NonwoodPlantFibers forPulpandPaper

ConsultantPulp&Paper,Kanpur,India

PratimaBajpai

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2021ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicor mechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem,without permissioninwritingfromthepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthe Publisher’spermissionspoliciesandourarrangementswithorganizationssuchastheCopyrightClearance CenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions .

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher (otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroadenour understanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecome necessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusing anyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationor methodstheyshouldbemindfuloftheirownsafetyandthesafetyofothers,includingpartiesforwhomthey haveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeany liabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceor otherwise,orfromanyuseoroperationofanymethods,products,instructions,orideascontainedinthe materialherein.

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

ISBN:978-0-12-821800-6

ForInformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: SusanDennis

AcquisitionsEditor: KostasKIMarinakis

EditorialProjectManager: SamanthaAllard

ProductionProjectManager: KumarAnbazhagan

CoverDesigner: VickyPearsonEsser

TypesetbyMPSLimited,Chennai,India

4.2Agriculturalresidues

4.2.1Sugarcanebagasse(Saccharumofficinarum

4.2.2Cornstalks(Zeamays)

4.2.3Cottonstalks(Goossypium)

4.2.4Ricestraw(

4.2.5Wheatstraw(

4.2.6Cerealstraw

4.3Naturalgrowingplants

4.3.1Bamboo(

4.3.2Esparto(Stipatenacissima

4.3.3Reeds(

4.3.4Papyrus(

4.4Nonwoodcropsgrownmainlyfortheirfibercontent

4.4.1Bastfibers

4.4.2Leaffibers

Chapter5:Problemsassociatedwiththeuseofnonwoodfibersandhow

Chapter6:Handling,storage,andpreparationofnonwoodrawmaterials

7.1Pulpingpropertiesofnonwoodyrawmaterials

7.2Pulpingofnonwoodyrawmaterials

7.2.1Alkalinepulping

7.2.2Sulfitepulping

7.2.3Organosolvpulping

7.2.4Chemimechanicalpulpingandotherpulpingmethods

7.3Washing,screening,andpurificationofnonwoodpulp

Chapter9:Chemicalrecovery

9.1Thechemistryofsilica

9.1.1Mineralcomposition,especiallysilica

9.2Desilicationofblackliquor

9.2.1Partialdesilicationbyrawmaterialcleaning

9.2.2Spontaneouspartialdesilicationofblackliquorbystoring(ageing)

9.2.3Desilicationofblackliquorbylimeaddition

9.2.4Desilicationbyblackliquorbycarbonation

9.3Desilicationofgreenliquor ...............................................................................177

9.4Sodarecovery ....................................................................................................178

9.5Alternativerecoveryprocesses

9.5.1Directalkalirecoverysystem

Chapter10:Beating/refiningandpapermaking

10.1Beating/refiningcharacteristicsofnonwoodpulp

10.2.1Thestrengthpropertiesofwetpaper ...................................................196

10.2.2Theadhesionpropertiesofwetpaper ..................................................197

10.2.3Drainagepropertiesofnonwoodpulps ................................................197

Chapter11:Useofnonwoodplantfibersinspecificpaperand

Chapter12:Advantagesanddisadvantagesofusingnonwoodfiberfor

Preface

Inrecentyears,thethreemajorproblemsthatarecontinuingtopuzzlethedevelopmentof thepaperindustryaretheshortageofresources,contaminationofenvironment,andthe leveloftechnicalequipment.Themostdominatingfactoristheshortageofrawmaterial resources,whichislargelyduetothecontradictionbetweenthestructureoftheraw materialandthestructureofthefiberresources.Therebynonwoodfiberspossessarich varietyofexcellentpropertiesinphysicalandopticalaspects,whichcouldbeusedto improvetheirproducts.However,throughouttheworld,nonwoodfiberaccountsforonlya smallfractionoftherawmaterialofpaperandpaperboard.Butinsomedeveloping countries,about60%ofthecellulosefibercomesfromnonwoodmaterials,suchasbagasse, cornstraw,bamboo,reed,grass,jute,flax,andsisal.ParticularlyinChinaandIndia,70% oftherawmaterialsusedinthepulpindustrycomefromnonwoodplantsincludingcereal strawandbagasse,andthesetwocountriesown80%ofthetotalnonwoodpulpproduction. Aroundtheworld,multitudinousnonwoodfibersareusedinthefieldofpulpand papermaking,whichincludeannualagriculturalwasteandnaturalgrowthorartificial cultivationgrassandsoon.

Thisbookexaminesthebackgroundtouseofnonwoodplantfibersforpulpand papermaking;worldwidepulpingcapacityofnonwoodfibers;categoriesofnonwoodyraw materials;problemsassociatedwiththeutilizationofnonwoodfibersandhowtheyare approached;pulping,bleaching,chemicalrecovery,andpapermakingofnonwoodraw materials;useofnonwoodplantfibersinspecificpaperandpaperboardgrades;and advantagesanddrawbacksofusingnonwoodfiberforpapermakingandfutureprospects. Thisbookwillprovideprofessionalsinthefieldwiththemostup-to-dateand comprehensiveinformationonthestate-of-the-arttechniquesandaspectsinvolvedinpulp andpapermakingfromnonwoods.

Acknowledgments

Iamgratefulforthehelpofmanypeople,companies,andpublishersforproviding informationandgrantingpermissiontousetheirmaterial.Deepestappreciationisextended toElsevier,Springer,WileyVCH,Appita,Hindawi,MDPI,Intech,andotheropen-access Journalsandpublications.MyspecialthankstoRobertW.Hurter,President,HurterConsult Incorporatedforprovidinginformationonuseofnonwoodplantfibersinspecificpaperand paperboardgrades.

