SolidOxideFuelCells

FromElectrolyte-BasedtoElectrolyte-FreeDevices

Editedby BinZhu RizwanRaza

LiangdongFan

ChunwenSun

Editors

BinZhu SoutheastUniversity SchoolofEnergyandEnvironment No.2SiPaiLou Nanjing210096 China

RizwanRaza COMSATSUniversityIslamabad CleanEnergyResearchLab(CERL) DepartmentofPhysics LahoreCampus Lahore54000 Pakistan

LiangdongFan ShenzhenUniversity CollegeofChemistryandEnvironmental Engineering DepartmentofNewEnergyScience andTechnology NanhaiAvenue3688 Guangdong Shenzhen518060 China

ChunwenSun

BeijingInstituteofNanoenergy andNanosystems ChineseAcademyofSciences No.30Xueyuanroad HaidianDistrict Beijing100083 China

CoverImages:SolidOxidefuelcell structure©Graphic_BKK1979/Getty Images,Electrolyte-freedeviceCourtesy ofProf.BinZhu,Background©Chad Baker/GettyImages

Allbookspublishedby Wiley-VCH arecarefullyproduced.Nevertheless, authors,editors,andpublisherdonot warranttheinformationcontainedin thesebooks,includingthisbook,to befreeoferrors.Readersareadvised tokeepinmindthatstatements,data, illustrations,proceduraldetailsorother itemsmayinadvertentlybeinaccurate.

LibraryofCongressCardNo.: appliedfor

BritishLibraryCataloguing-in-Publication Data

Acataloguerecordforthisbookis availablefromtheBritishLibrary.

Bibliographicinformationpublishedby theDeutscheNationalbibliothek TheDeutscheNationalbibliotheklists thispublicationintheDeutsche Nationalbibliografie;detailed bibliographicdataareavailableonthe Internetat <http://dnb.d-nb.de>.

©2020Wiley-VCHVerlagGmbH& Co.KGaA,Boschstr.12,69469 Weinheim,Germany

Allrightsreserved(includingthoseof translationintootherlanguages).No partofthisbookmaybereproducedin anyform–byphotoprinting, microfilm,oranyothermeans–nor transmittedortranslatedintoa machinelanguagewithoutwritten permissionfromthepublishers. Registerednames,trademarks,etc.used inthisbook,evenwhennotspecifically markedassuch,arenottobe consideredunprotectedbylaw.

PrintISBN: 978-3-527-34411-6

ePDFISBN: 978-3-527-81278-3

ePubISBN: 978-3-527-81280-6

oBookISBN: 978-3-527-81279-0

Typesetting SPiGlobal,Chennai,India PrintingandBinding

Printedonacid-freepaper 10987654321

Preface

Thefuelcellisapromisingcleanenergytechnology,whichisnotyetfullycommercialized.Therearedifferenttypesoffuelcellsbasedonthechemicalreactionsandchargetransportationmechanismsemployed,butthesolidoxidefuel cell(SOFC)technologyexhibitsmajorpotentialforlarge-scaleapplications.This technologyis,however,stillsubjecttomaterialandtechnologychallengesaccompaniedwithhighcosts.ThoughtheliteratureontheSOFCtechnologyisample coveringvariousaspectssuchasmaterials,devices,electrochemistry,andapplications,thecontributionsonthelatestdiscoveriessuchasthenon-electrolyte fuelcellprinciplesarerare.

Thisbookisauniquecollectionofcontributionsonthedevelopmentofsolid oxidefuelcellsfromelectrolytebasedtonon-electrolyte-basedtechnology.Since thescientificdiscoveryofthefuelcellprinciplesome180yearsago,afuelcellhas beenconstructedwiththreebasiccomponents,namely,theanode,electrolyte, andcathode,ofwhichtheelectrolyteplaysakeyrolefortheoperationofafuel cell.Theelectrolyteservesseveralimportantrolessuchasiontransportation,and itsupportsthefuelcellredoxreactions(hydrogenoxidationontheanodeand oxygenreductiononthecathode).Butitalsoprovidesaseparatortoblockagainst electronspreventingthemtopassthroughthedeviceandforcingthemtomove throughanexternalcircuit,thuspreventingthefuelcellfromshort-circuiting. Thus,thequestion:howcouldafuelcelldeviceatallworkwithouttheconventionalelectrolytelayerishighlyjustified?

Thisbookaimsatgivingamorecomprehensiveunderstandingontheadvances infuelcellsandtobridgetheknowledgefromtraditionalSOFCtothenew concepts.WewilltrackthedevelopmentfromtheconventionalSOFCtothe non-electrolyte(layer)orsingle-componentfuelcell,coveringresearchon theanode,electrolyte,andcathodecomponentmaterials,anddevelopment ofdevicesandstacksforapplications.Akeyareaofunderlyingscienceof thebookdealswithsemiconductorandsemiconductor–ionicprinciplesfor non-electrolyte-basedfuelcells.

Thisbookisdividedintothreeparts.PartIisontheconventionalSOFC, providinganupdateonthelatestdevelopmentofanode,electrolyte,andcathode materialsaswellastheSOFCtechnologies.PartIIdiscussesthenon-electrolyte orsemiconductor-basedmembranefuelcells.Thisnewconceptfuelcell deviceshavebeendevelopedinrecentyearswithextensiveeffortsandbroad innovationsfrommaterials,technologies,devices,andscientificprinciplesby

crosslinkresearchfromsemiconductorphysicsandbandtheory.Thisnewtype SOFCshadbeendevelopedfromthesingle-layerfuelcells(SLFCs)orelectrolyte (layer)-freefuelcells(EFFCs)inthefirstinventionstowardsemiconductor andsemiconductor–ionicfuelcells.Westartwiththeconceptualproofofthis technologyemployingbothexistingSOFCstate-of-the-artmaterialsandthen introducingnewfunctionalsemiconductor–ionicmaterialstodemonstrate varioussingle-componentandsemiconductor–ionicfuelcelltechnologies withoutusingtheelectrolyteseparator.TheemphasisofPartIIisonvarious newsemiconductorsandsemiconductor–ionicmaterialsincludingthescientific principles,materials,deviceconcepts,andfuelcelltechnology.Semiconducting materialswithionicpropertiesandmobilityandthephysicsofsemiconductor energybandstructures,whichplayasignificantroleinasingle-component fuelcell.PartIIIofthebookfocusesonengineeringeffortsfrommaterials,technology,devicetostackdevelopments,andvariousapplicationsand newopportunitiesofSOFCusingboththeelectrolyteandnon-electrolyte technologies,includingintegratedfuelcellsystemswithelectrolysis,solar energy,etc.Twoimportantissueshavebeenseriouslyaddressedtoaccelerate SOFCcommercialization:(i)technicallytheinterfacesoftheplanarcelland stackand(ii)commerciallydesignedSOFCstackproductstomeetdemands ofcustomersandapplicableuses.Thenextcommercialpotentialofthese technologieswilldependontheiradvantagesanddisadvantages,butthenew semiconductor-basedmaterialsandtechnologiesexhibitquiteafewadvantages overtheconventionalelectrolyte-basedfuelcells.

