https://ebookmass.com/product/recrystallization-and-related-

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Marine Protected Areas: Science, Policy and Management

John Humphreys (Editor)

https://ebookmass.com/product/marine-protected-areas-science-policyand-management-john-humphreys-editor/

ebookmass.com

Bontrager's Textbook of Radiographic Positioning and Related Anatomy 9th Edition John Lampignano

https://ebookmass.com/product/bontragers-textbook-of-radiographicpositioning-and-related-anatomy-9th-edition-john-lampignano/

ebookmass.com

UFO MOTHERSHIPS: - UNIDENTIFIED AERIAL PHENOMENA 1st Edition John Scott Chace C

https://ebookmass.com/product/ufo-motherships-unidentified-aerialphenomena-1st-edition-john-scott-chace-c/ ebookmass.com

Family Business Heterogeneity in Latin America: A Historical Perspective 1st Edition Claudio G. Müller

https://ebookmass.com/product/family-business-heterogeneity-in-latinamerica-a-historical-perspective-1st-edition-claudio-g-muller/ ebookmass.com

(eBook PDF) Research Methods in Kinesiology by Kent C. Kowalski

https://ebookmass.com/product/ebook-pdf-research-methods-inkinesiology-by-kent-c-kowalski/ ebookmass.com

Evidential Systems of Tibetan Languages Lauren Gawne

https://ebookmass.com/product/evidential-systems-of-tibetan-languageslauren-gawne/

ebookmass.com

Wolf to the Rescue Terry Spear

https://ebookmass.com/product/wolf-to-the-rescue-terry-spear-2/

ebookmass.com

The History and Political Transition of Zimbabwe: From Mugabe to Mnangagwa 1st ed. Edition Sabelo J. NdlovuGatsheni

https://ebookmass.com/product/the-history-and-political-transition-ofzimbabwe-from-mugabe-to-mnangagwa-1st-ed-edition-sabelo-j-ndlovugatsheni/ ebookmass.com

Photocatalysts and Electrocatalysts in Water Remediation: From Fundamentals to Full Scale Applications Prasenjit Bhunia

https://ebookmass.com/product/photocatalysts-and-electrocatalysts-inwater-remediation-from-fundamentals-to-full-scale-applicationsprasenjit-bhunia/ ebookmass.com

Experimental and Expanded Animation: New Perspectives and Practices 1st ed. Edition Vicky Smith

https://ebookmass.com/product/experimental-and-expanded-animation-newperspectives-and-practices-1st-ed-edition-vicky-smith/

ebookmass.com

RecrystallizationandRelated AnnealingPhenomena ThirdEdition JohnHumphreys

GregoryS.Rohrer

AnthonyRollett

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright © 2017ElsevierLtd.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicor mechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem,without permissioninwritingfromthepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthe Publisher’spermissionspoliciesandourarrangementswithorganizationssuchastheCopyrightClearance CenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher (otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroadenour understanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecome necessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusing anyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationormethods theyshouldbemindfuloftheirownsafetyandthesafetyofothers,includingpartiesforwhomtheyhavea professionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeany liabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceor otherwise,orfromanyuseoroperationofanymethods,products,instructions,orideascontainedinthe materialherein.

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

ISBN:978-0-08-098235-9

ForinformationonallElsevierpublicationsvisitour websiteat https://www.elsevier.com/books-and-journals

Publisher: JohnFedor

AcquisitionEditor: KostasMarinakis

EditorialProjectManager: MichelleFisher

ProductionProjectManager:VijayarajPurushothaman

Designer:GregHarris

TypesetbyTNQBooksandJournals

PrefacetotheFirstEdition Recrystallizationandtherelatedannealingphenomenawhichoccurduringthe thermomechanicalprocessingofmaterialshavelongbeenrecognizedasbeingbothof technologicalimportanceandscientificinterest.Thesephenomenaareknowntooccur inalltypesofcrystallinematerials;theyoccurduringthenaturalgeological deformationofrocksandminerals,andduringtheprocessingoftechnicalceramics. However,thephenomenahavebeenmostwidelystudiedinmetals,andasthisisthe onlyclassofmaterialforwhichacoherentbodyofworkisavailable,thisbook inevitablyconcentratesonmetallicmaterials.Althoughthereisavastbodyofliterature goingback150years,andalargecollectionofreviewswhicharedetailedinChapter1, therehaveonlybeentwomonographspublishedinrecenttimesonthesubjectof recrystallization,thelatestnearly20yearsago.Sincethattime,considerableadvances havebeenmade,bothinourunderstandingofthesubjectandinthetechniques availabletotheresearcher.

Metallurgicalresearchinthisfieldismainlydrivenbytherequirementsofindustry, andcurrently,amajorneedisforquantitative,physicallybasedmodelswhichcanbe appliedtometal-formingprocessessoastocontrol,improveandoptimizethe microstructureandtextureofthefinishedproducts.Suchmodelsrequireamore detailedunderstandingofboththedeformationandannealingprocessesthanwehave atpresent.Thedevelopmentoftheunderlyingsciencetoalevelsufficientforthe constructionoftherequiredmodelsfromfirstprinciplesprovidesagoalforperhaps thenext10 20years.

Thebookwaswrittentoprovideatreatmentofthesubjectforresearchersorstudentswho needamoredetailedcoveragethanisfoundintextbooksonphysicalmetallurgy,anda morecoherenttreatmentthanwillbefoundinthemanyconferenceproceedings.Wehave chosentoemphasizethescientificprinciplesandphysicalinsightunderlyingannealing ratherthanproduceacomprehensivebibliographyorhandbook.

Unfortunatelythegenerictermannealingisusedwidelytodescribetwometallurgical processes.Bothhaveacommonresultinthatahardenedmaterialismadesofter,butthe mechanismsinvolvedarequitedifferent.Inonecase,associatedwiththeheattreatment

offerrousmaterials,thesofteningprocessinvolvesthe g / a phasetransformation.In thesecondcase,whichistheonerelevanttothisbook,thesofteningisadirectresultof thelossviarecoveryandrecrystallization,ofthedislocationsintroducedbywork hardening.

Itisnoteasytowriteabookonrecrystallization,becausealthoughitisaclearlydefined subject,manyaspectsarenotwellunderstoodandtheexperimentalevidenceisoften poorandconflicting.Itwouldhavebeendesirabletoquantifyallaspectsofthe phenomenaandtoderivethetheoriesfromfirstprinciples.However,thisisnotyet possible,andthereaderwillfindwithinthisbookamixtureofrelativelysoundtheory, reasonableassumptionsandconjecture.Therearetwomainreasonsforourlackof progress.First,wecannotexpecttounderstandrecoveryandrecrystallizationindepth unlessweunderstandthenatureofthedeformedstatewhichistheprecursor,andthatis stilladistantgoal.Second,althoughsome annealingprocesses,su chasrecoveryand graingrowtharereasonablyhomogeneous,others,suchasrecrystallizationandabnormal graingrowthareheterogeneous,relyingonlocalinstabilitiesandevokingparallelswith apparentlychaoticeventssuchasweather.

