eTextbook 978-0133457100 Strategic Compensation: A Human Resource Management Approach

https://ebookmass.com/product/etextbook-978-0133457100-strategiccompensation-a-human-resource-management-approach/

ebookmass.com

Dirty December (Pine Ridge Universe) S.C. Principale

https://ebookmass.com/product/dirty-december-pine-ridge-universe-s-cprincipale/

ebookmass.com

The Billionaire's Best Friend: A Contemporary Christian Romance (Billionaire Next Door Book 2) Elizabeth Maddrey

https://ebookmass.com/product/the-billionaires-best-friend-acontemporary-christian-romance-billionaire-next-door-book-2-elizabethmaddrey/

ebookmass.com

American Government and Politics Today: The Essentials, Enhanced 19th Edition – Ebook PDF Version

https://ebookmass.com/product/american-government-and-politics-todaythe-essentials-enhanced-19th-edition-ebook-pdf-version/

ebookmass.com

Valuing

Businesses Using Regression Analysis C. Fred Hall

https://ebookmass.com/product/valuing-businesses-using-regressionanalysis-c-fred-hall/

ebookmass.com

William J. Rapaport

https://ebookmass.com/product/philosophy-of-computer-science-anintroduction-to-the-issues-and-the-literature-william-j-rapaport/

ebookmass.com

Dedicated to MyBelovedWife “ShailaShumi” and MyBelovedDaughter “OrnelaSuhiya”

OmarFaruk,Canada

UmeshP.Agarwal USDAForestService,Forest ProductsLaboratory,OneGiffordPinchotDrive, Madison,WI,USA

AbdullahAlMamun InstituteforMaterials Engineering,PolymerEngineering,Universityof Kassel,Kassel,Germany

PriyankaBhattacharya ProtonPower,Inc.,Lenoir City,TN,USA

SabornieChatterjee ChemicalSciencesDivision, OakRidgeNationalLaboratory,OakRidge, TN,USA

HoyongChung DepartmentofChemicaland BiomedicalEngineering,FloridaStateUniversity, FAMU-FSUCollegeofEngineering,Tallahassee, FL,USA

NorbertEisenreich Fraunhofer-ICT,Germany

GunnarEngelmann FraunhoferInstitutefor AppliedPolymerResearchIAP,Potsdam-Golm, Germany

OmarFaruk CentreforBiocompositesand BiomaterialsProcessing,FacultyofForestry, UniversityofToronto,Toronto,ON,Canada

MaikFeldmann InstituteforMaterials Engineering,PolymerEngineering,Universityof Kassel,Kassel,Germany

JohannesGanster FraunhoferInstituteforApplied PolymerResearchIAP,Potsdam-Golm,Germany

AzadehGoudarzi DepartmentofMaterials Engineering,TheUniversityofBritishColumbia, Vancouver,BC,Canada

ShayestehHaghdan DepartmentofWoodScience, ForestSciencesCentre,TheUniversityofBritish Columbia,Vancouver,BC,Canada

Hans-PeterHeim InstituteforMaterials Engineering,PolymerEngineering,Universityof Kassel,Kassel,Germany

Contributors

EmiliaReginaInone-Kauffmann Fraunhofer-ICT, Germany

JohnF.Kadla DepartmentofForestBiomaterials, NorthCarolinaStateUniversity,Raleigh,NC,USA

AdelR.Kakroodi CentreforBiocompositesand BiomaterialsProcessing,FacultyofForestry, UniversityofToronto,Toronto,ON,Canada

MuzafferA.Karaaslan DepartmentofMaterials Engineering,TheUniversityofBritishColumbia, Vancouver,BC,Canada

SimonKleinhans InstituteforMaterials Engineering,PolymerEngineering,Universityof Kassel,Kassel,Germany

FrankK.Ko DepartmentofMaterialsEngineering, TheUniversityofBritishColumbia,Vancouver,BC, Canada

MarkT.Kortschot DepartmentofChemical EngineeringandAppliedChemistry,Advanced MaterialsGroup,UniversityofToronto, Toronto,ON,Canada

YingjieLi DepartmentofMaterialsEngineering, TheUniversityofBritishColumbia,Vancouver,BC, Canada

Li-TingLin DepartmentofMaterialsEngineering, TheUniversityofBritishColumbia,Vancouver,BC, Canada

HelmutNaegele TecnaroGmbH,Germany

MohammadAliNikousaleh InstituteforMaterials Engineering,PolymerEngineering,Universityof Kassel,Kassel,Germany

NumairaObaid DepartmentofChemical EngineeringandAppliedChemistry,Advanced MaterialsGroup,UniversityofToronto,Toronto, ON,Canada

NikhilD.Patil FacultyofForestry,Universityof Toronto,Toronto,ON,Canada

Ligninisacomplexpolymerabundantlyfoundin plantsanditisthefibrouspartoftheplant.Traditionally,ligninisusedinawiderangeoflow-volume, nicheapplications.Industrialligninsarecurrently obtainedascoproductsofthemanufactureofcellulosepulpforpaper,aswellasfromotherbiomassbasedindustriesandtherearevarioustypesoflignin dependingontheirprocessandpurity.Ligninmarket isstilllimitedinitsapplicationinawiderangeoflowvolume,nicheapplications,butlignincanbeusedin awiderangeofapplicationssuchasinthemanufactureofvanillin,animalfeed,dyedispersants, micronutrients,resins,andcleaningchemicals.In addition,lowawarenessaboutligninamongmanufacturersisthekeyrestrainttothismarket.Itisalso foundthatthereisaweaklinkbetweentheindustry andresearchinstituteswhichresultsinthelow exposureofmanufacturerstothedevelopmentsof ligninindifferentapplications.Furthermore,the extractionandmodificationtechniquesandapplicationofligninarestillataprimarystage,which hamperstheligninmarketalso.Anotherobstacleof ligninexpansioninvalue-addedapplicationsis mainlyduetotheirlow-puritystandards,heterogeneity,smellandcolorproblemsoftheexisting commerciallignins.

