https://ebookmass.com/product/the-mechanics-of-threaded-

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Structural Adhesive Joints: Design, Analysis, and Testing K. L. Mittal

https://ebookmass.com/product/structural-adhesive-joints-designanalysis-and-testing-k-l-mittal/

ebookmass.com

Soil Mechanics and Foundation Engineering: Fundamentals and Applications Nagaratnam Sivakugan

https://ebookmass.com/product/soil-mechanics-and-foundationengineering-fundamentals-and-applications-nagaratnam-sivakugan/

ebookmass.com

Rock Mechanics and Engineering: Prediction and Control of Landslides and Geological Disasters Helin Fu

https://ebookmass.com/product/rock-mechanics-and-engineeringprediction-and-control-of-landslides-and-geological-disasters-helinfu/ ebookmass.com

Media Ethics: Key Principles for Responsible Practice (Ebook PDF)

https://ebookmass.com/product/media-ethics-key-principles-forresponsible-practice-ebook-pdf/ ebookmass.com

Myanmar: A Political Lexicon First Edition Nick Cheesman https://ebookmass.com/product/myanmar-a-political-lexicon-firstedition-nick-cheesman/

ebookmass.com

Practical Spring LDAP: Using Enterprise Java-Based LDAP in Spring Data and Spring Framework 6 2nd Edition Varanasi Balaji

https://ebookmass.com/product/practical-spring-ldap-using-enterprisejava-based-ldap-in-spring-data-and-spring-framework-6-2nd-editionvaranasi-balaji/ ebookmass.com

McGraw-Hill Education PTCE Review Kristy Malacos

https://ebookmass.com/product/mcgraw-hill-education-ptce-reviewkristy-malacos/

ebookmass.com

Industrial Clusters: Knowledge, Innovation Systems and Sustainability in the UK John F. Wilson

https://ebookmass.com/product/industrial-clusters-knowledgeinnovation-systems-and-sustainability-in-the-uk-john-f-wilson/

ebookmass.com

India in the Second World War Gupta

https://ebookmass.com/product/india-in-the-second-world-war-gupta/

ebookmass.com

Press' Passion (Wicked Winemakers: First Label Book 3)

Heather Slade

https://ebookmass.com/product/press-passion-wicked-winemakers-firstlabel-book-3-heather-slade/

ebookmass.com

TheMechanics ofThreadedFasteners andBoltedJoints forEngineering andDesign ToshimichiFukuoka

ProfessorEmeritusatKobeUniversity, Kobe,Japan

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2023ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronic ormechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem, withoutpermissioninwritingfromthepublisher.Detailsonhowtoseekpermission,further informationaboutthePublisher’spermissionspoliciesandourarrangementswithorganizationssuch astheCopyrightClearanceCenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions.

Thisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythe Publisher(otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperience broadenourunderstanding,changesinresearchmethods,professionalpractices,ormedicaltreatment maybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluating andusinganyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuch informationormethodstheyshouldbemindfuloftheirownsafetyandthesafetyofothers,including partiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assume anyliabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligence orotherwise,orfromanyuseoroperationofanymethods,products,instructions,orideascontained inthematerialherein.

ISBN:978-0-323-95357-3

ForinformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: MatthewDeans

AcquisitionsEditor: DennisMcGonagle

EditorialProjectManager: SaraGreco

ProductionProjectManager: FizzaFathima

CoverDesigner: ChristianJ.Bilbow

TypesetbySTRAIVE,India

2Fundamentalsofthreadedfasteners23

4.3Stressdistributionalongthreadroot

4.4Fatiguefailureofscrewthreads

4.5Evaluationmethodoffatiguestrengthofthreadedfasteners

4.6SeparationphenomenaofplateInterfaceandstress amplitude

4.7Stressamplitudealongthreadroot

4.8Improvementmeasuresoffatiguestrengthofthreaded fasteners

5Boltedjointsunderthermalload217

5.1Fundamentalsofthermalandmechanicalbehaviorsofbolted joints

5.2Evaluationmethodofamountofheattransferredthrough contactsurface

5.3Evaluationmethodofamountofheattransferredthrough asmallgap

5.4Thermalcontactcoefficientandapparentthermalcontact coefficientinboltedjoints

5.5Analysisofthermalandmechanicalbehaviorsofbolted jointsbyFEM

5.6Seizureofthreadedfasteners

6Looseningofthreadedfasteners247

6.1Rotationlooseningandnonrotationloosening

6.2Whyboltedjointsareeasytoloosen

6.3Boltforcereductionduetorotationloosening

6.4Boltforcereductionduetononrotationloosening

6.5Inspectionofbolttighteningstatebytorquemeasurement

7Thermalandmechanicalbehaviorsofpipeflangeconnections277

7.1Thermalandmechanicalbehaviorsinherenttopipeflange connections

7.2Gasketcompressioncharacteristicsandflangerotation

7.3Temperaturedependencyofgasketcompression

7.4Analysisofthermalandmechanicalbehaviorsinrunning conditionandduringshutdownoperation

7.5Thermalandmechanicalbehaviorsofpipeflangeconnections forlowtemperaturefluids

8Learningfromproblemsandaccidentswiththreaded fasteners291

8.1Introduction

8.2Fatiguefailureofwheelboltsforlargevehiclesspecified

8.3Fatiguefailureofthreadedportionofrollercoasteraxle

8.5Strengthandloadcapacityofreamerboltsusedforrigid flangedshaftcouplings

8.6Tighteningprocessofreamerboltbycooledfitting

8.7Sealingperformanceofoilsealplugsusedforhydraulic

8.8Modeanalysisofboltedjoints

Preface Threadedfasteners,typifiedbyboltsandnuts,arethemostwidelyandcommonly usedmachineelements,hence,theirexistenceisoftenforgotten.However,onceafailureorlooseningoccursinthreadedfasteners,thefunctionofmachinesandstructures clampedbythemmaybecompletelylost.Itcanbesaid,therefore,thattheprimary taskimposedontheengineersengagedinjobsrelatedtothreadedfastenersisthe designandassemblyofboltedjoints,sothattheyarenotbrokenorloosenedinthe tighteningprocessorinserviceconditions.

