MaterialsandProcessesforNextGeneration Lithography1stEditionAlexRobinsonAndRichard Lawson(Eds.)

https://ebookmass.com/product/materials-and-processes-fornext-generation-lithography-1st-edition-alex-robinson-andrichard-lawson-eds/

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Next-Generation Solar Cells: Principles and Materials Yoon-Bong Hahn

https://ebookmass.com/product/next-generation-solar-cells-principlesand-materials-yoon-bong-hahn/

ebookmass.com

Dynamic Intentions: DCMC Next Generation (DreamCatcher MC

Next Generation Book 1) Liberty Parker

https://ebookmass.com/product/dynamic-intentions-dcmc-next-generationdreamcatcher-mc-next-generation-book-1-liberty-parker/

ebookmass.com

Next Generation Compliance: Environmental Regulation for the Modern Era Cynthia Giles

https://ebookmass.com/product/next-generation-complianceenvironmental-regulation-for-the-modern-era-cynthia-giles/

ebookmass.com

Soil Mechanics and Foundation Engineering 2nd Edition P Purushothama Raj

https://ebookmass.com/product/soil-mechanics-and-foundationengineering-2nd-edition-p-purushothama-raj/

ebookmass.com

How to Make Your Money Work: Decide what you want, plan to get there Eoin Mcgee

https://ebookmass.com/product/how-to-make-your-money-work-decide-whatyou-want-plan-to-get-there-eoin-mcgee/

ebookmass.com

Cicero's Academici libri and Lucullus: A Commentary with Introduction and Translations Tobias Reinhardt

https://ebookmass.com/product/ciceros-academici-libri-and-lucullus-acommentary-with-introduction-and-translations-tobias-reinhardt/

ebookmass.com

Surgical Critical Care And Emergency Surgery: Clinical Questions And Answers 3rd Edition Forrest "Dell" Moore (Editor)

https://ebookmass.com/product/surgical-critical-care-and-emergencysurgery-clinical-questions-and-answers-3rd-edition-forrest-dell-mooreeditor/

ebookmass.com

Diagnostic Imaging : Oral And Maxillofacial. 2nd Edition Lisa J. Koenig

https://ebookmass.com/product/diagnostic-imaging-oral-andmaxillofacial-2nd-edition-lisa-j-koenig/

ebookmass.com

Blackouts: A Novel Justin Torres

https://ebookmass.com/product/blackouts-a-novel-justin-torres/

ebookmass.com

https://ebookmass.com/product/advanced-nanostructures-forenvironmental-health-lucian-baia/

ebookmass.com

FrontiersofNanoscience SeriesEditor:RichardE.Palmer

TheNanoscalePhysicsResearchLaboratory, TheSchoolofPhysicsandAstronomy, TheUniversityofBirmingham,UK

Vol.1 NanostructuredMaterials editedby GerhardWilde

Vol.2 AtomicandMolecularManipulation editedby AndrewJ.MayneandGe ´ raldDujardin

Vol.3 MetalNanoparticlesandNanoalloys editedby RoyL.JohnstonandJ.P.Wilcoxon

Vol.4 Nanobiotechnology editedby JesusM.delaFuenteandV.Grazu

Vol.5 Nanomedicine editedby HuwSummers

Vol.6 Nanomagnetism:FundamentalsandApplications editedby ChrisBinns

Vol.7 NanoscienceandtheEnvironment editedby JamieR.LeadandEugeniaValsami-Jones

Vol.8 CharacterizationofNanomaterialsinComplexEnvironmental andBiologicalMedia editedby MohammedBaaloushaandJamieR.Lead

Vol.9 ProtectedMetalClusters:FromFundamentalstoApplications editedby TatsuyaTsukudaandHannuHakkinen

Vol.10 StructureandPropertiesofNanoalloys editedby RiccardoFerrando

Frontiersof Nanoscience MaterialsandProcessesfor NextGenerationLithography Volume11 Editedby

UniversityofBirmingham,Birmingham, UnitedKingdom

Milliken&Company,Spartanburg,SC, UnitedStates

AlexRobinson

RichardLawson

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright © 2016ElsevierLtd.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans, electronicormechanical,includingphotocopying,recording,oranyinformationstorage andretrievalsystem,withoutpermissioninwritingfromthepublisher.Detailsonhowto seekpermission,furtherinformationaboutthePublisher’spermissionspoliciesandour arrangementswithorganizationssuchastheCopyrightClearanceCenterandthe CopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions

Thisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightby thePublisher(otherthanasmaybenotedherein).

Notices Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchand experiencebroadenourunderstanding,changesinresearchmethods,professional practices,ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgein evaluatingandusinganyinformation,methods,compounds,orexperimentsdescribed herein.Inusingsuchinformationormethodstheyshouldbemindfuloftheirownsafety andthesafetyofothers,includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,or editors,assumeanyliabilityforanyinjuryand/ordamagetopersonsorpropertyasa matterofproductsliability,negligenceorotherwise,orfromanyuseoroperationofany methods,products,instructions,orideascontainedinthematerialherein.

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

BritishLibraryCataloguinginPublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

ISBN:978-0-08-100354-1

ISSN:1876-2778

ForinformationonallElsevierpublicationsvisit ourwebsiteat https://www.elsevier.com

Publisher: JoeHayton

AcquisitionEditor: SimonHolt

EditorialProjectManager: SabrinaWebber

ProductionProjectManager: MohanambalNatarajan

CoverDesigner: AlanStudholme

TypesetbyTNQBooksandJournals

Contributors PanagiotisArgitis

InstituteofNanoscienceandNanotechnology,NationalCenterforScientific Research“Demokritos”,Athens,Greece

StuartA.Boden

ElectronicsandComputerScience,FacultyofPhysicalSciencesand Engineering,UniversityofSouthampton,Southampton,UnitedKingdom

ElizabethBuitrago

PaulScherrerInstitute,VilligenPSI,Switzerland

BrianCardineau

InpriaCorporation,Corvallis,OR,UnitedStates

GuyA.DeRose

KavliNanoscienceInstitute,CaliforniaInstituteofTechnology,Pasadena,CA, UnitedStates

YasinEkinci

PaulScherrerInstitute,VilligenPSI,Switzerland

RobertoFallica

PaulScherrerInstitute,VilligenPSI,Switzerland

AndreasFrommhold

SchoolofChemicalEngineering,UniversityofBirmingham,Birmingham, UnitedKingdom

MarcusKaestner

DepartmentofMicro-andNanoelectronicSystems,InstituteofMicro-and Nanoelectronics,FacultyofElectricalEngineeringandInformationTechnology, IlmenauUniversityofTechnology,Ilmenau,Germany

DouglasA.Keszler

DepartmentofChemistry,OregonStateUniversity,Corvallis,OR,UnitedStates; InpriaCorporation,Corvallis,OR,UnitedStates

YanaKrivoshapkina

DepartmentofMicro-andNanoelectronicSystems,InstituteofMicro-and Nanoelectronics,FacultyofElectricalEngineeringandInformationTechnology, IlmenauUniversityofTechnology,Ilmenau,Germany

TeroS.Kulmala

SwissLithoAG,Zurich,Switzerland

RichardA.Lawson

ResearchDivision,Milliken&Company,Spartanburg,SC,UnitedStates

ScottM.Lewis

SchoolofChemistry,TheUniversityofManchester,Manchester,UnitedKingdom

PatrickNaulleau

CenterforX-rayOptics,LawrenceBerkeleyNationalLaboratory,Berkeley,CA, UnitedStates

DimitraNiakoula

HeliospheraS.A.,Tripolis,Greece

D.FrankOgletree

MolecularFoundry,LawrenceBerkeleyNationalLaboratory,Berkeley,CA, UnitedStates

DeirdreOlynick

MolecularFoundry,LawrenceBerkeleyNationalLaboratory,Berkeley,CA, UnitedStates

PhilipC.Paul SwissLithoAG,Zurich,Switzerland

IvoW.Rangelow

DepartmentofMicro-andNanoelectronicSystems,InstituteofMicro-and Nanoelectronics,FacultyofElectricalEngineeringandInformationTechnology, IlmenauUniversityofTechnology,Ilmenau,Germany

AlexP.G.Robinson

SchoolofChemicalEngineering,UniversityofBirmingham,Birmingham, UnitedKingdom

AdamSchwartzberg

MolecularFoundry,LawrenceBerkeleyNationalLaboratory,Berkeley,CA, UnitedStates

XiaoqingShi

ElectronicsandComputerScience,FacultyofPhysicalSciencesand Engineering,UniversityofSouthampton,Southampton,UnitedKingdom

JamesW.Thackeray

DowElectronicMaterials,Marlborough,MA,UnitedStates

WillemF.vanDorp

DepartmentofImagingPhysics,DelftUniversityofTechnology,Delft, TheNetherlands

VeronikiP.Vidali

InstituteofNanoscienceandNanotechnology,NationalCenterforScientific Research“Demokritos”,Athens,Greece

AndrewK.Whittaker

AustralianInstituteforBioengineeringandNanotechnology,Universityof Queensland,StLucia,QLD,Australia

DongxuYang

SchoolofPhysicsandAstronomy,UniversityofBirmingham,Birmingham, UnitedKingdom

Preface Themodernworldisthoroughlypopulatedwithintegratedcircuits(ICs)andother microelectronicdevices.Theubiquityofthesedeviceshascomeaboutbecausetheir computingpowerhasincreasedexponentiallyovertime,whileatthesametimethe costpercomputingpowerhasdroppedduetoshrinkingthesizesofthetransistors. Theshrinkinfeaturesizeshasbeenenabledinalargemeasurebyadvancementsin lithography,whichisthetechniqueusedtoprintthecircuitfeaturesonsiliconwafers duringICfabrication.Thecriticalpiecesrequiredforscalingareboththematerials andtheprocessesusedforlithography.