Currently,environmentalpollutionandincreasing awarenessoflimitedresources,thereisgrowing

Preface

opportunityintheuseofligninasasubstitutefor fossil-basedrawmaterialsanditcouldbeusedin themanufactureofawiderangeofproductssuch asplastics,chemicalproducts,andcarbonfibers. Recentlyextensiveongoingresearchfocusingon lignindrawbacksisincreasingtheapplicationscope oflignininthemarket.

Inrecentyears,therehavebeenanumberof reviewpaperspublishedonlignincoveringlignin chemistry,modification,polymercompositesfrom lignin,oxidativeupgradeoflignin,biocomposites andnanocompositeswithlignin,industriallignin productionandapplications,andcarbonfibers fromlignin.Thisbookfocusesspecificallyon lignin-basedpolymercomposites(thermoplastic, thermoset,andbiopolymer,rubber,nano,carbon), lignin-basedaerogels,lignin-basedfoamingmaterials,aswellassourcesandtypesoflignin,lignin interunitlinkagesandmodelcompounds,extraction oflignin,characterizationandpropertiesoflignin, andapplicationsoflignin.Thebookwillbehelpful toresearchers,engineers,chemists,technologists, andprofessionalswhowouldliketoknowmore aboutthedevelopmentandpotentialofligninand lignin-basedcomposites.

ShayestehHaghdan,ScottRenneckarandGregoryD.Smith DepartmentofWoodScience,ForestSciencesCentre,TheUniversityofBritishColumbia,Vancouver,BC,Canada

1.IntroductiontoLignin

Thetermligninisderivedfromthelatinname lignummeaningwood(MccarthyandIslam,1999). Itwasfirstisolatedfromwoodinascientificreport bytheFrenchscientist Payen(1838) andlatergiven itscurrentnamein 1857 bySchulze.Ligninwas initiallydescribedasanincrustantofcellulose,and thispointisinsightfulaslignificationoccursafterthe depositionofthepolysaccharideframework.Inan extremelysimplifiedviewitisanalogoustothe matrixmaterialforafiber-reinforcedcomposite. Ligninhasseveralfunctionswiththecellwallsuchas changingthepermeabilityandthermalstability,butit hastheprimaryfunctiontoserveasastructural materialthataddsstrengthandrigiditytoplant tissue.Inthesenselignindistinguisheslignocellulosicbiomassfromotherpolysaccharide-richmaterials,byreinforcingthepolysaccharidescaffoldingof thecellwall.Itsperformanceissoeffectivethatit allowstreestooutcompeteotherplantsforsunlight formingthelargestorganismsontheplanet.

Asligninconstitutes15 40%ofdryweightof woodyplants,itisthemostabundantaromatic polymerontheearthandthesecondmostabundant organicpolymeraftercellulose.Basedonyearly biomassgrowthrates,theoverallproductionof ligninisontheorderof5 36 108 tons(dosSantos

etal.,2014).Hence,ligninhasthepotentialtobean importantsourceofaromaticchemicalsforthe chemicalindustry,arisingfromtheconversionof moderneraCO2,anditsefficientutilizationsolves apotentialpuzzleincreatingvaluableby-productsin abiorefineryscheme.Thisreasoningisbecauseif woodisconvertedtothebilliontonscaleforbiofuels andbiochemicals,thentherewillbegreaterthan 300milliontonsofligninpotentiallyavailable.To putthisinperspectiveitisroughlythesizeofthe globalpolymermarket.

Asmentionedabove,ligninisanaromaticpolymer.Themonomericprecursorshaveaphenolicring withathreecarbonsidechainprovidingabasicnine carbonstructurecommonlyreferredtoasaC9-unit and/orphenylpropaneunitasshownin Figure1.

Thesidechainisterminatedwithaprimary hydroxylgroupontheCg,whiletheCa andCb are connectedtogetherwithanunsaturatedbond.The phenolicringismethoxylated( OCH3)tovarious degrees,dependentuponthespecies; p-coumaryl alcohol,coniferylalcohol,andsinapylalcoholhave none,one,ortwomethoxylgroupsatthe3-and 5-positions,respectively.Basedontheligninmonomericcompositioninvolvedinpolymerization,the resultingligninisclassifiedintothreetypes:(1)lignin thatcontainsmainlyconiferylalcoholiscalled guaiacyl(G)ligninandisfoundpredominantelyin

technologiesdramaticallyimpactligninfunctionalityandmolecularweight.Asaresult,thepropertiesofligninrelatedtoitssolubilityaremodified. Severalstudieshaveshownthatlignincanbefractionatedbyusingseveralsolventswithlargely differentsolventparameters(Moercketal.,1986).A smallfractionofligninmaybesolubleinanonpolar solventliketoluene,nonhydrogenbondingsolvents likedichloromethane,whileotherfractionsare solubleinmorepolarsolventslikealiphaticalcohols.Thedifferentsolubilityofthefractionsshed lightontheheterogeneousnatureofligninevenifit isisolatedfromasoftwoodligninthatcontains95% guaiacyllignin.Delignificationcanmodifythe lignintoappreciativedegreesbytheadditionofthe reactantssuchassulfuroralcoholtotheligninor increasethemolecularweight(orchangetheinterunitlinkages)byreactionsofligninwithitself duringdelignification.Theseisolationprocesses resultinligninthatcontainsacidicgroups,lose aliphatichydroxylgroups,increasethefreephenolic groupsbybreakageofthe b-O-4linkage,and containmorecarbon carbonbondsbetweenunits (whicharereferredtoascondensedstructures). Becauseofthevarietyofintermolecularlinkages betweentheprecursors,ligninisalsoahighly heterogeneouspolymer(FengelandWegener,1983; Baucheretal.,1996).Thevarietyofbondsresultsin abranchedligninpolymerwithapotentiallycrosslinkedthree-dimensionalstructure(Schmidl,1992). Therecentliteraturehassuggestedthatligninmaybe moreuniformthanpreviousthought,witheither linearchaintopologies(Crestinietal.,2011)oreven beingcappedbyspecificligninmonomers(Sangha etal.,2014).However,itisclearthatligninpolymerizationisleftuptothefatesofthermodynamics asthepolymerizationprocessoccursoutsidethe controlofthecellcytoplasm(Ralphetal.,2004). Hence,thecellularcontrolislimitedtotheproductionandreleaseofthemonomersinvolvedinlignificationandtheenzyme-activateddehydrogenated monomerswillpolymerizewiththegrowinglignin chain.

