Theimportanceofdecision supportinmaterialsselection

LearningAims

Theoverallaimofthischapteristogainanoverviewofdecision-makinginvolved inmaterialsselection.Aftercarefullystudyingthischapteryoushouldbeableto understand:

● thecriticalstagesofthematerialsselectionprocessassociatedwithdesigningnew products

● thesignificanceofsupportingeffectivedecision-makinginmaterialsselection

● thenotionofrelationshipbetweendesign,materials,andmanufacturingprocesses

● thechallengesofselectingmaterialstosatisfyconflictingdesignrequirements

● theeconomicconsiderationsthatshouldbetakenintoaccountwhenselecting materials

● theapproachesthatcanbeusedforsubstitutingeitherconventionalornewmaterials inproductdesign

● theroleofmaterialsinthecreationofsustainableproducts.

1.1Introductiontomaterialsselection

Theselectionofthemostappropriatematerialforaparticularpurposeisacrucial functioninthedesignanddevelopmentofproducts.Materialsinfluenceproduct function,customersatisfaction,productionsystems,productlifecycle,whoisgoing touseorproduceit,usability,productpersonality,operatingenvironment,andcosts inacomplexway.

Materialsselectioncanbecarriedouttoeitherchoosealternativematerialsfor changestothedesignofanexistingproductinordertoreducesaycostorweight, meetnewlegalrequirements,overcomefailureoccurrence,orsatisfydifferentmarketdemands,oritcanbeusedtochoosematerialsforthedesignofacompletely newproduct.Thematerialsselectionprocessissimilarforexistingandnewproductsalthoughthestartingpointandinformationrequirementsmaydiffer.The interdisciplinaryeffortrequiredinmostcasesisnontrivialandtheengineering designernotonlyrequiresdetailed,accessible,andtimelyinformationaboutmaterials’propertiesbutalsoknowledgeofmulti-criteriadecision-making(MCDM).

ThisbookdescribesthemainprinciplesandstrategicapplicationofMCDM techniquestosupportengineeringproductdesignerscomparetheperformanceof establishedmaterials,hybridmaterials,andnewmaterials,whenselectingthemost appropriatematerialsfornewproductdesign.

1.2Backgroundandjustificationforformalized materialsselection

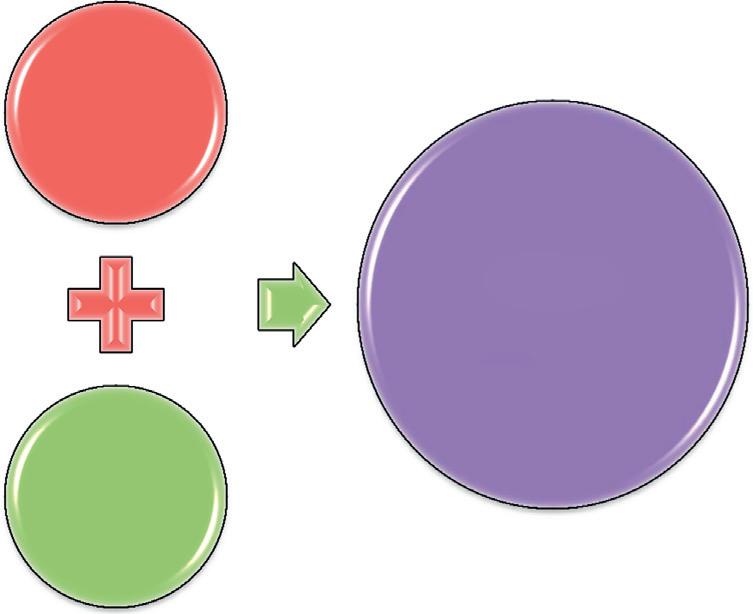

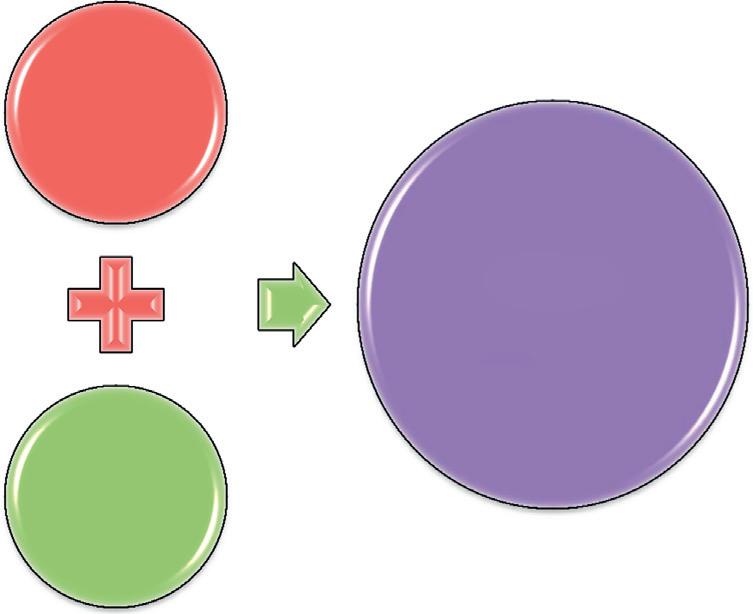

Thereareanenormousnumberofmaterialsavailable,eachwitharangeofdifferent propertiesandbehaviors.Newmaterialsarealsoconstantlybeingdevelopedwith enhancedproperties,expandingthelistofoptionsavailabletotheengineering designer.Thematerials’properties,andcombinationofpropertiesintheformof performanceindices,canbemappedontomaterials’selectioncharts,pioneeredby Ashby(2013).Inthecharts,thematerialsnaturallyclusterintothedifferentclasses ofmetals,polymers,elastomers,glasses,andceramics.However,onlypartsofthe chartsarepopulatedwithmaterials,leavingholesorgapsintheselectionspace. Newmaterialswithenhancedpropertiescanreducethesizeoforfillgapswithin clusters,orexpandtheboundaryofclusters,orthegapsbetweenclusterscanpotentiallybefilledor“bridged”withhybridormulti-materialssuchascompositematerialsasshownschematicallyin Fig.1.1

