https://ebookmass.com/product/nanotechnology-applications-

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Nanotechnology in the Agri-Food Industry: Food Packaging 1st Edition Alexandru Grumezescu

https://ebookmass.com/product/nanotechnology-in-the-agri-foodindustry-food-packaging-1st-edition-alexandru-grumezescu/ ebookmass.com

Food Safety and Preservation: Modern Biological Approaches to Improving Consumer Health First Edition Alexandru Mihai Grumezescu

https://ebookmass.com/product/food-safety-and-preservation-modernbiological-approaches-to-improving-consumer-health-first-editionalexandru-mihai-grumezescu/ ebookmass.com

Handbook of Food Bioengineering, Volume 5 : Microbial Production of Food Ingredients and Additives 1st Edition Alexandru Grumezescu

https://ebookmass.com/product/handbook-of-food-bioengineeringvolume-5-microbial-production-of-food-ingredients-and-additives-1stedition-alexandru-grumezescu/ ebookmass.com

Narrative Policy Analysis 1st ed. Edition R.A.W Rhodes

https://ebookmass.com/product/narrative-policy-analysis-1st-ededition-r-a-w-rhodes/ ebookmass.com

The Hand and the Heart: A Friends to Lovers Fantasy

Romance (The Darkwood Cycle | The Book of All Things 2)

Sarah M. Cradit & The Book Of All Things & Kingdom Of The White Sea

https://ebookmass.com/product/the-hand-and-the-heart-a-friends-tolovers-fantasy-romance-the-darkwood-cycle-the-book-of-allthings-2-sarah-m-cradit-the-book-of-all-things-kingdom-of-the-whitesea/ ebookmass.com

A Dictionary of Oil & Gas Industry Terms, 2nd Edition

Peter Roberts

https://ebookmass.com/product/a-dictionary-of-oil-gas-industryterms-2nd-edition-peter-roberts/

ebookmass.com

Lobstah Gahden: Speak out against pollution with a wicked awesome Boston accent! Alli Brydon

https://ebookmass.com/product/lobstah-gahden-speak-out-againstpollution-with-a-wicked-awesome-boston-accent-alli-brydon/

ebookmass.com

Life Hereafter: The Rise and Decline of a Tradition 1st Edition Paul Crittenden

https://ebookmass.com/product/life-hereafter-the-rise-and-decline-ofa-tradition-1st-edition-paul-crittenden/

ebookmass.com

Corbin's Concepts of Fitness And Wellness: A Comprehensive Lifestyle Approach ISE 13th Edition Charles B. Corbin

https://ebookmass.com/product/corbins-concepts-of-fitness-andwellness-a-comprehensive-lifestyle-approach-ise-13th-edition-charlesb-corbin/

ebookmass.com

Stealing Into Print: Fraud, Plagiarism, and Misconduct in

Publishing Marcel C. Lafollette

https://ebookmass.com/product/stealing-into-print-fraud-plagiarismand-misconduct-in-scientific-publishing-marcel-c-lafollette/

ebookmass.com

NanotechnologyApplicationsinFood Thispageintentionallyleftblank

NanotechnologyApplications inFood Flavor,Stability,NutritionandSafety EditedBy

AlexandraElenaOprea

DepartmentofScienceandEngineeringofOxideMaterialsandNanomaterials FacultyofAppliedChemistryandMaterialsScience UniversityPolitehnicaofBucharest,Romania

AlexandruMihaiGrumezescu

TheResearchInstituteoftheUniversityofBucharest-ICUB,Romania

AcademicPressisanimprintofElsevier

125LondonWall,LondonEC2Y5AS,UnitedKingdom

525BStreet,Suite1800,SanDiego,CA92101-4495,UnitedStates

50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom

Copyright © 2017ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicormechanical,including photocopying,recording,oranyinformationstorageandretrievalsystem,withoutpermissioninwritingfromthepublisher. Detailsonhowtoseekpermission,furtherinformationaboutthePublisher’spermissionspoliciesandourarrangements withorganizationssuchastheCopyrightClearanceCenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher(otherthanasmaybe notedherein).

Notices

Knowledgeandbestpracticeinthis fieldareconstantlychanging.Asnewresearchandexperiencebroadenourunderstanding, changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusinganyinformation, methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationormethodstheyshouldbemindfuloftheir ownsafetyandthesafetyofothers,includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeanyliabilityforanyinjury and/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceorotherwise,orfromanyuseoroperation ofanymethods,products,instructions,orideascontainedinthematerialherein.

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

ISBN:978-0-12-811942-6

ForinformationonallAcademicPresspublicationsvisitour websiteat https://www.elsevier.com/books-and-journals

Publisher :NikkiLevy

AcquisitionEditor :PatriciaOsborn

EditorialProjectManager :SarahJaneWatson

ProductionProjectManager :PaulPrasadChandramohan

Designer :VictoriaPearson

TypesetbyTNQBooksandJournals

B.N.Estevinho,F.Rocha

4.StrategicDesignofDeliverySystems forNutraceuticals

S.Lee

6.Nanoemulsions:ANewApproach forEnhancingPhytonutrient Efficacy

D.M.Mostafa,S.H.AbdEl-Alim,A.A.Kassem

Phytosomes

7.TechnologicalAspectsof NanoemulsionsandTheir ApplicationsintheFoodSector

A.Saxena,T.Maity,A.Paliwal,S.Wadhwa

1.Introduction 129

2.CompositionofNanoemulsion 130

2.1OilPhase 130

2.2AqueousPhase 131

2.3Stabilizer 132

3.FormationofNanoemulsion 132

4.SynthesisMethodsofNanoemulsions 133

4.1High-EnergyApproaches 133

4.2Low-EnergyApproaches 135

5.PropertiesofNanoemulsions 137

5.1StabilityofNanoemulsions 137

5.2RheologicalProperties 138

5.3OpticalProperties 138

6.CharacterizationTechniquesfor Nanoemulsions 138

6.1SeparationTechniques 138

6.2PhysicalCharacterization Techniques 139

6.3ImagingTechniques 140

7.ApplicationofNanoemulsionsinFood Industries 140

8.Nanoemulsion-BasedEncapsulation andDeliverySystems 141

9.Nanoemulsion-BasedCoatings/Films 143

10.AntimicrobialNanoemulsions 144

11.ToxicologyandRiskAssessment 144 12.Conclusions 146 References 146

8.PolyhydroxyalkanoatesintheFood PackagingIndustry

F.Masood

1.Introduction 153

2.BiosynthesisofPHAs 155

3.CommercialGrowthofPHAs 156

4.PropertiesofPHAs 159

4.1ThermalProperties 159 4.2Crystallinity 159

4.3MechanicalProperties 160 4.4Permeability 160 4.5Migration 160

4.6Degradability 161

5.PHABlends/Composites 161

5.1PHA/PLABlends 161

5.2PHA/PBSBlends 163

5.3PHA/PolyolefinBlends 164

6.4PHAs/CFs 169

6.5PHA/SiO2 Nanocomposites 169

7.PHAsforPaperCoating 169

8.PHA-BasedMultilayerFilms 170

9.PHA-BasedActiveFoodPackaging 170 10.ExamplesofPHAUsesinFood Packaging 171

11.Conclusions 171

12.FutureProspects 171 References 171

9.Nano-deliverySystemsfor NutraceuticalApplication

K.A.Ishak,M.S.MohamadAnnuar,N.Ahmad 1.Introduction 179

2.BioactiveFoodComponentsfor Encapsulation 181

3.StrategyforEnhancingOral BioavailabilityofNutraceutical 181

3.1DeterminationofBioactiveFood ComponentsCategory 183

3.2DesigningFoodMatrixforOral Consumption 183

3.3SelectionofNanoparticle-Based DeliverySystem 184

4.EngineeredNanoparticle-Based DeliverySystem 184

4.1DifferentTypesof Nanoparticle-BasedDelivery System 185

4.2DevelopmentofaNanoparticleBasedDeliverySystem 189

4.3Characterizationofa Nanoparticle-BasedDelivery System 192

5.EvaluatingOralBioavailabilityof Nutraceutical 193

5.1GastrointestinalIngestion 194

5.2Absorption 195

5.3DistributionandMetabolism 195

5.4Excretion 196 6.Conclusions 196 Acknowledgment 196 References 196

10.NanoemulsificationTechnologyin ImprovingBioavailabilityof LipophilicFunctionalFood-Grade IngredientsandQualityofFood Products

