NONLINEAR DIFFERENTIAL EQUATIONSIN

MICRO/NANO

MECHANICS

Applicationinmicro/nanostructures andelectromechanicalsystems

ALIKOOCHI

DepartmentofMechanicalEngineering UniversityofTorbatHeydarieh TorbatHeydarieh,Iran

MOHAMADREZAABADYAN

DepartmentofMechanical&AerospaceEngineering RamsarBranch,IslamicAzadUniversity Ramsar,Iran

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2020ElsevierLtd.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicor mechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem,without permissioninwritingfromthepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthe Publisher’spermissionspoliciesandourarrangementswithorganizationssuchastheCopyrightClearanceCenter andtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions.

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher(other thanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroadenour understanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusingany information,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationormethodsthey shouldbemindfuloftheirownsafetyandthesafetyofothers,includingpartiesforwhomtheyhaveaprofessional responsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeanyliability foranyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceorotherwise,or fromanyuseoroperationofanymethods,products,instructions,orideascontainedinthematerialherein.

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

ISBN:978-0-12-819235-1

ForinformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: MatthewDeans

AcquisitionsEditor: SimonHolt

EditorialProjectManager: GabrielaD.Capille

ProductionProjectManager: NirmalaArumugam

Designer: AlanStudholme

TypesetbyVTeX

TomywifeFatemeh, mydaughterKousar, andmysonKiarash.

AliKoochi

ToO.B.

ForO.B.wasaninspiringfriendeventhoughwe’venevermet. O.B.knewthesecretsofseasons, Andlivesfaraway,whereonemightmisshome.

...Ifallthesereasonsarenotenough,IwilldedicatethebooktoKOOCHIfromwhom O.B.grew... AndsoIcorrectmydedication:ToO.B.whenO.B.wasKOOCHI. MohamadrezaAbadyan

Preface ix Acknowledgments xi

1.Differentialequationsinminiaturestructures1

1.1. Introductiontominiaturestructures1

1.2. Physicsofsmall-scalestructures4

1.3. Modelingofsmall-scalestructures17

1.4. Conclusion 26 References 26

2.Semianalyticalsolutionmethods31

2.1. Introduction31

2.2. Homotopyperturbationmethod31

2.3. Adomiandecompositionmethods43

2.4. Green’sfunctionmethods63

2.5. Differentialtransformationmethod77

2.6. Variationiterationmethods84

2.7. Galerkinmethodforstaticproblems90

2.8. Conclusion100 References 100

3.Numericalsolutionmethods107

3.1. Introduction107

3.2. Generalizeddifferentialquadraturemethod107

3.3. Finitedifferencemethod124

3.4. Finiteelementmethod136

3.5. Conclusion156 References 156

4.Dynamicandtime-dependentequations161

4.1. Introduction161

4.2. Reduced-orderapproaches161

4.3. Runge–Kuttamethod195

4.4. Homotopyperturbationmethodfortime-dependentdifferentialequations217

4.5. Energybalancemethod227

4.6. Methodofmultiplescales237

4.7. Conclusion248 References 248 Index 253

Preface

Introduction

Withthenewadvancesinmicro-andnanotechnology,ultrasmallstructureshave beenincreasinglyconsideredinvariousengineeringandsciencebranches.In-depth knowledgeoftheminiaturestructuresundervariousphysicalphenomenacan significantlyreducethetimeandcostofdesigning,developing,andoptimizingthese structures,comparedtorepetitivefabricationandtestinginthelaboratory.

Thepurposeofthisbookistobringtogetherthevariousconcepts,methods, andtechniquesneededtoattackandsolveawidearrayofproblems,including modeling,simulation,analysis,anddesignofsmall-scalestructuressuchasmicro-and nanoelectromechanicalsystems(NEMS/MEMS).

Generally,accuratemodelsarecrucialfornanostructuredesignandanalysisdue tothehighcostsandcomplexityofexperimentalsetupsandfabricationprocesses. Ontheotherhand,reliablesimulationofminiaturesystemsrequiresacomprehensive understandingofthemechanicalbehaviorsofdevices,aswellastheinteractionbetween thesystemandexternalforcefields.Inthisway,newphysicalphenomenawillemergein thecaseofdecreasingthedimensionsofastructurefrommicroscaletonanoscale.The precisesimulationofMEMS/NEMSneedsacomprehensiveknowledgeofnanoscale phenomenaandefficientmethodstoincludetheseissuesinthefinalmodel.The mechanicalperformanceofnanostructurescanbemodeledusingvarioustechniques suchasmoleculardynamics/mechanics,multiscalemodeling,modifiedmechanics models,andthelike.Inthisregard,theuseofnonclassicalcontinuummechanicsis regardedasoneofthepowerfultechniquesformodelingminiaturestructures.The continuummechanicdoesnotrequirecomputationalequipmentasthemolecular dynamicsorab-initiomethodsandprovidessufficientlyaccurateresultsforsimulating nanostructures.However,continuummechanicsusuallyleadstoahighlynonlinear differentialequationthatcannotbesolvedusingconventionaltechniques.

Thisbookattemptstoapplyvariousefficientnumericalandsemianalyticalmethods forsolvingthenonlineargoverningequationsofmicro/nanostructuresthatemerged fromthemodifiedcontinuummechanicsmodels.Theproposedsolutionmethodsare employedtoevaluatethestaticanddynamicbehaviorsofmicro/nanostructuresthrough someappropriateexamples.Tothisaim,wesimulatedvariousstructures,including beamtypeMEMS/NEMS,carbonnanotubeactuators,nanotweezers,nanobridges, plate-typemicrosystems,nanoresonators,androtationalmicromirrors.Thebookalso includesthemodelingprocessneededforsimulatingnumerousnonlinearitiesinmicroandnanostructuresduetophysicalphenomenasuchasdispersionforces,dampingeffect,

nonclassicboundaryconditions,fluid–solidinteractions,electromechanicalinstability, surfaceenergies,nonlocalandsize-dependency.