Thehistoricalevolutionintheuseanddevelopmentofmaterialsreflectsthe progressoftheinterdisciplinarysciencefromtheearlycivilizationsuntiltoday (BrechetandEmbury,2013).Thestrategywithrespecttomaterialsusagestartedin theStoneAgebyusingtheavailablematerialssuchasstoneandwoodandthen latercopperandbronze(BronzeAge)andiron(IronAge).Afterwards,thestrategy graduallyfocusedontheoptimizationofspecificclassesofmaterials.Thisleadto thedevelopmentoftoolsforcomparingandselectingmaterialsfromdifferentclassesofmaterialsalreadyoptimizedintermsoftheirengineeringpotential.Today, theemphasishasshiftedmoretowardstheconsiderationofeconomicalaspectsand environmentalimpact.Thishascreatedatendencytowardsthedevelopmentof materialsusingdesignstrategieswithanincreasedimportanceofmodelingand multi-functionalityofmaterials(BrechetandEmbury,2013).However,thereisstill

alotoffundamentalmaterialsresearchbeingconductedwithoutcarefulconsiderationbeinggiventoitspracticalapplication(Edwards,2011).Thisnotonlyjustifies theneedforthegreateruseofmaterialsselectiontoolsbutalsotheimportanceof supportingdecision-makingtobetterunderstandandmanagethemulti-objective productdesignprocess.

1.3Decision-makingandconcessioninproductdesign

Introducingacompletelynewproductorimprovinganexistingproductinvolvesa complexchainofinterdependentactivitiesincludingdesign,analysis,materials selection,andconsiderationofmanufacturingprocesses,andalldependonMCDM. Aswellasinfluencingmaterialproperties,processselectionisaprerequisiteto manufacturingequipmentselection.However,materialsselectionusedtobeonlya minorpartofthedesignprocess(Chiner,1988)andthereforehasnotreceivedthe samelevelofresearchanddevelopmentasotherfieldsofdesign.Theselectionof suitablematerialsforaspecificpurposethoughisadifficult,time-consuming,and expensiveprocessbecauseofthelargenumberofavailablematerialswithcomplex relationshipsandvariousselectionparameters.Asaconsequence,approximations aremadewithmaterialsfrequentlybeingchosenby“trial-and-error”orsimplyon thebasisofwhathasbeensuccessfullyusedinthepast.Thisapproachthoughcan leadtocompromiseandunpredictableoutcomes,possibleprematurefailures,and limitstheabilitytoachieveanoptimalchoiceofmaterials.

Thestagereachedinthedesignprocessisimportantbecausetheneareraproductistomanufacturethegreateristhecostofmakinganydesignchange(Charles etal.,1997).Ithasbeenestimatedthattherelativecostofadesignchangeafter manufactureis10,000timesmorethanattheconceptualstageofdesign(Charles etal.,1997).Therefore,itisworthmakingdecisionscarefullyandspendingenough timeearlyoninthedesignprocessusingsystematicselectiontechniques.This makesiteasiertomanagethe“trade-offs”betweendesign,materials,shape,and manufacturingprocessesandleadtoanoptimumdesignsolution.

Tosatisfycustomerrequirements,manufacturingorganizationsmustbecontinuallyawareofproductcosts,reliability, durabilityandrecyclability,andmarket trends.Theseattributesshouldbeaddressedstrategicallybymanufacturers throughacontinuousprocessofimprovementinanongoingefforttoimprove theirproducts(JahanandEdwards,2013 ).Thiswillonlybefullyachieved throughoptimumdecision-makingabout design,materials,andmanufacturing processes( Chakladaretal.,2009;Blanchetal.,2011)andprovidestheopportunityforsustainableandprofitablegrowth.Tosupportthisprocess,MCDMtechniqueshavedevelopeddramaticallyinboththeoryandpractice,especiallyinthe fieldsofdesignandmanufacturing,withgrowinginterestintheirapplicationto materialsselection.

1.4Thepositionofmaterialsselectioninthe engineeringdesignprocess—fromconceptto detailstages

Thesuccessfuldesignofanengineeringcomponentisintegraltosatisfyingthe functionalandcustomerspecifiedrequirementsfortheoverallproductofwhichit formsapart,utilizingmaterialpropertiesandcapabilitiesofsuitablemanufacturing processes(Zarandietal.,2011).Thebehaviorofamaterialusedtocreateacomponentwillbeaffectedbycomponentgeometry,externalforces,propertiesofstock materialbeforeprocessing,andtheeffectofmanufacturing(orfabrication)method (Farag,2008a).Theevaluationofthetypicallylargenumberofdesignsolutions (alteringthesize,shape,andmassofthecomponent)andsuitabilityofaneven largernumberofdifferentmaterialsrapidlybecomestoocomplicatedtobeintuitive.ThishighlightsthevalueofbeingabletouseMCDMtosupportdecisionmakingintheengineeringdesignprocess.Althoughexperimental-basedselection ofamaterial,eg,testing,prototyping,etc.,foraspecificdesignsolutionisthemost accurate,itquicklybecomesunreasonableduetothetimerequiredandthehigh costsofexperiments,especiallyifseveralmaterialshavetobeconsidered. Alternatively,othermoreviableoptionscanbeconsideredsuchascomputer-based simulationsbuttherankingofmaterialsshouldhavealreadybeensuccessfullycompletedduringtheinitialstageofthedesignprocess(JahanandEdwards,2013).

