Grow hin Film

Paul-

-Henri

Haume

esser

To my father

First published 2016 in Great Britain and the United States by ISTE Press Ltd and Elsevier Ltd

Apart from any fair dealing for the purposes of research or private study, or criticism or review, as permitted under the Copyright, Designs and Patents Act 1988, this publication may only be reproduced, stored or transmitted, in any form or by any means, with the prior permission in writing of the publishers, or in the case of reprographic reproduction in accordance with the terms and licenses issued by the CLA. Enquiries concerning reproduction outside these terms should be sent to the publishers at the undermentioned address:

ISTE Press Ltd

27-37 St George’s Road

Elsevier Ltd

The Boulevard, Langford Lane London SW19 4EU Kidlington, Oxford, OX5 1GB UK UK

www.iste.co.uk

www.elsevier.com

Notices

Knowledge and best practice in this field are constantly changing. As new research and experience broaden our understanding, changes in research methods, professional practices, or medical treatment may become necessary.

Practitioners and researchers must always rely on their own experience and knowledge in evaluating and using any information, methods, compounds, or experiments described herein. In using such information or methods they should be mindful of their own safety and the safety of others, including parties for whom they have a professional responsibility.

To the fullest extent of the law, neither the Publisher nor the authors, contributors, or editors, assume any liability for any injury and/or damage to persons or property as a matter of products liability, negligence or otherwise, or from any use or operation of any methods, products, instructions, or ideas contained in the material herein.

For information on all our publications visit our website at http://store.elsevier.com/

© ISTE Press Ltd 2016

The rights of Paul-Henri Haumesser to be identified as the author of this work have been asserted by him in accordance with the Copyright, Designs and Patents Act 1988.

British Library Cataloguing-in-Publication Data

A CIP record for this book is available from the British Library Library of Congress Cataloging in Publication Data

A catalog record for this book is available from the Library of Congress ISBN 978-1-78548-092-8

Printed and bound in the UK and US

Acknowledgments

AsascientistinCEA-Leti,Ihavebeenfortunateenoughtobeconfronted withavarietyofstimulatingindustrialchallengesandacademicquestionsin thesamefieldofexpertise:theprecipitationofmetalsfromsolutions,either byelectrochemicalorchemicalprocesses.Ihavetriedtoputinthisbookthe essenceofwhatIhavelearntinthisfield.

Ihavelearntalotfrommycolleagues.Someofthemcontributedinthis work:MarylineCordeau,CélineJayet,MurielChaupin,SégolèneOlivier, AnneRoule,ThierryMourier,SylvainMaîtrejean,OlivierPolletandXavier Avalehaveallbeofgreathelpinthedevelopmentoftheelectroplatingand electrolessprocesses.IwillnotforgetCatherineSantini,mycolleagueinCPE Lyon,whohasintroducedmetothefascinatingworldofionicliquidsand whocontinuesbringingnewideasintheresearchonnanoparticle(NP) synthesis.IamalsogratefultoVincentJousseaume,FrédéricGaillard,Eric ChaînetandDanielLincotforsharingwithmetheirdeepscientific knowledge.

Ihavelearntalotfrommystudents.Ithankthemall:SandrineDaSilva, TifennDecorps,KarimSidiAliCherif,MarianaAmuntencei,Julien Cuzzocrea,PhilippeArquillière,IngaHelgadottirandWalidDarwich. Withoutthem,lifewouldhavebeenmuchlessenjoyableandthisbookwould nothavebeenpossible.

Finally,Iwouldliketothankmyfamily:mychildren,Oscar,Léonardand Mélisande,andmywife,Sandrine.Ithankthemfortheirpatienceandsupport asdeeplyasIlovethem.

Introduction

Masteringtheartofmetalworkwasadecisivemomentformankind severalthousandyearsago.Sincethemiddleofthelastcentury,another decisivetechnologicalbreakthroughchangedourworld.Microcomputing enteredourhomesmorethan30yearsago.Wehavebeencarrying microcomputersinourpocketssincetheearly2000s.Theyarenowinvading oureverydaylifeinavarietyof“connected”items.Thisspectacularevolution mirrorsthetremendousprogressintheminiaturizationofintegratedcircuits (ICs).Thesedevicespackaneverincreasingnumberofcomponentsinan eversmallervolume.Asaresult,thecircuitryneededtointerconnectthese componentsbecomesfinerandmorecomplexastechnologyprogresses.The metallicconductorshavenowsub-micronicsizes.Atthesametime,new objectsandapplicationsareemerginginwhichmetalisusedasnanoparticles (NPs).Asaresult, wemustnowmastertheartofmetalworkatthemicroscale andevenatthenanoscale.

Sinceancienttimes,metalhasbeenshapedintothedesiredobjectusinga top-down approach.Arawpieceofmetaliscut,hammeredormoldedintothe finalobject.TofabricatetheverysmallmetallicstructuresinICs,itis preferabletousea bottom-up approachinwhichmetalis grown toitsfinal shape.Thisisusuallydoneby precipitating themetalfromasolution containingsuitablechemicalprecursors.Forthisreason,theartof metalsworkatsmallscaleswouldbemoreofanalchemist’sroleratherthana blacksmith’s.

Thepurposeofthisbookistoexplainthewaysinwhichthisprecipitation reactioncanbecontrolledtoproducethedesiredobject.

Thenature,thesizeandtheshapeofthelatterisdictatedbyitsexactuse. ConductionlinesinICsarequitelong(uptoseveralcentimeters)butvery narrow(downtoseveraltensofnanometers).MetallicNPsaremetallic clustersbelow 10nm indiameter.InChapter1,bothtypesofmetallicobjects arepresented.TheprogressofICtechnologyisbrieflydescribed.Tosustain thepaceofcircuitminiaturization,Cuhasbeenintroducedasaconduction metalinICs.Thevariousprocessesinvolvedinthefabricationofadvanced Cuinterconnectstructuresandtheassociatedchallengesarereviewedfor conventionalintegrationaswellasmorerecentthree-dimensionalstacking strategies.InthelastsectionofChapter1,theneedformetallicNPsis formalized,andthedifficultiesassociatedwiththeelaborationand stabilizationofthesenano-objectsarediscussed.