S.Maiti

1.Introduction 203

2.EffectsofFoodMatrixComponents onBioavailability 205

3.BioavailabilityandFoodQuality 207

4.BiologicalFateandToxicity

11.NanoantimicrobialsinFood Industry

H.Hosseini,S.Shojaee-Aliabadi, S.M.Hosseini,L.Mirmoghtadaie

1.Introduction

2.NanoantimicrobialAgents 224

2.1InorganicNanostructured Materials 224

2.2OrganicNanostructuredMaterials 228

3.FoodAntimicrobialNanocarriers 229

3.1Nanoemulsions 229

3.2Nanoliposomes 231

3.3Nanoparticles/BiopolymerBased Nanocarriers/Colloidal Nanocarriers 233

3.4AntimicrobialNanocomposite Packaging 233

3.5AntimicrobialNanoliposomeand NanoemulsionEmbeddedInto FilmsandCoatings 235

4.ApplicationofNanoantimicrobials inFoods 235

4.1FruitsandVegetables 235

4.2DairyProducts

5.Conclusions

12.NanotechnologyinMicrobialFood Safety

C.S.Ranadheera,P.H.P.Prasanna, J.K.Vidanarachchi,R.McConchie, N.Naumovski,D.Mellor

1.Introduction

2.1FoodProcessingandPreservation 247

2.2BiofilmandMicrobial FoodSafety 249

2.3Nano-encapsulation 250

3.ApplicationsofNanotechnology inFoodPackaging 250

3.1NanomaterialsasBarriers 250

3.2NanopackagingMaterialsWith AntimicrobialProperties 252

4.UseofNanotechnologyand NanosensorstoDetectFoodBorne Pathogens

4.1 Escherichiacoli O157:H7

4.3 Listeriamonocytogenes 256

4.4 Mycobacteriumavium Subsp. paratuberculosis 257

4.5 Staphylococcusaureus 257

4.6 Vibrioparahaemolyticus 257

4.7Mycotoxins 258

4.8OtherPathogenicMicrobes 258

5.SafetyIssuesofNanotechnology 258

6.Conclusions 260 References 260

13.RecentAdvancesinMolecular TechniquesfortheDiagnosisof FoodborneDiseases

B.Bal,S.Nayak,A.P.Das

1.Introduction 267

2.FoodPathogens 268

3.SectorsDemandingFoodPathogen DetectionandControl 270

4.DifferentMethodsofFoodPathogen Detection 271

4.1ConventionalMethods 272

5.AdvancedMolecularTechniquesfor FoodPathogenDetection 275

6.Biosensors 275

6.1SurfacePlasmonResonance Biosensors 276

6.2OpticalBiosensors 276

6.3PiezoelectricBiosensors 276

6.4Cell-BasedBiosensors 276

6.5AmperometricBiosensors 277

6.6MicrobialMetabolism Based Biosensors 277

6.7DNA-BasedBiosensors 277

6.8Impedimetricand ConductimetricBiosensors 278

6.9Potentiometry,FET,andLAPS forPathogenDetection 278

6.10MultiplexPCRAssay

7.CommercializationofBiosensors

14.IntelligentSystemsintheFood PackagingIndustry:Contaminant SensorsandSecurity/ AnticounterfeitingDevices

T.Dilmac¸unal

1.Introduction

2.TheCurrentStatusofNanotechnology intheWorld

3.NanotechnologyApplicationsinthe World

3.1NanotechnologyinAgriculture andFoodIndustry

3.2NanotechnologyintheFood PackagingIndustry

4.IntelligentSystemsintheFood PackagingIndustry:Security/ AnticounterfeitingDevicesand ContaminantSensors

4.1ContaminantSensors

15.NanosensorsfortheDetectionof FoodContaminants

B.Kuswandi,D.Futra,L.Y.Heng

1.Introduction

4.FoodbornePathogenicBacteria

Salmonella and Escherichiacoli

16.NanoDevicesforContaminant Detection

S.Sahota,J.Singh,P.Kumar,S.Suresh, K.M.Pandey

1.Introduction 335

2.ContaminantsinFoodIndustry

3.SensorsandSensing 336

3.1BasicCharacteristicsofa Biosensor 336

4.ApplicationsofNanotechnology inContaminantSensorsfor FoodIndustry 340

4.1NanostructuredMaterialsfor BiosensingDevices 340

4.2BiosensingStrategiesforFood Safety 340

4.3ApplicationofBiosensorinFood Industry 340

5.ExamplesofSensorsforContaminant Detection 341

5.1BiosensorsinBacterialDetection 341

17.ImpactofBacterialNanocellulose ontheRheologicalandTextural CharacteristicsofLow-LipidMeat Emulsions

L.Marchetti,B.Muzzio,P.Cerrutti, S.C.Andre ´ s,A.N.Califano

1.Introduction

2.CaseStudy

2.4EffectofBNCAdditionon Thermo-RheologicalProperties

2.5ComparisonBetween CommercialSausages(20%Fat) andLow-LipidMeatSausages StabilizedWithBacterial

18.Bionanocompositesfor FoodPackagingApplications

F.Mohanty,S.K.Swain

1.Introduction

2.Bionanocomposites

19.PlantStressSignalingThrough CorrespondingNanobiotechnology Yogranjan,LalitM.Bal,G.K.Satpute, A.K.Srivastava 1.Introduction

1.1PrimeComponentsofSignal TransductioninPlants

1.3SignalTransductionThrough ROS AuxinCrossTalk 382

2.TwoTechnologies:CommonObjectives 384 2.1UnderstandingInteractionsatthe Nanobiointerface 385

2.2UseofNanotechnologiesin UnravelingtheInteraction BetweenROSandHormones 385 2.3CellularUptakeofNanoparticles forActivationofSignalProcessing Pathways 386

3.GenomicTechnologyinElucidationof PlantStressAdaptation 387

4.NanoparticlesinPotentialCandidate GenesTargetingandRegulation 387 4.1IntegrationofGenomic TechnologyWithAnotherHighly SensitiveNanotechnologyin ElucidationMechanism 387 5.ConclusionsandOutlook

ListofContributors S.H.AbdEl-Alim,NationalResearchCentre,Cairo,Egypt

N.Ahmad,DepartmentofChemistry,Universityof Malaya,KualaLumpur,Malaysia

S.C.Andrés,CentrodeInvestigaciónyDesarrolloen CriotecnologíadeAlimentos(CIDCA),CONICET, FacultaddeCienciasExactas,UNLP,CIC,LaPlata, Argentina;InstitutodeTecnologíadePolímerosy Nanotecnología(ITPN),UBA-CONICET,Facultadde Ingeniería,UBA,BuenosAires,Argentina

B.Bal,SikshaOAnusandhanUniversity,Bhubaneswar, Odisha,India

LalitM.Bal,JNAgriculturalUniversity,Collegeof Agriculture,Tikamgarh,MadhyaPradesh,India

A.N.Califano,CentrodeInvestigaciónyDesarrolloen CriotecnologíadeAlimentos(CIDCA),CONICET, FacultaddeCienciasExactas,UNLP,CIC,LaPlata, Argentina;InstitutodeTecnologíadePolímerosy Nanotecnología(ITPN),UBA-CONICET,Facultadde Ingeniería,UBA,BuenosAires,Argentina

P.Cerrutti ,InstitutodeTecnologíadePolímerosy Nanotecnología(ITPN),UBA-CONICET,Facultadde Ingeniería,UBA,BuenosAires,Argentina

A.P.Das,TripuraUniversity,(ACentralUniversity) Suryamaninagar,Agartala,India

T.Dilmaçünal,SüleymanDemirelUniversity,Isparta, Turkey

B.N.Estevinho,FaculdadedeEngenhariadaUniversidade doPorto,Porto,Portugal

D.Futra,UniversitiKebangsaanMalaysia,Bangi, Malaysia

A.Gandhi,GuptaCollegeofTechnologicalSciences, Asansol,India

L.Y.Heng,UniversitiKebangsaanMalaysia,Bangi, Malaysia

H.Hosseini,DepartmentofFoodScienceandTechnology, NationalNutritionandFoodTechnologyResearch Institute,FacultyofNutritionSciencesandFood Technology,ShahidBeheshtiUniversityofMedical Sciences,Tehran,Iran