Fig.1.2 showsconnectionofmaterialsselectionandcontinuousimprovementin productdevelopment.Thereistheoptiontodevelopanewmaterialbutthisadds costandrisktothedesigneffortsandhasbeenhighlightedherefortheoccasion whenthereisnoacceptablematerialoptions(Michael,2009;Edwards,2008). However,theaddedcostandriskmaybeworthwhileifthereisaninnovationthat providesaproductwithacompetitiveadvantagecomparedtoproductsproducedby othercompanies.In Fig.1.3,qualitytoolssuchasqualityfunctiondeployment (QFD)(MayyasandShen,2011;Kazemzadehetal.,2009)helpsmarketingand designteamsincorporatethevoiceofthecustomerinproductdesigns,increasing

Product design requirements

Design and select materials (apply design tools) Manufacture and test product

service experience (apply quality tools) Improve design and/or change materials

Figure1.2 Materialsselectionandcontinuousimprovementinproductdevelopment.

thelikelihoodthatthefinalproductwillsuccessfullysatisfythecustomer’sneeds. Failuremodesandeffectsanalysis(FMEA)(Chinetal.,2008)willindicatethe material’sattributesthatmustbeinvestigated,controlled,andmonitoredtoensure thereliabilityofthecomponentinwhichthematerialisused.Itwillalsoindicate themanufacturingprocessstepsandcontrolsthatarerequiredtomakeaproduct, subassembly,orcomponentthatwillconsistentlymeetitsdesignrequirements. Therefore,QFDandFMEA,whenusedasqualitytoolsindesign,candramatically improveproductdevelopmentefficiencybecausetheyleadtosystematicdesign, materialsselection,andmanufacture.

Ashby(2005) and Ashbyetal.(2013) maptheapplicationofdesigntoolsand materialsselectiononthetraditionalsystematicproductdevelopmentprocess.The resultingmethodologyisa“design-led”approachtomaterialsselection.Computerbaseddesigntools,ofwhichtherearemany,enablevisualization(eg,2D Computer-AidedDesign(CAD)),modeling(eg,3Dsolidmodeling),andanalysis (eg,finiteelementanalysis(FEA))tobeconducted,aswellasinteractivesimulationofevolvingdesignsolutions.Toensurethatproductdesign,materials,andprocessselectionaredonetogether,DesignforManufactureandRapidPrototyping toolsarealsoregularlyused.Therearefewertoolsavailablethatarededicatedto materialsselection,andevenlessformaterialsprocessselection,althoughmany designtoolsmakeuseofmaterialspropertiesdatabases.Ateachstage,fromconcepttodetaildesign,informationaboutthematerialsgraduallychangesinthelevel ofdetailandprecision,asthenumberofavailablematerialsreducesfrominitially allpossiblematerialstofinallyonematerial.

Fundamentally,thestrategyforselectingmaterialsisdeterminedbytheneedto satisfydesignrequirementsandinvolvesfivemainstages:

1. Definitionofthedesign(Chiner,1988).

2. Analyzingandtranslatingthedesignrequirements(expressedasconstraintsand objectives)intomaterialperformanceindices/properties(Ashbyetal.,2004;Dieter,1983, Chiner,1988; vanKesterenetal.,2006).

3. Comparingthepropertiesrequiredwithamaterialspropertydatabaseinordertoselecta fewcandidatematerialsthatlookpromisingfortheapplication(vanKesterenetal.,2006,

Figure1.3 Combiningmaterialsandproductinformationinthematerialsselectionprocess.

Jalham,2006;Ashbyetal.,2004;Dieter,1983,Chiner,1988; Giaccobietal.,2009; Farag,2002).Screeningisbasedontheideaofclassifyingperformancerequirementsinto “rigid”and“soft”requirements(Farag,1979).“Rigid”requirementscanbeusedforthe initialselectionofmaterialstoeliminateanyunsuitablegroups.Softrequirementsarenormallysubjectedtonegotiationandcompromiseandthereforeinvolvemorecomplicated decision-making.Examplesofrequirementsinthisgroupconsistofmechanicalproperties,physicalproperties,andcost,whicharenormallycomparedonthebasisoftheirrelativeimportancetoanengineeringdesign.Forinstance,high-specificstiffnessandstrength materialssuchasfiber/polymercompositesareusedforadvancedsportsequipment.

4. Developing,comparing,andrankingalternatives(Farag,2002;Ashbyetal.,2004; Jalham,2006; vanKesterenetal.,2006)andusing“soft”materialrequirementstofurther narrowthefieldofpossiblecandidatesdowntoafewpromisingmaterials.

5. Searchingforsupportinginformationaboutthetop-rankedcandidatematerials(Ashby etal.,2004),evaluationanddecisionfortheoptimalsolution(Dieter,1983;Chiner,1988, 2006; Farag,2002),andfinallyverificationtests(Chiner,1988).

1.5Understandingthefunctionalrequirementsand designcriteriainselectingmaterials

Theperformancerequirementsofmaterialscanbeclassifiedintotwomaincategories:“rigid,”or“go-no-go”requirementsand“soft,”orrelativerequirements (Farag,1979).“Rigid”requirementsshouldbemetbythematerialifitistobeconsideredatall.Suchrequirementscanbeusedfortheinitialselectionofmaterialsto eliminateunsuitableclassesofmaterials.Forinstance,metallicmaterialsareeliminatedwhenselectingmaterialsforanelectricalinsulator.“Soft,”orrelativerequirements,aresubjecttonegotiationandtrade-offs.

Apartfrommaterials’properties,otherrequirements,suchasthoseonmaterials processingduringcomponentmanufacturingandthoseonin-serviceconditions relatingtothematerialsofcomponents,shouldalsobetakenintoaccountinmaterialsselection(EdwardsandDeng,2007).