Anotherimportantaspectofpolymericmaterialsis theirmolecularweight.Absoluteknowledgeabout lignin’smolecularweighthasbeendifficulttoachieveasremovinglignintoanalyzeitautomatically impactstheligninstructure.Additionally,lignin molecularweightmeasurementssufferfromissues surroundingsolubility,aggregation,adsorption,and fluorescencemakingitoneofthemostdifficult

polymerstoanalyze.Earlyexperimentslookinginto themolecularweightoflignosulfonatessuggested thatdelignificationoccurredlikebreakinganetwork polymer(Gorning,1971).However,severaldifferent isolatedligninshavebeenanalyzedwithmodern analyticalequipment,andligninusuallyhas abimodaldistributionwithnumber-averagemolecularweightbetween3000and10,000andweightaveragemolecularweightfrom8000to80,000 dependentuponsolutionconditions,andlignintype (Guerraetal.,2007).Manytechnicallignins describedintheliteratureeitherhavelowermolecularweightsbecauseoffragmentationoflignininto oligomersormuchgreatermolecularweights.When delignificationoccurs,anumberofreactionscan occurbutmanyinvolveradicalformationand subsequentradicalcouplingwhereligninfragments canbecomebonded,increasingthemolecularweight.

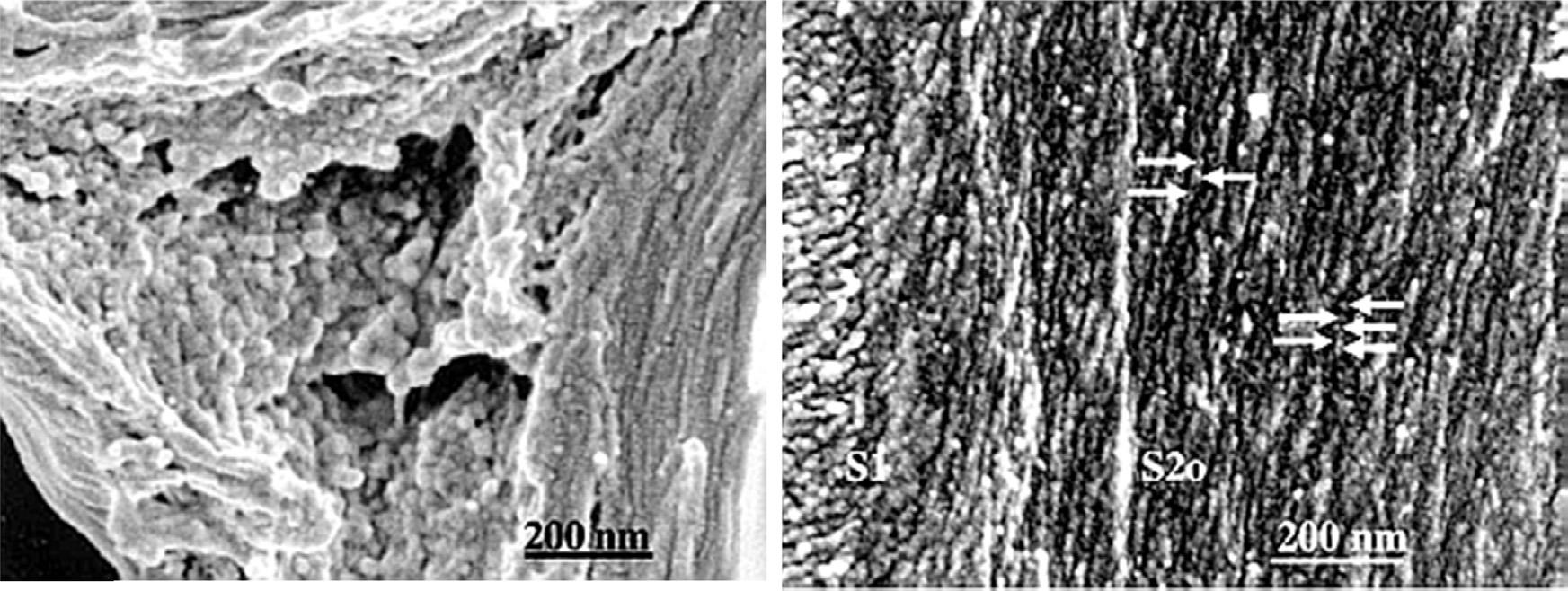

Additionalheterogeneityoflignininvolveshow thestructureofthispolymerdifferswithinagiven cellwalldependentonitslocationinthewall,plant species(hardwoodvssoftwood),andgrowth conditions,especiallyrelatedtoreactionwood formation(CampbellandSederoff,1996;deWild etal.,2010).Thesedifferencesarisefromthe monomericcompositionavailableduringthelignificationreactions.Overall,onecanseethe complexityoftryingtoanalyzealigninthatmaybe differentinvariouslocationsofthecellwall.Terashimahasshownthatligninmicrostructureis dependentuponitslocationinthecellwall.Inthe cellwallcorners,ligninformssphericalclusters, whilelignininthesecondarycellwallisgreatly reducedindimensionssurroundingthemicrofibril lamellarstructureofthecellwalllayersasshownin Figure4 (Terashimaetal.,2004).Workwiththe Ramanspectroscopyhasindicatedthatligninin thesecondarywallhasapreferredorientationalong themicrofibrilstructure(AtallaandAgarwal,1985).

