NANOMATERIALSFOR SENSINGAND OPTOELECTRONIC APPLICATIONS

Editedby M.K.JAYARAJ

CochinUniversityofScienceandTechnology,Kochi,India; UniversityofCalicut,Malappuram,India

SUBHAP.P.

CochinUniversityofScienceandTechnology,Kochi, Kerala,India

SHIBITHOMAS

DepartmentofPhysics,BharataMataCollege, Thrikkakara,Kochi,India

Elsevier Radarweg29,POBox211,1000AEAmsterdam,Netherlands TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2022ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyany means,electronicormechanical,includingphotocopying,recording,orany informationstorageandretrievalsystem,withoutpermissioninwritingfromthe publisher.Detailsonhowtoseekpermission,furtherinformationaboutthePublisher’s permissionspoliciesandourarrangementswithorganizationssuchastheCopyright ClearanceCenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions

Thisbookandtheindividualcontributionscontainedinitareprotectedunder copyrightbythePublisher(otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchand experiencebroadenourunderstanding,changesinresearchmethods,professional practices,ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledge inevaluatingandusinganyinformation,methods,compounds,orexperiments describedherein.Inusingsuchinformationormethodstheyshouldbemindfuloftheir ownsafetyandthesafetyofothers,includingpartiesforwhomtheyhaveaprofessional responsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,or editors,assumeanyliabilityforanyinjuryand/ordamagetopersonsorpropertyasa matterofproductsliability,negligenceorotherwise,orfromanyuseoroperationof anymethods,products,instructions,orideascontainedinthematerialherein.

ISBN:978-0-12-824008-3

ForInformationonallElsevierpublicationsvisitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: MatthewDeans

AcquisitionsEditor: EdwardPayne

EditorialProjectManager: IsabellaC.Silva

ProductionProjectManager: KameshRamajogi CoverDesigner: MilesHitchen

TypesetbyAptara,NewDelhi,India

Chapter1Facet-dependentgassensingpropertiesofmetaloxide nanostructures1

M.J.Priya,SubhaP.P.andM.K.Jayaraj

1.1Introduction1

1.2Metaloxide–basedgassensors2

1.3Strategiesforimprovingtheperformanceofmetal oxide–basedgassensors8

1.4Generalsynthesisroutesofhigh-energycrystal facet–exposedmetaloxides14

1.5Facet-dependentgassensingpropertiesofzincoxidegas sensors15

1.6Challengesandapproaches17

1.7Application19

1.8Summary19 References20

Chapter2Metaloxidesemiconductorthin-filmtransistorsforgas sensingapplications25 ManuShaji,K.J.SajiandM.K.Jayaraj

2.1Introduction25

2.2Varioustypesofgassensors26

2.3MetaloxideTFT–basedgassensors27

2.4HybridTFTsensors39

2.5Summary41 References41

Chapter3Recentdevelopmentsin2DMoS2

P.S.Midhun,K.J.SajiandM.K.Jayaraj

3.1Introduction45

3.2Sensingmechanismin2D-basedgassensors46

3.32D-basedgassensingdevices47

3.4MoS2 -basedgassensors51

3.5Summary58 References59

4.1Introduction63

4.2Templatednanostructures:synthesistechniquesand applications64

4.3Prospectsofbiocagesastemplatesinnanotechnology72

4.4Summary78 References79 Chapter5Anintroductiontobiosensors91

5.1Introduction91

5.2Fundamentalsofbiosensors92

5.3Classificationofbiosensors93

5.4Coupling/Immobilizationmethods97

5.5Field-effecttransistorbiosensors98

5.6Applicationsofbiosensor103

5.7Summary104 References104

Chapter6Luminescentnanoparticlesforbio-imagingapplication107

T.K.Krishnapriya,M.K.JayarajandA.S.Asha

6.1Introduction107

6.2Luminescence108

6.3Bioimaging113

6.4Luminescentnanoparticlesusedforbioimaging115

6.5Summary123 References124

Chapter7Nanophotonicbiosensorsfordiseasediagnosis129

R.AnjanaandM.K.Jayaraj

7.1Introduction129

7.2Plasmonicbiosensors130

7.3Evanescentfieldwaveguidebiosensors137

7.4Försterresonanceenergytransfersensors140

7.5Multimodalsensors143

7.6Summary144 References145

Chapter8Precisionnanoclusters:promisingmaterialsforsensing, optoelectronics,andbiology149

J.V.Rival,P.MymoonaandE.S.Shibu

8.1Introduction149

8.2LEDfabrication171

8.3Solarenergyharvesting173

8.4Photocatalysis177

8.5Bioimaging179

8.6Photodynamicandphotothermaltherapies184

8.7Summary187 References187

Chapter9Recenttrendsincore–shellnanostructures–based SERSsubstrates199

K.S.Anju,K.K.RajeevandM.K.Jayaraj

9.1Introduction199

9.2Surface-enhancedRamanspectroscopy199

9.3SERSsubstrates:anoverview203

9.4Core–shellnanostructures204

9.5Core–shellnanostructuresforbiologicalapplications213 Summary216 References216

Chapter10Noninvasivebiomarkersensorsusing surface-enhancedRamanspectroscopy221

NavamiSunilandBijiPullithadathil

10.1Introduction221

10.2Non-invasivebiologicalfluids225

10.3Challengesandfutureperspectives237 10.4Summary238 Acknowledgment238 References239

Chapter11Nanomaterials-basedflexibleelectrochemical sensorsforhealthcaremonitoring245

A.M.V.MohanandA.M.Starvin

11.1Introduction245

11.2Wearableelectrochemicalsensorsforsweatmonitoring246

11.3Flexiblemicrofluidicsensorsforsweatanalysis256

11.4Flexiblesensorsforsalivamonitoring258

11.5Flexiblesensorsforinterstitialfluidanalysis261

11.6Flexiblesensorsfortearfluidanalysis263

11.7Challengesandfutureperspectives265

P.S.Subin,K.J.SajiandM.K.Jayaraj

V.Sampath,S.vonGratowskiA.Irzhak,P.Lega,Z.Song, M.AlonsoCottaandV.Koledov

Contributors

M.AlonsoCotta

InstitutodeFÃsicaGlebWataghin,UniversidadeEstadualdeCampinas, 13083-859Campinas,SãoPaulo,Brazil.