ListofFigures

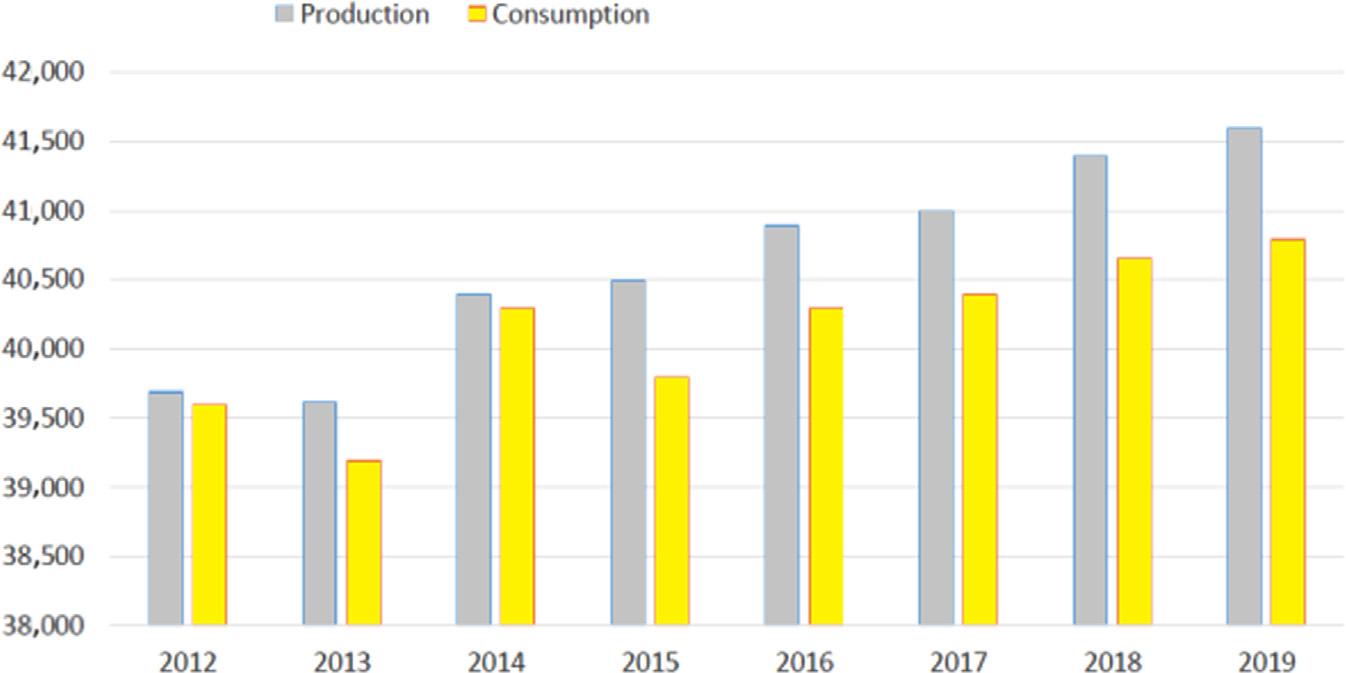

Figure1.1Worldpaperandpaperboardproductionandconsumption (10,000tons). 2

Figure1.2Portionsofatypicalmonocotstem(left)andherbaceousdicotstem (right,50 3 ). 13

Figure1.3Stemcrosssectionsof Cannabis (left,100 3 )and Linum (right,40 3 ). 13

Figure1.4Fibersofbamboo(left,withparenchyma,60 3 ),linen (center,150 3 ),andcottonseedhairs(right,150 3 ).

14

Figure1.5Stemcrosssectionofwheat(withpartofaleaf,50 3 ).15

Figure4.1SEMimagesofbagassesamples:(A)wholebagasse,(B)fiber, and(C)pith. 38

Figure4.2SEMofcornstalkfiber(withdifferentmagnification).41

Figure4.3SEMimageofcottonstalk.42

Figure4.4Ricestrawfiber.43

Figure4.5SEMimageofwheatstrawfiber.45

Figure4.6SEMimageofryestraw.46

Figure4.7SEMofbamboofiber.47

Figure4.8Scanningelectronmicrographsofespartograssfibers.50

Figure4.9Morphologyofreedfibersunderopticalmicroscope.53

Figure4.10Cross-sectionalimageofSabaigrassfiber.55

Figure4.11SurfaceimageofSabaigrassfiber.55

Figure4.12(A)Longitudinalview(5000 3 magnification)and(B)cross-section (180 3 magnification)ofjutefiber.

Figure4.13(A)Longitudinalviewand(B)cross-section(100 3 magnification) oframiefiber.

58

60

Figure4.14SEMofSunnhempfiber.60

Figure4.15(A)Longitudinalview(10,000 3 magnification)ofhempfiber (Smoleetal.,2013).(B)Cross-section(200 3 magnification) ofhempfiber.

61

Figure4.16Scanningelectronmicrographofkenafbastfiber.64

Figure4.17(A)Longitudinalview(10,000 3 magnification)and (B)cross-section(30 3 magnification)offlaxfiber.

65

Figure4.18ManilaHemp/Abaca.69

Figure4.19SEMimageofSisalfiber.70

Figure4.20(A)Longitudinalview(5000 3 magnification)and (B)cross-sectionofcottonfiber.

