Managementof ConcentrateFrom DesalinationPlants

NikolayVoutchkov

GiselaNoelleKaiser

1.2 Enablingconditionsfordesalination.............................................7

1.3 Overviewofexistingconcentratemanagementpractices.............8 1.4 Concentratemanagementregulations............................................8

3.3 Concentratetreatmentpriortosurfacewaterdischarge..............54

3.4 Designguidelinesforsurfacewaterdischarges..........................56

3.5 Costsfornewsurfacewaterdischarge........................................60

3.6 Codisposalwithwastewatereffluent...........................................64

3.7

5.1 Description.................................................................................131

5.2 Potentialenvironmentalimpacts................................................131

5.3 Effectonsanitaryseweroperations...........................................131

5.4 Effectonwastewatertreatmentplantoperations......................132

5.5 Effectonwaterreuse.................................................................133

CHAPTER6Deepwellinjection

CHAPTER7Landapplication

CHAPTER9Zero-liquiddischargeconcentratedisposal

CHAPTER10Beneficialuseofconcentrate .................................. 209

10.1 Technologyoverview.................................................................209

10.2 Extractionofmineralsfromconcentrate...................................213

10.3 Feasibilityofbeneficialreuse....................................................220 References..................................................................................220

CHAPTER11Regionalconcentratemanagement 223

11.1 Typesofregionalconcentratemanagementsystems................223

11.2 UseofbrackishwaterconcentrateinSWROplants.................224

11.3 Jointdesalinationandreuse.......................................................226 References..................................................................................230

CHAPTER12Nonconcentrateresidualsmanagement .................. 231

12.1 Spentpretreatmentbackwashwater..........................................231

12.2 Chemicalcleaningresiduals......................................................242 Reference...................................................................................243

CHAPTER13Selectionofconcentratemanagementapproach 245

13.1 Concentratemanagementalternatives.......................................245

13.2 Thefutureofconcentratemanagement.....................................251

13.3 Concludingremarks...................................................................253 References..................................................................................256

Appendix1:Abbreviations...................................................................................257

Appendix2:Units..................................................................................................261 Glossary.................................................................................................................263 Index......................................................................................................................271

Preface

Thisbookprovidesanoverviewofthealternativesformanagementofconcentrategeneratedbybrackishwaterandseawaterdesalinationplants,aswellassitespecificfactorsinvolvedintheselectionofthemostviablealternativeforagiven project,andtheenvironmentalpermittingrequirementsandstudiesassociated withtheirimplementation.Thebookfocusesonwidelyusedalternativesfordisposalofconcentrate,includingdischargetosurfacewaterbodies,disposalto wastewatersystems,deepwellinjection,landapplication,evaporation,beneficial reuse,andzero-liquiddischarge.Directdischargethroughnewoutfalls,discharge throughexistingwastewatertreatmentplantoutfalls,andcodisposalwiththecoolingwaterofexistingcoastalpowerplantsaredescribed,anddesignguidancefor theuseoftheseconcentratedisposalalternativesispresentedwithengineersand practitionersinthefieldofdesalinationinmind.Keyadvantages,disadvantages, environmentalimpactissues,andpossiblesolutionsarepresentedforeachdischargealternative.Easy-to-usegraphsdepictingconstructioncostsasafunction ofconcentrateflowrateareprovidedforallkeyconcentratemanagement alternatives.

Atpresent,membranereverseosmosis(RO)desalinationisthefastestgrowing technologyforproductionoffreshwaterfromsalinewatersources:desalination plantsuselessenergytoproducethesamevolumeoffreshwaterthanthermal desalinationfacilities.Therefore,thisbookfocusesexclusivelyontheconcentrate managementofROdesalinationprojects.

Planninganddesignforlocating,construction,funding,andoperationofdesalinationplantsismorecomplexanddemandingthanthatforconventionalwater treatmentfacilitiesintermsofprofessionalskills,knowledgeandunderstanding oftheenvironment,treatmentprocesses,technologies,andequipmentemployed indesalinationprocesses.Astheadvancesindesalinationtechnologymakedesalinationmorecompetitivewithotheralternativesourcesofwatersupply,planning anddesign,includingpreparationofaccuratecostestimatesforconstructionand operationofdesalinationprojectsbecomesofcriticalimportanceforidentifying thesizeandroleofdesalinationinthemixofalternativesthatprovideasustainableandreliablewatersupplyportfolioformunicipalcoastalcentersaroundthe world.

Thisbookprovidesdetailedinformationonhowtomanageconcentrateinthe implementationofseawaterROdesalinationplants.Thebookcontains13chapters,coveringcurrentdevelopmentsindesalinationandessentialknowledgeof prevailingmethodsofconcentratemanagement.Easy-to-useformulasandcost curvesareincludedtofacilitatedevelopmentofestimatedvolumesandcosts associatedwiththevarioustypesofconcentratemanagement.

Chapter1,IntroductiontoConcentrateManagement,providesabriefreview tothecurrentstatusofdesalinationworldwideandanoverviewofthemostcommonlyusedconcentratemanagementalternatives.Withtheelevatedriskofwater

scarcityduetoclimatechangeanddemandgrowth,desalinationisbecoming increasinglypopularfortheproductionoffreshpotablewater,especiallyinhighly urbanizedcoastalregions.Asthenumberofplantsandvolumesofdesalinated waterincrease,assurancemustbeprovidedoftheenvironmentalsustainabilityof suchdischargesoverextendedtimeperiods.Potentialenvironmentalimpactscan beminimizedthroughtreatmentofconcentrateandoptimaldischargeconfigurationanddesign,eitherdirectlyintothewaterbodyordisposedtogetherwithtreatedwastewaterorcoolingwaterfrompowerplants.

Chapter2,DesalinationPlantDischargeCharacterization,presentsthekey componentsofdesalinationplantwastestreams.Dischargefromdesalination plantsisconstitutedmainlyofROconcentrate,butmayalsocontainsignificant volumesoffilterbackwashwaterandcleaningsolutionsusedinwaterconditioningandmembranecleaning.Thequantityandqualityofeachsourcecanbecalculatedbasedontheplantcharacteristics.Thevolumeofconcentrateisafunction oftheplantrecoveryrate,andgiventhelargevolumesdischarged,concentrate managementmustbeintegraltopreliminarydesigndecisions.

Chapter3,SurfaceWaterDischargeofConcentrate,coversthemostcommon desalinationplantconcentratedisposalpractice.Asthenumberofdevelopments andvolumesofdesalinatedwaterincreases,assurancemustbeprovidedofthe environmentalsustainabilityofsuchdischargesoverextendedtimeperiods. Potentialenvironmentalimpactscanbeminimizedthroughmixingofconcentrate withdischargesofwastewatertreatmentplantsorpowerplantgenerationstations, orbytheuseofdiffusersystemsforaccelerateddissipationoftheconcentratein themarineenvironment.Ifproperlymanaged,thefootprintofincreasedsalinity canbeminimizedresultingintheeliminationofpotentialnegativeimpactsof concentrateandotherdesalinationplantdischargesonthereceivingaquatic environment.

Chapter4,CaseStudiesforSurfaceWaterDischarge,includescasestudiesof concentratemanagementpracticesinAustralia,Israel,Spain,andtheUnited States.Mostlargeplantshavedirectdischargetosurfacewaterbodies.Inthis chapter,permittingpracticesarecomparedbetweencountries.Asthetechnology hasevolvedrapidlyoverthepastdecades,standardizationwithincountriesis oftenstilllacking–mostcountrieshoweverhavesimilarpermittingrequirements fordesalinationplantdischarges.

Chapter5,DischargetoSanitarySewer,addressesthedisposalofconcentrate tothewastewatercollectionsystemasacommonpracticefromsmalldesalination plants.Typically,smallvolumesofbrinearecombinedwiththeinfluenttolarge treatmentplants.Thecostofdischargerelatesonlytoconveyanceintothewaste streamandisthuslow.Concentrateismanagedasindustrialeffluentwithboth quantityandqualityregulatedtohavenonegativeimpactonplantoperations. Increasedsalinitycanhavepotentialimpactoneffluentreuse,especiallyfor irrigation.