Currentlythereissignificantworldwideresearcheffortbothindustriallyandin academiaintonext-generationlithographyprocessessuchasEUV,advanced e-beam,nanoimprint,scanningprobe,andionbeamlithography.Thereislikewise similareffortinbotharenasintonext-generationmaterialsforlithographyincluding numerousnovelapproachestoresistchemistryandingeniousextensionsoftraditionalphotopolymers.Thisbookthereforeaimstobringtogethersomeofthe world’sforemostlithographicdevelopmentscientistsfromthevariouscommunities toproduceinoneplaceacompletedescriptionofthemanyapproachestolithographicmaterialsandprocessdesign,development,andcharacterization.

Resistchemistryfornext-generationlithographyislikelytobequitedistinctfrom thewell-knownprocessofphotochemistryincurrentuse.Fornoncontactmethodsthe actinicradiationunderconsiderationistypicallyfarmoreenergetic.Thisisdiscussed in Chapter1 togetherwithabriefintroductiontoresistchemistryinEUVandelectronbeamlithography,alongsideareviewofcurrentresistprocesses.In Chapter2, newinsightsintothemechanismsofEUVresistradiationchemistryarepresented fromtheperspectiveofanexaminationofthefundamentalinteractionsofsoft X-rayswithmatter,photoionization,andmolecularrelaxationprocesses.In Chapter 3,theexaminationoftheEUVresistmechanismisextendedfurtherviaadetailed analysisoftheinteractionsoflowenergyelectronsintheresistfilm,identifyingthe manyproductive(andnonproductive)reactionpathwaysavailable.

Chapters4and5investigatetheprocessandpatterningchallengesfacingEUV lithography themostlikelynext-generationcontender.In Chapter4,readersare introducedtothetechniqueofEUVinterferometriclithography,whichhasbeen usedtogeneratemanyoftheexperimentalresultsseeninlaterchapters.General resistmaterialchallengesarethenexaminedandpotentialstrategiesdiscussed. Chapter5 introducesEUVopticallithography usingamaskratherthanagrating forpatterngeneration andadetailedanalysisofthetoolchallengesfacedbyindustry.OneofthemostsignificantproblemsinEUVlithographyrelatestostochastic variations,andthischapterintroducesanewmodeltosimulatetheseeffectsand identifyareasofmostconcern.Finallytheprogressincommercialandresearch resistsexposedonamask-basedEUVtoolisreviewed.

Chapters6 13addressresistchemistry. Chapter6 presentsprogressinresists thatoperateviaamechanismofchainscission.Thesearetypicallyknownas

nonchemicallyamplifiedresists.Whilesuchsystemsaretypicallyconsideredtobe quiteinsensitive,newworkonhigh-speedvariantsispresented.ChemicallyamplifiedsystemsforEUVlithographyarereviewedin Chapter7.Whilemanychemicallyamplifiedsystemsareproprietary,andresultsintheliteratureoften presentedwithoutsignificantchemicaldetail,thischapterseekstoidentifythemajor recenttrendsinchemicallyamplifiedsystems.

Todatethemajorityofresistsystemshavebeenbasedonpolymericmaterials. However,inthelasttwodecadesasignificantamountofresearchintomolecularresist systemshasbeenundertaken. Chapter8 examinesawidevarietyofnegativetone molecularresistsystems,primarilybutnotexclusivelyoperatingviacross-linking mechanisms,while Chapter9 looksatpositivetonemolecularresistsystems,via, forinstance,solubilityswitchmechanisms.Anotherrecentalternativetopolymeric resistsareinorganicresists. Chapter10 introducestothemostwidelyusedofthe inorganicsystems,hydrogensilsesquioxane(HSQ).Theexposuremechanismis radicallydifferenttothatoforganicsystemsandisexplainedindepth,together withareviewofprocessing. Chapter10 alsoaddressesanexcitingnewmaterial class high-Znanoclusterresists,examinedviatheprototypicalhafniumperoxide sulfate.Thesedepartinalmosteverywayfromthetraditionalparadigmofaphotoresist,butnonethelesshavedemonstratedoutstandingperformance.Anothernovel approachthatutilizesorganometalliccomplexesispresentedin Chapter11.By selectingmetalatomsofhighEUVabsorbancetogetherwithappropriateligandsto enablespincoating,anddevelopment,anumberofhigh-speedEUVresistshave beendemonstrated.

Chapter12 takesafundamentallydifferentapproachtoresistdevelopment. AmaterialinitiallydevelopedtodemonstratehighopacityintheUV,soastoallow itsuseasanelectron-beamwritablephotomaskispresented.Goodresultsasa photomaskareindeeddemonstrated,buttheresisthasalsobeenfoundtoenable astonishinglyhigh-aspectratioelectronbeampatterning,primarilyduetothevery low-densitynatureofthefilm.Filmdensityissomethingthatisrevisitedin Chapter 13,aspartofanexaminationofaselectionoftheothernovelapproachesthathave beenundertakenrecently.

Thelastsectionofthebookaddressesseveralnewapproachestonext-generation lithography.WhileEUViscoveredextensivelyacrossthefirst13chapters,various otherapproachesarealsounderdevelopment. Chapter14 presentsashortreviewof thechallengesandpotentialsolutionsofnext-generationlithography.In Chapter 15,thetopicofscanningprobelithographyisexaminedingreatdepth,before focusingonelectricalfieldinteractionsofananoprobewithresist,andapproaches toscanningprobelithographythroughputenhancement. Chapter16 dealswith thermalscanningprobelithographyandintroducesthenewcommercialthermal probetooltheNanoFrazor,fromSwisslitho.Finallyin Chapter17,therecentdevelopmentoftheScanningHeliumIonBeamLithographytoolanditsapplicationto nanolithographyisdiscussed.

AlexP.G.RobinsonandRichardA.Lawson

Acknowledgments WewouldliketothankProfessorRichardPalmer,theserieseditorof Frontiersin Nanoscience,fortheopportunitytoworkonthisprojectthatseekstocompileathoroughdescriptionofthemanycurrentapproachestolithographicmaterialsandprocessdesign.Wewouldalsoliketothankallourcolleagueswhosehardworkwriting thechaptersmadethisbookpossible.AgreatdealofthanksgoestoSabrinaWebber, theeditorialprojectmanageratElsevier,whowascriticallyhelpfulthroughtheend oftheprocessandwasexceedinglypatientasweslowlydeliveredallthevarious partsofthebook.InadditiontoSabrina,HannahColfordandDerekColeman wereofgreathelpaseditorialprojectmanagersinvariousearlierstagesoftheprocessandwereparticularlyhelpfulaswegottheprojectofftheground.Additional thanksalsogotootherpeopleatElsevier,includingSimonHolt,SusanDennis, MohanambalNatarajan,andmanymoreworkingbehindthescenes.Finally,we wouldespeciallyliketothankourfamilieswhowereexceptionallypatientwith allthelonghoursputintowritingandeditingandwithoutwhosesupporttheproject wouldnothavebeencompleted.