Thematerialofthecurrentbookisorganizedasfollows.Chapter 1 introduces theessentialconceptsforthemodelingofultrasmallstructuresandexplainsthe physicalphenomenaemergingonthenano-andmicroscale.Chapter 2 discusses somesemianalyticalapproachestosolvenonlineardifferentialequations,inadditionto investigatingthebehaviorofvariousmicro-andnanostructuresbasedonsemianalytical methods.Chapter 3 presentsavarietyofnumericalapproachestosolvethenonlinear differentialequationsforevaluatingthebehaviorofsomemicro-andnanostructures. Finally,Chapter 4 providessomemathematicalapproachestosolvethenonlinearpartial differentialequationdescribingthedynamicperformanceofmicro/nanostructures.

Itshouldbeacknowledgedthatnomatterhowmanytimesthematerialisreviewed andhowmanyeffortsarespenttoguaranteethehighestquality,theauthorscannot ensurethatthemanuscriptisfreefromminorerrorsandshortcomings.Weare lookingforwardtoreceivingeveryone’sfeedbackandcommentsontheerrorsor subjectofthebook.Pleasesendyourcommentstothefirstauthor’semailatthe DepartmentofMechanicalEngineering,UniversityofTorbatHeydarieh,withthe address: A.koochi@gmail.com (AliKoochi).

Audience

Thisbookisacomprehensivetextonnonlineardifferentialequationsinmicroandnanostructures,andithasbeenpreparedforawiderangeofreaders,especially academics,whoneedtolearnhowtosolvenonlinearordinaryandpartialdifferential equations,andprofessionalresearcherswhoinvestigateinthefieldofnanostructuresand NEMS/MEMSmodeling.Theproposedmethodsareappropriateformultidisciplinary researchersinthefieldofmicro/nano-computations.Tobemoreprecise:

• Thebookissuitableforstudentsparticipatinginthecoursesandresearchesonthe nonlineardifferentialequationandanalyticalmethodsinmicro-andnanostructures.

• Thebookcanbeusefulforprofessionals,duetotheconsiderationofdifferent physicalphenomenaandvariousnano/microstructures.

• Thesolutionmethodsofthedifferentialequationsarepresentedpracticallyand straightforwardly.Therefore,thebookwillbesuitableforbothundergraduate andpostgraduatelevels,i.e.,forBachelorstudentsandMaster/PhDstudentsand lecturers.

• Thisbookcanalsobeadaptedforashort-termprofessionalcourseonthesubject matter.Engineersandappliedscienceresearcherswillbeabletodrawuponthe bookinselectinganddevelopingmathematicalmodelsforanalysisanddesign purposesinappliedconditions.

Differentialequationsinminiature structures

1.1.Introductiontominiaturestructures

Today,theapplicationofminiaturestructureshasincreaseddramaticallyinvariousindustriesbecauseoftheincreasingneedforpreciseinstrumentsandextensiveeffortsto reducethevolumeandweightofequipment.Thediminutivesize,lowpowerconsumption,highprecision,andreliabilityofthesesystemsmakethemattractive.Miniature structuresmightrefertomicrostructureornanostructures.The UnitedStatesNational NanotechnologyInitiative definesnanotechnologyas“theunderstandingandcontrolof matteratthenanoscale,atdimensionsbetweenapproximately1and100nanometers”[1].Referringtothisdefinition,ananostructurecanbedefinedasastructure thathasatleastonedimensionintherangeof1to100nm.Becauseananostructuremustbuildfromatomsandmolecules,thelowerlimitisfixedbythesizeofthe moleculesandatoms.Forinstance,thediameterofanH2 moleculeisabout0.25nm, andthefullerene(C60 )ballouterdiameterisabout1nm.Theupperlimitisroughly contractual.However,100nmisapproximatelythesizeatwhichnanoscalephenomena cannotbeobservedorarenegligible.Similarly,amicrostructurecanbedescribedasa structurewithatleastonedimensionsizedfrom1to100micrometers[2].

Microelectromechanicalandnanoelectromechanicalsystems(MEMS/NEMS)are well-knownultrasmallstructureswithbroadapplicationsinscienceandtechnology. ReferringtotheappellationofNEMS/MEMSmightbeasimplewaytorecognize theirmeanings:thefirstpartofMEMSsignifies“micro,”andthefirstpartofNEMS signifies“nano.”Thesetermsspecifytheirscales.HenceMEMSandNEMSaredevices onthe“micro”and“nano”scale,respectively.Thesubsequentpartsaresimilar.The “electro”componentspecifiesthatNEMSandMEMSuseelectronicsorelectricpower. “Mechanical”referstomechanicalactionormotion.The“system”indicatesthatthese devicesareasetofintegratedcomponents,notindividualparts.

NEMSandMEMShavedistinguishedpropertiesanduniquecharacteristics,such aseasyfabrication,highefficiency,lowpowerconsumption,andquickresponse.These devicescanbeutilizedassensorsandactuators.Therearedifferentactuationtechniques, suchasthepiezoelectric,thermal,piezoresistive,optical,electromagnetic,andelectrostaticmethods.Whiletheactuationmethodisdependentupontheapplicationofthe device,electrostaticsisthemostpopularactuatingandsensingmethod[3].