2.LigninFunctions

Ligninispartofthestructuralframeworkin plants,formingpartoftheprimaryload-bearing elementofthecellwall.Fromanevolutionary pointofview,ligninhasbeencreditedastheterrestrialadaptionthatpermitssignificantverticalgrowth. Asanessentialpartofthecell,ligninsupportsthe plantbyimpartingrigiditytothecellwall.Theplant withstandsnaturalenvironmentalstressesbecauseof

Figure4 Cellcornerregion.Largeglobularmodulusformaggregatesatrandom,leftandligninmodules(arrows) aregrowingalongcellulosemicrofibrils(CMFs)atanalmostregulardistance,right.

thiscellwallbuildingblock(Lopesetal.,2011; SarkanenandLudwig,1971).Ligninnotonly providesstiffnesstotheplantbutinconjunctionwith theheteropolysaccharides,itprovidesflexibility whichisfundamentalforanappropriateresponseto dynamicloadsfromwindandsnow.Inadditionto mechanicalsupport,ligninmodifiesthepolysaccharidenetworktomakeitresistanttooutside organisms.Ligninhelpstoprotectwoodytissuefrom themicrobialandfungalattackencasingthecarbohydratestructure,providingreducedaccessibilityof enzymesforhydrolysis.Limitedsolubilityand complexityoftheligninmakeitresistanttodegradationbymostmicroorganisms(Prasongsuketal., 2009;Bholayetal.,2012;BergandMeentemeyer, 2002;Crowetal.,2009;VermaandDwivedi,2014). Onecanimagineifligninonlycontainsasingle linkagethatwouldbecomethecellwall’sAchilles’ Heal.However,withthevarietyoflinkageswooddestroyingorganismsrequirethebreakageofboth arylcarbonbondsandaryletherbondsneedingto expandthecostofproductionofspecificenzymesor developnonspecificpathwaysfordelignification.In addition,ligninislesshydrophilicthanthepolysaccharideshelpingtochangethepermeabilityofthe cellwallbysealingitandenablingwatertransport throughthevasculartissue(TenandVermerris, 2013).Finally,thearomaticityofligninlendsitselfto enhancethethermalstabilityofwoodprovidingchar layer.Thishasbeenexploitedwithisolatedtechnical lignin,turningitintocarbonfibermaterialby controlledhigh-temperatureheating.Whileligninis seenasmorethermallystablebecauseofit,thenative structureofligninisgreatlyimpactedbythethermal modificationandresearchersshouldbecautioned

thatligninstructurecanchangeduringprocessingat temperaturesusedintheproductionorsomethermoplasticmaterials.Suchmodificationincludes depolymerization,lossoftheCg hydroxyl,and formationofnewacidicgroups.

3.SourcesofLignin

Thesourcefromwhichligninisobtained,the extractionmethodsandthesecondarytreatments applied,havestrongimpactsonitsphysicaland mechanicalproperties(Garciaetal.,2011;Khanam etal.,2006).Lignincanbederivedfromvarious sourcessuchaswood,pulpandpaper,sugarcane bagasse,andcerealstrawsusingavarietyofpulping methods.Intermsofweight,thelignincontentin woodyplantsfromgymnospermsandangiospermsis thehighestwiththeorderof30 40%whileother sourcesonlycontainaround3 25%(Smolarski, 2012).Thepulpandpapersectorproducesalarge amountoflignin(Jungmeier,2010;Dohertyetal., 2011)withevengreaterpotentialfromfuturelignocellulosicbiorefineries.Minimalligninisrecovered fromgrass,branches,leaves,andsolidwasteinurban andruralareaswheretheirlignincontentisestimated tobelessthan15%(Wangetal.,2011;Philippidis andHatzis,1997).

3.1Wood

Ligninhasnonuniformthicknessinthemiddle lamella,andintheprimaryandsecondarycellwalls dependingontheplantspeciesandcelltype (Figure5).Approximately70%ofthetotallignin contentofthecellwallisconcentratedinthe

thickestlayerofthesecondarycellwall.Lignin quantityandqualityvarynaturallyamongwood specieswith19 28%inhardwoods(angiosperms) and24 33%insoftwoods(gymnosperms)(Fengel andWegener,1983).Infact,hardwoods,ingeneral, containmorehemicelluloseandlessligninthan softwoods(Bjornsson,2014).Notonlytheamount ofligninvariesbetweenhardwoodsandsoftwoods, therelativeconcentrationalsodiffersinthelocation withinatree.Thejuvenilewoodhasahigherlignin contentthanlatewood(DelaCruz,2014;Bowyer etal.,2007).Lignincontentisalsovariablewithin populationsofplantsofthesamegenus.For example,theaveragecontentofligninrangesfrom 25%in Pinusmonticola to30%in Pinuspalustris withinthegenus Pinus.Reactionwoodforms mechanicalstressandhasdifferentlignincontentin comparisonwiththenormalwooddependingonthe conditionsandspecies(Tiimonen,2007).

Lignininhardwoodsissyringyl guaiacyltype andinsoftwoodsistypicallyguaiacylwithlimited p-hydroxyphenyllignininbothtypes.Bothofthese structureshavedifferencesarisingfromtheinterunit linkages.Guaiacyllignincanundergocoupling reactionsatthe5-positionofthephenylpropaneunit, andthisprovidesasignificantplaceforbranchingand cross-linkingreactions,especiallyoccurringduring

Figure5 Woodcellwallincludingmiddlelamella(ML), primarycellwall(P),layersofthesecondarycellwall (S1,S2,S3),andwartylayer(W)(Sjostrom,1993).

delignificationprocess.Thepresenceofsyringylunits makeshardwoodligninmorereadilyremovedduring thepulpingprocessbylimitingligninforming condensedstructuresattheopenmethoxyposition.In thecaseofcompression-woodlignin,itismore difficulttohydrolyzebecauseitcontainsahigher proportionofcondensed p-hydroxyphenylunits (CampbellandSederoff,1996;Novaesetal.,2010).

