https://ebookmass.com/product/sustainable-alternatives-for-

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Visions and Strategies for a Sustainable Economy: Theoretical and Policy Alternatives Nikolaos Karagiannis https://ebookmass.com/product/visions-and-strategies-for-asustainable-economy-theoretical-and-policy-alternatives-nikolaoskaragiannis/ ebookmass.com

Future Propulsion Systems and Energy Sources in Sustainable Aviation Farokhi

https://ebookmass.com/product/future-propulsion-systems-and-energysources-in-sustainable-aviation-farokhi/

ebookmass.com

Sustainable Aviation Technology and Operations: Research and Innovation Perspectives Roberto Sabatini

https://ebookmass.com/product/sustainable-aviation-technology-andoperations-research-and-innovation-perspectives-roberto-sabatini/

ebookmass.com

The Devil's Own Game Annie Hogsett https://ebookmass.com/product/the-devils-own-game-annie-hogsett-2/

ebookmass.com

Control of Mechatronic Systems Patrick O. J. Kaltjob https://ebookmass.com/product/control-of-mechatronic-systems-patricko-j-kaltjob/

ebookmass.com

The Christmas Blessing: A One-of-a-Kind Nativity Story about the Love That Brings Us Together Erin Guendelsberger

https://ebookmass.com/product/the-christmas-blessing-a-one-of-a-kindnativity-story-about-the-love-that-brings-us-together-eringuendelsberger/

ebookmass.com

Fundamentals of electric circuits Sixth Edition Alexander Charles K

https://ebookmass.com/product/fundamentals-of-electric-circuits-sixthedition-alexander-charles-k/

ebookmass.com

Data Assimilation for the Geosciences. From Theory to Application 1st Edition Edition Steven J. Fletcher (Auth.)

https://ebookmass.com/product/data-assimilation-for-the-geosciencesfrom-theory-to-application-1st-edition-edition-steven-j-fletcher-auth/

ebookmass.com

Enhancing Adobe Acrobat Forms with JavaScript : Take Your Forms to the Next Level! 1st Edition Jennifer Harder

https://ebookmass.com/product/enhancing-adobe-acrobat-forms-withjavascript-take-your-forms-to-the-next-level-1st-edition-jenniferharder/

ebookmass.com

https://ebookmass.com/product/without-saying-goodbye-laura-jarratt/

ebookmass.com

SUSTAINABLE ALTERNATIVESFOR AVIATIONFUELS SUSTAINABLE ALTERNATIVES FORAVIATIONFUELS Editedby

ABUYOUSUF

DepartmentofChemicalEngineering&PolymerScience, ShahjalalUniversityofScienceandTechnology,Sylhet-3114, Bangladesh

CRISTINAGONZALEZ-FERNANDEZ BiotechnologicalProcessesUnit,IMDEAEnergy,Móstoles,Spain

DepartmentofChemicalEngineeringandEnvironmental Technology,SchoolofIndustrialEngineering,Valladolid University,Valladolid,Spain

InstituteofSustainableProcesses,Valladolid,Spain

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2022ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicormechanical, includingphotocopying,recording,oranyinformationstorageandretrievalsystem,withoutpermissioninwriting fromthepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthePublisher’spermissions policiesandourarrangementswithorganizationssuchastheCopyrightClearanceCenterandtheCopyrightLicensing Agency,canbefoundatourwebsite: www.elsevier.com/permissions

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher(otherthanas maybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroadenour understanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusingany information,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationormethodsthey shouldbemindfuloftheirownsafetyandthesafetyofothers,includingpartiesforwhomtheyhaveaprofessional responsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeanyliabilityfor anyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceorotherwise,orfrom anyuseoroperationofanymethods,products,instructions,orideascontainedinthematerialherein.

ISBN:978-0-323-85715-4

ForinformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: CharlotteCockle

AcquisitionsEditor: PeterAdamson

EditorialProjectManager: ChrisHockaday

ProductionProjectManager: SuryaNarayananJayachandran

CoverDesigner: VictoriaPearsonEsser

TypesetbySTRAIVE,India

Dedication To MydearwifeSharminSultana childrenYaraShanumandIbrahAnum whohavebeendeprivedofmyattentionowingtothisbook -AbuYousuf

To Allresearchers,policymakers,andstakeholdersworkingforamoresustainableworld -CristinaGonzalez-Fernandez

1.Conversionpathwaysforbiomass-derivedaviationfuels1

AhasanulKarim,M.AmirulIslam,AbdullahNayeem,andAbuYousuf

2.Thermochemicalconversionofagriculturalwastetobiojetfuel27 NicolasVela-García,DavidBolonio,María-JesúsGarcía-Martínez,MarceloF.Ortega, andLaureanoCanoira

Introduction

3.Conversionoflignin-derivedbio-oiltobio-jetfuel49

MajidSaidiandPanteaMoradi

4.Mainfeedstockforsustainablealternativefuelsforaviation69 V^ anyaMarciaDuartePasa,CristianeAlmeidaScaldadaferri,andHenriquedosSantosOliveira

3 Aviationbiofuelfeedstocks Lipids73

4 Aviationbiofuelfeedstocks:Sugarandstarchycrops84

5 Lignocellulosicbiomass90

6 Conclusion 97 References 98

5.Advancedbiorefineriesfortheproductionofrenewableaviationfuel103 AraceliGuadalupeRomero-Izquierdo,ClaudiaGutierrez-Antonio,FernandoIsrael Gómez-Castro,andSalvadorHernández