S.M.Hosseini,DepartmentofFoodScienceandTechnology,NationalNutritionandFoodTechnology ResearchInstitute,FacultyofNutritionSciencesand FoodTechnology,ShahidBeheshtiUniversityof MedicalSciences,Tehran,Iran

K.A.Ishak,InstituteofBiologicalSciences,Universityof Malaya,KualaLumpur,Malaysia

SougataJana,GuptaCollegeofTechnologicalSciences, Asansol,India

SubrataJana,IndiraGandhiNationalTribalUniversity, Amarkantak,India

A.A.Kassem,NationalResearchCentre,Cairo,Egypt

B.Kumar,UniversidaddelasFuerzasArmadasESPE, Sangolqui,Ecuador;TATACollege,Chaibasa,India

P.Kumar,MANIT,Bhopal,India

B.Kuswandi,UniversityofJember,Jember,Indonesia; UniversitiKebangsaanMalaysia,Bangi,Malaysia

S.Lee,KhalifaUniversityofScience,Technology,and Research,AbuDhabi,UnitedArabEmirates

S.Maiti,GuptaCollegeofTechnologicalSciences, Asansol,India

T.Maity,DefenceFoodResearchLaboratory,Mysore, India

L.Marchetti,CentrodeInvestigaciónyDesarrolloen CriotecnologíadeAlimentos(CIDCA),CONICET, FacultaddeCienciasExactas,UNLP,CIC,LaPlata, Argentina;InstitutodeTecnologíadePolímerosy Nanotecnología(ITPN),UBA-CONICET,Facultadde Ingeniería,UBA,BuenosAires,Argentina

F.Masood,COMSATSInstituteofInformationTechnology (CIIT),Islamabad,Pakistan

R.McConchie,UniversityofSydney,Sydney,NSW, Australia

D.Mellor,UniversityofCanberra,Canberra,ACT,Australia

L.Mirmoghtadaie,DepartmentofFoodScienceand Technology,NationalNutritionandFoodTechnology ResearchInstitute,FacultyofNutritionSciencesand FoodTechnology,ShahidBeheshtiUniversityof MedicalSciences,Tehran,Iran

M.S.MohamadAnnuar,InstituteofBiologicalSciences, UniversityofMalaya,KualaLumpur,Malaysia

F.Mohanty,VeerSurendraSaiUniversityofTechnology, Burla,Sambalpur,India

D.M.Mostafa,NationalResearchCentre,Cairo,Egypt

B.Muzzio,CentrodeInvestigaciónyDesarrolloen CriotecnologíadeAlim entos(CIDCA),CONICET, FacultaddeCienciasExactas,UNLP,CIC,LaPlata, Argentina;InstitutodeTecnologíadePolímerosy Nanotecnología(ITPN),UBA-CONICET,Facultadde Ingeniería,UBA,BuenosAires,Argentina

N.Naumovski,UniversityofCanberra,Canberra,ACT, Australia

S.Nayak,SikshaOAnusandhanUniversity,Bhubaneswar, Odisha,India

A.Paliwal,AmityUniversity,Noida,UP,India

K.M.Pandey,MANIT,Bhopal,India

M.Pathak,IndianInstituteofTechnologyPatna,Patna, Bihar,India

P.H.P.Prasanna,RajarataUniversityofSriLanka, Anuradhapura,SriLanka

C.S.Ranadheera,VictoriaUniversity,Werribee,VIC, Australia;UniversityofSydney,Sydney,NSW,Australia

F.Rocha,FaculdadedeEngenhariadaUniversidadedo Porto,Porto,Portugal

S.Sahota,MANIT,Bhopal,India

G.K.Satpute,ICAR-IndianInstituteofSoybeanResearch, Indore,MadhyaPradesh,India

A.Saxena,AmityUniversity,Noida,UP,India

S.Shojaee-Aliabadi,DepartmentofFoodScienceand Technology,NationalNutritionandFoodTechnology ResearchInstitute,FacultyofNutritionSciencesand FoodTechnology,ShahidBeheshtiUniversityof MedicalSciences,Tehran,Iran

J.Singh,MANIT,Bhopal,India

K.Smita,UniversidaddelasFuerzasArmadasESPE, Sangolqui,Ecuador

A.K.Srivastava,JNAgriculturalUniversity,Collegeof Agriculture,Tikamgarh,MadhyaPradesh,India

S.Suresh ,MANIT,Bhopal,India

S.K.Swain,VeerSurendraSaiUniversityofTechnology, Burla,Sambalpur,India

J.K.Vidanarachchi,UniversityofPeradeniya,Peradeniya, SriLanka

S.Wadhwa,AmityUniversity,Noida,UP,India

Yogranjan,JNAgriculturalUni versity,Collegeof Agriculture,Tikamgarh, MadhyaPradesh,India

Foreword Nanoscienceandnanotechnologyareconcernedwiththedesign,fabrication,characterization,andexploitationofthe newlyoccurredpropertiesofmaterialsatnanoscalelevel(i.e.,lessthan100nminsize)tomakethemsuitablefordifferent practicalapplications.Nanotechnologyisemergingtodayinall fieldsofhumanactivity,includingfoodindustry. Nanotechnologybringsanessentialcontributionindifferentstepsofthefoodchain:(1)ensuringfoodqualitythrough contributionstothedevelopmentofnewpesticides;agrichemicaldeliveryandevaluationofsoilquality;identitypreservation;designofdifferentfoodingredientswithimprovedactivityatminimalconcentration;developmentofadvanced formulation,transport,release,andstabilizationnanosystemsfordifferentfoodcomponentsoradditivesthatcould influencetheproductshelflife,texture, flavor,andnutrientcomposition;manipulatingthefoodcontentatnanoscalelevels tomodifyitsorganolepticpropertiesornutritivecompositiontomeetconsumers’ preferences;anddevelopmentofnovel methodsforeliminatingcontaminants(e.g., filtermembranes)withoutaffectingthenutrientcontentofthefood;(2) improvingthefoodproductionyieldbyofferingnanostructuredsupportsfordifferentenzymesusedinfoodtechnology; (3)evaluatingfoodqualityandsafetybythedevelopmentofadvancedmicroscopicmethodsandothertoolstostudythe foodnanostructure;developmentofsamplingsystemsandnanosensorstodetectdifferenttypesofbiologicalorchemical contaminantsinfood;anddevelopmentofself-cleaningmaterialstobeusedinfoodindustry;and(4)infoodprocessing andpackagingbydevelopingfullybiodegradableandnontoxicmaterialstocontrolgasdiffusionandextendthelifetimeof variousfoodproductsbypreventingmicrobialcontaminationoffoodduringprocessing,storage,andtransportorto disinfectfoodprocessingsurfacesandbydevelopingnovelencapsulationandpackagingnanomaterials.

However,therapidprogressofnanotechnologyapplicationsinthefoodindustryrequiresthesimultaneousdevelopmentofappropriateregulationsandmethodsfortestingthesafetyofnanomaterialsandevaluatingthepotentialrisksof exposureinrelationwithhumanhealthandwiththeenvironmentalqualityandreexaminationofgenerallyrecognizedas safe(GRAS)listofnanoscaledfoodcomponents.Thiswillalsocontributetotheconsumers’ trustinsuchnovelproducts.

Throughthecarefulselectionofthechaptersincludedinthisvolume,itwillbringanimportantcontributiontothe understandingoftheimportanceofnanotechnologyfortheagro-foodsector;toimprovetheknowledgeofthepresent resultsandapplicationsalreadydeveloped,particularlyinthefoodpackagingandfoodsafety fi elds;andforhighlighting emergingadvancementsinthefoodindustry.

MarianaCarmenChifiriuc ICUB,TheResearchInstituteoftheUniversityofBucharest,Romania

Thispageintentionallyleftblank

Preface Inrecentyears,thenanotechnologyhasreachedimpressiveheights.Numerousnanomaterialshavefoundapplicationsin variousareasduetorapiddevelopmentofnanotechnology.Whiletheapplicabilityofnanotechnologyinmanyscience fieldssuchasmedicine,biology,materialsscience,physics,chemistryorengineeringisknownandacceptedworldwidefor afewyears,itsfunctionalityandapplicabilityinfoodsectorissomethingrelativelynewcomparedtobiomedical field,for example.