R.Anjana

CochinUniversityofScienceandTechnology,Kochi,India;Departmentof Physics,St.Albert’sCollege(Autonomous),Ernakulam,India

K.S.Anju

CochinUniversityofScienceandTechnology,Kochi,India

A.S.Asha

CochinUniversityofScienceandTechnology,Kochi,India;Centreof ExcellenceinAdvancedMaterials,CochinUniversityofScienceand Technology,Kochi,India

P.A.Aswathy

CochinUniversityofScienceandTechnology,Kochi,India;Departmentof Physics,St.Stephen’sCollege,Kollam,India

ManeeshChandran

DepartmentofPhysics,NationalInstituteofTechnologyCalicut,Calicut, India

A.Irzhak

InstituteofMicroelectronicsTechnology,RussianAcademyofSciences, Chernogolovka,142432,Russia

M.K.Jayaraj

CochinUniversityofScienceandTechnology,Kochi,India;Universityof Calicut,Malappuram,India

V.Koledov

KotelnikovInstituteofRadioEngineeringandElectronicsoftheRussian AcademyofSciences,Moscow,Russia

T.K.Krishnapriya

CochinUniversityofScienceandTechnology,Kochi,India

P.Lega

MagneticPhenomenaLaboratory,KotelnikovInstituteofRadio EngineeringandElectronics,RussianAcademyofSciences,Mokhovaya 11-7,125009,Moscow,Russia

P.S.Midhun

CochinUniversityofScienceandTechnology,Kochi,India

A.M.V.Mohan

Electrodics&ElectrocatalysisDivision,CSIR-CentralElectrochemical ResearchInstitute(CECRI),Karaikudi,India

P.Mymoona

ElectroplatingandMetalFinishingDivision(EMFD),CouncilofScientific andIndustrialResearch(CSIR)-CentralElectrochemicalResearchInstitute (CECRI),Karaikudi,India;AcademyofScientificandInnovativeResearch (AcSIR)-CSIR,Ghaziabad,India

SubhaP.P.

DepartmentofPhysics,CochinUniversityofScienceandTechnology, Kochi,Kerala,India

M.J.Priya

CentreofExcellenceinAdvancedMaterials,CochinUniversityofScience andTechnology,Kochi,Kerala,India

BijiPullithadathil

NanosensorLaboratory,PSGInstituteofAdvancedStudies,Coimbatore, India

K.K.Rajeev

DepartmentofInstrumentation,CochinUniversityofScienceand Technology,Kochi,India;CentreofExcellenceinAdvancedMaterials, CochinUniversityofScienceandTechnology,Kochi,India

J.V.Rival

SmartMaterialsLab,DepartmentofNanoscienceandTechnology, UniversityofCalicut,Kerala,India

K.J.Saji

InternationalSchoolofPhotonics,CochinUniversityofScienceand Technology,Kochi,India;CentreofExcellenceinAdvancedMaterials, CochinUniversityofScienceandTechnology,Kochi,India

V.Sampath

IndianInstituteofTechnologyMadras,Chennai-600036,India

ManuShaji

CochinUniversityofScienceandTechnology,Kochi,India

E.S.Shibu

SmartMaterialsLab,DepartmentofNanoscienceandTechnology, UniversityofCalicut,Kerala,India

Z.Song

InternationalResearchCentreforNanoHandling&Manufacturingof China,ChangchunUniversityofScienceandTechnology,Changchun 130022,China

A.M.Starvin

DepartmentofChemistry,ChristianCollege,Kattakada, Thiruvananthapuram,India

P.S.Subin

CentreofExcellenceinAdvancedMaterials,CochinUniversityofScience andTechnology,Kochi,Kerala,India

NavamiSunil

NanosensorLaboratory,PSGInstituteofAdvancedStudies,Coimbatore, India

ShibiThomas DepartmentofPhysics,BharataMataCollege,Thrikkakara,Kochi,India

S.vonGratowski

LaboratoryofSpectroscopyandMillimeterandSubmillimeterWave Measurements,KotelnikovInstituteofRadioEngineeringandElectronics, RussianAcademyofSciences,FryazinoBranch,FIRERAS,Vvedenski Sq.1,Fryazino,MoscowRegion,141190,Russia

Preface

Thisbookon“Nanomaterialsforsensingandoptoelectronicapplications”isdesignedforpostgraduateandresearchstudents.Nanomaterialsaredefinedbytheirnanoscaledimensions,wheresurfaceor interfacequalitiestakeprecedenceoverbulkfeatures.Thelargesurface areaofnanomaterialsgivesrisetonovelphysicalandchemicalproperties,whichmakethemsuitablefordevelopingdevicesandinstruments foravarietyofapplicationsinfieldsoflifesciences,chemicalindustry, pharmaceuticals,energyconversionandstorage,electronics,photonics,aviationandspace,foodsafety,andinformationtechnology.This bookleansmoretowardexperimentalmethodsandpracticalapplicationsratherthandetailingthefundamentalprinciples.Webelieve thattheframeworkofthisbookwillbetterbenefitanoviceresearcher. Thisbookbringstogetherreviews,recentstudies,andknowledgeon nanomaterialsforsensingandoptoelectronicapplications.