Theprecipitationofmetalisthecoreprocessinthebottom-upfabrication ofsmallmetallicobjects.Itisaspecialcaseofphasetransformation.Because suchphasetransformationsareofparamountpracticalandtechnological importance,theyhavebeenextensivelystudied.InChapter2,thegeneral conceptsassociatedwithphasetransformationareintroduced.Averysimple thermodynamicanalysisoftheproblemshowsthatitgenerallystartswiththe nucleationofextremelysmalldomainsofthenewphaseintheoldphase. Hence,controllingthisnucleationisthemostefficientstrategytooptimize bottom-upprocesses,especiallywhenextremelysmallsizesaretargeted.For thisreason,theso-called classicalnucleationtheory isdiscussedindetailin thischapter.Controllingthegrowth,aggregationandcoalescenceofthese nucleiisalsomandatory,asisillustratedbypracticalexamplesinthe subsequentchapters.Therefore,abrieftheoreticaldescriptionofthesesteps ofphasetransformationisalsoproposedinChapter2.

InChapter3,thesegeneralconceptsaredevelopedfurtherinthemore specificcaseofchemicalandelectrochemicalprecipitationsofmetals.In particular,theelectrochemicalmechanismsassociatedwithCuelectroplating arediscussed.Similarly,importantaspectsoftheelaborationandstabilization ofmetallicNPsinsolutionarebrieflyexposed.Hence,bothChapters2and3 shouldbeaniceintroductionforthestudentorthescientisttoquestionsof nucleation,growth,aggregationandcoalescence,especiallywhenchemical precipitationreactionsareinvolved.

Chapters4–6arededicatedtothedescriptionanddiscussionofvery specificprocessesforthefabricationofsmallmetallicobjects.InChapter4, thecontrolledgrowthofCuinelectroplatingprocessesisshowntoallowfor theso-calledsuperconformalfillofholesandtrenches.Thisparticularregime isusedtofabricatethemostaggressiveinterconnectstructures.InChapter5,

twoexamplesofthinfilmdepositionby(electro)chemicalreactionsare described.ThesearethinCuseedlayersandmetallicbarriersalsoneededin thefabricationoftheinterconnectstructures.Finally,averyoriginaland promisingapproachtofabricatemetallicNPsisdevelopedinChapter6.This verysimpleprocessusesanewclassofsolvents,theionicliquids(ILs).

Theseexampleshavebeenselectedbasedontheirrelevanceregardingthe technologicalchallengesmentionedinChapter1.Theyareallaimedat overcomingcurrentlimitationsofexistingprocesses.Assuch,theyprovide up-to-dateinformationforthetechnologistinterestedinthesequestions. Throughoutthesechapters,itisalsoshownhowtheconceptsintroducedin Chapters2and3canbe(atleastqualitatively)usedtoguidetheoptimization ofthesenewprocesses.Assuch,theyshouldbeexemplarytoresearchers involvedinsimilardevelopments.

TheFabricationofMicroandNanostructures

AsFeynmanfirststatedinhisvisionarylecturein1959[FEY92],thereis plentyofroomatthebottom.Indeed,thesourceofmostofourcurrent technologicalprogressesisourabilitytomanipulateandshapematterata verysmallsize,downtothenanometerscale.Inthischapter,itisnotour purposetoextensivelycovertheprogressesinmicrofabricationorthe emergenceofnanoscience.Rather,weshallillustratecurrentchallengesin bothfieldsthroughselectedexamples:thefabricationofadvanced interconnectstructuresinmicroelectronicdevicesandtheelaborationof metallicnanoparticles(NPs).

1.1.Thefabricationofadvancedinterconnectstructuresin microelectronicdevices

Oneofthemostprominentdiscoveriesduringthe20thCenturywasthe transistorinventedbyBardeenandBrattainattheBellLaboratoriesin1947 [BAR48].Lesspraised,butnotlessimportant,isthefirstdemonstrationin themid-1950sofanintegratedcircuitonasiliconsubstrate[KIL64].Indeed, thiswasthestartingpointofastillon-goingtechnologicalracetowardmore integrated,thusmorecomplex,circuits.Astheygetsmallerand“smarter”, thesedevicesarenolongerrestrictedtodeskcomputers,buthavebeen introducedinavarietyofmobileapplications(laptops,phones,tablets,GPS systems,etc.),cars,televisions,etc.Withtheadventofthe“Internetof Things”,theyaremeanttobringbrains(oratleastcommunicationskills)toa muchvasternumberofobjectsinoureverydaylife.

1.1.1. Ultralarge-scaleintegration

Sincethemid-1950s,thisevolutionhasdemandedtointegratemoreand moretransistorsperchip[MOO65].Todoso,thesizeofthetransistorshas progressivelybeenreduced,aswellasthesizeofallothersurrounding structuressuchasinterconnects.Bythemid-1960s,theindustrymovedfrom small-tomedium-scaleintegration(lessthan1,000transistorsperchip),then tolarge-scaleintegration(103 to 105 transistors)intheearly1970s.Since 1983,theso-calledverylargescaleintegrationschemehasbeenadopted,in whichthenumberoftransistorsexceeds 105 .Morerecently,theterm ultralarge-scaleintegrationhasappearedforcircuitscontainingmorethan 106 transistors.

Asaresult,thedensityoftransistorshasincreasedexponentiallyoverthe years,aspredictedsincetheearly1960sbyMoore[MOO65].Accordingto Moore’slaw,thedensityoftransistorsdoublesevery18months(Figure1.1 (left)).

Figure1.1. Evolutionof(left)thenumberoftransistorsperchipand (right)CPUclockfrequencyovertheyears

Untiltheendofthe1990s,thistrendwasonlysustainedbythe miniaturizationofthetransistorsandinterconnects,withoutanysignificant modificationoftheirstructure.Inthisperiod,theprogresswasmeasuredby therampupofthedevice’sclockfrequency,whichincreasedfrom 0.5MHz to 3GHz (Figure1.1(right)).Indeed,asthesizeofthetransistorswas reduced,sowastheircharacteristicresponsetime.However,inthemeantime, theresponsetimeoftheinterconnectstructureswasincreasingdueto capacitivecoupling.Soonenough,thedelaytimeassociatedwiththe interconnectsbecamelimiting.Currently,thedelaytimeassociatedwith interconnectstructuresexceedstheresponsetimeoftransistorsby 3 ordersof magnitude(Figure1.2).