Thisbookintendstoprovidethewidevarietyofknowledgeandinformation requiredforengineersinchargeofthreadedfastenersandboltedjointstoattainsecure tightening,sufficientstrength,andnoloosening;andthesethreemajorissuesare explainedinaneasy-to-understandmannerforpracticaluse.Atthesametime,to maintainmechanicalstringency,corechaptersandsectionsarewrittenlargelybased onreliableresearchresultspublishedbyprominentacademicsocietiesasjournal papersorconferenceproceedings.

Thecontentsofthisbookcoveravarietyofjoblevels,rangingfromthebasic designofboltedjoints,suchasthedeterminationofthejointassemblyprocedure, tothesophisticateddesignandstrengthevaluationofboltedjointsbyuseofadvanced CAEtechnologies.Theproblemsthatthisbookiswrittentosolveforreadersareas follows:

l Selectionofanappropriatetighteningmethodandestablishmentofareliabletightening procedure.

l Understandingwhatthestaticandfatiguestrengthsofboltedjointsareandhowtheybehave.

l Evaluationmethodsofstaticandfatiguestrengthsofboltedjointsbysolidmechanics andFEM.

l EstablishmentofpreventionmethodsoffatiguefailuresbysolidmechanicsandFEM.

l Effectofhighandlowtemperaturethermalloadsonthestrengthofboltedjointsbytaking accountofthermalcontactresistanceattheinterface.

l Understandingthelooseningmechanismofthreadedfastenersbyclassifyingintorotation looseningandnonrotationloosening.

l Establishmentofthemethodtopreventormitigatethelooseningofthreadedfasteners.

l HowtoapplyadvancedCAEtechnologiestodesignboltedjointswithhighsafetyandevaluatetheirthermalandmechanicalbehaviors.

In Chapter1,abriefhistoryofscrewthreadsandtheprogressintherelevantresearch areasareintroduced,andthebasicsofthreadedfastenersandboltedjointsare explainedfromthegeometricalandmechanicalpointsofview.Theideaofthepressureconeisdiscussedindetail,becausethecontactpressuredistributionattheinterfacesignificantlyaffectstheinterfaceseparationthatleadstothefatiguefailureof boltedjoints.Thelastsectionprovidesanoutlineofthestrengthandthethermal

andmechanicalpropertiesoffastenermaterials,wherevariouspropertiesofengineeringmaterialscommonlyusedforthreadedfastenersaretabulatedwiththeirtemperaturedependency.

In Chapter2,inordertounderstandthefundamentalsofthreadedfasteners,the essentialcharacteristicsoftheirstrengthandstiffnessarediscussedindetail.Itis shownhowthetrueprofileofthecrosssectionofscrewthreadscanbeexpressed bymathematicalformulas,bywhichfiniteelementmodelsofboltedjointswithperfectgeometrycanbeconstructedinordertoperformnumericalanalysiswithhigh accuracy.Inaddition,asummaryoftheinterfacestiffnessandthermalcontactresistance,bothofwhichareprimarilyduetothemicroprojectionsexistingoncontactsurfaces,isgiventoconductfiniteelementanalysisbytakingaccountoftheconditionsof contactsurfacesexistinginboltedjoints.

In Chapter3,thetighteningmethodsofthreadedfastenersarediscussed—which representsthefirstproblemofboltedjoints.Thefourcommonlyusedmethods, i.e.,torquecontrolmethod,elasticanglecontrolmethod,directtensionmethod, andthermalexpansionmethod,areexplainedingreatdetailfromthepracticalpoint ofview.Thechapteralsocoversthetighteningprinciple,applicationrange,andtighteningguidelinesofeachmethod.Anewtighteningmethodthatcombinestorquecontrolmethodwithelasticanglecontrolmethodisproposed.Thiscanevaluatenut factor,whichrelatestighteningtorquetoboltforce,duringthetighteningoperation withhighaccuracy.Theproblemofelasticinteraction,whichoccursinthecaseof tighteningmultipleboltsonebyone,issolvedwithhelpofFEM,anditisshown howtoestimatetheboltforcescatterandobtaintheoptimaltighteningsequence.

In Chapter4,thestaticandfatiguestrengthsinherenttothreadedfastenersandboltedjointsaredealtwith—whichisthesecondproblemofboltedjoints.ThedistributionsofstressandstressamplitudealongthethreadrootareevaluatedbyFEanalysis usinghelicalthreadmodels.Itispointedoutthatboltedjointdiagrams,whichhave widelybeenusedforboltedjointdesign,havesomeessentialdefectsandareeffective onlyinlimitedconditions.Anotherimportantpointisthatthefatiguefailureofbolted jointsisgreatlyaffectedbytheinterfaceseparationbetweenfastenedplates.The fatiguestrengthcanprimarilybeimprovedbyraisingtheboltforce,whichissubstantiatedbycomprehensiveFEanalysis.Inaddition,variouspracticalmeasuresareintroducedtoenhancethefatiguestrengthofthreadedfastenersandboltedjoints.

In Chapter5,thermalandmechanicalbehaviorsofboltedjointsaredescribed basedonthetheoryofthermalstressandtheresultsofFEanalysis.Highandlowtemperaturethermalloadsoftencausethefailureorlooseningofthreadedfastenersand boltedjoints.Inordertoanalyzethephenomenawithhighaccuracy,itisexplained howtotakeaccountoftheeffectoftheheattransferredthroughcontactsurfacesand smallgapsusingthethermalcontactcoefficientandapparentthermalcontactcoefficient.Themechanismofseizureoccurrenceinthreadedfasteners,whichisanasty problemsometimesencounteredduringthetighteningoperation,isclarifiedbyusing thetheoryofheatconduction,anditspreventionmethodsareexplainedfromthetheoreticalpointofview.