Chapter6,DeepWellInjection,detailshowconcentratefromdesalination plantscouldbedisposedofindeepconfinedsalineaquifers.Thecapacityofsuch

aquifersislimitedbypermeabilityandtransmissivity,whiletheunderground injectionzonemustbecompatiblewiththewaterqualityofthemembraneconcentrate.Theinjectionzonereceivingconcentratemustalsobeover10,000mg/L TDS.Concentratemayrequirepretreatmenttopreventnegativeimpactsonthe receivingaquifer.Monitoringofgroundwaterinthearea,andpressureinthe aquiferarecriticaltoearlyidentificationofleaksandregulatingthisformof disposal.

Chapter7,LandApplication,explainshowconcentratecanbedisposedina mannerwhichinvolveseithersprayirrigationonsalt-tolerantplantsorinfiltration throughearthenrapidinfiltrationbasins.Landapplicationistypicallyusedfor smallvolumesofbrackishwaterconcentrateonlyanditsfull-scaleapplicationis limitedbyclimateconditions,seasonaldemandandbyavailabilityof suitablelandandgroundwaterconditions.Agriculturalapplicationstovegetation toleranttosalinityholdspromiseofimprovingbeneficialuse.

Chapter8,EvaporationPonds,describesthecircumstancesunderwhichconcentratecanbedisposedtoponds,wherewaterisevaporatedthroughsolarpower, whiletheremainingsaltsarecollectedperiodicallyincrystalizedformandtransportedtolandfill.Landareaneededforthepondsismainlydependentonthevolumeofconcentrateandthesite-specificevaporationrate.Additionalstorage capacityisrequiredtoallowforaccumulationofthemineralsthathavecrystalizedatthebottomoftheponds.Solarpondsareevaporationpondswithan enhanceddepthwhichareconfiguredtogenerateenergy.

Chapter9,Zero-LiquidDischargeConcentrateDisposalSystems,explores currentdevelopmentsinreducingbothenvironmentalimpactandcostofconcentratemanagementbysubstantiallyreducingconcentratevolumes.Zero-liquiddischargetechnologiesconvertconcentratetopurewateranddrycrystalsordense brinewhichcanbeeitherusedforcommercialpurposesordisposedoftoalandfill.Processintensificationcombinesanumberofexistingprocessestoimprove therecovery,butdisruptivetechnologiesarelikelytobenecessarytosignificantly reducecostsandenergyrequirements.

Chapter10,BeneficialUseofConcentrate,buildsonzero-liquiddischargein identifyingpotentialmarketsforthebyproductsderivedfromthebrinesuchas high-valuemineralsandraremetals.Beneficialuseofconcentrateprovidesthe opportunitytotransformdesalination,renderingitfarmoresustainablebynot onlyreducingthenegativeenvironmentalimpactofdischarge,butbyproviding revenuethroughmineralrecovery.

Chapter11,RegionalConcentrateManagement,introducestheintegrationof concentratefromvarioussourcesinrelativelycloseproximitytoexploitpotential efficiencies.Giventhecomparativelyhighcostofconcentratemanagement,benefitscanbeobtainedbyconsolidatingeffluentfromanumberofsourcestoprovide infrastructurethatminimizesenvironmentalimpactwhiletakingadvantageof economiesofscale.Usingavarietyofsourcesandtypesofeffluent(i.e.,brackish andseawater)hastheadvantageofdilutionthatcanfurtherpositivelyimpactthe environment.

Chapter12,NonconcentrateResidualsManagement,describesthedisposalof nonconcentrateresidualssuchasspentfilterbackwashwaterfromseawaterpretreatment,spentmembranecleaningsolutionsandotherprocesssidestreams. Pretreatmentbackwashquantityandqualityvariesdependingonwhethermembraneorgranularsystemisemployed.Wherequalityisnotdetrimentaltothe environment,spentbackwashwaterisblendedwithconcentrateanddischargedto waterbodies.Alternatively,on-sitetreatmentisrequiredpriortoblending. Chemicalsusedtoperiodicallycleanmembranesresultinresidualdischargethat typicallyneedstobeeithertreatedandblendedwithconcentratebeforedisposal, orconveyedtothenearbywastewatercollectionsystem.

Chapter13,OverviewofConcentrateSelectionManagementApproach,comparesthevariousmethodsofconcentratedisposalandhighlightstheiradvantages anddisadvantages.Feasiblemethodsofdisposalneedtobeidentifiedandthen costedforthelifeoftheproject.Feasibilityisinfluencedbyregulations,environmentalsensitivityandphysicalconstraints.Costofconcentratemanagementis impactedbythesizeofthedesalinationproject,sourceseawaterquality,thetype andsensitivityofthemarineenvironmentinthevicinityofthedischarge,and preventiveormitigationmeasuresthatneedtobeimplementedinordertominimizeenvironmentalimpacts.

Thisbookisintendedfordesalinationprojectplanners,engineers,and designers;waterutilityprofessionalsinvolvedindevelopmentofwaterresource managementplans;equipmentandmembranedevelopers;operationandtroubleshootingspecialists;aswellasforstudentsandteachersinthedesalinationfield. Itcontainsneed-to-knowdesalinationconcentratemanagementpracticesand information,whichwouldbenefitpractitioners,decision-makers,andscholars alike.

Introductiontoconcentrate management

Desalinationisbecomingincreasinglypopularfortheproductionoffresh potablewatersincemanyinlandandcoastalmunicipalitiesandutilitiesinarid regionsoftheworldarelookingfornew,reliable,anddrought-prooflocalsources ofwater.Climatechangeincreasestherisksofwaterscarcity,whichareamplifiedinvulnerablecommunitieslackingessentialinfrastructure.Desalinationisa tried-and-testedadaptationoptiontoincreasethereliabilityofwaterresourcesbut hasrelativelyhigherproductioncost,energydemand,andcarbonfootprintas comparedtoconventionalwatersupplyalternatives.Similartoconventionalwater treatmentplantsandwaterreclamationfacilities,desalinationplantsalsogenerate discharge,whichcontainstheplant’ssourcewatertreatmentbyproducts.Fora desalinationprojecttobeviable,plantdischargehastobedisposedofinan environmentallysafeandsustainablemannerthatiscompliantwithallapplicable governmentalregulatoryrequirements.

Oneofthekeylimitingfactorsfortheconstructionofnewdesalinationplants istheavailabilityofsuitableconditionsandlocationfordisposalofthehighsalinitywastestreamgeneratedduringthedesalinationprocess,commonly referredtoasconcentrateorbrine.Monitoringprogramsatexistingplantsworldwidehaveshownthatimpactsonthemarineenvironmentarenonexistentorvery limitedandlocalizedwithproperplantoutfallconfiguration,siting,anddesign. Publicizinginformationofsuchmonitoringprogramshavethecapabilityof improvingtrustindesalinationtechnology,andensuringenhancedsustainability offutureplantdevelopments.Thisbookprovidesanoverviewofexistingconcentratemanagementoptions,theiradvantages,disadvantages,andimplementation constraints.

1.1 Currentstatusofdesalination

Accessiblefreshwatermakesuponlyafraction( , 2.5%)oftotalwateronthe planet.Populationsaroundtheworldhistoricallyreliedonsurfacewater(from rainfall)andgroundwater,butbothofthesesourcesarevulnerabletochangesin climateandvariabilityinweather.Aspopulationsgrewinlocationswhere

freshwaterwasscarce,newsupplysourceswerepursued.Thefirstthermaldesalinationplantswerebuiltinthebeginningofthe20thcentury,whilethefirstcommercialbrackishandseawaterreverseosmosis(RO)plantscameintooperationin the1960sand1970s,respectively.Withtechnologyadvancing,recyclingand reuseofwaterisnowalsoviable,expandingtheoptionsofpotablewatersupply.