NEMS/MEMSandmicrostructures/nanostructureshavebeenusedwidelyindifferentbranchesofscienceandtechnologyassensorsandactuators.Theapplicationof

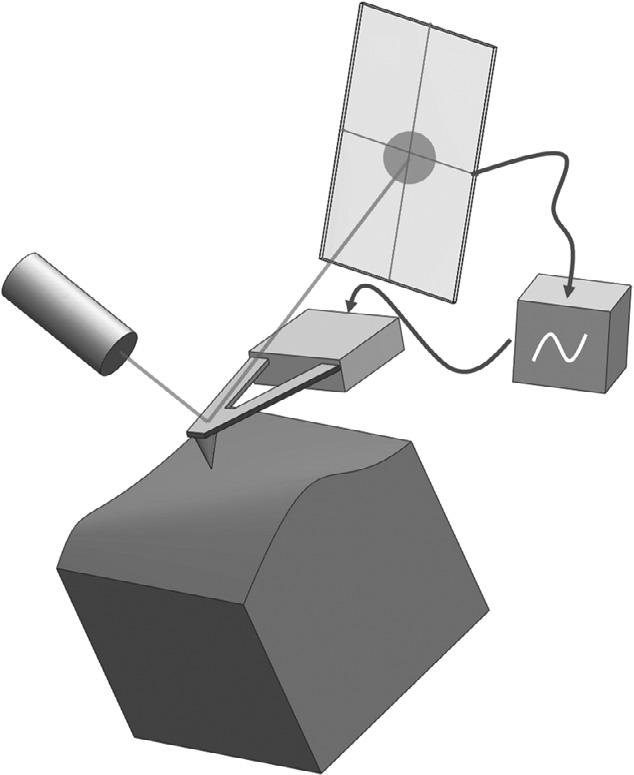

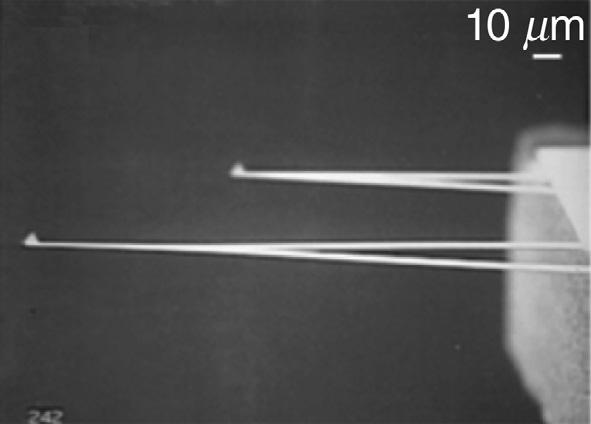

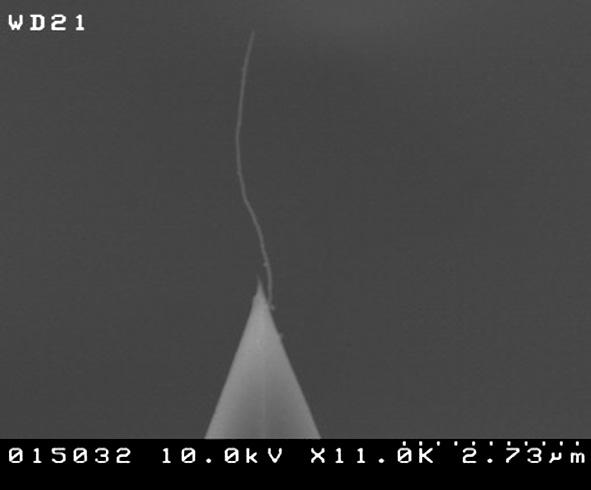

Figure1.1 Atomicforcemicroscopysensor[12]:(A)schematicview,(B)SEMimage.