Inthelastdecade,foodindustryhasbeeninvestingimpressiveamountsofmoneyintonanotechnologyresearchto developnewmethodstocreatenew flavors,extendfoodshelflife,andenhancethesafetyandthenutritionalvalueoffood products.Theapplicationofnanotechnologyinfoodareawillprovideintelligentdeliverymechanismsofnutrients, “smart” foods,nanodevices/nanosensorsforcontaminantdetection,innovativefoodpackaging,antimicrobialadditives, encapsulation,andalsogreennanotechnologies.

Thedevelopmentofnanotechnologyinthefoodsectorbringsinnovativefoodpackagingthatcandetectspoilageor preventmicrobialcontamination.Inthenearfuture,interactive “smart” foodscould “personalize” meals(new flavor, nutrients,texture,color)foreachconsumer’snutritionaltasteorhealthneeds.Adeliverysystemfornutrientsandsupplementsrepresentsawaytoobtainfunctionalizedfoodthatmayreducetherisksofdiseasesorimprovehealth. Thedeliverysystemhastheroletocontrolthereleaserateofthefunctionalmaterialandtheconditionsthattriggerrelease. Deliverysystemhasalsotheroletoprotectthefunctionalizedmaterialsfrombiologicalorchemicaldegradation. Deliverysystemmaybecapabletoencapsulatematerialssuchas(nano/micro)emulsions,simplesolutions,colloids, biopolymers,etc.

Oneofthemostpromisingareasofnanotechnologyapplicationisrepresentedbynanoencapsulationofadditivesand foodingredients.Nanoencapsulationallowsincorporationofbioactiveagentsinsmallcapsules(micro-andnanosize diameters)toprotectthemfromdifferentdamagingagents(i.e.,pHvariation,heat,humidity)attherighttimeandright place.Thematerialsusedfornanoencapsulationapproachescurrentlyinclude,butnotlimitedto,probiotics,vitamins, lipids,proteins,antioxidants,bioactivepeptides,cellulose,polymers,andcarbohydrates.Theconsumersatisfactionis largelyinfl uencedby fl avors.Flavorsareveryvolatileandsensitivetoenvironmentconditions;thereforeencapsulation representsapromisingalternativetopreservetheminthebestconditions.Therearemanymethodsofencapsulation processessuchasmeltinjection,coacervation,spraydrying,extrusion,andemulsifi cation.

Thebookentitled NanotechnologyApplicationsinFood:Flavor,Stability,NutritionandSafety offersacomprehensive viewofthecurrentstateofthenanotechnologyappliedinfood.Itdescribestheadvantagesanddisadvantagesofeach applicationtohelpresearcherstoimproveanddevelopthemethodsofobtainingfoodingredientsandmonitorfoodsafety.

Thisbookcontains19chapters,preparedbyoutstandinginternationalresearchersfromPortugal,India,Ecuador, UnitedArabEmirates,Egypt,Malaysia,Australia,SriLanka,Turkey,SaudiArabia,Indonesia,andCalifornia.

InChapter1, AKeyfortheFutureoftheFlavorsinFoodIndustry:NanoencapsulationandMicroencapsulation, Berta N.Estevinhoetal.presentthemaintechniquesofencapsulationandtheinfluenceoftheencapsulatingagentinthe controlledreleaseprocesses.Also,theimportanceofthe flavorinfoodandthemethodstokeepthemforalongertime periodinthebestconditionsaredescribed.

SougataJanaetal.,inChapter2, NanotechnologyinBioactiveFoodIngredients:ItsPharmaceuticalandBiomedical Approaches,discussesaboutthepotentialoffoodingredients.Inparticular,thechapterfocusesontheapplicationin differentnanodevicesforsuccessfuldeliveryofbioactivefoodingredients.

Chapter3, ScopeofNanotechnologyinNutraceuticals,preparedbyBrajeshKumaretal.,presentsthepotentialroleof nutraceuticaldeliverysystemsintheformofnanoparticles,absorptionandmetabolismofnano-nutraceuticalsinhuman subjectsandtissues.

InChapter4, StrategicDesignofDeliverySystemsforNutraceuticals,SungmunLeehighlightsthecharacteristicsof nutraceuticalsanddiscussesaboutstrategicdesignsofnutraceuticaldeliverysystems.

ManabendraPathak,inChapter5, NanoemulsionsandTheirStabilityforEnhancingFunctionalPropertiesofFood Ingredients,compilestheexistingdataaboutdifferentissuesofimplementingnanoemulsionsasencapsulationandthe effectofemulsifi ersonnanoemulsionsstructures.Also,theauthorprovidesadescriptionoftheiressentialpropertiesfor enhancedstability.

Chapter6, Nanoemulsions:ANewApproachforEnhancingPhytonutrientEfficacy,byDinaMahmoudMostafaetal., givesanoverviewabouttheenhancedpotencyandmedicalefficacyofphytonutrients.Thesecharacteristicshavebeen studiedintermsofencapsulationinnano-drugdeliverysystems.

InChapter7, TechnologicalAspectsofNanoemulsionsandTheirApplicationsintheFoodSector,AlokSaxenaetal. describevariousintegralcomponentsandtherecenttrendsinnanoemulsionformulation.Theauthorsprovideabrief descriptionaboutdevelopingpackagingmaterialsforfoodandassociatedhealthrisks.

InChapter8,preparedbyFarhaMasood, PolyhydroxyalkanoatesintheFoodPackagingIndustry,theauthorreviews themaincharacteristicsandthebiosynthesisofthepolyhydroxyalkanoates(PHAs)andprovidesadescriptionaboutthe applicationsofPHAs.Applicationssuchasblends/composites,nanocomposites,papercoating,multilayer films,andactive foodpackagingarediscussed.

KhairulAnwarIshaketal.,inChapter9, Nano-DeliverySystemsforNutraceuticalApplication,describethedevelopmentoftheavailablenanoparticle-baseddeliverysystemsandtheircharacterization.Theirpotentialuseasnutraceutical bioavailabilityenhancerisalsodiscussedhere.

SabyasachiMaiti,inChapter10, Nanoemulsi ficationTechnologyinImprovingBioavailabilityofLipophilicFunctional Food-GradeIngredientsandQualityofFoodProducts,compilestheexistingdataonthenanoemulsificationtechnology. Theroleoffoodmatrixcomponentsonenhancingbioavailabilityoflipophilicnutraceuticalsandthequalityoffood productsafterincorporationofnanoemulsifiedbioactiveagentsintofoodmatrixarerevealed.

Hosseinietal.inChapter11, NanoantimicrobialsinFoodIndustry,presentvarioustypesofnanoantimicrobials,some methodsofdelivery,andtheirantimicrobialmechanism.Theauthorsalsorevealdifferentexamplesofnanoantimicrobial applications.

Chapter12, NanotechnologyinMicrobialFoodSafety,preparedbySenakaRanadheeraetal.,presentsanup-to-date overviewaboutadvancesandfuturetrendsinnanotechnology.Inparticular,thechapterfocusesonmicrobiological applicationsinenhancingfoodqualityandsafety.

Chapter13, RecentAdvancesinMolecularTechniquesfortheDiagnosisofFoodborneDiseases,byB.Baletal., highlightsthebasicprincipleanddistinctivenessofcurrentmolecularpathogenidenti ficationmethodsforfoodborne pathogens.

InChapter14, IntelligentSystemsintheFoodPackagingIndustry:ContaminantSensorsandSecurity/ AnticounterfeitingDevices,TubaDilmaçünalrevealsthenanotechnologicalapplicationsincontaminantsensorsand security/anticounterfeitingdevices.

BambangKuswandietal.,inChapter15, NanosensorsfortheDetectionofFoodContaminants,compiletheexisting dataaboutthepossibleapplicationofnanosensorstothefoodcontaminantdetectionandanalysis.

ShivaliSahotaetal.,inChapter16, NanoDevicesforContaminantDetection,giveageneraloverviewofthesensors andtechnologiesthatarecapableofdetectingandmonitoringcontaminantinthefoodindustry.Inparticular,thechapter summarizestheeffectofpH,odor,taste,temperature,microbialnature,andotherphysicochemicalparametersinthefood products,aswellsensorqualityandlifespan.