Figure1.2. Evolutionofdelaysassociatedwithtransistorsand interconnectsastechnologyprogresses.Adaptedfrom[YEA13]

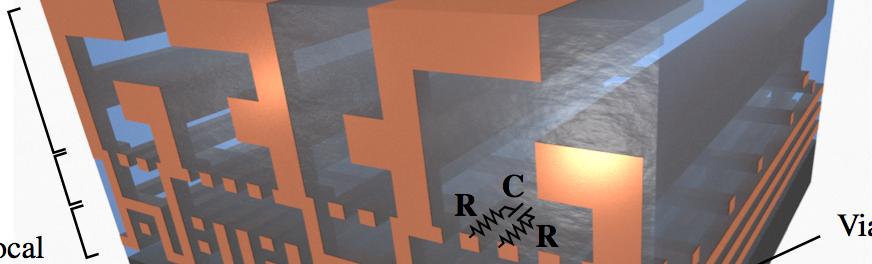

AsshowninFigure1.3,typicalinterconnectstructuresareformedbymetal linesisolatedbyadielectricmaterial[LE13].Severallevelsoftheselinesare neededtoformalltherequiredinterconnectionsinacircuit.Eachofthese “metallevels”isconnectedtothelevelsaboveandbelowbycontactholes called vias.

Electrically,thelinesareresistors(R).Adjacent,parallelmetalliclinesalso formcapacitors(C ,seeFigure1.3).Initsmostsimplisticdescription,sucha circuithasacut-offfrequencygivenby:

Inotherwords,thiscircuitisexpectednottobeabletopropagatesignals whosefrequencyexceeds fRC .Toincreasethiscut-offfrequency,itisthus necessarytoeitherreduce R or C.Inthelate1990s,chipmanufacturersdid both.

1.1.2. Thedamascenearchitecture

Untilthen,themetalanddielectricmaterialusedtofabricateinterconnect structureswereAlandSiO2 ,respectively.Toreduce R and C ,thesematerials

wereabandonedandreplacedbyCuandso-called low-K dielectricmaterials. ThelatterareSiO2 derivatives,incorporatingapolarchemicalspeciessuchas methylgroupstodecreasetheirrelativepermittivity[LE13].Morerecently, porousvariantshavebeenintroduced:theincorporationofnanosizedporesin thematerialallowedfurtherreductionofthe K valuedownto2.2[GRI01].

Figure1.3. Typicallocalarrangementofamicrochip,includinglocal, intermediateandglobalinterconnectsarrangedinseveral“metallevels” connectedtoeachotherbyvias

1.1.2.1.

Cuasaconductingmetal

CuwasselectedasareplacementmetalforAlbecauseofitslower resistivity(ρCu =1.67 μΩ·cm),butalsobecauseofitsbetterresistanceto electromigration(EM)ascomparedtothemoreconductiveAgandAu(see section5.2.1formoredetailsaboutEM).

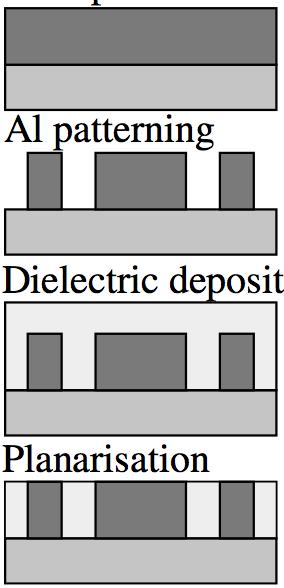

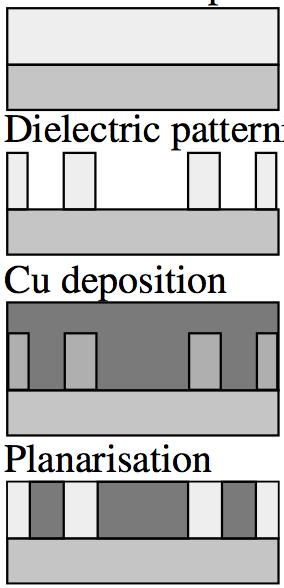

However,theintroductionofCuhasnotbeenstraightforward.Indeed,this metalwasnotcompatiblewiththeprocessflowusedtofabricateametallevel withAl.ThelatterisshowninFigure1.4(left).Inafirststep,Alisdeposited onthesubstrate(whichalreadyhasametallevelorcontactplugstothe transistorsifthisisthefirstmetallevel).Theconnectionstructures(linesor vias)arethenpatternedintothemetal.Inthisstep,theexcessmetalisetched toleaveonlythefinalstructures.Then,thedielectricmaterialisdeposited.A chemicalmechanicalpolishing(CMP)processisfinallyappliedtoremovethe excessinsulatingmaterialandtoplanarizethemetallevel.

TheFabricationofMicro-andNanostructures5

Itturnsoutthatthereisnoindustrialprocesscapableofproperlyetching Cu.Forthisreason,analternativeprocessflowwasdevised(Figure1.4 (right))[AND98].Inthissequence,alayerofdielectricmaterialisdeposited first,inwhichtheinterconnectstructuresareetched.Then,themetalfillsthe trenches(lines)orholes(vias)andtheexcessmetalisfinallypolishedaway. Thisarchitecturehasbeencalled damascene,afteranancienttechniqueused injewelleryinwhichgoldisinterlacedintoironorsteel[HES07].

Aldeposition

Dielectricdeposition

Dielectricdeposition

Dielectricpatterning

Figure1.4. Comparisonbetween(left)theconventionalintegrationof Aland(right)thedamascenearchitecture

Thesuccessofthisapproach,whichwascrucialtofurtherimprovethe performancesofmicroelectronicdevices,dependedononecondition:a processwasrequiredwhichwascapableoffillingthetrenchesandholes withoutleavinganyvoid.ThisprocesswasintroducedbyresearchersatIBM inthelate1990s[AND98]:itisCuelectroplating.

