndercolS.A.S,Medellı´n,Colombia

ShaliniChaturvedi

SamarpanScienceandCommerceCollege,Gandhinagar,India

CintilJoseChirayil

DepartmentofChemistry,NewmanCollege,Thodupuzha,India

Ang ´ elicaColpo

Post-GraduationPrograminMechanicalEngineering,UFRGS,PortoAlegre,Brazil

PragneshN.Dave

DepartmentofChemistry,SardarPatelUniversity,VallabhVidyanagar,India

VirginiaA.Davis

DepartmentofChemicalEngineering,AuburnUniversity,Auburn,AL,UnitedStates

EduardoA.W.deMenezes

Post-GraduationPrograminMechanicalEngineering,UFRGS,PortoAlegre,Brazil

S.Devaraju

PolymerCompositesLab,DivisionofChemistry,DepartmentofScienceandHumanities, Vignan’sFoundationforScience,TechnologyandResearch(VFSTR),Vadlamudi,India

HomNathDhakal

SchoolofMechanicalandDesignEngineering,AdvancedMaterialsandManufacturing(AMM) ResearchGroup,UniversityofPortsmouth,Portsmouth,UnitedKingdom

JohnR.Ebdon

InstituteforMaterialsResearchandInnovation,UniversityofBolton,Bolton,UnitedKingdom

MarcoFrediani

DepartmentofChemistry“UgoSchiff”,UniversityofFlorence,SestoFiorentino,Florence,Italy

LeandroFriedrich

Post-GraduationPrograminMechanicalEngineering,UFRGS,PortoAlegre,Brazil

CincyGeorge

DepartmentofChemistry,NewmanCollege,Thodupuzha,India

Z.M.Hafizi

AdvancedStructuralIntegrityandVibrationResearch(ASIVR),FacultyofMechanicaland ManufacturingEngineering,UniversitiMalaysiaPahang,Pahang,Malaysia

M.H.M.Hamdan

StructuralMaterialsandDegradationFocusGroup,FacultyofMechanicalandManufacturing Engineering,UniversitiMalaysiaPahang,Pahang,Malaysia

MedBenHassen

CollegeofEngineering,IndustrialEngineeringDepartment,TaibaUniversity,SaudiArabia; DepartmentofTextileEngineering,TextileEngineeringLaboratory,HITSofKsarHellal, UniversityofMonastir,Tunisia

MaheshHosur

DepartmentofMaterialsScienceEngineering,TuskegeeUniversity,Tuskegee,AL,UnitedStates

SikiruOluwarotimiIsmail

Manufacturing,Materials,BiomedicalandCivilDivision,SchoolofEngineeringandTechnology, HuttonBuilding,UniversityofHertfordshire,Hertfordshire,UnitedKingdom

KeilashC.Jajam

DepartmentofMechanicalEngineering,AuburnUniversity,Auburn,AL,UnitedStates

JoseJames

DepartmentofChemistry,St.Joseph’sCollege,Moolamattom,Idukki,India;Internationaland InteruniversityCentreforNanoscienceandNanotechnology,MahatmaGandhiUniversity, Kottayam,India;SchoolofChemicalSciences,MahatmaGandhiUniversity,Kottayam,India

J.Jamiluddin

StructuralMaterialsandDegradationFocusGroup,FacultyofMechanicalandManufacturing Engineering,UniversitiMalaysiaPahang,Pahang,Malaysia

J.Jayapriya

DepartmentofAppliedScienceandTechnology,A.C.Tech.,AnnaUniversity,Chennai,India

BaljinderK.Kandola

InstituteforMaterialsResearchandInnovation,UniversityofBolton,Bolton,UnitedKingdom

EktaKhosla

DepartmentofChemistry,HansRajMahilaMahaVidyalaya,Jalandhar,India

QiongLi

KeyLaboratoryofBio-BasedPolymericMaterialsTechnologyandApplicationofZhejiang Province,NingboInstituteofMaterialsTechnologyandEngineering,ChineseAcademyof Sciences,Ningbo,P.R.China;UniversityofChineseAcademyofSciences,Beijing,P.R.China

SongqiMa

KeyLaboratoryofBio-BasedPolymericMaterialsTechnologyandApplicationofZhejiang Province,NingboInstituteofMaterialsTechnologyandEngineering,ChineseAcademyof Sciences,Ningbo,P.R.China

RicardoBallesteroMendez

CenterforPolymersandAdvancedComposites,AuburnUniversity,Auburn,AL,UnitedStates; DepartmentofChemicalEngineering,AuburnUniversity,Auburn,AL,UnitedStates

SmitaMohanty

SchoolforAdvancedResearchinPolymericMaterials(SARP) LARPMCentralInstituteof PlasticsEngineering&Technology(CIPET)-IPT,Bhubaneswar,India

SanjayK.Nayak

SchoolforAdvancedResearchinPolymericMaterials(SARP) LARPMCentralInstituteof PlasticsEngineering&Technology(CIPET)-IPT,Bhubaneswar,India

MedAminOmri

DepartmentofPhysics,LaMaCoP,FacultyofSciencesofSfax,UniversityofSfax,Tunisia

ShivkumariPanda

SchoolofAppliedSciences(Chemistry),KIITUniversity,Bhubaneswar,India

JyotiA.Pandit

SchoolofChemistry,Dr.VishwanathKaradMITWorldPeaceUniversity,Pune,India

V.Ramamurthy

DepartmentofBiotechnology,PSGCollegeofTechnology,Coimbatore,India

M.R.M.Rejab

StructuralMaterialsandDegradationFocusGroup,FacultyofMechanicalandManufacturing Engineering,UniversitiMalaysiaPahang,Pahang,Malaysia

EmmanuelRichaud

PIMM,UMR8006,ENSAM CNRS CNAM,HESAMUniversit ´ e,Paris,France

LucaRosi

DepartmentofChemistry“UgoSchiff”,UniversityofFlorence,SestoFiorentino,Florence,Italy

SushantaK.Samal

SchoolforAdvancedResearchinPolymericMaterials(SARP) LARPMCentralInstituteof PlasticsEngineering&Technology(CIPET)-IPT,Bhubaneswar,India

S.M.Sapuan

DepartmentofMechanicalandManufacturingEngineering,UniversitiPutraMalaysia,Selangor, Malaysia

N.Saranya

DepartmentofAppliedScienceandTechnology,A.C.Tech.,AnnaUniversity,Chennai,India

AruniShajkumar

SchoolforAdvancedResearchinPolymericMaterials(SARP) LARPMCentralInstituteof PlasticsEngineering&Technology(CIPET)-IPT,Bhubaneswar,India

ArijitSinha

Dr.M.N.DasturSchoolofMaterialsScienceandEngineering,IndianInstituteofEngineering ScienceandTechnology,Shibpur,Howrah,India

J.P.Siregar

StructuralMaterialsandDegradationFocusGroup,FacultyofMechanicalandManufacturing Engineering,UniversitiMalaysiaPahang,Pahang,Malaysia

PavleM.Spasojevic

FacultyofTechnicalSciences,UniversityofKragujevac,Cacak,Serbia;InnovationCenterof FacultyofTechnologyandMetallurgy,UniversityofBelgrade,Belgrade,Serbia

AgnieszkaTercjak

Materials+Technologies Group(GMT),DepartmentofChemicalandEnvironmentalEngineering, FacultyofEngineeringGipuzkoa,UniversityoftheBasqueCountry(UPV/EHU),Donostia-San Sebastian,Spain

C.Tezara

DepartmentofMechanicalEngineering,FacultyofEngineeringandQuantitySurveying,INTI InternationalUniversity,NegeriSembilan,Malaysia

GeorgeV.Thomas

DepartmentofChemistry,St.Joseph’sCollege,Moolamattom,Idukki,India

SabuThomas

SchoolofChemicalSciences,MahatmaGandhiUniversity,Kottayam,India;Internationaland InteruniversityCentreforNanoscienceandNanotechnology,MahatmaGandhiUniversity, Kottayam,India

HareeshV.Tippur

DepartmentofMechanicalEngineering,AuburnUniversity,Auburn,AL,UnitedStates

A.Triki

DepartmentofPhysics,LaMaCoP,FacultyofSciencesofSfax,UniversityofSfax,Tunisia

JacquesVerdu

PIMM,UMR8006,ENSAM CNRS CNAM,HESAMUniversit ´ e,Paris,France

XiweiXu

KeyLaboratoryofBio-BasedPolymericMaterialsTechnologyandApplicationofZhejiang Province,NingboInstituteofMaterialsTechnologyandEngineering,ChineseAcademyof Sciences,Ningbo,P.R.China;SchoolofMaterialsScienceandEngineering,ZhejiangUniversity ofTechnology,Hangzhou,P.R.China

JinZhu

KeyLaboratoryofBio-BasedPolymericMaterialsTechnologyandApplicationofZhejiang Province,NingboInstituteofMaterialsTechnologyandEngineering,ChineseAcademyof Sciences,Ningbo,P.R.China

UNSATURATEDPOLYESTER

RESINS,BLENDS,

INTERPENETRATINGPOLYMER NETWORKS,COMPOSITES,AND NANOCOMPOSITES:STATEOFTHE

ARTANDNEWCHALLENGES

AnjaliA.Athawale1 andJyotiA.Pandit2

1DepartmentofChemistry,SavitribaiPhulePuneUniversity,Pune,India 2SchoolofChemistry,Dr.Vishwanath KaradMITWorldPeaceUniversity,Pune,India

1.1 INTRODUCTION

Unsaturatedpolyesters(UPs)aresyntheticcopolymershavingapplicationsasfibers,plastics,composites,andcoatings.Dependingonthechoiceofmonomers,initiators,curingagents,additives, andmodifiersused,differentvarietiesofproductscanbeproducedexhibitingawiderangeof chemicalandmechanicalproperties.Thelowcostinvolvedintheirproductionmakesthemattractive.Theirmainapplicationisasmatricesinthecompositeindustry.Amongthecomposites,fiber glass reinforcedcompositesareofprimeimportance.