In Chapter6,looseningofthreadedfasteners,whichisthethirdproblemofbolted joints,isdiscussedbyclassifyingthelooseningmechanismintorotationlooseningand

nonrotationloosening.Asfortheformer,thelooseningmechanismisanalyzedin detailbyfiniteelementsimulation.Hence,itisshownthattheslipoccurrenceon thenut-orbolthead-bearingsurfaceisadecisivefactor.Incontrast,nonrotationlooseninginevitablyoccurstosomeextent.Therefore,itisexplainedhowtoestimatethe boltforcereductionbyuseofaboltedjointdiagram.Inaddition,practicalcountermeasuresareintroducedthatareeffectiveinpreventingrotationlooseningandmitigatingnonrotationlooseningforvarioustypesofboltedjoints.Inthelastsection, theinspectionmethodsofboltedjointintegritybytorquemeasurementarediscussed.

In Chapter7,thermalandmechanicalbehaviorsofpipeflangeconnectionsare expoundedbyconductingexperimentsandfiniteelementanalysis,aimingat preventingtheleakageofcontainedfluidsathighorlowtemperature.NumericalanalysisbyFEMandexperimentsquantitativelyclarifyhowmuchboltforceisreducedin therunningconditionandduringtheshutdownoperationofpipelines.Itisshownthat themechanicalbehaviorofgaskets,thestiffnessofwhichismuchlowerthanthatof metalgaskets,istheprimaryinfluencingfactoronleakage.Oneofthemostimportant issuesstatedhereisthatthestiffnessofsheetgasketsandspiralwoundgasketsissignificantlyreducedatelevatedtemperatureandthiscausesboltforcereductionleading totheleakageofcontainedfluids.

In Chapter8,aimingatprovidingeffectivehintstosolvevariouson-siteproblems concerningthreadedfastenersandboltedjoints,severalproblemsandaccidentsthat actuallyhappenedinthepastarediscussedbasedonrigorousresearchresults.This coverswheelfalling-offaccidentsoflargevehicles,theruptureofthethreadedportion ofarollercoasteraxle,fatiguefailuresofreamerboltsusedforrigidflangedshaft couplings,etc.Alsotreatedishowmuchthenaturalfrequenciesofboltedjoints areincreasedwithincreasingboltforce.Inthelastsection,inordertoperformfinite elementanalysiseffectively,someconcretemeshpatternsandsimplifiedmodelsof engagedthreadportionsareshown,andafewpracticalstrategiestoimprovethecomputationalefficiencyarepresentedbyutilizingthegeometricsymmetryofbolted joints.

Theauthorwouldliketoexpresshissincereappreciationtothreedistinguished professors,i.e.,thelateProf.MinoruHamada,Prof.HiroshiKitagawa,andProf. NoboruKikuchi.Prof.Hamadaenthusiasticallysupervisedtheauthor’sPhDthesis onthemechanicalbehaviorofboltedjointsandProf.Kitagawaledtheauthorto theworldofnumericalanalysisatOsakaUniversity.Prof.Kikuchimotivatedthe authortoapplythelatesttheoriesofcomputationalmechanicstoboltedjointsat TheUniversityofMichigan.Theauthorwouldalsoliketoexpressspecialthanks tohismanyex-studentsfortheircooperationinachievingtheresearchresultsforming thebasisofthisbook.Finally,theauthorwouldliketogivethedeepestappreciationto hiswifeNorikoforherprovidingacomfortableenvironmentover40yearstosupport hisresearchactivity.