Thoughthisbookusesaspecificfuelcelltechnology,thesolidoxidefuelcells, asbasisfordescribingadvancesinfuelcells,theintentionisalsotoprovidea strongervisioninfuelcellmaterialsandtechnologiesingeneral.Seriousandconcreteresearcheffortsarenecessarytostrengthenthisfieldandtoprovidenew pathsforinnovationsandbreakthroughthinkingonfuelcells.

Thebookwillserveasimportantreferenceworktostudents,researchers,and technologydevelopersinthefuelcellfield.Wehopethisbookwouldgivereaders freshideas,newknowledge,andinspiration.

10August2019

BinZhu,RizwanRaza,LiangdongFan, andChunwenSun (Editors)

PeterD.Lund (Scientificadviser)

StockholmandHelsinki

Contents

Preface xiii

PartISolidOxideFuelCellwithIonicConducting Electrolyte 1

1Introduction 3 BinZhuandPeterD.Lund

1.1AnIntroductiontothePrinciplesofFuelCells 3

1.2MaterialsandTechnologies 5

1.3NewElectrolyteDevelopmentsonLTSOFC 10

1.4BeyondtheStateoftheArt:TheElectrolyte-FreeFuelCell(EFFC) 20

1.4.1FundamentalIssues 23

1.5BeyondtheSOFC 25 References 28

2Solid-StateElectrolytesforSOFC 35 LiangdongFan

2.1Introduction 35

2.2Single-PhaseSOFCElectrolytes 37

2.2.1OxygenIonicConductingElectrolyte 37

2.2.1.1StabilizedZirconia 37

2.2.1.2DopedCeria 39

2.2.1.3SrO-andMgO-DopedLanthanumGallates(LSGM) 42

2.2.2Proton-ConductingElectrolyteandMixedIonicConducting Electrolyte 42

2.2.3AlternativeNewElectrolytesandResearchInterests 44

2.3IonConduction/TransportationinElectrolytes 49

2.4CompositeElectrolytes 52

2.4.1Oxide–OxideElectrolyte 52

2.4.2Oxide–CarbonateComposite 53

2.4.2.1MaterialsFabrication 54

2.4.2.2PerformanceandStabilityOptimization 57

2.4.3OtherOxide–SaltCompositeElectrolytes 60

2.4.4IonicConductionMechanismStudiesofCeria–Carbonate Composite 62

2.5NANOCOFCandMaterialDesignPrinciple 66

2.6ConcludingRemarks 67 Acknowledgments 69 References 69

3CathodesforSolidOxideFuelCell 79

TianminHe,QingjunZhou,andFangjunJin

3.1Introduction 79

3.2OverviewofCathodeReactionMechanism 80

3.3DevelopmentofCathodeMaterials 82

3.3.1PerovskiteCathodeMaterials 82

3.3.1.1Mn-BasedPerovskiteCathodes 83

3.3.1.2Co-BasedPerovskiteCathodes 85

3.3.1.3Fe-BasedPerovskiteCathodes 88

3.3.1.4Ni-BasedPerovskiteCathodes 89

3.3.2DoublePerovskiteCathodeMaterials 89

3.4MicrostructureOptimizationofCathodeMaterials 94

3.4.1NanostructuredCathodes 94

3.4.2CompositeCathodes 97

3.5Summary 102 References 103

4AnodesforSolidOxideFuelCell 113

ChunwenSun

4.1Introduction 113

4.2OverviewofAnodeReactionMechanism 114

4.2.1BasicOperatingPrinciplesofaSOFC 114

4.2.1.1TheAnodeThree-PhaseBoundary 115

4.3DevelopmentofAnodeMaterials 117

4.3.1Ni–YSZCermetAnodeMaterials 117

4.3.2AlternativeAnodeMaterials 118

4.3.2.1FluoriteAnodeMaterials 118

4.3.2.2PerovskiteAnodeMaterials 120

4.3.3Sulfur-TolerantAnodeMaterials 124

4.4DevelopmentofKinetics,ReactionMechanism,andModelofthe Anode 126

4.5SummaryandOutlook 135 Acknowledgments 137 References 137

5DesignandDevelopmentofSOFCStacks 145 WanbingGuan

5.1Introduction 145

5.2ChangeofCellOutputPerformanceUnder2DInterfaceContact 145

5.2.1Designof2DInterfaceContactMode 145

5.2.2VariationsofCellOutputPerformanceUnder2DContactMode 147

5.2.32DInterfaceStructureImprovementsandEnhancementofCell OutputPerformance 149

5.2.4Contributionsof3DContactin2DInterfaceContact 151

5.2.5MechanismofPerformanceEnhancementAftertheTransitionfrom 2Dto3DInterface 153

5.3ControlDesignofTransitionfrom2Dto3DInterfaceContactand TheirQuantitativeContributionDifferentiation 156

5.3.1ControlDesignof2Dand3DInterfaceContact 156

5.3.2QuantitativeEffectsof2DContactontheTransientOutput PerformanceofaCell 158

5.3.3QuantitativeEffectsof2DContactontheSteady-StateOutput PerformanceoftheCell 161

5.3.4QuantitativeEffectsof3DContactonCellTransient Performance 163

5.3.5QuantitativeEffectsof3DContactontheSteady-StatePerformanceof aCell 166

5.3.6DifferencesBetween2Dand3DInterfaceContacts 169

5.4Conclusions 171 References 172

PartIIElectrolyte-FreeFuelCells:Materials,Technologies, andWorkingPrinciples 173

6Electrolyte-FreeSOFCs:Materials,Technologies,andWorking Principles 175 BinZhu,LiangdongFan,Jung-SikKim,andPeterD.Lund

6.1ConceptoftheElectrolyte-FreeFuelCell 175

6.2SLFCUsingtheIonicConductor-basedElectrolyte 177

6.3DevelopmentsonAdvancedSLFC 179

6.4FromSLFCstoSemiconductor–IonicFuelCells(SIFCs) 184

6.5TheSLFCWorkingPrinciple 196

6.6Remarks 204 Acknowledgments 207 References 207

7CeriaFluoriteElectrolytesfromIonictoMixedElectronicand IonicMembranes 213 BaoyuanWang,LiangdongFan,YanyanLiu,andBinZhu