1 Introduction 103

2 Productionprocessesofrenewableaviationfuel105

3 Biorefineriestoproducerenewableaviationfuel111

4 Futuretrendsintheproductionofrenewableaviationfuelthroughbiorefineries116

5 Conclusions 119 Acknowledgments120 References 120

6.Roleofcatalystsinsustainableproductionofbiojetfuelfromrenewable feedstocks125

AbuYousuf,Md.AnisurRahman,MohammadJalilurRahman,andMd.ShahadatHossain

1 Introduction 125

2 Rolesofcatalystondifferentfeedstock127

3 Rolesofcatalystondifferentstagesofbiojetfuelproduction155

4 Futurelook 164

7.Biojetfuelsandemissions177

ReyesGarcía-Contreras,JoseA.Soriano,ArántzazuGómez,andPabloFernández-Yáñez

1 Biojetfuelsproperties177

2 Biojetfuelsemissionsinjetengines183

3 Biojetfuelsemissionsincompressionignitionengines188

4 Strengthsandweaknessesoftheuseofbiojetfuels196 References 196

8.Governanceandpolicydevelopmentsforsustainableaviationfuels201 MarinaEfthymiouandTimRyley

1 Introduction 201

2 Governanceofsustainableaviationfuels203

QingYangandFuyingChen

10.Sustainabilitytensionsandopportunitiesforaviationbiofuel productioninBrazil237

MarPalmerosParada,WimH.vanderPutten,LuukA.M.vanderWielen,PatriciaOsseweijer, MarkvanLoosdrecht,FarahnazPashaeiKamali,andJohnA.Posada 1

Contributors DavidBolonio

DepartmentofEnergyandFuels,SchoolofMiningandEnergyEngineering,Universidad PolitecnicadeMadrid,Madrid,Spain

LaureanoCanoira

DepartmentofEnergyandFuels,SchoolofMiningandEnergyEngineering,Universidad PolitecnicadeMadrid,Madrid,Spain

FuyingChen

StateKeyLaboratoryofCoalCombustion,HuazhongUniversityofScienceandTechnology, Wuhan,Hubei,PRChina

HenriquedosSantosOliveira

DepartmentofChemistry,InstituteofExactSciences,FederalUniversityofMinasGerais,Belo Horizonte,MinasGerais,Brazil

MarinaEfthymiou

DublinCityUniversityBusinessSchool,Dublin,Ireland

PabloFerna ´ ndez-Ya ´ n ˜ ez

SchoolofIndustrialandAerospaceEngineeringofToledo,UniversityofCastilla-LaMancha, CiudadReal,Spain

ReyesGarcı´a-Contreras

SchoolofIndustrialandAerospaceEngineeringofToledo,UniversityofCastilla-LaMancha, CiudadReal,Spain

Marı´a-Jesu ´ sGarcı´a-Martı ´ nez

DepartmentofEnergyandFuels,SchoolofMiningandEnergyEngineering,Universidad PolitecnicadeMadrid,Madrid,Spain

Ara ´ ntzazuGo ´ mez

SchoolofIndustrialandAerospaceEngineeringofToledo,UniversityofCastilla-LaMancha, CiudadReal,Spain

FernandoIsraelGo ´ mez-Castro

ChemicalEngineeringDepartment,NaturalandExactSciencesDivision,CampusGuanajuato, UniversityofGuanajuato,Guanajuato,Guanajuato,Mexico

ClaudiaGutierrez-Antonio

EngineeringSchool,AutonomousUniversityofQueretaro,ElMarques,Queretaro,Mexico

SalvadorHerna ´ ndez

ChemicalEngineeringDepartment,NaturalandExactSciencesDivision,CampusGuanajuato, UniversityofGuanajuato,Guanajuato,Guanajuato,Mexico

Md.ShahadatHossain

DepartmentofChemicalEngineeringandPolymerScience,ShahjalalUniversityofScienceand Technology,Sylhet,Bangladesh

M.AmirulIslam

LaboratoryforQuantumSemiconductorsandPhoton-basedBioNanotechnology,Department ofElectricalandComputerEngineering,FacultyofEngineering,UniversitedeSherbrooke, Sherbrooke,QC,Canada

AhasanulKarim

DepartmentofSoilSciencesandAgri-foodEngineering,UniversiteLaval,Quebec,QC,Canada

PanteaMoradi

SchoolofChemistry,CollegeofScience,UniversityofTehran,Tehran,Iran

AbdullahNayeem

DepartmentofChemicalEngineering,CollegeofEngineering,UniversitiMalaysiaPahang, Gambang,Pahang,Malaysia

MarceloF.Ortega

DepartmentofEnergyandFuels,SchoolofMiningandEnergyEngineering,Universidad PolitecnicadeMadrid,Madrid,Spain

PatriciaOsseweijer

DepartmentofBiotechnology,DelftUniversityofTechnology,Delft,TheNetherlands

MarPalmerosParada

DepartmentofBiotechnology,DelftUniversityofTechnology,Delft,TheNetherlands

V^ anyaMarciaDuartePasa

DepartmentofChemistry,InstituteofExactSciences,FederalUniversityofMinasGerais,Belo Horizonte,MinasGerais,Brazil