Asthecostofwaterincreasesthroughdiversificationofsupplybeyondrelianceonrainfall,sothevalueofwaterbecomesmoreapparent.Sustainablewater managementrequiresthatallwaterinthesystemisaccountedfor,anddemand managementformsanimportantaspectofreconcilingdemandandsupply. Demandmanagementshouldbethefirst,andisgenerallytheleastcostlyinterventiontostretchavailablesupply,buttherearelimitstoefficiencies,beyond whichadditionalwaterresourceswillinevitablyberequired.

Whilethevalueofwaterneedstobebetterappreciated,andtheworldaspires toacirculareconomyandclosed-loopresourcesystems,growthinpopulation andqualityoflifewillrequireadditionalpotablewaterintheforeseeablefuture. Theoceanhastwouniqueanddistinctivefeaturesasawatersupplysource:Itis drought-proofandispracticallylimitless.Overhalfoftheworldpopulationlives inurbancentersborderingtheocean.Inmanyaridpartsoftheworldsuchasthe MiddleEast,Australia,NorthernAfrica,andSouthernCalifornia,thepopulation concentrationalongthecoastexceeds75%.Usuallycoastalzoneshavethehighestpopulationgrowthaswell,resultinginseawaterdesalinationbeingalogical solutionforsustainable,longer-termwaterresourcemanagementtomatchgrowingwaterdemandpressuresincoastalareas.

Desalinationremovesthesalts,pathogensandimpuritiesfromsalinewaterto renderitpotable.Desalinatedwaterisproducedeitherfrombrackishwater(saline waterwithtotaldissolvedsolids[TDS]contentoflessthan10,000mg/L)orfrom seawater(TDSbetween30,000and50,000mg/L).Althoughbrackishaquifers andsurfacewatershavebeenusedforproductionoffreshdrinkingwaterforover 50years,thesebrackishwatersourcesareoflimitedavailabilityandhavealong replenishmentcycleresultinginlimitedlong-termsustainability.Incontrast,the world’soceanscontainover97%oftheplanet’swaterresources,providingan essentiallyunlimitedrawmaterialforseawaterdesalination.Inmosturbancenters,thefreshwaterproducedbydesalinationofseawaterisreturnedbacktothe oceanintheformoftreatedwastewater.Usuallywastewatertreatmentplantsare withina25 50kmradiusofthedesalinationplantsalongthecoastandthetime toreturnover80%ofthedesalinatedseawatertotheoceanaswastewaterdischargeistypicallylessthan1week.Mostoftheremaining20%ofthedesalinatedwaterislosttoevaporationandgroundpercolationasdrinkingwaterand wastewatergeneratedfromitaremainlyusedforirrigation.Thismakesseawater desalinationoneofthewatersupplyoptionswiththeshortestwatercycle,shorter thanlake,river,orbrackishwatersources.

Withgrowingwaterscarcityandsignificantlyreducedcost,interestindesalinationhasriseninrecentdecades.ThisisparticularlytrueintheMiddleEast, whereseverewaterscarcityandrelativelylowcostofenergyhavefacilitatedthe

earlyadoptionofdesalinationasamainsourceofpotablewatersupply.Driven byrisingdemandandcommercialinnovation,thecostofdesalinationhas decreasedsignificantlyovertime,andisbecominganincreasinglyfeasibleand sustainableoptionformostothercountriesworldwide.

Atpresent,over16,000desalinationplantsworldwideprovidedrought-proof watersupplyforalargenumberofaridurbancoastalmunicipalitiesofthe MiddleandFarEast,Europe,Africa,Australia,andtheAmericas(Jonesetal, 2018).Almosthalfoftheseplants(44%)areinthestillfast-growingMiddleEast region.However,otherregionsoftheworld,notablyAsia(inparticular,China), theUnitedStates,andLatinAmericaarealsoexperiencingaccelerateddesalinationplantcapacitygrowthof6% 8%peryear,whichfarexceedsthegrowthrate ofconventionalwatersupplysources(2% 3%peryear).

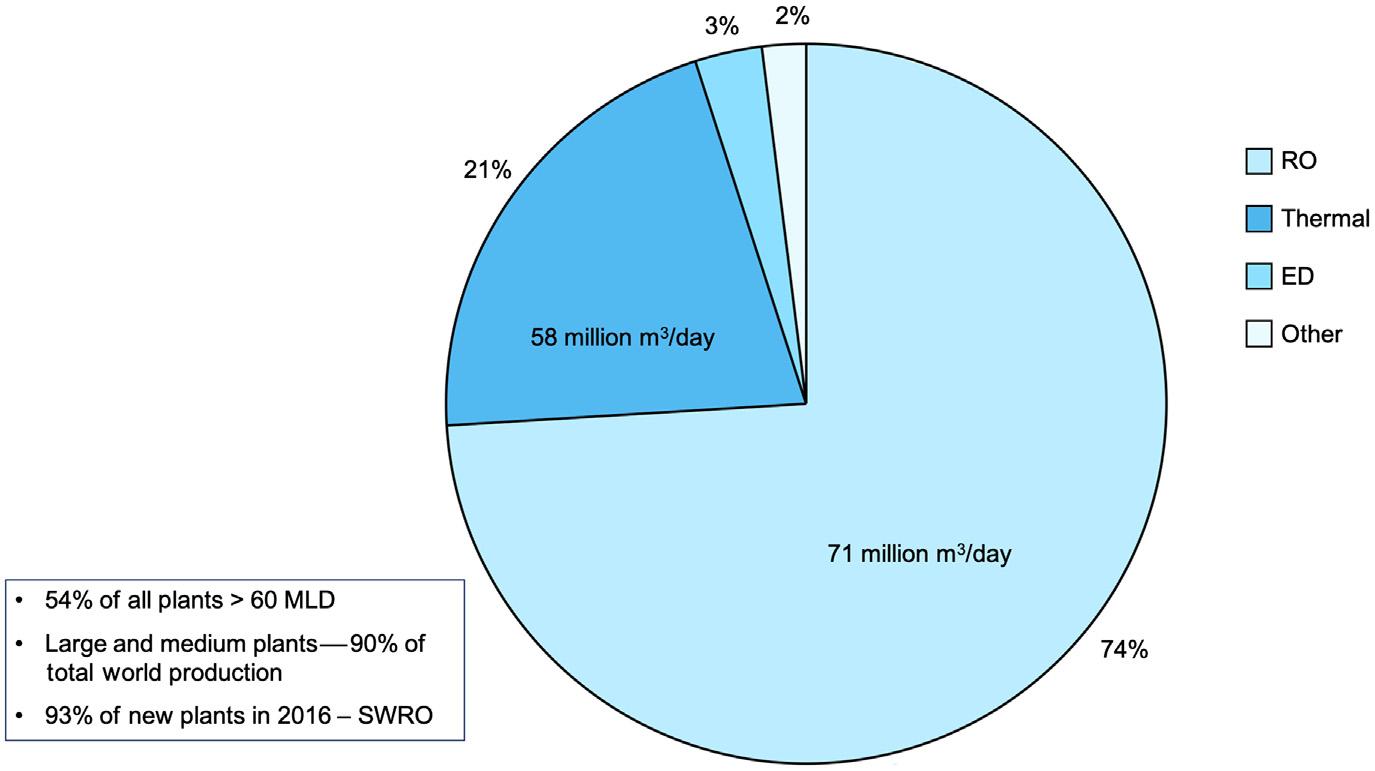

Productionoffreshwaterbydesalinationin2019totaledapproximately95 millionm3/day(24,300MGD).Thecorrespondingcumulativevolumeofconcentrategeneratedbythedesalinationplantsinoperationatpresentisestimatedtobe 142millionm3/day(37,500MGD).Approximately74%oftheexistingdesalinationplantsusemembraneROtechnologyforsaltseparation;21%applythermal evaporation;and5%useothersaltseparationtechnologies,suchaselectrodialysis (ED)andionexchange(IX)toproducefreshwater(see Fig.1.1).After2015, mostMiddleEasterncountrieshavedrasticallyreducedtheconstructionofnew thermaldesalinationplantsandhaverefocusedontheuseofmembranedesalinationduetoitslowerenergydemandandoperationalflexibility.