Developingsensorswithahighresponse,improvedselectivity, andafasterrecoverytimearetheprimegoalsforresearchersworkingonsensors.Ananostructureddesignhelpstheminiaturization ofthesensingdevicewithimprovedperformance,pavingtheway forportablesensors.Suchsensorscanbeabreakthroughinvariousfields,includingbiomedicalresearchandenvironmentalmonitoring.Intriguingresultsusingmetaloxidesemiconductor–basedand thin-filmtransistor–basedgassensorshavebeenreportedinrecent years.Metaloxidesemiconductorswithexposedhigh-energyfacets havebeenreportedtohaveimprovedgassensingperformance.The firstthreechaptersprovideanoverviewofnanostructuredgassensorsusingmetaloxidesemiconductorsandtwo-dimensionaltransitionmetaldichalcogenides.Chapter4detailsthesignificanceof developingnanostructureswithinterestingfeaturesusingtemplateassistedsynthesis.Chapter5givesanintroductiontobiosensorsand thephenomenonofluminescence,aswellasvarioustypesofluminescentnanoparticlesemployedinbioimaging,whicharethoroughly explainedinChapter6.Themajorchallengesinbioimagingandthe useofluminescentnanoparticlesasabioimagingprobearealsodiscussed.Early,fast,accuratediseasediagnosisisthemostdemanding needfrombiomedicine,thefirststeptowardfightingagainstdiseases. Chapter7detailsthedifferentnanophotonictechniquesthatcanbe usedfordiseasediagnosis.Precisionnanoclustershavebeenused forabroadspectrumofapplications,suchasmolecular/metalion sensing,devicefabrication,greenenergyharvesting,photocatalysis,

andinthebiomedicalfield.TheuseofatomicallyprecisenanoclustersintheseapplicationsisdiscussedinChapter8.Surface-enhanced Ramanspectroscopy(SERS)hasevolvedasauniquesensingtechniquesinceitcombinesmolecularfingerprintspecificitywithsinglemoleculesensitivity.Recentadvancementsindevelopingcore–shell nanostructuresforthedevelopmentofSERSsubstratesarealsodiscussedinChapter9.SERSisalsoalabel-freetechniqueformonitoring biomarkersinbiologicalmatricesattrace-levelconcentrations.The recentadvancesinthefieldofSERS-basedsensorsforbiomarkerdetectioninbodyfluidssuchassweat,saliva,andtearwithanemphasis ontheanalysisofbiomarkers,fabricationtechniques,andpotential real-timeapplicationsforbiochemicalsensingareincludedinChapter 10.Thereisalwaysgrowingdemandforflexibleandskin-interfaced sensorscapableofthereal-timemonitoringofrelevantbiomarkers fromhumanbodyfluids,likesweat,saliva,tear,andinterstitialfluid. Thedesignofnanomaterials-basedelectrochemicalsensorsenhances thesensitivityofdetection,andChapter11discussesnanomaterialsbasedflexibleelectrochemicalsensorsforhealthcaremonitoring.Artificialsynapticdevicesareoneofthemostfar-fetchedapplicationsof nanostructuredmaterials.Artificialneuralnetworksbasedonresistive switching(RS)devicesareconsideredoneofthemoststraightforward andcost-effectivewaysofrealizingthistechnology.Apartfromthat,RS hasfoundimmenseapplicationsinsemiconductorelectronicsaswell. ThemechanismofRSinnanostructuresanditsnumerousapplications arediscussedinChapter12.Shapememoryalloys(SMAs)aresmart materialsthatexhibittheuniquepropertyofashapechangeupon exposuretoachangeintemperature.ThecombinationofnanomaterialsandSMAshelpstotailorthepropertiesandtofabricateseveral nanodevicesbasedonindividualnanoobjects.Oneoftheemerging technologiesofnanotweezersbasedonshapememorycompositematerialsandtheirapplicationformanipulatingrealnanoobjectslike nanotubesandnanowiresisdiscussedinChapter13.Thefinalchapterofthisbookelaboratesontheoutstandingphysicalandchemical propertiesofdiamond.Varioustechniquesforthegrowthofdiamond intheformofthinfilmsondifferentsubstratesandtheircharacteristics areexplained.

Itisveryexcitingtofinallypublishthisbookon“Nanomaterials forsensingandoptoelectronicapplications.”Therearemanypeople towhomwearegratefulfortheirvaluablecontributions.Weextend oursincerethankstoMs.Priya,M.J.,Mr.Manu,S.,Mr.Midhun,P.S., Ms.Krishnapriya,T.K.,Ms.Anju,K.S.,Mr.Subin,P.S.,Ms.Navami, S.,Mr.Jose,V.R.,Dr.Anjana,R.,Dr.Pillai,A.M.,Dr.Saji,K.J., Dr.Asha,A.S.,andpresentandformerresearchersatNanophotonicandOptoelectronicDevicesLaboratory(NPOED),Department ofPhysics,CochinUniversityofScienceandTechnology.Theyhave