3.2PulpandPaperIndustry

Softwoodandhardwoodspecies,andcertaintypes ofannualplants,havecommercialinterestasasource ofcellulosefibersfortheproductionofpaperand boardproducts.Ligninisnoteasytoisolateinthe nativeformfromplantmaterial(Leisolaetal.,2012). Thepulpandpaperindustryistheprimarily commercialsourceoflignin,however,thedelignificationprocessmodifieslignintovariousdegrees.In technicalfiberliberationprocesses,suchasalkaline orsulfitepulping,hugequantitiesofligninaredissolvedasalkaliligninandlignosulfonates,respectively.Largeamountsofligninaremadeavailable annuallyfromthepulpandpaperindustryasbyproductsofthedelignificationprocess.Thesesulfite orsulfateligninshavevaryinglevelsofcovalently bondedsulfurresultinginthepolymerwithdifferent characteristicsthantheoriginallignin(Sainsbury, 2013;Khanametal.,2006;LoraandGlasser,2002). Typically,ligninimpuritiesincludelow-molecularweightsugarsandresinacidsthatareremovedduring thepurificationprocess.Forexample,kraftligninis usuallypurifiedfromkraftblackliquorswhichare complexmixturesoffibrousmaterialsanddissolved organicssuchaslignins,hemicelluloses,sugars,acids, andresinsandalsoinorganicsaltssuchasash(Wallbergetal.,2003).Therecenttechnologyinenhancing ligninrecoveryfromblackliquorbyCO2 acidification hasbeentransferredtotheindustryandhascreated areadilyavailabledryligninpowderstream(Ohman etal.,2013;Kouisnietal.,2012).Asshownin Table1, inallcommercialpulpingprocessesthelignin extractionmethodswillaffectthevalueoftheproducts thatcanbederivedfromitandwillalterthestructureof theligninincomparisonwiththenativeone(Smolarski,2012).

3.3SugarcaneBagasse

Sugarcanebagasseisthefiberthatremainsafterthe sugarshavebeenextracted.Asanagro-industrial residue,sugarcanebagasse(Saccharumofficinarum)

Table1 LigninPuritywithItsAssociatedSources(Holladayetal.,2007)

LigninTypeLigninPuritya

LignosulfonatesMedium(somereducingsugar (upto20wt%)andsulfur)

PotentialProducts

Dispersants,agriculturalchemicals,emulsion stabilizer,industrialbinders,carbonblack,ink andpigments,andconcreteadditives

KraftMedium(someashandsulfur)Dispersants,carbonfibers,emulsifiers, activatedcharcoal,andbinders

OrganosolvHigh(sulfurfree)Aromaticpolyols,newdiacids,activatedcarbon, phenolicresins,carbonfibers,vanillin,phenol derivatives,andantioxidants

aPresenceofresidualcarbohydrates,ash,andproteinsdependsonfeedstockandprocess.

isanothersourceofligninrawmaterial.Itisabyproductofthesugarcaneindustrywithapproximately32 34%cellulose,19 24%hemicellulose, 25 32%lignin,6 12%extractives,and2 6%ash (SakdaronnarongandJonglertjunya,2012;Rezende etal.,2011;Pandeyetal.,2000).Chemicalcompositionofsugarcanebagasseissimilartotheotherplant cellwalls.Eachclassofplants,grasses,softwoods, andhardwoodsproducesaligninrichinonetypeof thephenylpropanerepeatunit.Sugarcanebagasse ligninhasahigherproportionofH-typelignin, phydroxyphenyl,andhencealowermethoxycontent thansoftwoodandhardwoodlignins(Dohertyetal., 2007).Approximately250 280kgofbagasseis generatedfromprocessingeachtonofsugarcane whichroughlyyielded54milliontonsofbagasse annually(Canilhaetal.,2012).Currently,alarge amountofbagasseisburntasalow-gradefuelfor energyrecovery,andonlyalimitedquantityhasbeen usedtomakepulps,boardmaterials,andcomposites. Itisestimatedthat200milliontonsofligninis producedannuallyfrombagasse(Singhetal.,2005).

3.4AgriculturalResidues

Theadvantagesofusingagriculturalresiduesare threefolds:economic,environmental,andtechnological.Unlikewoodpulps,agriculturalpulpscanbe producedusingmoreenvironmentallybenignprocessingandbleachingmethods(Clancy-Hepturn, 1998).Inthewoodpulpingprocess,mostofthepulp isbleachedusingchlorineorchlorine-basedchemicalswhilestrawcanbetreatedwithminimaladditionsofchlorine-freechemicalswhichresultsinno productionoftoxicchemicals.Moreover,agriculturalresidueshavegenerallyamoreporousstructure andalowerlignincontentthanwoodyplantswhich facilitatetheirpulpingprocess.Examplesofthe

agriculturalresiduesarericeandwheatstrawswhich arediscussedinthissection.Ricestrawalsocalledas cerealstrawisanothersourceforligninproduction. Totalworldproductionofricestraw, Oryzasativa,is 525milliontonsperyear.

About90%ofthericestrawisproducedinAsia. Chinahasthegreatestcapacityforpulpingricestraw. Ithasapproximately30 35%cellulose,25 30% hemicellulose,15 28%lignin,and4 7%ash (Marquesetal.,2010).Thehighashcontentarises fromthesilicainthecellwalllimitingtheabilityto burnthismaterialwithoutcausingasignificantenvironmentalnuisance.Highsilicacontentinricestraw, ashighas18%incleanricestraw,makesthepulping processmorecostlyduetoincreasedchemical recoverydifficultiesandcosts.Inadditiontorice straw,wheatstraw, Triticumaestivum,isannually generatedinabundanceof529milliontonsperyear. Whenfarmedintensively,wheatstrawcanbe producedinalargerscale.Theamountofligninof wheatstrawvariesbetween5%and17%depending onthegeographicallocationoftheplantswhichis comparabletohardwoods(BuranovandMazza, 2008).Wheatstrawhasoneofthehighestcellulose contentsofalloftheagriculturalfibers.Strawpapers areknowntopossessgoodprintingqualitiesandare madefrompulprequiringlowenergyrelativetothat requiredtoprocesswoodpulp.Researchersfoundthat wheatstrawmustbepulpedunderconditionsofless energyandfewerchemicalsincomparisonwiththe woodpulpstomaximizepulpyields(Clancy-Hepturn, 1998).Tomakethestrongestproduct,papermakers willlikelycombinesomestrongerhardwood,kenaf, orhemppulpwithstrawpulp.Despitetheadvantages ofusingagriculturalresidues,thehighcollection, transportation,andhandlingcostsassociatedwith theseresources,aswellastheirseasonalavailability, limittheirapplicationsinpaperproduction.