1.1.2.2. Cuelectroplating,seedlayerandbarrierdeposition

Conceptually,Cuelectroplatingisrathersimple.Itconsistsof electrolyticallydepositingcopperontothesubstratefromanelectrolyte1, essentiallycomposedofCusulfateandsulfuricacid.However,itwasfound thatbyincorporatingappropriateadditivesinthiselectrolyteaspecific depositionregimetakesplace,inwhichdepositionissignificantlyfaster insidethefeatures(Figure1.5).Thisparticularregimeisreferredtoas

1Theprinciplesofmetalelectroplatingarediscussedinsection3.1.

superconformal deposition[AND98].Thissuperconformalregimeistheonly onecapableofreliablyfillingtheinterconnectfeaturesandcanbeconsidered asthecornerstoneofthedamasceneapproach.Itsdescriptionisthemain topicofsection4.2.

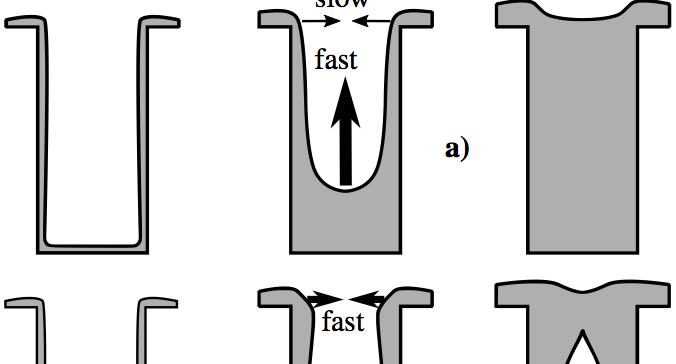

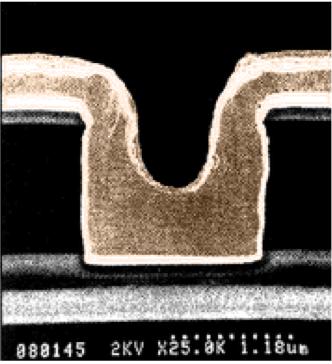

Figure1.5. Schematicrepresentationofthea)superconformal;b) subconformaldepositionregimes;c)earlyexampleofsuperconformal filladaptedfrom[AND98]

ToinitiateCuelectroplating,aconductingsurfaceisneeded.Therefore,a thinmetalliclayerisdepositedfirstonthesubstrate.Usually,aCucoatingis used,depositedbyphysicalvapordeposition(PVD)[NIS07].ThisthinCu lineriscalledthe seedlayer .Theelaborationofthisthinmetalliclayerwithan electroplatingprocessalternativetoPVDisdiscussedinsection5.1.

Atthisstage,thefinaldifficultyremainswiththeuseofCu.Indeed,this metalisknowntoeasilydiffuseintoothermaterialssuchasSioritsoxides. Also,Cuisacontaminantthatcreatesdeeplevelsintheelectronicstructure ofSi,compromisingtheoperationoftransistors[IST02].Inlarger concentrations,CucanevenformcompoundswithSiandcompletelydestroy thedevices[NEW82].Forthesereasons,itismandatorytoconfineCuwithin theinterconnectstructures.Thisiswhyspecificbarrierlayershavebeen addedinthestructurestopreventCudiffusion.Thefirstoneisdeposited beforethemetal(i.e.beforetheCuseedlayer),andisusuallyabilayerof TaNandTa.ThisbarrierisdepositedbyPVD,usuallyinthesameequipment

c)

TheFabricationofMicro-andNanostructures7

asfortheseedlayer2.Thesecondbarrierisdepositedoncethemetallevelis formed,afterthepolishingstep.Thisupperbarrierisusuallyformedbya dielectricmaterial(typicallyaSinitrideand/orcarbide)depositedby plasma-enhancedchemicalvapordeposition[LE13].Recently,ametallic coatinghasbeenproposedtoadvantageouslyreplacethislayer.Thiswillbe thesubjectofsection5.2.

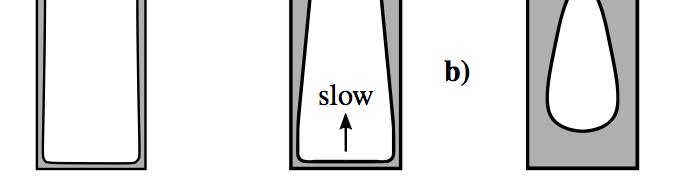

Finally,theconventionalmetallizationsequencecomprisingbarrierand seeddeposition,Cuelectroplating,polishingandencapsulationisdepictedin Figure1.6.

Figure1.6. Schematicrepresentationofthemetallizationsequenceof hollowtrenchesandviasincluding(1)barrierdeposition,(2)seedlayer deposition,(3)superconformalCufill,(4)CMPand(5)encapsulation

1.1.3. 3Dintegration

Theco-integrationoflow-KdielectricmaterialsandCuisstillusedtoday intheindustry.Becauseofthisarchitecturalmodification,thedevice 2Thisisneededtoavoidairexposureofthebarrier,whichwouldresultintheoxidation oftheTa-basedbarrier,seesection5.1.4.

manufacturershavebeenabletopursueMoore’slawinrecentyears[LE13]. However,ascharacteristicdimensionsareshrinkingdowntoafew(tensof) nanometers,physicallimitsarebeingapproached.

Forinstance,thewidthoftheCulinesisreducedto 40nm inthemost recenttechnologies[ITR13].Thisdimensionbecomescomparablewiththe meanfreepathofelectronsinCu,whichisabout 50nm at 293K [HAN02]. Thismeansthatelectronsarenolongermovinginaninfinitemedium;the probabilitythattheycollidewithawallbecomessignificant.Thisphenomenon causesanincreaseintheresistivityoftheCulines.Insuchnarrowlines,the resistivityofCucanexceed 3μΩ·cm [HAU06].