Itmustberecognizedthatwearewritingaboutaliveandevolvingsubject.Verylittle isfinishedandthebookshouldthereforebeseenasasnapshotofthesubjectatthis particulartimeasseenbytwoscientistswhoareundoubtedlybiasedinvariousways. Wehopethatwhenasecondeditionofthisvolumeisproducedinperhaps10years time,oranewtreatmentisattempted,manyaspectsofthesubjectwillhavebecome clearer.

Recoveryandrecrystallizationdependonthenatureofthedeformedstateandinvolve theformation,removalandmovementofgrainboundaries.Forthesereasonswehave includedtreatmentsofthedeformedstateinChapter2,andthenatureofgrainboundaries inChapter3.Thesearebothlargetopicswhichmeritcompletebooksinthemselves,andwe havenotattemptedacomprehensivecoveragebuthavemerelyaimedtoprovidewhat weregardasessentialbackgroundinformationinordertomakethevolumereasonably self-contained.Chapter4isconcernedwiththemigrationandmobilityofgrainboundaries, andthiscontainssomebackgroundinformation.

Themaintopicsofthebook recovery,recrystallizationandgraingrowth arecovered inChapters5 11andincludespecificchaptersonorderedmaterials,two-phasealloys andannealingtextures.Inordertoillustratesomeoftheapplicationsoftheprinciples discussedinthebookwehaveselectedaveryfewtechnologicallyimportantcasestudiesin Chapter12.Thefinalchapteroutlinesthewaysinwhichcomputersimulationandmodeling arebeingappliedtoannealingphenomena,andintheappendixweprovideanintroduction tothemeasurementandrepresentationoftexturesforthebenefitofreaderswhoarenot specialistsinthisarea.

JohnHumphreys ManchesterMaterialsScienceCentre UniversityofManchesterInstituteofScienceandTechnology UK

MaxHatherly SchoolofMaterials UniversityofNewSouthWales Australia August1994

Theneedtoreprintthebookhasprovidedanopportunityforustocorrectsomeofthe errorsandtocarryoutminormodificationstothetext.

May1996

PrefacetotheSecondEdition Thissecondeditionhasasimilarphilosophyandformattothefirst,although developmentsinthesubjecthavenecessitatedsomesignificantchanges. Recrystallizationremainsaveryactiveresearcharea,judgingbythenumberof publicationsandconferencesonthisandrelatedareas,andthecontinuingdevelopments inmanyareasmakeitadifficultsubjecttocapture.Asintheprefacetothefirst edition,weaskthereadertorememberthatthisbookpresentsapersonalviewofthe subject,ataparticularmomentintime.

Therehavebeentwoimportantchangesinmethodsofinvestigatingandanalyzing recrystallizationsincethefirstedition.Thefirstisintheexperimentaldeterminationof microstructureandtexture,wheretheincreaseinthepowerandapplicationofthe ElectronBackscatterDiffraction(EBSD)techniquehasprovideddataofatypewhich waspreviouslyunavailable,andmanyexamplesofitsuseareincludedinthebook. Theotherchangeisintheincreasedamountofmodelingandsimulationofannealing processeswhichisnowcarriedout.

Intermsofthesubjectareas coveredinthefirstedition ofthebook,therehasbeen significantnewactivityintwoareasoffundamentalimportancetotheunderstandingof recrystallization;thecharacterizationofthedeformedstate,andthemeasurementof grainboundaryproperties.Somenewareashavealsoopenedup.Inthefirsteditionwe brieflymentionednewresearchwhichindicatedthatdeformationtoverylargestrains mightleadtomicrostructuralstabilityonsubsequentannealing.Thishasnowbecomea majorresearchareawhichisnotonlyofscientificinterest,butisalsoapotential methodofproducingstrongalloys,andthis isgivendetailedcoverageinthisedition. Developmentsinthisandotherareashavehighlightedthedifficultiesofapplyingthe traditionalterminologiestonewphenomena,anditisnowconsiderednecessaryto subdividerecovery, recrystallizationandgraingrowthinto“discontinuous”and “continuous”variants.

Changesinthelayoutofthebookincludeaseparationofdeformationmicrostructure (Chapter2)anddeformationtexture(Chapter3),introductionofasimpleanalyticalmodel whichembracesrecovery,recrystallizationandgraingrowth(Chapter10),aconsideration

ofcontinuousrecrystallizationduringandafterlargestraindeformation(Chapter14),anda summaryofthemethodsofmeasuringrecrystallization(Appendix2).

Finally,accesstovideoclipsofsomeinsituannealingexperimentsandsimulationswhich maybeofinterest,isprovidedattheWebsite: http://www.recrystallization.info.

JohnHumphreys MaxHatherly April2003

PrefacetotheThirdEdition Thisthirdeditionhewscloselytoitspredecessorswithsignificantadditionsincertainareas wheresubstantialadvanceshaveaccumulated.Inallareas,thetexthasbeenreviewedand, whereappropriate,re-writtentoaccountforrecentadditionstotheliterature.Concerning theauthorship,MaxHatherlyisnolongerwithus,sadly;JohnHumphreyshasretiredandis nottobeblamedforanyerrorsormistakesthatwemayhaveintroducedinthisnew edition.Intermsofcontent,computermodelingofgrainboundarieshasresultedinnew insightsabouttheirproperties,especiallyenergyandmobility.Thecombinationof automatedserialsectioningandsynchrotron-basedcharacterizationhasprovided3-Dmaps ofmicrostructureandadditionalnewinsights.Thedescriptionsofworkhardeningand texturehavebeenstrengthened.

AnthonyRollett

GregoryRohrer

August2017

Acknowledgments Figureshavebeenreproducedwithpermissionfromthefollowingsources:

Thefollowingfiguresarecopiedfrom ActaMaterialia withthepermissionofElsevierScience, P.O.Box800,OxfordOX51DX:Fig.13.10fromNes,E.,Marthinsen,K.2002toDaalandand Nes1995.OriginofcubetextureduringhotrollingofcommercialAl Mn Mgalloys.Mater. Sci.Eng.A322,176(Fig.6).Fig.2.10fromLiu,Q.,JuulJensen,D.,Hansen,N.,1998.Effect ofgrainorientationondeformationstructureincoldrolledaluminium.ActaMater.46,5819 (Fig.2).Fig.16.7fromUpmanyu,M.,Srolovitz,D.J.,Shvindlerman,L.S.,Gottstein,G.,1999. Misorientation/dependenceofintrinsicboundarymobility.ActaMater.47,3901(Fig.2).

Fig.4.21fromGoukon,N.,Yamada,T.,Kajihara,M.,2000.Boundaryenergiesof S11 [110]asymmetrictiltboundaries.ActaMater.48,2837(Fig.2).Fig.5.2fromWinning,M., Gottstein,G.,Shvindlerman,L.S.,2001.Stressinducedgrainboundarymotion.ActaMater. 49,211(Figs.12and13).Fig.5.33fromProtasova,S.G.,Gottstein,G.,Sursaeva,V.G., Shvindlerman,L.S.,2001.Triplejunctionmotioninaluminumtricrystals.ActaMater.49, 2519(Fig.5).Fig.2.26fromDuckham,A.,Knutsen,R.D.,Engler,O.,2001.Influence ofdeformationvariablesontheformationofshearbandsinAl 1Mg.ActaMater.49, 2739(Fig.3).