7.1Introduction 213

7.2DopedCeriaastheElectrolyteforIntermediateTemperature SOFCs 214

7.3SurfaceDopingforLowTemperatureSOFCs 216

7.4Non-dopedCeriaforAdvancedLowTemperatureSOFCs 222 References 235

8ChargeTransferinOxideSolidFuelCells 239 JingShiandSiningYun

8.1OxygenDiffusioninPerovskiteOxides 239

8.1.1OxygenVacancyFormation 239

8.1.2OxygenDiffusionMechanisms 242

8.1.3AnisotropyOxygenTransportinLayeredPerovskites 244

8.1.3.1OxygenTransportinRuddlesden–Popper(RP)Perovskites 244

8.1.3.2OxygenTransportinA-SiteOrderedDoublePerovskites 244

8.1.4OxygenIonDiffusionatGrainBoundary 246

8.1.5FactorsControllingOxygenMigrationBarriersinPerovskites 248

8.2ProtonDiffusioninPerovskite-TypeOxides 249

8.2.1ProtonDiffusionMechanisms 249

8.2.2Proton–DopantInteraction 253

8.2.2.1InfluenceofDopantsinA-site 253

8.2.2.2InfluenceofDopantsinB-Site 254

8.2.3Long-rangeProtonConductionPathwaysinPerovskites 255

8.2.4Hydrogen-InducedInsulation 256

8.3EnhancedIonConductivityinOxideHeterostructures 259

8.3.1EnhancedIonicConductionbyStrain 259

8.3.2EnhancedIonicConductivitybyBandBending 263

8.3.2.1SurfaceState-inducedBandBending 263

8.3.2.2BandBendinginp–nHeterojunctions 265

8.3.2.3p–nHeterojunctionStructuresinSOFC 265

8.4Summary 266 Acknowledgments 267 References 267

9MaterialDevelopmentII:NaturalMaterial-basedComposites forElectrolyteLayer-freeFuelCells 275 ChenXiaandYanyanLiu

9.1Introduction 275

9.1.1MaterialsDevelopmentforEFFCs 275

9.1.2NaturalMaterialsasPotentialElectrolytes 276

9.2Industrial-gradeRareEarthforEFFCs 279

9.2.1Rare-earthOxideLCP 280

9.2.2Semiconducting–IonicCompositeBasedonLCP 281

9.2.2.1LCP–LSCF 282

9.2.2.2LCP–ZnO 284

9.2.3StabilityOperationandSchottkyJunctionofEFFC 288

9.2.3.1PerformanceStability 288

9.2.3.2InSituSchottkyJunctionEffect 288

9.2.4Summary 290

9.3NaturalHematiteforEFFCs 291

9.3.1NaturalHematite 292

9.3.2Semiconducting–IonicCompositeBasedonHematite 295

9.3.2.1Hematite–LSCF 295

9.3.2.2Hematite/LCP–LSCF 297

9.3.3Summary 300

9.4NaturalCuFeOxideMineralsforEFFCs 302

9.4.1NaturalCuFe2 O4 MineralforEFFC 302

9.4.2NaturalDelafossiteCuFeO2 forEFFC 305

9.4.3Summary 308

9.5Bio-derivedCalciteforEFFC 308

9.5.1Bio-derivedCalciteforEFFC 309

9.5.2Summary 312 References 314

10ChargeTransfer,Transportation,andSimulation 319 MuhammadAfzal,MustafaAnwar,MuhammadI.Asghar,PeterD.Lund, NaveedJhamat,RizwanRaza,andBinZhu

10.1PhysicalAspects 319

10.2ElectrochemicalAspects 320

10.3IonicConductionEnhancementinHeterostructureComposites 321

10.4ChargeTransportationMechanismandCouplingEffects 326

10.5SurfaceandInterfacialState-InducedSuperionicConductionand Transportation 330

10.6IonicTransportNumberMeasurements 331

10.7DeterminationofElectronandIonicConductivitiesinEFFCs 332

10.8EISAnalysis 334

10.9SemiconductorBandEffectsontheIonicConductionDevice Performance 335

10.10Simulations 339 Acknowledgments 343 References 343

11Electrolyte-FreeFuelCell:PrinciplesandCrosslink Research 347 YanWu,LiangdongFan,NaveedMushtaq,BinZhu,MuhammadAfzal, MuhammadSajid,RizwanRaza,Jung-SikKim,Wen-FengLin,andPeterD. Lund

11.1Introduction 347

11.2FundamentalConsiderationsofFuelCellSemiconductor Electrochemistry 353

11.2.1PhysicsandElectrochemistryatInterfaces 353

11.2.2Electrochemistryvs.SemiconductorPhysics 355

11.3WorkingPrincipleofSemiconductor-BasedFuelCellsandCrossing LinkSciences 356

11.4ExtendingApplicationsbyCouplingDevices 367

11.5FinalRemarks 368 Acknowledgments 372 References 373

PartIIIFuelCells:FromTechnologytoApplications 377

12ScalingUpMaterialsandTechnologyforSLFC 379 KangYuan,ZhigangZhu,MuhammadAfzal,andBinZhu

12.1Single-LayerFuelCell(SLFC)EngineeringMaterials 379

12.2ScalingUpSingle-LayerFuelCellDevices:TapeCastingandHot Pressing 383

12.3ScalingUpSingle-LayerFuelCellDevices:ThermalSprayCoating Technology 386

12.3.1TraditionalPlasmaSprayCoatingTechnology 387

12.3.2NewDevelopedLow-PressurePlasmaSpray(LPPS)Coating Technology 388

12.4ShortStack 395

12.4.1SLFCCells 395

12.4.2BipolarPlateDesign 396

12.4.3SealingandSealant-FreeShortStack 396

12.5TestsandEvaluations 397

12.6DurabilityTesting 399

12.7ACaseStudyfortheCellDegradationMechanism 400

12.8ContinuousEffortsandFutureDevelopments 404

12.9ConcludingRemarks 409 References 411

13PlanarSOFCStackDesignandDevelopment 415 ShaorongWang,YixiangShi,NaveedMushtaq,andBinZhu

13.1InternalManifoldandExternalManifold 415

13.2InterfaceBetweenanInterconnectPlateandaSingleCell 416

13.3AntioxidationCoatingoftheInterconnectPlate 418

13.4DesigntheFlowFieldofInterconnectPlate 419

13.4.1MathematicalSimulation 420

13.4.2EffectofCo-flow,Crossflow,andCounterflow 422

13.4.3AirFlowDistributionBetweenLayersinaStack 424

13.5TheImportanceofSealing 424

13.5.1ThermalCyclingoftheSealing 428

13.5.2DurabilityofSealing 428

13.6TheLifeoftheStack:TheChemicalProblemsontheInterface 429

13.7TowardMarketProducts 431

13.8ConcludingRemarks 443 References 443

14EnergySystemIntegrationandFuturePerspectives 447 GhazanfarAbbas,MuhammadAliBabar,FidaHussain,andRizwanRaza