1.2 TYPESOFUNSATURATEDPOLYESTERRESINS

Basedontheirstructure,unsaturatedpolyestersresins(UPR)canbeclassifiedas:(1)orthoresins; (2)isoresins;(3)bisphenolAfumarates;(4)chlorendics;or(5)vinylester(VE)resins.

1.2.1 ORTHORESINS

Orthoresinsarealsoreferredtoasgeneral-purposepolyesterresinsandarebasedonorthophthalic acid,namely,phthalicanhydride(PA),maleicanhydride(MA)/fumaricacid,andglycols.PAisrelativelycheapandprovidesrigiditytothebackbone.However,ithaslimitedthermalandchemical resistanceandprocessability.Amongtheglycols,resinsformedusing1,2-propyleneglycol(PG) aremoreimportantincomparisontootherglycols.ThependantmethylgroupinPGlowersthe crystallinityofresinandimprovesitscompatibilitywithcommonlyusedreactivediluents(suchas

UnsaturatedPolyesterResins.DOI: https://doi.org/10.1016/B978-0-12-816129-6.00001-6 © 2019ElsevierInc.Allrightsreserved.

styrene).NeopentylglycolorhydrogenatedbisphenolAyieldsresinswithhighheatandchemical resistance.

1.2.2 ISORESINS

Isoresinsarepreparedusingisophthalicacid,MA/fumaricacid,andglycol.Theyarerelatively expensiveandhaveconsiderablyhighviscosities.Hence,theyrequirealargeproportionofreactive diluent,whichalsoimpartsimprovedwaterandalkaliresistancetocuredresins.Theyfindapplicationsasgelbarriercoatsinmarineenvironmentssincetheyhavebetterthermalandchemicalresistanceandmechanicalproperties.

1.2.3 BISPHENOLAFUMARATES

Thesearesynthesizedusingethoxy-basedbisphenolAandfumaricacid.Thoughexpensive,they exhibitsuperiorchemicalpropertiesaswellascorrosionresistanceascomparedtoorthoandiso resins.ThepresenceofbisphenolAinthebackbonerendersahigherdegreeofhardnessandrigidityandimprovedthermalperformance.Duetothereducednumberofinteriorchainestergroups, theirhydrolysisresistanceisbestamongcommercialunsaturatedresins.

1.2.4 CHLORENDICS

Chlorine/bromine-containinganhydridesorphenolsareusedforpreparingchlorendics.They exhibitflameresistancealongwithgoodchemicalandcorrosionresistance.Forexample,thereactionbetweenchlorendicanhydride/chlorendicacidandMA/fumaricacidandglycolyieldsresin withbetterflameretardancythangeneral-purposeUPR.Othermonomersusedincludetetrachloroortetrabromophthalicanhydride.Thebrominecontentmustbeatleast12%inordertoobtaina self-extinguishingpolyester.

1.2.5 VINYLESTERRESINS

VEresinscontainunsaturatedsitesonlyattheterminalpositionasbisacryloxyorbismethacryloxy derivativesofepoxyresins.Theyarepreparedthroughthereactionofacrylicacidormethacrylic acidwithepoxyresin(e.g.,diglycidyletherofbisphenolA(DGEBA),epoxyofthephenolnovolac type,orepoxybasedontetrabromobisphenolA).Theseresinswerefirstcommercializedin1965 byShellChemicalCompanyunderthetradenameEpocryl [1].In1966DowChemicalCompany introducedasimilarseriesofresinsformoldingpurposesunderthetradenameDerakaneresins [1].Theviscosityofneatresinsishigh;hence,reactivediluents(e.g.,styrene)areaddedtoobtain solutionswithlowerviscosities(100 500poise).NotableadvancesinVEresinformulations includelow-styrene-emissionresins,automotivegradeswithhightensilestrengthandheatdeflectiontemperature,hybridgradesthatbalanceperformanceandeconomy,andmaterialsforcorrosion resistance.

1.3 SYNTHESISOFUNSATURATEDPOLYESTERRESINS

UPisoftensynthesizedasaviscousliquidthroughthemeltcondensationofanaromaticdicarboxylicacidsuchasphthalicacidoranhydridewithpolyhydricalcoholandunsaturateddicarboxylic acidoranhydride.Theviscosityofthereactionproduct/oligoester(OER)isreducedusingareactivediluentsuchasavinylmonomer,usuallystyrene.FreeradicalcopolymerizationbetweenstyreneandthedoublebondsofUPresultsinarigidthree-dimensionalcross-linkedstructure,which isaheterochainthermosettypeofpolymer.Methylethylketoneperoxide(MEKP)isastandard catalystthatinitiatesthecuringreactionincombinationwithacobaltorcobalt-amineactivatorsystem/acceleratoratroomtemperature.OtherfreeradicalsusedforcuringUPRsincludebenzoylperoxide(BPO)orcumenehydroperoxide [2].Aftersynthesis,aninhibitorisaddedtotheresinto providealongstoragelife,fastcure,andtominimizecatalyzedoruncatalyzeddrift,undesirable colors,odors,orsideeffects.Hydroquinone,4,4-dihydroxybiphenyl,andsubstitutedcatecholsare someexamplesofinhibitors [3].

Attemptshavebeenmadebyvariousresearcherstotailorthemechanical,thermal,corrosion, andfireresistancepropertiesofUPRsforvariousapplications.Parkeretal.suggestedtheuseof isophthalicacidforimprovedmechanicalpropertiesandcorrosionresistance [4].Atwo-stagesynthesisprocesswaspatentedbyWatanabeetal.toaddressthenecessaryimprovementsusing dimethylterephthalateinsteadofisophthalicacid [5].Styrene,vinyltoluene,tert-butylstyrene, chlorostyrene,anddiallylphthalatehavebeenusedasreactivediluents.Theeffectsofvariousconcentrationsofanhydride(PAandMA)onmechanicalpropertieswerereportedbyThomasetal., with60% 70%MAshowingthebestmechanicalproperties [6].Theyalsosynthesizedvariousformulationsbyvaryingboththeanhydrideandthealcoholconcentration.Amixtureof60%MA withPAyieldedanUPRwiththebestmechanicalproperties.However,resinwithahigherproportionofPAwasfoundtobetoughandflexible.Similarly,diethyleneglycol(DEG)increasedthe toughness,impactstrength,andflexibility,whichwaslostonstanding.Optimalpropertiesare observedwitha20/80ratioDEG/PGresintogetherwithanequimolaramountofMAandPA [7] UPRshavealsobeensynthesizedfrombio-deriveddiestersofunsaturateddiacidssuchasitaconic, succinic,andfumaricacidswithvariousdiolsandpolyolstoaffordresinsof M n B480 477,000 andglasstransitiontemperature(Tg)ofbetween 30.1 Cand 16.6 Cwithsolubilitiesdiffering basedonthestartingmonomersused [8].Yoonetal.regeneratedUPRafterrecyclingcuredUPR. TherecycledUPRexhibitedafastercuringratethanthatofneatresin.Acomparisonofthe mechanicalpropertiesoftheneatresinandthemixtures(neatresinandrecycled)revealedthat althoughthepropertiesofneatresinweresuperior,thoseofthemixturesweredependentoncompositionandwerefoundtobesuitableformanyapplications [9].

Differentproportionsofcobalt(Co)curingagentwereused(0.05% 1%).Anincreaseinthe concentrationofCofrom0%to1%ledtoadecreaseincuringtime.Thiswasreducedtohalfin thepresenceof0.05%Co [10].Theeffectofvolumeratiosofcuringagents,viz.,cobaltoctoateas anacceleratorandMEKPasaninitiator,ongelationtimeandexothermbehaviorofaUPRhas alsobeenstudied.Thegelationoftheresinwasfoundtocorrespondwiththeonsetofanincrease intemperatureduringresincuring.Thegelationtimewasfoundtovaryinverselywiththeconcentrationsofacceleratorandinitiator [11].Theviscosityoftheliquidsystemwasfoundtodecrease withincreasingtemperature,butincreasedatthecuringtemperature.ThequalityofthecuredUPR

waspredictedonthebasisofitsfragilityparameter(Mc).IntheUPR MEKPsystem,thesmaller theMcthelargerthe Tg andthebettertheheatresistance [12]

ThecuringbehaviorofUPRwasstudiedusinganexperimentalandtheoreticalmodelbyKosar andGomzi [13].Thekineticbehaviorofthecuringsystemwasinvestigatedusingbothdynamic andisothermalmeasurementsandagoodagreementwasestablishedbetweenthetwo(intermsof presentedkineticparametersandreactionheat).Heatgeneratedfromthecurereactionwasmeasuredinmoldsofcylindricalshape.Thedifferenceinheatconductivitybetweenglassandcopper wasthemainreasonforthegreaterheatgeneratedintheglassmold.