Thefollowingfiguresarecopiedfrom ScriptaMaterialia withthepermissionofElsevier Science,P.O.Box800,OxfordOX5IDX:Fig.5.12fromMolodov,D.A.,Czubayko,U., Gottstein,G.,Shvindlerman,L.S.,1995.Mobilityof <111> tiltgrainboundariesinthe vicinityofthespecialmisorientation P¼7inbicrystalsofpurealuminium.Scr.Metall. Mater.32,529(Figs.4and5).Onthedescriptionofmisorientationsandinterpretationof recrystallisationtextures.Scr.Mater.35,579(Fig.4).Fig.12.7fromEngler,O.,2001b. AnEBSDlocaltexturestudyonthenucleationofrecrystallizationatshearbandsinthe alloyAl3%Mg.Scr.Mater.44,299(Fig.1).Fig.4.7fromYang,C.-C.,Rollett,A.D., Mullins,W.W.,2001.Measuringrelativegrainboundaryenergiesandmobilitiesinan aluminumfoilfromtriplejunctiongeometry.Scr.Mater.44,2735(Fig.4).

Thefollowingfiguresarecopiedfrom MaterialsScienceandEngineering,withthe permissionofElsevierScience,P.O.Box800,OxfordOX5IDX:Fig.2.5fromHughes, D.A.,2001.Microstructureevolution,slippatternsandflowstress.Mater.Sci.Eng.A319,

46(Fig.4).Fig.2.5bfromNes,E.,Marthinsen,K.,2002.Modelingtheevolutionin microstructureandpropertiesduringplasticdeformationoff.c.c.-metalsandalloys an approachtowardsaunifiedmodel.Mater.Sci.andEng.A322,176(Fig.6).Fig.6.27from Haslam,A.J.,Phillpot,S.R.,Wolf,D.,Moldovan,D.,Gleiter,H.,2001.Mechanismsof graingrowthinnanocrystallinefccmetalsbymolecular-dynamicssimulation.Mater.Sci. Eng.A318,293(Fig.4).Fig.15.3fromEngler,O.,Hirsch,J.,2002.Texturecontrolby thermomechanicalprocessingofAA6xxxAl Mg Sisheetalloysforautomotive applications areview.Mater.Sci.Eng.A336,249(Fig.10).

Thefollowingfigureiscopiedfrom Intermetallics,withthepermissionofElsevierScience, P.O.Box800,OxfordOX5IDX:Fig.8.7fromHuang,Y.D.,Froyen,L.,2002.Recovery, recrystallizationandgraingrowthinFe3Al-BasedAlloys.Intermetallics10,473(Fig.5).

Thefollowingfiguresarecopiedfrom MaterialsScienceandTechnology withthe permissionofManeyPublishing,1CarltonHouseTerrace,LondonSW1Y5DB:Fig.3.3 fromHirsch,J.,1990b.Correlationofdeformationtextureandmicrostructure.Mater.Sci. Technol.6,1048(Fig.3).Fig.15.15fromHayes,J.S.,Keyte,R.,Prangnell,P.B.,2000. Effectofgrainsizeontensilebehaviorofasubmicron-grainedAl 3wt%Mgalloy.Mater. Sci.Technol.16,1259(Fig.6).

Thefollowingfigureiscopiedfrom MaterialsScienceForum,withthepermissionofTrans TechPublicationsLtd.,Brandrain6,CH-8707,Ueticon-Zuerich,Switzerland:Fig.3.15 fromBenum,S.,Engler,O.,Nes,E.,1994.Mater.Sci.Forum157 162,913.

Inthefirsteditionofthisbookweacknowledgedagreatdebttothosewithwhomwehad discussedandarguedoverthesubjectscoveredbythisbookoveraperiodofverymany years.Duringthewritingofthebookwehadparticularlyusefuldiscussionsand correspondencewithBrianDuggan,BevisHutchinson,andErikNes.Alargenumberof othershelpedbyprovidingadvice,material,andinmanyotherways.Theyinclude SreeramamurthyAnkem,MahmoudArdakani,ChristineCarmichael,MichaelFerry,Brian Gleeson,GuntherGottstein,BrigitteHammer,AlanHumphreys,PeterKrauklis,Lasar Shvindlerman,TonyMalin,PaulMunroe,NigelOwen,PhilPrangnell,FredScott,Karen Vernon-Parry,andDavidWillis.

Asignificantamountofthenewresearchwhichhascontributedtothesecondeditionofthe bookhasbeencarriedoutinManchester,andthestrongsupportoftheEngineeringand PhysicalSciencesResearchCouncilandAlcanInternationalisgratefullyacknowledged. Thehelp,advice,andsupportofPeteBatehasbeenparticularlyvaluable,andthe ManchesterLightAlloyProcessingGroup,includingPhilipPrangnell,NormanRidley, HediehJazaeri,PeterHurley,YanHuang,AndrewClarke,MartinAshton,IanBrough,and MatthewJones,andtheirprovisionofdataandfigureshasmadeamajorcontributiontothis edition.Duringthepreparationofthesecondedition,criticalcommentsandsuggestions

fromMichaelFerryandRobertMoonoftheUniversityofNewSouthWaleshavebeen extremelyvaluable.

ThethirdeditionowesmuchtotheresearchconductedatCarnegieMellonUniversityon interfaces,largelyunderthesupportfromtheUSNationalScienceFoundationofthe MaterialsResearchScienceandEngineeringCenter.ADRandGSRaregratefultothe manyindividualswhohelpedwithdiscussion,data,figures,etc.

Symbols Thefollowingnotationisgenerallyusedinthetext.Thesubscripts i or n indicatetheuseof lettersornumbersforparticularsymbols.Onrareoccasionswherethelettersorsymbolsare usedforotherpurposes,thisisspecificallystated.

b Burgersvectorofadislocation

c,cn,C,Cn,Kn Thesedenote“local”constantswhicharedefinedinthetext

d Diameterofsecond-phaseparticle

D Grainorsubgraindiameter

Di Diffusivity(s ¼ bulkdiffusion,b ¼ boundarydiffusion,c ¼ core diffusion)

Ei Energy,e.g.,storedenergyofdeformationED

Fv Volumefractionofsecond-phaseparticles

G Shearmodulus

k Boltzmannconstant

M Boundarymobility

n Exponent,e.g.,intheJMAKequation

Nv Numberofgrainsorsecond-phaseparticlesperunitvolume

Ns Numberofparticlesperunitarea

PorPi Pressureonaboundary

QorQi Activationenergy,(fordiffusion:s ¼ bulk,b ¼ boundary,c ¼ core)