AlexP.G.RobinsonandRichardA.Lawson

Listofabbreviations AAAcidamplifier

ADAdamantylester

AEVEAdamantylethylvinylether

AFMAtomicforcemicroscopy

AILAchromaticinterferencelithography

ASITPA4,40 ,400 -tris(Allylsuccinimido)triphenylamine

ATLAchromaticTalbotlithography

BCMTPB1,3,5-tris[4-(Tert-butoxycarbonylmethoxy)phenyl] benzene

BCPsBlockcopolymers

BEBindingenergy

BEsBackscatteredelectrons

BPY2,20 -Bipyridine

BZABenzoicacid

CAChemicalamplification

CARsChemicallyamplifiedresists

CDCriticaldimension

b-CD

b-Cyclodextrins

CMC(n)AOMep-Chloromethylmethoxycalyx[n]arenemolecule

CVDChemicalvapordeposition

DBU1,8-Diazabicycloundec-7-ene

DCTDoseCalibrationTool

DDRMDrydeveloprinsematerial

DDRPDrydevelopmentrinseprocess

DEADissociativeelectronattachment

DIDissociativeionization;Dissolutioninhibitor

DNQDiazonaphthoquinone

DOFDepthoffocus

DPI-TsDiphenyliodoniumtosylate

DPNDip-pennanolithography

DSADirectedself-assembly

DUVDeepultraviolet

E-beamElectronbeam

EBLElectronbeamlithography

EMAX Doseformaximumfilmthicknessretention

ENEthylenediamine

ESIZE Sizingdose

ESRspectroscopyElectronspinresonancespectroscopy

ETMDElectrontransferemediateddecay

EUVExtremeultraviolet

EUVresistExtremeultravioletresist

EUV-ILExtremeultravioletinterferencelithography

EUVLExtremeultravioletlithography

FBMPoly(hexafluorobutylmethacrylate)

fccFace-centered-cubic

FEFieldevaporation

FE-SPLFieldemissionSPL

FEBIDFocusedelectronbeam-induceddeposition

FEBIPFocusedelectronbeam-inducedprocessing

FIBlithographyFocusedionbeamlithography

FTIRFourier-transforminfrared

GFISGasfieldionsource

GPCGelpermeationchromatography

HFHydrofluoricacid

HIBLHeliumionbeamlithography

HIMHeliumionmicroscope

HMDSHexamethyldisilazane

HOMOHighestoccupiedmolecularorbital

HPlinesHalf-pitchlines

HPVEHyperlactylvinylether(1-vinyloxy-4-oxatricyclo [4.1.13.8]undecane-5-on)

HSQHydrogensilsesquioxane

HVMHigh-volumemanufacturing

IBLIon-beamlithography

ICDIntercoulombicdecay

ICsIntegratedcircuits

ILInterferencelithography

ILSImagelogslope

IMFPInelasticmeanfreepath

IPAIsopropanol

ITRSInternationalTechnologyRoadmapforSemiconductors

KOHPotassiumhydroxide

LAOLocalanodicoxidation

LELELitho-Etch-Litho-Etch

LERLine-edgeroughness

LUMOLowestunoccupiedmolecularorbital

LWRLine-widthroughness

MAAMethacrylicacid

MCBMonochlorobenzene

MCNMethacrylonitrile

MFSMinimumfeaturesize

MGMolecularglass

MIBKMethylisobutylketone

ML2Masklesslithography

MOREMolecularorganometallicresists

MPPMMultivariatePoissonpropagationmodel

NANumericalaperture

NCAresistsNonchemicallyamplifiedinorganicresists

NDNeutraldissociation

NGLNext-generationlithography

NILNanoimprintlithography

NILmethodNanoimprintmethod

NILSNormalizedILS

NMRNuclearmagneticresonance

NRTNormalizedremainingthickness

NTDNegative-tonedevelopment

ODOpticaldensity

OOBradiationOut-of-bandradiation

PABPost-applicationbake

PAGPhotoacidgenerator

PBMSPly(butylmethylsilane)

PBPresistsPolymer-boundPAGresists

PBSPoly(1-butenesulfone)

PDAPhotodestructiveanion;Photodestructiveacid

PDBsPhotodecomposablebases

PDMSPoly(dimethylsiloxane)

PDNPhotodecomposablenucleophile

PEBPost-exposurebake

PECProximityeffectcorrection

PGMEPropyleneglycolmethylether;Propyleneglycol monomethylether

PGMEAPropyleneglycolmethyletheracetate

PHEMAPoly(2-hydroxyethylmethacrylate)

PHOSTPolyhydroxystyrene

PHSPolyhydroxystyrene

D,L-PLAPoly(D,L-lacticacid)

L-PLAPoly(L-lacticacid)

PMGIPolymethylglutarimide

PMMAPolymethylmethacrylate

PMPSPoly(methylphenylsilane)

POSSPolyhedraloligomericsilsesquioxane

PPAPolyphthalaldehyde

PS-b-PDMSPolystyrene-block-polydimethylsiloxane

CHAPTER Overviewofmaterialsand processesforlithography 1 RichardA.Lawson*, 1,AlexP.G.Robinsonx *ResearchDivision,Milliken&Company,Spartanburg,SC,UnitedStates xSchoolofChemicalEngineering,UniversityofBirmingham,Birmingham,UnitedKingdom 1Correspondingauthor:E-mail:richard.lawson@milliken.com

CHAPTEROUTLINE 1.1Introduction.........................................................................................................2

1.2OverviewofLithographyProcess...........................................................................5

1.3LithographicExposureSourcesandProcesses.......................................................7

1.3.1UltravioletLithography........................................................................7

1.3.2DUVLithography 248nmand193nm,Immersion,andMultiple Patterning..........................................................................................8

1.3.3ExtremeUltravioletLithography.........................................................12

1.3.4E-BeamLithography.........................................................................13

1.3.5OtherLithographyProcesses IonBeam,ScanningProbe,and Nanoimprint....................................................................................15

1.4CharacterizationandFiguresofMeritforResists.................................................18

1.5ResistMaterialsandChemistry...........................................................................26

1.5.1NonchemicallyAmplifiedResists.......................................................26

1.5.2ChemicallyAmplifiedResists............................................................28

1.5.3ResistPhysicalPropertiesandEtchResistance..................................31

1.5.4PhotoacidGeneratorChemistryandPhysics........................................33

1.5.5MolecularResistsandInorganicResists.............................................38

1.6ChallengesinModernResistDesign....................................................................44

1.6.1ExposureStatisticsandShotNoise....................................................45

1.6.2PhotoacidDiffusion..........................................................................46

1.6.3Resolution,LineEdgeRoughness,andSensitivityTrade-off.................51

1.6.4PatternCollapse...............................................................................54

1.7Conclusions.......................................................................................................60 References...............................................................................................................61

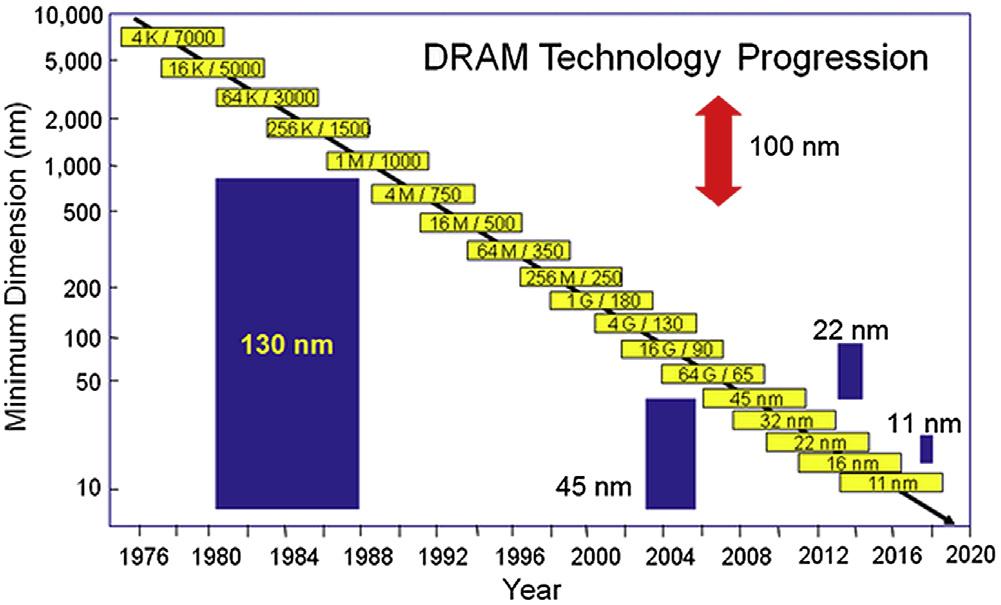

1.1 INTRODUCTION Themodernworldisthoroughlypopulatedwithintegratedcircuits(ICs)andother microelectronicdevices.Thesedevicesarepresentinallaspectsofsocietyandare integraltotherunningofgovernment,business,healthcare,transportation,security, andevendomestictasks.Oncefoundprimarilyincomputers,ICsarenowpervasive inalmosteverythingoneinteractswith,includingcellphones,automobiles,televisions,toys,evenappliancessuchasrefrigeratorsandcoffeemakers.Theyhave changedthewaypeoplework,play,andcommunicate.Theubiquityofthesedevices hascomeaboutbecausetheircomputingpowerhasincreasedexponentiallyover time,whileatthesametimethecostpercomputingpowerhasdropped.ThisperformanceandcosthasbeenenabledbytheabilityoftheICmanufacturerstodoublethe numberoftransistorsperchiproughlyeverytwoyears.1 Thistrendiscommonly referredtoasMoore’sLaw.2,3 GordonMooreobservedthistrendin1965,andhe predictedthisscalingwouldcontinueforanotherdecade.Itcontinuednotonly foranotherdecade,butithascontinuedforover50years.Itstartedasanobservation onscaling,butthenbecameanindustrymandate.