FarahnazPashaeiKamali

DepartmentofBiotechnology,DelftUniversityofTechnology,Delft,TheNetherlands

JohnA.Posada

DepartmentofBiotechnology,DelftUniversityofTechnology,Delft,TheNetherlands

Md.AnisurRahman

DepartmentofChemicalEngineeringandPolymerScience,ShahjalalUniversityofScienceand Technology,Sylhet,Bangladesh

MohammadJalilurRahman

DepartmentofChemistry,ShahjalalUniversityofScienceandTechnology,Sylhet,Bangladesh

AraceliGuadalupeRomero-Izquierdo EngineeringSchool,AutonomousUniversityofQueretaro,ElMarques,Queretaro,Mexico

TimRyley

GriffithAviation,SchoolofEngineering&BuiltEnvironment,GriffithUniversity,Brisbane, QLD,Australia

MajidSaidi SchoolofChemistry,CollegeofScience,UniversityofTehran,Tehran,Iran

CristianeAlmeidaScaldadaferri

CollegeofEngineeringandPhysicalSciences,EnergyandBioproductsResearchInstitute,Aston University,Birmingham,UnitedKingdom

JoseA.Soriano

SchoolofIndustrialandAerospaceEngineeringofToledo,UniversityofCastilla-LaMancha, CiudadReal,Spain

WimH.vanderPutten DepartmentofTerrestrialEcology,NetherlandsInstituteofEcology,Wageningen,The Netherlands

LuukA.M.vanderWielen

DepartmentofBiotechnology,DelftUniversityofTechnology,Delft,TheNetherlands;Bernal Institute,UniversityofLimerick,Limerick,Ireland

MarkvanLoosdrecht DepartmentofBiotechnology,DelftUniversityofTechnology,Delft,TheNetherlands

NicolasVela-Garcı ´ a DepartmentofChemicalEngineering,InstituteforDevelopmentofAlternativeEnergiesand MaterialsIDEMA,UniversidadSanFranciscodeQuito,Quito,Ecuador

QingYang

StateKeyLaboratoryofCoalCombustion,HuazhongUniversityofScienceandTechnology, Wuhan,Hubei;China-EUInstituteforCleanandRenewableEnergy,HuazhongUniversityof ScienceandTechnology,Wuhan,PRChina;JohnA.PaulsonSchoolofEngineeringand AppliedSciences,HarvardUniversity,Cambridge,MA,UnitedStates

AbuYousuf

DepartmentofChemicalEngineeringandPolymerScience,ShahjalalUniversityofScienceand Technology,Sylhet,Bangladesh

Preface Environmentalpollutionandglobalwarmingaregreatconcernscausedbythecombustionoffossilfuels.Biofuelsareproposedaspotentialalternativesforfossilfuelsinthe transportationsector.Recently,biofuelshavebeenintroducedintheaviationtransportationsector.Yet,theuseofbiofuelsislimitedduetothelackofacommerciallyviable andattractiveproductionmethod.Biojetfuel,alsoknownassyntheticparaffinickerosene(SPK),iscomposedofrenewablehydrocarbonswhosepropertiesarealmostsimilar tothatoffossiljetfuel.ThecombustionofSPKproduceslowerCO2 emissionsthanfossil jetfuel.Therefore,biojetfuelhasbeenidentifiedbytheInternationalAirTransport Association(IATA)asthemostviablealternativetosubstitutefossilfuelsinaviation.

Biojetfuelcanbesynthesizedfromvarioussourcesofbiomassthroughdifferentprocessingrouteslikeoleochemical,thermochemical,andbiochemical.Biomassthatcanbe usedfortheproductionofbiojetfuelaretriglycerides,lignocellulosicbiomass,sugar,and starchyfeedstock.Allofthecarbonsourcesusedasfeedstockshaveadvantagesanddisadvantages.Triglycerides-basedfeedstockslikecanolaoil,jatrophaoil,soybeanoil,and castoroilareexpensivebutrequirelow-costprocessing.Bycontrast,low-costmaterials likelignocellulosicbiomass,themostabundantorganicmaterialsontheearth,require longprocessingstepsthatresultinincreaseofcost.Therefore,theselectionofthebest productionprocesswilldependontheavailabilityoftherawmaterials,lowprocessing cost,andindustrialviability.

Noneofthebooksavailableinthemarketfocusonbiojetfuelsfromtechnical,economic,environmental,societal,andpolicyaspectsunderasingletitle.Thisbook, SustainableAlternativesforAviationFuels,providesanin-depthdescriptionofthemain challengesfortheproductionofalternativeaviationfuelsforbothresearchersandindustries.Inparticular,thebookfocusesonthebiojetfuelprocesspathway,feedstock availability,conceptualprocessdesign,processeconomics,engineperformance,technoeconomicanalysis,environmentalissues,policydesign,andsustainabilityofalternative aviationfueltechnology.