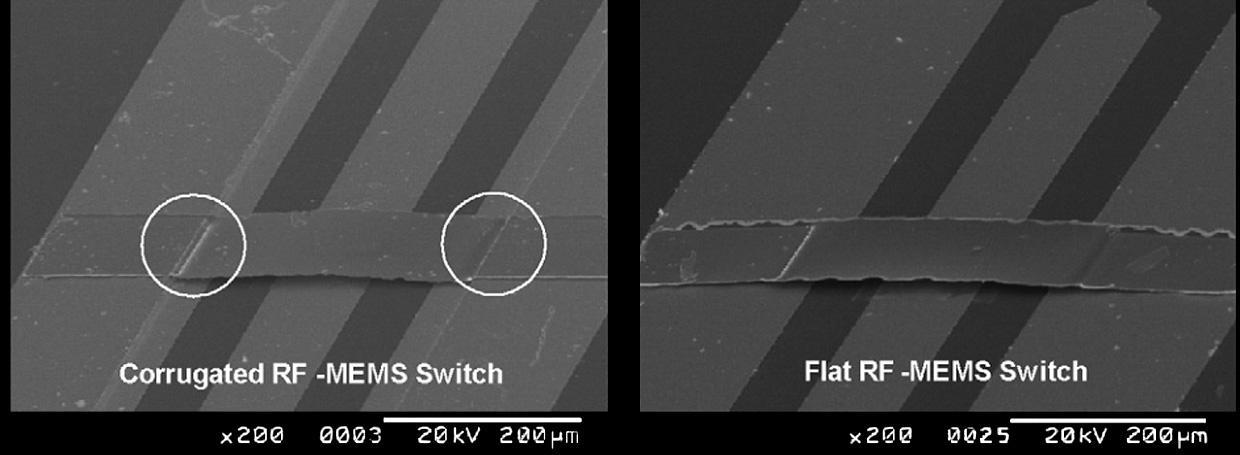

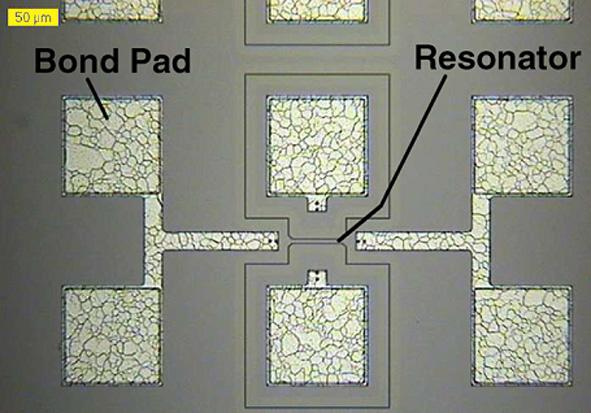

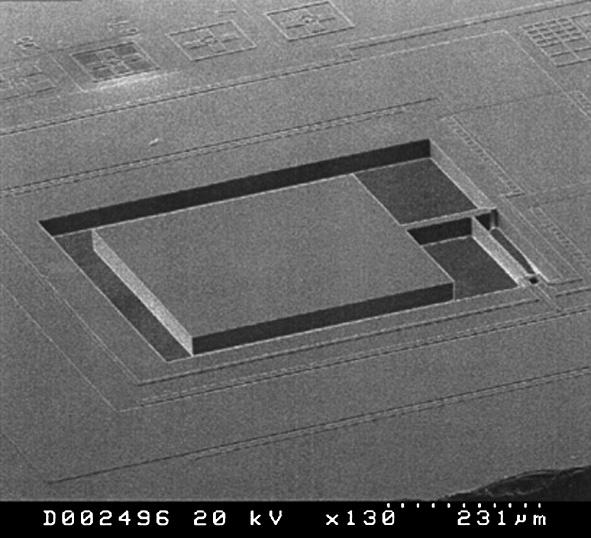

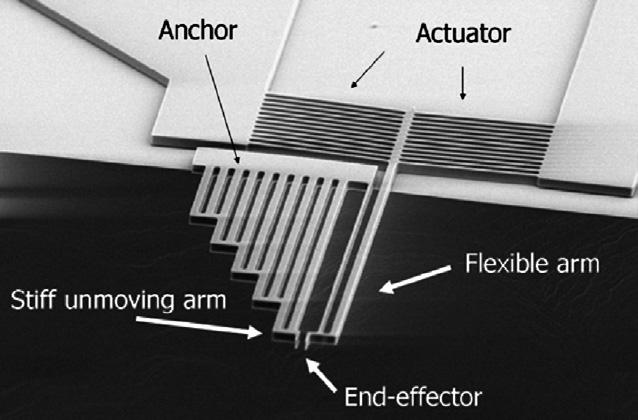

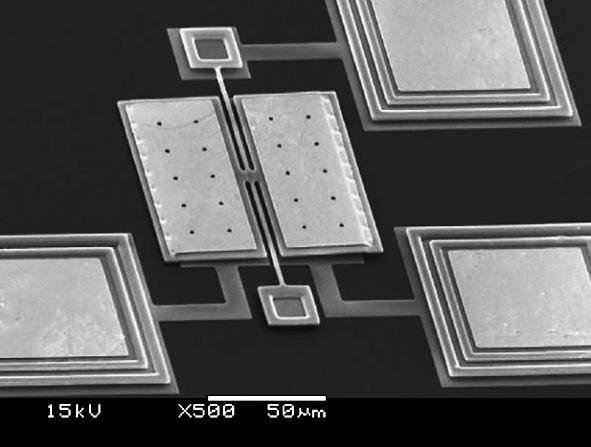

thesesystemsincludes,butisnotlimitedto,atomicforcemicroscopy(AFM)[4],microandnanoswitches[5],micro-andnanoresonators[6],pressuresensors[7],accelerometers[8],micro-andnanotweezers[9],neuronalrecordingsdevice[10],andmicro-and nano-opticalswitches[11].Fig. 1.1 showsthescanningelectronmicroscope(SEM)imageandschematicviewofanatomicforcemicroscope(AFM)sensor.Ascanbeseen, theAFMsensorcanbemodeledasacantilevermicro/nanobeam.TheSEMimageofa radiofrequency(RF)microswitchandamicroresonatorarepresentedinFigs. 1.2 and 1.3,respectively.Aclamped–clampedmicro/nanobeamhungoverafixedsubstratewith adielectricin-betweencanmodelthesestructures.Fig. 1.4 demonstratestheSEMimageofanaccelerometermicrosensor.Thesesensorscanbesimulatedasacantileverbeam withaconcentratedmassonthetip.TheSEMimageofmicrotweezersisillustratedin Fig. 1.5.Thisstructurecanbemodeledasatwoparallelcantilevermicro/nanobeams witharectangular,orcircularcross-sectiondependsonthemanufacturingmethod.

Figure1.2 SEMimageofanRFmicroswitch[13].

Figure1.3 Amicroresonator[6].

Figure1.4 AnMEMSaccelerometersensor[14].

AtypicalopticalswitchisillustratedinFig. 1.6.ThistypeofNEMS/MEMScanbe simulatedasaplatesupportedbytorsionalarms.Acarbonnanotubeprobeusedinthe tipofanatomicforcemicroscopyisshowninFig. 1.7.

1.2.Physicsofsmall-scalestructures

Whendimensionsofasystemarereducedtosubmicronscale,somephysicalaspects appear,whichmaynotexistatthemacroscale.Inthissection,theessentialphysical phenomenaofNEMSandMEMSarediscussed.Theimpactoftheproposedphenomenaontheperformancesofmicro-andnanostructuresarediscussedthroughseveral examplesinthesubsequentsections.

Figure1.5 SEMimageofnanotweezers[15].

Figure1.6 SEMimageofanopticalmicroswitch[16].

Figure1.7 SEMimageofacarbonnanotubeprobe[17].

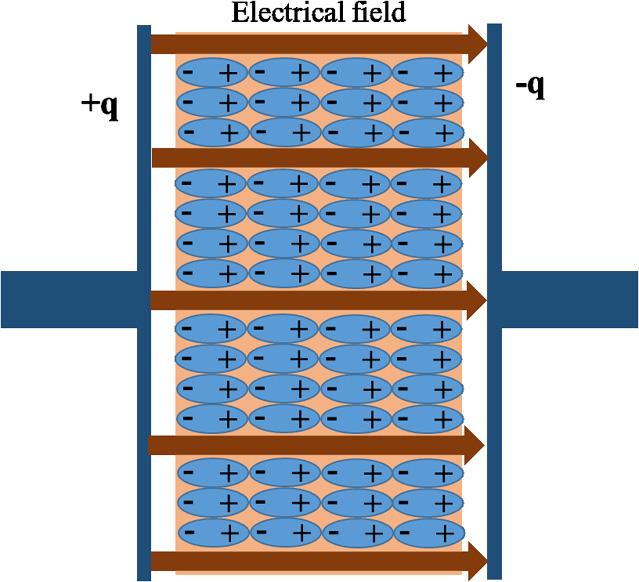

Figure1.8 Theidealelectricfieldbetweenparallelplates’capacitors.