14.1SolarCellandFuelCell 447

14.2FuelCell–SolarCellIntegration 450

14.3SolarElectrolysis–FuelCellIntegration 452

14.4FuelCell–BiomassIntegration 453

14.5TheFuelCellSystemModelingUsingBiogas 454

14.5.1ActivationLoss 457

14.5.2OhmicLoss 457

14.5.3ConcentrationVoltageLoss 458

14.6TheFuelCellSystemEfficiency(HeatingandElectrical) 458

14.6.1TheEffectofDifferentTemperaturesonSystemEfficiency 458

14.6.2TheFuelUtilizationFactorandEfficienciesoftheSystem 458

14.6.3TheSystemEfficienciesandOperatingPressure 460

14.7IntegratedNewCleanEnergySystem 460

14.8Summary 462

References 462

Index 465

PartI

SolidOxideFuelCellwithIonicConductingElectrolyte

Introduction

BinZhu 1,* andPeterD.Lund 2,*

1 SoutheastUniversity,SchoolofEnergyandEnvironment,No.2SiPaiLou,Nanjing210096,China

2 AaltoUniversity,SchoolofScience,P.O.Box15100,Puumiehenkuja2,EspooFI-00076,Finland

1.1AnIntroductiontothePrinciplesofFuelCells

Fuelcellshavebeenunderdevelopmentformorethan180yearssinceits discoveryintheearlynineteenthcentury.Severaltypesoffuelcellshaveresulted fromextensiveresearchanddevelopmentwork,butonlytwotypeshavereached astageofcommercialization.Oneisthepolymerelectrolytemembranefuel cell(PEMFC)andtheotheristhesolidoxidefuelcell(SOFC).Itisagenerally acceptedopinionthattheformerisbetterapplicablefortransportationandthe latterforstationarypowerapplications.ThisbookfocusesonSOFCsranging fromtraditionalelectrolyte-basedtoelectrolyte-freeornon-electrolyte-based devices.Thefocusofcontentswillbeonmaterialsandtechnologies.

Goingbacktothehistoryoffuelcells,thefirstmajorstepindevelopmentwas thediscoveryofthewaterelectrolysistosplitwaterintohydrogenandoxygen usingelectricityatthebeginningofthenineteenthcentury.Electrolysisisactuallyareverseprocesstothefuelcell.Thefuelcellprinciplewasdiscoveredby HumphryDavyintheearlynineteenthcentury,whichwasfollowedbythepioneeringworkbyChristianFriedrichSchönbeinandSirWilliamGrovein1838, whorealizedthefuelcellconceptbyinventingthe“gasvoltaicbattery.”InGrove’s seriesofexperimentsonagasbatteryin1838/1839,anelectriccurrentcouldbe producedfromanelectrochemicalreactionbetweenhydrogenandoxygenover acatalystelectrodecouple[1].Figure1.1showsthefirstlaboratoryprototype deviceusingironandcoppersheetsashydrogenandoxygenredoxelectrodes (anodeandcathode),andasolutionofsulfateofcopperanddiluteacidasthe electrolyte.Thisisverysimilartoaphosphoricacidfuelcell.

Thetermfuelcellappearedinliteraturefirstin1889,whenresearchersdevelopedcoalgas,alsoreferredtofuelgas,andcoaldirectlyasafueltogenerate electricity.ThusGrove’sgasbatterywasnaturallynamedas“fuelbattery”and then“fuelcell.”Thefuelcell(FC)ismoresuitabletopresentGrove’sinvention,

*Correspondingauthors:Dr.BinZhu,binzhu@kth.se;Dr.PeterD.Lund,peter.lund@aalto.fi SolidOxideFuelCells:FromElectrolyte-BasedtoElectrolyte-FreeDevices, FirstEdition.EditedbyBinZhu,RizwanRaza,LiangdongFan,andChunwenSun. ©2020Wiley-VCHVerlagGmbH&Co.KGaA.Published2020byWiley-VCHVerlagGmbH&Co.KGaA.

Figure1.1 SketchofWilliam Grove’s1839fuelcell,Grove’s 1839gasvoltaicbattery diagram.Source:Grove1839 [1].Reproducedwith permissionofTaylor& Francis.

whichalsoindicatesitscleardifferencefrombatteryenergystorageduetothe natureofconversion.Shortlysincedemonstratedin1839bySirGrove,allFCs havebeenconstructedwiththreefunctionalcomponents:anode,electrolyte,and cathode,togethercalledthemembraneelectrodeassembly(MEA).Inallcurrent FCtechnologies,theelectrolytehastobedensetopreventgaspermeability[2]. Theanodeandcathodeneedhydrogenandoxygencatalystsandsufficientionic andelectronicconductivitytocreatefuel(e.g.H2 )oxidationandoxidant(e.g. O2 )reductionprocesses.H+ orO2 ionsaresubsequentlytransportedthrough theelectrolytetoconvertthefuel’schemicalenergyintoelectricity,asshownin Figure1.2.

Sulfuric

Phosphoric acid

Figure1.2 Classicalfivetypesofelectrolyte-baseddevicesinfuelcellfamily.

Thethree-componentMEAtechnologyrequiresacomplexFCstructureand technologyasallcomponentshavetobestableandcompatible.Theinterfaces betweenelectrolyteandanodeandcathode,respectively,contributetomajor polarizationlosses[3],whiletheFCdeliverspower,andacomplextechnology leadstohighcostsaswell,delayingFCcommercialization.Amongthethreecomponents,theelectrolyteisthekey[4].Itisoftencalledasamembranebecause afuelcelldeviceisanassemblybasedontheelectrolytemembrane,whichacts astheseparatorbetweentheanodeandcathodetoblockelectronicconduction toavoidelectronshort-circuitingproblem.Therefore,theelectrolyteisthepure ionicconductor,andanyelectronicconductioncanmakeelectrochemicalleakageleadingtolossesinthedevicevoltageandpoweroutput.Ontheotherhand, theelectrolytemusttransportionstosupportthefuelcellredoxreactions,i.e. hydrogenoxidationreaction(HOR)andoxygenreductionreaction(ORR).

SeveraltypesofFCshavebeendevelopedbasedonthetypeofelectrolytes, suchasPEMFCbasedonH+ transportinapolymerelectrolyte,AFC(alkaline fuelcell),OH ionsinasolution,PAFC(phosphoricacidfuelcell)withH+ in phosphoricacid,MCFC(moltencarbonatefuelcell)withCO= 3 inmoltencarbonates,andSOFCwithO2 inceramicoxides[4,5].Theelectrolytetypeandits electricalpropertiesdeterminewhichtypeofFCtechnologiesandfinalsystem canbeusedandwhichenergyconversionefficiencycanberealizedatacertain temperature.Figure1.2showsthesefivetypesofclassicalfuelcellsclassifiedby theelectrolyteused.

PAFC,MCFC,andAFChavebeenusedindifferentspecialapplications:e.g. kW-sizedAFCwasusedinApollo’smoonlandingprograminthe1960sand 1970swithsuccesstoproducebothpowerandwater.PAFCandMCFCwereprecommercializedinthelate1980s,andtherearestillongoingMCFCcommercial demonstrationplants,butthesetechnologiesneverreachedthescaleofcommercialization.OnlyPEMFCandSOFCareleftpushingtowardcommercialization.