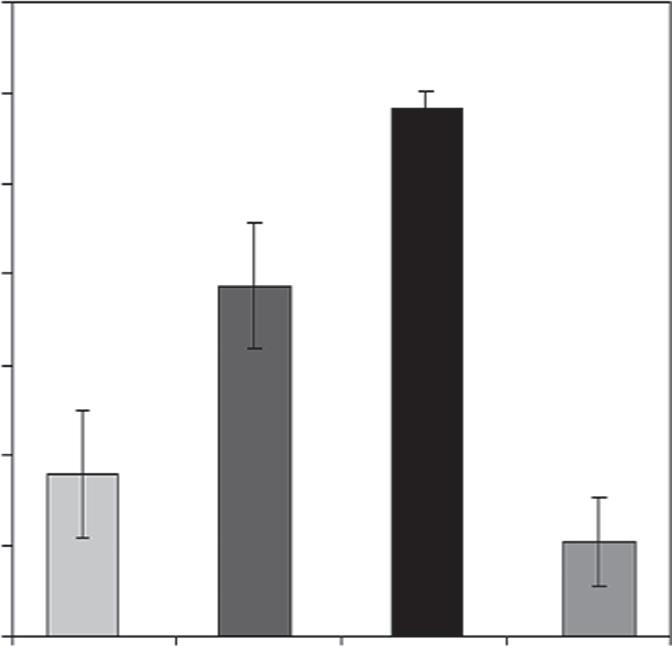

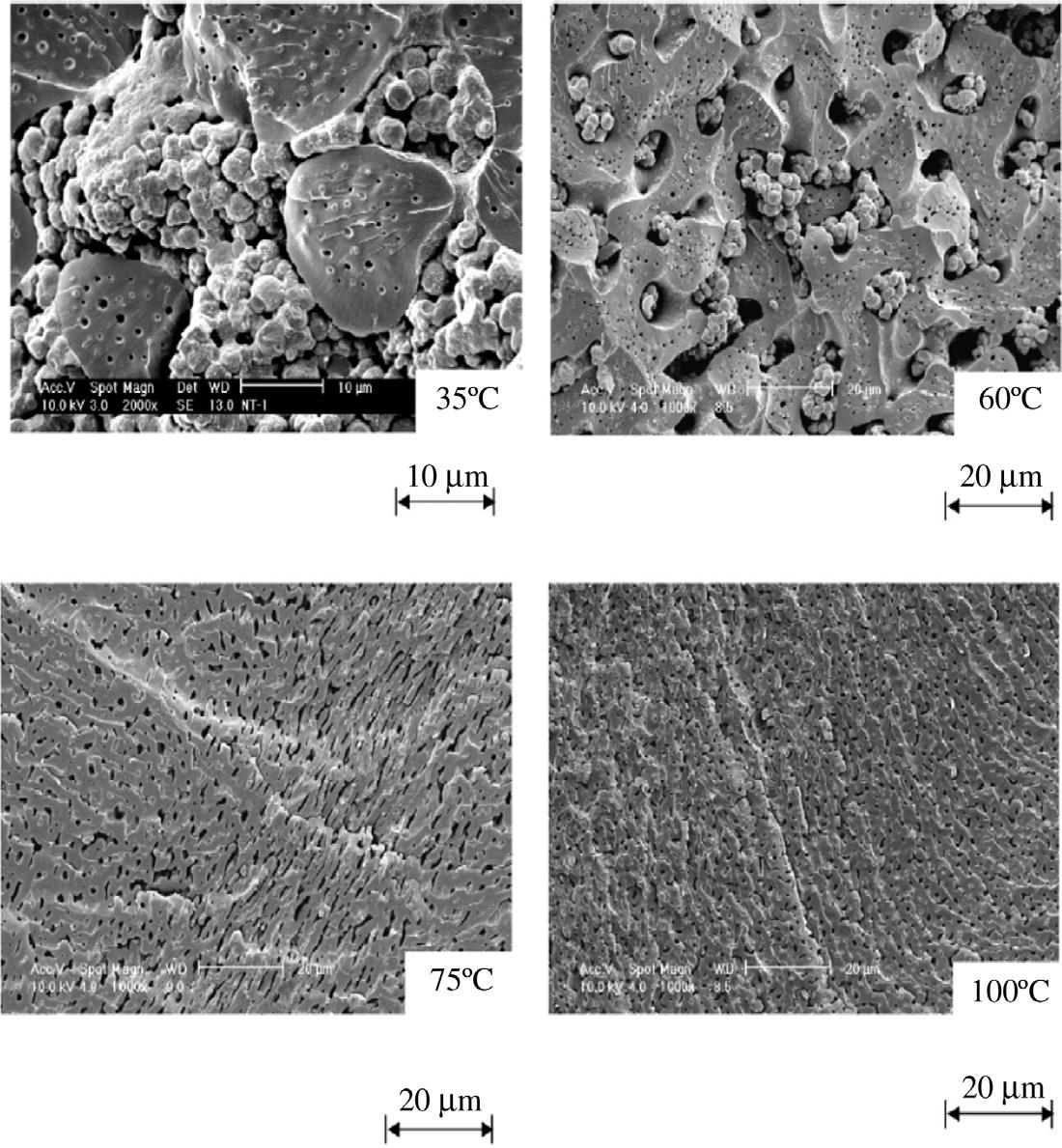

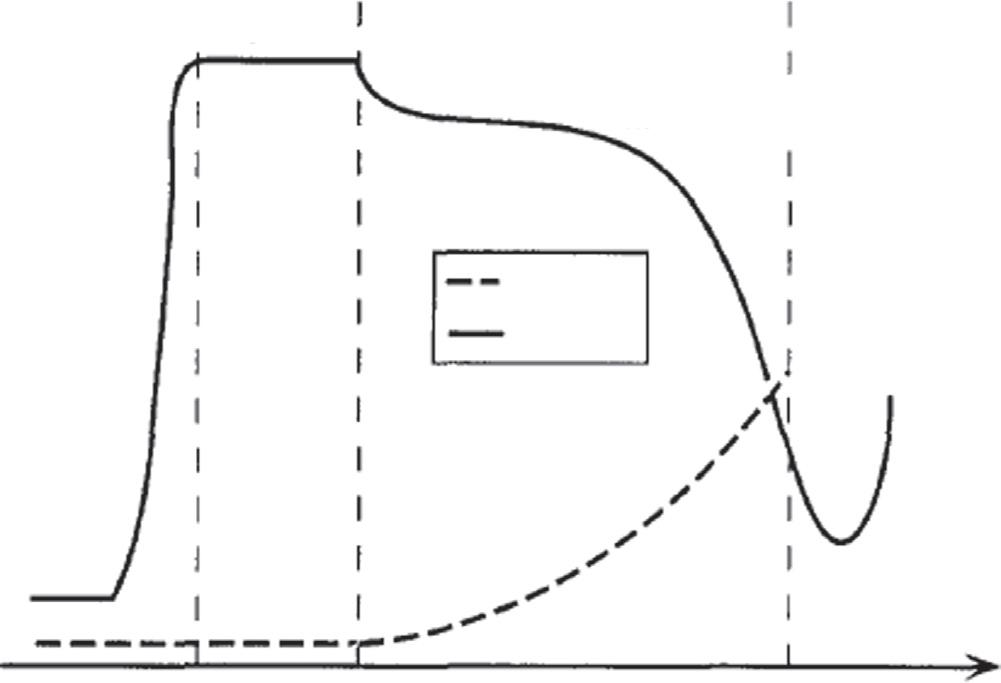

Controloverresinshrinkageofresidualmonomersisanimportantconcerninlow-temperature moldingprocesses.Thepresenceoflow-profileadditives(LPAs)canreducetheshrinkageofUPR/ styreneresinsunderproperprocessingconditions,butmayincreasetheresidualstyrenecontent.A systematicstudywascarriedouttoinvestigatetheeffectoftheinitiatorsystemandreactiontemperatureonthesamplemorphology,finalresinconversion,andresinshrinkageofUPRwithLPA. Theresultsshowedthatthefinalconversionoftheresinsystemcouldbeimprovedbydualinitiators,withtheeffectbeingprominentatlowtemperatures.Thestudyonshrinkagecontrolreported thatgoodLPAperformanceswereachievedatlow(35 C)andhigh(100 C)temperatures,but worseperformanceswereobservedintheintermediatetemperaturerange(e.g.,60 C 75 C) (Fig.1.1).Thefinalshrinkageisinfluencedbytheeffectoftemperatureonthemorphology,the relativereactionrateintheLPA-richandUPR-richphases,andmicrovoidformation [14].The samplemorphologyshowsatwo-phasecocontinuousstructureat35 C(Fig.1.2).Oneisaparticulatephase(LPA-rich)havinglooselypackedsphericalparticleswithdiametersrangingfrom1to 5mm.Theotherphaseisaflake-likeregion(UPR-rich)withdomainsizesrangingfrom10to 20mm.Atacuringtemperatureof60 C,asimilartwo-phasestructureisobserved,butitisnolongercocontinuous.Theparticulateregionissmallerandbecomesthedispersedphasewithadomain

VolumeshrinkageofUP/St/LPAsystemscuredatdifferenttemperatures(3.5%LPA,0.5%CoOct.,1.3% MEKP,0.4%TBPB,300ppmBQ).

FIGURE1.1

FIGURE1.2

MorphologyofSt/UP/LPAsamplescuredatdifferenttemperatures(3.5%LPA,0.5%CoOct.,1.3%MEKP, 0.4%TBPB,300ppmBQ).

sizeoflessthan20mm,whiletheflake-likeregionformsthecontinuousphase.Onincreasingthe temperatureto75 Cand100 C,thesizeoftheparticulateregionisfurtherreduced.Thevarious morphologicalstructuresresultindifferentinterfaceareas,stronglyaffectingtheshrinkagecontrol.

CommercialUPRscontain30% 40%styrenebymass.Themiscibilityofresinandstyrene dependsontheresincomposition.Phaseseparationisreportedwithanincreaseinstyreneconcentration.Thermalstabilityandmechanicalpropertiesaregovernedbythephasebehaviorofthemixtureandcan,therefore,becontrolledbystyrenecontent [15].Dynamicmechanicalanalysis(DMA) testshaveshownphaseseparationincuredresinwithhighstyreneconcentrations. Tg isalsodependentonstyreneconcentrationtogetherwiththermalstabilityandmechanicalbehavior [16].