1.2.1Electrostaticactuation

Asmentionedpreviously,electrostaticactuationisthemostpopularactuationmethod inMEMSandNEMS.BecauseawidespreadgroupofNEMSandMEMScanbe consideredasparallelbeamsorplates,theelectricalfieldbetweentwoparallelplates isintroduced.Whenavoltagedifferenceisappliedbetweentwoparallelplates,the platesconstructacapacitor.Theelectricalforceactingonthepartscanbeachieved bydifferentiatingthestoredpotentialenergyofthecapacitor.Fortwoinfiniteparallel plates,theelectricalfieldisuniform,asshowninFig. 1.8.Forthisidealcase,the capacitanceoftwoparallelplatesisdirectlyproportionaltotheplates’areaandinversely proportionaltotheseparationordistancebetweentheplates.Hence,thecapacitance canbeformulatedas[18]

where ε isthepermittivityofvacuum.Theelectricalenergyperunitlengthisdeterminedas

Therefore,theelectricalforcebetweentwoinfiniteparallelplatesisachievedas

TheelectricalforceexplainedinEq.(1.3)isfortwoinfiniteparallelplates.Inthisequation,theelectricalfieldisassumedtobeideallyuniform,andtheeffectoftheplate’s

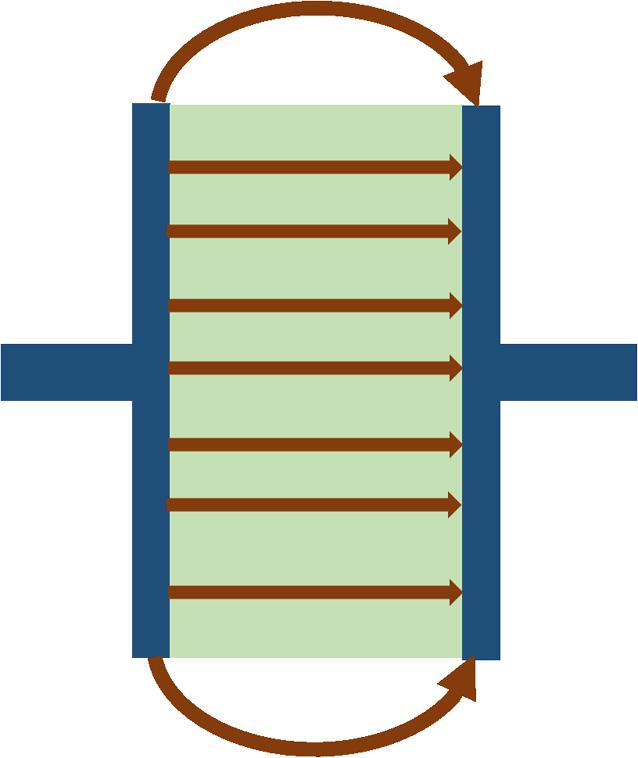

Figure1.9 Fringingfieldeffectinparallelplates’capacitors.

thicknessisneglected.However,forafiniteplate,theimpactofthenonuniformelectricalfieldintheedges(i.e.,flingingfield)mightaffectthecapacitance(seeFig. 1.9). Toincorporatethefringingfieldinthesimulationoftheelectricalforce,severalmodifiedmodelshavebeendeveloped.Forafiniteplate(beam)withthickness h,width b, andlength L ,paralleltoaninfiniteplateatdistance g ,themodelsforcapacitanceby consideringfringingfieldeffectaresummarizedinTable 1.1.

1.2.2Pull-ininstability

NEMSandMEMSarewidelyappliedassensorsandactuators.WhiledetectionmethodsrequireforNEMS/MEMSsensors,theactuationtechniquesareessentialinthe applicationofNEMS/MEMSasactuators.Asensingordetectionmethodisatransforminaphysicalquantitysuchasforce,pressure,acceleration,ortemperatureinto ameasurableelectricalsignal.Conversely,anactuationmethodisthetransformation ofelectricalpotentialtothemechanicalmovement,whichcanbeusedformotion, applyingforce,andswitching.Therearedifferentsensingandactuationtechniquesin NEMSandMEMS,includingelectro-thermal[26,27],electromagnetic[28,29],electrostatic[30,31],piezoelectric[32,33],andpiezoresistive[34,35]methods.Whilethe actuationmethodstronglydependsonthepracticalapplicationofthedevices,theelectrostaticactuationschemeisthemostcommonlyusedinMEMSandNEMSbecause ofitsnumerousinherentbenefits[3].However,thismechanismresultsinhighlynonlinearinstabilitybehaviorcalled“pull-ininstability.”Theelectricvoltageactsonan NEMS/MEMS,leadingtoanelectrostaticforcefollowedbythedeflectionofthemoveablecomponentsintoanewequilibriumposition.Theelectricalforcehasanupper

Table1.1 Capacitancemodelsbyconsideringthefringingfieldeffect. ModelCapacitanceperunitlength

Palmer[19]

Chang[20]

YuanandTrick[21]

SakuraiandTamaru[22]

VanderMeijsandFokkema[23]

Elliott[24]