4.LigninPotential

Currentlyaround50milliontonsofligninis producedperyearbythepulpandpapersectorbutonly 2%ofthatisusedforapplicationsotherthancombustionandenergyproduction(deWildetal.,2014;Fengel andWegener,1983;Schmidl,1992;Thielemansetal., 2002).Therearelimitationsinutilizationduetothe ligninstructure,heterogeneity,andtheindustrialprocessingcostsfordelignification(Holladayetal.,2007; Vanholmeetal.,2010;Neutelings,2011;ElHageetal., 2009;Chiang,2005).Toimproveupontheselimitations,differenttypesofmodificationsaredoneto increaseitschemicalreactivityanduniformity,reduce thebrittlenessoflignin-derivedpolymers,increaseits solubilityinorganicsolvents,andimprovetheeaseof processingthelignin(Argyropoulos,2012).Lignin potentialscanalsobeconsideredintheproductionof additives,resins,andcoatingmaterials(Jungmeier, 2010;VishtalandKraslawski,2011).Thisrenewable aromaticpolymercanequallybereplacedwith syntheticpolymersandaromaticchemicals(Zakzeski etal.,2012).Highantioxidantcapacityofligninandits applicationsinpolymerenhancementhavebeen experimentallyproved(Piazzaetal.,2014).Thefindingsofresearchonlignindepolymerizationshowed thatduetotheligninmacromolecularstructureoflignin withmanyphenolicunits,lignindepolymerizationcan beusedasalarge-scalesourceforproductionofvaluablechemicals(Kleinertetal.,2009;Meieretal.,1992; Hora ´ ceketal.,2012).Ligninalsohaspotentialtobe usedinthefabricationofcompositematerials. ElMansourietal.(2007) showedthatexterior-grade particleboardsmadewithlignin-basedadhesives successfullymettherequirementsofinternational standards.Thepotentialoflignininpolymeric compositeswillbediscussedinlaterchapters.

References

Adam,M.,Ocone,R.,Briens,C.,Berruti,F.,2011. ModellingthePyrolysisofLignin. Argyropoulos,D.,2012.HighValueLigninDerivatives,Polymers,andCopolymers,andUseThereof inThermoplastic,Thermoset,andComposite Applications.USPatentApplication.

Atalla,R.H.,Agarwal,U.P.,1985.Ramanmicroprobe evidenceforligninorientationinthecellwallsof nativewoodytissue.ComptesRendusBiologies 227(4687),636 638.

Baucher,M.,Chabbert,B.,Pilate,G.,Van Doorsselaere,J.,Tollier,M.T.,Petit-Conil,M., 1996.Redxylemandhigherligninextractability bydown-regulatingacinnamylalcoholdehydrogenaseinpoplar.PlantPhysiology112, 1479 1490.

Berg,B.,Meentemeyer,V.,2002.Litterqualityin anorthEuropeantransectversuscarbonstorage potential.PlantandSoil242(1980),83 92.

Bholay,A.,Bhavna,B.,Jadhav,P.,Palekar,K., Dhalkari,M.,Nalawade,P.,2012.Bacteriallignin peroxidase:atoolforbiobleachingandbiodegradationofindustrialeffluents.UniversalJournalof EnvironmentalResearchandTechnology2(1), 58 64.

Bjornsson,S.,2014.AdvancedControlMethodology forBiomassCombustion.UniversityofWashington. Bowyer,J.,Shmulsky,R.,Haygreen,J.,2007.Forest ProductsandWoodScience:AnIntroduction, fifthed.BlackwellPublishing,Ames,IA.

Buranov,A.U.,Mazza,G.,2008.Lignininstraw ofherbaceouscrops.IndustrialCropsand Products28(3),237 259. http://dx.doi.org/10. 1016/j.indcrop.2008.03.008.

Campbell,M.M.,Sederoff,R.R.,1996.Variationin lignincontentandcomposition.PlantPhysiology 110,3 13.

Canilha,L.,KumarChandel,A.,dosSantos Milessi,T.S.,FernandesAntunes,F.A.,daCosta Freitas,W.L.,dasGrac¸asAlmeidaFelipe,M.,da Silva,S.S.,2012.Bioconversionofsugarcane biomassintoethanol:anoverviewaboutcomposition,pretreatmentmethods,detoxificationof hydrolysates,enzymaticsaccharification,and ethanolfermentation.JournalofBiomedicine& Biotechnology1 16. http://dx.doi.org/10.1155/ 2012/989572.

Chiang,V.L.,2005.Understandinggenefunctionand controlinligninformationinwood.Agricultural Biotechnology17,139 144.

Clancy-Hepturn,M.,1998.Agriculturalresidues: apromisingalternativetovirginwoodfiber.JournalofReinforcedPlasticsandComposites29. Washington,DC,USA.IssueinResources Conservation,BriefingSeriesNo.1Resources ConservationAlliance.

Crestini,C.,Melone,F.,Sette,M.,Saladino,R., 2011.Milledwoodlignin:alinearoligomer. Biomacromolecules12(11),3928 3935. http:// dx.doi.org/10.1021/bm200948r.

Schmidl,G.W.,1992.MolecularWeightCharacterizationandRheologyofLigninsforCarbonFibers. UniversityofFlorida.