InChapter17, ImpactofBacterialNanocelluloseontheRheologicalandTexturalCharacteristicsofLow-LipidMeat Emulsions,LucasMarchettietal.describeanovelapplicationofbacterialnanocellulosetolow-fatmeatemulsions formulatedwithhigh-oleicsunfloweroil.

Chapter18, BionanocompositesforFoodPackagingApplications,preparedbyFanismitaMohantyetal.,presentsthe hydrocolloidsandthefundamentaldiscussionoftheresearch findingsandtheirsignificance.Inthischapterthefunctional propertiesandrelationbetweenthefunctionalpropertiesandthenanostructuresofbacterialpolysaccharidesarealso described.Themostimportantapplicationsinfoodindustryarehighlighted.

Preface xvii

Chapter19, PlantStressSignalingThroughCorrespondingNanobiotechnology,byYogranjanetal.,presentsthe powerofgenomictechnologyinintegrationwithanotherhighlysensitivenanotechnology-basedapproachinelucidationof plantstressadaptationmechanism.Thisstresssensingnanoapproachcouldcontrolvegetalfoodquality.

AlexandraElenaOprea DepartmentofScienceandEngineeringofOxideMaterialsandNanomaterials FacultyofAppliedChemistryandMaterialsScience UniversityPolitehnicaofBucharest

Romania

AlexandruMihaiGrumezescu TheResearchInstituteoftheUniversityofBucharest ICUB

Romania

Thispageintentionallyleftblank

AKeyfortheFutureoftheFlavors inFoodIndustry:Nanoencapsulation andMicroencapsulation B.N.EstevinhoandF.Rocha FaculdadedeEngenhariadaUniversidadedoPorto,Porto,Portugal

1.INTRODUCTION Flavorsareconsideredimportantingredientsinanyfoodformula,playingasignificantroleinconsumersatisfactionand influencingfurtherconsumptionoffood(Madeneetal.,2006).Mostavailable flavorsareproducedviachemicalsynthesis orextractionfromnaturalcompounds,beingusuallyexpensive,delicate,andvolatile(Milanovicetal.,2010).Consequently,foodmanufacturersareusuallyconcernedaboutthepreservationofthesepreciousadditives.

Theincreasinginterestonthestabilityof flavorsindifferenttypesoffoodproductshasbeenrelatedtotheirrelation withthequalityandacceptabilityofthefoodproducts.However,itisdif ficulttocontrolandstabilize flavors,mainly becauseofthestorageandmanufacturingprocesses.Packagingingredientsinfoodproductsoftenprovokealterationsin overall flavorbyreducing flavorintensityorbyproducingoff- flavorcomponents(Madeneetal.,2006).

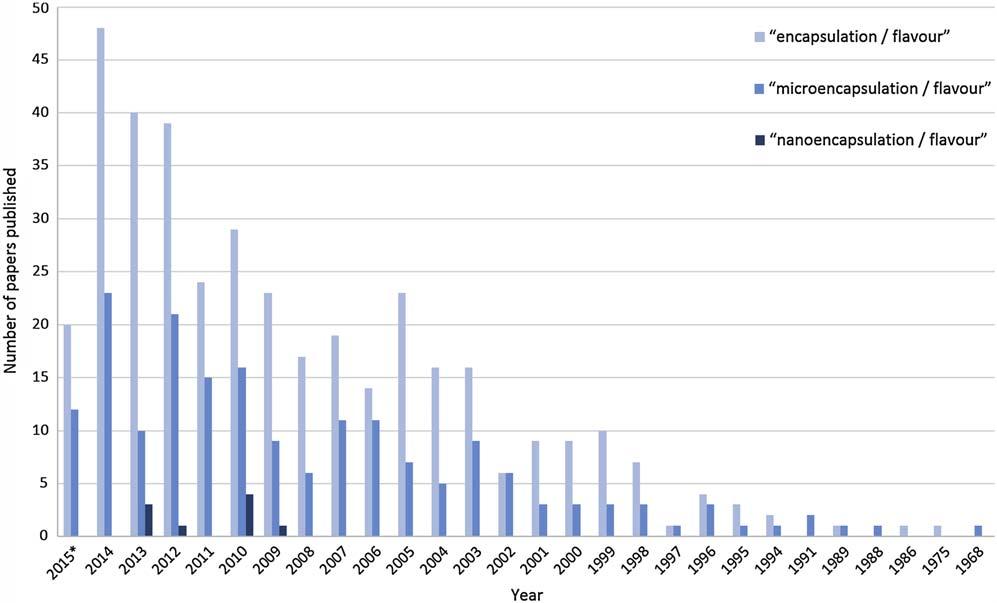

Encapsulation,includingmicroencapsulationandnanoencapsulation,hasbecomeachallengingapproachtodesign newmaterialswithbiotechnologicalapplications.Inthisspecifi ccase,encapsulationcanbeusedtocoveranactive compound(fl avor)withaprotectiveencapsulatingagent,givingprotectionagainstevaporation,chemicalreactions(such as fl avor flavorinteractions,light-inducedreactions,oxidation),ormigrationinafood.Encapsulationcanalsobeusedto retain flavorsinfoodproductsduringprocessingorstorageand/ortoallowforacontrolledrelease(Milanovicetal.,2010). The flavor-encapsulatingprocessesinfoodindustryincreasedinanexponentialformoverthepasttwodecades (ChampagneandFustier,2007;Ghosh,2006),alongwiththenumberofpublicationsrelatedtothem. Fig.1.1 presentsthe numberofpaperspublishedperyearwithoneofthefollowingexpressions: “encapsulation/fl avour,”“microencapsulation/ flavour,” and “nanoencapsulation/ flavour.”

Basedonthenumberofpublications,the flavormicroencapsulationismorerelevantthanthe flavornanoencapsulation thatstartedtobemoredevelopedonlyinthelastyears.Thereareseveralmethodsofmicroencapsulation,suchasspray drying,spraycooling,spraychilling, fluidizedbed,coacervation,alginatebeads,liposomes,andspinningdisk (Gouin,2004;Yoshiietal.,2001).Differentencapsulatingagentscanbeused,includingproteins,carbohydrates,lipids, fats,andgums.Some flavorsaremorestableinwater-solubleencapsulatingagentsandsomearemorestableinlipid-based coating(Milanovicetal.,2010).

Therefore, flavorsareveryimportantfortheacceptanceoffoodproducts;however,therearemanyfactorsthataffectthe overallqualityofthe flavorsandconsequentlyofthefoodproducts.Sotolimit flavordegradationorlossduringprocessing andstorage,itisbeneficialtoencapsulate flavors.Inthefollowingsections,theseconceptswillbediscussedmoredeeply.

2.IMPORTANCEOFFLAVORSINTHEFOODINDUSTRYANDINTHEGLOBALMARKET Tastyornottasty?Thisisthemostimportantquestionforthefoodindustry.Flavorsareextremelyimportantforthe acceptanceofthefoodproductsbytheconsumers.Ifaproductdoesnothaveanacceptabletaste,itwillnotbeacceptedby themarketandwillleadtolossofmoney.

FIGURE1.1 Numberofpaperspublishedwiththeexpressions “encapsulation/flavor,”“microencapsulation/flavor,” and “nanoencapsulation/flavor” since1968. www.scopus.com; )May27,2015.

Theglobal flavorindustrycanbecharacterizedashighlytechnical,specialized,andinnovativeandishighlycompetitive andconcentrated,comparedtoothermarketsoffoodandbeverage(Bureau,2011).Theglobal flavorsmarketreached aroundUS$11billionin2013andisexpectedtogrowatanaverageannualrateof3.2%toreacharoundUS$13billionin 2018(IALConsultants,2014).ThemainglobalmarketregionsareAsia-Pacific,followedbyNorthAmericaandWestern Europe.Infact,theseareasaccountforapproximately80%oftheglobalsales(Bureau,2011).TheWestEuropeanand NorthAmericanmarketsarematureandquitestable.Thebiggestpotentialforgrowthofthe flavorsmarketisinCentral& EasternEurope,MiddleEast,Africa,SouthAmerica,andAsia-Pacificregions(IALConsultants,2014).