71

Figure4.21SEMimagesofcottonlinters.72

Figure7.1Processflowdiagramforpulpandpaperproduction.112

Figure7.2StructuresofanthraquinoneandsolubleAnthraquinone.116

Figure7.3Cyclicactionofanthraquinone.117

Figure7.4Sideviewdiagramofthepulpingextruder.134

Figure8.1Reactionbetweenphenolicligninunitsandchlorinedioxide.154 xivListofFigures

ListofTables

Table1.1Chemicalcompositionofhardwoodandsoftwood.4

Table1.2Percentageoftypesofnonwoodpulpusedinpaper production. 5

Table1.3Comparisonofnonwoodandwoodresourcesforpulp andpapermaking. 6

Table1.4Usersofnonwoodfibersinpapermaking.8

Table1.5Averagepulpyieldsofdifferentpapermakingrawmaterials.9

Table1.6Fiberpropertiesofsomenonwoodfibers.10

Table1.7Fiberpropertiesofsomewoodyrawmaterials.10

Table1.8Chemicalpropertiesofnonwoodfibersandtheircomparison withwoodyrawmaterials. 11

Table1.9Chemicalcomposition(%)ofcerealstraws.11

Table2.1Reasonsforuseofnonwoodfibers.20

Table3.1Distributionofnonwoodpulpproductionintheworld.26

Table3.2Estimatedproductionofnonwoodpulpindifferentparts oftheworld. 27

Table3.3Availabilityofnonwoodfibersindifferentpartsoftheworld.28

Table3.4Production/consumptionofnonwoodpulp.28

Table3.5Imports/exportsofnonwoodpulp.28

Table3.6NonwoodfibersproductioninChina(Milliontons).29

Table4.1Estimatedannualcollectableyieldsofvariousnonwood rawmaterials. 34

Table4.2Lengthandwidthofsomecommonnonwoodfibers.34

Table4.3Chemicalcompositionofsomecommonnonwoodfibers andcomparisonwithwoodfibers. 35

Table4.4Categoriesofnonwoodrawmaterials.36

Table4.5Usesofabacafiber.68

Table5.1Drymatteryieldsfornonwoodfibercrops.84

Table5.2Deteriorationduringstorageofwoodandsomenonwoods.85

Table5.3Problemsinwetdepithing.87

Table5.4Generationofpollutantsinwetdepithing.88

Table5.5Short-periodcontinuouspulpingofdifferentrawmaterials.89

Table5.6Typicalpapermachinespeedsfordifferentfurnishes.91

Table5.7Sizeofnonwoodpulpmills.93

Table5.8Reductioninpollutionloadafterimplementationofwaste minimizationmeasures. 93

Table6.1Sodapulpingofwheatstrawwith C. subvermispora Strains1 and2atreducedalkalicharges.

Table6.2Effectofcookingtimeonsodapulpingof C.subvermispora treatedwheatstraw.

Table7.1Delignificationstagesofstrawandsoftwood.109

Table7.2Reasonsforfastersolubilizationofligniningramineous strawmaterials. 109

Table7.3Pulpingmethodsfornonwoodyplants.113

Table7.4Propertiesofpulpproducedwithdifferentalkalinepulping methods.

Table7.5Propertiesofpulpproducedwithdifferentsulfitepulping methods.

Table7.6SolventsusedinOrganosolvpulping.123

Table7.7AdvantagesofOrganosolvprocess.124

Table7.8Propertiesofpulpproducedwithdifferentalcohol pulpingmethods.

128

Table7.9Propertiesofpulpproducedwithdifferentorganicacids.130

Table7.10Propertiesofpulpproducedwithdifferentchemi-mechanical pulpingmethods. 131

Table7.11Benefitsfrompulpwashing.136

Table8.1Chemicalsusedinbleachingprocesses.148

Table8.2Functionsofdifferentbleachingagents.149

Table8.3Advantagesanddisadvantagesofdifferentbleachingagents.150

Table8.4Classificationofbleachingchemicals.151

Table8.5Physicalstrengthpropertiesofbleachedwheatstrawpulps byanOQPosequence.

158

Table8.6Propertiesofwheatstrawpulpsfromdifferentstages.158

Table8.7ECFbleachingofnonwoodpulps.160

Table8.8TCFbleachingsequencesusedforwheatstrawpulp.161

Table9.1Environmentalandeconomicbenefitsofchemical recoveryprocess.

167

Table9.2Presenceofligninandsilicainmainnonwoodyrawmaterials inpercentage. 168

Table9.3Problemsassociatedwiththepresenceofsilicateionsin blackliquor. 168

Table9.4Effectofstorageondesilicationofblackliquor.172

Table9.5Desilicationofblackliquoratdifferenttemperatures.175

Table9.6Desilicationofblackliquorofvariousrawmaterials.175

Table9.7Advantagesofdesilicationofgreenliquorwithlime.178

Table9.8Effectoftwo-stagecausticizationofgreenliquor.178

Table9.9Advantagesoffluidizedbedreactor.180

Table9.10Costcomparisonofthecostofconventionalandferrite recoveryprocesses. 183

Table9.11Solubilityofsilicainregeneratedalkali.183

Table10.1Responseoffibersduringbeatingandrefining.189

Table10.2Factorsaffectingrefining.190

Table10.3Majoreffectsofrefining.191 Table10.4Factorsinfluencingtheresponseofpulpfiberstorefining.191 Table10.5PFI-refiningofenzyme-treatedandcontrol(noenzymetreatment) LF-3pulps. 194

Table10.6Thewetstrengthpropertiesofnonwoodpulps.197 Table11.1Paperproducedfromnonwoodpulps.204 Table11.2PaperproducedfromBagasse.205 Table11.3PaperproducedfromStraw(cerealandrice).206 Table11.4Paperproducedfrom Phragmites communisReeds.206 Table11.5PaperproducedfromBamboo.206 Table11.6PaperproducedfromKenaf(wholestalk).207 Table11.7PaperproducedfromKenaf(bastfiber).207 Table11.8PaperproducedfromEsparto.207 Table11.9PaperproducedfromFlax(bastfiber).208 Table11.10PaperproducedfromtrueHemp(bastfiber).208 Table11.11PaperproducedfromJute(bastfiber).208 Table11.12PaperproducedfromSisal.208 Table11.13PaperproducedfromAbaca.209 Table11.14PaperproducedfromCotton.209 Table11.15PaperproducedfromEkara,Knagra&Nalgrassmixed.209 Table12.1Advantagesofusingnonwoodfiber.212 Table13.1Interestintheuseofagriculturalresiduesforpapermaking.219