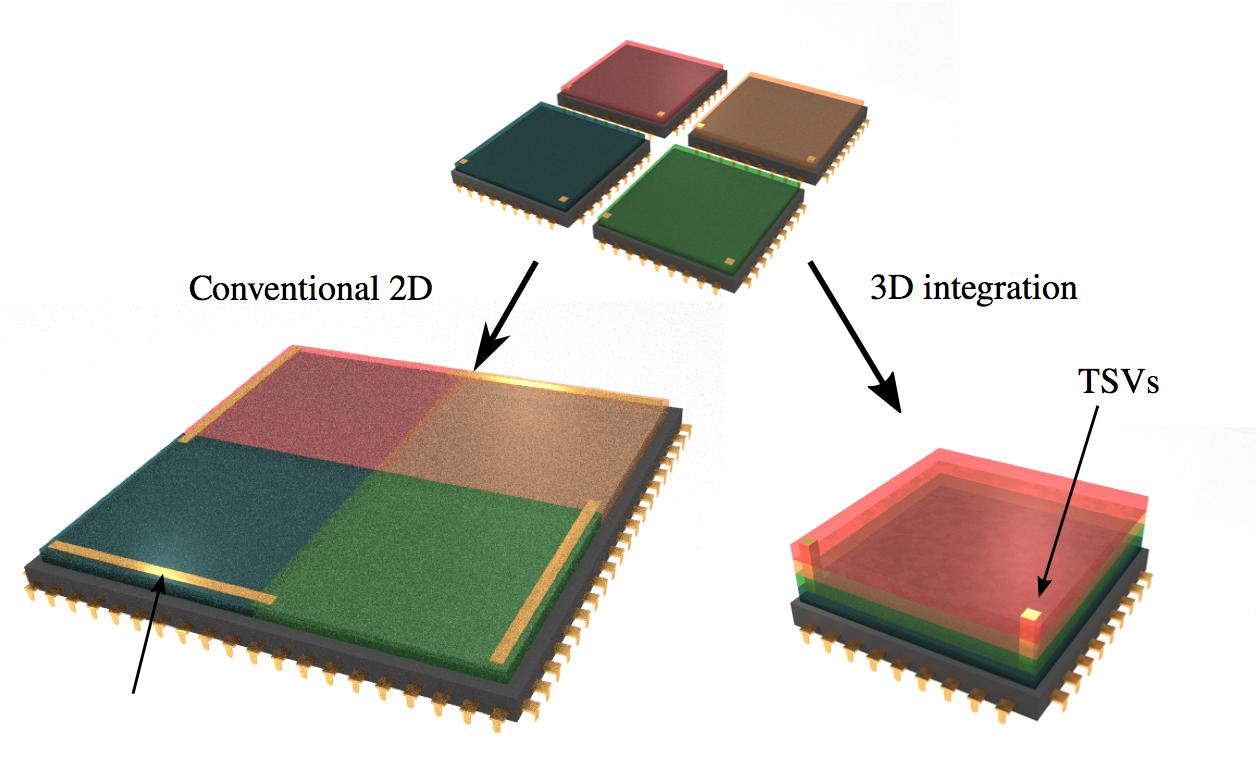

Becauseoftheselimitations,pursuingMoore’slawbyminiaturization onlyisbecomingmoreandmoredifficultandwillevenbeimpossibleinthe foreseeablefuture.Forthisreason,chipmanufacturersaredevisingan alternativeapproach,referredtoasthree-dimensional3Dintegration [LED08].ThisapproachisschematicallyexplainedinFigure1.7.The conceptisquitesimple:severallayersoftransistors(oranyotherdevice)can bestackedtoincreasetheirnumberperunitsurfacearea.Inaddition,this significantlyshortensthe“longdistance”interconnectsinchips,resultingin improvedperformances.Thisstrategyisconceptuallysimpleandelegant,but raisestechnologicalchallenges,suchasdrillingandmetallizingdeepcontact holestoconnectadjacentlayers.Thesestructures,calledthroughsiliconvias (TSVs),arekeyenablersforthe3Dintegration[KAT10].

ThemetallizationofTSVsproceedsthroughasimilarsequenceasfor damasceneinterconnects(Figure1.6).However,allthedepositionprocesses, includingbarrier,seedlayerandCuelectroplatingneedtoberevisedto complywiththedepthofTSVs,aswillbediscussedinsections4.3and5.1.

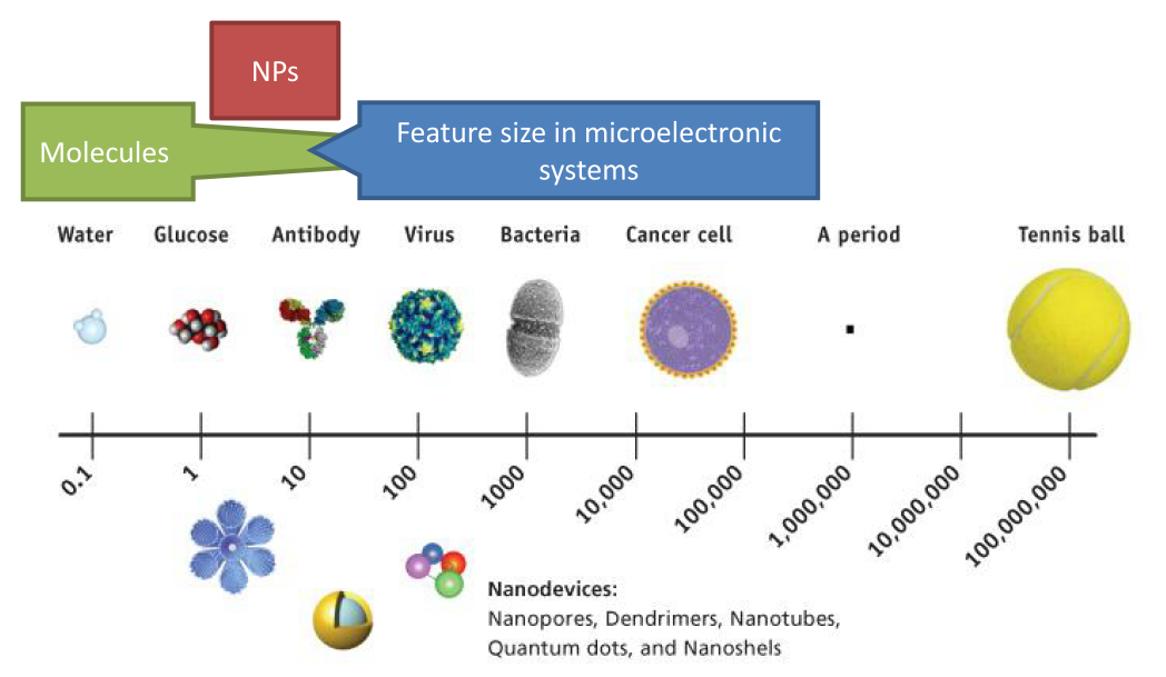

1.2.ElaborationofmetallicNPs

Todaynanosciencesareamajorfieldofresearch.Indeed,objectsatthe nanoscale(whosesizerangesfrom 1 to 10nm)areatthecrossroadsbetween themoleculesmanipulatedbychemistsandthetechnologicaldevices fabricatedbytechnologists(Figure1.8).Thesedifferentscientificfieldsare nowconvergingintheexplorationofthisfascinating“nanoworld”[BAL05].