Schulze,H.,1857.Neuenburg.Einegeschichtlich staatsrechtlicheSkizzenebsteinerBeleuchtung derneuestenschweizerischenDenkschriftvom7. Heinicke,p.48.

Singh,R.,Singh,S.,Trimukhe,K.D.,Pandare,K.V., Bastawade,K.B.,Gokhale,D.V.,Varma,A.J.,2005. Lignin-carbohydratecomplexesfromsugarcane bagasse:preparation,purification,andcharacterization.CarbohydratePolymers62(1),57 66. http://dx.doi.org/10.1016/j.carbpol.2005.07.011.

Sjostrom,E.,1993.WoodChemistry:Fundamentals andApplications.Nature,p.293.

Smolarski,N.,2012.High-ValueOpportunitiesfor Lignin:UnlockingItsPotentialLigninPotential. Frost&Sullivan,pp.1 15.Retrievedfrom: http:// www.greenmaterials.fr/wp-content/uploads/2013/ 01/Highvalue-

Ten,E.,Vermerris,W.,2013.Functionalizedpolymersfromlignocellulosicbiomass:stateofthe art.Polymers5(2),600 642. http://dx.doi.org/ 10.3390/polym5020600.

Terashima,N.,Awano,T.,Takabe,K.,Yoshida,M., 2004.Formationofmacromolecularligninin ginkgoxylemcellwallsasobservedbyfield emissionscanningelectronmicroscopy.Comptes RendusBiologies327(9 10),903 910. http://dx. doi.org/10.1016/j.crvi.2004.08.001.

Thielemans,W.,Can,E.,Morye,S.S.,Wool,R.P.,2002. Novelapplicationsofligninincompositematerials. JournalofAppliedPolymerScience83(2), 323 331. http://dx.doi.org/10.1002/app.2247.

Tiimonen,H.,2007.LigninCharacteristicsand EcologicalInteractionsofPtCOMT-modified SilverBirch.UniversityofOulu.

Vanholme,R.,Demedts,B.,Morreel,K.,Ralph,J., Boerjan,W.,2010.Ligninbiosynthesisand

structure.PlantPhysiology153(3),895 905. http://dx.doi.org/10.1104/pp.110.155119.

Verma,S.R.,Dwivedi,U.N.,2014.Ligningenetic engineeringforimprovementofwoodquality: applicationsinpaperandtextileindustries,fodder andbioenergyproduction.SouthAfricanJournal ofBotany91,107 125. http://dx.doi.org/10.1016/ j.sajb.2014.01.002.

Vishtal,A.,Kraslawski,A.,2011.Challengesin industrialapplicationsoftechnicallignins.Bioresources6(3),3547 3568.

Wallberg,O.,Jonsson,A.-S.,Wimmerstedt,R.,2003. Fractionationandconcentrationofkraftblack liquorligninwithultrafiltration.Desalination154 (2),187 199. http://dx.doi.org/10.1016/S00119164(03)80019-X.

Wang,M.,Wang,J.,Tan,J.X.,2011.Lignocellulosic bioethanol:statusandprospects.EnergySources, PartA:Recovery,Utilization,andEnvironmental Effects33(7),612 619. http://dx.doi.org/10.1080/ 15567030903226249.

deWild,P.J.,Huijgen,W.J.J.,Gosselink,R.A.,2014. Ligninpyrolysisforprofitablelignocellulosicbiorefineries.Biofuels,BioproductsandBiorefining8 (5),645 657. http://dx.doi.org/10.1002/bbb.

deWild,P.J.,vanderLaan,R.R.,Wilberink,R.,2010. Thermolysisofligninforvalue-addedproducts.In: XVMeetingoftheInternationalHumicSubstances Society.EnergyResearchCentreoftheNetherlands,Tenerife,CanaryIslands,Spain,pp.1 27. Wu,S.,Argyropoulos,D.S.,2003.Animproved methodforisolatinglignininhighyieldand purity.JournalofPulpandPaperScience29(7), 235 240.

Zakzeski,J.,Jongerius,A.L.,Bruijnincx,P.C.A., Weckhuysen,B.M.,2012.Catalyticligninvalorizationprocessfortheproductionofaromaticchemicals andhydrogen.ChemSusChem5(8),1602 1609. http://dx.doi.org/10.1002/cssc.201100699.

HoyongChung 1 andNewellR.Washburn 2, 3

Ligninisthesecondmostabundantterrestrial biopolymeraftercelluloseandisthelargestrenewablesourceofaromaticgroupsinnature.Ligninis foundinplantcellwallsandisanimportantstructuralcomponentofwoodyplants.Themainfunctions oflignininplantsaretoprovidephysicalstrength, toformwater-conductingvascularnetworksusing hydrophobicinteractionsandtoprotectplantsfrom microorganismsandinsects.Chemically,ligninis composedofarandomnetworkofphenylpropane groups.Thethreebasicstructuralmonomerunitsare coumarylalcohol,coniferylalcohol,andsinapyl alcohol,asshownin Figure1.Innature,these monomerunitsoxidizetophenoxyradicalsby peroxidaseandthenundergopolymerizationthrough multiplereactivesitestoformacomplexthreedimensionalpolymer.Thisbiosynthesisisreferred toasdehydrationpolymerization,andtheresulting monomerunitswithinligninarereferredtoas p-hydroxyphenyl(H),guaiacyl(G),andsyringyl (S).Differencesinligninaccordingtovariousplant sourcescanbemanifestedindifferencesinmonomerconcentrations(Vanholmeetal.,2010),with gymnosperms,suchasthevarioustypesofpines,

comprisingprimarilyofG-unitswithsmallconcentrationsofH-units.Incontrast,angiospermdicots, includingmanyhardwoods,haveamixtureofGand S-units,whichreducebranchingconcentrationsand canimproveligninprocessibility.