Introduction

Chapteroutline

1.1GeneralBackground1

1.2Taxonomy12

1.3Monocots(monocotyledons)12

1.4Dicots(dicotyledons)12

1.5Anatomy12

1.6Usefulfibers14

1.7Nonwoodfiberidentification15

1.8Strawmorphologyconsiderations15

1.9Depithing16

References16

Furtherreading18

Relevantwebsites18

1.1GeneralBackground

Thepulpandpaperindustryisoneofthelargestindustrialsectorsintheworld.Itis supplyinggloballytomorethan5000millionpeople.Inthebeginning,pulpand papermakingwasaslowandrequiredalargeexpenditureoflabor.However,nowadays theseprocessesaredrivenbycapitalintensiveequipmentandsophisticatedpapermachines runningathighspeed.Thissectorincludesproductssuchasofficeandcatalogpaper,glossy paper,tissue,andpackagingpaper,usingmorethan40%ofallindustrialwoodtraded worldwide.UnitedStatesiscurrentlyoneofthelargestpaperconsumersintheworld.

NorthAmerican,NorthernEuropean,andEast Asiancompaniesaredominatingthepulpand paperindustry.InAustralasiaandLatinAmericaalso,therearelargenumberofpulpandpaper mills.ChinaandIndiawillbecomemajorplayersintheindustryinthenextfewyears.The worldwideproductionofpaperandboardwasabout407millionmetrictonsin2015(Fig.1.1). Itisforecasttogrowto467milliontonnesby2030(https://www.poyry.com/news/world-fibreoutlook-2030-global-consumption-papermaking-fibre-and-specialty-pulps-has-grown-125).

Onethirdoftheproductionwasattributabletographicpaperandmorethanhalfofthat productionwasattributabletopackagingpaper.Globalpaperconsumptionin2020is expectedtoamountto500milliontons.Thelargestpaperproducingcountriesinthe worldareChina,theUnitedStates,andJapanandaccountforhalfofthetotalpaper

Worldpaperandpaperboardproductionandconsumption(10,000tons). Source:Foodand AgricultureOrganizationoftheUnitedNations.From http://en.dagongcrg.com/uploadfile/2018/0211/ 20180211113719767.pdf

productionintheworld.GermanyandtheUnitedStatesaretheleadingpaperimporting andexportingcountries.China’sproductionofprocessedpaperandcardboardhadranged atabout10.68milliontonsinApril2018.Withsome407.5millionmetrictonsofpaper consumedgloballyin2014,theworld’spaperconsumptionisroughlyequaltothe amountofpaperproducedannually.Chinaistheworld’slargestpaperandpaperboard consumerintheworld,usingmorethan103millionmetrictonsyearly,followedbythe U.S.withaconsumptionrateofmorethan71millionmetrictons.NorthAmerica,however,hasworld’shighestpercapitaconsumptionofpaperofanyregion,consuming 221kilogramspercapita,whichisgivencontextwhencomparedtotheworldaverage percapitaconsumptionofpaperofjust57kilogramsperyear.

Bajpai(2018a)

Overthepast40years,theglobaldemandforpaperhasincreasedatanaveragerateof 4.7%annually.Althoughfuturegrowthisexpectedtoreduceto2% 3%,theexistingwoody rawmaterialsmaynotbesufficientformeetingthisgrowingrequirementforpaper particularlyintheEasternEuropeandAsiaPacificregion.Furthermoreloggingiscoming undergrowingpressurefromenvironmentalorganizationsworriedabouthabitatdevastation andotherlong-termeffectsofforestharvesting.So,itisimportanttoconsiderothertypeof fibersourcesformeetingthepossibledeficitofwoodfibersforproducingpaper.Appropriate nonwoodfibersareavailableinabundanceinseveralcountriesandarethemainsourceof fiberforproducingpaperinfewdevelopingcountries(www.tandfonline.com).

Inactualfact,paperproducershavebeenusingnonwoodfiberssincepaperwasinventedinthe 1stcenturyADChina.Bytheendof19thcentury,woodbecamethemajorrawmaterialforall butveryspecialpapers;andinthe20thcentury,nonwoodfiberswereutilizedcontinuously.

Figure1.1

Nowseveralpapersareavailablewhichneedcertainmechanicalpropertiesandattributes: somedielectricandelectrolyticpapers,casingpapersusedbymeatprocessors,liquidfiltration media,andseveralotherswhichdemandacertainappearanceand/ororganolepticproperties whichusepulpsfromsisal,abaca,andflaxforachievingthesought-afterobjectives.Moreover, withthedevelopmentandgrowthofwet-laid(andother)nonwovenstechnologiescommencing inthe1950sand1960s,fiberssuchasjute,sisal,abaca,flax,andotherssuchaskenafand “truehemp”havebeenconsideredandused(paper360.tappi.org).

Generally,nonwoodfibersareanytypeofplantmaterialwhichisnotclassifiedasatree andutilizedforproducingpulpandpaper.Thereisabroadvarietyinthephysicalnatureof diversenonwoodfibersdeliveredtothepulpmillandinthefiberpropertiesofthepulp produced.Thedissimilaritybetweenfibersmayhaveaneffectonthemilldesign,selection ofequipment,andthequalityofpulp.