ToshimichiFukuoka

Listofsymbols A boltcylindricalarea,othercross-sectionalareas

A1, A2, A3 truecross-sectionalareasofscrewthread

AI, AII cross-sectionalareasofstraightbar

Aap, Are apparentcontactareaandrealcontactarea

Acn contactarea

Ae truecross-sectionalareaofmalethread

Aex, Ain cross-sectionalareasofmaleandfemalethreads

Af cross-sectionalareaoffastenedplates

Afk contactareaonthreadsurface

Ains truecross-sectionalareainsidefemalethread

An nut-bearingsurfacearea

Ar cross-sectionalareaatthreadroot

As stressareaofscrewthread

a, b innerandouterradiiofhollowbolt,hollowcylinderandhollowshaft

a1, a2 constantsforrepresentingloaddistributions

ap radiusofcontactareaofmicroprojection

B meandiameterofhexagonboltheadorhexagonnut

Bp diameterofboltpitchcircle

b1, b2 constantsfordeterminingapproachofinterface

C1–C5, C1n, C2n constantsforrepresentingtruecross-sectionalareas

c, c1, c2, c3 constants

co, mo constantsintheOstrovskyequation

csp specificheat

D, D1, D2 major,minor,andpitchdiametersoffemalethread

Do outerdiameteroffastenedplates

d nominaldiameter,majordiameterofmalethread,diameterofroundbar

d1, d2 minorandpitchdiametersofmalethread

dbt equivalentdiameterofbottomingtorque

dc diameterofprojectionpartofbottomingstud de truepitchdiameter

dh boltholediameter

dhd equivalentfrictiondiameterofbolthead-bearingsurface

dnu equivalentfrictiondiameterofnut-bearingsurface

dr threadrootdiameter

drm diameterofreamerbolt

ds diameterofstressarea

E, EI, EII Young’smodulus

Eb, Ef Young’smoduliofbolt-nutandfastenedplates

Eex, Ein Young’smoduliofmaleandfemalethreads

e widthacrosscornerofhexagon

F axialforceactingalongboltaxis

F02 boltforcecorrespondingto0.2%proofstress

Fb axialboltforce,boltpreload

Fb0 axialboltforceforthecasewithoutinclinationatbearingsurface

Fb1, Fb2, Fb3

axialboltforcesofmultiboltedjoints

Fbi initialboltforce

Fbt compressionforcegeneratedbybottomingtorque

Fc reductionofcompressionforceinfastenedplatesduetoexternalforce

Fcn compressionforceactingonbottomsurfaceofbolthole

Ff objectiveboltforceintighteningoperationbyhydraulictensioner

Fi initialboltforceofbolt i,normalforceactingonbolt i

FiN, Fiμ bearingforceandfrictionforcesustainedbybolt i

Finn Fout boltforcesgeneratedininner-wheelandouter-wheeltighteningprocesses

Fn normalforceactingoncontactsurface

Fnu, Fhd, Fpl frictionforcesactingonjointcontactsurfaces

Fo, f1, f2 axialforcesgeneratedwhentighteningouternut

Frm1, Frm2 normalforcesactingonreamersurface

Fs shearforce,shearload

Fslp criticalshearloadcorrespondingtowholeslip

Ft initialtensionappliedbyhydraulictensioner

Fth axialforcegeneratedinengagedthreadsofbottomingstud

Fz boltforcereductionduetoembedment

f naturalfrequencyofbendingvibration

H heightoffundamentaltriangle

H1 threadoverlap

Hnu thicknessofnut

HV, HV1, HV2 Vickershardness

h platethickness,beamheight

hc thermalcontactcoefficient

hcv coefficientofconvectionheattransfer

he apparentthermalcontactcoefficient

hr coefficientofradiationheattransfer

I secondmomentofarea

i numberofthreads,boltnumber,orderofvibrationmode

K nutfactor

K restraintcoefficient

[K],[M] stiffnessmatrixandmassmatrix

Kcn, Kth, Knu, springconstantsrepresentinginterfacestiffness

Khd, Kf

Kinn, Kout nutfactorsininner-wheelandouter-wheeltighteningprocesses

Ktru truenutfactor

k springconstant,springconstantofstraightbar

kA, kB springconstantsofplateandthinhollowcylinder

kb springconstantofbolt-nutconnection

kbm, kplc, kple springconstantsofjointedcomponentsundershearload

kcyl springconstantofboltcylindricalportion

kex, kin springconstantsperoneridgeofmalethreadandfemalethread

kf, kf∗ springconstantsoffastenedplates

kn, kt springconstantsrepresentinginterfacestiffness

ks springconstantofunengagedthreads

kpt springconstantoffastenedplatesundertension

kth springconstantofengagedthreads

ktotal springconstantofentireboltedjoint

L leadofscrewthread,lengthofstraightbar

L1, L2, La lengthsofjointedpartsundereccentricexternalforce

Lcyl lengthofboltcylindricalportion

Lex lengthofprotrusionaddedtojointendportion

Lf griplength

Lfk lengthofhelix

Lhd equivalentlengthofbolthead

Ls lengthofunengagedthreads

Lth equivalentlengthofengagedthreads

m parallelrownumberofmultiboltedjoint

mh, nh constantsinequationforevaluatingthermalcontactcoefficient

N numberofrepeatedexternalforce,numberofmicroprojections

Nu Nusseltnumber

n numberofbolts,perpendicularrownumberofmultiboltedjoint,matingnode numbersatinterface