FIGURE1.1

Currentstatusofworldwidedesalinationtechnologyuse.

DatafromIDADesalinationYearbook2018 19.

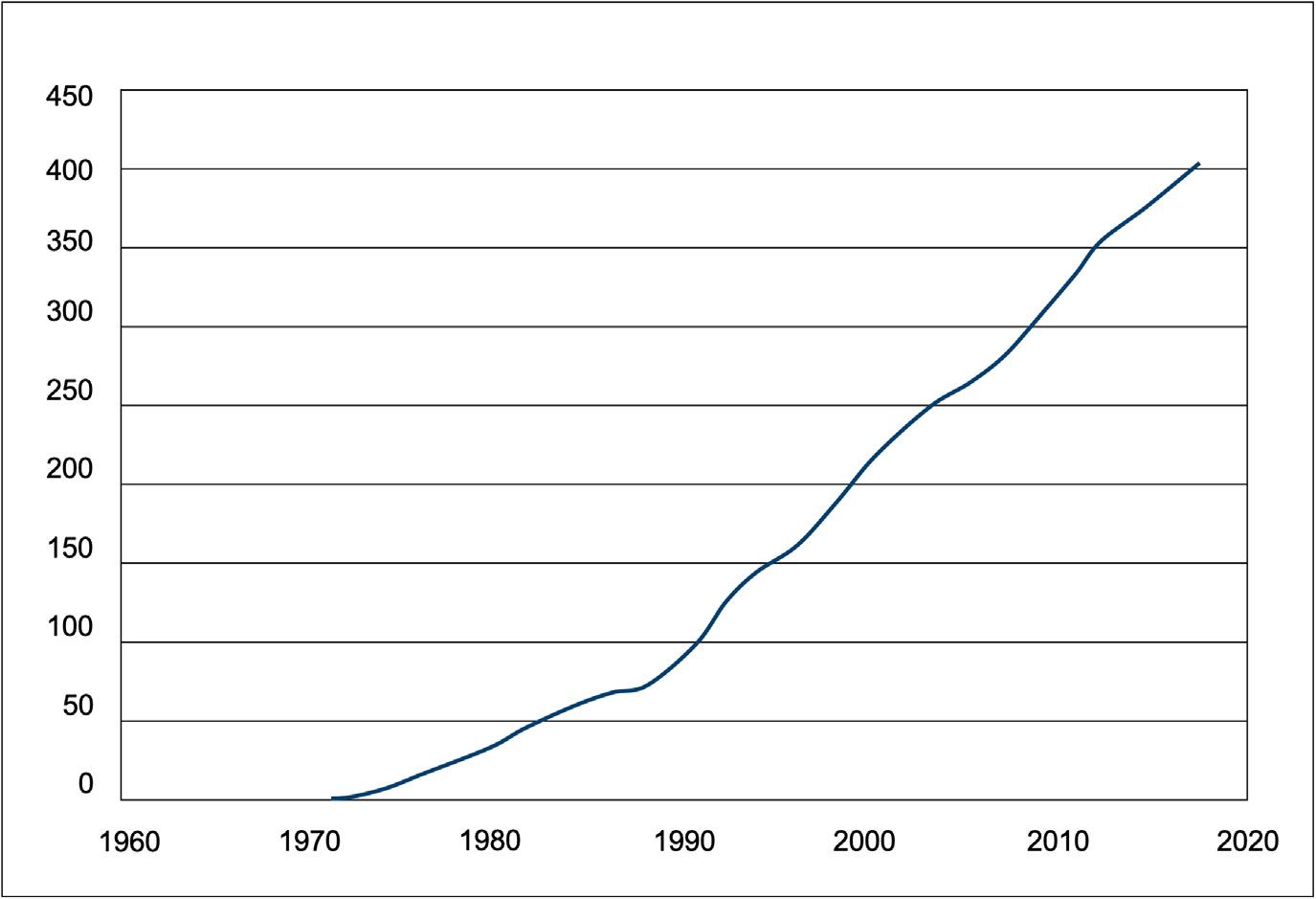

Desalinationofbrackishandseawaterisbecomingincreasinglypopularfor productionoffreshpotablewaterintheUnitedStates.Basedona2017survey (Mickley,2018)atpresentthereareapproximately400desalinationplantsinthe UnitedStatesandtheirnumberisgrowingsteadily(see Fig.1.2).Mostdesalinationplantsusenanofiltration(NF)andROmembranesforsaltseparation.

Thesteadytrendofreductionofdesalinatedwaterproductionenergyandcosts coupledwithincreasingcostsofconventionalwatertreatmentandwaterreuse, drivenbymorestringentregulatoryrequirements,areexpectedtoacceleratethe currenttrendofrelianceontheoceanasanattractiveandcompetitivewater source.Thistrendislikelytocontinueinthefutureandtofurtherestablishocean waterdesalinationasareliabledrought-proofalternativeforamajorityofcoastal communitiesworldwideinthenext15years.Atpresent,desalinationprovides approximately10%ofthemunicipalwatersupplyoftheurbancoastalcentersin theUnitedStates,Europe,Israel,andAustralia,andover50%ofthedrinking wateroftheGulfCooperationCountries;by2030thispercentageisexpectedto exceed25%and80%,respectively.

Increasedrelianceonseawaterdesalinationisoftenparalleledwithongoing programsforenhancedwaterreuseandconservationwithalong-termtargetof achievingabalanceofconventionalwatersupplysources,seawaterandbrackish waterdesalination,waterreuseandconservationtothetotalwatersupplyportfoliooflargecoastalcommunities.Surfacewatersourcesareusuallysignificantly cheaperwithwell-developedmanagementsystemsandoperationsinplace.

FIGURE1.2

CumulativenumberofmunicipaldesalinationplantsintheUnitedStates.

Addingmorecostlydesalinatedwatertothesupplymixrequiresimproved demandmanagementandderivingfullvalueofreusepotentialtooptimizethe valueofpotablewater.

Near-andlong-termdesalinationtechnologyadvancesareprojectedtoyielda significantdecreaseincostsofproductionofdesalinatedwaterby2030.Indesalination,innovativetechnologieshavebeenaddressinglongstandingissuesthat havehamperedthedevelopmentofthisalternativeresource.Newtechnologies suchasnanoparticleenhancedmembranes,biomimeticmembranesandforward osmosisaswellasbeneficialextractionofraremetalsfromthebrinegenerated bydesalinationplantsareaimedatreducingenergyconsumption(by20% 35%), reducingcapitalcosts(by20% 30%),improvingprocessreliabilityandflexibility,andgreatlyreducingthevolumeoftheconcentratedischarge.

1.1.1 Desalinationasastrategicwaterresourceoption

Despitesignificantreductionincost,desalinationremainsmoreexpensivethan otherbulkwatersourcesandneedstobeusedstrategicallytoaddressalimited rangeofproblems.However,todaytheinstancesoftheseproblemsarefast expanding.Desalinationisprovingappropriateforcertainmarketsthatrequirea highqualityandcompletereliabilityofserviceandinwhichcustomersorgovernmentscanaffordtopaythehighercost.Forexample,desalinationcanproduce high-qualitypotablewaterthatsuitstheneedsoflargecitiesinwhichthereare highconcentrationsofpeoplewhodemandaquality24/7waterserviceandwho arepreparedtopayforthatservice.Desalinationcanalsoprovideareliablesupplyoflargevolumesofwatertohigh-valueindustry,commerce,andtourism. Theseusestypicallyvaluewaterappropriatelyandcanaffordtopayunsubsidized costforproductionofdesalinatedwater.