1.2MaterialsandTechnologies

SOFCresearchanddevelopmentaredominatedbytheyttria-stabilizedzirconia (YSZ)electrolyte.In1899NernstfirstdiscoveredthatYSZcouldreachoxideion conductionataround1000 ∘ C(0.1Scm 1 ).Today,theYSZisstillthechoiceofthe electrolytematerialforhigh-temperatureSOFC.Atemperatureof800–1000 ∘ C istypicallyneededfortheYSZelectrolyteinordertoobtainasufficientlyhigh ionicconductivity[6,7],whichputsmajorconstraintstothechoiceofconstructionmaterialsandhasresultedinhighcosts,thusslowingthecommercialization forthelastdecades.Therehasbeenmuchefforttodevelopalternativeelectrolyte materialsforSOFCstolowertheoperatingtemperature[4,8,9].Examplesare fluorite-structuredion-dopedceria[10],perovskite-typeoxides[11],O2 conductingoxides[12],andprotonconductingceramics[13]aswellasothercomplexmaterialssuchasLa2 Mo2 O9 [14],BaIn-basedoxides[15],andapatite-type oxides[16].GoodenoughproposedthatSOFCshouldbedevelopedtowardlower enoughtemperaturestomakeittechnicallyuseful[17].Hisapproachwasto developoxideionconductorsbydesignfromstructuresbasedondiscovered

Figure1.3 Goodenoughproposedoxideionconductorbydesign:astructuralmethodby cationdopingtocreateoxygenvacancy.Source:Reproducedwithpermissionfrom Goodenough[17].Copyright2000,SpringerNature.

materials.Forexample,theYSZfluoritestructureispresentedinFigure1.3.By usingalowervalencycation,e.g.2+ or3+,toreplacehighervalentZr4+ ,some oxygenvacancymustbeproducedinordertomaintaintheelectricalneutrality inthecrystal.Inmostcases,trivalentY3+ ischosentoreplacetetravalentions, Zr4+ ,tocreatetheoxygenvacancysothatO2 canmovethroughvacanciesin theY-dopedzirconiastructure.

However,thisapproachisconstrainedbythestructureandtheobjectivehas notyetbeenrealized(tobediscussedlater).Usingmodernthinfilmtechnologies toreducethethicknessoftheYSZelectrolytefrommillimetertometer,toeven nanometerlevel,theelectrolyteresistanceandtheoperationaltemperature couldbereduced.Followingthis,strongdevelopmenteffortshavebeenmadeon employingvariousadvancedthinfilmtechnologiessuchassputtering,atomic layerdeposition(ALD),molecularextensiongrowth,laserdeposition,spark plasmasintering,andinsitusurfacenanoparticleexsolutionmethods,tofabricatethinfilmYSZ-basedelectrolyte.Forexample,Kosackipreparedathin(down to15nm)filmwithhighlytexturedYSZmembranethroughPLD(plasmalayer deposition)[18].Surprisingly,theconductivitiescouldbesignificantlyenhanced to0.6Scm 1 at800 ∘ Cwithsignificantlowactivationenergy(E a )of0.45eV.This conductivityisaboutoneorderofmagnitudehigherthanthatofaconventional YSZatthistemperature.ThebulkYSZreaches0.1Scm 1 ataround1000 ∘ C

O2– ion

Dopant Cation (2+ or 3+)

Host cation (4+) Vacancy

Current

Cathode: LSC

Electrolyte: YSZ

Anode: NiO–YSZ

Substrate: LSTN–YSZ/STS

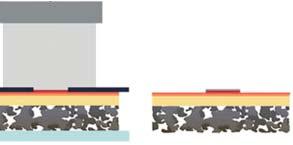

Figure1.4 Schematicsofthefabricationprocessofmicro-SOFCsupportedonLSTN–YSZ/STS substrate.(a)Tapecasting.(b)Lamination.(c)FiredsubstrateinH2 .(d)MEAdeposition.(e) Currentcollectordeposition.(f)Micro-SOFC.Source:Kimetal.2016[21].Reproducedwith permissionofSpringerNature.

andactivationenergyisaround1.0eV.Thefirstdevelopmentofmicro-SOFCs (μSOFCs)usingthethinfilmYSZmembranesof50–150nmthicknesseswas successfullyfabricatedusingsputteringtechnologywiththePtelectrode.The devicedelivered60and130mWcm 2 at350and400 ∘ C,respectively[19].The pinhole-free,composition-controllable,andconformableelectrolytemembranes werefabricatedbyALDtechnology[20];thedeviceoperationaltemperature wasfurtherreducedto265 ∘ Cwhilemaintainingsufficientperformance.These pioneeringstudieshaveinturnstimulatedextensiveresearchonnanofilms for μSOFCs,bothfromfundamentalandappliedperspectives.Kimetal.[21] reportedsomedetailson μSOFCfabricationbyPLD(seeFigure1.4);achieving decentperformance,thepeakpowerdensitywas235,370,and560mWcm 2 at 450,500,and550 ∘ C.Figure1.5displaysitsmicrostructurewithacross-sectional viewofthedenseYSZaround1.5nminthickness.

Withlowtemperature(LT) <600 ∘ CSOFCdevelopmentsinadditionto reducingelectrolyteresistancebythinfilmtechnologies,anothercriticalissue arisesinvolvinginsufficientkineticprocessandcatalystfunctionleadingtoespeciallyslowerORRforthecathodereactionandpoweroutput.Thisisactually alimitingfactortodeterminethedeviceperformanceandefficiencyforlow temperatureoperations.Toovercomethesluggishkineticsfromtheelectrodes, especiallytominimizethecathodicpolarizationlossandenhancetheORR, toenablethedevicesufficientefficiencyandpoweroutput,mostresearchand developmenthavebeenfocusedonnewfunctionalcathodematerialstogether withmicrostructurecontrollinginthedevicefabrications.Variouseffectson themicrostructureincludethecomposition,particleandporesizesandtheir distributions,particleconnections,porosity,tortuosity,specificsurfacearea, ionicandelectronicconductivities,electrodethickness,andinterfacialbonding, whicharenotedforresearchanddevelopmentofanewcathodematerial,

(d)

Figure1.5 Imageofmicro-SOFC.(a)SchematicofathinfilmMEAsupportedonporousSTS substrate.(b)Photographofacell.AlogoisatrademarkofPohangUniversityofScienceand Technology(POSTECH)andisprotectedbycopyright;itisusedinthisfigurewithpermission. Cross-sectionalSEMimageof(c)Pt/LSC/YSZ(Inset:magnifiedviewofPt/LSC),(d) YSZ/Ni-YSZ/LSTN-YSZ,and(e)LSTN-YSZcontactlayer.Source:Kimetal.2016[21].Reproduced withpermissionofSpringerNature.

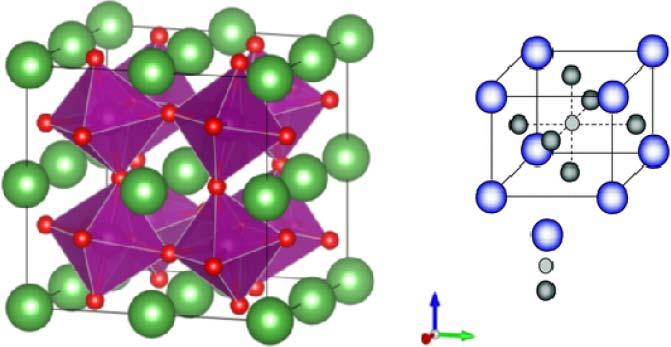

especiallybelow600 ∘ C[22,23].Perovskite-structuredoxides,ABO3 ,asshown inFigure1.6,havebeenusedsuccessfully[24].La(Mn/Co)O3 basedonA-site andB-sitedopingbyrareearth,alkalineearth,andtransitionelementsare successfulexamplesofhighperformance,moredurableandcomparablewith otherSOFCdevicecomponents.