Nano-objectspossesspropertiesbetweenthebulkmaterialandthe molecule.Forinstance,metallicNPsofferopticalpropertiesthatcannotbe obtainedfrombulkmetals.Thesepropertieshavebeenusedsinceantiquity, likeforinstanceinthefamousLycurguscupwhosecolorchangesfromgreen

TheFabricationofMicro-andNanostructures9 toreddependingontheincidenceoflight(Figure1.9).Thisdichroicbehavior isduetothepresenceofgoldNPsintheglass.

Longglobalinterconnects

Figure1.7. Schematicrepresentationof3Dintegrationascomparedto theconventional2Dlayout.Thelonginterconnectlinesin2Dconventional assemblyarereplacedbyTSVsinthe3Dintegration.Foracolorversionof thisfigure,seewww.iste.co.uk/haumesser/metals.zip

Figure1.8. Theconvergenceofchemistryand technologyinthe“nanoworld”

TheLycurguscup,fourth century–BritishMuseum,London

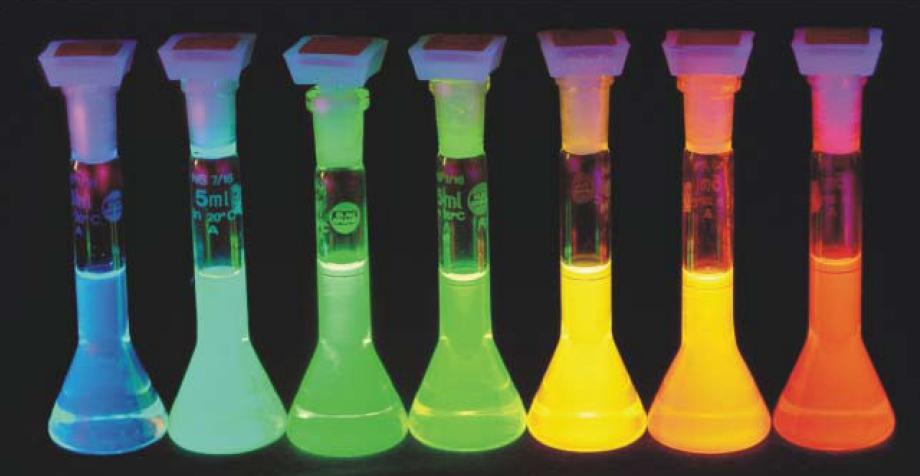

Moreover,theseuniquecharacteristicsaretunablewiththesizeandshape ofthesenano-objects.Forinstance,theircolormayvaryastheirdiameter decreases(thesamefortheirfluorescence,seeFigure1.10).Thisisbecause theirphysicalpropertiesevolvewiththeirsize,eitherbyclassicalorquantum effects.Inaddition,NPsusuallyexhibitenhancedorunexpectedchemical reactivitybecausetheypossessasignificantamountofsurfaceatoms.The fractionofsurfaceatomsiscalled dispersion andscaleswiththeinverse diameteroftheNP[ROD06].Below 3nm,surfaceatomstypicallybecome themainconstituentsofNPs(Figure1.11).Becausesurfaceandedgeatoms havefewerneighborsascomparedtotheinneratoms,theyaremoreproneto interactwithothersurroundingspecies.Thisabilitymaybeusedtoenhance ormodifythereactivityofthelatter,whichisthebasisofthecatalytic propertiesofmetallicNPs[FRE11].Itisalsoresponsibleforthe chemisorptionofcompoundsonmetallicNPs,whichisusedtostabilize colloidalsuspensions(seesection3.2.2).

Today,theversatilepropertiesofmetallicNPsareusedinavarietyof applications,suchasmedicalimaging(usingluminescentormagnetic properties),pigments,(bio)sensors,energyconversionandstorage,and catalysis[GOE10].

Figure1.9.

Figure1.10. FluorescenceofCdSe-CdScoreshellNPswitha diameterof1.7nm(blue)upto6nm(red).Foracolorversionofthis figure,seewww.iste.co.uk/haumesser/metals.zip

Figure1.11. Evolutionofthedispersionwith sizeforicosahedralRu-NPs

Inalltheseapplications,thesizeoftheNPsmustbeaccuratelycontrolled tocomplywiththedesiredproperties.Thismeansthatnotonlythe averagesizeneededforagivenapplicationisrespected,butalso thatsizedistributionisasnarrowaspossibletoensurehomogeneous performances.

TherearetwomainapproachestoelaborateNPs.Inthefirstone,called top-down,thenanostructuresarecarvedoutofthebulkmaterial.Thismaybe achievedeitherbyextensivegrinding,orusingmoresophisticatedapproaches involvinglithographypatterning.Theformerispronetocontaminationand agglomerationoftheNPs.Besides,NPsbelow 50nm areonlymarginally reachable.Withthelattertechniques,majordrawbacksaretheircostandthe wasteofremovedmaterial.

Hence,apreferredstrategyisthe bottom-up elaborationofNPsby combiningatoms.Thiscanbeachievedeitherfromthegasortheliquidphase atamoderatetolowcost.Inmostcases,theseprocessesyieldquitepureNPs. However,thecontrolofsizeandthetendencytoagglomerationremain challenging.TheelaborationandstabilizationofmetallicNPsfromliquid phaseprocessesisfurtherdescribedinsection3.2.Aspecificandinnovative approachtothisquestionistheobjectofChapter6.

1.3.Conclusions

Thefabricationofmetallicobjectsatthesmallsize,eitherthinfilmsor NPs,isofparamountimportanceforcurrentandfuturetechnological applications.Thiselaborationispreferentiallycarriedoutusingbottom-up approaches,inwhichthestructuresareassembledfromindividualatoms. Mostoftheseprocessesmustbecontrolledatthenanometerscale.Thisis mandatoryeithertoobtainNPswithpredictablesize,orformthinfilmswith optimizedstructureandproperties.