Desalinationisofspecificinterestincertainlocationsinwhichtheothersupplyalternativesareequallyormorecostlyand/ortheriskofsupplyfailureor inabilitytosecuresustainablealternativewaterresourcesishigh.Desalinationis, however,demandingintermsoflocation.Waterhasaveryhighratioofbulkto valueandisveryexpensivetoliftortransport.Thisdrivesthelocationofadesalinationplant:tobenearitssource,thesea,andtobeclosetoitsmarketorpoint ofuse.Hence,thetypicallocationofadesalinationplantisalongacoastalcity orcoastalindustrialzone,supplyingarelativelywell-offindustrial,commercial, ordomesticdemand.Wherethephysicalandsocioeconomicconditionsareright, seawaterdesalinationprovidesastrategicsolutionforthesustainable,long-term satisfactionofpartofthisgrowingwaterdemand.

Aswaterscarcitygrowsandwithadvancesindesalinationtechnologyand reductionsinproductioncost,policymakersaroundtheworldarerightfullyasking whetherdesalinationshouldplayapartinclosingthegapbetweensupplyand demandinfutureyears.Althoughmostofthesupply demandgapsolutionswill stillcomefromthetraditionalsupplyanddemandsidemanagementoptions, desalinationisoneoftheviableoptionswithstrategicrelevance.

Desalinationalsoprovidesasolidresponsetoexogenousriskssuchasdependency.Singapore,forexample,optedforlarge-scaledesalinationtoreduceits dependenceonincreasinglyexpensiveimportedwaterfromMalaysia.Thestable, efficientsuppliesofurbanandindustrialwaterthatdesalinationprovidescanhelp governmentsmanagearangeofeconomic,social,andpoliticalrisks.

1.1.2 Currentdesalinationprojectrisksandcosts

Desalinationprojectsareoftenmegasizedwithriskassessment,management,and mitigationcomprisingkeycomponentsofprojectplanning.Allbusinessdecisions requirenotonlyanassessmentofcostsandreturnsbutalsoanevaluationofthe risksattachedtoaprojectandmeasuresformanagingoreliminatingrisks togetherwithcontingencyarrangementsformitigatingpossibleimpacts.Clearly, therisksassociatedwithmegaprojectsareconsiderableandriskassessment formsakeypartofplanning.Keyrisksassociatedwithdesalinationprojects include(1)permittingorlicensingrisks,(2)entitlementrisks,(3)technology risks,(4)constructionrisks,(5)regulatoryrisks,(6)financialrisks,(7)source waterqualityrisks,(8)powersupplyrisks,(9)O&Mrisks,and(10)desalinated waterdemandrisks.

Selectingtherightprocurementmethodisimportantformatchingriskexposuretomanagerialcapacityandultimatelyachievingthebestvalueformoney. Thesponsorofaninfrastructureprojecthasalternativeoptionstodealwitheach oftheserisks:(1)decidetomanageit(keeptherisk),ifthesponsorbelievesthere isthetechnical,managerial,orfinancialcapacityrequiredtohandleit;(2)insure orhedgetherisk,ifandwherethemarketofferssuchsolutions;or(3)transferit orshareitwithathirdparty.Theconditionsunderwhichtheserisksaretransferredorsharedwithaprivatepartneraredeterminedbytheprocurementinstrumentadoptedtodeveloptheinfrastructure.Inturn,theselectionofthe procurementinstrumentshouldbemadetoallocatethedifferentrisksinvolved withthepartythatisbestplacedtomanagetheminacost-effectiveway,which isnotnecessarilyalwaystheprivatesector.

Commonlyuseddesalinationprojectdeliverymethodsinclude:

1. theturnkeyapproach,alsoreferredtoas“engineering,procurement,and construction”(EPC),inwhichtheprivatecontractorisresponsibleforthe designandtheconstructionofthefacility;

2. the“design build operate”method(DBO),inwhichthecontractorisalso responsiblefortheoperationoftheplantforalimitednumberofyears, usuallytwotofive;and

3. the“build own operate transfer”method(BOOT),bywhichtheprivate partnerfinancesthedesalinationfacilityandoperatesitforalongperiodof time,usually20 25years,inexchangefortariff-basedpaymentslinkedto plantcapacityandactualwaterdemand.

Thetraditionalinfrastructureprocurementapproach,alsoknownas “design bid build”(DBB),israrelyusedfordesalinationprojects.

1.2 Enablingconditionsfordesalination

TheadvanceoftheROdesalinationtechnologyissimilarindynamicstothatof computertechnology.Whileconventionaltechnologies,suchassedimentation andfiltrationhaveseenmodestadvancementsincetheirinitialusefor potablewatertreatmentseveralcenturiesago,newmoreefficientseawaterdesalinationmembranesandmembranetechnologies,andequipmentimprovementsare regularlyreleased.Similartocomputers,theROmembranesoftodayaremany timessmaller,moreproductiveandcheaperthanthefirstworkingprototypes. ThefutureimprovementsofROmembranetechnologywhichareprojectedto occurby2030areforecasttoencompass:

• developmentofmembranesofhighersaltandpathogenrejection, productivity,reducedtrans-membranepressure,andfoulingpotential;

• improvementofmembraneresistancetooxidants,elevatedtemperature,and compaction;

• extensionofmembraneusefullifebeyond10years;

• integrationofmembranepretreatment,advancedenergyrecovery,andSWRO systems;

• integrationofbrackishandseawaterdesalinationsystems;

• developmentofnewgenerationofhigh-efficiencypumpsandenergyrecovery systemsforSWROapplications;

• replacementofkeystainless-steeldesalinationplantcomponentswithplastic componentstoincreaseplantlongevityanddecreaseoverallcostofwater production;

• reductionofmembraneelementcostsbycompleteautomationoftheentire productionandtestingprocess;

• developmentofmethodsforlow-costcontinuousmembranecleaningwhich allowreductionindowntimeandchemicalcleaningcosts;and

• developmentofmethodsforlow-costmembraneconcentratetreatment,inplantandoff-sitereuse,anddisposal.

Althoughnomajortechnologybreakthroughsareexpectedtodramatically reducethecostofseawaterdesalinationinthecomingyears,thesteadyreduction ofdesalinatedwaterproductioncostscoupledwithincreasingcostsofwatertreatmentdrivenbymorestringentregulatoryrequirements,areexpectedtoaccelerate thecurrenttrendofincreasedrelianceontheoceanasanattractiveandcompetitivewatersourceby2030.

Thistrendisforecasttocontinueinthefutureandtofurtherestablishseawater desalinationasareliabledrought-proofalternativeformanycoastalcommunities

Table1.1 Forecastofdesalinationenergyuseandcostsformediumand largeplants.

Parameterforbest-inclassdesalinationplants202020222030

Totalelectricalenergyuse(kWh/m3)3.5 4.02.8 3.22.1 2.4

Costofwater(US$/m3)0.8 1.20.6 1.00.3 0.5

Constructioncost(US$/MLD)1.2 2.21.0 1.80.5 0.9

Membraneproductivity(m3/membrane)28 4855 7595 120

worldwide.Thesetechnologyadvancesareexpectedtoentrenchthepositionof SWROtreatmentasviableandcost-competitiveprocessforpotablewaterproductionandtoreducethecostoffreshwaterproductionfromseawaterby25%in 2022andbyupto60%by2030(see Table1.1).

Therateofadoptionofdesalinationincoastalurbancentersworldwideis dependentonthemagnitudeofwaterstresstowhichtheyareexposedandavailabilityoflower-costconventionalwaterresources.

Infuture,desalinationislikelytobeadoptedasmainwatersupplyinaridand semi-aridregionsoftheworldsuchandtheMiddleEast,NorthAfrica,the WesternUnitedStates,andAustraliaandinlocationsofconcentratedindustrial demandforhigh-qualitywatersuchasSingapore,China,andNorthernChile.