np divisionnumberofone-pitchhelicalmodelinaxialdirection

P threadpitch

pm plasticflowstressofmaterial

pn contactpressureatinterface

pnu contactpressureonnut-bearingsurface

Pr Prandtlnumber

pt stressintangentialdirection

Qth, Qshk, amountsofheatflowingthrougheachpartofboltedjoint

Qhd, Qf

Qtotal totalamountofheatflowingthroughboltedjoint

q heatflux

R, S constantsinBach’sequation

{R} loadvector

Ra1, Ra2 arithmeticmeanroughnessofmatingsurfaces

Rat sumofarithmeticmeanroughnessofmatingsurfaces

Rcn thermalcontactresistance

Re Reynoldsnumber

Ri shearload-bearingratioofbolt i

RiN, Riμ shearload-bearingratiosbybearingforceandfrictionforce

Rrm, Rμ shearforcetransferratiosbyreamersurfaceandfrictionforce

Rz, Rz1, Rz2 maximumheightroughness

Rzt sumofmaximumheightroughnessofmatingsurfaces

r, r1, r2 radialcoordinates

ri radialcoordinateofnode

s widthacrossflatofhexagon

T temperature,torque

T1, T2 threadtorqueandnut-bearingtorque

Tb, Tf bolttemperatureandtemperatureoffastenedplates

Tbt bottomingtorque

Te temperaturedifferencebetweenmatingsurfaces

Tinn, Tout tighteningtorquesofinnernutandouternut

Tl looseningtorque

Tl1, Tlbt looseningtorquesofbottomingstud

Trt re-tighteningtorque

Tsng snugtorqueinelasticanglecontrolmethod

Tst secondtighteningtorque

Tt tighteningtorque

U strainenergy

Uf circumferentialforceactingonthreadsurface

u displacement,axialdisplacementofstraightbar

u fg, u fg displacementvector,accelerationvector

u uniformdisplacementappliedtoboltcylindricalportion

uhd , unu meandisplacementsunderbolthead-andnut-bearingsurfaces

ui nodaldisplacement

uslp criticaldisplacementcorrespondingtowholeslip

uup , udw uniformdisplacementsappliedtoboltcylindricalportion

V amountofvolumepushedawaybynut-bearingsurface

v slidingspeed

W externalforce

Wtrq, Wth, Wnu tighteningenergy

wfk contactwidthbetweenmaleandfemalethreads

Z embedmentfactor

z axialcoordinate

α threadangle,stressconcentrationfactor

α1 flankangle

α1 0 flankangleintheplaneperpendiculartohelix

αΙ –αIV stressconcentrationfactorsofplateswithsemicircularnotch

αb, αf coefficientsoflinearexpansionofbolt-nutandfastenedplates

αex, αexI, αexII coefficientsoflinearexpansion

β leadangle,notchfactor

γ effectivetensilecoefficient

γ c contactratio

ΔFb variationofboltforce

Δri averagewidthbetweennodes

ΔT, ΔTI, ΔTII temperaturechangeortemperaturedifference

ΔTb, ΔTf temperaturechangesofboltandfastenedplates

ΔTe temperaturedifferencebetweenmatingsurfaces

ΔTm meantemperatureincreaseofmicroprojection

Δσ b variationofaxialboltstress

Δσ f variationofcompressionstressoffastenedplates

Δσ rm boltstressreductionperunittemperaturedifference

Δϕ returnrotationangleofnut

δ boltelongation,amountofthermalexpansionorshrinkage

δair gapsizeofairlayer

δb elongationofbolt-nutconnection

δc fitofreamerbolt

δf shrinkageoffastenedplates

δpl clearanceatbearingsurfaceofoilsealplug

δz amountofembedment

εp plasticstrain

ζ approachofinterface

ζ max maximumvalueofapproachofinterface

ζ t displacementintangentialdirectionduetointerfacestiffness

ζ th, ζ nu, ζ hd, ζ f approachesofinterfaceateachjointinterface

η boltforcegeneratedperunitnutrotationangle,notchsensitivityfactor

η3, η4 efficienciesoftriangularandsquarescrewthreads

θ angle,circumferentialcoordinate

θ1–θ6 anglesspecifyingthreadgeometry

θcn pressureconeangle

θhd inclinationangleofbolthead-bearingsurface

θnu, θtp inclinationangleofnut-bearingsurface

λ, λ1, λ2 thermalconductivity

λair thermalconductivityofair

λi Eigenvalueof ithmode

μ, μr, μθ coefficientoffriction

μhd coefficientoffrictiononbolthead-bearingsurface

μith, μinu coefficientsoffrictionininner-wheeltighteningprocess

μoth, μonu coefficientsoffrictioninouter-wheeltighteningprocess

μth, μnu coefficientsoffrictiononthread-andnut-bearingsurfaces

ν Poisson’sratio

ρ rootradius,threadrootradius

ρdn density

ρmax, ρnmax upperlimitsof ρ and ρn

ρn radiusoffemalethreadroot

ρth, ρth 0 frictionanglesofthreadsurfaceforsquareandtriangularthreads

σ stress,truestress,thermalstress,standarddeviation

σ vonMisesstress

σ 1, σ 2, σ 3 threecomponentsofprincipalstress

σ I, σ II thermalstressesgeneratedinbarIandbarII

σ a stressamplitude

σ B tensilestrength

σ b axialboltstress

σ bi initialboltstress

σ bnd bendingstressgeneratedinbolt

σ IN, σ OUT axialstressesonboltcylindricalsurfaceinradialdirection

σ L, σ R axialstressesonboltcylindricalsurfaceincircumferentialdirection

σ max maximumstressoccurringatnotchroot

σ max maximumvonMisesstress

σ n meanstressatnotchedcrosssection

σ r meanstressatthreadroot

σ th tensilestressofboltthreadedportion

σ Y yieldstress

σ w fatiguelimit

σ wo fatiguelimitofsmoothedtestspecimen

σ z axialstress

τ shearstress

τth shearstressofboltthreadedportionduetothreadtorque

τw fatiguelimitofshearstress

ϕ nutrotationangle

ϕu loadfactor

Threadstandardsandforms 1.1Briefhistoryofscrewthreadsandrelevant researchactivities Itissometimessuggestedthattheoriginofscrewthreadstracesbacktothe“screw pump”inventedbyAristotlebeforetheCommonEra,afterwhich,large-sizedwooden powerscrews,suchasthescrew-typemechanicalpress,cametobeused.Then,metal screwsappearedinthe16thcentury.Itwasin1543thatscrewthreadswerefirstintroducedintoJapanalongwiththearrivalofguns.Ithasbeenreportedthatgunsmithsof thedaystruggledtoprocessthescrewthreadsofthetailplugs.

IntheIndustrialRevolutionerainthe19thcentury,MaudslayintheUnitedKingdomsucceededinthemanufacturingofscrewthreadswithamodernprocessing methodusinglathes.Clement,whoworkedinMaudslay’sfactory,devisedatapthat couldformfemalethreadsbyacuttingoperation.Whitworth,whowasoncean apprenticeofMaudslay,iscalledthefatherofmodernscrewthreadsbecauseheproposedascrewstandardforthefirsttimein1841,theearlystageoftheIndustrialRevolution.Threadcuttinglathes,inventedinthosedays,hadalmostthesamestructureas thepresentones,whichenabledthemassproductionofpowerscrewsandfastening screws.Athreadrollingdevicewasdesignedin1851byBroomannintheUnited Kingdom,andthenthePWCorporationinGermanymanufacturedthreadrolling machinesin1938thathadasimilarstructuretothepresentones.Detailedhistory onscrewthreadsisavailablein [1,2],forinstance.

Theprimarypurposeofthisbookistoexplainthemechanicsofthreadedfasteners assimplyaspossible,aimingattheprovisionofanefficientdesignmethodforbolted jointswithahighlevelofsafety.Inthefollowing,abriefreviewismadeofhow researchonscrewthreadsprogressed,whichbuiltthefoundationofthecurrent designmethod.

Themaincauseofthefailureofscrewthreadsismetalfatigue.Thestudyofmetal fatiguewasstartedaround1860byWohler,whoisfamousfordevelopingtheS-N curve.ResearchonthefatiguestrengthoffasteningscrewswasbegunbyThumin the1930s.Theideaofaboltedjointdiagram,whichiswidelyusedtodaytoevaluate thefatiguestrengthofthreadedfasteners,firstappearedinthebookwrittenbyRotcher [3].Heproposedtheideaofapressureconewithrespecttotheareaattheinterface composedofclampedplates,overwhichcontactpressureisexertedduetoboltforce. Goodier,whoisthecoauthorofthehistoricalmasterpiecethe“TheoryofElasticity” writtenbyTimoshenko,evaluatedtheparticularloaddistributionpatternalongthe engagedthreadsofabolt-nutconnection.Hesucceededintheevaluationbyapplying thetheoryofelasticitytothedisplacementsmeasuredontheoutersurfaceofthenut [4].Sopwithfurtherdevelopedthestudyofscrewthreadsbymeansofthetheoryof elasticity,andheproposednutshapesthatcouldimprovetheloaddistributionpattern alongtheengagedthreads [5].

TheMechanicsofThreadedFastenersandBoltedJointsforEngineeringandDesign. https://doi.org/10.1016/B978-0-323-95357-3.00002-2 Copyright © 2023ElsevierInc.Allrightsreserved.