Ontheotherhand,the fl avorsindustryremainsverycountry/regionspeci fic,with flavorformulationsvaryingfrom countrytocountryorregiontoregion.Processedfoodsandtheir flavorsandtexturesareadaptedtolocalconsumer preferences(Bureau,2011).

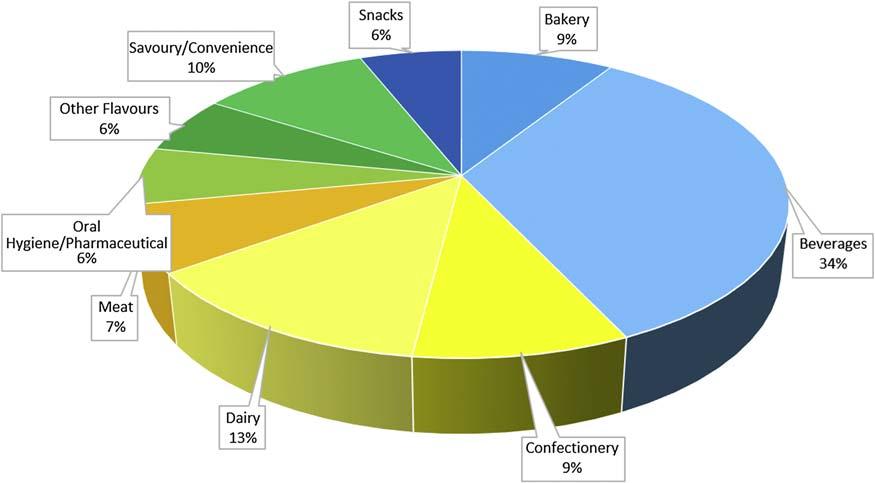

Flavorshavealargescopeofapplicationsinthefoodindustry.Consideringthedistributionofthe flavorsforsectors (Fig.1.2),thebeveragesectorwasthelargestglobalmarketfor flavorsin2013(34%),followedbythedairyindustry (13%)andsavory/convenience(10%)(IALConsultants,2014).However,some flavorsarehighlysensitivetoambientor industrialprocessesconditions.Flavorsareveryvolatile,reactwithothercomponents,andaresusceptibletoheatand moisture(Gouin,2004;Yoshiietal.,2001).Flavorlossduringtheprocessingorstorageoffoodsisacommonoccurrence inthefoodindustry.Itsometimesreachesvaluesof60 95%whenthefoodisinthefreeform(Pothakamuryand Barbosa-Cánovas,1995).Flavorstabilityhasbeenofincreasinginterestbecauseofitsrelationshipwiththeacceptability andqualityoffoodproducts,butitisdif ficulttocontrol(Madeneetal.,2006).

Inothercases,itisexpectedthatthe fl avorwillonlybeavailableatthemomentoffoodingestionorwillberetainedin foodforalongerperiod(Estevinhoetal.,2013a).Somanufacturingandstorageprocesses,packagingmaterials,andthe ingredientsinfoodproductsfrequentlyaltertheoverall fl avorbyreducing flavorintensityorbyproducingoff-flavor components(Madeneetal.,2006).

Forallthesereasons,microencapsulationandnanoencapsulationareimportanttoprotectandretainthe flavorinthe bestconditiontobeingested(PothakamuryandBarbosa-Cánovas,1995;Yoshiietal.,2001). Gouin(2004) discussedthe applicabilityofamicroencapsulationprocessinthefoodindustryandmarketsandconcludedthatanoptimizationbetween

FIGURE1.2 Flavorsglobalmarket2013:distributionofsectors. AdaptedfromIALConsultants,2014.AnOverviewoftheGlobalFlavours& FragrancesMarket,ninthed.Release,Press,London,UK.

the finalpriceoftheproductanditsbenefitsisindispensable.Ifitisanexpensivecompoundtobemicroencapsulated,the cost-in-usemustbelowerthanthatofthenonencapsulatedcompound,butifmicroencapsulationprovidesthecompound withaspecificandspecialproperty,thenthecost-in-usecanbeslightlyhigherthanthatofthenonencapsulatedingredient. Therefore,consideringthecharacteristicsofthefoodproductsandfoodformulationswithmicroencapsulatedcompounds, whichrepresent1 5%ofthe fi nalproduct,themaximumcostforamicroencapsulationprocessinthefoodindustryis approximatelyestimatedat V0.1/kg(Gouin,2004).

3.ENCAPSULATIONINTHEFOODINDUSTRY Theadvantagesandimportanceoftheapplicationofmicroencapsulationinthefoodindustryhavebeendiscussedby severalauthors(ChampagneandFustier,2007;Ghosh,2006;Gouin,2004).Itisemphasizedanddescribedthatmicroencapsulationmayprotectthecorecompound,decreaseitsreactivitywithexternalfactors,reducethetransferratefromthe coretotheoutsideandcontrolthereleaseofthecorecompound,promoteeasierhandling,maskthecoretaste,anddilute thecore(microencapsulatedcompound)inthe finalproductwhenitistoxicinlargequantities(Gharsallaouietal.,2007; PothakamuryandBarbosa-Cánovas,1995).

Thenumberoffoodingredientsorcompoundsthathavebeenmicroencapsulatedorsubmittedtoothercontrolled releasetechniqueshasbeenincreasing,forexample, flavors(deRoos,2003;Yoshiietal.,2001),dyes(Ersusand Yurdagel,2007),stabilizers(Guillardetal.,2009),antioxidants(Gemilietal.,2010),enzymes(SangeethaandAbraham, 2008),probiotics(ChampagneandFustier,2007;Heidebachetal.,2010),lipids(KeoghandO’Kennedy,1999),mineral salts(OnedaandRé,2003),andvitamins(Yooetal.,2006),amongothers(PothakamuryandBarbosa-Cánovas,1995).

Oneofthemostrecentnoveltiesinthefoodindustryisbasedontheincorporationofprobioticsinfoodproducts,which aredefinedbytheWorldHealthOrganizationas “livemicroorganismswhich,whenadministeredinadequateamounts, conferahealthbenefitonthehost” (AnalandSingh,2007;Corona-Hernandezetal.,2013).However,thelossofprobioticsduringprocessingisthemostimportanttechnologicalobstaclethatmustbesolved.Producingenoughamountsof viableandstableprobioticcultureshasbeenatechnologicalchallengefortheindustry(Salemetal.,2013).Theeffi cacyof probioticsismainlyrelatedtotheirviabilityinaproductatthepointofconsumption.Notonlythefoodproduction processesandstorageconditionsbutalsothephysicalcircumstancesofthehumangastrointestinaltract(acidicconditions ofthestomachaswellasenzymesandbilesaltsinthesmallintestine)afteroralapplicationstronglyinfluencethesurvival ofprobioticmicroorganismsandaccordinglytheireffectiveness(SchellandBeermann,2014).Toavoidundesirablelossof probiotics,useofprotectivemicroencapsulationtechniqueswithdifferentmatricesisgenerallyagoodsolution(Burgain

etal.,2014;Corona-Hernandezetal.,2013;Salemetal.,2013;SchellandBeermann,2014).Themicroencapsulation processessolveseveralproblemsandcanbeusedtoenhancetheviabilityduringprocessing,andalsoforthetargeted deliveryingastrointestinaltract(AnalandSingh,2007).

Anotherexampleofapplicationinthefoodindustryisthemicroencapsulationofenzymes.Immobilizedenzymesare generallymorestable,andtherearemanypotentialapplicationsthatrangefromfoodindustrytobiotechnologyand medicine(HaiderandHusain,2008).Morethan70%oftheworldpopulationsuffersfromlactoseintolerancecausedby thelackof b-galactosidaseactivity.Thereareseveralstudiesbasedonthemicroencapsulationof b-galactosidasetoallow thehydrolysisoflactoseinthepresenceofgastric fl uid.Forexample, Rodriguez-NogalesandDelgadillo(2005) microcapsulated b-galactosidaseinliposomes,whicharesimplyvesiclescomposedofamembraneoflipidmolecules. Liposomescanentrapawiderangeofactivecompounds.

Antioxidantsandvitaminsalsohavebenefitswhenmicroencapsulated.

Thelossofvitaminsandantioxidantsisconsiderableduringcooking,theprocessingoffoods(chilling,heating, reheating),andstorage(MurugesanandOrsat,2011).Someauthorsstudiedthepossibilityofmicroencapsulatingthem withthepurposeofincreasingtheirresistancetothecookingprocess,oxidation,orstorage(Abbasetal.,2012).