contributedtheirresearchresultsmeticulouslyforeachchapterof thisbook.Wealsotakethisopportunitytothankwithdueregards, Prof.Kumar,K.R.,DepartmentofInstrumentation,CochinUniversityofScienceandTechnology;Dr.Shibu,E.S.,Departmentof NanoscienceandTechnology,UniversityofCalicut;Dr.Biji,P.,DepartmentofChemistryandNanoscienceandTechnology,PSGInstitute ofAdvancedStudies;Dr.Vinu,M.V.M.,CSIR-CentralElectrochemicalResearchInstitute(CECRI),Karaikudi;Prof.Sampath,V.,Indian InstituteofTechnologyMadras,India;VonGratowski,S.andKoledov, V.,KotelnikovInstituteofRadioEngineeringandElectronicsofthe RussianAcademyofSciences,Moscow,Russia;andDr.Chandran, M.,DepartmentofPhysics,NationalInstituteofTechnology,India,for theircontribution.

ItwasapleasantexperiencetoworkwiththeElsevierEditorial team,whohaveenabledthetimelypublicationofthisbook.

Dr.M.K.Jayaraj Dr.P.P.Subha Dr.T.Shibi

1

Facet-dependentgassensingpropertiesofmetaloxidenanostructures danglingbonds,atomicsteps,andedges,whichleadstomoreactive sitesforgasadsorption;hencesensingmaterialsexposedwithhighenergyfacetsshowgreaterreactivitythanthoseexposedwiththelowenergyfacets(Gao&Zhang,2018; Kuangetal.,2014; Pal&Pal,2015; Shang&Guo,2015).

ThischaptergivesabasicidearegardingMOS-basedsensors,includingtheirgassensingmechanism,thedesignofthegassensor,the designofthegassensingmeasurementunit,differentperformance parameters,anddifferentstrategiesadoptedfortheimprovementof theperformanceofMOSgassensors.TheimportanceofMOSswith exposedhigh-energyfacetsintheimprovementofgassensingperformancehasbeendiscussedindetail.Also,theeffectsofdanglingbond densityongassensingpropertieshavebeendiscussed.Accordingto theresearchandcalculation,surfaceengineeringbyselectivelyexposinghigh-energyfacetsprovidesaneffectivewaytoobtainMOSgassensitivematerialswithsuperiorperformance.Theunderstandingof thefacet-dependentpropertiesofMOSwillleadtothefabricationof moreeffectivegassensorsinthefuture.

1.2Metaloxide–basedgassensors

1.2.1Gassensingmechanism

ThefundamentalprincipleofMOS–basedchemoresistivesensors isthechangeintheconductivityoftheMOSduetotheoxygenadsorptionanddesorptionreactionsonthemetaloxidesurface.Inthe caseofann-typeMOS-basedgassensorthesensingmechanismisas follows:inambientairatmosphere,oxygenadsorbedonthesurfaceof thesensinglayerbyextractingelectronsfromtheconductionbandof theMOS,whichresultsintheformationofaSchottkypotentialbarrier inMOS(Shankaretal.,2016).Theadsorptionofoxygenonthesurface ofMOSdependsontheoperatingtemperatureofthesensor.Atlower temperatures(<150°C),oxygenmoleculesareadsorbedintheformof molecularoxygenions(O2 )viathetrappingofacomparablyfewer numberofelectrons;however,athighertemperatures(>150°C),more electronsaretrappedbytheadsorbedoxygenandformatomicoxygen species(O andO2 )(Kashifetal.,2013).Theprocessesinvolvedin theadsorptionofoxygenonthemetaloxidesurfacecanbedescribed asfollows:

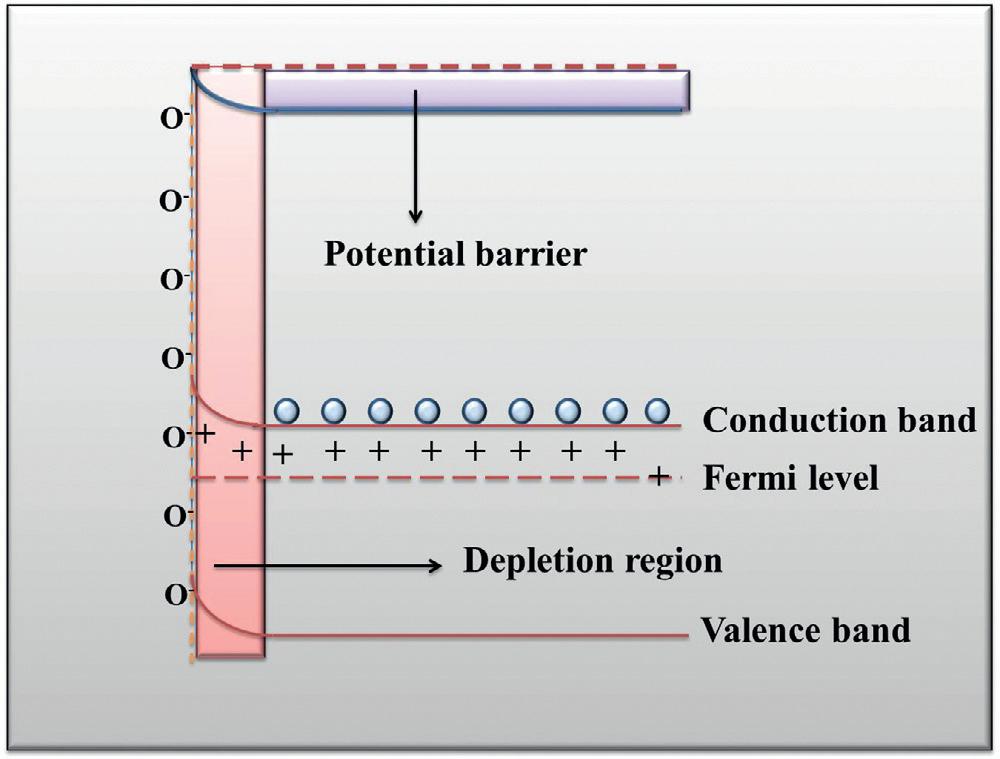

Theextractedelectronsfromthe conductionband(Ec )leavebehindpositivelychargedions,resultinginupward bandbendingandtheformationofan electron-depletionregionoraspacechargelayerintheMOS,asshownin Fig.1.1.Theheightanddepthofthe bandbendingdependontheamount andtypeofadsorbedoxygen.Dueto theformationoftheelectrondepletion region,anincreaseintheresistanceof theMOScanbeobserved.Whenthis surfaceisexposedtoreducinggases suchasacetoneandammonia,theadsorbedoxygenionsinteractwiththetargetgasesandthetrappedelectronsare releasedbackontotheMOSsurface.Theamountofoxygenremoved fromthesurfaceisproportionaltotheconcentrationofthereducing gas.Thustheheightanddepthofbandbendingandtheresistance oftheMOSdecrease(Ananya,2018; Shankaretal.,2016; Wangetal., 2010).TheoxygendesorptionfromtheMOSsurfaceinthepresenceof areducinggas(say,R)canbedescribedasfollows:

Figure1.1. Schematic representationofbandbending aftertheadsorptionofoxygen species(Priyaetal.,2021).

TheseelectronsarereleasedbackontotheMOSsurfaceandthe producedgasandwatermoleculearereleasedintotheatmosphere.On theotherhand,anoxidizinggasdepletesthechargecarriers,leadingto anincreaseinresistance.Similarly,inthecaseofp-typeMOS,where positiveholesarethemajoritychargecarriers,adecreaseintheresistanceisobservedinthepresenceofanoxidizinggasandanincrease intheresistanceinthecaseofareducinggas(Barsanetal.,2012; Neri, 2015; Subha&Jayaraj,2019). Table1.1 clearlysummarizestheresponse ofn-andp-typeMOStowardreducingandoxidizinggases.

1.2.2DesignofMOSgassensors

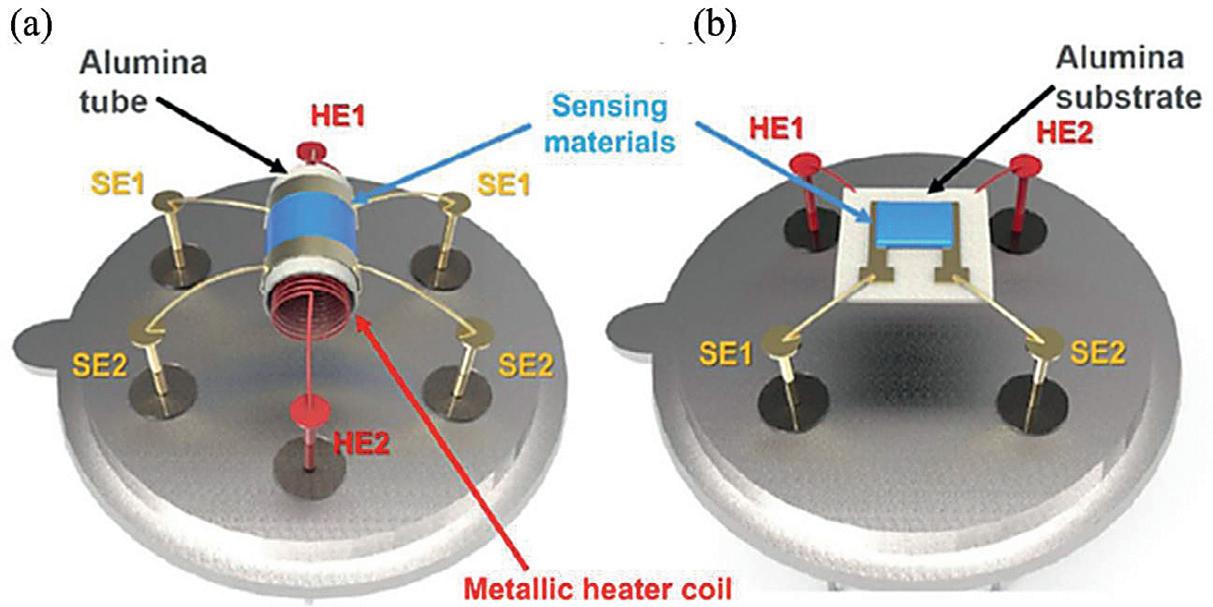

Thecommonlyavailableconfigurationsforthedesignof semiconductor-basedgassensorsare(1)sinteredpelletgassensors (Kazemietal.,2016),(2)thick-filmgassensors(Arshak&Gaidan, 2005),and(3)thin-filmgassensors(Mirzaeietal.,2019).The disadvantagewiththeuseofsinteredpelletgassensorsistheir relativelylowgasresponseduetothelimitedsurfacearea(Mirzaei etal.,2019).Thereforeresearchersaremoreinterestedintheuse ofthin-orthick-filmgassensorseitherinthetubularorplanar configuration,asshownin Fig.1.2.

Table1.1Changeintheresistanceofn-andp-typeMOSwhenexposed toreducingandoxidizinggases.