R Grainorsubgrainradius

s Shearstrain

t Time

T,Tm Temperature,meltingtemperature(K)

v Velocityofdislocationorboundary

V Volume

X Fractionrecrystallized

a, b Constants

g Energyofaninterfaceorboundary

gSFE, gRSFE Stackingfaultenergy,reducedstackingfaultenergy

gb Energyofahigh-angleboundary

gs Energyofalow-angleboundary

ε Truestrain

_

ε Truestrainrate

q Misorientationacrossaboundary;also,workhardeningrate

l Interparticlespacing(definedinEq.A2.13)

n Poissonratio

n0 Atomicvibrationalfrequency

r Dislocationdensity

Sn Coincidencesitelattice(CSL)grainboundaries.1/nisthefraction ofsitescommontobothgrains

s Truestress

s Shearstress

41, F, 42 Eulerangles,Bungeconvention(definedinAppendix1)

U Orientationgradient

Abbreviations ARB Accumulativerollbonding

CA Cellularautomata

CLS Cahn,Lu¨cke,Stu¨we(theoryofsolutedrag)

CPFEM Crystalplasticityfiniteelementmodeling

CSL Coincidencesitelattice

DDW Densedislocationwall

DRX Dynamicrecrystallization

EBSD Electronbackscatterdiffraction

ECAE Equalchannelangularextrusion

ECD Equivalentcirclediameter

FE Finiteelement(modeling)

FEGSEM Fieldemissiongunscanningelectronmicroscope

GBCD Grainboundarycharacterdistribution

GBE Grainboundaryengineering

GNB Geometricallynecessaryboundary

HAGB High-anglegrainboundary

HSLA High-strengthlow-alloy(steel)

HVEM High-voltagetransmissionelectronmicroscope

IDB Incidentaldislocationboundary

IF Interstitialfree(steel)

JMAK Johnson Mehl Avrami Kolmogorovkineticmodel

LAGB Low-anglegrainboundary

MD Moleculardynamics

MLI Meanlinearintercept

ND,RD,TD Normal,rollingandtransversedirectionsinarolledproduct

ODF Orientationdistributionfunction

PSN Particle-stimulatednucleationofrecrystallization

SEM Scanningelectronmicroscope

SFE Stackingfaultenergy

SIBM Strain-inducedboundarymigration

SMG Submicron-grained(alloy)

SPF Superplasticforming

TEM Transmissionelectronmicroscope

Introduction 1.1AnnealingofaDeformedMaterial 1.1.1OutlineandTerminology

Thefreeenergyofacrystallinematerialisraisedduringdeformationbythepresenceof dislocationsandinterfaces,andamaterialcontainingthesedefectsisthermodynamically unstable.Althoughthermodynamicswouldsuggestthatthedefectsshouldspontaneously disappear,inpracticethenecessaryatomisticmechanismsareoftenveryslowatlow homologoustemperatures,withtheresultthatunstabledefectstructuresareretainedafter deformation(Fig.1.1a).

Ifthematerialissubsequentlyheatedtoahightemperature(annealed),thermally activatedprocessessuchassolidstatediffusionprovidemechanismswherebythedefects mayberemovedoralternativelyarrangedinconfigurationsoflowerenergy.

Thedefectsmaybeintroducedinavarietyofways.However,inthisbookwewillmainly beconcernedwiththosedefects,andinparticulardislocations,whichareintroduced duringplasticdeformation.Thepointdefectsintroducedduringdeformationannealoutat lowtemperaturesandgenerallyhavelittleeffectonthemechanicalpropertiesofthe material.Inconsideringonlymaterialsthathaveundergonesubstantialplastic deformation,wenecessarilylimittherangeofmaterialswithwhichwewillbeconcerned. Metalsaretheonlymajorclassofcrystallinematerialtoundergosubstantialplastic deformationatlowhomologoustemperatures,andmuchofthisbookwillbeconcerned withtheannealingofdeformedmetals.However,athightemperatures,manymineralsand ceramicsreadilydeformplastically,andtheannealingoftheseisofgreatinterest.In addition,someannealingprocessessuchas graingrowth arerelevanttosintered,cast,or vapordepositedmaterialsaswellastodeformedmaterials.