Wheatstrawisgenerallyharvestedonetimeinayearafter6 8weeks,sobaledstraw shouldbestockpiledfortherequirementofwholeyear.Preparationofwoodchipsdiffers considerably.Horizontaltubedigestersaretypicallyusedfornonwoods,whereasforwood Kamyr-typedigestersareused.Cookingtimeincaseofstrawisshorterandtheuseof chemicalsislesser.Thesodapulpingprocessisgenerallyused.Chemicalrecoveryisquite difficultbecauseofsilica,andthedrainageofstrawpulpisslow,thereforealongwetend inpapermachineisrequired.Incontrast,thechippingofbambooandgiantreedcanbe conductedjustlikewoodandprocessedinthesamemillprocessingwood.Specialty nonwoodfibershaveotherproblemsandrequirementsthatwillalsovarydependingonthe specificfiber(paper360.tappi.org).

Ingeneral,fibersforpulpandpaperareobtainedfromtreesoragriculturalcrops.These includethefollowing:

•Plantmaterials—wood,straw,andbamboo—obtaineddirectlyfromtheland.

•Plantmaterialby-productsorresidualfromothermanufacturingprocesses.Examples, woodchipsfromsawmills,bagassefromsugarmill,andcottonlinter.

•Fiberrecoveredfromrecycledpaperorpaperboard(Ince,2004).

Forestresourceshaveimportantvalueinproducingarangeofdifferentwoodresources forpulpandpaper-basedindustries.Woodresourcesaredividedintotwotypeswhich aresoftwood(suchasspruce,pine,fir,larchandhemlock)andhardwood(suchaseucalyptusandbirch).Hugemajorityofwoodresources(morethan90 92%offibres)are usedforpulpandpaperproductionglobally.Thesewoodresourcesareusedinmany kindsofpapergradesduetoitssmoothsurfaceareaandstrongstrength.

Holik(2006), Dicketal.(2006), Jime´nezetal.(2009), Sridach(2010a)

Table1.1 showsthecomparisonofchemicalcompositionbetweenhardwoodandsoftwood

Woodcontainslargelycellulose,hemicellulose,lignin,extractives,andash.Thechemical compositionvariesfromspeciestospecies(Henricson,2004).Generally,hardwoodshave highercelluloselowerligninandextractivescontentsincomparisontosoftwoods.In hardwoods,thecellulose,lignin,andextractivesare43% 47%,16% 24%,and3% 8%, respectively,whereasinsoftwoodsthecellulose,lignin,andextractivesare40% 44%, 25% 31%,and10% 15%,respectively.

Treesusedtomeetvirginwoodfibredemandoftheforestproductindustryarealready growingexceptforthenewfastgrowingplantations.Therefore,inglobalterm,therewill notbealong-termfibreshortage.However,fibresupplieswithinandacrossparticular regionswilltighten.Theseregionalimbalancesarealreadysignificantandwillcontinue togrow.Asiaispresentlythelargestfibredeficitregion,followedbyWesternEurope. Atthesametime,Asiaisthefocusoffibredemandgrowthforpulpandpaper.Ifthis assessmentisaccurate,pulpandpaperindustry’sdependenceonvirginfibresmustbe reducedbyexpansionintheuseofrecoveredpaperandgrowthintheuseofnonwood plantfibreinAsia.

Chandra(1998), HeandBarr(2004)

Thesedays,inpaperindustry,theenvironmentalissuesarebringingforwardthe requirementforcleanorgreentechnologywherethenewnonwoodyrawmaterialshave beenintroducedforreplacingconventionalresourcessuchaswoodyrawmaterialswith nonwoodyrawmaterials.Thecleanertechnologyisusedforachievinghigherproduction withsmallesteffectparticularlyontheenvironmentandreducethedumpingexpenses, steadinesshazards,andresourcecostresultinginareducedburdenonthenatural environmentandalsoincreasetherevenuesinpulpandpaperindustries(Sridach,2010b). Theabundanceofnonwoodresourcesinsomecountriesmadethemresponsibleforitsuse inpulpandpaperindustry.Thisisconsideredthebestmethodandmoreadvantageousfor nonwoodfiberstobeusedasalternativefibersinpulpandpaperindustry.

Table1.1:Chemicalcompositionofhardwoodandsoftwood.

Source:Basedon Henricson,K.,2004.Woodstructureandfibers. ,https://noppa.lut.fi/noppa/opintojakso/bj60a1400/ materiaali/2-wood-structure-and-fibers.pdf. and Koch,G.,2006.Rawmaterialforpulp.In:Sixta,H.(Ed.),Handbookof Pulp.Wiley-VCHVerlagGmbHandCo.KGaA,Germany,pp.21 68.

Somenonwoodfibersareusedforpapermakingduetotheirfinepapermakingproperties butmostofnonwoodfibersisusedforovercomingtheshortageofwoodfibers.Theuse ofnonwoodfibersismorecommonincountrieswithshortageofwood.

Bajpai(2018a,b)

Severalstudieshavebeenconductedontheabilityofnonwoodrawmaterialsthatare tobaccostalks,wheatstraw,giantreed,canolastraw,Tunisianalfa,vinestems,etc.asa goodrawmaterialforreplacingthewoodinpulpandpaperindustry(Gominhoetal.,2001; Shakhesetal.,2011;Jime ´ nezetal.,2002a;ShatalovandPereira,2006;Hosseinpouretal., 2010;Marrakchietal.,2011;Mansourietal.,2012;Mosselloetal.,2010).

Table1.2 representsthepercentageoftypesofnonwoodpulpusedinpaperproduction.

InAsia,theproductionofnonwoodpulpforpaperproductionmainlytakesplaceinthe countriesthatarelackingwoodsupplyparticularlyChina,whereitisproducing approximatelymorethantwo-thirdsofthenonwoodpulpgloballyfortheproductionof paperandboard(Hammettetal.,2001).VietnamandBangladeshareusingnonwood particularlyjuteandbambooasotherfibersinpulpandpaperindustryforreplacingorigin woodfiberandincreasingtheirpaperproduction(Bay,2001;Jahanetal.,2009).