TypeofMOS

Whenexposedto reducinggases

Whenexposedto oxidizinggases

n-typeResistancedecreaseResistanceincrease p-typeResistanceincreaseResistancedecrease

Figure1.2. Schematicdiagram ofmetaloxidegassensor configurations:(A)tubularand (B)planar(SEandHErepresent thesensorelectrodeandheater electrode,respectively). Reproducedwithpermission from(Lee,2018),Copyright2018, Elsevier.

Thin-orthick-filmsensorsarepreparedbydepositingasensitive layeronaninsulatingsubstratesuchasalumina(Al2 O3 )andSi/SiO2 wafer.Themetaloxidepowderisgroundtogetherwithsuitablesolventslikeethanolandterpineolusinganagatemortartoformaslurry forthetubularconfiguration.Thentheslurryiscoatedonanalumina tube,onwhichapairofAuelectrodeshadbeenprintedpreviously, followedbydryingandsubsequentannealingathightemperatures. Finally,asmallNi–Cralloycoilisinsertedintothetubeasaheaterso astoadjustandoptimizetheworkingtemperatureofthegassensor.

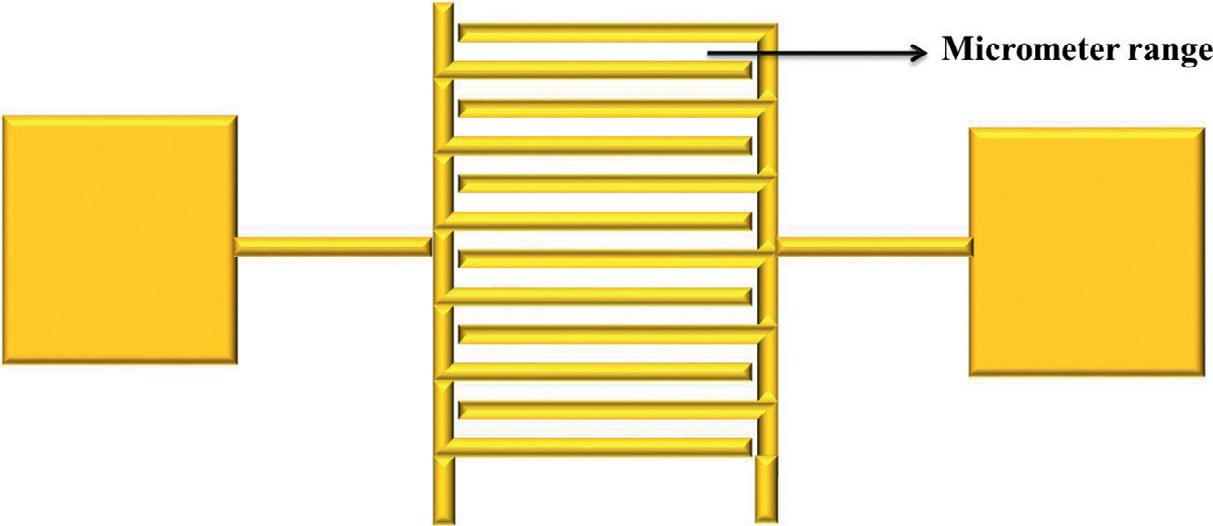

Thetubularconfigurationisshownin Fig.1.2A.Si/SiO2 oraluminasubstratewithpreprintedinterdigitatedgoldelectrodesiscommonlyused forthefabricationofplanarsensors(Fig.1.2B).Aschematicdiagram oftheinterdigitatedpatternisshownin Fig.1.3.Theuseofplatinum electrodesislimitedduetotheirhighcost.InsuchcasesAuelectrodes aremorepreferred.Theworkingtemperatureisobtainedbyplacing thedeviceontheexternalheaterorwiththehelpofaninternalheater printedatthebackofthesubstrate.Theplanarconfigurationismore

preferredforlarge-scaleproductionduetotheimprovedfabrication productivityandqualityofthesensor(Lee,2018; Mirzaeietal.,2019).

Whenweconsiderthesubstratematerial,aluminaisthebestavailablesubstratematerialduetoitshighthermalconductivityandstability,lowthermalexpansioncoefficients,highmechanicalstrength, andlowelectricalconductivity(Lee,2018).Thehighthermalstabilityof aluminaisanimportantfeaturesincemostMOS-basedsensorswork atrelativelyhighertemperatures.However,forthefabricationofelectrodesinthemicrometerrange(<10μm),microfabricationtechniques suchasUVorelectron-beamlithographyhastobeemployed,which leadstothepreferenceofaSi/SiO2 waferasthesubstratematerial overthealuminasubstrateduetothesurfaceroughnessofalumina substrate.

Plasticfoilscanalsobeusedassupportingmaterialsduetothe increasingdemandforflexiblegassensors.Theadvantagesofplastic foilsaretheirfoldableandwearabledesign,lightweight,transparency, andmassproductivityduetoroll-to-rollprintingprocesses.Polymers suchaspolyimide(PI),withrelativelyhighthermalstability,havebeen widelyusedassupportingmaterialsforflexiblesensorsoperatingata relativelyhighertemperature.However,theoperationofMOSsensors above400°CisdifficultusingPIsubstrates(Wangetal.,2016).