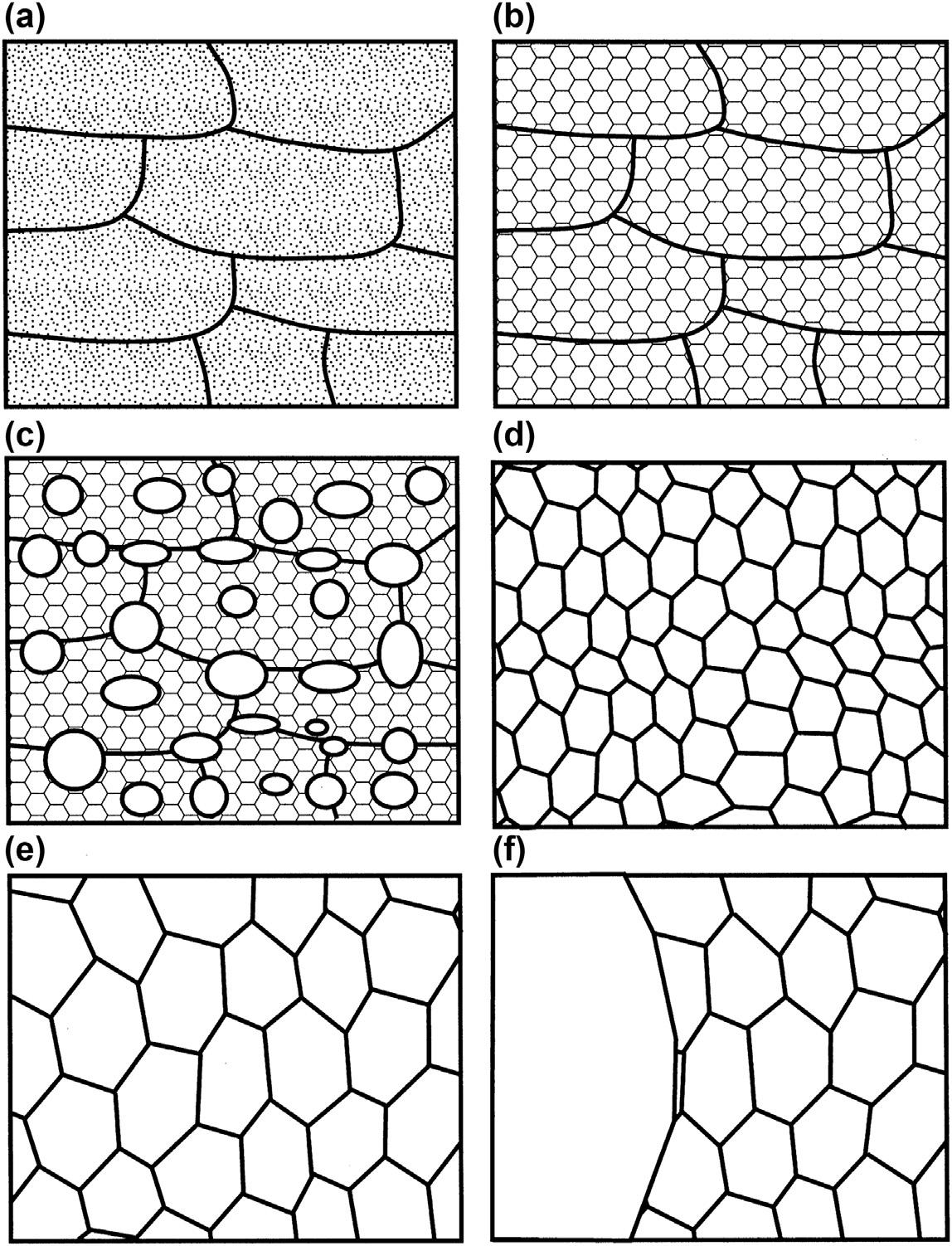

Onannealingacold-workedmetalatanelevatedtemperature,themicrostructureandthe propertiesmaybepartiallyrestoredtotheiroriginalvaluesby recovery inwhichannihilation andrearrangementofthedislocationsoccurs.Themicrostructuralchangesduringrecovery arerelativelyhomogeneousanddonotusuallyaffecttheboundariesbetweenthedeformed grains;thesechangesinmicrostructureareshownschematicallyin Fig.1.1b.Similar recoveryprocessesmayalsooccurduringdeformation,particularlyathightemperatures,and this dynamicrecovery playsanimportantroleinthe creep and hotworking ofmaterials.

RecrystallizationandRelatedAnnealingPhenomena. http://dx.doi.org/10.1016/B978-0-08-098235-9.00001-X Copyright © 2017ElsevierLtd.Allrightsreserved. 1

Figure1.1

Schematicdiagramofthemainannealingprocesses.(a)Deformedstate;(b)recovered; (c)partiallyrecrystallized;(d)fullyrecrystallized;(e)graingrowth;and(f)abnormalgrain growth.

Recoverygenerallyinvolvesonlyapartialrestorationofpropertiesbecausethedislocation structureisnotcompletelyremoved,butreachesametastablestate(Fig.1.1b).Afurther restorationprocesscalled recrystallization mayoccurinwhichnewdislocation-free grainsareformedwithinthedeformedorrecoveredstructure(Fig.1.1c).Thesethengrow andconsumetheoldgrains,resultinginanewgrainstructurewithalowdislocation density(Fig.1.1d).Recrystallizationmaytakeplaceduringdeformationatelevated temperaturesandthisisthentermed dynamicrecrystallization.

Althoughrecrystallizationremovesthedislocations,thematerialstillcontainsgrain boundaries,whicharethermodynamicallyunstable.Furtherannealingmayresultin grain

Table1.1: Examplesofstaticannealingphenomena.

RecoveryRecrystallizationGrainGrowth ContinuousSubgraingrowthContinuousrecrystallizationNormalgraingrowth DiscontinuousDiscontinuoussubgraingrowthPrimaryrecrystallizationAbnormalgraingrowth

growth,inwhichthesmallergrainsareeliminated,thelargergrainsgrow,andthegrain boundariesassumealowerenergyconfiguration(Fig.1.1e).Incertaincircumstancesthis normalgraingrowth maygivewaytotheselectivegrowthofafewlargegrains (Fig.1.1f),aprocessknownas abnormalgraingrowthorsecondaryrecrystallization.

Recentresearchhasshownthatborderlinesbetweenthevariousannealingphenomenaare oftenunclear,anditisknownthatrecovery,recrystallization,andgraingrowthmayoccur intwoways.Theyoccurheterogeneouslythroughoutthematerial,suchthattheymaybe formallydescribedintermsof nucleation and growth stages,andinthiscase,theyare describedas discontinuous processes.Alternatively,theymayoccuruniformly,suchthat themicrostructuresevolvegraduallywithnoidentifiablenucleationandgrowthstages.In thiscase,theprefix continuous isusedtocategorizethephenomena.Itshouldbe emphasizedthatthisisaphenomenologicalcategorizationthatdoesnotimplythe operationofanyparticularmicromechanism.The“continuous”phenomenainclude recoverybysubgraingrowth,continuousrecrystallizationandnormalgraingrowthand the“discontinuous”phenomenaincludediscontinuoussubgraingrowth,primary recrystallization,andabnormalgraingrowth.Therefore,asshownin Table1.1,thereare atleast six staticannealingphenomenathatneedtobeconsidered.Notethemodern approachtophasetransformationsdistinguishesbetweenfirst-orderwithlatentheat,i.e., discontinuitiesinthefirstderivativeoffreeenergy(withlatentheat)versussecond-order withdiscontinuitiesinthesecondderivative.Again,primaryrecrystallization,forexample, certainlyreleasesheat(asmeasuredbycalorimetry)likeafirst-ordertransitionbutthere clearlyisnosenseinwhichonecandefineathermodynamicequilibrium.Therefore,all annealingprocessesare,strictlyspeaking,second-ordertransitions.

Althoughtheseprocessesareanalyzedseparatelyinlaterchapters,therearecircumstances whentheycanbeconsideredwithinaunifiedframework,asdiscussedinChapter10.This hasthemeritofnotonlyemphasizingthecommonfeaturesofthevariousprocesses,but, inbreakingdowntheconventionaldistinctionsbetweenthevariousannealingphenomena, allowsalsofortheemergenceofnewphenomenawhichmaynotconvenientlyfitintothe traditionalcategories.

1.1.2ImportanceofAnnealing Manymetallicmaterialsareproducedinitiallyaslargecastings,whicharethenfurther processedinthesolidstatebyforging,rolling,extrusion,etc.,toanintermediateorfinal

product.Theseprocedures,whichmaybecarriedouthotorcold,andwhichmayinvolve intermediateanneals,arecollectivelytermed thermomechanicalprocessing.Recovery, recrystallizationandgraingrowtharecoreelementsofthisprocessing.

Toalargeextentthemechanicalpropertiesandbehaviorofametaldependonthe dislocationcontentandstructure,thesizeofthegrainsandtheorientationor texture of thegrains.Ofthese,thedislocationcontentandstructurearethemostimportant.The mechanicalpropertiesdependprimarilyonthenumberofdislocationsintroducedduring coldworkingandtheirdistribution.Asthisincreasesfrom w1011 m 2,typicalofthe annealedstate,to w1016 m 2,typicalofheavilydeformedmetals,theyieldstrengthis increasedbyupto5 6timesandtheductilitydecreased.Ifthestrainhardenedmaterial issubsequentlyheatedto wTm/3,dislocationlossandrearrangementoccurandthisis manifestedbyadecreaseinstrengthandincreasedductility.Thereisanenormous literatureonthemagnitudeofthesechanges,andanyadequatetreatmentisbeyondthe scopeofthisbook.Fordetailsofthesethereaderisreferredtotheappropriatevolumesof MetalsHandbook

Thegrainsizeandtextureafterannealingaredeterminedmainlybythe recrystallizationprocess,andtherearenumerousexamplesoftheneedtocontrolgrain size.Forexample,asmallgrainsizeincreasesthestrengthofasteelandmayalso makeittougher,whichisknownastheHall Petcheffect.However,alargegrainsize mayberequiredinordertoreducecreepratesforuseathightemperaturesbecause grainboundariesactassourcesandsinksofpointdefectsaswellasnucleationpoints fordamage.Singlecrystalturbinebladesinnickel-basedsuperalloysrepresentthe ultimateengineeringrealizationofthevalueineliminatinggrainboundariesforhigh temperatureservice.Superplasticforming,inwhichalloysaredeformedtolargestrains atlowstresses,isanimportanttechnologicalprocessfortheshapingofadvanced materials.Greatingenuity mustbeexercisedinproducingtherequiredfinegrainsize andpreventingitsgrowthduringhightemperaturedeformation.Thecontroloftexture isvitalforthesuccessfulcoldformingofmetalsandparticularlyimportantexamples arethedeepdrawingofaluminumorsteeltoproducebeveragecansandcarbody parts.Intherelativelynewfieldofgrainboundaryengineering,deformationand annealingisusedtochangethetypesofgrainboundariesinthematerialswithout changingthegrainsize.