Additionally,UnitedStatesandEuropearealsousingnonwoodyrawmaterialssuchas agriculturalresidues(hempandwheatstraw)forproducingpulpandpaperbecauseit preventstherequirementfordumping,whichispresentlyescalatingthecostoffarmingand environmentalworseningthroughpollution,fires,andpests(Chandra,1998).Additionally, oilpalmfibers(WanRosliandLaw,2011),kenaf(Ibrahimetal.,2011;Mosselloetal., 2010),andbananastemfiber(AbdRahmanandAzahari,2012)areexamplesofnonwood rawmaterialsthatarebeingexploredforpulpandpaperindustryinMalaysiaduetothe copioussources,fordiminishingdumpingintolandfillandforstoppingdeforestation activities.Heavymarketdemandsandalsotheenvironmentalproblemsduetothelargeuse ofwoodsupplyinpulpandpaperindustryhaveincreasedtheinteresttoexplorenonwood fiberresourcesassubstitutionfiberwhichisalso environment-friendly (Gonza ´ lez-Garcı ´ a etal.,2010;Jime ´ nezetal.,2002a).Thustheuseofnonwoodfiberisasuperioroptionfor producingpulpandpaperforreducingdeforestationofrainforestsorprimitiveforestsin theworldincludingMalaysia.Nonwoodplantsarealsotherawmaterialsfortheproduction

Table1.2:Percentageoftypesofnonwoodpulpusedinpaperproduction.

Source:Basedon Sridach,W.,2010b.Theenvironmentallybenignpulpingprocessofnon-woodfibers.SuranareeJ.Sci. Technol.17(2),105 123.

ofspecialtypapersofhigherquality(Gominhoetal.,2001;WanRoslietal.,2004). Nonwoodyplantshaveshownseveraladvantages(Table1.3).

Moreover,anadditionalbenefitforthesefibreresourcesisitcangiveadditionalincometo thefarmersforfoodcrop-wastesuchasstraw,bagasseandgrasses.Apartfromtheabove reasons,somenonwoodplantfibresareindemandforpulpandpaper-makingduetothe specialpropertiesthatmakethembetterthanwoodfibre.Forexample,abacaisanexcellentrawmaterialformanufacturingofspecialtypaper,foritslongfibrelengthandhigh strengthpropertiessuchastear,burstandtensileindices.Inaddition,sisalcanbemade intostrongproductswhereascottonlintersareusedforpremiumqualityletterheadpaper, currencypaper,dissolvingpulpandotherspecialtyproducts.Moreover,bagasseandstraw arebestatcontributingexcellentformationtopapersandcanreplacehardwoodchemical pulpsforprintingandwritingpaper.

Salmelaetal.(2008), Peralta(1996), Chandra(1998), Shietal.(2010), Sridach(2010b)

Basedontheavailability,generally,nonwoodfiberscanberoughlydividedinto agriculturalresidues,naturalgrowingplants(annualplants),andnonwoodcropsgrown mainlyfortheirfiber(Sridach,2010b;Navaee-Ardehetal.,2004;Jime ´ nezetal.,2002b; Flandezetal.,2010;Hemmasietal.,2011;Madakadzeetal.,2010;Chandra,1998).

First,agriculturalresidueshavealowerpriceandthequalityismoderate.Theseare availableinabundanceafterharvestingseason.Examplesarericeandwheatstraw,corn stalk,andsugarcanebagasse.

Thenaturallygrowingplantsconsistofbamboo(Dendrocalamusstrictus),reeds (Phragmitescommunis Trinius),sabaigrass(Euaiopsisbinata),papyrus(Cyperuspapyrus), andelephantornapiergrass.

Table1.3:Comparisonofnonwoodandwoodresourcesforpulpandpapermaking.

Cellulose content

HighercellulosecontentLowercellulosecontentdependsonthetypesof nonwood LignincontentContainhigherlignincontentContainlowerlignincontent ChemicalusesUsealargevolumeofchemical duringpulpingprocess Useasmallamountofthechemicalinpulping process

PulpingtimeNeedlongtimeforpulpingprocessShortentimeforpulpingprocess OperationcostExpensiveduetothelimitation resources Cheapercostbecausetheabundanceresources

Environmental impact Increaseenvironmentalproblem suchasglobalwarmingandsoil erosion

Reduceenvironmentalimpactwhichreducesthe deforestationproblemandimprovessustainable forestry

Source:Basedon RousuP.,Pa¨ivi R.,AnttilaJ.,2002.Sustainablepulpproductionfromagriculturalwaste.Resour.Conserv. Recycl.32(1),85 103; Kissinger,S.,Gerard,G.,Victoria,M.,Nicole,R.,Ford,J.,Kelly,S.,etal.,2007.WoodandnonwoodpulpproductioncomparativeecologicalfootprintingontheCanadianprairies.Ecol.Econ.62,552 558.

Thethirdclassofnonwoodfiberarefiberfrombastfiber,jute(Corchoruscapsularis), ramie(Boehmerianivea),leaffibers,abaca(Musatextiles),seedhairfiber,cottonfiber, ragsandlinters,andkenaf(Hibiscuscannabinus).Thisclassofnonwoodfiberisthemost importantresourceinthemanufacturingofpulpandpaper.

Inagriculturalresidues,cellulosecontentishighandlignincontentislowerincomparison toannualplantsandnonwoodcrops.Thesecontentsingeneralprovidethehigher mechanicalpropertiesofhandsheet.Thechemicalandphysicalpropertiesofnonwood fibersalsohaveaneffectontheirmechanicalproperties.Forinstance,elephantgrass,in annualplantshaslowerlignincontentandshortfiberlengthwhichimparthighstrength properties.