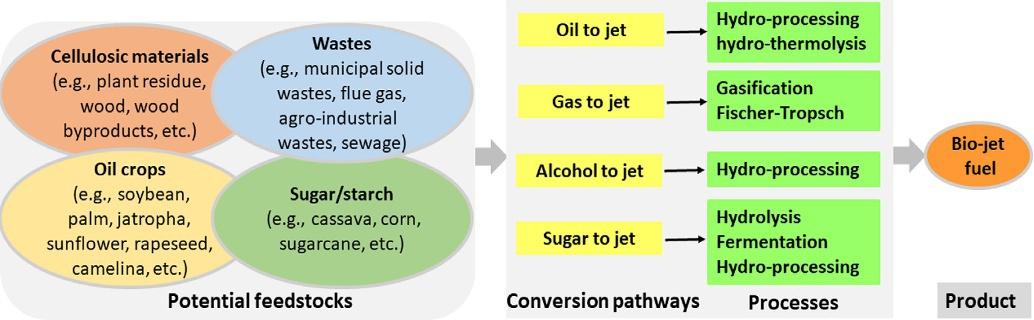

Chapter1 explainsthefourpredominantpathwaystoproducerenewablejetfuels includingoil-to-jet,alcohols-to-jet,sugar-to-jet,andsyngas-to-jetpathways.Thechapterillustratestheconceptualprocessandaddressesthekeychallengesofthesepathwaysin detail.

Chapter2 comprehensivelyassessesthepotentialofASTM-approvedroutesforbiojetfuelproductionfromagriculturalwastes.Itemphasizesthethermochemicalandbiochemicalconversionroutesoflignocellulosicagriculturalwastes/residuesfrom oleaginouscropsandtheirpotentialuseinbiojetfuelproduction.

Chapter3 providesanoverviewofthereactionnetworkandtheeffectofoperating parametersonthepropertiesoflignin-derivedjetfuelhydrocarbonrange.Toinvestigate thereactionnetwork,thechapterprovidesabriefreviewoftheeffectofvariablecatalysts onproductdistributionandadetailedsummaryusingtheinvestigatedprimaryandsecondaryproducts.

Chapter4 presentsarangeofmaterialsthatcanbeusedasfeedstockfordifferent productionprocessesofsustainableaviationfuels(SAFs).InordertoacceleratetheproductionofSAFs,thechapterextensivelydiscussesthebiomassproductionchainsand wasteprocessingtoconvertfattymaterialsandforest,agriculture,industrial,andmunicipalwastesintobiokerosene.

Chapter5 focusesontheproductionofrenewableaviationfuelinbiorefinery schemes.Italsoincludesthemaininformationabouttheindividualproductionprocesses.

Chapter6 summarizesthedifferenttypesofcatalystsalongwiththeircatalyticreactionmechanismusedinthecatalyticconversionofdifferentbiomassfeedstockstobiojet fuel.Thechapteralsoaddressesthelimitationsassociatedwithsomecatalyticprocesses andsuggestspossiblefutureresearchdirections.

Chapter7 evaluatestheeffectofbiojetfuelsonemissionsinaircraftenginesfromthe viewpointofthecompositionandmainphysicochemicalpropertiesandtheemissions associatedwithbiofuelsinjetenginesandcompressionignitionengines.

Chapter8 focusesonthegovernanceandpolicydevelopmentsratherthanthetechnicalaspectsofSAFproduction.Thechapterstartswithanintroductoryargumentabout theenvironmentalneedforSAFgovernanceandpolicy.Thesubsequentsectionsoutline thegovernancesurroundingSAFandprovideamorespecificpolicyframework,followedbysomeongoingpolicylessonsfromrecentdevelopments.

Chapter9 summarizesthebiomassfeedstocksavailableforaviationfuelandtheir conversionpaths.Then,thetechnical,economic,andenvironmentalimpactsofbiojet fuelarereviewedfromtheperspectiveoflifecycleassessment.

Chapter10 presentsanovelcontext-dependentex-antesustainabilityanalysisofaviationbiofuelproductionfocusedonthesoutheastregionofBrazil,whichincludeseconomic,environmental,andsocietalaspects.Basedoninputsfromlocalstakeholdersand sustainabilityliterature,eightaspectsofsustainabilityaredescribed:climatechange,commercialacceptability,efficiency,energysecurity,investmentsecurity,profitability,social development,andsoilsustainability.

Researchersandscientistswithstrongacademicbackgroundsandpracticalexperienceshavesharedthethoughtsandfindingsoftheirinvestigationsinthisbook.We believethebookwillenrichtheforesightofcurrentresearchersandindustrialistswho arededicatedlyworkingonSAFs.

CristinaGonzalez-Fernandez Madrid,Spain

AbuYousuf Sylhet,Bangladesh

Acknowledgments Weexpressourgratitudetoallthedistinguishedauthorsfortheirthoughtfulcontributionsthathaveaddedtothesuccessofthisbookproject.Theirpatienceanddiligencein revisingthefirstdraftofthechaptersafteradaptingthesuggestionsandcommentsare highlyappreciated.

Weacknowledgethesolicitouscontributionsofallthereviewerswhospenttheir valuabletimeinaconstructiveandprofessionalmannertoimprovethequalityof thebook.

WearegratefultothestaffatElsevier,particularlyDr.PeterW.Adamson(Acquisitions EditorforRenewableEnergy),whoprovideduswithtremendoussupportthroughout theprojectandforhisgreatideasandencouragingthoughts.WealsoacknowledgeLetı´cia Lima(EditorialProjectManager),ChrisHockaday(EditorialProjectManager),and SrinivasanBhaskaran(CopyrightsCoordinator)fortheirearnesthandlingofthebook.