1.3.1 LOW-STYRENE-EMISSIONUNSATURATEDPOLYESTERRESIN

StyrenehasremainedapreferredreactivediluentforaddingtoUPduetoitscostandavailability. Itcontrolstheviscosityandfacilitatesthecuringofpolyestersatroomtemperature.However,the useofstyreneisassociatedwithserioushealthproblemssuchasrespiratorydiseasesandskin

irritation.Itiscarcinogenicandalsoattacksthecentralnervoussystemonexposureoveralong periodoftime,leadingtopossibleheadachesanddepression.Theminimizationofstyrenevolatilizationoritseliminationusingalternativemonomersisbeingattemptedtoovercomethese problems.

Thevolatilizationofstyreneisreducedbyparaffinicwaxeswhichactasabarrier.However, thewaxlayerneedspriorremovaltoavoidproblemsofadhesiontootherparts.Theambientconcentrationofstyrenevaporcanbereducedusingspraygunsthatcanmonitortheamountofresin sprayed.Sincealternativessuchasvinyltoluene,alpha-methylstyrene,anddiallylphthalatesuggestedforstyrenealsoinvolvehealthhazards,PoillucciandHansenproposedtheuseofbioderivedlimoneneoilandpetroleum-derivedvinylneodecanoateandvinyllauratesasothersubstitutesforstyrene,buttheyexhibitlimitedchemicalcompatibility.Thestyrenecontentwasreduced by50%usingtrimethylolpropanediallylether [17].Marianiusedvariouscross-linkingagentssuch as2-hydroxyethylacrylates(HEA)oramixtureconstitutedofdiurethanediacrylateandstyreneor HEAforfrontalcuringofUPRderivedfromthereactionofMAand1,2propanediol [18].Zang etal.reportedabenzylend-cap-UPresinwithlowstyreneemissionusingbenzylalcoholasthe end-capper [19]

Fornonhalogenatedresins,amarkedrestrictioninstyreneemissionisachievedbyincluding long-chainalpha-olefinswith18 40carbon(C)atomswithouttheadditionofwax.Theseolefins ontheirownwillnotusuallyprovidesuchamarkedrestrictioninstyreneemission,butwillallow fortheincorporationofawaxycompoundinanamountsufficientlylargetoachievethedesired styreneemissionrestrictionwithoutincurringtheexpecteddisadvantagesassociatedwiththeincorporationofsuchlargeamountsofwaxycompound [20]

1.3.2 STYRENE-FREECOMPOSITIONSFORCURABLECOATINGS

WhenUPRsareusedascoatings,styrene-freecompositionsarefavoredsincevolatileemissionsby suchcompositionsareexpectedtobelow.Anexampleofsuchaformulationconsistsofonecomonomerselectedfromthe(meth)acrylatesofcycloaliphaticalcoholsandoptionalcomonomerscould betetrahydrofurfuryl(meth)acrylate,methoxypolyethyleneglycol,mono(meth)acrylate,ethylene glycoldimethacrylate,anddi(ethyleneglycol)di(meth)acrylatewhilethecuringcanbedoneby radiationand/orthroughtheperoxideorthermalroutes.Morespecifically,curingcanbeperformed byadoptingaprocesscomprisingatleastonestepofradiationand/orperoxidecuring [21].

Styrene-freeUPRcoatingscuredbyinfraredradiationsaredescribedascontaininganunsaturatedethercomponentaswellassaturatedmonohydricalcoholalongwithdicarboxylicacidand dihydricalcohol [22].Also,radicallycurablestyrene-freecoatingsareclaimedtobecomposedof compoundscontaininga(meth)acryloylgroupand/orvinylethergroupsalongwithparaffin,aplasticizer,andcarbamicacid [23].Styrene-freecompositionsarereportedbyusingvariousreactive diluentssinglyorincombinationsuchas2-hydroxyethylmethacrylate,2-hydroxypropylmethacrylate,2-HEA,2-hydroxypropylacrylate,andrelatedcompounds [24]

UPRcanalsobeobtainedasareactionproductofatleastonediolhaving2 8Catoms,one monoalcoholwithatleastoneallylicunsaturation,andatleastonesaturatedaliphaticmonoalcohol having4 10Catomsoronearomaticmonoalcoholhaving7 10Catoms.Thecoatingormolding compositionofsuchaUPRiscurablebyradiationand/orthroughtheperoxideorthermalroutes [25].McAlvinreportedUPRderivedfrombiologicallyrenewableresourcesandrecycledmaterials,

whicharestyrene-freeandultralowvolatileorganiccompound(VOC)resinsthatprovidematrix materialstoproducemoreecologicallyfriendlycomposites [26].Astyrene-freeUPRforminga stabledispersioninwaterhasbeenreported.Themodificationwasdonebyintroducingpolar hydrophilicgroupssuchascarboxylicandsulfonicgroups(sodium5-sulfonatoisophthalicacid) intotheresinmolecule,whichensuregoodtolerancetowater.Styrenehasbeenreplacedwiththe glycerolmonoethersofallylalcoholandunsaturatedfattyalcoholsasreactivebuilt-incross-linking monomersforresinmodification [27].

1.3.3 MODIFICATIONOFUNSATURATEDRESINFORVISCOSITYCONTROL

UPRshavereplacedsheetmetalinmanyapplicationssuchasintheautomotive,electric,andhome applianceindustriesasaconsequenceoftheirpropertiessuchasbeinglightweight,havinghigh strength,andtheirnoncorrosivenature.UPRcompositeproductsaremanufacturedbycompression moldingintheformofsheetmoldingcompounds(SMCs)orbulkmoldingcompounds(BMCs), throughinjectionmoldingintheformofBMC,resintransfermolding,casting,andhandlayup. Chiuetal.attemptedtodevelopUPRsystemsexhibitingviscosityprofilepropertiessuchasrapid increaseduringmaturation/thickeningandmoldfillingsothattheycanbehandledeasily,have goodfibercarryingcharacteristics,andlong-termstability.Forgoodmaterialflow,asignificant reductioninviscosityisrequiredduringmoldingwhichfacilitatesthecompletefillingofthemold aswellasthecompletewettingofthefillerandotheringredientsinthesystembytheUPR [28].

Fig.1.3 showstheidealviscosityprofilesforSMCsandBMCsduringmolding.

Chemically,thickeningor“maturation”occursbylinkingupvariousUPRmoleculestogetherto formpolymerchainsofconsiderablyhighermolecularweights.Usually,thisisdonebyaddinga

FIGURE1.3

IdealviscosityprofileforSMCsorBMCsduringmolding:(I)thickening;(II)storage;(III)moldfilling;and(IV) curing.

di-ormultifunctionalcompoundtothesystemwhichcouplestwoormorepolyestermolecules togetherviatheirterminalhydroxyland/orcarboxylgroups.AsUPRmoleculesusuallycontain morethantwofunctionalgroups,theactualproductformedisacomplexnetworkofinterconnected polymerchainsratherthandiscreteindividualchains.CompoundsusedforthickeningUPRsare knownas“thickeningagents”or“maturationagents.”Twotypesofcompoundsareusedasthickeningagents.ThefirsttypecomprisesGroupIIAmetaloxidesandhydroxides,forexample,MgO [29].MaturationwiththistypeofagentoccursviatheformationofionicbondsthroughthereactionofMgOwiththecarboxylicacidendgroupsofpolyestermolecules.Theothertypeofmaturationagentisdiisocyanate [30].Diisocyanatesoperatebyformingcovalentbonds,specifically urethanelinkages,withtheterminalhydroxylgroupsofpolyestermolecules.Eachtypeofmaturationagenthasitsownadvantagesanddisadvantages.ThematurationprocesswithMgO-typeagents isslow.Theyformionicbondswhichweakenatelevatedtemperaturesencounteredduringmolding.Thisresultsinareducedcompoundviscosityandhencethedesiredmaterialflow. Diisocyanatematurationagentsexhibitrapidthickening.Thecovalentbondsformedwith isocyanate-typethickenersdonotweakenatmoldingtemperaturesandhencematerialflowismore difficult.MgO-typematurationagentsarehighlysensitivetohumidityaftermaturation,whereas diisocyanatesarenot.Athermallybreakabledi-ketogroupcanbeintroducedontotheUPRmoleculebeforecuringthroughsaltformation.Thisgroup,alongwiththesalt,maybreakatelevated temperatureinmostUPRmoldingoperationsandthereforereducethecompoundviscosityupon heating;hencethedesiredamountofmaterialflowisrealized.ModifiedresinsarefurtherthickenedwithMgOordiphenyldiisocyanate.Thisexhibitsafastviscosityriseduringmoldinganda stableviscosityduringroomtemperaturestorage [28]

MoldedarticlesmadewithconventionalUPRsoftenexhibitpoorsurfacefinishes.ThisisprobablyduetoshrinkageoftheUPRduringthemoldingoperation.LPAsareusedtoovercomethis problem.AlongwithLPAs,goodmaterialflowduringmoldingisalsonecessarytoobtainfinishes ofthehighestquality.ThereducedmaterialflowencounteredwhendiisocyanatesareusedasthickenersreducestheeffectivenessofLPAinthesesystems,whichinturnmayleadtosignificantfinishproblems.OneproposaltoovercomethislimitationistouseacombinationofbothMgO-type anddiisocyanate-typethickenersinthesamesystem [31].