Thedesignofaproductiseithercostdrivenorperformancedrivenandthe approachtakenmakesasignificantdifferencewhenchoosingmaterials.Anexampleofacost-drivenproductisamassproducedmotorcarorbeveragecan/bottleand anexampleofaperformance-drivenproductisabespokebiomedicalprosthesis/ implantoratennisracquet.Theselectionofcheapermaterialsmayleadtoreduced manufacturingorganizationcostbuttheselectionoflightermaterialsalthoughmore expensive,insayamotorcaroraircraft,mayreducefuelconsumption,servicecost, andenvironmentalpollution.

1.6Combiningfunctionalandhuman-centeredattributes inmaterialsselection

Theprocessofselectingmaterialsforthedesignofproductsiscomplicatedbecause oftheneedtomatchasetofcontradictorydesignrequirements,bothfunctionaland 6Multi-criteriaDecisionAnalysis

human-centered(user)attributes,toarangeofmaterialpropertiesandcharacteristics(sensorialqualities),allhavingeconomicimplications(Brechetetal.,2001). Thisoftenleadstocompromiseinthedesignandchoiceofmaterials,resultingin poorproductsandusersatisfaction(LjungbergandEdwards,2003).Thereare methodsavailabletohelpselectmaterialsandthesehaveprovedeffectivenessfor productfunctionalrequirements.Themethodsaremostlysystematicandnumericallybased,withsomeimplementedascomputersoftwarepackages,anddependon matchingthedesiredmaterialpropertyattributesagainstthosefromavailablematerials.Itisalsorelativelyeasytoaccessalotofdetailedtechnicalinformationthat isavailablefrommanydifferentsources.Thereismuchlesssupportavailablefor human-centeredrequirementsdespiteitbeingequallyasimportanttothesuccessof aproduct.Thisismainlybecausehuman-centeredrequirementsarenotconducive toformalsystematicprocedures,andinformationonmaterialcharacteristicsis muchlessavailable.Also,thepropertiesandcharacteristicsofmaterialsareinterrelatedandideallyshouldbeconsideredtogether(UlrichandEppinger,2004).

Mostproductsaredifferentiatedbytheirtechnicalfunctionsandbywhatthe materialstheyaremadeofmeantotheuser(Karana,2006).However,unlikefunctionalrequirements,whicharedefinedinquantitativetermsandcanbeassessed objectively,human-centeredrequirementsareexpressedinqualitativetermsand hencearemoresubjectiveanddifficulttointerpret(SchiffersteinandHekkert, 2007).Also,thelackofstructuredapproachescanleadtounpredictableoutcomes, withmaterialcharacteristicsnotbeinggivensufficientpriorityinthedesignprocess. Thereisthereforealotofrelianceontheskillandexperienceofproductdesigners whenselectingmaterials.Foreffectivematerialsselectioninproductdesign,both functionalandhuman-centeredrequirementsneedtobethoroughlyconsidered (Karanaetal.,2008).Unfortunately,thepropertiesandcharacteristicsofmaterials areoftendivergent,whichregularlyresultsinconflictwhentryingtosatisfyallthe designrequirements.Therefore,prioritieshavetobegiventothedesignrequirementsthatareconsideredtobeessentialandrestrictedbywhatmaterialswillallow.

Thematerialsselectionprocessessentiallyconvertsasetofdesignrequirements intoalistofsuitablematerialsasshownin Fig.1.3.Tobesuccessful,theprocess reliesheavilyonaccesstoinformationondifferentmaterialpropertiesandfeatures andproductfeaturesanduses.However,unlikematerialproperties,materialcharacteristicsaremuchmoredifficulttoquantify,andhencemorechallengingtolocate, sort,anduseappropriately.Therearesimilarproblemswiththeuseofexisting productdesignfeatures,oruseofmaterialsinproducts,becausetheyaredifficultto categorizeforretrievalpurposesandthereforemostlyrelyonintuitionandexperiencewhencomparingwithnewproductdesigns.Thisregularlyleadstonewproductsbeingdesignedwithintheconfinesoftheexistingknowledgeofmaterialsand productsonly,andasaconsequencestiflingdesigninnovation.

Thematerialsselectionmethodsusedforfunctionalrequirementsarebasedon systematicanalysis.Themethodsdependonpreciseinformation,models,andsets ofrulesthatcanbemanipulatedtoaccuratelymatchdesignrequirementswith materialproperties.Thematerialsselectionmethodsusedforhuman-centered requirementsarebasedonanalogyandsynthesis.Themethodsrelyonpast

8Multi-criteriaDecisionAnalysis

experienceandtheabilitytomatchdesiredfeatureswiththoseofpreviousdesign solutions.However,foraproducttobesuccessful,thedifferentmethodsofmaterialsselectionhavetobecombinedstrategicallyandusedappropriatelytoallow decisionstobemadethataresensitivetothechangingnatureoftheselectionproblemasthedesignevolves(vanKesteren,2008).However,iftheinformationis quantifiable,analysiscanbeusedandiftheinformationisqualitative,synthesis canbeused.Thematerialsselectionprocesswillthereforealternatebetween analysis-andsynthesis-basedmethodsandthisneedstobecarefullymanagedto helpensureconsistencyindecision-making.TheMCDMtechniquecanbeusedto provideoverallsupportofthematerialsselectionprocessbyallowingthesimultaneousconsiderationofdesignrequirements,materialpropertiesandcharacteristics, andproductfeaturesanduses(Jahanetal.,2010).