Conversionpathwaysforbiomassderivedaviationfuels AhasanulKarima,M.AmirulIslamb,AbdullahNayeemc,andAbuYousufd aDepartmentofSoilSciencesandAgri-foodEngineering,UniversiteLaval,Quebec,QC,Canada bLaboratoryforQuantumSemiconductorsandPhoton-basedBioNanotechnology,DepartmentofElectricalandComputer Engineering,FacultyofEngineering,UniversitedeSherbrooke,Sherbrooke,QC,Canada cDepartmentofChemicalEngineering,CollegeofEngineering,UniversitiMalaysiaPahang,Gambang,Pahang,Malaysia dDepartmentofChemicalEngineeringandPolymerScience,ShahjalalUniversityofScienceandTechnology,Sylhet,Bangladesh

1.Introduction Theutilizationoffossilfuelssuchastransportationfuelshasresultedinanincreaseof atmosphericgreenhousegasesparticularlycarbondioxide(CO2) [1].Numerousinitiatives,includingtheexpansionofbiomass-basedrenewableenergyresourceshavebeen introducedtolowertheCO2 emissions [2].Severalcountriesandautomobileindustries haveavisiontopartiallyorcompletelyreplacegasolinefueledjetsbysole-electricor hybridalternatives [3].However,thefossilfuelresourcesarestillbeingusedasmain sourceintheaviationindustry.Notably,thecurrentenergysourceforjetfuelisamixture ofhydrocarbonparaffins,isoparaffins,aromatics,andcycloalkanes,withdefinedcarbon chainlengthsandproperties [4,5].

Thedemandforjetfueliscontinuouslyincreasingdaybyday.Anannualincreaseof about5%isprojectedby2050accordingtothepredictionofInternationalAirTransport Association(IATA) [2,6].Furthermore,thefleetnumberandsizewillbecometriplein thenexttwodecades [7,8].Inthelast20years,thetotalconsumptionofjetfuelbyairlinesamplifiedfrom260millionto340millionperyear [2].Itisprojectedthatthefleet sizewillincreasefrom340milliontomorethan500millionperyearby2026 [9].Inthis context,therenewableaviationfuelcouldbeapotentialreplacementtodecreaseCO2 emissionsandachievethegoalsofdecarbonizationin2050 [10,11].Theliterature showedthatbiojetfuel(orrenewablejetfuel(RJF))producedfromrenewablefeedstocks coulddrasticallyreduce( 80%)emissionofgreenhousegases [12,13].Therefore,the demandforRJFhasstimulatedfortheaviationtransportation [14]

Generally,theaviation-fuelisamixtureofdifferenthydrocarbons,suchasbranched chainisoalkanes,n-paraffins,aromatics,andcyclicalkanes [15].However,thecarbon numbersandmolecularweightsofthefuelsubstantiallydependontherefineryprocess anddistributionofmolecularsizerangingfromC8 toC16 [16].Ingeneral,therenewable

feedstocks,especiallybiomassareregardedasapotentialsubstituteoffossilfortheaviationindustry [17].ThecommonbiomassfeedstocksforRJFproductionareclassified intofourpredominantgroups,includingcellulosicmaterials,oilcrops,sugarsand starch,andwastes [18].ThesefeedstockscanbeconvertedintoRJFusingseveralpathways(Fig.1),suchassugar-to-jet,gas-to-jet,alcohol-to-jet,andoil-to-jet [15,19]. Theseconversiontechniqueshavebeenextensivelyusedbytheindustries,particularly theoil-to-jetpathway,whichinvolvesthehydro-processingmethod.Hydroprocessingtechnologyisconsideredmoreadvantageousthantheotherconversion pathwaysasitisassociatedwiththeutilizationoflow-qualityfeedstocks [20,21].However,inbiomass-basedRJFproduction,themainproblemisthatthebiomassinherentlycontainsawidevarietyofcomponentsrangingfromlowtohighmolecular weightsintheirstructure.AccordingtotheEuropeanUnion(EU)andAmericanSocietyforTestingMaterials(ASTM)standards [22],theoxygenmustbeseparatedfrom RJFhydrocarbonscomprisingasmallcarbonchainlength,whichischallengingincurrentconversionpathways.Thus,theseconstraintslimittheapplicationofbiomassbasedprocessestoproducebiojetfuel.

Inthiscontext,severalinitiativeshavebeentakentoenhancetheproductionofbiomassderivedbiojetfuel.Inadditiontothat,biojetfuelhasrenewedattentionduetothe environmentalandeconomicaspects.Thus,significantresearchworkshavebeenconductedincludingvariousprocessingtechnologies(thermochemical,bio-chemical,and chemo-catalyticconversion)andproductrecoverypathways.However,researchfocus shouldbegivenfordevelopingefficienttechnologytoconvertthelipidfeedstocks andsaccharides,includingcomplexstructuredlignocellulosicbiomass(LCB)feedstocks intoRJF [23,24].Inthischapter,theproductionpathwaysforRJFfromdifferentfeedstocksarecomprehensivelydiscussed.Moreover,RJFassociatedproductssuchasisoparaffinblends,aromatics,orcycloalkanes,etc.producedbythepathwaysarealsoreviewed inthischapter.

Fig.1 Thecommonbiomassfeedstocksandtheirconversionpathwaysforrenewablejetfuel(RJF) production.