2TheMechanicsofThreadedFastenersandBoltedJointsforEngineeringandDesign

InJapan,somenoteworthystudieswerepublishedinthe1970s.Sawaetal.clarified variousmechanicalbehaviorsofboltedjoints,suchastheamountsofequivalentlengths ofengagedthreadsandboltheadthatrepresentthestiffnessofabolt-nutconnection,by applyingthethree-dimensionaltheoryofelasticityinasophisticatedmanner [6].Using complexstressfunctions,Otakianalyzedhowgeometricfactors,suchasnominaldiameterandthreadpitch,affectthestressconcentrationatthethreadroot [7] andthefatigue strength [8].Asapioneeringstudybynumericalanalysis,Maruyamaevaluatedthe stressconcentrationfactoratthethreadroot [9],inwhichapoint-matchingmethod wasincorporatedintotheFEM(finiteelementmethod)whenmodelingthegeometry ofengagedthreads.Bretletal.calculatedtheloaddistributionalongengagedthreadsby replacingtheengagedthreadswithastackoflayeredfiniteelements [10].Milleretal. proposedasimplemethodusingspringelements,whicharediscussedlaterinthisbook, forcalculatingtheloaddistributionalongengagedthreads [11].Tanakaetal.proposeda finiteelementapproachthatcouldsolvecontactproblemsandanalyzedvarious mechanicalpropertiesofboltedjoints [12],andtheyalsocalculatedtheloaddistributionalongengagedthreadsinaningeniouswaybymeansofspringelements [13].

Asforexperimentalstudiesthatevaluatedthestressdistributioninaboltedjoint,a seriesofresearchesbyHetenyithroughphoto-elasticexperiments [14] areworthyof specialmention,inwhichtheresearcherrevealedthespecificloaddistributionsalong engagedthreadsinspecialnutswithvariousconfigurations.Itcanbesaidthathis researchachievementswerethestartingpointofalotofcontrivancesfoundthereafter invarious-shapednuts,aimingatsmoothingtheloaddistributionalongengaged threadsandmitigatingthestressconcentrationatthethreadroot.Stressconcentrations atthethreadrootofactualbolt-nutconnectionsweresuccessfullymeasuredbythe copperplatingmethod.MaruyamacomparedthemeasuredresultstothestressconcentrationfactorsobtainedbyFEM [9,15].Seikaetal.obtainedthemagnitudeand locationofthemaximumstress [16] usingthesameexperimentalmethod.Theyconcludedthatitoccurredatthemalethreadroot2/3pitchapartfromthenut-bearing surface.

Thejointedportionsfastenedbyuseofscrewthreadsaregenerallycalledabolted joint.Inthisbook,therefore,thecomponentsclampedbyvariouskindsofthreaded fastenersarereferredtoasboltedjoints.Basicformsandtheusagesofscrewthreads havebeenfundamentallyunchangedsincetheIndustrialRevolution.Nevertheless, threadedfastenersandboltedjointshavecontinuouslybeenimportantresearch objectsinthemechanicalengineeringfield.Thebiggestreasonisthattheexternal loadsexertedonboltedjointsarecontinuouslybeingincreased!

1.2Geometryandapplicationpurposesofscrewthreads Screwthreadsareroughlyclassifiedintotwotypes,whichareusedforclampingand movementtransmission,respectively.Mostthreadedfastenerssuchasboltsandnuts arebasicallyusedforclampinganumberofpartscomposingmachinesandstructures. Ontheotherhand,screwthreadsusedformovementtransmissiondelivervarious movementsbyutilizingtheirhelicalshape.Theyarefurthercategorizedintotwo

types.Oneisusedforgeneratinglargeforcesbymakinguseoftheactionofthethread asaninclinedplane,e.g.,ajackforliftingheavyparts;theotherfacilitatestheconversionbetweenlinearandrotationalmotions,e.g.,feedscrewsbuiltintomachine tools.Asasimilarexample,amicrometerprovidesadimensionalaccuracyof 10 μm,inwhichalargerotationangleisconvertedintoasmalllinearmovement.A certaintypeofmicrometerequippedwithadigitaldisplaydeviceprovideshigheraccuracyof1 μm.