Thedoublingofthenumberoftransistorsperchiphasbeendonebyshrinking thesizesofthetransistors.Theshrinkinfeaturesizeshasbeenenabledinalarge measurebyadvancementsinlithography,whichisthetechniqueusedtoprintthe circuitfeaturesonsiliconwafersduringICfabrication.4 Avisualexampleofthe scaleofshrinkisshownin Fig.1,whichshowsthetransistordimensionrequired tomaintainMoore’slawalongwithacrosssectionofthephotoresistpattern

FIGURE1

TransistordimensionrequiredtomaintainMoore’slaw.The darkrectangles showthescaling ofthephotoresistpatternheightandwidthrequiredtoproducethesetransistordimensions. ReproducedfromLawsonRA,2011. Molecularresistsforadvancedlithography design,synthesis, characterization,andsimulation [Ph.D.dissertation].Atlanta,GA:GeorgiaInstituteofTechnology. http://hdl.handle.net/1853/39601

requiredtoproducethesedimensions.5 Photoresistsaretheradiation-sensitivematerialsusedforformingthereliefpatternsrequiredtobuildupICdevices.Asshown in Fig.1,transistorshavecontinuedtoshrinktowherecurrentfeaturesizesaresub20-nm,andsub-10-nmfeaturesareonlyafewyearsaway.Asfeaturesrapidly approachmolecularandevenatomiclengthscales,anumberoftechnologicalchallengeshavearisenthatthreatentohaltthissteadyprogress,andthustheentireIC industry.

Thecriticalpiecesrequiredforscalingareboththematerialsandtheprocesses usedforlithography.Currentlythereissignificantworldwideresearcheffortboth industriallyandinacademiaintonext-generationlithographyprocessessuchas extremeultraviolet(EUV),advancede-beam,nanoimprint,scanningprobe,and ionbeamlithography.Thereislikewisesimilareffortinboththeindustrialand theacademiclithographyarenasintonextgenerationmaterialsforlithography includingnumerousnovelapproachestoresistchemistryandingeniousextensions oftraditionalphotopolymers.Thisbookthereforeaimstobringtogethersomeofthe world’sforemostlithographicdevelopmentscientistsfromthevariouscommunities toproduceinoneplaceacompletedescriptionofthemanyapproachestolithographicmaterialsandprocessdesign,development,andcharacterization.Resist chemistryfornext-generationlithographyislikelytobequitedistinctfromthe well-knownprocessofphotochemistryincurrentuse.Fornoncontactmethods, theactinicradiationunderconsiderationistypicallyfarmoreenergetic.Thiswill bediscussedin Section1.3 ofthischapter,togetherwithabriefintroductiontoresist chemistryinEUVandelectronbeamlithography,alongsideareviewofcurrentresist processes.InChapter2,newinsightsintothemechanismsofEUVresistradiation chemistryarepresentedfromtheperspectiveofanexaminationofthefundamental interactionsofsoftX-rayswithmatter,photoionization,andmolecularrelaxation processes.Theseprocessescanleaddirectlytochemistrynotpresentatlongerwavelengths,butalsototheproductionoflowenergyelectronswhichareimportantfor EUVresists.InChapter3theexaminationoftheEUVresistmechanismisextended furtherviaadetailedanalysisoftheinteractionsoflowenergyelectronsintheresist film,identifyingthemanyproductive(andnonproductive)reactionpathways available.

Chapters4and5investigatetheprocessandpatterningchallengesfacingEUV lithography themostlikelynextgenerationcontender.Chapter4introducesthe techniqueofEUVinterferometriclithography,whichhasbeenusedtogenerate manyoftheexperimentalresultsseeninlaterchapters.Generalresistmaterialchallengesarethenexaminedandpotentialstrategiesarediscussed.Chapter5introduces EUVlithographywhichusesmoreconventionaloptics,i.e.,usingamaskandprojectionopticsratherthanagratingforpatterngeneration,andadetailedanalysisof thetoolchallengesfacedbyindustry.OneofthemostsignificantproblemsinEUV lithographyrelatestostochasticvariations,bothduetothehighenergyperphoton, andthuslowphotonnumberperdose,butalsothevariabilityofmulticomponent resistmaterialspushedtothelimitsoftheirperformance.Chapter5introducesa newmodeltosimulatetheseeffectsandidentifyareasofmostconcern.Finally

theprogressincommercialandresearchresistsexposedonamask-basedEUVtool isreviewed.

FromChapter6onward,thebookaddressesresistchemistry.Thefirstofthese chapterspresentsprogressinresiststhatoperateviaamechanismofchainscission. Thesearetypicallyknownasnonchemicallyamplifiedresists,asoneexposureevent leadstoasinglechemicaleventintheresist.Whilesuchsystemsaretypically consideredtobequiteinsensitive,newworkonhigh-speedvariantsispresented. ChemicallyamplifiedsystemsforEUVlithographyarereviewedinChapter7. Whilemanychemicallyamplifiedsystemsareproprietary,andresultsintheliteratureoftenpresentedwithoutsignificantchemicaldetail,thischapterseekstoidentify themajorrecenttrendsinchemicallyamplifiedsystems.

Todatethemajorityofresistsystemshavebeenbasedonpolymericmaterials. However,inthelasttwodecadesasignificantamountofresearchintomolecular resistsystemshasbeenundertaken.Chapter8examinesawidevarietyofnegativetonemolecularresistsystems,primarilybutnotexclusivelyoperatingviacrosslinkingmechanisms,whileChapter9looksatpositive-tonemolecularresistsystems, via,forinstance,solubilityswitchmechanism(see Section1.2 ofthischapterfora discussionofresisttone).Anotherrecentalternativetopolymericresistsareinorganic resists.Chapter10introducesthemostwidelyusedoftheinorganicsystems, hydrogensilsesquioxane(HSQ).Theexposuremechanismisradicallydifferentto thatoforganicsystemsandisexplainedindepth,togetherwithareviewofprocessing.Chapter10alsoaddressesanexcitingnewmaterialclass:high-Z nanoclusterresists,examinedviatheprototypicalhafniumperoxidesulfate(HafSOx).Thesedepart inalmosteverywayfromthetraditionalparadigmofaphotoresist,butnonetheless havedemonstratedoutstandingperformance.Anothernovelapproachutilizing organometalliccomplexesispresentedinChapter11.Byselectingmetalatomsof highEUVabsorbancetogetherwithappropriateligandstoenablespincoatingand development,anumberofhigh-speedEUVresistshavebeendemonstrated.

Chapter12takesafundamentallydifferentapproachtoresistdevelopment.A materialinitiallydevelopedtodemonstratehighopacityintheUV,soastoallow itsuseasanelectronbeamwritablephotomaskispresented.Goodresultsasaphotomaskareindeeddemonstrated,butserendipitouslytheresisthasalsobeenfoundto enableastonishinglyhighaspectratioelectronbeampatterning,primarilyduetothe verylow-densitynatureofthefilm.Electronbeampatterningresistfeatureswith aspectratiosfarbeyondanythingthatcouldbeachievedinotherresistsareshown. FilmdensityissomethingthatwillberevisitedinChapter13,aspartofanexaminationofaselectionoftheothernovelapproachesthathavebeenundertaken recently.ThechapteraddressesnovelapproachestoEUVlithography,including lowandhighabsorbancyfilmsandnovelnanoparticle-basedresists.

Thelastsectionofthebookaddressesseveralnewapproachestonext-generation lithography.WhileEUViscoveredextensivelyacrossthefirst13chapters,various otherapproachesarealsounderdevelopment.Chapter14presentsashortreviewof thechallengesandpotentialsolutionsofnext-generationlithography.InChapter15, thetopicofscanningprobelithographyisexaminedingreatdepth,beforefocusing

onelectricalfieldinteractionsofananoprobewithresist,andapproachestoscanning probelithographythroughputenhancement.Chapter16dealswiththermalscanning probelithographyandintroducesthenewcommercialthermalprobetooltheNanoFrazorfromSwisslitho.FinallyinChapter17,therecentdevelopmentofthescanning heliumionbeamlithographytoolanditsapplicationtonanolithographyisdiscussed.