1.2HistoricalPerspective

1.2.1EarlyDevelopmentoftheSubject

Althoughtheartofmetalworkingincludingtheproceduresofdeformationandheatinghas beenpracticedforthousandsofyears,itisonlycomparativelyrecentlythatsome

understandinghasbeengainedofthestructuralchangesthataccompanytheseprocesses. Theearlyhistoryoftheannealingofdeformedmetalswaschronicledveryelegantlyby Beck(1963),anditisclearthatthepaceofscientificunderstandingwaslargelydictated bythedevelopmentoftechniquesformaterialscharacterization.Itshouldbenotedthat thisconstraintstillapplies,butrecentadvancesinthescopeofcomputersimulationsand three-dimensionalmaterialscharacterizationhavecreatedmanynewopportunities.

1.2.1.1CrystallinityandCrystallization In1829,theFrenchphysicistFelixSavartfoundthatspecimensfromcastingotsof variousmetalsexhibitedacousticanisotropy,andconcludedthatcastingotsconsistedof crystalsofdifferentorientations.Healsofoundthat,althoughanisotropychangedasa resultofsubsequentplasticdeformationandannealing,heatingaloneproducednochange. Thisisthefirstrecordedevidenceforastructuralchangeoccurringduringtheannealing ofacold-workedmetal.

Inthemid-19thcentury,theconceptofthecrystallizationofmetalswasextensively discussed,anditwaswidelythoughtthatplasticdeformationrenderedmetalsamorphous. Thisbeliefarosefromtheinabilitytoobservegrainstructuresinthedeformedmetals usingvisualinspection.Onreheatingthedeformedmetal,however,thegrainstructure couldsometimesbeseen(Percy,1864;Kalischer,1881)andthiswastheninterpretedas crystallization ofthemetalfromitsamorphousstate.

TheintroductionofmetallographyusingreflectionopticalmicroscopybySorbytookthe subjectastepforwardandculminatedinhispaperof1887.Hisopticalmetallographyshowed elongatedgrainsindeformedironandthatonheating,anewequiaxedgrainstructurewas produced,aprocessthathetermed recrystallization.Furthermore,Sorbyrecognizedthatthe distortedgrainsmustbeunstable,andthatrecrystallizationallowedareturntoastable condition.DespiteSorby’swork,theideathatcold-workedmetalswereamorphouspersisted forsomeyearsandwasnotfinallyabandoneduntiltheBakerianlecturebyEwingand Rosenhainin1900inwhichitwasclearlyshownthatplasticdeformationtookplacebyslip ortwinning,andthatinbothoftheseprocessesthecrystalstructurewaspreserved.

1.2.1.2RecrystallizationandGrainGrowth Althoughrecrystallizationhadbeenidentifiedbythebeginningofthe20thcentury, recrystallizationandgraingrowthhadnotclearlybeendistinguishedasseparateprocesses. TheoutstandingworkbyCarpenterandElam(1920)andAltherthum(1922)established thatstoredenergyprovidedthedrivingforceforrecrystallization,andgrainboundary energythatforgraingrowth.Thisisshownbytheterminologyfortheseprocessesused byAltherthum,viz.Bearbeitungsrekristallisation(cold-workrecrystallization)and Oberflachenrekristallisation(surfacetensionrecrystallization).

In1898,Steadproposedthatgraingrowthoccurredbygrainrotationandcoalescence,and althoughEwingandRosenhainpresentedconvincingevidencethatthemechanismwas oneofboundarymigration,Stead’sideawasperiodicallyreviveduntiltheworkof CarpenterandElamfinallysettledthematterinfavorofboundarymigration.

1.2.1.3ParametersAffectingRecrystallization By1920,manyoftheparametersthataffecttherecrystallizationprocessandtheresultant microstructurehadbeenidentified.

Kinetics:Therelationshipoftherecrystallizationtemperaturetothemeltingtemperature wasnotedbyEwingandRosenhain(1900)andHumfrey(1902)showedthattherateof recrystallizationincreasedwithanincreaseinannealingtemperature.

Strain:Sauveur(1912)foundthattherewasacriticalstrainforrecrystallization,anda relationshipbetweengrainsizeandpriorstrainwasreportedbyCharpy(1910).Carpenter andElam(1920)laterquantifiedbothoftheseeffects.

Graingrowth:Inaveryearlypaperonthecontrolofmicrostructureduringannealing, Jeffries(1916)showedthat abnormalgraingrowth inthoriatedtungstenwaspromoted inspecimensinwhichnormalgraingrowthhadbeeninhibited.

Furtherdevelopmentsintheunderstandingofrecrystallizationwerenotpossiblewithouta moredetailedknowledgeofthedeformedstate.Thiswasprovidedbythedevelopmentof thedislocationtheoryin1934,andanotableearlyreviewofthesubjectfollowingthe adventofthedislocationtheoryisthatofBurgers(1941).

Fromaboutthisperioditbecomesdifficulttodistinguishthepapersofhistoricalinterest fromtheearlykeypapersthatarestillrelevanttocurrentthinking.Thelatterarecitedas appropriatewithinthevariouschaptersofthisbook.However,itmaybehelpfultothe readertohaveasourcelistofbooks,reviews,andconferencesonthesubjectfromthe past50years,whichisgivenbelow.

1.2.2SelectedKeyLiterature(1952 2003)

MonographsonRecrystallization

Byrne,J.G.(1965), Recovery,RecrystallizationandGrainGrowth.McMillan, NewYork.

Cotterill,P.andMold,P.R.(1976), RecrystallizationandGrainGrowthinMetals. SurreyUniv.Press,London. Novikov,V.(1997), GrainGrowthandControlofMicrostructureandTexturein PolycrystallineMaterials.CRCPress,BocaRaton.

Multiauthor, EditedCompilationsonRecrystallization

Himmel,L.(ed.),(1963), RecoveryandRecrystallizationofMetals.Interscience, NewYork.

Margolin,H.(ed.),(1966), Recrystallization,GraingrowthandTextures.ASM, Ohio,USA.