AswillbeshownChapter2,thetransformationofisolatedatomsinafluid phase3 intobulkmetalusuallyproceedsthroughthenucleationofsmall clustersthatgrowandcoalesceintothedensemetal.Thisisthecaseforthe precipitationofametalfromasolutioncontainingsuitableprecursors,which isthetransformationinvolvedineitherthe(electro)chemicaldepositionof metallicthinfilmsorthechemicalsynthesisofmetallicNPs.Fortunately, thereexistmanywaysinwhichthisnucleation–growth–coalescencesequence canbemodifiedbytuningexperimentalconditions.Thereasonswhyare explainedinChapters2and3.Inthesubsequentchapters,theseconceptswill beappliedtoprocessesoftechnologicalinterestinthefabricationof interconnectstructures(Chapters4and5)ortothesynthesisofmetallicNPs withaccuratesizecontrol(Chapter6).

3Thefluidphasemaybeamelted,butalsoagaseousorliquid,solution.

PhaseTransition:Nucleation,Growth, AggregationandCoalescence

Inthischapter,thegeneralquestionofphasetransformationisdiscussed fromaquitefundamentalstandpoint.Thenotionof nucleation isintroduced. Thisconceptiscentraltounderstandandcontrolthesolidificationprocesses describedinChapters5and6forthefabricationofthinfilmsornanoparticles. Thesubsequentstepsofphasetransformation,growth,aggregationand coalescencearealsodiscussed.Alargepartofthisdiscussionisinspiredfrom therecentbookbyKashchiev[KAS00].Here,onlytheessentialconcepts andequationsareretainedandupdatedwhenevernecessary.

2.1.Whatistheeasiestpathforaphasetransition?

Phasetransitionsareprofoundtransformationsofmatter.Likeother naturalprocesses,theymustfollowtheeasiestpath.Therefore,itisagood ideatofigureoutwhatthispathmightbe.Insuchasituation,thermodynamic considerationsareusuallyextremelyuseful.Inthissection,basic thermodynamicnotionswillberecalled.Then,theywillbeusedtoidentify thedrivingforceforphasetransition.Resistancesagainsttransformationwill beconsideredaswell.Finally,ageneraldiscussionofthewholeprocesswill beproposed.

2.1.1. Gibbsenergyofahomogeneousphase

Aphase α canbethermodynamicallycharacterizedbyitsentropy Sα , volume Vα andcomposition.Thelatterisdescribedbythequantities nα,i of

thevariouschemicalspeciesthatconstitutethephase.Itsenergy Uα isrelated tothesevariablesthrough[GUG85]:

where T and P arethetemperatureandpressure,respectively,and

isthe chemicalpotential ofspecies i inphase α.However,itismorepractical tousetheso-called Gibbsenergy Gα asacharacteristicfunctionofphase α. Thisfunctionisdefinedby:

Since Uα ishomogeneousoffirstdegree,itispossibletouseEuler’s theoremtoobtain:

2.1.2. Thedrivingforce:supersaturation

Letusconsiderthetransformationofahomogeneousphaseintoanother homogeneousphase.Letusagreetocalltheinitialphase“old”andthefinal phase“new”.Thetransformationoftheoldphaseintothenewphaseis possibleonlyif:

Letuslimitourselvestothecasewherethistransformationconcerns a singlespecies,andletusagreetocalltheunitbuildingblockofthenewphase (whichcanbeanatom,amolecule,etc.)a monomer .Ifthetransformation

PhaseTransition:Nucleation,Growth,AggregationandCoalescence15

involves M monomers,theGibbsenergiescanberelatedtotheirchemical potentialsintheoldandnewphases:

Bydefinition, Δμ iscalledsupersaturation.Itcorrespondstothefavorable balanceinGibbsenergy,whichdrivesthephasetransformation.The larger(themorenegative)thisdifference,themorefavorablewillbethe phasetransformation.

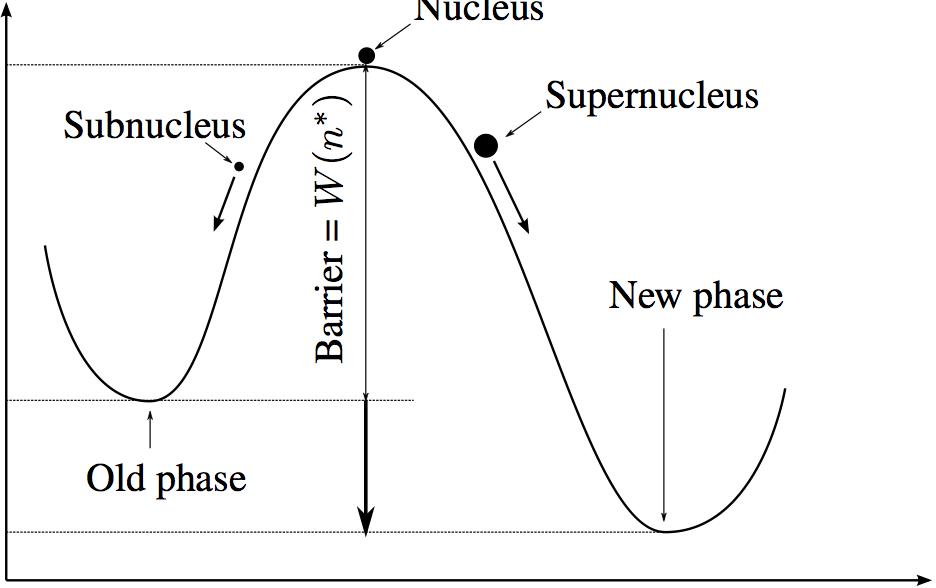

2.1.3. Theresistanceforce:theenergeticbarrier

Nowcomesthequestionoftheactualpathfollowedbythesystemto transformtheoldphaseintothenewphase.Thistransitionnecessarily proceedsbysomecontinuousevolutionofthesystemfromtheinitial(old phase)tothefinalstate(newphase).Inotherwords,thesystemhastogo throughasuccessionofintermediatestates.Generally,thesestateshappento belessstablethantheoldphase,sothat μinter >μold (or Ginter >Gold ,see Figure2.1).Inotherwords,theoldphasecorrespondstoa localminimumof theGibbsenergy (thetrueminimumcorrespondingtothenewphase).For thisreason,theoldphaseissaidtobeina metastablestate.