A-cationsarelocatedineveryhole,whichiscreatedbyeightBO6octahedra, asshowninFigure1.6,thushavinga12-foldcoordinatesite,andtheB-cations in6-foldoxygencoordination.TherearemanyABO3 compoundsforwhich theidealcubicstructureisdistortedtoalowersymmetry(e.g.tetragonal, orthorhombic,etc.).Oxygenvacanciescanbecreatedbyionicdopingwithin theperovskitestructure,similarwithfluoritestructure.Iondopingeffect cancreateanimpactonbothelectronandiontransport.Oneofthebest perovskitecathodesforlow-temperaturesolidoxidefuelcells(LTSOFCs)is Ba0.2 Sr0.8 Co0.6 Fe0.4 O3 [25];itselectronicandoxygenionicconductivitiesat 600 ∘ Care200and0.1Scm 1 ,respectively.

Figure1.6 PerovskitestructureoxidesforfunctionalLTSOFCcathodecatalystmaterial.In ABO3 ,thereare(a)corner-sharing(BO6 )octahedrawithAionslocatedin12-coordinated intersticesand(b)B-sitecationatthecenterofthecell.Source:Kanetal.2016[24]. ReproducedwithpermissionofRoyalSocietyofChemistry.

Othertypesofperovskitestructureoxideshavebeenalsodevelopedfor LTSOFCs.Atypicalexampleisdoubleperovskites,Sr2 FeMoO6 (SFM)[26], becausetheunitcellistwicethatofperovskite.Ithasthesamearchitecture of12-coordinateAsitesand6-coordinateBsites,buttwocationsareordered ontheBsite.InthecaseofSr2 FeMoO6 ,theFeandMoatomsareorderedin a3Dchessboard-typefashion.Also,theratiobetweenFeandMocanmakea significanteffectonelectricalandcatalystfunctions.Typically,Sr2 Fe1.5 Mo0.5 O6 �� (SF1.5 M0.5 )hasbeenreportedforremarkableelectricalconductivityof550Scm 1 inairand310Scm 1 inhydrogenat780 ∘ C,asoneofthebestredoxstable electrodesforLTSOFCs;thismakesitavailableforbothanodeandcathode materialsinSOFCs.InthecaseofSFM0.5astheanodeandcathodetoconstruct asymmetricalSOFC,thedevicehasachievedapeakpowerdensityofover 835mWcm 2 at900 ∘ CusingH2 asfuelandambientairastheoxidant[26].

TheSFMshowsalsoagoodcatalystforoxidationofhydrocarbonfueloperation,e.g.directoxidationmethanolusingtheSFM0.5astheanodeandperovskite andBa0.5 Sr0.5 Co0.8 Fe0.2 O3 (BSCF)asthecathodebasedonperovskiteionicelectrolyte,La0.8 Sr0.2 Ga0.83 Mg0.17 O3 toconstructtheallperovskiteSOFCdevice, inaconfigurationofSF1.5 M0.5 /La0.8 Sr0.2 Ga0.83 Mg0.17 O3 (electrolyte)/BSCF.This deviceobtainedamaximumpowerdensityof391mWcm 2 at800 ∘ C[27].

Inadditiontoperovskitecathodes,othertransitionmetaloxidesarealsoefficientforlowtemperatureoperations,typicallynickeloxide,ironoxide,cobalt oxideandtheircomposites,orlithiatedoxides,suchaslithiatedorLicompound layerstructureoxides,suchasLix M(M = Ni,Fe,Co)O2 .Theseoxideshaveshown mucheffectivecatalystfunctionsduetoitsgreatprotonconductivity,sofarthe bestofprotonceramicmaterials,0.1Scm 1 at500 ∘ C[28],andotherunique advantages,e.g.triplechargecarriersofH+ ,O2 ande asshowninFigures1.7 and1.8[29,30].

Li xAl0.5Co0.5O2

Li x H yAl0.5Co0.5O2

Figure1.7 Layerstructurereportedhavingthehighestprotonconductivity0.1Scm 1 at 500 ∘ C.Source:ReproducedwithpermissionfromLanandTao[28].Copyright2014,John Wiley&Sons.

Pure e– conductor

Pure H+ conductor

Mixed O2–/e– conductor

H2O evolution point at triple phase boundary (TPB)

Mixed H+/e– conductor

Ternary H+/O2–/e– conductor

H2O evolution point and line at double phase boundary (DPB) (a) (b) (d) (c)

Figure1.8 TriplechargetransferinLTSOFCcathodeandschematicillustrationsoftheoxygen reductionandwatergenerationpathwaysinvariouscathodes:(a)pureelectronicconductor; (b)mixedO2 /e conductor(mixedelectronicandionicconductor[MIEC],left)andMIEC compositedwithH+ conductingoxide(right);(c)mixedH+ andeconductor(mixedproton andelectronconductor[MPEC])and(d)triple-conducting(H+ /O2 /e )oxides.Source: ReproducedwithpermissionfromFanandSu[29].Copyright2016,Elsevier.

Figure1.8displaysthelayerstructureofLiNi0.8 Co0.2 O2 withatriple (H+ /O2 /e )conductingcatalystmaterial.Thetriplechargeconductingmaterial canspeedupthecathodicORRprocess,toreducesignificantlythecathodic polarization,thusenhancingthedeviceperformance.

1.3NewElectrolyteDevelopmentsonLTSOFC

AsproposedbyGoodenough,newmaterialsneedtobedevelopedtoreplace YSZ[19]tomakeSOFCoperationalatlowenoughtemperatures.Thismeans

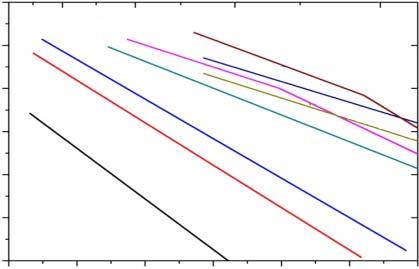

Figure1.9 Temperaturedependenceofconductivitiesforvariousoxideelectrolytesfrom High-TemperatureSolidOxideFuelCells:Fundamentals,Design,andApplications byS.C.Singhal andK.Kendall(Eds.).Publisher:ElsevierScience(2004).Source:Reproducedwithpermission fromSinghalandKendall[31].Copyright2003,Elsevier.

thatalternativeelectrolytesshouldbedesignedforlowtemperatures;commonly acceptedtemperatureisbelow600 ∘ CforLTSOFC.Therefore,newelectrolyte materialsshouldreachanionicconductivityof0.1Scm 1 < 600 ∘ C.Following thisdirection,worldwideLTSOFCmovementhasbeenconductedtolookfor newelectrolytematerials.However,noalternativetobegoodenoughtocompete withYSZonoverallrequestshasnotyetbeenfound.Figure1.9displayssomeof thenewelectrolytematerialsdevelopedinthisline.