1.3 Overviewofexistingconcentratemanagement practices

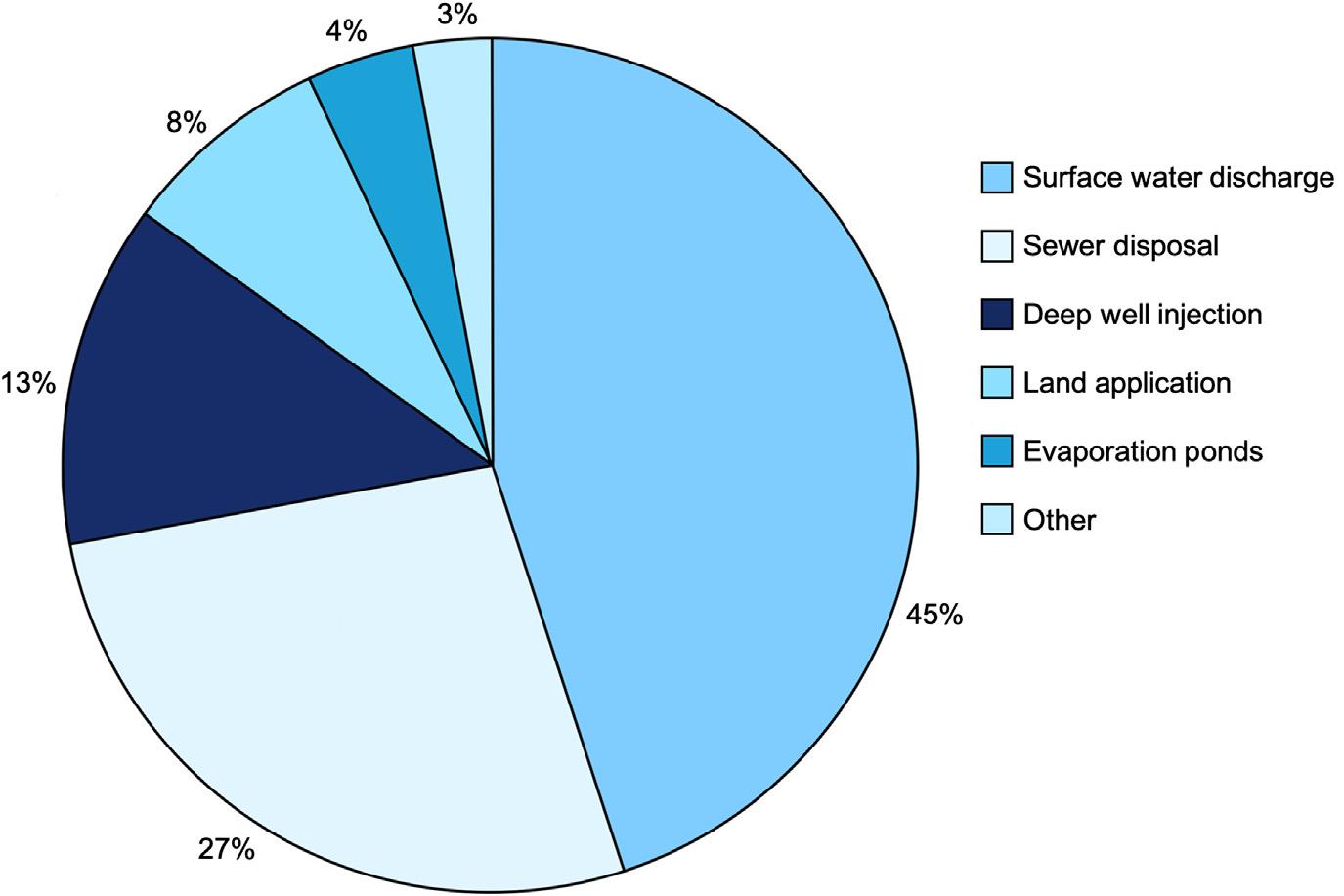

Accordingtothe2018reportonconcentratetreatmentpreparedbytheUnited StatesBureauofReclamation(Mickley,2018)thefivemostcommonlyusedconcentratemanagementalternativesintheUnitedStatesare:(1)surfacewaterdischarge,(2)sewerdisposal,(3)deep-wellinjection,(4)landapplication,and(5) evaporationponds(see Fig.1.3).Thedesalinationconcentratemanagementpracticesshownin Fig.1.3 havesimilarfrequencyofapplicationworldwide.

1.4 Concentratemanagementregulations

Atpresent,therearenofederalregulationsintheUnitedStatesorstateregulations elsewhereintheworldspecificallydevelopedtoaddresswastedischargesfrom desalinationplants(WaterReuseAssociation,2011).Desalinationplantdischarges areclassifiedbytheUnitedStatesEnvironmentalProtectionAgency(USEPA)as industrialwastedespitethefactthatthesedischargesaredistinctivelydifferent frommostindustrialdischarges.SeveralregulatoryprogramsintheUnitedStates thatimpactthedisposalofdesalinationplantdischarges,includingtheCleanWater

Act(CWA),theUndergroundInjectionControl(UIC)Program,ordinancesthat protectgroundwater,andtheResourceRecoveryandConservationAct(RCRA)for anysolidwasteresiduals.Disposaloptionsfordesalinationplantdischargesand associatedregulatoryandpermittingagenciesinclude:

• DisposaltosurfacewaterdischargerequiresaNationalPollutantDischarge EliminationSystem(NPDES)permit.

• Sewerdischargerequiresapermitissuedbythelocalseweragencytomeetits sewerordinanceandtheCWAIndustrialPretreatmentProgram(IPP) requirements,asstipulatedintheagency’sNPDESpermit.

• Concentratedisposalbylandapplication(percolationponds,rapidinfiltration basins,landscapeandcropirrigation,etc.)mustcomplywithfederalandstate regulationstoprotectgroundwater,publichealth,andcrops/vegetation.Land applicationrequiresapermitfromstateagencies.

• Concentratedisposalbydeep-wellinjectionisregulatedbytheUICprogram oftheSafeDrinkingWaterAct.Therelatedconstruction,monitoring,and otherpermitsareissuedandenforcedbytheUSEPAregionorstateagency thathasprimacy.

• RCRAregulatesthedisposalofsolids,suchasprecipitatedsaltsandsludge;if suchsolidscontainarsenicorothertoxinsanddonotpassthetoxic characteristicleachingprocedure(TCLP)test,theyareconsideredahazardous wasteandmustbehandledaccordingly.

FIGURE1.3 Currentconcentratemanagementpractices.

ThemostimportantregulationspertainingtodisposalofdesalinationplantdischargesarethoserelatedtotheCWA,includingtheNPDESprogram.Underthe CWA,desalinationplantdischargesareregulatedasindustrialwastesasthe USEPAhasnotestablishedspecificregulationsconcerningthedisposalofwater treatmentplantresiduals,includingdesalinationplantdischarges.Forsurface waterdischarge,NPDESpermitisrequiredpursuanttotheCWA;itsantidegradationpolicypreventstherelaxationofdischargelimitsforcontaminantsspecified inaNPDESpermit,particularlyifthereceivingwaterisdesignatedassensitive orimpaired.IfawatertreatmentplantcurrentlyhasaTDSdischargelimit,combininghighTDSconcentratefromthedesalinationplantROsystemwiththe existingdischargemaynotbeallowed.

PermittingpracticesintheMiddleEastareverysimilartotheseintheUnited States.TheregulationspertainingtodesalinationplantsinAustralia,Spain,and Israel,whichatpresenthavethelargestnumberofdesalinationplantsoutsideof theMiddleEast,haveanumberofsimilaritiestothoseintheUnitedStates.Inall ofthesecountriesthepermittingprocessforsuchdischargesisthesameasthis appliedforpermittingofdischargesfromwastewatertreatmentplants.Australia hasdischargeregulationsmostsimilarinstructuretotheseintheUnitedStates, wherethefederalgovernmenthasestablishedthebaselinelegalframeworkfor regulationofwastedischargesandtheindividualstateshaveenhancedthefederal regulationswithstateandlocation-specificregulatoryrequirements(Mickleyand Voutchkov,2016).