Batraetal.[25]

c0 =−5 40

c1 = 4 60

c2 = 0 325

c3 = 0 126

c4 =−0.554

c5 =−0.00388

c6 = 0.891

c7 = 3.47

c8 = 0.118

Batraetal.[25] C = ε b g + c0 + c1 b g c2 + c3 h g c4

c0 =−0.36

c1 = 0.85

c2 = 0.2

c3 = 2.5

c4 = 0 24

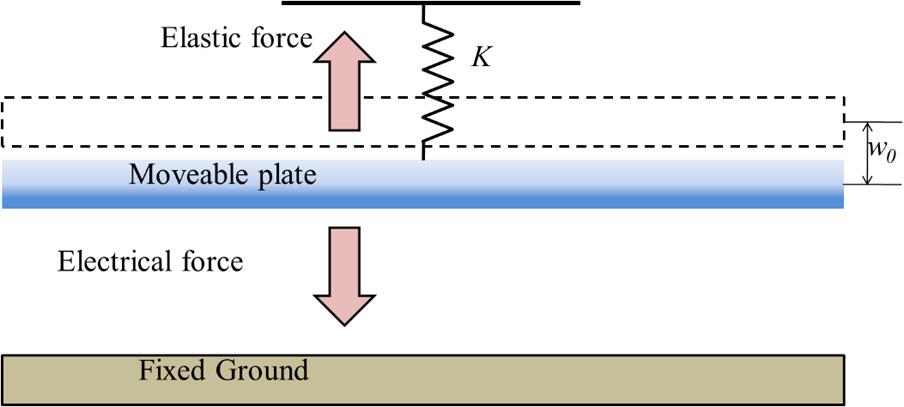

Figure1.10 Aparallelplatecapacitor(theupperplatehungbyaspring).

limit.Iftheelectricalforcepassesthislimit,itovercomesthemechanicalresistance, therebyincreasingthemoveablecomponentdeflection.Accordingly,theelectrostatic forceisenhancedinapositiveloop.Thisphenomenonisknownas“pull-in,”andits pertinentvoltageisknownasthe“pull-involtage”[36].Sometimesthepull-inphenomenonistheessentialaspectfortheproperperformanceofNEMS.Forexample,the pull-ininstabilityorganizesthebasisoftheRFswitchoperation[37,38].Conversely, thekeypointinthedesigningofmicronanoresonatorsandmicromirrorsareavoiding thepull-inphenomena[39,40].

Toexplainthisphenomenonmoreclearly,consideraparallelplatemicrocapacitor. Thisstructurecanbeconsideredasamovableplatehungoverafixedgroundbya spring,asdemonstratedinFig. 1.10.Itshouldbenotedthatthissimplemodel,known asthe“lumpedparametermodel,”issometimesusedtomodelthebehaviorofbeamtypeMEMSandNEMS[41].Thelumpedparametermodelisdiscussedindetailin Section 1.3.1.Theplate’sareaisassumedtobe0.16mm2 ,theinitialgapbetweenthe platesis4 µm,andthespringconstantis0.816N/m.Byapplyingthevoltagedifference betweentwoplates,themoveableplatemovestowardthefixedoneuntiltheelectrical forceisequaltothespringforce.Theelectricalandspringforcesfordifferentvalues ofexternalvoltageareplottedinFig. 1.11.Theinteractionpointbetweentheelectricalandspringforcesistheequilibriumpoint.Whentheappliedvoltageislowerthan thepull-invalue,therearetwoequilibriumpoints(Fig. 1.11A–B);byincreasingthe appliedvoltage,thespringforceistangenttotheelectricalforceatthepull-involtage (Fig. 1.11C).Iftheappliedvoltagerisesmore,thereisnointersectionbetweenthe electricalandspringforces.Inotherwords,theelectricalforceisalwayshigherthanthe springforce.Therefore,thespringforcecannotovercometheelectricalforce,andthe upperplatefallstothefixedground,i.e.,instabilityoccurs.

ItisworthnotingthatwhentheDCvoltageleadstopull-in,theinstabilityiscalled “staticpull-in”orjust“pull-in.”However,inthecaseofACloadingortransientDC voltage,theinstabilityisknownas“dynamicpull-in”[42].

Figure1.11 Electricalandspringforcesfordifferentappliedvoltages:(A) V = 2volts;(B) V = 3volts; (C) V = 3 3057volts(pull-in);and(D) V = 3 4volts.

Figure1.11 continued

1.2.3Dispersionforces

Thedispersionforcesaretheforcesthatactlikegravitybetweenallatomsandmolecules, evenbetweentwounchargedbodiesinavacuum.LifshitzdevelopedthecohesivetheoryofthevanderWaalsandCasimirforcesassubdivisionsofdispersionforces[43]. Basedonthistheory,thedispersioninteractionbetweentwoparallelplatesisrelatedto thefrequency-dependentdielectricpermittivitiesandmagneticpermeabilitiesofplates’ materials.Whenthedistancebetweenthebodiesissmallerthantheretardationlength, thevanderWaalsforceshouldbeconsidered.ThevanderWaalsattractionbetween twoinfiniteparallelplatesisproportionaltotheinverse-cubeofthedistancebetween theplates[44].ThevanderWaalsattractionperunitareabetweentwoidealparallelflat platesisdefinedas[45]

where g isthedistancebetweentheplatesand A istheHamaker’sconstant.

AnappropriatemethodforcalculatingthevanderWaalsforcebetweentwoarbitrary bodiesistoemploytheLennard-Jonespotential,whichexpressesthepotentialbetween twoatomsas

where C12 istherepulsiveconstant, C6 istheattractiveconstant,and rij isthedistance oftheatoms.Fordistancesgreaterthan3.4Å,therepulsivetermisnegligibleincomparisonwiththeattractiveterm.Areliablecontinuummodelhasbeenestablishedto computethevanderWaalsenergyusingthedouble-volumeintegraloftheLennard-

Jonespotential,whichis[46]

where υ1 and υ2 representthetwodomainsofintegration,and ρ1 and ρ2 arethedensitiesofatomsinthesedomains.Thedistancebetweenanytwopointson υ1 and υ2 is r (υ1 ,υ2 )

AnothersubdivisionofdispersionforceistheCasimirforce.Thisforceactsatlarger separationsthanthevanderWaalsforce.Indeed,whentheseparationbetweenthe twobodiesisgreaterthantheretardationlength,theCasimirforceisdominant.The Casimirattractionperunitareabetweentwoparallelconductingplatesisnotaffectedby thematerial’spropertiesandisproportionaltotheinversefourthpowerofdistance.For twoinfiniteconductingparallelsseparatedbyadistance, g theCasimirforceisdefined as[47]

where c = 2.9979 × 108 m/sisthelightspeedand h = 1.0546 × 10 34 J.sisthereduced Planck’sconstant.