1.2.3Gassensingmeasurementsystem

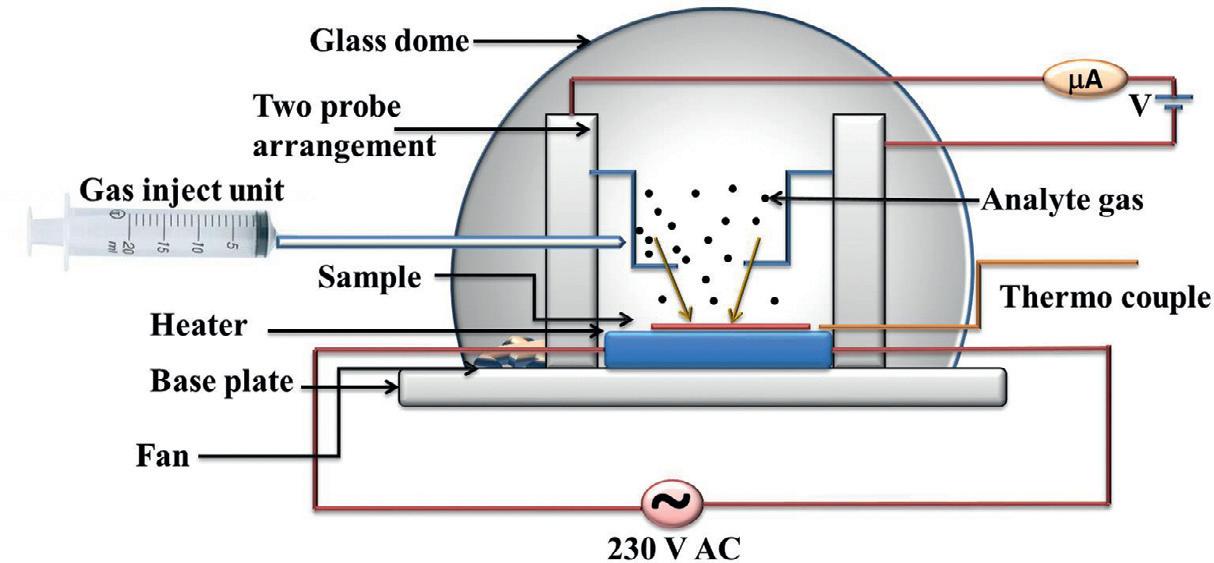

Generally,twotypesofmeasurementsystemsarecommonlyused forstudyingthegassensingpropertiesofthedevice:staticanddynamic. Fig.1.4 showstheschematicdiagramofastaticmeasurement system.Thesystemconsistsofatransparentgaschamberofadefined volumewithagasinlet.Thesampleisplacedinsidethechamberunder acontrolledtemperatureandhumidity.Theoperatingtemperatureof thesamplecanbeadjustedbyvaryingtheheatingvoltage.Duringthe measurement,afixedamountofanalytegasisinjectedthroughthegas

Figure1.3. Schematicdiagram oftheinterdigitatedelectrode pattern.

Figure1.4. Schematicdiagram ofthestaticgassensing measurementsystem(Mirzaei etal.,2018, 2019; Patil,2007).

Figure1.5. Schematicdiagram ofthedynamicgassensing measurementsystem.

inletwiththehelpofasyringe.Touniformizethedistributionofthe injectedtestgas,anelectricalfanisinstalledinsidethechamber.The concentrationofanalytegasiscalculatedwiththeratioofthevolumeof theinjectedgastothevolumeofairunderstandardatmosphericpressure.Afterreachingsaturationinthecurrent,thechamberisopened torecovertotheinitialcurrentintheairatmosphere.Theprocedure isrepeatedfordifferentanalytegasesatdifferentconditions(Mirzaei etal.,2018, 2019).