1.7Costconsiderationsofmaterialsselection/ substitution

Whenconsideringthefactorsthatdecidethesuccessofaproductinthemarkettoday itbecomesclearthatcostisascrucialasqualityandfunctionality(Layeretal.,2002). Thetermcostmeansthesumofmoneyexpendedintermsoflabor,materials,useof equipment,etc.,toproduceaproduct(Layeretal.,2002).Productdesign,especially theselectionofmaterials,canhighlycontributetototalproductcost(AsieduandGu, 1998).Thechoiceofmaterialshasimplicationsthroughoutthelifecycleofaproduct, influencingmanyaspectsofeconomicandenvironmentalperformance.Ithasimpacts ontheconsumptionofrawmaterialsandenergy(ThurstonandLocascio,1994). Economicadvantagecanbeachievedasaresultofintroducingcheapermaterials, morecost-effectiveuseofmaterials,lowercostofprocessing,betterrecyclabilityand lowercostofdisposal,orlowerrunningcostoftheproduct(Farag,2008b).Although bothdesignandeconomicjustificationshavethecommongoalofarrivingatacompetitiveproduct,theirgoalsarediametricallyoppositetoeachother(Nobleand Tanchoco,1990).Therefore,costcanbeemployedasanevaluationcriterionindesign eitherinadesign-to-costordesign-for-costcontext.Design-for-costistheconscious useofengineeringprocesstechnologytoreducelifecyclecost(LCC),whiledesignto-costcreatesadesignsatisfyingthefunctionalrequirementsforagivencosttarget. LCCanalysisprovidesaframeworkforspecifyingtheestimatedtotalcost.Thegrowingdemandtodevelopproductsthatareinexpensivehasnecessitatedtheconsideration ofproductLCCduringthedesignstage.LCCincludesallthecostsincurredthrough productcreation,use,anddisposal.However,duringthematerialsselectionstage,the useofLCCanalysisshouldberestrictedtothecostthatcanbecontrolled(Asieduand Gu,1998).EstimatingtheLCCofaproposedproductduringitsdevelopmentphaseis requiredforanumberofreasons(AsieduandGu,1998):

1. Determiningthemostcost-efficientdesignamongstasetofalternatives.

2. Determiningthecostofadesignforbudgetarypurposes.

3. Identifyingcostdriversfordesignchangesandoptimization.

Fig.1.4 showsthreeinterrelatedfactorsthataffectthecostofaproduct. Componentdesignisthespecificationofsize,shape,andconfiguration,andsome partofthecostofacomponentisassociatedwithitsdesign.

Intermsofeconomics,itisnecessarytoselectthematerial(s)withtherequired propertiesthataretheleastexpensive.Materialpriceisusuallyquotedperunitmass. Thecomponentvolumemaybedeterminedfromitsdimensionsandgeometry, whichisthenconvertedintomassusingthedensityofthematerial.Inaddition,duringmanufacturingthereissomeunavoidablematerialwaste,whichshouldalsobe takenintoaccountinthecalculations.Asalreadystated,thechoiceofmanufacturing processwillbeinfluencedbyboththematerialselectedandcomponentdesign.The majorcostconsiderationsformanufacturingincludecapitalequipment,tooling, labor,repairs,machinedowntime,andwasteasshownin Fig.1.5 (Callisterand Rethwisch,2007).Therateofproductionisalsoasignificantconsideration,aswell ascostsassociatedwithinspectionandpackagingofthefinalproduct.Thereare otherfactors,includinglaborfringebenefits,supervisoryandmanagementlabor, researchanddevelopment,propertyandrent,insurance,profit,andtaxes,thatare notdirectlyrelatedtodesign,material,ormanufacturingbutalsoinfluencethesellingpriceoftheproduct.Inthecontextofmaterialssubstitutionforhighvolumeproduction,theproblemofhowtoaccuratelypredictthecostsareofthehighest importanceintoday’shighlycompetitiveindustries(Henriquesetal.,2014).

TheLCCofaproductismadeupofthecoststothemanufacturer,user,andsociety asshownin Table1.1.WhiletheLCCistheaggregateofallthecostsincurredina product’slife,therearedifferencesbetweenthecostissuesthatwillbeofinterestto thedesigneroftheproductandthecompanydevelopingtheproductinanLCC

Cost of a product Material(s) used

Manufacturing technique(s)

Component design

Figure1.4 Interrelatedfactorsthataffectcostofaproduct.

Figure1.5 Someimportanteconomicelementsinmanufacturingandproductdevelopment.

Table1.1 Lifecyclestagesandcosts(Kusiak,1993) CompanycostUsercostSocietycost

DesignMarketrecognition, Development

ProductionMaterials, consumptionof energy,facilities, wages

UsageTransportation, storage,waste, breakage, warrantyservices

Disposal/ Recycling

Transportation,storage, materials,energy efficiencyoffinal product,maintenance

Waste,pollution, healthdamages, emissionstothe environment

Packaging,waste, pollution,health damages

Disposal/recyclingfeesWaste,disposal, pollution,health damages

analysis.Whilethecompanymustknowthetotalcostoftheproduct,thedesigneris onlyinterestedinthecoststhatcanbecontrolled.

Withregardtothetimeofuse,threedifferenttypesofcalculationaredistinguishedforcostfactors(Normung,1989; Layeretal.,2002):

1. Precalculation.

2. Intermediatecalculation.

3. Postcalculation.

Precalculationisonlyabletoaccessproductdescribingdata,andunfortunately suchdatamaybeincompleteoruncertain.Theuseofunreliabledatanecessitates suitabledecision-makingmethodsfordesignselection.Duringtheproductdevelopmentcycle,intermediatecalculationsarecarriedoutandthenappliedtocontrol costs.Therefore,becausethemethodsforprecalculationcomemainlyfromthefield ofengineeringsciences,intermediateandpostcalculationmethodshavecomefrom businessadministrationconcerns(Layeretal.,2002).Costdecisioncertaintyseldomexistsinacompetitivesociety(AsieduandGu,1998),andthisisoneissue

Performance over cost method of substitution

The compound objective function method

Figure1.6 Methodsforeconomicmaterialselection/substitution.

thathasbeenlargelyignoredincostestimatingmodels.Differentmethodological approachesforcostestimationduringtheproductdevelopmentprocessare describedandclassifiedinascientificcontextintheliterature.Dependingonthe approachchosen,costestimationmethodsprovideeitheraqualitativeoraquantitativeresult(Layeretal.,2002).Althoughrawmaterialcostsarenormallyeasily available,second-orderfactorssuchastoolsanddiescost,amountofscrap,rework andothers,arequitedifficulttopredicttosupportthesubstitutiondecision (Henriquesetal.,2014).Anoverestimatedcostwillpreventacompanyfrom remainingcompetitive,whileanunderestimatedcostwillresultinlosses.