Haessner,F.(ed.),(1978), RecrystallizationofMetallicMaterials.Dr.RiedererVerlag,G.m.b.HStuttgart.

ReviewArticlesandBooksContainingChaptersonRecrystallization

Burke,J.E.andTurnbull,D.(1952), RecrystallizationandGrainGrowth.Progressin MetalPhys., 3,220.

Beck,P.A.(1954), AnnealingofCold-workedMetals.Adv.Phys., 3,245.

Leslie,W.C.,Michalak,J.T.andAul,F.W.(1963), Theannealingofcold-workediron In: IronanditsDiluteSolidSolutions.(eds.)SpencerandWerner.Interscience. NewYork.119.

Christian,J.W.(2002), TheTheoryofTransformationsinMetalsandAlloys.Second edition,Pergamon,Oxford.

Jonas,J.J.,Sellars,C.M.andTegart,W.J.McG.(1969), StrengthandStructureUnder HotWorkingconditions.Met.Revs., 130,1.

Martin,J.W.andDoherty,R.D.(1976), TheStabilityofMicrostructureinMetals. CambridgeUniversityPress. Cahn,R.W.(1996),in PhysicalMetallurgy.(eds.)CahnandHaasen.Fourthedition. North Holland,Amsterdam. Hutchinson,W.B.(1984), DevelopmentandControlofAnnealingTexturesinLowCarbonSteels.Int.Met.Rev., 29,25. Honeycombe,R.W.K.(1985), ThePlasticDeformationofMetals.EdwardArnold. Humphreys,F.J.(1991), RecrystallizationandRecovery.In: ProcessingofMetals andAlloys.(ed.)R.W.Cahn.VCH.Germany.371. Doherty,R.D.,Hughes,D.A.,Humphreys,F.J.,Jonas,J.J.,JuulJensen,D.,Kassner, M.E.,King,W.E.,McNelly,T.R.,McQueen,H.J.andRollett,A.D.(1997), Current issuesinrecrystallization:areview.Mats.Sci.&Eng., A238,219. Verlinden,B.,Driver,J.,Samajdar,I.,andDoherty,R.D.(2007), Thermomechanical ProcessingofMetallicMaterials,Elsevier.

ProceedingsofInternationalConferences

InternationalRecrystallizationConferenceSeries(1990 1999)

Chandra,T.(ed.),(1991), Recrystallization’90.TMS,Warrendale,USA. Fuentes,M.andGilSevillano,J.(eds.),(1992), Recrystallization’92.Trans.Tech. Pubs.Switzerland.

McNelley,T.R.(ed.),(1997), RecrystallizationandRelatedAnnealingPhenomena Rex’96

Sakai,T.andSuzuki,H.G.(1999), RecrystallizationandRelatedPhenomena Rex’99.JapanInst.Metal.

InternationalGrainGrowthConferences(1991 1998)

Abbruzzese,G.andBrozzo,P.(eds.),(1991). GrainGrowthinPolycrystallineMaterials.Trans.Tech.Publications,Switzerland.

GrainGrowthinPolycrystalsII,KitabyushuJapan(1995).

Weiland,H.,Adams,B.L.andRollett,AD.(eds.),(1998), GrainGrowthinPolycrystalsIII. TMS.

InternationalConferencesonRecrystallizationandGrainGrowth

Acombinationoftheformer Recrystallization and GrainGrowth seriesofInternationalconferences,whichareheldeverythreeyears,startingin2001.Themostrecent conferencewasheldinPittsburgh,USAin2016.

InternationalTextureConference(ICOTOM)Series

Conferencesareheldeverythreeyears.The17thConferencewasheldinDresden, Germanyin2014.

InternationalRisøSymposia

HeldannuallyinRisø,Denmark,theproceedingsin1980,1983,1986,1991,1995, 2000,and2015areofparticularrelevance.

InternationalThermomechanicalProcessingConferences(Thermec)

Generalcoverageofallaspectsofthermomechanicalprocessing.ThelastThermecconferencewasheldinGraz,Austriain2016.

DeformationMechanisms,Rheology,andTectonics:Microstructures,Mechanics,and Anisotropy

ThisisaregularseriesofconferencessponsoredbytheGeologicalSociety(London) whichoftendealswithgraingrowthandrecrystallizationingeologicalmaterials.Each proceedingappearsasa“specialpublication”withadifferenteditor(s).

OtherInternationalConferences

RecrystallizationintheControlofMicrostructure.InstituteofMetals,London. KeynotepaperspublishedinMetalScienceJ., 8.(1974).

RecrystallizationintheDevelopmentofMicrostructure.Leeds.InstituteofMetals, London.PublishedinMetalScience, 13.(1979).

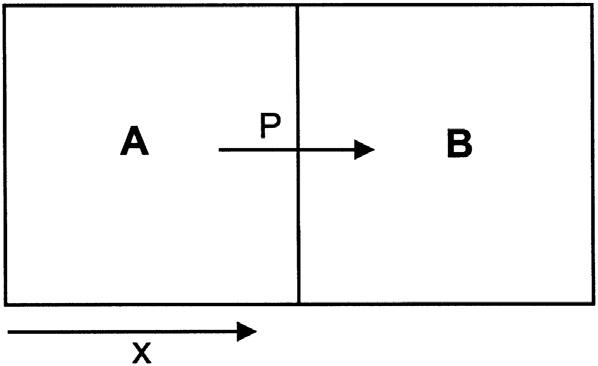

Figure1.2 Thepressureonaboundary.

MicrostructureandMechanicalProcessing.Cambridge.InstituteofMaterials, London.KeynotepaperspublishedinMaterialsScienceandTech., 6.(1990).

FundamentalofRecrystallization.Zeltingen,Germany.Anumberofshortpapers fromthismeetingarepublishedinScriptaMetall.Mater., 27,(1992).

ThermomechanicalProcessing TMP2,Stockholm,ASM,(1996).

DeformationProcessingofMetals,London.PublishedinPhil.Trans.RoyalSoc., 1441 1729,(1999).

ThermomechanicalProcessing:Mechanics,MicrostructureandControl,University ofSheffield,Palmiere,MahfoufandPinna(eds.)BBRSolutions,(2003).

1.3Forces,Pressures,andUnits Theannealingprocessesdiscussedinthisbookmainlyinvolvethemigrationofinternal boundarieswithinthematerial.Theseboundariesmoveinresponsetothermodynamic drivingforces,andspecificquantitativerelationshipswillbediscussedintheappropriate chapter.Itis,however,usefulatthisstagetosetoutsomeoftheterminologyusedand alsotocomparetheenergychangeswhichoccurduringthevariousannealingprocesses withthosewhichdrivephasetransformations.

1.3.1PressureonaBoundary Theprocessesofrecovery,recrystallization,andgraingrowtharealldrivenbythedefect contentofthematerial.Considerasmallpartofthemicrostructureofasingle-phase crystallinematerialasshownin Fig.1.2,whichconsistsoftworegions A and B separated byaboundaryatposition x.Letusassumethatthetworegionscontaindifferentdefect concentrationsandthatthefreeenergiesoftheseregionsperunitvolumeareGA andGB respectively.