Despitethesimilarities,thepermittingofmediumandlargesizeprojectsin theUnitedStatesusuallytakeslongerthanthatinAustralia,SpainandIsrael.For example,thepermittingoftheTampaBayandCarlsbadSWROdesalinationprojectswascompletedwithin2.4and5years,respectively.Forcomparison,the averagetimeneededforpermittingofsimilarsizeprojectsinAustraliais1.5 2 yearsandinSpainandIsraelis9 12months.Themainreasonsareasfollows:

• Streamlinedregulatoryprocess:Usuallyonlyoneortwoagenciesareinvolved intheenvironmentalreviewofthedesalinationprojectascomparedtofourto sixagenciesinmostUSstatesandupto24agenciesinCalifornia.

• Priorityreviewofdesalinationprojects:Spain,Israel,andAustraliarecognize thenational/statestrategicimportanceofseawaterdesalinationforsecuring sustainableanddrought-prooflong-termwatersupplyinthesecountries.Asa result,theyhavelong-termplansfordevelopmentandimplementationof desalinationprojects,whichareunderthecloseoversightofthecentral governmentinSpainandIsraelandthestategovernmentinAustralia.Since thetimelyimplementationofsuchplantsisconsideredofhighimportanceand priorityfortherespectivecountries,theregulatoryagenciesaregivensupport atfederallevelinthecaseofSpainandIsrael,andatstatelevelinthecaseof Australiaintermsofexpertise,direction,andfundstoexpediteandgive priorityoftheenvironmentalreviewofdesalinationprojectsascomparedto othertypesofprojects.

• Superiorexpertiseofregulatoryagenciesinpermittingofdesalinationplants:In theUnitedStates,mainlybecauseoffundingconstraints,manyoftheregulatory agenciesinvolvedinthepermittingofdesalinationprojectsusuallydonot maintainstaffwithalltypesofexpertiseneededtocompleteanexpeditedreview ofdesalinationprojectssuchasmarinebiologists,expertsinoutfalldischarge modeling,andengineerswithexperienceinthedesignandoperationof desalinationplants.Forcomparison,thekeyagenciesinvolvedindesalination projectreviewinSpain,Australia,andIsraelhavesuchexpertsonstafforifsuch expertswerenotoriginallyavailable,theywereretainedinexpeditiousmannerat thebeginningoftheprojectreviewtominimizetimeneededforenvironmental projectreview.Forcomparison,mostoftheagenciesinvolvedindesalination reviewinCaliforniadonothavesuchexpertsandasaresulttheenvironmental reviewprocessgoesthrough6 12roundsofrequestsforadditionalinformation bytheregulatoryagencyreviewerssincetheylearnonthejobandwork piecemealontheirquestionsastheylearnmoreabouttheproject.

• Sharingofregulatoryexpertisebetweenvariousagencies:inallofthelisted states,thekeyregulatoryagenciesinvolvedinpermittingofdesalination projectshaveinternalmeetingswheretheyshareexperiencewithvarious permittingissues.Suchregulatorsalsoactivelyparticipateinprofessional conferencesandpublicforumspresentinginclearmannertheirrequirements andexpectationsassociatedwiththetypeanddetailofinformationthatneeds tobesubmittedbytheprojectsponsorsinordertominimizetimeneededfor projectpermitting.Mainlyduetolackoffunds,USregulatorsinvolvedin permittingofdesalinationprojectsusuallydonothavesuchprofessional experienceexchangeopportunitiesinandoutofstateandrarelyattend professionalconferencesorpresenttheirexpectationsinprofessionalforums.

Inallcountriesreferencedearlier,thedesalinationplantpermitsareissued afterathoroughenvironmentalreviewoftheimpactoftheplantdischargeonthe surroundingaquaticenvironment,whichisdeterminedbasedon

• Projectionsofconcentratewaterqualitydevelopedbasedonsourceseawater qualitycharacterizationandthespecificdesignfeaturesofthedesalination plant(plantrecovery,productwaterquality,typeofintake,anddischarge).

• Biologicalsurveyofthedischargeareaaimingtodocumentthetypeand quantityofmarinespeciesinhabitingthisareaandtheirsalinitytolerance.

• Inallofthereferencedcountriesthesalinitytoleranceofmarineorganismsis determinedbasedonchronic(orinthecaseofsomeAustralianstates),acute wholeeffluenttoxicity(WET)testingofthemostsensitivespeciesinhabiting thedischargearea.InAustraliathemarineorganismsaretestedinembryonic stageofdevelopment,whichhasresultedinthemoststringentrequirements forconcentratedilutionascomparedtotheseinSpainandIsraelwherethe testspeciesusedfordeterminingsalinitytoleranceareinadultphase.

• Themixingrequirementsforthedesalinationprojectsaredeterminedbasedon theWETtestingstudyandhydrodynamicmodelingofthedischargearea.

InSpainandIsraelusuallyonlyoneenvironmentalregulatoryagencyhasthe righttomakedecisionsandestablishdischargepermitrequirementsandmitigationmeasures.Ifotheragenciesareinvolvedintheprojectreview,theyprovide commentstotheleadagencybuthavenorightorjurisdictiontochangepermittingrequirementsexceptbyinternalconsensus.InAustralia,keydecisionsare madeatstatelevelbyoneleadagency.Forcomparison,theindependentmultiagencyreviewprocesstypicalforstatessuchasCaliforniaresultsinnumerous conditionsandpermitswhichregulatethedischargeandwhichmayhavedifferentrequirementsintermsofmitigationofenvironmentalimpacts.Suchpractices notonlydelaythepermittingprocessbutalsoputasignificantburdenontheprojectsponsorassociatedwithprojectimplementation,operationsmonitoringand datareporting.

Regulationsapplicabletosurfacewaterdischargeacrosstheworldare expandedoninChapter3,SurfaceWaterDischargeofConcentrate.

References

Mickley,M.C.,2018.UpdatedandExtendedSurveyofU.S.MunicipalDesalination Plants.DesalinationandWaterPurificationResearchandDevelopmentProgram ReportNo.207.Denver:USBureauofReclamation.

Mickley,M.C.,Voutchkov,N.,2016.Databaseofpermittingpracticesforseawaterconcentratedisposal.WaterEnviron.ReuseRes.Found.

Jones,E.,Qadir,M.,vanVliet,M.T.H.,Smakhtin,V.,Kang,S.,2018.Thestateofdesalinationandbrineproduction:aglobaloutlook.Sci.TotalEnviron.657,1343 1356. WaterReuseAssociation,2011.SeawaterConcentrateManagement,WhitePaper.WRA, Alexandria,VA.