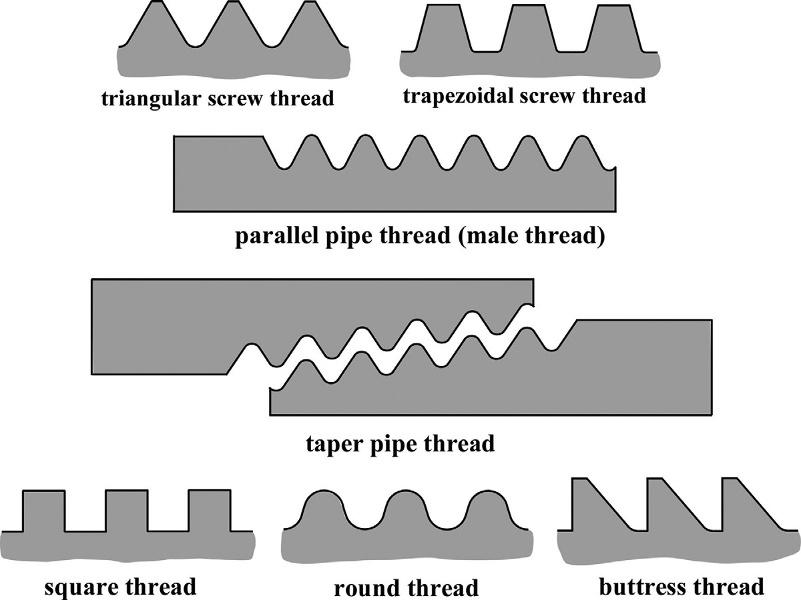

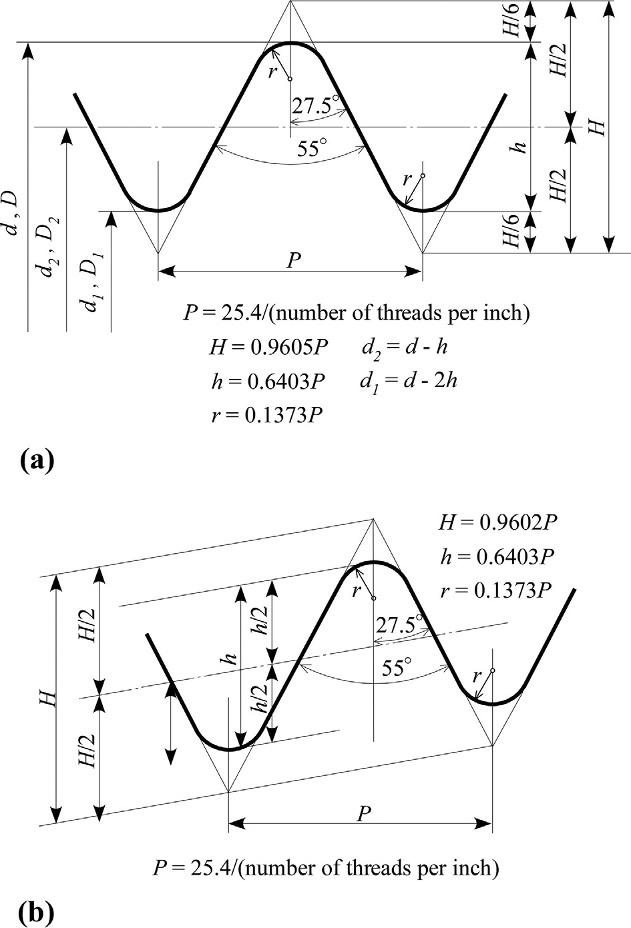

Fig.1.1 showsscrewthreadsofvariousforms.Triangularscrewthreadsarethe mostcommonlyusedwhenclampingmultipleparts.Ontheotherhand,trapezoidal screwthreadsareusedformotionandpowertransmission.Thesetypesofscrew threadsareoftencalledpowerscrews [17].Therelationshipbetweenthreadform andapplicationpurposeisexplainedindetailinsection3.2.4.Toexplainitbriefly fornow,triangularscrewthreadsareprimarilyusedforclampingbecauseoftheirhigh antilooseningperformance.Trapezoidalandsquarescrewthreadsareemployedfor motionandpowertransmissionduetohighthreadefficiency.Pipethreadsareclassifiedintoparallelpipethreadsandtaperpipethreads.Theformerisusedformechanicaljoiningofstructureswithhollowcylindricalshapes.Thelatterisappliedto connectingpipelinesthatrequireleakagepreventionperformancetocontainfluids. Taperpipethreadsareprocessedonthetargetsurfacealongone-sixteenthoftaper. Thematingthreadsurfacescomeintoclosecontactasmalethreadsareprogressively screwedintofemalethreads.Thethreadangleoftriangularscrewthreadsis60 degrees,whiletheangleofpipethreadsis55degrees.

Besidestheaforementionedtypesofscrewthreads,squarethreads,roundthreads, andbuttressthreadsaresometimesused.Thethreadefficiencyofsquarethreadsis

Fig.1.1 Threadridgeformsofvarioustypesofscrewthreads.

higherthanthatoftrapezoidalscrewthreads;however,duetotheprocessingdifficulty,thethreadsurfaceisoftenmanufacturedtohaveaninclinedangleofabout5 degrees [17].Roundthreadscanberegardedastrapezoidalscrewthreadstowhich largeradiiareaddedtothecrestandthreadroot.Althoughthestressconcentration atthethreadrootislowered,roundthreadshaveanessentialdrawbackofsmallthread overlap.Buttressthreadsareshapedlikeasawwithasymmetricgeometrytosupport largeforcesactingfromonedefiniteside.Thebuttressthread’ssurfaceoftenhasan inclinedangleofabout7degrees [17] forthesamereasonasinthecaseofsquare threads.

Powerscrews,suchasacmethreads,whoseshapeissimilartotrapezoidalscrew threads,andbuttressthreadsarestandardizedbyANSI(AmericanNationalStandards Institute).Thetappingscrew,althoughnotshownin Fig.1.1,isakindoftriangularshapedscrewthreadusedforclampingparts.Itisamalethreadscrewedintothemain body,thusproducingafemalethreadhole.Thepartstobeclampedarecommonlythin metalplatesorwoodenplates,wherefemalethreadsareeasilyprocessedandhigh workingefficiencyisrequired.Thetighteningprocessoftappingscrewscanbeevaluatedintermsofthreetorques,i.e.,tappingtorquerequiredforprocessingfemale threads,tighteningtorqueforseatingthescrewheadandgeneratingclampingforce, andbreakagetorquecausingtheruptureofthetappingscrew [18].Fromthepointof viewofthetighteningoperation,itisnecessarythatthebreakagetorquebelargerthan thetighteningtorque,totheextentthattheruptureofscrewthreadsdoesnotoccur evenifbeingsomewhatover-tightened.

Inthisbook,thefocusisplacedonboltsandnutswithtriangularthreadgeometry, whicharemostwidelyusedforclampingallkindsofparts.

1.3Standardsofscrewthreads 1.3.1Standardspecificationsofscrewthreads InJapan,forinstance,standardspecificationsofscrewthreadsarespecifiedindetail inJIS(JapaneseIndustrialStandards).Sincescrewthreadsarecommonlyusedforall sortsofmachines,structures,electricdevices,etc.,thehighestlevelofinternational consistencyisrequiredinthestandardspecifications.Accordingly,thestandardson screwthreadsspecifiedinJISalmostcompletelyagreewithISO(InternationalOrganizationforStandardization)standards,aswellasthenationalstandardsestablishedin manycountries.However,perfectconsistencybetweenJISandISOispractically impossible.Tocopewiththosecases,therefore,thedegreeofinconsistencybetween ISOandJISisexplainedforeachspecificationinJIS.Asaresultofconsideringthe abovesituation,thescrewsandthreadedfastenerstreatedinthisbookarebasically standardizedinJIS.ThecorrespondencebetweenJISandISO,describedinthisbook, ispresentedin Table1.1,inwhichthestandardsspecifictoJISareshownseparately. Accordingtotheunitoflength,screwthreadsareclassifiedintometricthreadand inchthread.Themostcommonlyusedscrewthreadsaremetric.Pipethreads employedinpipingsystemsareinchthreads.Unifiedthreads,whichareanothertype 4TheMechanicsofThreadedFastenersandBoltedJointsforEngineeringandDesign

Table1.1 CorrespondencebetweenJISandISOinorderofappearance.