1.2.4Sizedependency

Experimentalobservationdemonstratedthatthestiffnessofmetal-basedultra-small structuresisscale-dependent.Forexample,empiricalobservationofthebendingof nickelmicrobeamscarriedoutbyStolken,andEvans[48]confirmedthatwhenthe beamthicknessdecreases,themicrobeamplasticworkhardeningisenhancedconsiderably.Flecketal.[49]investigatedthetorsionalhardeningofcopperwires.Theydetected thehardeningofa12-µmdiameterwiretobeaboutthreetimesgreaterthanthehardeningofasimilar170-µmdiameterwire.Thisphenomenonhasalsobeendiscovered insomepolymers.ChongandLam[50]demonstratedthatadecreaseinthethickness ofepoxybeamsresultsintheenhancementoftheirnormalizedbendingstiffness.They determinedthatthebendingrigidityofanepoxybeamwitha20-µmthicknessisabout 2.4timesgreaterthanthebendingstiffnessofasimilarbeamwitha115-µmthickness. McFarlandandColton[51]evaluatedthestiffnessofpolypropylenemicrocantilevers anddeterminedittobeatleastfourtimesgreaterthanthevaluesexpectedwiththe classicalelasticitytheory.Thissize-dependentbehaviorofmaterialsandstructurescannotbesimulatedthroughclassicalcontinuumelasticity.Tobridgethegapbetweenthe theoreticalsimulationandtheexperimentalresults,varioussize-dependentcontinuum theorieswereproposed.

In1962,Mindlindevelopedthecouplestresselasticitytheoryforsimulatingthe scale-dependentbehaviorofminiaturestructures[52].Forthispurpose,ahigher-order

Figure1.12 Simpleillustrationofincreasingthesurfacetovolumeratiobyreducingthesize.

stresstensor(i.e.,couplestresstensor)wasintroducedinadditiontotheclassicalstress tensor.Thecouplestresstensorcomponentswereexpressedintermsofthegradientof elementsrotationandnewmaterialconstants,whichwerepertinenttotheconventional materialconstantsbythemateriallengthscale.Yangetal.[53]modifiedtheMindlin couplestresstheory.Theydevelopedthecouplemomentsequilibriumratherthanclassicalforcesandmomentsequilibrium.Thisadditionalequilibriumconditiondictated thatthecouplestresstensormustbesymmetric.Thereby,twomateriallength-scaleparametersofageneralcouplestresstensorwerereducedtoonematerialparameterinthe modifiedcouplestresstensor.

ThemostcomprehensivestraingradientmodelwasexpressedbyMindlin[54].This theoryincludesfiveaddedmaterialparameters,andtheotherstraingradienttheories canextractfromtheMindlingeneralstraingradienttheoryLametal.[55]expressed amodifiedstraingradient.Theydecomposedthesecond-orderdeformationgradient tensorintothestretchgradienttensorandtherotationgradienttensor.Thisdecompositionreducedthemateriallength-scaleparameterfromfiveinthegeneralstraingradient theorytothreeinthemodifiedstraingradienttheory.

Eringendevelopsthenonlocaltheoryinthe1970s[56].Intheclassicalorlocal continuummechanics,thestressateachpointdependsonthestrainsatthatpoint.In contrast,inthenonlocalcontinuummechanic,thestressatareferencepointinthe domaindependsnotonlyonthestrainsatthatpointbutalsoonthestrainfieldatevery pointinthebody.Inthisregard,scale-dependentparameters(internalcharacteristic length)appearintheconstitutiveequationswhichcansimulatethesizedependencyof theminiaturestructures.

1.2.5Surfaceeffects

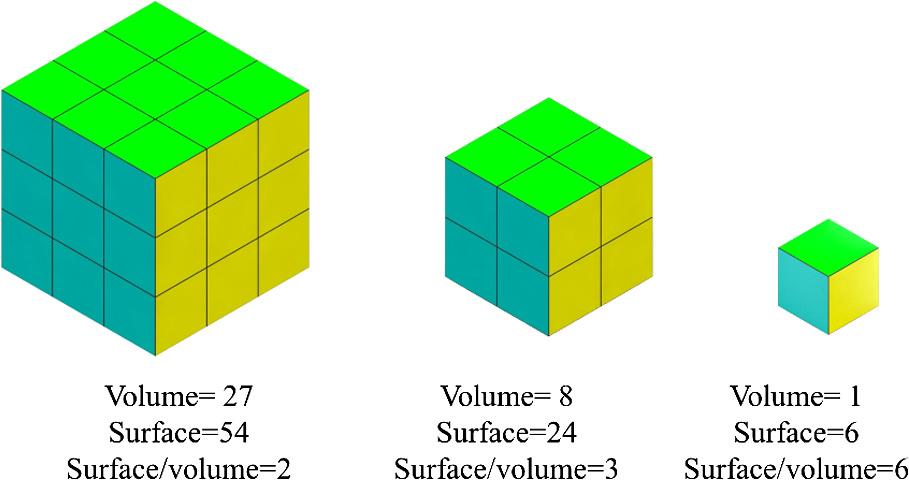

Reducingthestructuresizeenhancesitssurfacearea-to-volumeratio.AsimpledemonstrationoftheenhancementofthesurfacetovolumerationisillustratedinFig. 1.12.As seenbyreducingthevolumefrom9tooneunit,thesurfacetovolumeratioincreases from2to6.Toclarifythisfact,thesurface-to-volumeratioasafunctionofthebasicdi-

Figure1.13 Surface-to-volumeratioasafunctionofbasicdimension.

mensionisillustratedinFig. 1.13.Thisfiguredemonstratesthatthesurface-to-volume ratioofa1nmwidthcubeis109 timesgreaterthanthesurface-to-volumeratioofa 1mwidthcube.Thesamecanbeobservedforananoscalesphere.