1.4 UNSATURATEDPOLYESTERSRESINBLENDS

Polymerblendsaremadebythephysicalmixingoftwoormoredifferentpolymersorcopolymersto produceamixturewithdesirablemechanicalandphysicalproperties.Usually,the Tg ofcuredUPRs arehighandtheirbrittlenesspresentsanobstaclefortheiruseinengineeringapplications [32].The mechanical,physical,andthermalpropertiesofUPRcanbeimprovedbyblendingwithotherpolymersorbyreactingthemwithdifferentadditivesormodifierswhichgenerallyformaseconddispersedphaseaftertheresiniscured.Blendsshowthedemandedperformanceatlowcost.

1.4.1 UNSATURATEDPOLYESTERSRESIN ELASTOMERBLENDS

TheadditionofelastomericphasestoUPRsusuallyimprovestheiroverallductilityoverawide rangeoftemperatures,toughness,andimpactresistances.ElastomersareblendedwithUPRbefore

curingbyphysicalandchemicalmethods.Whenblendsareformedbythephysicalmixingoftwo ormorepolymersatleast5%ofanotherpolymerisnecessarytoformablend.Ifthecomponent polymersaremiscible,asingle-phaseblendisobtained.Iftheyareimmiscible,amultiphaseblend isformed.Evenifrubberadditivesaresolubleinuncuredresin,phaseseparationduringcuringis advantageoussincetheseblendsaretougherthanhomogeneousblends [33,34].Thepresenceof elastomericdomainsincreasestheabsorptionanddissipationofmechanicalenergy.Various mechanismsproposedfortougheningbyblendingwithrubberincludethedebondingoftherubber matrixinterphase,energyabsorptionbyrubberparticles,matrixcrazing,shearyielding,andcombiningshearyieldingandcrazing [32,33].

Essentialcharacteristicsofelastomersfortougheningare [35]:

1. Thepresenceofasufficientnumberofpolargroupstoenhancesolubilityintheresin.

2. Theelastomershouldhaveaslowrateofcross-linkingcomparedtotheUPRusedtofacilitate thedistributionofdiscreteelastomericparticlesduringcross-linking.

3. Theweightoftheelastomershouldberelativelyhigh.

4. Themajorpartoftheelastomershouldbethermodynamicallyincompatiblewithresin.

1.4.1.1 Unsaturatedpolyestersresin naturalrubberblends

Naturalrubberisanelasticmaterialpresentinlatexfromrubbertrees.Itseasyavailability,low cost,andexcellentphysicalpropertiessuchasgoodresilience,hightensilestrength,superiorresistancetotearandabrasion,goodtack,andself-adhesionhaveledtoitsuseinpreparingblends.On theotherhand,ithaspoorageresistanceandoilresistance.

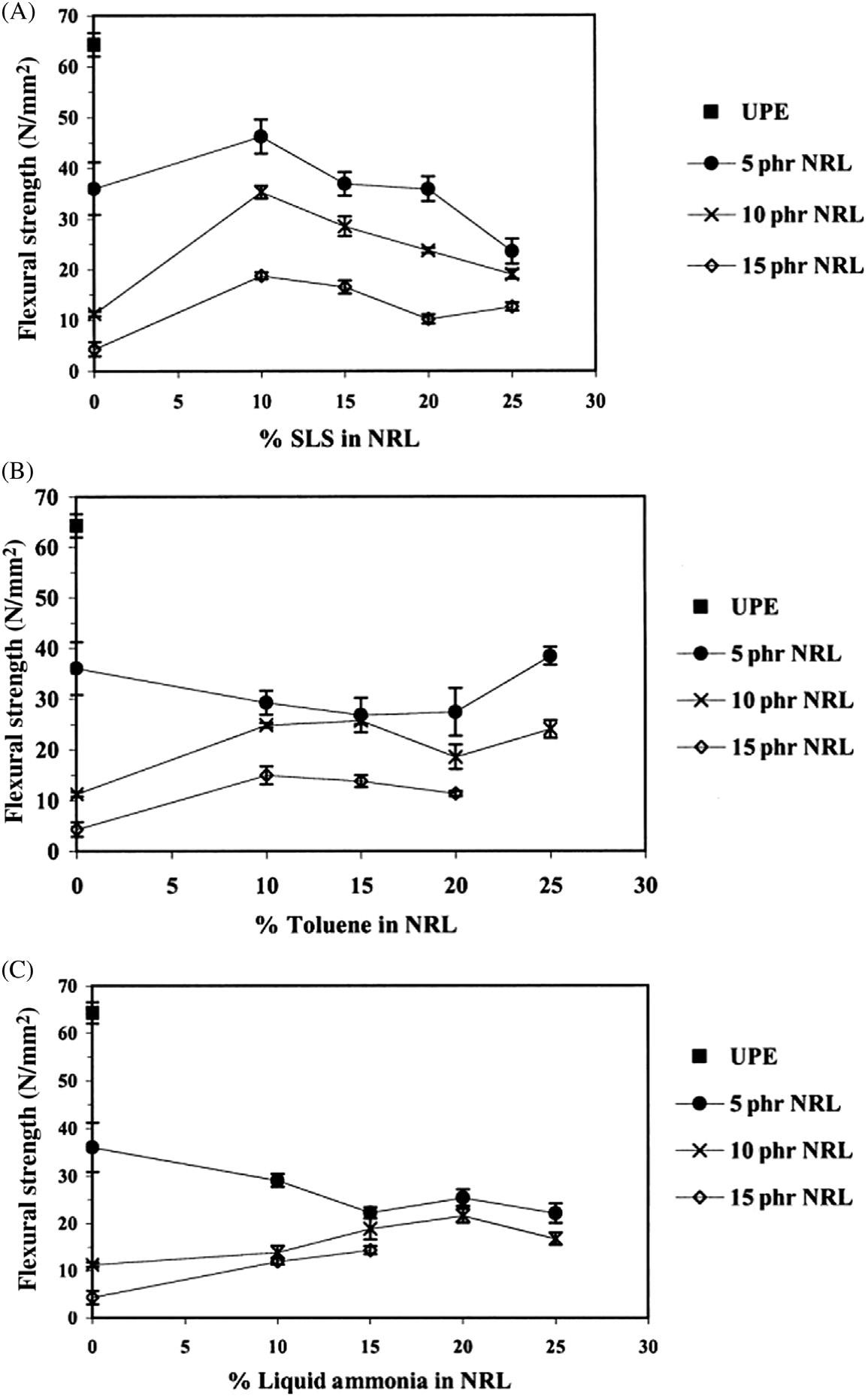

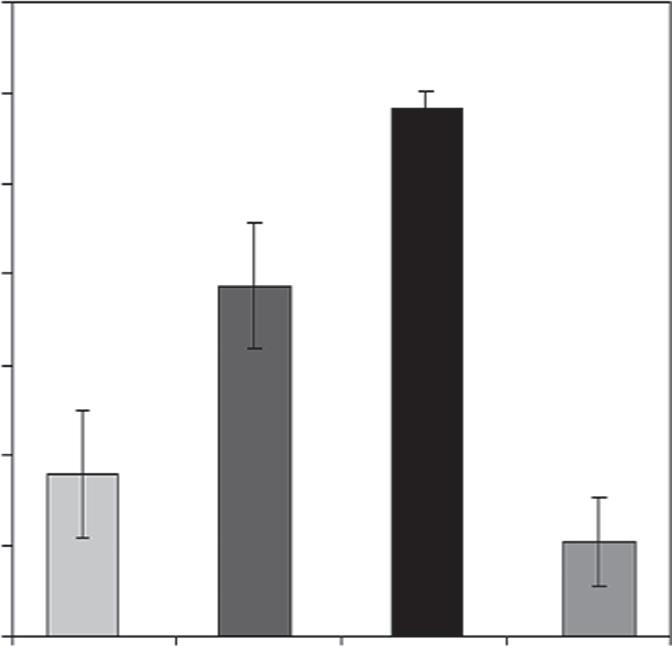

BlendsbasedonUPRfromrecycledpoly(ethyleneterephthalate)(PET)wasteswithvarying percentages(0% 7.5wt.%)ofliquidnaturalrubber(LNR)havebeenpreparedbyHishametal. Theyarefoundtoexhibitgoodcompatibilitycomparedtocommercialresins,butshowhigher Tg. Ablendwith2.5wt.%LNRrenderedthehigheststrengthandbestdispersionofelastomerparticles whilecommercialresinrequired5%ofLNRtoachieveoptimumproperties [36].Studiesonthe influenceofthesourceofwaterandimmersiontimeonthemechanicalpropertiesofUPR natural rubberblendshaverevealedincreasesintheimpactstrengthandstrainratesanddecreasesinthe Young’smodulusofpolymerblendsunderidenticalconditions [33].HybridprotonexchangemembranesasanalternativeforNafioninpolymerelectrolytemembranefuelcell(PEMFC)weredevelopedbyJimenezetal.UPR naturalrubberblendswerepreparedandsubjectedtotheprocessof vulcanizationandTiO2 wasaddedasaninorganicload.TheblendsexhibitedhigherYoung’smoduliandstrainscomparedtocommercialNafionmembranes.Thewateruptakeaswellasion exchangecapabilitiesofthevulcanizedmembranewasfoundtobesuperior [37].Naturalrubber latex(NRL)whenblendedwithUPRinthepresenceofdispersionaidssuchassodiumlaurylsulfate(SLS),toluene,andammonialedtoanimprovementinimpactstrength.However,theflexural strengthdecreasedwithNRLcontentintheblend(Fig.1.4).Theimpactstrengthwashighestwhen NRLandtoluenewere15phrand20wt.%,respectively [38].