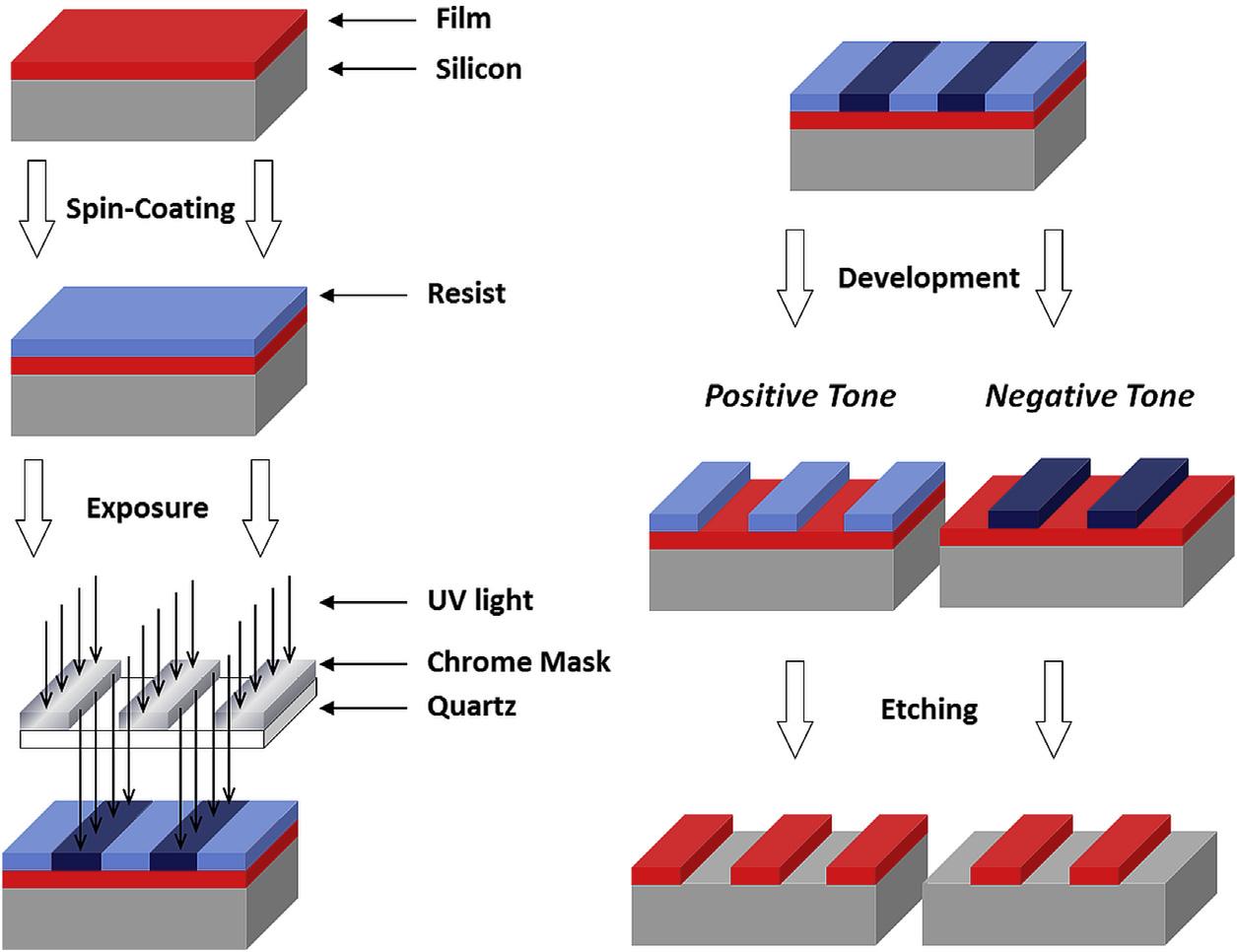

1.2 OVERVIEWOFLITHOGRAPHYPROCESS Lithographyistheartandscienceofproducingapatternonasubstrate.Thetermis usedmostoftentodayinconnectionwithsemiconductorprocessing.Additionaladjectivesareoftenusedtomorespecificallydefinethetechniquesuchasoptical lithographyorphotolithography(usingUVlighttogeneratethepatterns),imprint lithography(amoldispressedorimprintedintoamaterialtogeneratethepatterns), e-beamlithography(electronbeamsareusedtogeneratethepattern),orEUVlithography.Themostcommonlyusedformoflithographyinhighvolumemanufacturing isopticallithographyandageneralizedoverviewoftheprocessisshownin Fig.2.

Ahighlysimplifieddescriptionoftheprocessisasfollows.Thesubstrate(usuallyasiliconwafer)isusuallycoatedwithathinfilmofafunctionalmaterialora multilayerstackofmaterialsthatcouldserveanynumberofrolessuchaslow-kor high-kdielectric,etch-resistanthardmask,orconductinglayer.Photoresist,whichis aphotosensitivematerialthatistypicallycomposedmostlyofanorganicpolymer,is thenspincoatedontothefilmstack.Thetermphotoresistisoftenshortenedsimply toresistwhichisalsoamoregeneraltermforthesetypesofmaterials;especially sinceresistsformanyalternativeandfutureexposuresourceswouldnotbeexposed tophotonsbutratherelectrons,ions,orotherphysicalsourcesofapattern.

UVlightisthenshonethroughamask,whichselectivelyallowslightthrough certainregionstogenerateapatternontheresist.Themaskhashistoricallybeen madeofquartzwithchromepatternsontopthatcontrolwherethelightshinesthrough themask.TheradiationpatternfromtheUVlightinduceschemicalchangesinthe resist,whichselectivelymodifiesthesolubilityoftheexposedregionsinaliquid calleddeveloper.Thewaferiscommonlybakedafterthisexposurestep[calledapostexposurebake(PEB)]tofurtherinducechemicalchangeintheexposedregions.

Thedevelopmentstepisnext,andiswheredeveloperispouredorsprayedonto theresistandcertainregionsoftheresistaredissolved,whileotherregionsremain onthewafer.Theexposedregionswilleitherbedissolvedorremaindependingon thetoneoftheresist.Positive-toneresistsarethosewheretheexposedareasaredissolvedduringdevelopment;thesolubilitychangeisoftenduetochemistrythatoccursduringexposureorinthePEBwhichchangesthepolarityorfunctionalgroups oftheresist.Negative-toneresistsarethosewheretheexposedregionsarenotdissolvedduringdevelopmentandtheexposedareasaredissolvedinstead.Solubility changeinthesematerialscanlikewiseoccurbymanydifferentmethods,although twoofthemostcommonarecross-linkingtoformhighmolecularweightnetwork structuresandchangesinfunctionalgroupsoftheresistwhichaffectpolarity.

Generalizeddiagramoftheopticallithographyprocess.Theprocessstartsinupperleftand goestop-to-bottomandthentherightsidetop-to-bottom.Resistisspincoatedontoa substrateconsistingofasiliconwaferandotherdepositedfilms.Theresistispatterned throughamasktoselectivelyexposeareasontheresistandthenthewaferiscommonly bakedonahotplate.Developmentgeneratesthethree-dimensionalreliefpatterninthe resistandthatpatternistransferredintothesubstratethroughanetchprocess.

Finally,theremainingpatterninthedevelopedresististransferredintotheunderlyingfilmstackusinganetchprocess.Thisetchprocesscouldbeawetorchemicaletchwhereliquidchemicalsselectivelyremovetheunderlayer(UL)while havingaminimaleffectontheremainingphotoresist.However,itismorecommon thattheetchingisdoneusingplasmaetchingwherehighenergyparticlesselectively etchtheULcomparedtotheremainingresist.Plasmaetchingallowsahighlevelof controlandselectivityatboththenanoscaleandwafersizescalebychangingthe variousparametersintheetchchambersuchasetchgasesandspecies,voltage, biasonthewafer,pressure,andlocalwafertemperature,amongmanyothers.By controllingthetimeandtypeofgasesused,plasmaetchingcangofromisotropic tohighlyanisotropicetchingprofiles.Recentadvanceshaveevenshownthepossibilityofatomiclevelcontrolwiththeintroductionofatomiclayeretching.6 8

Afterallthedesiredmodificationsarecompletedintheunderlyingfilmstack, anyremainingphotoresistisremovedthroughaplasmaorchemicalstrippingprocess.Thislithographicprocessisthenrepeated(sometimesmultipletimes)for eachlayerofthedevicetoallowforfabricationofcompleteICs.

FIGURE2

1.3 LITHOGRAPHICEXPOSURESOURCESANDPROCESSES Whendiscussinglithographicimaging,itisimportanttospecifytheradiationsource usedtoexposetheresistandtransferthepattern.Althoughmuchofthelithography processissimilarorthesamewithdifferingsources,itisimportanttounderstandthe differencesbetweeneachtypeofcommonlyusedexposuresourceandhowthe choiceofexposuresourceaffectsthechoiceandoptimizationofresistmaterial. ThemostcommonlyusedexposuresourcesareUVanddeepUV(DUV)lightgeneratedbyamercurylamporlaser.ModificationsinDUVlithographyat193-nmwavelengthhaveledtoatechniquethatiscalledimmersionlithography.Thisexposure wavelengthhasbeenextendedevenfurthertosmallerfeaturesizesthroughthe useofdoubleandmultiplepatterningaswillbediscussedlater.Intenseresearch anddevelopmenthasbeencarriedoutontheapplicationofEUVlithographyfor futuregenerationsofICmanufacturing.9 11 Electronbeam(e-beam)asasource ofexposingradiationhasbeenusedindustriallyformaskproductionformanyyears andisusedcommonlyinresearchanddevelopmentapplicationsduetoitsveryhigh resolutionandabilitytorapidlyproduceawidevarietyofpatterns.Workhasalso beencarriedoutonuseofionbeamlithographywhichusesfocusedbeamsof ionstopatterntheresist.12,13 Therehavealsobeenextensivedevelopmentsinlithographicprocesseswheretheresistisnotexposedtoaradiationsource,butinstead isphysicallymodifiedinsomeotherway.Someexamplesofthisincludenanoimprintlithography14 18 wheretheresistpatternismadebypressingamoldinto theresisttoreplicatethemoldpatternorscanningprobelithography19 22 where thepatternismadebyselectivelyscanningananoscaleprobesuchasanatomic forcemicroscope(AFM)tipoverthesurfaceoftheresistandmodifyingtheresist throughthermal,chemical,orelectricalchanges.Eachoftheseexposuresources andprocessestypicallyhasitsownspecifictypeofresistswithuniqueproperties thatallowthemtoworkwellforthatsource,althoughsomeresistscanbeused acrossmultipleplatforms.Thissectionwillfocusonthesourcesandtechniques andamorethoroughdiscussionofresistswillbegivenin Section1.5.