TheboundarywillmoveiftheGibbsfreeenergyofthesystemistherebylowered,andif anarea a oftheboundarymovesadistance dx,thenthechangeinfreeenergyofthe systemis

The force, F,ontheboundaryisgivenby dG/dx,andthe pressure, P,ontheboundary,is givenby F/a,andthus

If DGin Eq.(1.2) isgiveninunitsofJ/m3,thenthepressureontheboundary(P)isin N/m2.Thereissomeconfusionintheliteratureregardingterminology,andtheterms force onaboundary and pressureonaboundary arebothusedfortheparameterthatis definedaboveby P.Since P hasunitsofN/m2,whicharethoseofpressure,thereissome logicinusingtheterm pressure,andthereforeweadoptthisterminology.

1.3.2UnitsandtheMagnitudeoftheDrivingPressure Althoughwewillbediscussingtheforcesandpressuresactingonboundariesinsome detailinlaterchapters,itisusefulatthisstagetoexamine,withexamples,someofthe forcesinvolvedinannealing.Thiswillservetodemonstratethe units usedinthebookand alsotogivesomeideaoftherelativemagnitudesoftheforcesinvolvedinannealing.A gooddiscussionofforcesarisingfromavarietyofsourcesisgivenbyStu ¨ we(1978).

1.3.2.1Recrystallization:DrivingPressureDuetoStoredDislocations

Thedrivingforceforrecrystallizationarisesfromtheeliminationofthedislocations introducedduringdeformation.Thiscanbeestimatedbyformingtheproductofthe energyperunitlengthofadislocation(i.e.,thelinetension)andthedislocationdensityas linelengthperunitvolume.Accordingly,thestoredenergyduetoadislocationdensity r is w0.5 rGb2,where G istheshearmodulusand b theBurgersvectorofthe dislocations.Adislocationdensityof1015 1016 m 2,whichistypicalofthecold-worked stateincopper(G ¼ 4.2 1010 N/m2, b ¼ 0.26nm)thereforerepresentsastoredenergy of w2 106 2 107 J/m3 (w10 100J/mol)andgivesrisetoadrivingpressurefor primaryrecrystallizationof w2 20MPa.

1.3.2.2RecoveryandGrainGrowth:DrivingPressureDuetoBoundaryEnergy

Recoverybysubgraincoarseningandgraingrowthfollowingrecrystallizationareboth drivenbytheeliminationofboundaryarea.Iftheboundaryenergyis g perunitarea and theboundariesformathree-dimensionalnetworkofspacingD,thenthedrivingpressure forgrowthisgivenapproximatelyas3g/D.Iftheenergyofalowanglegrainboundary (gs)is0.2J/m2,andthatforahighangleboundary(gb)is0.5J/m2,wefindthat

P w0.6MPa forthegrowthof1 mmsubgrainsduringrecovery,andthat P w10 2 MPa forthegrowthof100 mmgrains.

Notethatthisbriefdiscussiontreatsthedrivingforceforgraingrowthwithoutregardtoa localmechanism.Amoredetailedexaminationshowsthatthelocalmotionofagrain boundaryisdrivenbycurvature.Thatistosay,aboundarywillmovetowarditscenterof curvatureinordertodecreasetheexcessenergyassociatedwiththeboundary.Wewill showlateronthatgrainboundaryenergydependsonthenormalasmuchasitdoesonthe latticemisorientationacrosstheboundary.Thismeansthattheso-calledtorqueterm(the differentialoftheboundaryenergywithchangeinorientation)cancontributesignificantly tothedrivingforce,asoriginallydevelopedbyHerring.Anelegantwaytoexpressthe combinedeffectsofsurfacetensionandtorquetermswasdevelopedbyHoffmanand Cahn(1972)andCahnandHoffman(1974)asthecapillarityvector, x.Theseaspectsof graingrowtharediscussedinmoredetailintherelevantchapters.

1.3.2.3ComparisonWiththeDrivingForcesforPhaseTransformations Itisofinteresttocomparetheenergychangesthatoccurduringannealing,asdiscussed above,withthosethatapplytophasetransformations.Forexample,atypicalvalueofthe latentheatoffusionforametalis w10kJ/mol andthatforasolidstatetransformationis w1kJ/mol.Wethereforeseethattheenergiesinvolvedinannealingofacold-worked metalareverymuchsmallerthanthoseforphasetransformations.

TheDeformedState 2.1Introduction Theemphasisinthisandthefollowingchapterisquitedifferenttothatoftheremaining chaptersofthebook.Themostsignificantofthemanychangesassociatedwith recrystallizationandotherannealingphenomenaisthedecreaseinthedensityof dislocations.Inthischapter,weareconcernedwithdislocation accumulation ratherthan dislocation loss andwiththeincreasesinstoredenergythatarearesultofdeformation. Thedeformedstatelargelydefinesthesubsequentmicrostructuralevolutionintermsof grainsize,shape,andorientation,particularlywithrespecttorecrystallization.The dislocationstructure,especiallyitsheterogeneouscharacteristics,thusdeterminesthe drivingforceaswellasthepatternofnucleationfortheannealingphenomenadealtwith intheremainingchapters.Morethanthis,onecouldsaythatthemicrostructureremaining attheendofdeformationdetermineswhatwillhappenintheremainingannealing.Onlyif thepossibilityexistsfor,say,concurrentprecipitationdoesthetemperatureand/orheating rateinfluencetheoutcometoanysignificantdegree.

Acomparisonofthepresentchapterwiththosedealingwithannealingwillreveal discrepanciesbetweenourcurrentknowledgeofthedeformedstateandourrequirements fortheunderstandingofannealing.Forexample,wecurrentlyhaveanincomplete understandingoftheratesofdislocationaccumulationduringdeformationandofthe large-scaledeformationheterogeneitiesthatareimportantinnucleatingrecrystallization, andthisimpedestheformulationofquantitativemodelsofrecrystallization.Pokharel etal.(2014)havereviewedtheavailableliteraturethatcomparesexperimental characterizationofthedeformedstatewithcrystalplasticity-basedsimulationsandfound thatgoodagreementisonlyobtainedatthestatisticallevel.Atthelocalgrainscale, however,thecomparisonsdonotvalidatethesimulationsandsignificantdifferences persist.Ontheotherhand,wenowhaveagreatdealofinformationabouttheformationof boundariesduringdeformation,buthavenotyetformulatedannealingtheoriesthat adequatelytaketheseintoaccount.Suchdiscrepanciesprovideusefulpointerstoareasthat requirefurtherresearch.

Duringdeformationthemicrostructureofametalchangesinseveralways.First,andmost obvious,thegrainschangetheirshape,whichleadstoasurprisinglylargeincreaseinthe totalgrainboundaryarea.Thenewgrainboundaryareahastobecreatedduring

RecrystallizationandRelatedAnnealingPhenomena. http://dx.doi.org/10.1016/B978-0-08-098235-9.00002-1 Copyright © 2017ElsevierLtd.Allrightsreserved.