1.4.1.2 Unsaturatedpolyestersresin-syntheticrubberblends

SyntheticrubbershavealsobeenusedforblendingwithUPRs.BinarypolymerblendsofUPRand differentweightratios(0%,5%,10%,and15%)ofnitrilebutadienerubber(NBR)havebeenpreparedbymechanicalmixingusingtolueneasasolvent.However,theyshowedpoormechanical

FIGURE1.4

ImpactstrengthofpureUPRandUPR/NRLblendsusingdifferentdispersionaids:(A)usingSLSasadispersion aid;(B)usingtolueneasadispersionaid;and(C)usingliquidammoniaasadispersionaid.

properties,exceptfortheirstrainrateswhichwerehigher.Thewearratesoftheblendswerefound todecreasewithincreasingNBRcontent [39].CherianandThachilpreparedblendsofUPRwith elastomersbearingreactivefunctionalgroupssuchashydroxy-terminatedpolybutadiene,epoxidizednaturalrubber,hydroxy-terminatednaturalrubber,andmaleatednitrilerubber.Theseelastomersshowbettercompatibilitywithresinandimpartsuperiortoughness,fractureresistance,and impactresistanceascomparedtounmodifiedelastomers [34].TheauthorsalsosynthesizedUPR blendsusingtwodifferentstrategiesforincorporatingrubber.Thefirstmethodinvolvesthedissolutionofmasticatedelastomerssuchasnaturalrubber(NR),styrenebutadienerubber(SBR),NBR, butylrubber(IIR),andchloroprenerubber(CR)instyrenefollowedbyblendingwithUPR,while inthesecondmethod,elastomersaremodifiedwithMAandthendissolvedinstyreneandblended withUPRtogetmaleatedelastomers.BlendshavingelastomersmodifiedwithMAshowimproved mechanicalproperties(toughness,impactresistance,andtensilestrength)comparedtounmodified rubbers(Tables1.1and1.2).Theperformanceofnitrilerubberisfoundtobefarsuperiorin

Table1.1SummaryofPropertiesofUPRModifiedWith0%

5%Elastomers

MaximumImprovementAchieved(%)/Elastomer Concentration(%)

PropertyUPR

Tensilestrength(MPa)33.357.8/2.553.9/283.4/2.540.8/2.516.4/2

Modulus( 3 102 MPa)14.124.2/2.515.1/28.6/2.521.3/2.52.9/2

Elongationatbreak(%)2.2544.4/2.533.8/288.9/2.524.4/2.57.1/1

Toughness(MPa)0.36136/2.5111/2286/2.597.2/2.541.7/2

Impactstrength( 3 10 2 J/mm2)1.21150/2.5107/2239/2.590.1/2.550.4/2

Hardnessshore D 88 0.6/1 0.6/10/1 1.1/1 1.7/1

Abrasionloss(cc)0.3732.4/518.9/521.6/527.0/537.8/5

Waterabsorption(%)0.2190.5/538.1/547.6/557.1/576.2/5

Table1.2SummaryofPropertiesofUPRModifiedWith0% 5%MaleatedElastomers

Tensilestrength(MPa)33.2884.0/2.563.0/297.8/2.571.5/2.535.0/2

Modulus( 3 102 MPa)14.124.8/2.510.8/28.9/2.515.2/2.56.0/2

Elongationatbreak(%)2.2558.7/2.558.2/295.6/2.564.9/233.8/2

Toughness(MPa)0.36214/2.5161/2303/2.5184/2.588.9/2

Impactstrength( 3 10 2 J/mm2)1.21203/2.5116/2.5247/2.5136/366.9/2

Hardnessshore D 88 0.6/1 0.6/10/1 1.1/1 1.1/1

Abrasionloss(cc)0.3737.8/518.9/527.0/532.4/548.6/5

Waterabsorption(%)0.21100/542.9/557.1/571.4/590.5/5

comparisontoallotherrubbers [32].Tougheningagentslikecarboxylandvinylterminatednitrile rubbersaswellasurethanerubbershavealsobeenusedforpreparingblends.Theincorporationof flexiblepolyorganosiloxanesegmentsintheUPRnetworkenhancesitsflexibility [34].Thethermal stabilityoftoughenedUPR NBRimprovedonreinforcingitwithslagpowder.Thesamplemodifiedwithstearicacidshowedbettermechanicalproperties.Afireresistancetestshowedreduced masslosswhenexposedtodirectopenflame [40].

Suspeneetal.observedanimprovementinthecompatibilityofaUPR carboxyl-terminated butadiene-acrylonitrilerubber(CTBN)blendbyexchanging10%CTBNforepoxy-terminatednitrile rubber(ETBN)inablendwith5phrofrubber.Intheresultingtriblockcopolymeradecreasein particlesizeofthedispersedrubberyphasefrom12to5 μmwasobservedandtheinterfacialtensionbetweenUPRandCTBNisalsoreduced.Theimpactbehaviorofthetriblockcopolymerwas enhancedduetoareductioninfailurescausedbythepresenceoflargeparticles [41].

1.4.2 UNSATURATEDPOLYESTERSRESIN PHENOLFORMALDEHYDERESIN BLENDS

UPRsarehighlyflammableandproducelargequantitiesofsmokeandtoxicgasesonburning.The flameresistanceofUPRcanbeimprovedbyaddingflame-retardantadditivesorbyblendingit withotherpolymerssuchasphenolicformaldehyderesins(PF).Theadditionofadditivesusually leadstounfavorablereactionsbetweenthepolymerandadditivesresultinginthedeteriorationof themechanicalpropertiesofpolymerstosomeextent.BlendsofUPRandPFshowgoodfireretardantabilitiesduetothehighcharringtendencyofPF.PFisknowntogeneratelesstoxicgasesand smokeandleavealargeamountofcarbonresidue [42]

Amongphenolicresins,resolesandnovolacsareimportant;oncuring,theyproducehighly cross-linkedthermallystablenetworkstructures,whichonexposuretohighheatorfire,char,thus producingrelativelylowlevelsofcombustiblevolatiles [43].Kandolaetal.usedethanol-soluble epoxyandallyl-functionalizedphenolicresolestoovercometheincompatibilityofUPRandPF resinsresultingfromtheirchemicalstructuresandcuringmechanisms.Theydemonstratedan increaseincompatibilitywithfunctionalization.Allyl-functionalizedresoleexhibitedthebestcompatibilitywithUPR.Amechanismhasbeenproposedfortheirdecompositionandinteractionsand theireffectsonflammabilitybasedonthermalbehaviorandinfraredspectroscopicanalysisofvolatiledegradationproducts [44].Mahadaretal.blendedUPRwithresoletoproducematerialswith goodflameretardancy.Theblendsshowedgoodcompatibilitywhencompoundedwithkenaffiber, whichisanaturalfiber.Althoughthethermalstabilityoftheblendswasimproved,themechanical propertieswerefoundtobeslightlyinferior [42].Novolacresinwasmodifiedwithfree-radically curablemethacrylategroups(M-Nov)withstyrenetogiveamaterialwithahigher Tg,betterthermalandthermo-oxidativestabilities,andbetterflameretardancythancuredUPR,withanapproximately20%lowermodulusatroomtemperature(RT) [43].Analternativemodificationofnovolac withthevinylbenzylgrouptoobtainahomogeneous,free-radicallycocuredphenolic/UPRblend withbetterflameretardancythanthosemadeusingM-Novhasalsobeenattempted.Thecured vinylbenzylatednovolacanditscocuredblendswithUPRexhibitedsuperiorflameretardancyin comparisontocuredUPRandhavepotentialapplicationsasmatrixresinsinglass-reinforcedcompositelaminates,especiallyformarinestructures [45]

1.4.3 UNSATURATEDPOLYESTERSRESIN EPOXYRESINBLENDS

UPRandepoxyresinaremisciblewitheachotherandshowgoodcompatibility.Hybridpolymer networks(HPNs)basedonUPRandepoxidizedphenolicnovolacs(EPNs)havebeenprepared throughreactiveblending.EPNshowsgoodmiscibilityandcompatibilitywithUPR.Theblend showssubstantiallyimprovedtoughnessandimpactresistancealongwithbetterthermalstability. Blendswith5wt.%ofEPNexhibitthehighesttensilestrength [46,47].HPNswerealsosynthesized bycoreactingUPRwithepoxidizedcresolnovolacandDGEBA.Cocuredblendedresinsshowed substantialimprovementsintoughnessandimpactresistancealongwiththermalstabilityand dampingproperties.TheperformanceoftheblendswithEPNwasfoundtobesuperior [47].

AnewbioresinwasproducedbyMustaphaetal.byblendingUPRwithepoxidizedpalmoil (EPO)in10,20,and30wt.%.TheadditionofEPOinUPRresinloweredthe Tg at20wt.%loadingofEPO, Tg decreasedby 6 5 C,andthestoragemodulusdecreasedbyabout20%incomparisontoUPR.However,theimpactpropertiesincreasedwiththeamountofEPOadded.EPO providesarubberyphaseandabsorbstheenergyappliedbytheimpactloadings.Bio-basedthermosetUPRblendedwithEPOmayreducethedependencyonconventionalcompositematrixsystems madefrompetrochemicals [48]

UPRswerepreparedbyreactingbisphenolAepoxyresinwithvariousglutaconicacidsusinga basecatalyst.Theywerefunctionalizedbytreatmentwithacryloylchloridetoyieldacrylated polyesters(APEs).BlendingoftheseAPEswerecarriedoutwithstyrenemonomers.Incomparison toAPEs,theseblendsexhibitedhighcuringtemperatures,slowdegradationofproducts(i.e.,low weightloss),goodchemicalresistances,andgoodmechanicalandelectricalstrengths [49]

1.4.4 UNSATURATEDPOLYESTERSRESIN ESTERSBLENDS

ArdhyanantablendedVEandUPRcontainingaromaticbenzenerings(10% 80wt.%).TheUPR/ VEblendswerepreparedbymechanicalblendingandcuredatroomtemperatureusing4%of MEPKintheabsenceofanaccelerator.Themechanicalandthermalpropertiesoftheblendswere foundtobesuperior [50].Polymerblendsofunsaturatedpolyetheresterresinsanddicyclopentadienepolyesterresinsyieldcuredthermosetresinshavinghightensileandflexuralstrengths.The coactionresultingfromblendedpolymersprovidesaneconomicwaytoimproveboththestiffness andstrengthofcuredpolyetheresterresins [51]

Styrenatedpolyesterresinswereblendedwithpoly(vinylacetate)(PVAc).Acocontinuous phasemorphologywasobservedinblendscontainingPVAcwithconcentrations $ 6%andstyrene levels $ 40%.Anincreaseinthestyrenecontentfrom20%to80%resultedinthesharpeningof theprincipaldynamiclosspeak,andthepeaktemperaturereachedamaximumataconcentration of40%.ThechangefromparticulatePVActococontinuousstructurewasassociatedwithasharp dropinGBcandKBc.Parallelstudieshaveshownthistransitiontobeimportantin“low-profile” behavior [52].