1.3.1 ULTRAVIOLETLITHOGRAPHY UVlithographyhasbeenthemostusedexposuresourceinthesemiconductorindustryfordecadesandiscommonlyusedinmanyotherindustriesthatrequire patterningsuchasflatscreentelevisions.Althoughithasbeenreplacedbyother techniquesandexposuresourcesforthehighestresolutionfeatures,itisstill commonlyusedformultiplelevelsofpatterningatfeaturesizesof0.3 mmand larger.23 TheoriginoftheUVlightiscommonlyamercuryarclamp,whichhas itsownuniquespectralemissioncharacteristics.Threeofthestrongestemission wavelengthsintheUVareat436,405,and365nm,whicharecommonlyreferred toasg-line,h-line,andi-linerespectively.

TherearethreedifferentsetupsthatarecommonlyusedtopatternwithUV lithography:contactprinting,proximityprinting,andprojectionprinting.Incontact

printing,themaskisplacedindirectcontactwiththewaferandphotoresist.Proximityprintingissimilarexceptthatasmallgapisleftbetweenthewaferand mask.Projectionprintingcollectslightfromthelampusingaseriesoflensesand focusesitontothemask.Thelightfromtheopenareasofthemaskarethencollected byanotherlens,whichprojectsthepatternontothewafer.Contactandproximity printingtoolsarelessexpensivethanprojectiontoolsbecauseofthesimplersetup thatrequiresmuchlesssophisticatedopticsandsoarecommonlyusedinresearch anddevelopmentlabs;however,projectionlithographyisbyfarthedominant methodinhighvolumemanufacturingbecauseithasseveraladvantagesoverthe othertwotechniques.

Resolutionforalithographicprocessisthesmallestfeaturethatcanbesuccessfullyprintedwithacceptablequalityandcontrol.24 Proximityprintingworksinthe near-field(Fresnel)diffractionregimeandisresolutionlimitedbythewavelengthof light(l)andthegapbetweentheresistandthemask(L)to z lL p ,about2 4 mmin practice.Contactprintingimprovesresolutiontoabouttheorderofthewavelength ofthelight(andpotentially,ifnotpractically,higher),butputsthemaskandresistat highriskofdamageanddefectivityduetothedirectcontact.Contactandproximity printingbothrequiremasksthatarethesamesizeasthewafers,andmaskfeatures thesamesizeasthefeaturestobeprintedintheresist.Projectionprintingovercomes thedefectivityissuesbecausethemaskisfurtherawayfromthewaferandisprotectedbyapellicle,25 27 whichpreventsparticlesfromlandingonthemask.Projectionprintingcanalsousemaskswithfeatureslargerthantheopticalpatternsatthe waferlevelbecausetheprocessallowsforthereductionofthemaskimage,typically a4 reductioninthemaskfeatures;thisallowsforeasiermaskproduction.Finally, projectionprintinghasthebigadvantageofhigherintrinsicresolution.Theoptical resolutionlimitforfarfield(Fraunhoffer)diffractionlimitedprojectionlithography isgivenbytheRaleighcriterionshownin Eq.(1) where l iswavelengthofradiation used, NA isthenumericalapertureofthelensintheexposuresystem,and k1 isa processdependentfactorthatdependsonavarietyoffactorsandtoolissues.For manyprojectiontools, k1 isbelow0.5and NA isnear1(orevengreaterforimmersionlithography),soresolutionisactuallysmallerthanthewavelengthoflight (comparedtoseveraltimesgreaterthanthewavelengthforproximityprinting).

1.3.2

DUVLITHOGRAPHY 248nmAND193nm,IMMERSION,AND MULTIPLEPATTERNING Asfeaturesizesshrink,tooloptimizationgenerallyreachesalimitmeaningthat k1 cannotshrinkmuchmoreand NA cannotincreasefurther.Thismeansthatresolution cannotbereducedunlessthewavelengthoflightisreducedasshownin Eq.(1).This wasamajordriverfortheinvestigationofDUVexposuretoolsinthe1980s 1990s becausethelowerwavelengthsallowforbetterresolution.Thefirstmajor

commercialproductionofwafersusingDUVexposuretoolswasin1990toproduce waferswithacriticaldimension(CD)of0.9 mm. 28 Mercurylampshaveaweakpeak around254nm(around10%orlesstheintensityoftheg-,h-,andi-linepeaks),and theuseofHg-Xelampsextendstheusablerangedownto220nmwithastronger peakataround248nm.However,industrialapplicationofDUVisalmostentirely doneusingexcimerlaserstoproducethelightusedforexposures.Theearliest DUVexposuretoolsusedawavelengthof248nm,whichisproducedbyaKrFexcimerlaser.Asthesetoolswerefurtheroptimized,therewasatransitiontoalower DUVwavelengthof193nmproducedbyanArFexcimerlasertofurtherimprove theultimateresolutionoftheprintingsystem.Thesetoolsuseaseriesofquartz lensesandamasksimilartoUVlithographytogeneratetheaerialimage,which istranslatedbythephotoresistintoareliefimage.Significantresearchanddevelopmentwentintoanevenlowerwavelengthof157nmwhichusedF2 excimerlasers, butitwasultimatelyabandonedduetodifficultiesfindingasuitablereplacementfor quartzasalensmaterial.29

Giventhelackofaneasilyaccessiblelowerwavelengthexposuretoolatthe time,analternativeapproachwasdevelopedtofurtherimprovetheresolutionof 193-nmlithographyandcontinuefeatureshrink.Ithaslongbeenknownthatthe resolvingpowerofanopticalmicroscopecanbeimprovediftheairgapbetween theobjectivelensandthesampleisfilledwithahighrefractiveindexoil.Asimilar approachwastakentoimplementso-calledimmersionlithography,andconsistsof introducingafluidbetweenthefinallensandwafer.30 Thisfluid,whichhasahigher refractiveindexthantheairthatistypicallybetweenthelensandwafer,changesthe opticalpathsofexposurelightandeffectivelyresultsinahigher NA in Eq.(1).The NA ishigherbecause NA ¼ ni sin q,where ni isrefractiveindexand q isthepropagationangleoflight.31 TheNAofa“dry”exposuresystemdoesnotgobeyond1.0; otherwise,theexposurelightwillbetotallyreflectedbackatthelens/airinterface.32

Useofultrapurewaterasanimmersionfluid(index ¼ 1.44at193nm)hasallowed productionoftoolswith1.35 NA capabilityandaresolutiondownto45-nmhalfpitch.33 This45-nmhalf-pitchisapproximatelythecurrentresolutionlimitforsingle opticalpatterninginproductiontoday.Therewassignificantinvestigationinto higherrefractiveindexfluidsthanwater,whichwouldimproveresolutioneven further,butthesewereneverimplementedbecauseatechniquecalledmultiple patterning,whichcouldprovidesuperiorresolution,wasrapidlydevelopedand employedfirst.33

Multiplepatterningisamethodthatallowsprintingofpatternsthataresmaller thanthesingleexposurelithographicresolutionlimitthroughtheuseofmultiple processstepstoprintasinglelayer.Multiplepatterningisthemostgeneraldescriptionoftheprocess,butitwasfirstusedintheformofdoublepatterning(equivalent totwosingleexposures)andthenlaterquadruplepatterningwasdevelopedand implemented(equivalenttofoursingleexposures).Thestrictdefinitionoftheresolution,definedbytheRayleighcriterionin Eq.(1),relatestotheseparation,rather thanthefeaturesize,oftwoobjectsandthuswhenthepitchbetweenobjectsis relaxedthefeaturesizecanbereducedfurther,forinstancebyaggressiveresist

processing,exposuredosebias,etc.Bypatterninginmultiplesteps,closelyspaced featurescanbeseparatedintodifferentpatterningsteps effectivelyrelaxingthe pitch.Onewaytodescribemultiplepatterningisthatitprovidesawaytocontinue scalingthroughtheuseofaddedprocesscomplexity(byrequiringmultiplerepeats ofanexistingprocess)ratherthanaddedtoolortechnologycomplexity(suchasby modifyingoptics,changingwavelength,etc.).Thisdescriptionisobviouslyoversimplifiedbecausespeciallydesignedtoolswillimprovetheprocess,butitillustratesthatthemethodcould,intheory,beappliedwithexistingequipment.The applicationofmultiplepatterningasanindustrialproductionprocesswasinmany waysachangeintheparadigmofscalingthathaddriventhesemiconductorindustry formostofitslifetime.