Finally, flavorshavealargescopeofapplicationsinthefoodindustry.However,someofthemareverysensitiveto ambientorindustrialprocessconditions.Flavorlossduringthestorageprocessoffoodsisacommonoccurrenceinthe foodindustry.Somicroencapsulationisimportanttoprotectandretainthe flavorinthebestconditiontobeingested.This topicwillbediscussedinthenextsection.

4.ENCAPSULATIONOFFLAVORS Theencapsulationtechnology,namely,microencapsulation,hasbeenusedbythefoodindustryformorethan60years (DesaiandPark,2005a,b).Duringtherecentyears,thenumberoffoodcompounds,suchas flavoringagents,thatwere microencapsulatedornanoencapsulatedhasbeenincreasing(deRoos,2003;Yoshiietal.,2001).

Microencapsulationandnanoencapsulationaretechnologiesthatcanbeusedtoincreasetheeffectivenessofmany compoundsintheindustryand,asothertechniquesofcontrolledrelease,allowthereformulationofalargenumberof products,improvingandgivingthembetterandnewproperties(Carvalhoetal.,2016;ChampagneandFustier,2007; DesaiandPark,2005a,b;Ghosh,2006;Gouin,2004;PatelandPatel,2010;Youanetal.,2003).Someheat-,temperature-, orpH-sensitivecompoundscanbeusedmoreconvenientlywhenencapsulated,andthiscanalsoavoidthelossof fl avor, vitamins,proteins,enzymes,essentialoils,mineralsalts,etc.,duringcertainindustrialprocesses(Estevinhoetal.,2014a, 2014b,2012;PothakamuryandBarbosa-Cánovas,1995).Someadvantagesofthemicro-andnanoencapsulationprocesses areusefulespeciallyfor flavors:protectionofthe flavor,reductionofthe flavorreactivitywithexternalfactors,decreasing thetransferratefromthecoretotheoutsideandcontrollingthereleaseofthe fl avor,andpromotingeasierhandling (Gharsallaouietal.,2007;PothakamuryandBarbosa-Cánovas,1995).

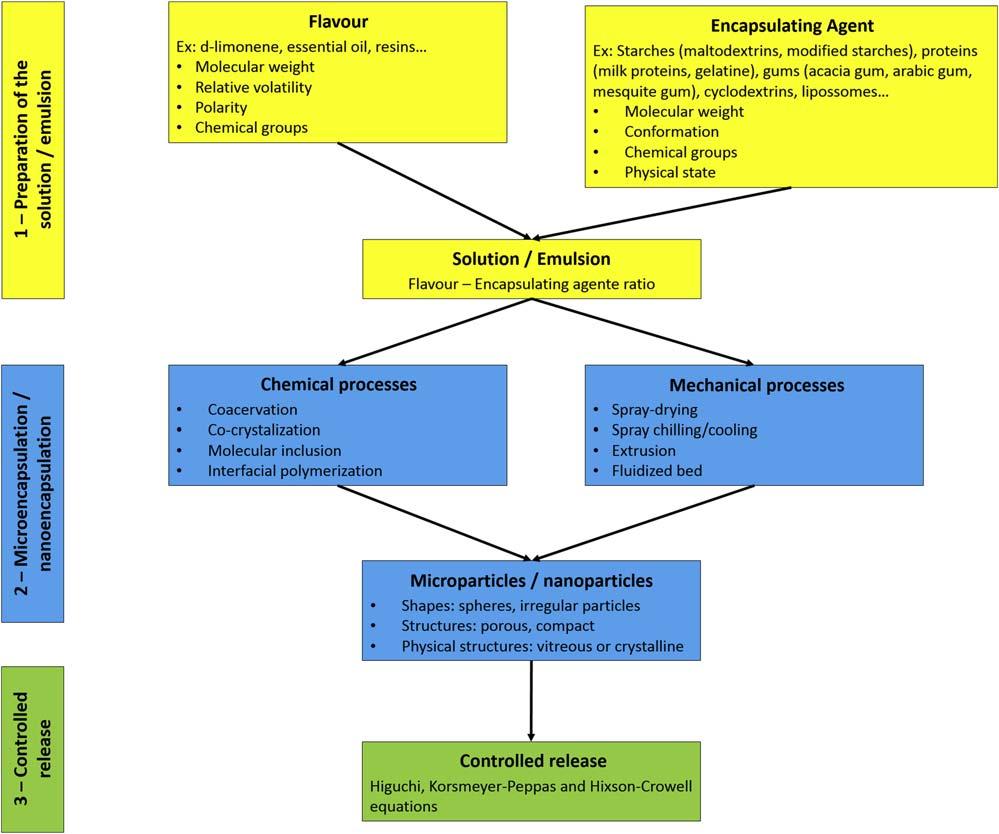

Microencapsulationisatechniqueinwhichliquiddroplets,solidparticles,orgasmoleculesareentrappedinan encapsulatingagent.Suchcompoundsaretotallyincorporatedinacoatingmaterialorembeddedinahomogeneousor heterogeneousmatrixtoformsmallcapsules(Ghosh,2006).Thesizeoftheparticlesformedbyencapsulationmaybe classi fiedasmacro(>5000 mm),micro(1.0 5000 mm),andnano(<1.0 mm)(Jafarietal.,2008).Thedifferenttypesof microcapsulesandnanocapsulesareproducedfromawiderangeofencapsulatingagentsandbyalargenumberof differentencapsulationprocesses(Fig.1.3).

The firststepin flavormicroencapsulationprocessesistheselectionofasuitableencapsulatingagent,basicallya filmformingbiopolymer,fromawidevarietyofnaturalorsyntheticpolymers;dependingonthe flavorandthedesired characteristicsofthemicrocapsules,differentmaterialshavebeenused,includingproteins,carbohydrates,lipids,fats,and gums.

Themostcommonmicroencapsulationprocessesarespraydrying,spraycooling,spraychilling,freeze-drying,air suspensioncoating, fluidizedbed,extrusion,centrifugalextrusion,coacervation,rotationalsuspensionseparation, cocrystallization,liposomeentrapment,interfacialpolymerization,andmolecularinclusion(Carvalhoetal.,2016;Desai andPark,2005a,b;Gouin,2004).Thenanoparticlescanbeproduced,ingeneral,bythesemethodswithorwithoutsome speci ficadaptationsorbymorespecializedones,suchasspraydryingwithmicro fluidizationandultrasonication,physical adsorption,complexformation,nanosizedself-structuredliquid,andnanoemulsifi cation(Madeneetal.,2006).

Dependingonthephysicochemicalpropertiesofthecore,theencapsulatingagent,andthemicroencapsulation techniqueused,differenttypesofparticlescanbeobtained,suchasasimplespheresurroundedbyacoatingofuniform thickness(singlecore),particlescontaininganirregularlyshapedcore,severalcoreparticlesembeddedinacontinuous matrixofencapsulatingagent(multicore),severaldistinctcoreswithinthesamecapsule,andmultiwalledmicrocapsules

The flavormicroencapsulationprocesses. AdaptedfromMadene,A.,Jacquot,M.,Scher,J.,Desobry,S.,2006.Flavourencapsulationand controlledrelease areview.Int.J.FoodSci.Technol.41,1 21.

(Gharsallaouietal.,2007).Theparticlesformedwithasinglecorearetypicallyproducedbycomplexcoacervation, fluidizedbeddrying,dropletcoextrusion,andmolecularinclusionandhavehighcoreloading(90%ofthetotalcapsule weight).Themicroparticleswithmulticoreareproducedmainlybyspraydrying.Inthiscasethecorematerialisdispersed throughouttheencapsulatingagentandfrequentlyhasacoreloadingaround20 30%ofthetotalcapsuleweight (Jafarietal.,2008).

Differenttypesofmicroparticlesareproducedfromawiderangeofencapsulatingagentsandbyalargenumberof microencapsulationprocesses(Ghosh,2006).Theselectionofthemicroencapsulationmethodandtheencapsulatingagent isinterdependent(DesaiandPark,2005a,b).