Thesystemneedstoovercomeanenergeticbarrierinordertotransform theoldphaseintothenewphase,andthisbarrierplaysacentralrolein thephasetransformation.

Fromthesesimpleconsiderations,anextremelyimportantconclusioncan bedrawn: thetransformationishighlyunlikelytoinvolvetheMspeciesat once.Indeed,theassociatedbarrierwouldbe M (μinter μold ).By comparison,foranalternativepathwayinvolvingasmallnumberofspecies n<<M ,theassociatedenergeticbarrierisonly n (μinter μold ).If n is reallysmallascomparedto M (severalordersofmagnitudeinmostpractical cases),thelatterbarrierisbyfareasiertoovercome.Forthisreason, first-ordertransformationsusuallyproceedby nucleation (formationofsmall aggregatesor clusters ofthenewphase),whichsubsequently grow to progressivelytransformtheoldphaseintothenewphase.

Figure2.1. Schematicrepresentationofthetransitionpath fromtheoldtothenewphase

Bydefinition, nucleation istheprocessbywhichextremelysmall(usually nanometric)aggregates(or clusters)ofthenewphaseareformed,which irreversiblygrowintomacroscopicdomainsofthenewphase.These clustersmayforminthebulkoftheoldphase(homogeneousnucleation), butalsoattheinterfacewithasubstratephase(heterogeneousnucleation).

Consequently,toproperlydescribethephasetransition,itisnecessaryto determinethecharacteristicsoftheseclusters.Again,thisisequivalentto findingthe easiest path(withsmallestenergeticbarrier)betweentheoldand thenewphases.Thisispreciselythepurposeofthevarioustheoriesof nucleation.

2.1.4. Nucleus,subnucleusandsupernucleus

Indeed,thegranulartheoriesofnucleationallaimatdeterminingthework neededtoformaclusterofagivensize(expressedherebythenumber n of monomerscontainedinthecluster).Thisworkcorrespondstothedifference inGibbsenergybetweentheinitialstate(homogeneousoldphase)andthe

PhaseTransition:Nucleation,Growth,AggregationandCoalescence17

intermediatestate(aclusterof n monomersembeddedintheoldphase,see Figure2.1): W (n)= Ginter (n) Gold

Remarkablyenough,mostofthenucleationtheoriesleadtoageneral expressionofthisworkasthebalancebetweensupersaturationandenergetic penalties[KAS00]:

ThefirsttermcorrespondstothegaininGibbsenergyassociatedwiththe formationofthe n-sizedclusterinthesupersaturatedoldphase.Thesecond termgathersallcontributionsresistingthenucleation(i.e.allphenomena associatedwiththeformationoftheclusterthatcauseanincreaseinthe system’senergy).

Onthebasisofthisdescription,theenergeticbarriertobeovercomeforthe phasetransformationisclearlythemaximumvalueofthiswork.Thisvalue, noted W ∗ ,correspondstotheformationofaclusterwithasize n∗ ofthenew phase.Thisspecificsizeiscalled critical,andsuchaclusterisreferredtoasa nucleus (Figure2.1).Indeed,anysmallercluster(n<n∗ )willspontaneously redissolve(backtothelocalenergyminimum,i.e.theoldphase),whereasany largercluster(n>n∗ )willgrowtoformmoreofthenewphase.

Thereisacriticalsize n∗ (correspondingtothenucleus)belowwhich clustersarenon-viableandredissolve(n<n∗ , subnuclei),andabove whichclusters(n>n∗ , supernuclei)cangrow(Figure2.1).Thiscritical sizeisdeterminedbytheconditionofmaximum W (n):

(n)

Inthiscase,equation[2.8]becomes:

W ∗ iscalled workofnucleation.

2.1.5. Phasetransition:astep-by-steptransformation

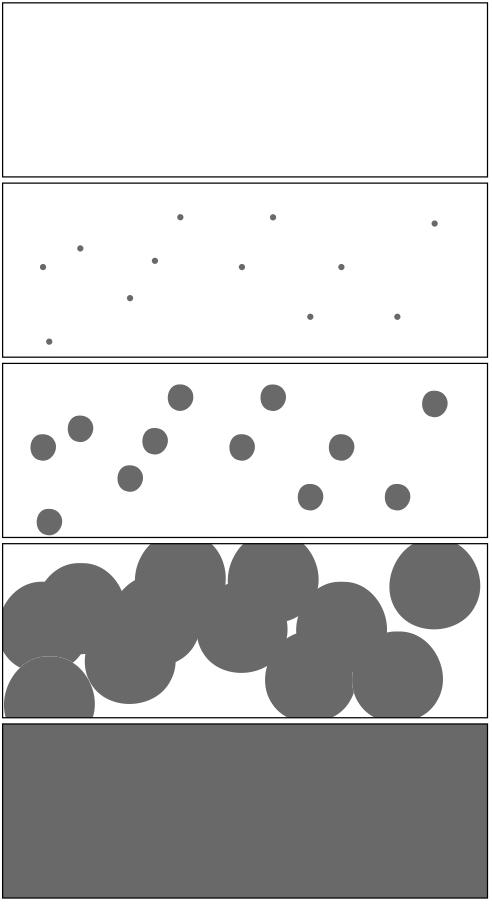

Fromtheconsiderationsabove,nucleationhasbeenidentifiedasthe preferredprocesstotransformtheoldphaseintothenewphase.However, nucleationisjustastart.Thenucleiareusuallyverysmall,andinmanycases alotofmonomersremainintheoldphase.Therefore,asignificantportionof thetransformationimpliesthegrowthofsupernuclei.Astheirsizeand numberincrease,theystarttocoalesce,untilallmonomersareconsumed. ThesedifferentstagesareschematicallydepictedinFigure2.2.Ourgoalin thefollowingsectionsistostudyeachoftheseprocessesaswellastheir interplay.

2.2.Nucleation

Oldphase Nucleation Growth Coalescence Newphase Aggregation

Theconceptofnucleationhasbeenintroducedintheprevioussectionon thebasisofenergeticconsiderations.Here,weshalldescribethis phenomenonintermsofelementaryprocesses.Wepurposelyrestrict ourselvestotheso-called classicalnucleationtheory,whichissufficientto

Figure2.2. Thedifferentstagesofphasetransformation