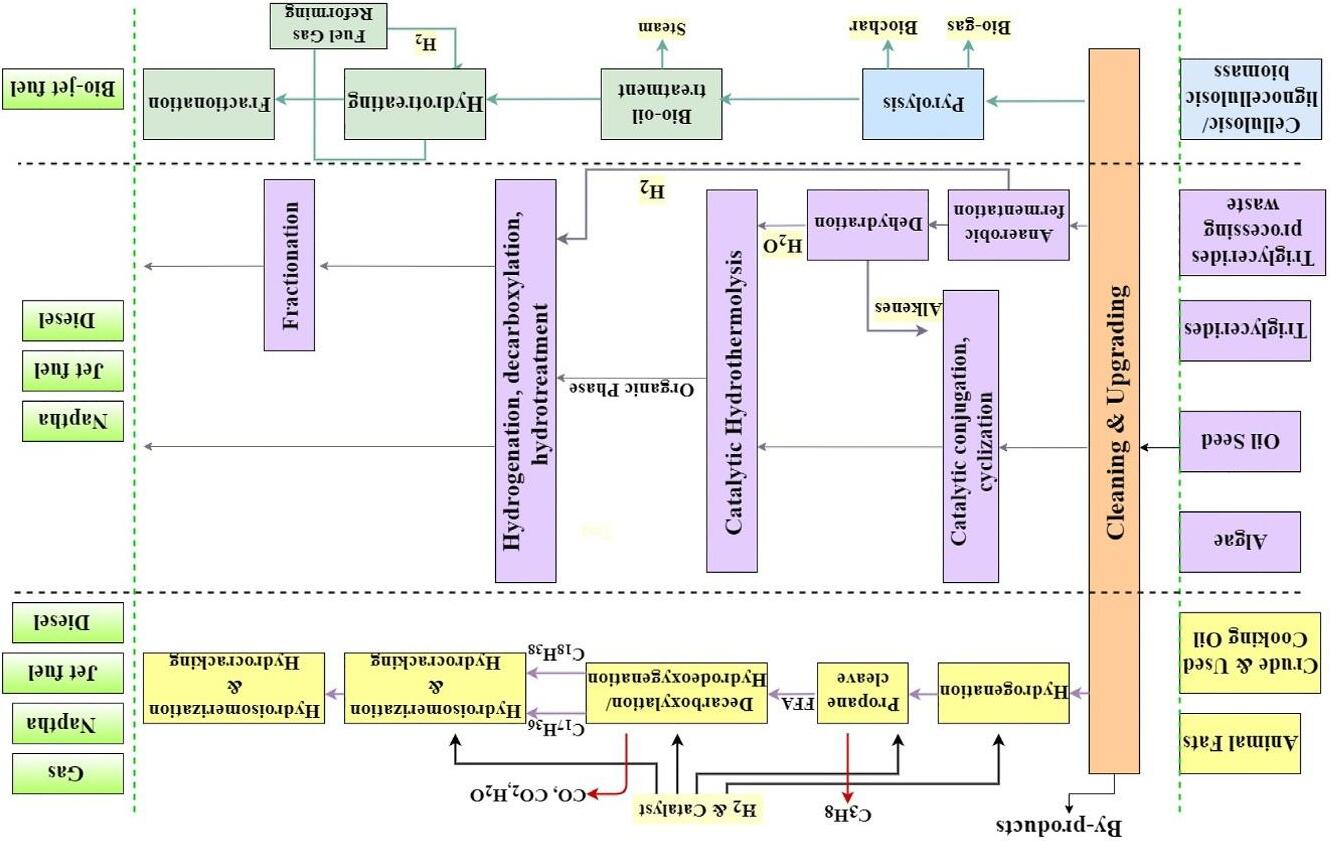

2.Conversionpathwaysofbiojetfuel 2.1Oiltojetfuel Oiltojet(OTJ)conversionpathwaycanbecategorizedintothreeprocesses:(a)hydroprocessedrenewablejet(HRJ)ortermedashydro-processedestersandfattyacids (HEFA);(b)catalytichydro-thermolysis(CHT),whichisalsoknownashydrothermal liquefaction(HTL);and(c)hydro-treateddepolymerizedcellulosicjet(HDCJ)orfamiliarizedasfastpyrolysisupgradationtojetfuel.However,onlyHRJ/HEFAconversion pathwayproductsarenowpermittedforblendingandachievedASTM-specifiedcertification [19].Triglyceride-basedfeedstocksareusedbothintheHRJandCHTpathways althoughtheproductionprocessesforfreefattyacids(FFAs)aredifferent.TheFFAsare formedviathermalhydrolysisintheCHTprocesswhiletheyareproducedthroughthe cleavageofpropaneglyceridesintheHRJprocess.Ontheotherhand,thebio-oilsare generatedbypyrolyzingthebiomassfeedstocksintheHDCJconversionprocess.Furthermore,theconversionpathwaysofjetfuelproductioncanfluctuatebasedonthe oilfeedstocktypes.Forinstance,animalfats,cookingoil,andvegetableoilsaresuitable feedstocksforHEFA/HRJprocesswhereasalgaloilsoroilfromplantsourcesareconsideredefficientforCHT/HTLprocess [13].However,thedownstreamhydrotreatmentmethodsareidenticalforallthreeprocesses [19]

2.1.1Hydro-processedrenewablejet HRJorHEFAistheprocessofbiojetfuelproductionbyhydro-treatingthetriglycerides, unsaturatedorsaturatedfattyacidsofusedcookingoils,animalfats,andvegetableoils. Thefuelproducedbythistechniquecouldbedirectlyusedintheflightengineseven withoutblending.Notably,theHEFAproducedbiojetfuelshavebeenusedinthe USmilitaryflights [25].Intermsofproperties,thefuelissimilartotheconventional petroleum-basedfuel.Itcontainshighthermalstabilityandcetanenumber,goodcold flowbehaviors,lowtailpipe/greenhousegasemissions,andlowsulfurandaromatic content [26,27].AgraphicalrepresentationofHEFA/HRJprocessflowispresented in Fig.2.Themethodcanusuallybesplitupintotwophases.