Mostproductscompriseofanassemblyofseveralindividualcomponents,eachof whichhaveacost. Fig.1.6 showstwocommonlyusedmethodsforeconomicmaterialselection/substitutionforacomponent(Farag,2008b).Thefirstmethodseparatelycomparestheperformance(P)andtotalcost(Ct)ofacandidatematerial againstacurrentlyusedmaterial.ParameterPcoversallrequirementsofthematerial exceptforcost,anditisestimatedusingweightedpropertiesmethod(Farag,2002). Aspresentedin Eq.(1.1), C1 isthecostofmaterialusedinmakingthecomponent; C2 isthecostofmanufacturingandfinishingthecomponent; C3 istherunningcost overtheentirelifeofthecomponent;and C4 isthecostofdisposalandrecycling.

Ifthepurposeofsubstitutionistoimproveperformanceandtoreducethetotal costofacomponent,theonethatgivesthehigher(P/Ct)overthecurrentlyused materialisselected.Thecompoundobjectivefunctionmethod(Farag,2008b)comparesthecompoundobjectivefunctionofthecandidatematerialsagainstthecurrentlyusedmaterial.Theperformanceindexisdefinedastheweightedsumofall thenormalizedmaterialperformancerequirements,includingtotalcost(Ct).

1.8Therelationshipbetweenmaterialsselection andprocessing

Theselectionofamaterialmustbecloselycoupledwiththeselectionofamanufacturingprocess.Manufacturersarealwaysonthelookoutfornewmaterialsandimproved processestoproducebetterproducts,andthusmaintaintheircompetitiveedgeand

increasetheirprofitmargin(Farag,2008b).Recentdevelopmentsinmanufacturing techniquesarefacilitatingthedevelopmentofnewmaterialsandimprovingthepropertiesofcurrentmaterialsfordifferentengineeringapplications.Consequently,thenumberofmaterialsandnewmanufacturingprocessesisconstantlyontherisewithtwo mainobjectives:lowcostandhighperformance(Jahan,2012).Anychangeinamaterialwilllikelycauseachangeinthemanufacturingprocess,geometry,shape,andperformance(Fig.1.7).Oftentherearemanywaysofcreatingcomponents(shaping, joining,finishing,etc.)butchoosingtheoptimumrouteisdifficult(Edwardsand Deng,2007).Withtheincreasinglevelofsophisticationinbothmaterialsandprocessing,itisinsufficienttojustrelyonexperiencealone(LovattandShercliff,1998).The largenumberofmaterialsandthegrowingnumberofprocessesandsubprocesses availabletoengineeringdesigners,coupledwiththecomplexrelationshipsbetween differentselectionparameters,oftenmaketheselectionofmaterialsforagivencomponentadifficulttaskespeciallywhentherearecostlimitations.

Ashby(2005) extendedhisconceptsofmaterialsselectionchartsforproperties attheconceptualdesignstagetothedevelopmentofprocessselectioncharts.Alot ofattentionhasbeendirectedinrecentyearstowardsdevelopingdesignmethodologiesformanufacturingandassemblyforenhancingmanufacturabilityandintegratingmaterialandprocessconceptsthroughproperdesignwiththeaimofreducing thecost,enhancingtheproductquality,andenhancingthespeedofdelivery.

Theproductionoftailoredmaterialsrequiresthedevelopmentofnewprocessing routesorimportantchangestoconventionalroutes(BrechetandEmbury,2013). Thissubjectisstronglyimportantwithregardstothenewtendencyformultifunctionalmaterials,modeling,andcomputationalmaterialsengineering.Thegoal istoselectamaterialandprocessthatmaximizesthequalityandminimizesthe costofproduct.Thedesignandmanufacturingprocess,exceptforthesimplestof products,isverycomplicatedandinvolvesmakingthousandsofdecisionsinwhich anymistakecanleadtounnecessaryactivities,extracost,andcustomerdissatisfaction.Therefore,achievingoptimumdecision-makingintheintegratedchainof actionsfordevelopingnew,orimprovingexisting,productsisessential(Jahanand

Shape Material Process

Figure1.7 Theinteractionbetweenmaterial,function,shape,andprocess.

Edwards,2013). Fig.1.8 showsthestagesofmaterialselectionanditsintegration withprocessselection(Ashbyetal.,2004).

Recently,thefollowingsequenceoftoolswas proposedtofacilitateselectionprocessesasanintegratedmaterialandprocessselectionframework(AlbinanaandVila, 2012):

1. Documentationmanagementthatallowsideastobetranslatedintoengineeringdesign.

2. Matricesthatrelateincompatibilitybetweenmaterialsandmanufacturingprocesses.

3. Matricesthatrelatetypicalpropertiestospecificrequirements.

4. Modelsofmanufacturingprocessesthattakeintoaccountlimitationsinthegeometryof components.

5. Multi-criteriaanalysistechniques.

6. Screeningpreselectiontechniques.

1.9Thesignificanceofdesignadaptationandmaterials substitution

Figure1.8 Thedifferentstagesformaterialsandprocessselectionindesign.

meetthedemandsofcostreductionandperformanceenhancement.Ifadecisionis takentosubstituteanewmaterialforanestablishedone,caremustbetakento ensurethatallthecharacteristicsofthenewmaterialarewellunderstoodbecausea largenumberofproductfailureshaveresultedfromnewmaterialsbeingused beforetheirlong-termpropertieswerefullyknown(Farag,2008b).Theintroduction ofnewormodifiedoralternativematerialsandprocessesforagivenapplicationis dependentonsatisfyingalotofdifferentfactors(Edwards,2004).Thecommon reasonsformaterialssubstitutioninclude(Edwards,2004):

● Takingadvantageofnewmaterialsorprocesses.