ItcanbeseenfromFigure1.9thatalmostnoalternativeoxideelectrolytematerialscanreach0.1Scm 1 below600 ∘ C.ThoughBi2 O2 –Y2 O3 isusedatthislevel, itcouldnotbeusedforSOFCsduetoitsdirectreductiontoBimetalinfuelcell operation,thusthelossoftheionicconduction.Anotherapproachtodevelop newelectrolytematerialsbasedonsurfaceandinterfacialionicconductionis alsopublishedinNatureinthesameyearofGoodenough’structuraldoping[32]. Toobtaintheinterfacialhighionicconductivity,nanoandcomposite,so-called nanocomposite,approachhasbeendemonstratedtobemoreeffective.Avery successfulcasemaybeexampledbyceria-basedtwo-phasecompositematerials [33–36].SuchmaterialshavebeenfoundveryfunctionalforLTSOFCsbetween 300and600 ∘ C.Figure1.10presentsaschematicdrawingforsuchamethodology.

Figure1.10 Combiningnanoand compositeapproachtodevelopeffective newfunctionalelectrolytematerialsfor LTSOFC.

Nanocomposite

Ononehand,nanotechnologycancreatehighsurfaceareaandactivesites withdefectsforhighionictransportationthustoenhancetheionicconductivity; ontheotherhand,thecompositeapproachcanenhancethenanomaterial stabilityandfurtherenhancetheionicconductionbytheinterfacialmechanism. Therefore,thenanocompositeapproachcanbeveryeffectivetodevelophigh ionicconductorsforLTSOFCelectrolytedemands.Ceriahasastablefluorite structureasYSZbyCetoreplaceZrwithawiderrangeofdopantsthanthat inzirconia.Usingrareearthelementdoping,e.g.samarium,gadolinium,and yttrium,dopedCeO2 havehighexpectationtoreplaceYSZbecauseitsO2 conductivitycanreachthesamelevel,0.1Scm 1 at800 ∘ C,i.e.200 ∘ Clower thanthatofYSZ.However,exceptgoodionicconductivityatalowertemperature,manyotheraspectsarenotasgoodaswithYSZ.Forexample,infuel cell-reducedatmosphere,Ce4+ canbereducedtoCe3+ ,whichresultsindirect electronicconductionandshort-circuitingproblemandthusinasignificantloss indevicevoltageandpoweroutput;withCe4+ toCe3+ reduction,thebigatom volumechangecausesmicrocrackingandleadstogasleakageandfinallythe deviceinvalidduringthefuelcelloperation.Evenmore,0.1Scm 1 canoccur onlyat800 ∘ C,stillnotsufficientforLT(<600 ∘ C).Thesechallengeshavemade ceriaitselfnotyetsuccessfulforthealternativeelectrolyteandSOFCtechnologies.Torealizeceria-basedelectrolytes,amoreeffectivewayistodevelop ceria-basedcompositeelectrolytes[36]asillustratedinFigure1.10,whichhave beenextensivelyinvestigatedanddemonstratedbyexcellentperformancesfor SOFCsatLTs.Amongvariousceria-basedcompositematerials,ceria–carbonate two-phasecompositeshavebeenmostwidelyinvestigatedasnewelectrolytes withsuccessfulapplicationsinLT,300–600 ∘ CSOFCs[33–37].Hybridproton andoxygenionicconductionandeventripleions(H+ /O2 /CO= 3 )transport processeshavebeenstudiedandreportedwithexcellentfuelcellperformances [36,38–41].

Figures1.11and1.12presenthybridandtripleiontransportfuelcelldevices basedonceria–carbonatecompositeelectrolytes.

Figure1.11 HybridH+ /O2 conductionintheceria-basedcompositeelectrolyte.Source:Zhu 2006[36].http://www.electrochemsci.org/ESG.htm.LicensedUnderCCBY4.0.

O2–H+

Figure1.12 Tripleiontransportmechanismintheceria–carbonatecompositeelectrolyte.

Source:ReproducedwithpermissionfromXiaetal.[39].Copyright2009,Elsevier.

TheO2 conductioninceriaphaseisdeterminedbytheoxygenionvacancies (amechanism)inthecerialattice;H+ conductionmaybeproducedby theformationofbondingwiththecarbonatethroughtemporalbonding, H+ –CO3 = (HCO3 )mechanism.BothH+ andO2 conductioncanbeintegrated intoonecompositetoenhancethesystemconductivitybasedonthecomposite effect.Thiseffectconcernstheionconductionatinterfaces,orinterfacial conduction,asthekey.Figure1.11presentsaschematicforsuchhybridproton andoxygenionconductionmodelanddepictsalsothehybrid/dualH+ /O2 conductionroutesandtheconductingchain:H⋅⋅⋅O–H,H–O–HandO–H⋅⋅⋅O atoms/ions.Thisreferstoaninterfacialconductingpath/mechanismfortheH+ (markedbytwosmallbolls/dotsinFigure1.11)andO2 (largerboll).

InFigure1.12,atripleiontransportmechanismhasbeenproposedbyXiaetal. [39].TheyintroducedsomeCO2 intheceria–carbonateelectrolytefuelcelland operatedabovethecarbonatemeltingpoint,achieving1700mWcm 2 at650 ∘ C, thebestperformanceoftheceria–carbonateelectrolytefuelcells.Theyproposed triple-chargetransportmechanismtointerpretsuchexcellentperformance,presentedinFigure1.12.

BecauseH+ andO2 ionsarefuelcellsourceions,hybridH+ /O2 conduction canenhancethedevicechargecarrierconcentrationresultinginhighercurrent andthuspoweroutputs.1150mWcm 2 hasbeenachievedat490 ∘ C[42],while intripleionicprocess,byaddingonemoresourceionofCO2= 3 ,thefuelcell devicereached1700mWcm 2 at650 ∘ C.Moreinterestingly,theceria–carbonate fuelcellcanbedevelopedinvariouselectrochemicaloperationmodesasSOFC, MCFC,orjointSOFC/MCFC[43].

Successfulhybridionicconductingcompositeelectrolytematerialsfor LTSOFCsmayalsobehighlightedbyheterostructure,whichcanbepreparedby directlyusingprotonandoxideion-conductingoxidesinthecomposite.Zhuand SchoberfirstpresentedsuchahybridsystembasedonBZY(BaZr0.8 Y0.2 O3 d ) proton-conductingperovskitewithsamarium-dopedceria(SDC),afluorite structurewithoxideionconductorcomposite.Thisnovelcompositesystemcomposedoftheprotonandoxideion-conductingoxidessuccessfullydemonstrated

afuelcelldevicereaching250mWcm 2 at550 ∘ C[44].Followingthisroute, highsinteringtemperatureat1550 ∘ CwasemployedforBZY/SDCcomposite system,whichproducedanewperovskitephaseofBaCe1.6 Y0.2 Gd0.2 O4.9 (BCYG) betweenSDCandBZYphases.Asreportedsuchanewphase,BCYGdisplayed ionicconductivityhigherthanthatofconstituentBZYandSDCmaterials. Thisnewcompositesystemwasappliedastheelectrolyteforthefuelcellto achieve657Wcm 2 at700 ∘ C[45].ThissystemsuggeststhattheBZY–SDC two-phasecompositemaybetransferredtothree-phasebyhightemperature heattreatment,whiletheintermediatephaseformedbetweentwoconstituent phasesstilldominatedtheionicconductivityandtransportinsuchcomposite material.Buttheionictransportmechanismisnotverycleartodemandfurther investigation.Forexample,eitherH+ orO2 orbothmaybetransportedin thisnewlyformedBCYGphase.Thebasicphenomenonstillbelongstoionic transportinthecompositeandheterostructurematerials.