Theunitoperationsinpapermakingfromnonwoodfibersarethesameasusedinthecase ofwoodfibers.Nonwoodfibersareharvested,deliveredtothepulpandpapermill,stored foracertainperiodoftime,preparedforpulping,pulped,andthenbrownstockissubjected towashing,screening,andcleaning.Thisisfollowedbybleachingandthenpapermaking. Therecanbesignificantdifferencesdependingonthetypeofnonwoodfiber.

Therearemanyproblemswiththeuseofnonwoodfibersinpulpandpaperindustry. Rightfromsupplyofrawmaterialtothepropertiesoffinishedpaper,themajorityof nonwoodrawmaterialhasproventobeeconomicallyinferiortowood.Butduringthe lastfewyears,thetechnologicaldevelopmentsinalmostallthefieldsofpapermaking havemadenonwoodmorecompetitivewithwoodasarawmaterialforpapermaking.

Bajpai(2018b)

Duetoenvironmentalconsiderations,utilizationofnonwoodresourcesforpulpand papermakingiscurrentlyshowinganincreasingtrendinthecountrieshavingenough supplyofwood.Earlieritwasfoundincountrieshavinglimitedwoodsupply(Table1.4). Withtime,thistrendshouldgrowfurther.Thefutureofnonwoodplantfibersaspulping andpapermakingrawmaterialappearspromising.

Thedemandfornonwoodplantfibersforpapermakingisexpectedtoincreaseinthe highlyindustrializednationsofEuropeandNorthAmericaduetotheenvironmentalconcernslikedepletingforestresourcesanddisposalofagriculturalresidues.Europehasan additionalproblemwiththeshortageofshortfiberedhardwoodpulp,whichcanbe replacedbysomenonwoodfibers.Thiswillrequireknowledgeoftheprocessesand developmentsalreadyinplaceinthecountriesalreadyusingtheserawmaterialsinthe paperindustry.Already,anumberofnonwoodfibersarecommonlyusedinmanycountriesforpapermaking.Strawsarebyfarthelargestsourceofnonwoodfibersfollowed bybagasseandbamboo.

scholar.lib.vt.edu

Threesourcesfornonwoodfibers—agroindustrialresidue,dedicatedfibercrops,and naturallyoccurringfibers—areingeneralrecognized.

Table1.4:Usersofnonwoodfibersinpapermaking. China

India

Pakistan

Mexico

Peru

Indonesia

Colombia

Thailand

Brazil

Venezuela

UnitedStates

Greece

Spain

Source:Basedon Atchison,J.E.,1995.Twenty-fiveyearsofglobalprogress innon-woodplantfibrepulpingHistoricalhighlights,presentstatusand futureprospects.In:PulpingConference,1 5October1995,Chicago,IL. TappiProceedings,Book1.TappiPress,Atlanta,GA,pp.91 101and FAO,1997.ProvisionalOutlookforGlobalForestProductsConsumption, ProductionandTradeto2010.ForestryDepartment,Rome.

Cornstalksandcobs,wheatandcerealstraws,sugarcanebagasse,andotherfibersremainingfromagriculturalproductionhaveeconomicvalueforproductionofcommoditypulps onalargerscaleandalsoforbio-energyfuels,fiberboard,andotheruses.Theemergence ofcropresidueasavaluableresourcehasevolvedtothepointwheretherearecompeting usesforit—thismustbeunderstoodwhenconsideringthemedium-tolong-termviability ofagivenresourceforthepaperindustry.Fibercrops—includingabaca,bamboo,sunn hemp,kenaf,ramie,falseyucca,andswitchgrass,tonameafew—offerthepotentialto developmaterialstomeetspecificrequirements.Someofthesecrops,suchasbamboo, maybeabundantandnaturallyoccurring;however,duetotheirgrowingimportancefor industrialapplications,theyarenowbeingcultivatedasalternativeagriculturalcrops.But thereareissuestoconsiderregardingenvironmentalimpactsoftheintroductionoflargescalemonocultures.Naturallyoccurringfibersthatcouldbeusedforpapermakinghave region-specificavailability,andtherearemanyvariablesdependingonlocalconditions. Thelarge-scaleuseofanyofthematerialsobtainedfromthesesourcesimpliestheneed fordevelopmentofaninfrastructure,fromfieldorprocessingfacilityforward. paper360.tappi.org

Likewood,thechemicalandphysicalpropertiesaredissimilarwithinthedifferentgroups dependingonthenonwoodfiberresources.Theexistingusesofnonwoodpulpsinclude almosteverygradeofpaper-Printingandwritingpapers,Linerboard,Corrugatingmedium, Newsprint,TissueandSpecialtypapers(Hurter,2001).

Table1.5 showstheannualyieldsofdifferentpapermakingrawmaterials. Ingeneral,commonnonwoodpulpsorhardw oodsubstitutesareproducedinintegratedpulpandpapermills,andsoftwoodkr aftorsulfitepulpisaddedforproviding

Table1.5:Averagepulpyieldsofdifferentpapermakingrawmaterials.

RawmaterialPulpyield(tons/year/ha)

Wheatstraw1.9

Ricestraw1.2

Bagasse4.2

Bamboo1.6

Kenaf 6.5

Hemp 6.7

Elephantgrass5.7

Canarygrass4.0

Scandinaviansoftwood0.7

Fast-growingsoftwood4.0

Temperatesoftwood1.7

Fast-growinghardwood7.4

Source:Basedon Pierce,B.,1991.Recycledhowmanytimes?TimberProaucer1991(April),18 21.

thestrengthtothepaper.Specialtynonwoodpulpcanbealsousedinsteadofsoftwoodkraftorsulfitepulptherebyproducingapaperhaving100%nonwood.And,in fewcases,wastepaperpulpmaybeaddedinthefurnish.Thenonwoodportioninthe furnishusuallyvariesfrom20to90%andcanreachupto100%dependingonthe papergradeandthedesiredpaperquality. Thepossiblecombinationsareinfiniteand canbeadjustedformeetingmarketneeds.M oreover,itispossibletoblendsmall amounts(upto20 30%)ofcommonnonwoodpulpstomainlywoodpulp-based paperswithoutaffectingpaperpropertieso rrunnabilityofpapermachine.Thisprovideswood-basedmillslackinghardwoodb utlocatedwithinaregionwithavailable nonwoodfiberresourcessuchascornstalk sorcerealstrawwiththeoptionofadding onanonwoodpulpinglineforaddingontheirfiberrequirements.