Formechanicalelementswithahighsurface–volumeratio,thesurfaceenergiescan significantlyaffecttheirmechanicalproperties.Tosimulatethesurfaceenergies,the moleculardynamicmethodcanbeemployed.However,thismethodishighlytimeconsumingandrequireshigh-performancecomputers.Toovercometheinefficiencyof themoleculardynamicsprocedureforstructures,thesurfaceelasticitytheorydeveloped byGurtinandMurdoch[57]canbeemployed[58].Itiscapableofsimulatingboththe residualsurfacestressandthesurfaceelasticity.

1.2.6DampinginNEMS/MEMS

TheresourcesforenergydissipationinNEMS/MEMScanbeclassifiedintointrinsic andenvironmentaleffects.Theintrinsicenergylossresourcesincludethermoplasticdampingandsurfacephononscattering.Also,themostcommonenvironmental resourcesofenergylossinNEMSandMEMSareanchors,acoustic,andviscousdamping[36].Intheultrasmallstructures,theintrinsicenergylossisnegligibleincomparison withtheexternalresources.Nevertheless,theintrinsiceffectshouldbeconsideredwhen achievingahigh-qualityfactorisdesired.Todeterminetheeffectofallenergydissipationresources,eachsourcecanbedefinedintermsofacorrespondingqualityfactor (Qi ).Thetotalqualityfactorisgivenby

Table1.2 Parameter α inEq.(1.10)[36].

BoundaryconditionVibratingmode

Thequalityfactorhasaninverserelationshipwiththedampingratio(ξ )andtheenergy lossofthesystem.Therefore,ahigherqualityfactorindicatesalowerrateofenergyloss relativetothestoredenergy.Incontrast,alowerqualityfactorindicatesahigherrateof energylossrelativetothestoredenergy:

Energylossinthesupportsinknownasanchorloss.Thislossisduetouncanceledshear forcesandmomentsintheendsupports.Amongthese,theshearforceshaveamore dominanteffectonenergyloss.Therefore,byneglectingtheimpactoftheuncanceled moment,thequalityfactorforcantileverandclampedbeamsisgivenby[59]

where L isthebeamlength, h isthebeamthickness,and α isaparameterthatdepends ontheboundaryconditions,modeofvibration,andPoisson’sratio.Theparameter α forcantileverandclampedboundaryconditionbyconsideringthePoisson’sratioequal to0.28isdemonstratedinTable 1.2.

1.2.6.1Dragforce

Dragforceactingistheresistanceforceoppositetotherelativemotionofabodymoved throughthefluid.Inmicro-andnanostructures,thedragforcemightresultinenergyloss.Therefore,thedragforcecanbeconsideredasadampingresource.Some researchersinvestigatedthedragforceofcomplexsystemsbydividingthemintosimple shapes.Forexample,thebeamhasbeensimulatedasaseriesofspheres,andthesphere dragforceisusedtofindthedragforceoverabeam[60,61].Byneglectingtheeffectof addingmass,thedragforceoveraspherewithradius R andvelocity u isgivenby

Intheaboveequation,thedampingcoefficientofasphereforthefrequency ω isdefined as

Figure1.14 Squeezedfilmbetweentwoplates.

where μ isthefluidviscosityand ρ isthefluiddensity.Also,abeamcanbesimulated asastringofdisheswiththediameterofthedishesequaltothewidthofthebeam.By usingthisapproach,Bao[62]determinedthedampingcoefficientofabeamequalto 8μ

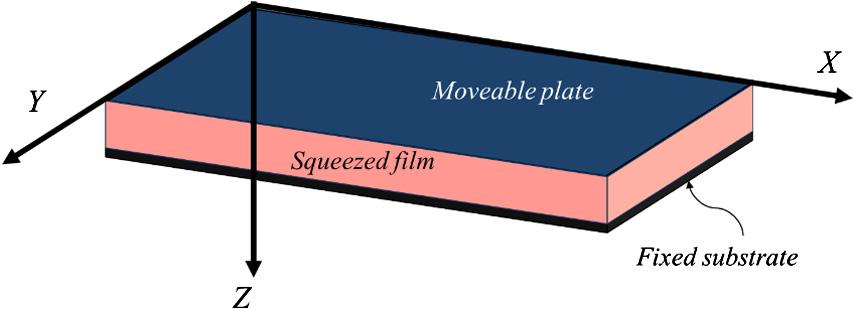

1.2.6.2Squeezedfilmdamping

Thedynamicofsmallpartsinanultrasmallsystemcanbeaffectedbythemovement ofthefluidtrappedunderneaththeplate,whichisknownassqueezedfilmdamping (seeFig. 1.14).ForNEMS/MEMSwithamoveableplate,squeezefilmdampingcan affectthesystemfrequencyresponse.Squeezefilmdampingisthemostcommonand dominantenergylossmechanisminNEMS/MEMS.Ingeneral,thedynamicofthe squeezefilmisgovernedbybothviscousandinertialeffectsonfluid.However,for ultrasmallstructures,theinertialeffectcanbenegligible.Insuchacase,assumingideal gaslawandisothermalconditions,thebehaviorofaNewtonianfluidcanbeexpressed bytheReynoldsequationas

where P isthepressure, m istheviscosity, t isthetime,and g indicatestheseparation betweenthemoveableandfixedplate.Itshouldbenotedthatthevariationofpressure acrossthefilmthickness(i.e., Z direction)isignoredinderivingtheReynoldsequation.

NEMS/MEMSmightoperateinlow-pressureconditions.Inthissituation,thefluid cannotconsiderasacontinuum.Therefore,Eq.(1.13)mightnotpredictthebehavior ofsqueezedfilmcorrectly.However,bymodifyingtheviscosity,moreaccurateresults canbeachievedfromEq.(1.13).Variousmodelshavebeenproposedfor“effective viscosity,”whichdependsdirectlyontheKnudsennumber.Somemodelsforeffective viscosityarepresentedinTable 1.3

Forincompressiblegas,thederivativeofpressurewithrespecttotimeiszero.Also, forbeamtypeNEMS/MEMS,thelengthofthebeamisconsiderablymoresignificantthanthebeamwidths.Therefore,thepressureinthelongitudinaldirection(x)