(1) Thefirststageistoconverttheunsaturatedfattyacidsandtriglyceridesintosaturated fattyacidsthroughthecatalytichydrogenation.Inthisstep,a β-hydrogeneliminationreactionofthetriglyceridesisoccurredtoproduceafattyacid [28].Generally, renewableoilsandfatsthatpossessvariousdegreesofunsaturationandrequirea hydro-generationprocessforsaturatingdoublebonds.Toconverttheglycerides andliquid-phaseunsaturatedfattyacidsintosaturatedfattyacids,thecatalytic hydro-generationprocessisusedasacommontechnique [29].Thesaturatedfatty acidsarethenconvertedintoalkanescontainingC15–C18 straightchainby hydro-de-oxygenationandde-carboxylation [30].Thecommonby-productsare propane,H2O,CO2,andCO.Theoxidesandzeolitessupportedbynoblemetals

Fig.2 Oil-to-jet(OTJ)conversionpathwaysincludinghydro-processedrenewablejet(HRJ),catalytichydro-thermolysis(CH),andhydro-treated depolymerizedcellulosicjet(HDCJ)tojetfuel.

weretheearly-developedcatalystsforthisstep.Later,otheralternativessuchassome transitionmetalsincludingCo,Ni,Mo,ortheirsupportedbimetalliccompositesare usedaswell [31–33]

(2) Crackingwithisomerizationreactionsisthesecondstep.Inthisstage,thealkanes havingde-oxygenatedstraightchainsareselectivelyhydro-crackedanddeepisomerizedtoproducemixedliquidfuelscontaininghighlybranchedalkanes. VariouscatalystsincludingNi,Ptorotheractivatedcarbonsupportedprecious alloys,i.e.,Al2O3,zeolitemolecularsievesareusedtofacilitatethereactioninthis step [34,35].ThezeolitesupportedNicatalystshowedoutstandingactivities,however,anovercrackingandlowisomersyieldwereseenforthestrongacidiccatalysts. Finally,afterafractionationprocess,thehydro-isomerizationandhydro-cracking processesaredonetoisolatethemixedliquidfuelstoparaffinickerosene (HRJ-SPK)(jetfuel),naphtha,paraffinicdiesel,andlightgases [13].Generally, thebiojetfuelsshouldhaveasuperiorflashpointaswellasexcellentcoldflowpropertiestomeetthejetfuelspecification [19].Thus,itisemergenttohydro-crackand hydro-isomerizethenormalparaffinsthatareproducedfromde-oxygenationtoa syntheticparaffinickerosene(SPK),aproductwithcarbonchainsrangingfrom C9–C15 [27].Notably,thecrackingandisomerizationreactionsareeithersequential orsimultaneous [29].Theisomerizationprocesstakesthestraight-chainhydrocarbonstoturnthemintothebranchedstructuresforreducingthefreezingpointto meetthejetfuelstandard [36].Primarily,thehydrocrackingreactionsincludecrackingandsaturationofparaffins.However,overcrackingmayresultinlowyieldsofjet fuel-rangealkanesandhighyieldsoflightspeciesrangingfromC1 toC4 andnaphtha rangingfromC5 toC8.Botharetheoutofjetfuelrangeandhavelowereconomic valuecomparedtodieselorjetfuel [19].Furthermore,thehightemperature (250–260°C)andpressureareusuallyrequiredinthisprocess.Theglycerol by-productpurificationprocessisenergyintensivethatisaddingcosttothe overallprocess,however,thiscouldbeoffsetbyglycerolsellingvalueduetoitsvariousapplicationsinthepharmaceutical,technical,andpersonalcareproduct industries [37]

2.1.2Catalytichydro-thermolysisprocess CHTorHTLisanalternativepathwayforjetfuelproductionfromalgalorplantoil. AppliedResearchAssociates,Inc.hasdevelopedthispathwaytoproduce“renewable, aromatics,anddrop-in”typesoffuelwhichiswell-knownas“ReadiDiesel”or “ReadiJet” [38].Triglyceridesareconvertedintoabranched,straightchainandcyclic hydrocarbonmixtureduringthehydrothermalprocessthroughaseriesofchemicalreactions(Fig.2),includingcracking,hydrolysis,isomerization,decarboxylation,andcyclization [39].ThetemperaturerangeandpressureoftheCHTpathwayaremaintained between450°Cand475°Candaround210bar,respectively [19].Oxygenatedspecies,

carboxylicacids,andunsaturatedmoleculescanbeproducedinthisprocess,whichare thentransferredtothehydro-treatmentprocessaftercompletingthedecarboxylation processtosaturateandremoveoxygen.Theproducts(rangingfromC6 toC28)including n-alkanes,cycloalkanes,isoalkanes,andaromaticscouldbeobtainedaftertreatment, whichrequirethefractionationprocesstoseparatedieselfuel,jetfuel,andnaphtha [13].