4.1EncapsulationTechniques Theincorporationof flavormoleculesintocapsulesisofgreatinterestinthefoodindustrybecauseencapsulationimproves thechemicalstabilityofthe flavorsandprovidescontrolledrelease.Overtheyears,newencapsulationtechniqueshave beendevelopedandtheoldoneshavebeenimprovedinthefoodindustry(AnalandSingh,2007;Azeredo,2005; ChampagneandFustier,2007;Freitasetal.,2005;Ghosh,2006;Gouin,2004;Krajewska,2004;SinghandO’Hagan, 1998;Sinhaetal.,2004;deVosetal.,2010).Thereareseveralencapsulationtechniques,withdifferentadaptationsand specificities,consideringthetypeofmicrocapsuledesired(sizeandshape),thechemicalandphysicalpropertiesofthe

FIGURE1.3

compoundandtheencapsulatingagent,thetypeofcontrolledrelease,andthescaleofproduction(Ghosh,2006;deVos etal.,2010).Theapplicabilityandspeci ficcharacteristicsofthemostcommonmicroencapsulationtechniquesappliedto flavormicroencapsulationaresummarizedin Table1.1.Thetwomajorindustrialprocessesarespraydryingandextrusion; also,freezedrying,coacervation,andadsorptiontechniquesareusedintheindustry(Madeneetal.,2006).

Physicalandchemicalmethodsareusedfor flavorencapsulation.Chemicalmethods,suchasmolecularinclusion,are distinguishedbythereactivityoftheexternalwallmaterial(encapsulatingagent)surroundingtheencapsulatedcore.The mostfrequentlyusedphysicalmethodsincludeextrusionandspraydrying,whicharecharacterizedbytheuseof temperatureandpressuretodrivetheformationofthewallthatcoatsthecorematerial(ErasoandHerrera,2013).

4.1.1ChemicalTechniques 4.1.1.1Coacervation

Coacervationconsistsoftheseparationofcolloidparticlesfromasolution,whichthenagglomerateintoaseparateliquid phasecalledcoacervate.Normallythecorematerialusedinthecoacervationmustbecompatiblewiththerecipient polymerandbeinsoluble(orscarcelysoluble)inthecoacervationmedium(Madeneetal.,2006).

Coacervationisathree-stepprocess:(1)formationofanoil-in-water(o/w)emulsion(activecompoundisdispersedin theaqueousphaseandpolymerisdissolvedintheorganicphase),(2)depositionoftheliquidpolymercoatingonthecore material,and(3)stabilizationandhardeningofthecoatingmaterialtoformself-sustainingmicrocapsules(Carvalhoetal., 2016;Lazkoetal.,2004).Theformedmicroparticlescanbecollectedbycentrifugationor fi ltrationandthereafterwashed withtheappropriatesolvent,dried,andhardenedbythermal,cross-linking,ordesolvationtechniques(Carvalhoetal., 2016;Pengetal.,2014).

Coacervationcanbesimpleorcomplex.Simplecoacervationinvolvesonlyonetypeofpolymer(asencapsulatingagent) andtheadditionofstronglyhydrophilicagentstothecolloidalsolution,whereascomplexcoacervationinvolvestwoor moretypesofpolymers(Madeneetal.,2006).Gelatinandgumarabicarethemostcommonandextensivelyusedpairof encapsulatingagentsincomplexcoacervation(ÐorC evicetal.,2014).Forexample, Lvetal.(2014) producedheat-resistant nanocapsulesofjasmineessentialoilwithacombinationofgelatin/gumarabicbyacomplexcoacervationtechnique.

Thismethodhassomeproblemsthatneedtobesolved,namely,theoptimizationofwallmaterialconcentrationinthe emulsi fication,theevaporationofvolatiles,thedissolutionofactivecompoundintotheprocessingsolvent,andproduct oxidation.Thecomplexcoacervatesarehighlyunstableandtoxicchemicalagents,suchasglutaraldehyde,arenecessaryto stabilizethem(ÐorC evicetal.,2014;Madeneetal.,2006).

4.1.1.2MolecularInclusion

Molecularinclusionisanothermeansofachievingencapsulationandisdefi nedastheresultofinteractionsbetween compoundsinwhichasmallerguestmolecule fitsintoandissurroundedbytheother(Madeneetal.,2006).

b-Cyclodextrinisacyclicderivativeofstarchpreparedfrompartiallyhydrolyzedstarch(maltodextrin)byanenzymatic process.Cyclodextrinsareagroupofnaturallyoccurringcyclicoligosaccharideswithsix,seven,oreightglucoseresidues linkedby a(1 / 4)glycosidebondsinacylindricalstructurethataredenominated a-, b-,and g-cyclodextrins,respectively(ÐorC evicetal.,2014).Ingeneral, flavorsexhibitmoreaffi nityfor b-cyclodextrin(ÐorC evicetal.,2014).The externalpartofthecyclodextrinmoleculeishydrophilic,whereastheinternalpartishydrophobic.Theguestmolecules, whichareapolar,canbeentrappedintheapolarinternalcavitybyhydrophobicinteraction.Thisinternalcavityofabout 0.65nmdiameterpermitstheinclusionofoneormore flavorvolatilemolecules(DesaiandPark,2005a,b).Therearethree mainmethodstoproducethe flavor cyclodextrincomplex:

l Firstmethod:Cyclodextrinisdissolvedinwatertoformanaqueoussolution,andthe flavorsareaddedtoforman inclusioncomplexincrystallineform.Thecrystalobtainedisthenseparatedanddried.

l Secondmethod:Cyclodextrinisdissolvedinalesseramountofwaterthaninthe firstmethodtoformaconcentrated suspension,andthe flavorsaremixedtoformaninclusioncomplexincrystallineform.Thecomplexthenmustbe separatedanddried.

l Thirdmethod:Cyclodextrinisdissolvedinamuchloweramountofwatertoformapaste,andthe fl avorsaremixed duringkneadingtoformaninclusioncomplex.Thismethodissuperiortotheformertwomethodsbecauseitdoesnot requirefurtherseparationanddrying(DesaiandPark,2005a,b).

Toincreasetheprocessyieldofthemolecularinclusionortoimprovethesolubilityoftheinclusioncomplex,various additivescanbeadded(polymers,acids,orbases)(ÐorC evicetal.,2014).

TABLE1.1 TheMainMethodsUsedintheMicroencapsulationofFlavors Techniques

Encapsulation Method Propertiesof MethodsFlavor

Chemical Coacervation

l Expensive

l Complex mechanisms

l Sensitive toenvironmental conditions

l Canbeappliedfor heat-sensitive actives

l Encapsulation efficiency,40 90%

l Useof organicsolvents

l Lavender oil

l Vanillaoil

l Propolis

Encapsulating Agents

l Soyprotein

l Pectin

l Gelatin

l Gumarabic

l Chitosan

Particle Size (mm)

Encapsulated Form Propertiesof Encapsulationand Controlled Release MechanismReferences

5 200 l Paste

l Powder

l Capsule

l Core/shell

l Multiwall

l Spherical, multinucleate particles

l Heatresistant

l Controlled releaseof actives

l Goodstorage stability

l Prolonged release (diffusion)and startedrelease (pH, dehydration, mechanical effect, dissolution,or enzymatic effect)

Lvetal. (2014),Nori etal.(2011), Xiaoetal. (2014),and Yangetal. (2014)

Molecular inclusion

l Inclusionefficiency, from30%to100%

l Highprice ofcyclodextrins

l Restrictedto low-molecularweightcompounds

l Olive,wild bergamot, onion,and black pepper essential oils

l b-Cyclodextrin5 50

l Powder

Mechanical Spraydrying

l Easyhandling

l Lowoperatingcosts

l High productionrates

l Reproducibility

l Widechoice ofencapsulating materials

l Peach flavor

l Strawberry flavor

l Rosemary essentialoil

l Mandarin oil

l Modified chitosan (watersoluble)

l Gumarabic

l Guargum

l Iranian gum tragacanth

l Maltodextrin

1 50 l Powder

l Matrix type

l Increased solubilityof hydrophobic molecules

l Controlled releaseof actives

l Particles (b-cyclodextrins) tendto agglomerate

l Spherical particles (powders)

l Good stabilityof encapsulates

l Nonuniform particles

Garcı´aSegoviaetal. (2011)

BringasLantigua etal.(2012), DeBarros Fernandes etal.(2014), Estevinho etal. (2013a), Continued