● Improvingserviceperformance,includinglongerlifeandhigherreliability.

● Meetingnewlegalrequirements.

● Reducingcostandmakingtheproductmorecompetitive.

● Environmentalconstraints.

Withthelargerangeofpropertiesthatdescribeanymaterial,itwouldbevery raretofindamaterialthathastheabsoluteidealvaluesforafunction.Therefore, eithera“trade-off”ofpropertiestoselectthebestoptionfromavailablematerials, ortailoringamulti-functionalmaterialbasedontherequirementsisusually required.BothapproachesneedMCDMtodealwithconflictingobjectivesdesign toobtainoptimumperformance.

1.10Useofnewhybridmaterialsasopposedto currentlyavailablematerials

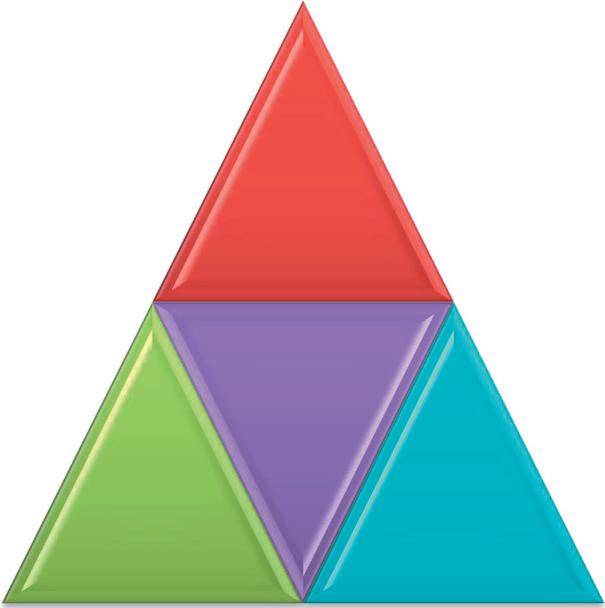

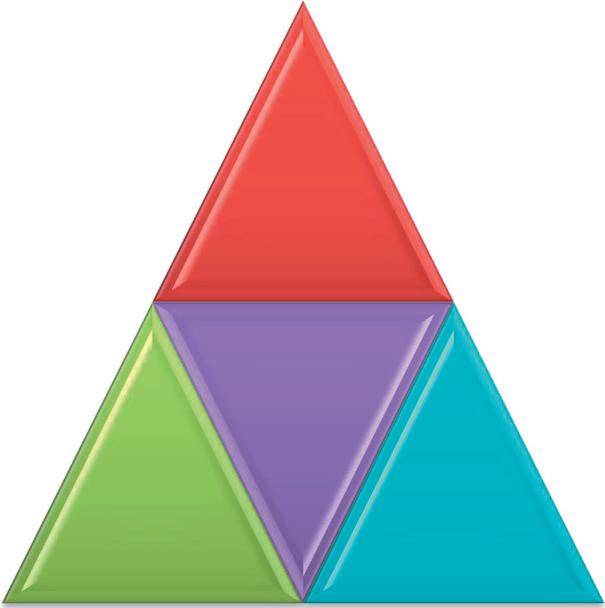

Variousmaterialshavebeendevelopedtomeetthedemandforenhancedfunctioningandprovidingimprovedqualityoflifewithreducedcost.Therapidgrowthin thedevelopmentofnewmaterialsisevidenceofthevulnerabilityofcurrentmaterialsinfulfillingthedesireddesignrequirements.Materialengineershavedeveloped hybridmaterialsthatarecomprisedoftwoormoredifferentmaterials,designedin suchawayastoofferattributesnotprovidedbyanyonematerialalone(Ashby, 2013).Newmaterialsarebeingcreatedbasedontwodistinctstrategies(Fig.1.9):

1. Theconventionalstrategyinwhichthegoalistoprovideahomogeneousanduniform structure,andmostavailablematerialsaredevelopedbasedonthisstrategy.

2. Therecentnovelstrategythataimsatdistributingtheconstituentsinaselectivelyheterogeneousandcontrolledwaytoprovidemulti-functionsandaddressconflictingrequirementsinnicheapplications(BrechetandEmbury,2013).

Inthefirststrategy,homogenizationinvolvesacompromisebetweenthedesirablecharacteristicsofthematerialrequiredforaspecificapplication.Examplesof thematerialsdevelopedbythisstrategyareengineeringalloysandpolymersin whichthenewmaterialsaregeneratedbymanagingthegrainsize,precipitation, crystallizationstate,anddesignofpolymerchainandinterchainbonding,respectively.Thesematerialsusuallypossesssomeimprovedpropertiesattheexpenseof areductioninothercharacteristics.Theheterogeneousmaterialsdesignedbasedon 14Multi-criteriaDecisionAnalysis

thesecondstrategyincludesfiberandparticlereinforcedandstructuralcomposites (combinationoftwomaterials),porousmaterials(cellularmaterials),andthemost recent,functionallygradedmaterialsorFGMs(combinationoftwoormorematerials,ofwhichonecouldbecellular).