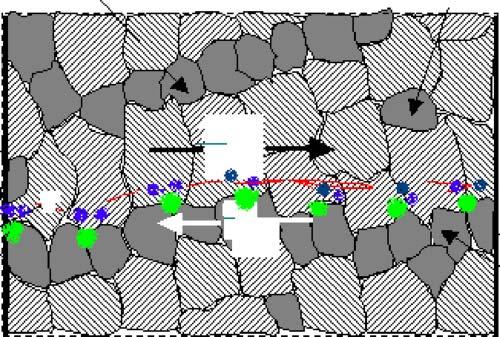

Twophasesbasedonprotonandoxideion-conductingoxidesmaymake severalwaysforionictransportation,H+ andO2 transportindividuallyin respectiveprotonandoxideionphases,andmoresignificantly,superionic conductionthroughinterfacesbetweentwoconstituentmaterialsasionic highways,asshowninFigure1.13.

InordertodevelopalternativeYSZelectrolytematerialswithsufficientionic (H+ ,O2 orhybrid)conductivities,say,0.1Scm 1 ,thenanocompositepresented anotherpowerfulwaybydesigninginterfacesandinterfacialsuperionicconductionbetweentwophasesoftheheterostructurecomposite.Suchanapproach calledmultifunctionalnanocompositeforadvancedfuelcells(nanocompositesforadvancedfuelcells[NANOCOFC],www.nanocofc.com)focusingon advancedmaterialandfunctionalitiesdesignoninterfaces;seeFigure1.14.In suchcompositestructure,twoconstituentphasesmayhavemoderateionic conductivity,ormoreoftenwithoneinsulatingphase,e.g.aninsulatingoxide;

Figure1.13 Proton,oxideionpathsinrespectiveprotonandoxideionconductingphaseand interfacialionichighways.

O2–conduction

H+ conduction

Superionic conduction

Figure1.14 Superionictransitionattwoconstituentphases’interfacesinthecomposite materials.

amuchhighionicconductivitywithagreatenhancementcomparedtothe constituentphasecanbeproducedbetweenthetwo-phasecontactingregions, i.e.interfaces.Thisisso-calledinterfacialsuperionicconductivity.Itshouldbe pointedoutthatsuchconductionmechanismdoesnotinvolveanymaterial structuralchanges,butonlychangesintheinterfaceduetomicrostructuresand interactionsbetweentwophases.

Atheoreticalcalculationhasbeencarriedoutbetweenceriaandcarbonate compositeelectrolyteindicatingtheexistenceoftheinterfacialionichighways.A modelpresentedinFigure1.15basedoncoulombicinteractionpointsoutthere areverylowactivationenergiesforionictransport,0.2eVforO2 and0.1eVfor H+ transport,respectively[46].

AccordingtotheArrheniusrelation, �� = �� 0 exp( ��a /kT ),theinterfacialionic transportdesignisveryfavorabletodevelopsuperionicconductorsbecausethe interfacialmechanismisfavorablebyoptimizingallparameterstopromotehigh ionicconductivityfromthefollowingaspects:

(i) Highmobileionconcentration, n (�� 0 ).Itisdirectlyproportionaltotheionic conductivityvaluelevel,whileatinterfaceorparticlesurfaces,highdefects canbecreatedwithoutstructuralfactorlimitations.Butinstructuraldoping approach,itisoftenalimitingfactor,e.g.only8%yttriumallowedtostabilize cubicfluoritestructure,YSZwithinzirconia.

(ii) Lowactivationenergy, ��a .Theionicmigrationactivationenergyismore effectivetodetermineconductivityduetoionicconductivitydependence beingareciprocallyexponentialfunction.Interfacialpathshavenostrong bondenergytobreakinordertoactivateionmobile,thusrequiringmuch loweractivationenergycomparedthatoftheionmobilityinthestructure.

Figure1.15 Interfacialsuperionic(H+ andO2 )conductingpathsinceria–carbonate compositeelectrolyte.(a)Interactionsandpotentialbetweentheoxygenionsontheceria particleandM+ (Li+ ,Na+ ,orK+ )cationsofthecarbonate,andelectricalfieldintheinterfaces betweentwoconstituentphaseparticles.(b)Theoxygenionsontheceriaparticlesand interactionswithcationsofthecarbonatesmayessentiallyconsistofconducting highways/pathsatinterfacesofthetwo-phasematerials,resultingininterfacialsuperionic conduction.Source:ReproducedwithpermissionfromZhuetal.[46].Copyright2008,Elsevier.

(iii) Longionictransportpath, L (�� 0 ).Thiseffectisagainproportionalto conductivity.Whileionstransportatinterfaces,one-stepjumpdistance isfromparticletoparticlethroughsurfacedefects.Suchjumpingstep lengthisinnanometerlevelfornanocompositesorevenlonger.Butin structuredesign,defectsarecreatedwithinthestructureunitcell,which isinangstromlevel,i.e.ionsjumpingstepsbetweenlatticeunitsfrom celltocellinangstromlevel,evenless,becausebasedonEinstein–Nernst equation,1/6probabilityisallowedfordirectionalmobilitydrivenbyan externalelectricalfield.Inthiscase,interfacialconductionhasnosuch limitbecausethree-dimensionalinterfacescanbeconstructedonparticles, whichcanadjusttransportpathsdirectedbythedrivenfield.

Fromtheaboveanalyses,wecanseethemoreadvancedmaterialdesignon interfacialsuperionicconductivitywithalloptimizedparametersindicatedby Arrheniusrelationthanthatoftheion-dopedstructuraldesign.Suchinterfacialapproachhasdemonstratedagreationicconductivity,0.1Scm 1 at300 ∘ C, firstreportedbyWangetal.inaceria–sodiumcarbonatecore–shellstructure composite;seeFigure1.16[47].

Wangetal.proposedthe“Swing”modeltodescribeprotonpathwayand transportprocess;seeFigure1.17fortheSDC/Na2 CO3 compositesystem.This isessentiallyaninterfacialconductionmechanism.Protoncantransportinthe carbonate–SDCcontactregion,i.e.interface,throughCO= 3 anionbondingto formtemporalHCO3 ,whichcanbetransferredthroughonecarbonateanionto another.

Theinterfacialionicconductionmechanismshavebeenfurtherinvestigated byShalimaandGulgun[48],whoproposedtheinterfacialiontransportmodel showninFigure1.18.Core–shellstructuredSDCparticlesareconnectedbycarbonatenetworks.