AnintegratedCHTprocessingconceptwassuggestedbyLietal. [39] toconvert triglyceridesobtainedfromthecropoilstononesterbiofuels(Table1).Itconsistsofthree stepssuchastriglyceridespretreatment,CHTconversion,andpostrefiningprocesses. Thepretreatmentssuchasconjugation,cyclization,andcross-linkingareappliedto enhancethemolecularstructures.DuringtheCHTconversion,theproductsgothrough acrackingandhydrolysisreactioninthepresenceofH2Oandcatalysts.Thereafter,the morestableandlow-molecular-weightcarboxylicacids(C7 orless)andglycerolproducedfromtriglyceridehydrolysisundergodecarboxylationanddehydrationprocess toformalkenes.Finally,alkanesareobtainedfromstraight-chain,branchedandcycloolefinsthroughthepostrefininghydrotreatmentandfractionation.Highlevelofcyclics andaromaticsisoneoftheimportantcharacteristicsofCHTbiofuel.Tung-oil-based biofuelsoriginatedfromtheCHprocesscontainupto60%aromatics,whichcanbea desirableingredientforfuelblendsincludingbiofuelsderivedfromotherprocesses [39].ASTMandmilitary(MIL)specificationsarefulfilledforthejetfuelobtainedfrom theCHTmethodduetoitsoutstandingcombustionquality,stability,andcoldflowcharacteristics [19].Accordingtothepreviousresearchreports,varioustriglyceridefeedstocks suchastungoil,soybeanoil,camelinaoil,andjatrophaoilcanbeusedtoproducebiojet fuelsusingtheCHTprocess [19]

2.1.3Hydro-processeddepolymerizedcellulosicjet HDCJisanewtechnologyforoilupgradationbyconvertingcellulosicbiomassintodiesel,gasoline,andjetfuels,whichwasestablishedbyKior.Ittransformsbio-oils,generated frompyrolysisorhydrothermaltreatmentofLCBintojetfuelusinghydrotreatment [40] Biomasspyrolysisoilsusuallycontainunattractivepropertiessuchaslowenergydensity, inadequatethermalinstability,andhighcorrosivitybecauseofhighoxygencontent [41]. Therefore,theseoilsrequiresomehydro-treatingprocessestobetransformedintojetfuel rangedproducts(Fig.2).Biojetfuelcanbeproducedfromvariousbiomassfeedstocks, suchassugarcanebagasse,forestresidue,cornstover,switchgrass,algaebiomass,and guineagrass,etc.canproducethroughthisconversionpathway [42,43]

Ingeneral,atwo-stephydro-processingisthekeytechnologytoupgradebio-oil.At first,catalystshelptohydrotreatthebio-oilundermildconditions.Secondly,traditional hydrogenationset-upwithcatalystsisusedtoachievehydrocarbonfuelunderhightemperature [44].Wangetal. [45] usedpyrolysistechniquetocovertstrawstalkoilsinto dieselandjetfuelviaathree-stepreactions.Bio-oilwascrackedthroughacatalyticpathwaytoobtainlightolefinsandlow-carbonaromatics.Later,aromatichydrocarbons

Table1 Mainprocessingstepstoconverttriglyceridesintononesterbiofuels.

ProcessingstepsTypicalconditionsReactionsPurpose

1.Catalyticconjugation170°C,atmospheric,4–8h, Ni/Ccatalysts

- Isomerizationofpolyunsaturatedfattyacidstoshiftdouble bondsintoconjugatedform

2.Cyclization/crosslinking 170–240°C,15bar, <1h (a) Diels-Alderadditionof alkenestotheconjugatedfatty acids

(b) Cross-linkingamongdifferent fattyacidsatdoublebonds

- Preparationforcyclizationvia Diels-Alderreaction

- Creationofcyclicsandmolecular matrixwithlowdegreesofcrosslinking

3.Catalytichydro thermolysis

240–450°C,15–250bar, 1–40min,water/ oil ¼ 1:5–5:1,catalysts

(a) Crackingandhydrolysisofthe modifiedoilmixturewiththe helpofwaterandcatalysts

(b) Catalyticdecarboxylation/ dehydration(seesteps4and5 below)

4a.Catalytic decarboxylation/ dehydration

4b.C3 andC4 decarboxylation andC2,C3,andC4 dehydration

5.Soybeanwaste anaerobic fermentation

6.Postrefining hydrotreating fractionation

330–450°C,15–250bar, 5–40min,catalysts

330–450°C,15–250bar, 5–40min,catalysts

37°C,atmospheric,6–12h, pH5.0–5.5

<400°C, <1000psig,Co Mocatalyst,1–2LHSV

- Removalofcarboxylicgroups offattyacids,andremovalof hydroxylgroupsfromthecarbonbackbone

- Eradicationofcarboxylicgroups ofthevolatileacids,andremoval ofhydroxylgroupsofthe alcohols

- Productionofmicrobial hydrogen

- Convertstraight-chain, branched,andcycloolefinsinto correspondingalkanes

- Formationofaspectrumof straight,branched,cyclic,and aromaticmolecules,withaminimumgasproducts

- Deoxygenationtoincreasefuel energycontent

- Supplyofalkenesforthe cyclizationstep

- SupplyofH2 forthehydrogenationandbyproductsforalkene production

- Necessarytoachievethermal stabilityrequiredforjetfuel

ReproducedwithpermissionfromL.Li,E.Coppola,J.Rine,J.L.Miller,D.Walker,Catalytichydrothermalconversionoftriglyceridestonon-ester biofuels,EnergyFuels 24(2)(2010)1305–1315.Copyright2010,AmericanChemicalSociety.