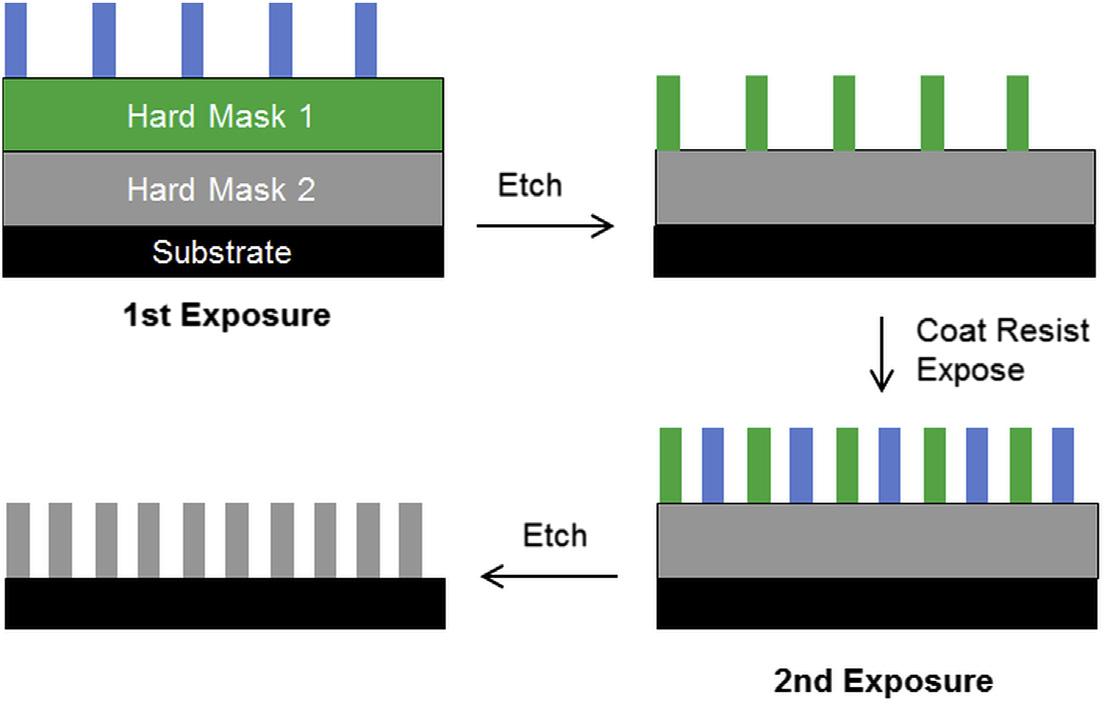

Althoughtherearemanydifferentpotentialwaystoimplementdoubleandmultiplepatterning,34 onlyafewwillbebrieflyreviewedhere.Onemethodisknownas Litho-Etch-Litho-Etch(LELE)anditinvolvestwolithographicexposureandetch stepstocreateasinglelayer.Themethodinvolvesfirstdepositingafilmstackconsistingofoneormorehardmasksontothewafer.Oneexposureisdoneneartheresolutionlimitofthetoolandthispatternisetchedintotheunderlyingfilmstack.A secondexposurepatternthatisoffsetfromthefirstpatternisthencarriedoutand transferredintotheUL.Thecombinedpatternfromthetwodifferentexposuresis atdoublethepitchofeachindividualpattern.Theprocessisdemonstratedin Fig.3.Thisprocesshasanadvantageinthatitcan,intheory,beappliedtoanygeneralpattern,butitishighlysensitivetooverlayerror,whichistheerrorbetweenthe alignmentofeachmasktotheunderlyingpattern.

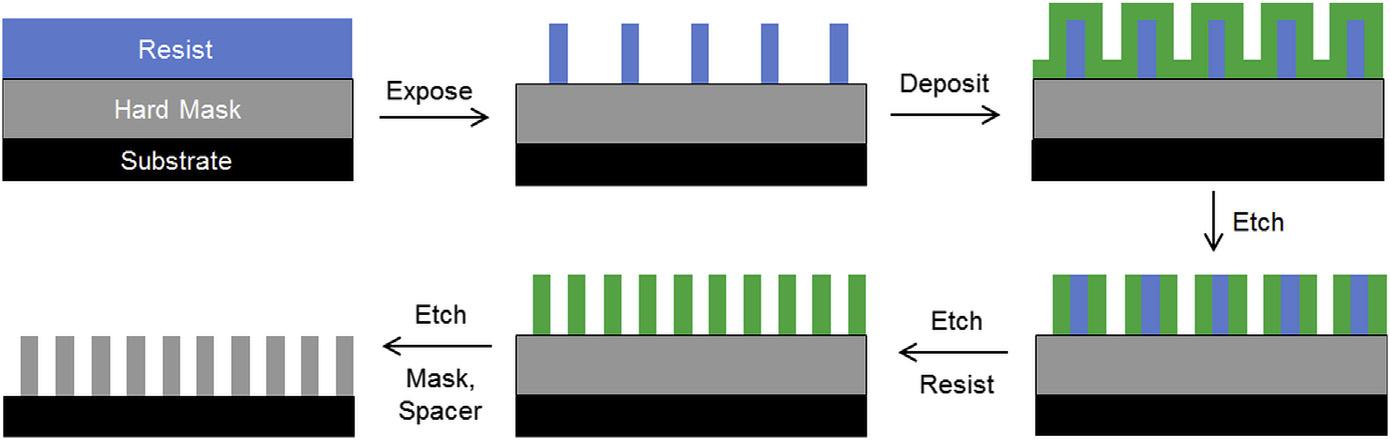

Anothercommonlyusedmethodofdoublepatterningiscalledself-aligneddoublepatterning.35 Itinvolvesthedepositionofaconformalcoatingofafilmontoa singleresistpattern.Thefilmcanthenberemovedbyaselectiveetcheverywhere butonthesidewallsoftheoriginalresist.Theresististhenremovedandtheremainingsidewallpatternwillbeatasmallerpitchandresolutionthantheoriginalresist. Transferofthisremainingsidewallpatternintothesubstratecompletestheprocess. Thismethodisillustratedin Fig.4.ThisprocessisslightlysimplerthanLELEand haslessstringentoverlayerrorrequirements,butisgenerallylimitedtoamore restrictivesetofpatternssuchasalternatinglines.Thisprocesscanalsoberepeated asecondtimeonthefirstsidewallpatternstoeffectivelyquadrupletheoriginalresist pitchinaprocessknownasself-alignedquadruplepatterning.

Multiplepatterningtechniq uesusingdirectedself-assembly(DSA)oforganic materialssuchasblockcopolymers(BCPs)havereceivedmuchinterest.35 43 BCPsarepolymerscomposedoftwoormorediscreteblocksofhomopolymers thatarecovalentlyjoinedtogether;someexamplesofBCPsinclude polystyrene-block-polymethylmethacry late(PS-b-PMMA)orpolystyrene-blockpolydimethylsiloxane(PS-b-PDMS).BCPsareofinterestbecausetheycanphase separatetolengthscalesthatarecommensuratewithdesiredlithographicpatterns. DSAisthemethodwherebytheself-assemblyisspatiallycuedorcontrolledto producelithographicallyusefulphase-se paratedstructuresthatareatasmaller pitchthanisaccessiblefromasingleexposurestep.

FIGURE3

DiagramofLitho-Etch-Litho-Etchprocess.

FIGURE4

Diagramofself-aligneddoublepatterning(SADP)process.

SeveraldifferentwaystocontrolDSAofBCPshavebeeninvestigated44 suchas graphoepitaxy,45 chemoepitaxy,46,47 orvariouscombinationmethods.Achemoepitaxyprocessisillustratedin Fig.5.Conventionallithographyisusedtopatternan ULtoproduceareaswithdifferentchemicalaffinityforeachblockoftheBCP. ThedifferentareascanbeproducedbychemicalmodificationoftheULthrough plasmatreatmentorbyselectiveremovalofareasinthefirstULandadeposition ofanothermaterialsuchasabrushpolymer.Finally,theBCPiscoatedontothe patternedULandannealed.Becauseeachblockhasdifferentaffinityforeach areaoftheUL,specificblocksarealignedtocreatethedirectedself-assembled pattern.MuchprogresshasbeenmadeonevaluatingDSAasapotentialmethod forpitchmultiplication48 andimprovingdefectivity,37,49 however,ithasnotyet beenimplementedindustriallyforcommercialsemiconductorproduction.

Chemoepitaxyprocessflowfordirectedself-assembly(DSA)ofblockcopolymers(BCPs).

1.3.3 EXTREMEULTRAVIOLETLITHOGRAPHY EUVlithographyhasreceivedsubstantialattentioninthelast10þ yearsasa“next wavelength”replacementfor193-nmDUVlithography.11 Overthistime,ithasbeen predictedtobeonlya“few”yearsfromcommercialimplementationmultipletimes, buthasnotyetbeenusedinhighvolumemanufacturing.Partofthisdelayisdueto concernsovertheproductionreadinessofvariousaspectsofthetoolandprocess whichwillbediscussedlater,butalsoduetocontinuedadvancesinmultiple patterningwhichhavekeptpacewiththetechnologyroadmapsuntilnow,although ataveryhigh,andincreasing,cost.