JISB0206B0208B0205B0209-1B0216B0202B0203 ISO26326368-1, 261, 262 965-12901, 2902, 2904 228-17-1

JISB1180B1181B1001B1052B1051B1083B1056

ISO4014–4018, 8676,8765 4032–4036, 8673–8675 273898-2, 898-6 898-116,0472320

JIS specific B1082B1173B2238B2251B1089B1090B1451

ofinchthread,areextensivelyusedinaircraft,andarespecifiedinJISB0206andJIS B0208.

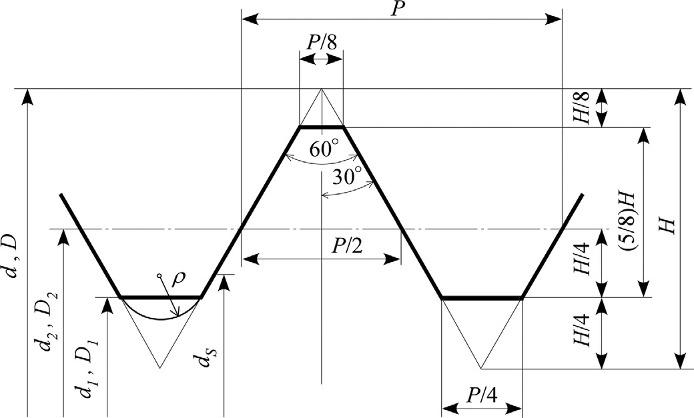

1.3.2Basicprofileofscrewthreads Fig.1.2 representsthebasicprofileofmetrictriangularscrewthreadsforgeneraluse, specifiedinJISB0205.Theexternalor“male”threadisprocessedontheoutersurfaceofcylindersorcones,whiletheinternalor“female”threadisprocessedonthe innersurfaceofhollowcylindersorhollowcones.Majordiameterofexternalthread d isequaltomajordiameterofinternalthread D.Thetwomajordiametersarethe basicdimensionsrepresentingthesizeofscrewthreadsandthreadedfasteners,which aredenotedasnominaldiameter.Thepitchdiametersofmaleandfemalethreads, d2 and D2,arevirtualdiameters,atwhichthewidthofthethreadridgeisequaltothat ofthethreadgroove.Theyareusedwhenevaluatingthreadstrengthandcalculating thehelixangleofthescrewthread,termedtheleadangle.Minordiameterofexternal thread d1 isequaltominordiameterofinternalthread D1.Thedimensionsofeachpart

Fig.1.2 Basicprofileofmetrictriangularscrewthread.

6TheMechanicsofThreadedFastenersandBoltedJointsforEngineeringandDesign

oftriangularscrewthreadsareexpressedasfollows,bymeansofnominaldiameter d, threadpitch P andfundamentaltriangleheight H:

Threadpitch P isthedistancebetweenthecorrespondingpointsonneighboring ridges. H1 denotesbasicthreadoverlap,whichistheengagedlengthofmaleand femalethreadsintheradialdirection.However,itisdifficulttoderivearigorous equationthatcanpreciselyevaluatethestrengthofscrewthreadstakingintoaccount thecomplexhelicalthreadgeometry.InJISB1082,therefore,aconceptofstressarea As proposedtoevaluatethestressandstiffnessofhigh-strengthbolts,inwhichthe threadedportionisreplacedbyacylinderofcross-sectionalarea As:

InEq. (1.5), d3 correspondstothediameteratthreadrootwhenrootradiusisequalto H/6. ds isanimportantdimensionforstrengthevaluationanddesignatesthediameter ofstressarea.Theamountof ds canbecalculatedintermsofnominaldiameter d and threadpitch P:

ComparingEq. (1.6) toEqs. (1.2)and(1.3),itisfoundthat ds islocatedbetweenminor diameter d1 andpitchdiameter d2,asshownin Fig.1.2. Highstressconcentrationoccursatthethreadrootduetoitsnotchedshape.To lowerthestressconcentration,therefore,anappropriatesizeofradiusisprocessed there.Asfortherootradius ρ ofthemalethread,itisrecommendedinJISB2091that ρ shouldbelargerthan0.125P forboltsofstrengthclassificationof8.8and higher.Thedefinitionofstrengthclassificationisexplainedin Section1.6.1.

ρ 0 125P (1.7)

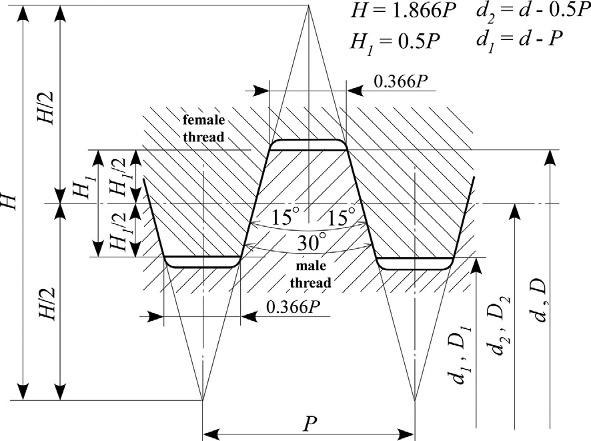

Fig.1.3 showsthebasicprofileofmetrictrapezoidalscrewthreads,asspecifiedin JISB0216.Thethreadangleis30degrees,whichishalfthatoftriangularscrew threads. Fig.1.4 depictsthebasicprofilesofparallelandtaperpipethreads,specified

Fig.1.3 Basicprofileofmetric trapezoidalscrewthread.

Fig.1.4 Basicprofilesofparallelandtaperpipethreads.(A)Parallelpipethreadand(B)taper pipethread.