Compositematerialsprovidesomesuperiorcharacteristics,includinghighspecificmodulus(modulusoverdensity)andhighspecificstrength(strengthoverdensity),whichmakesthemusefulmaterialsinalargenumberofindustrial applications.Inthedesignofcompositematerials,themainconcernsarewell bondedanddurableinterfacesbetweenthematrixandreinforcement.Forexample, indentistry,differentfiber-reinforcedepoxymatrixcompositeshaverecentlybeen usedwherethefibershavebeenmadeofcarbon,polyamide,ultra-highmolecular weightpolyethylene,orglass,individuallyorincombination.Amongthese,glass fiber reinforcedpolymerhasshownproperties(strengthandmodulus)comparable tothatofdentaltissues,inadditiontogoodadhesiontothepolymermatrixand

Figure1.9 Strategiesformaterialdevelopment.

aestheticappearance(Khanetal.,2015).Porosityprovidesthepossibilitytooptimizethestiffness,strength,anddensityofamaterial.Inapplicationssuchasbone andtissuescaffolds,porosityreducestheelasticmodulusofthematerialandatthe sametimeallowsthepenetrationofcellsintothematerial(matchingbothbiologicalandmechanicalpropertiestothatofnaturaltissue).Someofthepresentlyused materials,suchasstainlesssteels,titaniumalloysandaluminaceramics,arenot bioactiveandthereforecannotstronglyconnecttoboneortissue.Thisdrawback, therefore,limitstheiruseinclinicalapplicationsduetothenonactivebondwithtissueinthehumanbody.

Anothergroupofmaterials,designedbythesecondstrategyabove,isFGMs. Thesematerialscanbedefinedasheterogeneouscompositesusuallydesignedto haveacompositionalorstructuralgradientselectivelyfromonesideofthecomponenttotheotherorfromthecoretothesurface,resultingincontinuousvariationin propertiesthroughthickness.Therefore,FGMsbenefitfromthepureformofeach constituenteliminatingthetrade-offbetweenthepropertiesandutilizethecharacteristicsofallconstituents.Thesematerialsarefindingabroadrangeofapplicationsfromnuclearreactorcomponentstomedicaldevices.FGMscomposedof metalandceramicarewell-recognizedforimprovingthepropertiesofthermalbarriersystems,becausecrackingordelamination,usuallydetectedinconventional multi-layermaterials,areeliminatedbecauseofthesmoothtransitionofcompositionandpropertiesinthecomponentsused(Jhaetal.,2013).Inbiomedicalengineering,metal ceramicporousFGMhasbeentheoreticallyshowntohavehigh potentialinorthopedicssuchasthefemoralcomponentofkneeprostheses,where thelowmodulusofelasticity(similartobonemodulus)iscombinedwithoutstandinganchoragetotheboneononesideandhighwearresistanceontheotherside (Bahraminasabetal.,2013).

Oneimportantissueinthesuccessfuldesignofhybridmaterialsisthatitcan usefullybebiomimetic,suchasconsideringhumantissuestructuresorotherbiologicalassemblieslikeporouscancellousboneorgradedcartilagestructure.Theother issueisthechoiceofconstituents,volumefractions,configuration,andtheway theycanbeconnectedtoeachother.Thismakesthedesignprocessadifficulttask inwhichdesignandqualitytoolssuchasFEA,DesignofExperiments,QFD,and MCDManalysiscanbeusedinordertoobtaintheoptimalmaterialdesign. However,itshouldbenotedthatthedevelopmentofhybridmaterialsneedsinnovativenewprocessingroutesthatcandirectlycontrolthedesiredvariationsofstructureandproperties.

1.11Materialsselectionandsustainableproducts

Themainaimofso-called“green”designorecodesign,designforenvironment, andsustainabledesignistomanufactureproductsinawaythatreducestheuseof nonrenewableresources,useslessenergy,doesnotdirectlyorindirectlypollutethe environment,andcanbereusedorrecycledattheendoftheirusefullife(Pfeifer, 16Multi-criteriaDecisionAnalysis

2009).Theevaluationofaproducts’sustainabilityshouldconsidertherawmaterialsproduction,thefabricationprocess,energyconsumption,transportation,and recycling.Therefore,oneofthemajoropportunitiesforpracticingsustainabilityis throughmaterialselectionduetoitspotentialimpactonnaturalenvironmentalsystems.Theoptionsavailableattheendofaproducts’lifearerepresentedin Fig.1.10 (Ishiietal.,1994).

Thesustainabilitytermsaredefinedasfollows:

1. Recycling:Theuseofwasteorawaste-derivedmaterialasarawmaterialforproducts, whichmayormaynotbesimilartotheoriginal.

2. Remanufacturing:Throughcertainrefurbishingorrestorationprocesses,someunserviceableproductscanregainthefunctionandperformancesoftheproductswhicharesimilar tonewones(YanandGu,1995).

3. Reuse:Furtheruseofawasteproductinitsoriginalform,suchastherefillingofapreviouslydiscardedcontainer(YanandGu,1995).

4. Disposal:Thisreferstotheeliminationofthewasteproductwithoutrecoveringany intrinsicvalue(Ishiietal.,1994).

Inparticular,asustainablematerialselectionmeansselectingmaterialsthatminimizeenvironmentaldegradationoverthewholelifecycleofthematerial,frominitialacquisitiontoeventualdisposalorrecycling(Djassemi,2012).

Someexamplesofsustainabledesignofproductsinfluencedbymaterialsoccurringatthedifferentstagesoftheproductlifecycleincludetheuseoflowtoxic emissionaqueous-basedpaintsystemsreplacingsolvent-basedpaintsystemsfor motorcarbodiesattheproductmanufacturingstage,theuseoflowenergyconsumingflorescentlightbulbsreplacingincandescentlightbulbsattheproductuse stage,andtheuseofrecyclableorbiodegradablebeveragecontainersfortheproductdisposalstage.

Theprocessingofmaterialshassignificantimpactsontheenvironment,including theuseofwater,landusepatterns,undesirableemissionstoair,waterandland,and theconsumptionofotherimportantenvironmentalresources(Allwoodetal.,2011). Therefore,materialsselectionintheproductdesignprocessmustbecarriedout

Figure1.10 Rawmaterials,productlifecycle,andrecycling.