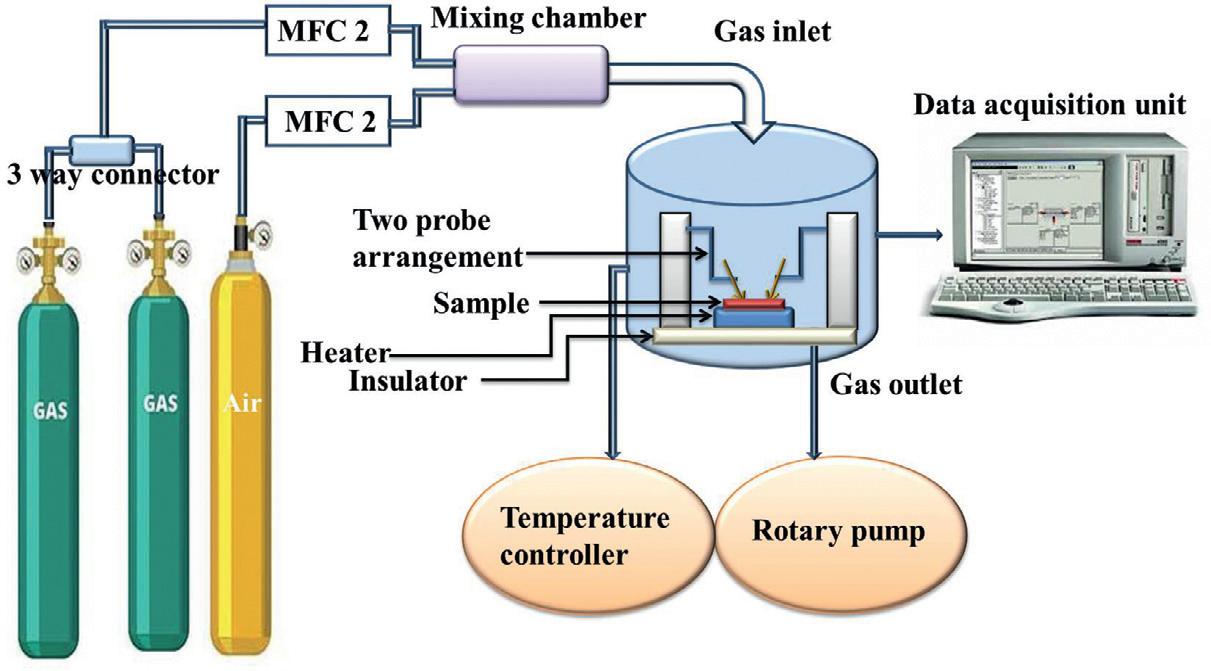

Adynamicsystemconsistsofgascylinderswithaknownconcentration,massflowcontrollers(MFCs),atestchamberwithagasinletandoutlet,heatingarrangement,electricalmeasurementarrangements,anddataacquisitionsystems,asshownin Fig.1.5.Withthe helpofMFCs,theflowrateofanalytegasesandsyntheticaircan becontrolled.Theconcentrationofanalytegasescanbechangedby mixingproperlywithsyntheticairornitrogeninamixingchamber connectedpriortothetestchamber.Thenthemixedvolumeofgas

ispassedintothetestchamberthrough thegasinlet.Thesampleisplacedon anexternalheaterandtheworkingtemperaturecanbecontrolledwithatemperaturecontroller.Thesampleisconnectedtoameasurementunittorecord thecurrentvariationcontinuously.Duringmeasurement,thecurrentthrough thesampleinairandinthepresence ofanalytegasatdifferenttemperatures isrecorded.Finally,afterthemeasurement,thegasfromthetestchamberis removedwiththehelpofarotarypump arrangement.

1.2.4Performanceparameters

Thegas-sensingperformanceofsensorsisevaluatedusingthefollowingimportantparameters(Balaguru2004; Tonezzeretal.,2015; Tshabalalaetal.,2016).

1.2.4.1Gasresponseandsensitivity

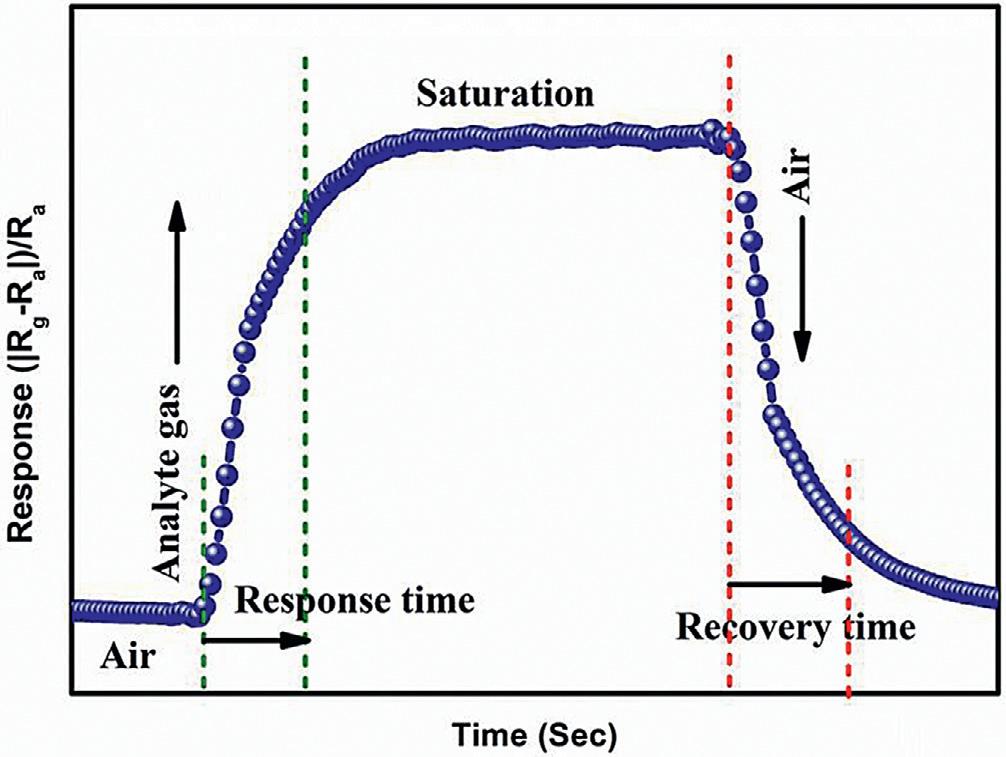

Generally,theresponseofasemiconductor-basedgassensoris definedasfollows: Response = Rg Ra Ra (1.6) where Ra and Rg representtheresistancesofthegassensorinthe presenceofairandtargetgas,respectively.Atypicalresponsecurve isshownin Fig.1.6.Sensitivityisthechangeinmeasuredresistance ( R)withachangeinanalyteconcentration( C),i.e.,theslopeofa calibrationgraph:S = S = R/ C .

1.2.4.2Selectivity

Itistheabilityofasensortodifferentiateaspecifictargetgasfrom amixtureofgases.Agoodsensorwilldetectaparticulargaswhile remaininginsensitivetoothergases.Theselectivitycoefficient(K)of agassensorcanbewrittenas K = SI SII (1.7) where SI and SII arethesensingresponsesofthesensortowardtwo differentgases,IandII,respectively.

1.2.4.3Stability

Stabilityisdefinedasthereproducibilityofthedeviceinthesensing measurementafterlonguse.Toavoidtheeffectsofnonrepeatability

Figure1.6. Typicalresponse curveofanMOS-basedgas sensor.