EUVradiationcoversthewavelengthrangefrom10nmuptoabout120nmand alsocanoverlapwitharegionconsideredsoftX-rays.Thewavelengthsthatarethe mostlithographicallyinterestingareintherangeof11 14nm.Consideringthe Raleighcriterionshownin Eq.(1),thiswavelengthrangewouldpotentiallyrepresentasubstantialimprovementinresolutionover193-nmDUV;however,there aremanyimportantdifferencesinthephysicsandtooldesignwhenthewavelength isdroppedintotheEUV.Sinceallmaterialsabsorbatthesewavelengths,thesystem mustberuninavacuumratherthaninairandtransparentopticscannotbeusedin thewayquartzcanbeusedintheDUV.Fortunately,theuseofmultilayerfilmstacks ofalternatingmaterialscanproducereflectingopticswithreasonableefficiency.50 ThemostcommonlyusedEUVreflectorstackconsistsofmultiplealternatinglayers ofmolybdenumandsilicon,whichshowsaround70%reflectionefficiencywitha peakwavelengthof13.5nm.51

EUVexposuretoolsformanufacturingwillrequiremultiplemirrors(6to12þ)to projectasufficientlyhighfidelityimage.Giventhereflectivityof70%foreach mirror,only1 5%ofthegeneratedphotonswillactuallyreachthewafer.This lossmeansthatEUVlightsourcesneedsufficientlyhighpowertoprovidethe requiredwaferthroughputtomakeEUVeconomicallyviable.ProgressinEUV sourcepowerhasbeenslowandhasbeenamongthetop,ifnotthetopconcern/roadblockforimplementationofEUVcommercially.Currentestimatessuggestasource powerof250Wwillbeneededwithlong-termreliableoperation.Asofspring2016, alabdemonstratedpowerof200Whadbeenreported,butsourcesinactualfield demonstrationunitswerearound80W.52 Thelowsourcepoweralsomeansthat EUVresistsneedverygoodsensitivitywhichwillbediscussedlater.

EUVmaskshavealsorequiredsignificantwork.Inadditiontoreflectiveoptics, EUVusesamaskcomposedofareflectivemultilayer.Thereflectivemaskrequires off-axisilluminationandthiscombineswiththeeffectofthethicknessofthemask

FIGURE5

absorbertocreateshadowingeffects,53 whichdegradepatternqualityandmustbe accountedforinmaskandsystemdesign.TheEUVlightthatisreflectedfroma multilayerissomecumulativedistributionofthereflectionsatinterfacesbetween allthelayers.Thisisimportantbecauseitimpliesthatanydefectsburiedinthe multilayercanhaveaneffectontheprojectedpattern.54,55 Thesedefectswillbe difficulttofindusingconventionaldefectanalysisbecausetheywillbeverysmall scaleandpotentiallyinvisibletomanyinspectionmethodsastheyareburied.As aresult,aspecializedtechniquehadtobedevelopedeventoinspectEUVmasks fordefectsbasedonactinicinspection.56 58

AlthoughEUVcanbeconsideredaformofopticallithography,theinteractions ofanEUVphotonwitharesistaresignificantlydifferentthanaDUVphoton,dueto themuchhigherenergyatEUVandthetypicallyhigherabsorbanceatEUV.Anincident13.5-nmEUVphotonhasabout92eVofenergycomparedto5.0and6.4eVfor theDUVwavelengthsof248and193nm,respectively.Thisenergydifference meansthereisasignificantlydifferentphotonfluxontotheresistatequivalentdoses. Thereareapproximately10photons/nm2 atEUVforadoseof15mJ/cm2,while thereare146photons/nm2 attheequivalentdoseat193nm.AtDUV,thephoton isabsorbedbytheresistandittemporarilyexcitesanelectroninamoleculetoan excitedstatebeforereturningtothegroundstate.Whenthe92-eVEUVphotonis absorbedbytheresist,aphotoelectronofabout80eV(onaverage)isgenerated.59 Thephotoelectronwillscatterthroughtheresistandgeneratemoresecondaryelectrons(aroundtwotofivetotalsecondaryelectronsfortypicalorganicresists)ina mannersimilartothecascadeofsecondaryelectronsgeneratedbyscanningelectron microscope(SEM)ore-beamlithographyinteractions.Thechemistryandphysics thatoccurinaresistduringEUVexposurearethereforeasmuchrelatedto e-beamexposureastheyarerelatedtoDUVexposure,althoughitisultimatelya combinationofthetwo.

1.3.4 E-BEAMLITHOGRAPHY E-beamlithographyusesafocusedbeamofelectronstodirectlyexposearesist.The electrongunisoftenatungstenthermionicemissioncathode.23 Thebeamisfocused ontoaverysmallspotsizethatcanbelessthan10nmusingaseriesofcondenser lensesandbeamdeflectioncoils.ComparedtoUV,DUV,andEUVlithography, e-beamlithographyisamasklessformoflithographyinthatitrequiresnomask becausethedeflectorsandcoilsallowarbitrarydeflectionofthefinelyfocused beam.Indeed,e-beamlithographyisthetechniquethatismostcommonlyusedto patternthemasksusedinotherformsoflithography.Theflexibilityofe-beamallowsalmostanyarbitrarygeometrytobeprogrammedandpatterned,although certainapplicationsthatrequirehighfidelityandalignmentincircularpatterns suchasbit-patternedmediawillusemorespecializedtoolsthatallowforacircular rotatingstage.60,61

Amongthemanydifferenttypesofcommonlyusedlithography,e-beamis widelyconsideredtohavethehighestresolution,especiallywhenusing50to 1.3

100þ keVprimaryelectrons.Featuresassmallas5nmandbelowhavebeenfabricatedusinge-beamlithography.62 Althoughe-beamlithographyhasresolutioncapabilitythatfarexceedscurrentproductionDUVtools,ithassignificantlyslower throughput,whichlimitsitsuseinhighvolumecommercialmanufacturing. Throughputforamodernopticallithographyscannerexceedswelloverahundred wafersperhour.Astandardsinglebeame-beamtoolcantakeseveralhoursto exposeasinglewaferanduptoseveraldaysforsomecomplexmasksortemplates. Thistimewillbelongerasthedesiredspotsizeisdecreasedtoimproveresolution. Patterningine-beamcanalsotakemoretimebecausethehighestresolutionresists areoftennonchemicallyamplifiedresistswhichrequiremuchhigherdosesthanthe chemicallyamplifiedresists(CARs)commonlyusedinopticallithography.Thelow throughputhashistoricallylimitede-beamlithographytomaskmakingandresearch anddevelopmentpurposes;however,workhasbeencarriedoutandcontinueson methodsandtooldesignswhichcouldimprovethroughputsuchasprojection e-beam,63 66 multiple-beam,67,68 shape-variablebeam,69 andreflectivebeam.70

Multiple-beame-beamlithographyispotentiallythemostadvancedoptionatthis time,andimprovesthroughputbymassivelyparallelizingthebeamsthatpattern thewafer.71

Themostimportantradiation materialinteractioninopticallithographyatUV andDUVwavelengthsisdirectphotonabsorptiontotemporarilyexciteamolecule toanexcitedstateasdiscussedearlier.Ine-beamlithography,theradiation materialinteractionisverydifferentandisinmanywayssignificantlymorecomplex.72 Highenergyprimaryelectrons(typically50 100keV)enterthetopsurfaceand scatterthroughtheresistbyaseriesofelasticandinelasticcollisions.Theinelastic collisionscausealossofenergyandgeneratemultiplesecondaryelectrons.Thesecondaryelectronscanlikewisescatterthroughtheresistwithsimilarphysicsand generateevenmoreadditionalfreeelectrons.Inthismanner,asingleincidentelectroncangeneratealargecloudofelectrons.Thiscloudofelectronsoftenhasa teardrop-shapedinteractionvolumewiththeresistasshownin Fig.6.Theelectron trajectoriesandsecondaryelectrongenerationcanbesimulatedusingMonteCarlo techniques.73,74

Theelectronswhichscatterthroughtheresistasdescribedearlierandshownin Fig.6 canbeconsideredforwardscatteringoftheelectronsbecausemostoftheelectronsarescatteredatsmallanglesforwardintotheresist.Thereisanotherscattering phenomenonthatisimportantine-beamlithographycalledbackwardscattering. Thisoccurswhenelectronsarescatteredatmuchhigheranglesfromthesubstrate backwardintotheresist.Backwardscatteringismorelikelywhenelectrons encounterhigher Z elementsasarecommonlyfoundintheinorganicsubstrates.It isaconcernbecauseitseffectsarefeltoveramuchlargerdimensionalrange,up tomicronsawayfromtheincidentbeamratherthanthenanometerlengthscale forforwardscattering.Backwardscatteringtendstocausedensefeaturestoreceive ahighereffectivedosethansparsefeaturesbecausethebackwardscatteredelectrons fromneighboringfeaturescontributetothetotaldosewhilethesparsefeatureshave fewneighbors.Thisisknownastheproximityeffect75 andproximityeffect