Bajpai(2018b)

Thespecialtynonwoodshavephysicalpropertiessuperiortosoftwoodsandcanbeused inloweramountsinthefurnishwhenusedasasoftwoodsubstitute.Specialtypapers suchascurrency,cigarettepapers,teabags,dielectricpaperetc.maybemadefromafurnishof100%nonwoodspecialtypulps.Specialtypulpsalsomaybeusedincombination withwoodpulptoproducelightweightandultralightweightprintingandwritingpapers. Combinationsofcommonandspecialtynonwoodpulpswillallowtheproductionofvirtuallyanygradeofpapertomeetanyqualityrequirementsdemandedintheglobalmarket.Addingpossiblecombinationswhichincludewoodpulp,nonwoodpulpandrecycled wastepaperpulpincreasesthepossibilitiesfordevelopingpaperwithspecificsheetpropertiesdesignedtomeetspecificcustomersrequirements.

Bajpai(2018a,b).

Tables1.6and1.7 presentthefiberpropertiesofsomenonwoodyandwoodyfibers. Table1.8 showsthecomparisonofchemicalpropertiesofnonwoodfiberswiththoseof woodyrawmaterials. Table1.9 showsthechemicalcompositionofcerealstraws.

Table1.6:Fiberpropertiesofsomenonwoodfibers.

Source:Basedon Atchison,J.E.,McGovern,J.N.,1993.Historyofpaperandtheimportanceofnon-woodplantfibres.In: Hamilton,F.,Leopold,B.(Eds.),PaperandPaperManufacture,Vol.3—SecondaryFibresandNon-WoodPulping.Tappi Press,Atlanta,GA,p.3andChandra,M.,1998.UseofnonwoodplantfibresforpulpandpaperindustryinAsia: potentialinChina(master’sthesis).VirginiaPolytechnicInstituteandStateUniversity.

Table1.7:Fiberpropertiesofsomewoodyrawmaterials.

Source: Basedon Atchison,J.E.,McGovern,J.N.,1993.Historyofpaperandtheimportanceofnon-woodplantfibres.In: Hamilton,F.,Leopold,B.(Eds.),PaperandPaperManufacture,Vol.3—SecondaryFibresandNon-WoodPulping.Tappi Press,Atlanta,GA,p.3andChandra,M.,1998.UseofnonwoodplantfibresforpulpandpaperindustryinAsia: potentialinChina(master’sthesis).VirginiaPolytechnicInstituteandStateUniversity.

Table1.8:Chemicalpropertiesa ofnonwoodfibersandtheircomparisonwithwoodyrawmaterials.

KenafStrawBagasseBambooEucalyptusBirchSpruce Holocellulose(%)76.578.177.876.6b 74b 81b 71b

Hemicellulose(%)32.624.127.919.5b 18b 40b 27b

Lignin(%)16.218.420.823.4b 26b 19b 29b

aExpressedondrymatter. bExtractivefreebasis.

Source:Basedon Ashori(2006)

Table1.9:Chemicalcomposition(%)ofcerealstraws.

RiceBarleyWheatRyeOat

Alpha-cellulose36.233.839.937.439.4 Pentosans24.524.728.230.527.1 Lignin11.914.516.719.017.5 Ash16.16.46.64.37.2 Nitrogen Extractives

0.61.10.40.70.5

EtOH benzene4.64.73.73.24.4

Coldwater10.616.05.88.413.2 Hotwater13.316.17.49.415.3 1%NaOH49.147.041.037.441.8

Source: Basedon Aronovsky,S.I.,Nelson,G.H.,Lathrop,E.G.,1943.Pap.TradeJ.117(25),38 48.

Thesizeofnonwoodfibersarebetweenthoseofhardwoodsandsoftwoods.Thecellulosecontentofmostofnonwoodsiscomparabletothatofwoodsgenerallyusedfor papermaking,whereasthelignincontentismuchlowerincomparisontowoods.Hence, thedelignificationofnonwoodsisrelativelyeasyandconsumeslesschemicals.

Ashori(2006)

InternationalfiberconsultantsHurterConsultIncorporatedhavemadeananalysisofsomepossible candidatesforNorthernBleachedSoftwoodKraft(NBSK)replacement(www.hurterconsult.com). Hurter(2013) haspresentedthesecandidates,alongwithcommentsaboutthepossible opportunitiesandchallengesforeach.

SomepossiblenonwoodsubstitutesforBleachedEucalyptusKraftpulp(BEKP)arewheat straw,bagasse,cornstalks,sorghumstalks,bambooetc.(ByrdandHurter,2013).Wheat strawisavailableinlargevolume.Silicacontentmaybeaproblem.Newdesilication processesareavailable.Sugarcanebagasserequiresdepithingandcompetesasafuel source.Cornstalksisavailableinverylargevolumeatareasonablecost.Sorghumstalks areavailableinmoderatelylargevolume.Severalthousandspeciesofbambooareavailable andcanbeprocessedinwoodpulpmill.SomespecieshavefiberlengthsimilartoBEK. Giantreedcanbeprocessedinwoodpulpmillandisconsideredaninvasivespeciesinthe