1.4.5 UNSATURATEDPOLYESTERSRESIN POLYSACCHARIDEBLENDS

ModifiedUPwasblendedwithcelluloseandethylcellulose(5% 25%)atambientconditionsin thepresenceofMEKPasacuringagent.TheblendsshowedcompatibilitywithmodifiedUPasa

resultofthepolar OHgroupsintheirstructure.Theresultsindicatethatcelluloseincreasesthe impactstrength,hardness,anddielectricconstantanddecreasesthebendingoftheblends,while ethylcellulosecausesanincreaseintheimpactstrength,hardness,andbendingbutadecreasein thedielectricconstantoftheblends [53].TheworkdonebySalihetal.involvestheblendingof UPRwithstarchpowder(0 3wt.%fraction)withparticlesizeslessthan45 μm.Theblendswere furtherirradiatedbyUVacceleration.TheUVirradiationshadanoticeableeffectonmostofthe mechanicalpropertiesoftheblends.ThemechanicalpropertieswerefoundtobeafunctionofparticlesizeandthedispersionofstarchpowderintheUPmatrix.Asignificantdecreasewasobserved intheultimatetensilestrengthandelongationpercentagewithincreasingweightfractionsofstarch powder,whilethemodulusofelasticityoftheblendshowedasignificantincrease.Othermechanicalpropertiesoftheblendssuchashardness,impactstrength,fracturetoughness,andflexural strengthalsoincreasedwithincreasingweightfractionsofstarchpowder(1%),excepttheflexural modulusat1.5%,followedbyadecreaseathigherpercentagesofstarch [54].

1.4.6 THERMOPLASTICBLENDS

XanthosandWanreportedthemeltblendingofpolypropylene(PP)withanonconventionallow molecularweightUPR(5:3PP/UPRwt.ratio)inthepresenceoforganicperoxidebyreactiveprocessing.Thereactedblendexhibitedafinerandmoreuniformmorphologyanddifferentproperties.The resultsindicatethepossibilityoftheformationofblockand/orgraftPP/UPRcompatibilizingcopolymers [55].UPRblendsofdifferentcompositionswerepreparedwithtwodifferentthermoplastics, polystyrene(PS)andpolycarbonate(PC),bymixingsolutionsofthepolymersinchloroform.Amiscibilitystudyofthesesolutionblendswascarriedoutusingsimpleandinexpensivetechniques.The UPR/PSblendwasfoundtobemisciblewhiletheUPR/PCblendwasimmiscible [56]

Hydrogenbondinginteractionsbetweenthetwocomponentsinpoly(ethyleneoxide)(PEO)/ OERblendsandPEO/cross-linkedUPRblendswereunderstoodbyFouriertransforminfraredspectroscopy(FTIR)study.Thesehydrogenbondinginteractionsareresponsibleforthemiscibilityof theblends.ThecrystallizationkineticsandmorphologyofPEOinthePEO/UPRblendwasfound tobedependentoncross-linking.Atthecrystallizationtemperature,theoverallcrystallizationrate ofPEOinthePEO/UPRblendwaslargerthanthatinPEO/OERblend [57].Lietal.usedan improvednuclearmagneticresonance(NMR)methodtomeasuretheinterphasethicknessandto interpretthephasebehavior,miscibility,heterogeneousdynamics,andmicrodomainstructureofa thermosetblendofUPRwithacotriblockpolymerofPEO-block-poly(propyleneoxide)-block-PEO (PEO-PPO-PEO).Theresultsindicatedthatthermodynamicinteractionbetweentheblockcopolymerandthecross-linkedthermosetresinisakeyfactorincontrollingthephasebehavior,domain size,andinterphasethicknessoftheseblends [58].Althoughpoly(ε-caprolactone)(PCL)wasfound tobemisciblewithuncuredpolyester/OER,itispartiallymisciblewithcrosslinkedpolyesterresin (PER).ThemiscibilityofPCLandOER/PERwasfoundtobeaconsequenceofintermolecular hydrogenbondingbetweenthecomponentsoftheblend.Theimportanceofthecontributionof entropytothemiscibilityofthermosettingpolymerblendsisalsoshownfromFTIRresults.The spheruliticmorphologyoftheblendswasremarkablyaffectedbycross-linking.BirefringentspheruliteswereobservedinuncuredPCL/OERblends,whereasadistinctpatternofextinctionrings, whichwasabsentbothinthepurePCLorintheuncuredPCL/OERblends,wasapparentinthe cross-linkedPCL/PERblends [59]

1.4.7 SIMULATIONSTUDIESONBLENDS

Ruffieretal.performedasimulationtoshowtheconnectionbetweenvoidsscatteredinsidethe UPR polyvinylacetateblendandtheblendphaseseparationmechanism [60].Theeffectofcuring temperatureonthemorphologyofUPR/styrene/PVAcblendswith5%and10%PVAccured between75 Cand150 Cwasstudied.Acocontinuousphaseseparatedstructureresultedfor10% PVAc.Aninsignificantchangeinmorphologywithcuringtemperaturewasobservedforthiscomposition [61].

Acomputersimulationmodeltoanalyzethereactioninjectionmoldingprocessofpolyurethane andUPblendshasalsobeenproposed [62].Mezzengaetal.modeledthefreeenergyofmixing duringpolymerizationinblendsofUPR,styrene,andallyletherfunctionalizedhyperbranched polyesters.TheycombinedtheFlory Hugginstheoryandgelpermeationchromatography(GPC) molecularweightmeasurementsduringmodeling.ThecurebehaviorsofUPR,phenol,andUPR/ phenolblendsweredetectedandsimulatedusingdifferentialscanningcalorimetry(DSC)and DMA.Curebehaviorwasusedtocalculateandpredictthecurerate,curetemperature,conversion, andchangesinthe Tg alongwithvariouscureordersinordertoobtaintheoptimumparametersfor processing [63].Withdynamicscanning,isothermalDSCprocedures,andBorchardt Daniels dynamicsoftware,curedatafortheUPresinwereobtained;90%oftheconversionrateat100 C beingachievedafter15minutes.However,forthephenolandUPR/phenolblends,gradually increasingthetemperaturewasfoundtobethebestforcuringaccordingtotheDSCandDMAtest results [64]

1.5 INTERPENETRATINGNETWORKSOFUNSATURATEDPOLYESTER RESIN

Thesearearelativelynewtypeofpolymerblendswhichconsistsoftwoormorecross-linkedpolymersinwhichatleastonenetworkissynthesizedinthepresenceoftheother.Althoughdifferent modificationprocessesarereported,theformationofinterpenetratingpolymernetworks(IPNs)isa promisingmethod.

1.5.1 UNSATURATEDPOLYESTERSRESIN POLYURETHANEINTERPENETRATING POLYMERNETWORKS

Mutuallypermeablesemi-IPN-typenetworksconsistingofUPRandpolyurethaneresin(PUR) (semi-IPNUPR/PUR)havebeenpreparedusinganewmethodofaddingPURtostyrene.Both resinsformdispersedphaseswithheterogeneousmicrostructures.PURseemstoaffectthemechanicalpropertiessignificantly,buttheeffectceasesonincreasingthePURcontentabove10%.The dynamicelasticitymodulusdependsonlyoncomposition [65].IPNswithfourdifferenttypesof UPRs(commerciallyavailableunsaturatedpolyester(UPE),partiallyendcappedUPE,OH-free, andhavingacetatelinkagesattheend)andPUwerecuredwithUV.Thereactionsequencewas foundtobeanimportantfactorindeterminingthephasemixing,phasemorphology,andhence,the

mechanicalpropertiesoftheIPNs.Thesimultaneousreactionofthetworeactingsystemsresulted inacocontinuousstructurethatprovidedenhancedtensilepropertiesandimpactstrengths [66]

AseriesofBaTiO3 fiberandnanopowderunfilledandfilledIPNscomposedofpolyurethane (PU)andUPRwerepreparedusingasimultaneouspolymerizationprocess.Thedampingbehaviors anddegreeofphaseseparationoftheunfilledandfilledIPNswerestronglydependentonthePU/ UPcomponentratios,typesoffiller,andtheamountofnanopowderadded.ThefilledIPNsexhibitedsynergisticeffectsondampingproperties.Performingapolarizingprocessenhancedtheproperties.Thetemperaturerangesexhibitedexcellentconsistencyofmaximumdielectriclossand dielectricconstantwithdampinglossfactor [67].