2

2.1 Desalinationplantwastestreams

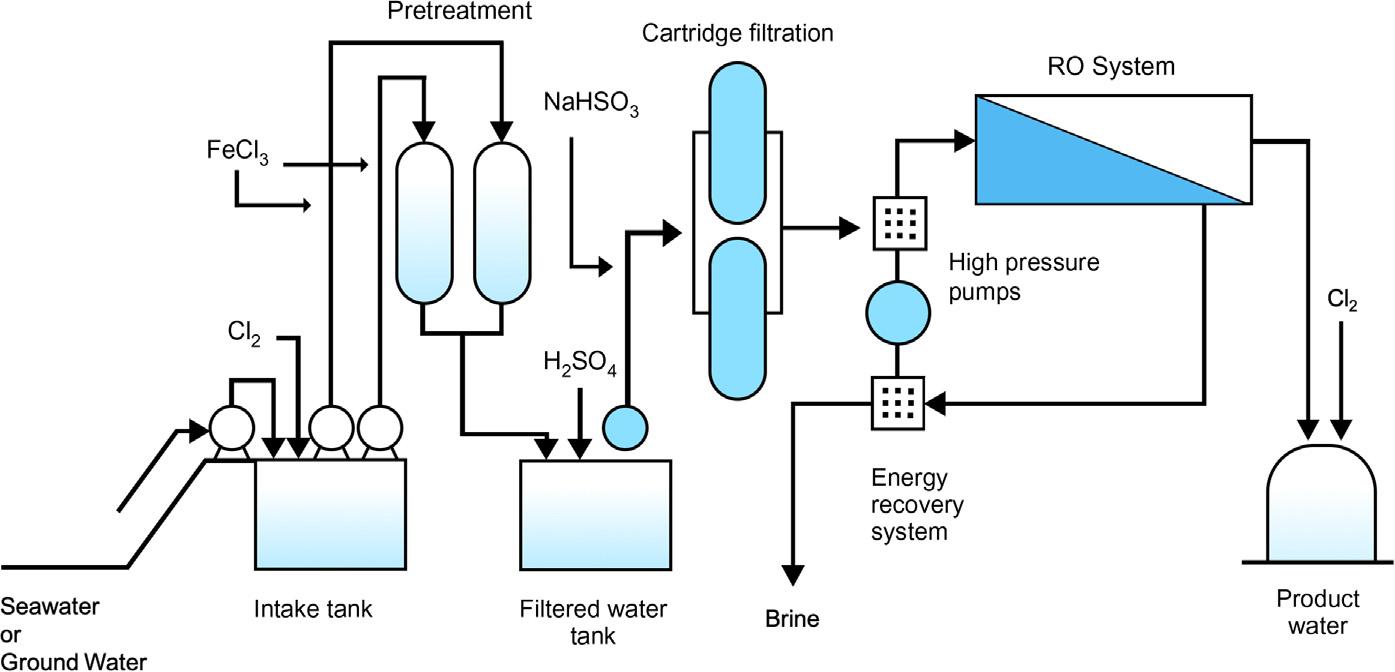

Mostmembranedesalinationplantshavethefollowingcomponents,whichare shownin Fig.2.1:

• apointofintaketocollectsalinesourcewater(ground-orseawater);

• atypeofpretreatmentsystemwiththemainpurposeofremovingsuspended solids,organics,andscalingmineralsfromthesalinesourcewater;

• asystemofreverseosmosis(RO)membranesandequipmentwhichprocess thesourcewatertoproducefresh,lowsalinitywater(calledpermeate)by separatingdissolvedsolidsfromthepretreatedsalinewater;and

• aposttreatmentsystemtoaddbacknecessarymineralstotheproductwaterto makeitsuitablefordistributionandfinaluse.

Brackishwaterdesalinationplantsincludemostofthesamekeytreatment processcomponentsasseawaterdesalinationfacilities.However,inmanybrackishplants,aportionofthesourcewaterisbypassedandblendedwithplantpermeatetoachievetargetwaterquality.

Desalinationplantresidualstypicallyinclude:

• ConcentrategeneratedbytheROsystem,whichcontainsdissolvedand particulatecontaminantsremovedfromthefeedwater.Concentratemayalso containchemicalsfromthesourcewaterconditioningandthepretreatment facilities.

• Spentfilterbackwashwatergeneratedbythedesalinationplantpretreatment system.

• Spentcleaningsolutionsfromtheperiodicchemicallyenhancedcleaningof theROandpretreatmentmembranes(ifmembranepretreatmentisused). Thesewastestreamscontainahighconcentrationofthecleaningchemicals, alongwiththefeedwatercontaminantsremovedduringmembranecleaning.

Desalinationplantsareusuallydesignedtooperateandproducepermeatecontinuously.Concentrateisgeneratedasabyproductwhenevertheplantis

Schematicoftypicalmembranedesalinationplant.

operational.Thevolumeandfrequencyofbackwashwatergeneratedisdependent onthetypeofpretreatmentsystem;granularmediafiltershavebackwashcycles withdurationof24 48hours,whilemembranepretreatmentsystemshavecycles farshorter,typicallybetween30and60minutes.Spentcleaningsolutionsgeneratefarsmallervolumesofdischarge,dependingontherequiredfrequencyofRO membranecleaningwhileside-streamsfrompretreatmentmembraneclean-inplace(CIP)cleaningareusuallygeneratedmonthlyoronceeveryseveralmonths (Voutchkov,2011a).

TheROandpretreatmentmembranesaretypicallycleanedwithacid(mineral orcitric)toremoveinorganicfoulantsandwithalkalinesolutions(i.e.,sodium hydroxide,oftenincombinationwithdetergents/surfactantsandsometimeswith chelatingagents)toloosen,dislodge,andremovebiofilmsandorganicfoulants. Sodiumhypochloriteisalsoappliedforperiodic(onceperdaytoonceperweek) enhancedbackwashofthepretreatmentmembranestocontrolexcessivebiogrowthonthemembranefibers.

2.2 Concentrate

Separatingmineralsandcontaminantsfromsourcewaterresultsintwoliquid streams:onewithamuchreducedconcentrationofminerals(freshwater),the otherwithfarhigherconcentration.Thestreamwithhighersalinityconcentration thatcontainsthemineralsremovedfromthesourcewaterisknownas“concentrate.”Theconcentratealsocontainstheantiscalingchemicalsaddedduringthe sourcewaterconditioningprocesspriordesalination.

FIGURE2.1

2.2.1 Quantity

Thevolumeofconcentratedependsonthesizeofthedesalinationplantandon theratiobetweentheproducedfreshwaterandthesalinesourcewatercollected foritsproduction.Thisratioistypicallyreferredtoasarecoveryrateand expressedinpercentofthecollectedsourcewater.Desalinationplantsareclassifiedintermsofthevolumeoffreshwatertheyproduce,wheresmallplantsare consideredfacilitiesthatyieldlessthan20MLDwhilelargeplantsproducehundredsofmillionsoflitersperday.Therecoveryratesdifferdependingonthe typeofplantandotheroperationalconditions:mostseawaterROplantstypically haverecoveryratesbetween40%and55%whilebrackishwaterdesalination plantsoperateatsignificantlyhigherrecoveryof65% 85%(Voutchkov,2011a).

Therecoveryrateofaplant(R )issimplytheratioofthevolumeoffresh waterproduced( Qp )dividedbythevolumeofsalinesourcewater(Q s)collectedforproductionofthisfreshwater.Thevolumeofconcentrateproduced ( Qc )isthedifferencebetween Qs and Qp .Asdesalinationplantsareclassified intermsofthevolumeoffreshwaterp roducedandtherecoveryratherthan thevolumeofsourcewaterrequired,thevolumeofconcentratecanbecalculatedas(Voutchkov,2011a):

Example

Foralargeseawaterdesalinationplantoffreshwaterproductioncapacityof100MLDoperating atarateofrecoveryof45%,thedailyconcentratevolumeiscalculatedasfollows:

Qc seawaterplant 5 100; 000m3 =day 3 1

=day

Withthesamefreshwaterproductioncapacityof100MLD,abrackishwaterdesalination plantdesignedatrecoveryrateof80%willgeneratenearlyfivetimeslessconcentratethanthe seawaterplant:

Qc brackishwaterplant 5 100; 000m3 =day 3 1 0 80 ðÞ=0 80 5 25; 000m3 =day

2.2.2 Quality

Thequalityofconcentrateismainlyafunctionofthecompositionofthesource water,andisinfluencedbytherecoveryrate.Thehighertherecoveryrate,the highertheconcentrationofmineralswillbeintheconcentrate. Witharecoveryratebetween65%and85%,thesalinityofbrackishplant concentratecanbebetween4and10timeshigherthanthatofthesalinesource water.Thefarlowerrecoveryofseawaterplantsresultinconcentrateofbetween