1.5.2 UNSATURATEDPOLYESTERSRESIN ACRYLATEINTERPENETRATING POLYMERNETWORKS

Polyester poly(ethylacrylate- co-styrene)IPNsweresynthesizedusingatwo-stepinsitusequential technique.Bothsemi-andfullIPNsweresynthesized.Poly(ethylacrylate-co-styrene)actsasthe rubberyphaseandpolyesterasahardphase.Withincreasingproportionsofethylacrylateinthe IPN,theelongationatbreak,toughness,andmolecularweightbetweencross-linkswashigher,but tensilestrength,modulus,tearstrength,anddensitywerelower.ThefullIPNsshowedhighertensilestrength,modulus,tearstrength,density,andhardness,butlowerelongationatbreakand toughnesscomparedtosemi-IPNs.Thesemi-IPNsshowedhighertoughnessandelongation.The extentofcross-linkingoftheelastomerhadadeterminingroleinthemechanicalpropertyprofile. Thediameterofthedomaindependedontheamountofelastomeradded [68].Acrylate-modified PURresinwasfirstpreparedandthenaddedtoUPRtoobtainanIPNthatcouldbecuredatRT. Animprovementinmiscibilityledtohigherdegreeofpenetrationandentanglement,thusresulting inimprovedmechanicalproperties [69].Aseriesofsemi-IPNsbasedondifferentcompositionsof anacyclicPEToligomerandUPRwerepreparedwithstyreneasacross-linker,MEKPasacatalyst,andcobaltnaphthenateasapromoter.ThemixturewascuredatRT.Thetensilestrengthof theIPNsdecreased,whereastheelongationatbreakincreasedwiththeconcentrationofPET oligomer [70].

1.5.3 UNSATURATEDPOLYESTERSRESIN EPOXYRESINSINTERPENETRATING POLYMERNETWORKS

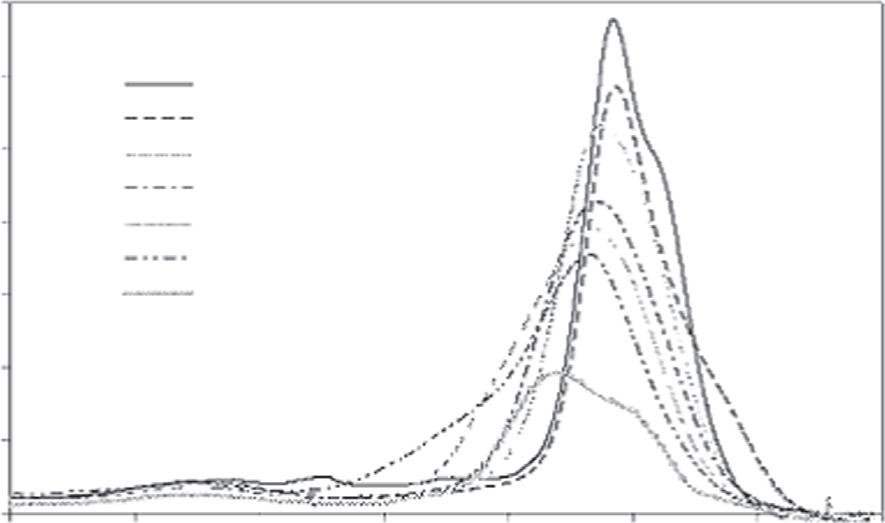

SimultaneousIPNsbasedonepoxy(DGEBA)andUPwerepreparedusing m-xylenediamineand BPOascuringagents.Single Tg suggestedgoodcompatibilityofepoxyandUP.Interlockbetween thetwogrowingnetworksledtoaretardedviscosityincrease.ThehydroxylendgroupsintheUP catalyzedthecuringreactionofepoxy;leadingtorapidincreaseinviscosity.Entanglementaffected thecrackingenergyabsorptionandwasreflectedinanimprovementintoughness [71].The Tg of simultaneousIPNswasfoundtoincreasewiththeEP(epoxypolyester)content(10% 90wt.%). IPNscontaininghigherEPcontentsexhibitedhighervaluesoftan δ (max.)(Fig.1.5)andlower cross-linkingdensitiesintherubberystateprobablyduetotheplasticizationeffectoftheEPcomponentalongwiththeheterogeneousnetworkstructure [2].StudiesonthecuringkineticsofsimultaneousUP/DGEBAIPNsshowedlowertotalheatofreactioncomparedtothatobservedwhile curingpureresins.Thiscouldbeaneffectofnetworkinterlockthatcouldnotbecompensated

100EP

10UPR:90EP

30UPR:70EP

50UPR:50EP

70UPR:30EP

90UPR:10EP 100UPR

FIGURE1.5 tan δ versustemperatureofBPO/THPA-curedIPNs,BPO-curedUPR,andTHPA-curedEP.

completelybyanincreaseincuringtemperature.Incompletecuringinisothermalmodeiscaused bybothnetworkinterlockandthevitrificationofDGEBA.Therateconstantfor50/50ofUP/ DGEBAwashigherwhiletheactivationenergywaslowerpresumablyduetothecatalyticenvironmentprovidedbythehydroxylendgroupofUPintheIPN [72,73].

AseriesofIPNswithexcellentflame-retardantanddampingpropertiesweredeveloped.The flexibilityandrangeofthermaltransitionincreasedasthecontentofUPRincreasedintheIPNs whilethehomogeneitydecreased.Theheatresistance,damping,andmechanicalpropertieswereall improvedsimultaneouslywiththeadditionofplate-shapedcarbonblack(CB)intotheUPR/epoxy IPNs [74].ShinandJengalsopreparedUPR/epoxyIPNs.AseriesofIPNsbasedonUP/epoxy weredeveloped.PhaseseparationwasobservedwhentheUPRcontentwashigherthan30%.The bestmiscibilityforIPNwasobtainedforacompositionwithsimilaramountsofhydrogendonors andcarbonylgroup [75].FromakineticstudyofEP/UPRitwasfoundthattheheatresistanceof UPwasenhancedwiththeadditionofaflame-retardantorepoxyresin [76].

Aseriesoftranslucent,compatibleIPNswerepreparedbyShakeretal.usinganelastomeric amine-curedepoxyandUPR.A45%increaseintoughnesswasobservedforoneofthecompositions.Thiswasareflectionofthehomogeneousdistributionoftherubbercomponent [77].SemiIPNsofepoxyandUPRhavebeensynthesizedwithdifferentproportionsofUPR(0% 50%). Trimethylenetetraminewasusedasaroomtemperaturecuringagent.IPNswith11.1%ofUPR exhibitedimprovedmechanicalproperties.Theblendswerefurthermodifiedbyaromaticamines suchasbenzidineanddiphenylamine.Themechanicalpropertiesoftheblendmodifiedwithdiphenylaminewerefoundtobesuperior [78].

1.5.4 UNSATURATEDPOLYESTERSRESIN PHENOLANDUNSATURATED POLYESTERSRESIN NYLONINTERPENETRATINGPOLYMERNETWORKS

IPNsofUPRandseveralphenolicresoleshavebeenreportedbyAvendanoetal.TheseIPNswere foundtoshowbothphysicalandchemicalcompatibilityastheycocuresuchthattheyresultin

cocontinuousIPNs.Theparticipationoftheallylgroupsofresoleinthecross-linkingprocessof IPNscouldbeconfirmedfromthesolid-state 13C-NMRspectra [79]

Novelsemi-IPNsofUPRandnylonhavebeenproducedbymixingdifferentamountsofNylon 66oligomers(residuesofindustrialNylon66polymerization)intoUPRandheatingfollowedby cross-linking.Nylon66wasobtainedfromindustrialwaste.Threeimportantaspectsofthiswork include(1)thepossibilityofproducingnewmaterialswithimprovedimpactstrengths,(2)theplastifyingeffectofNylon66oligomersontheUPresin,and(3)ecologicallymoreimportant,thefeasibilityofreutilizingwastematerialsforproducingengineeringmaterialswithtailoredproperties [80].

1.6 UNSATURATEDPOLYESTERSRESINCOMPOSITES

Compositesareheterogenousmaterialsmadeupoftwoormorechemicallydistinctconstituents. Thebasiccomponentsareareinforcementandamatrix.Eachoftheseshouldhaveappropriate characteristicsandfunctionbothindividuallyandcollectivelysothatcompositesattainthedesired superiorproperties.Thereinforcementcontributestothestrengthandmodulustothecomposite, whilethemainroleofthematrixistotransmitanddistributestressesinthereinforcement. Reinforcementsareoftwotypes,namelyparticulateandfibers.Commercially,glassfiber(GF)reinforcedpolyestercompositesareimportantduetotheirhighstrength-to-weightratio,lowcost, andeasymanufacturingmethods.Incomparisontoparticulate-filledcomposites,manyfiber-filled compositesareanisotropicwithtremendousstrengthinonedirection;althoughuniaxiallyoriented fibercompositeshaveveryhighmoduliinonedirection,theothermoduliarelow.Thereforetoget goodpropertiesinatleasttwoorthreedirections,fiberscanberandomlyorientedsuchthatcompositesarenearlyisotropicinaplane.Inthecaseoffibersasareinforcement,italsoprovidesprotectionagainstbothfiberaberrationandfiberexposuretomoistureorotherenvironmentalconditions.

1.6.1

CommercialinterestinGF-reinforcedUPRcompositesisduetotheirhighstrength-to-weightratio, andlowcost.

E-GFcompositespreparedusingahandlayuptechniquewithconcentrationsvaryingbetween 15and60wt.%renderedexcellentmechanicalproperties. Table1.3 showstheimprovementinthe mechanicalpropertiesasafunctionoffillercontent [81] Table1.3EffectofGlassFiberofFabricatedCompositesContentsonTensileStrength