Asaresultoftherandomradicalpolymerizationof phenylpropanemonomers,ligninadoptscomplex three-dimensionalstructureswithvarioustypesof functionality.Asshownin Figure2,importantC O linkagesare b-O-4, a-O-4,and4-O-5;andC Clinks are b-5,5-5, b-1,and b b linkages(Koch,2008; Calvo-FloresandDobado,2010).Also,common functionalgroupsinligninincludemethoxyl,phenolic hydroxyl,aliphatichydroxyl,andothercarbonyl groups(ChakarandRagauskas,2004).

Figure1 Monomericligninbuildingblocks: p-coumaryl alcohol,coniferylalcohol,andsinapylalcohol.

Figure2 Schematicmodeloftheligninstructurewithimportantlinkages(Koch,2008;Calvo-FloresandDobado, 2010; LaurichesseandAverous,2014).

Chemicalcharacterizationoflignin,ligninderivatives,andotherlignin-basedmaterialsisnota simpletaskduetothethree-dimensionalarchitecture, diversityofchemicallinkagesandfunctionalgroups, difficultisolation,andpoorsolubilityinmany organicsolvents(Figure2).Thisisfurthercomplicatedbymanydifferenttypesoflignindependingon theplantsourceandprocessingmethod.Numerous analyticalapproacheshavebeenemployedtocharacterizethestructureofligninandotherlignin-based materials.

Nuclearmagneticresonancespectroscopyisoneof themostusefultechniquestodeterminethechemical structureoflignin(Ralphetal.,1999;Ralphand Landucci,2010).Lignincontainsahighfractionof methoxygroupsandaromatichydrogens,allowing thesegroupstobereadilydeterminedby 1HNMR. However, 1HNMRisnotsuitableforcharacterizing themostabundantreactivegroup,thehydroxylgroup. Hydroxylgroupcontentisbestdeterminedafter acetylationofhydroxylgroupsbyaceticanhydride inthepresenceofpyridine(BonnerandMcnamara, 1968; ChungandWashburn,2012).Theacetoxy groupsproducedinthisreactioncorrespondto

hydroxylgroupsofligninandappearatchemical shiftsofapproximately2ppm(Lundquist,1992; ChungandWashburn,2012).Afteracetylation,the phenolichydroxylgroupcanbedeterminedselectivelybyrelativelyfastandselectivedeacetylation ofphenolicacetylgroups(Ma ˚ nsson,1983).Alkylationofthehydroxylgroupwasperformedtodeterminehydroxylgroupsin 1HNMRspectra(Adler etal.,1987).While 1HNMRprovidesquantitative information,certainpeaks,suchasthosedueto methoxygroups,canappearbroadandfeatureless becauseofthediversityofchemicalenvironments (Liitiaetal.,2003).Two-dimensional 1H-13CNMR spectroscopycanprovidedetailedinformationon connectivity.Modellignincomplexesprovided detailedinformationnecessaryforpeakassignments (EdeandRalph,1996),andnumerouspulsesequences havebeendevelopedtoelucidatetheconnectivityof functionalgroupsandidentifyspecificlinkages (EdeandBrunow,1992;Kilpelainenetal.,1994). Forexample,thesyringyl-to-guaiacyl(S/G)ratio wasfollowedduringkraftpulpingusingheteronuclearsinglequantumcorrelationNMR,which providedinformationonchangesduetooxidation

duringprocessing(Ibarraetal.,2007).Adifferent approachthatprovidesinformationonalcohol functionalityutilizes 31PNMRinwhichhydroxyl groupswereconvertedtophosphitylgroupsby 2-chloro-4,4,5,5-tetramethyl-1,3,2-dioxaphospholane todo 31PNMRanalysis(GranataandArgyropoulos, 1995;Froassetal.,1998).For 31PNMRanalysis, phosphitylationwascarriedoutbyanotheragent, 1,3,2-dioxaphospholanylchloride(Argyropoulos, 1994;Froassetal.,1996).Mostoftheligninsfrom theprocessingmethodsdescribedherehavebeen characterizedbyNMRspectroscopy.

Size-exclusionchromatography(SEC)analysisof ligninisanimportantanalysistodeterminemolecular weightandmolecularweightdistribution,whichare criticaldataformaterialsdevelopment(Himmeletal., 1995;Hortlingetal.,1995).However,thereliability ofSECanalysiscanbelimitedduetothemany functionalgroupsinlignin,suchashydroxylgroups andcarboxylicacids,andtheligninanalytecanhave stronginteractionswiththecolumnsupportmaterials orbetweenotherligninspecies(Sarkanenetal.,1981, 1982,1984;Iversen,1985).Therefore,thehydroxyl groupsareacetylatedandcarboxylicacidgroups aremethylatedpriortotheSECanalysistoexclude possiblenoncovalentinteractions,suchashydrogen bondingandelectrostaticaggregation,fromthelignin (Himmeletal.,1995;Kimetal.,2007).Ligninisalso characterizedbyvariousmorphologicalmethodssuch

asthermalanalysisandRaman/IRanalysis(Agarwal andAtalla,1999,2010;GlasserWolfgang,1999).

Thechemistryandmaterialpropertiesoflignin havebeenreviewedextensively(Goldsteinetal., 1983;Lewisetal.,1999;ChakarandRagauskas, 2004;Calvo-FloresandDobado,2010; Hatakeyama andHatakeyama,2010; DuvalandLawoko,2014)as wellaschemicalmethodsformodifyingandblending it(Wangetal.,1992;Meister,2002;Liitiaetal., 2003;Mohantyetal.,2009;Dohertyetal.,2011; WashburnandChung,2012).Inthischapter,we presentextractionmethodsandtypesofcommercialgradeligninfromarawbiomass.Abetterunderstandingoftypesandproductionmethodsofligninis animportantstartingpointtostudyligninasnew materials,biofuel,andrenewablesourcesoffine aromaticchemicals.

2.Commercial-GradeLignins

Ligninisbiosynthesizedfrommonomericsubstitutephenylpropyleneunits,coumarylalcohol,coniferylalcohol,andsinapylalcohol,aslignocelluloses aswellasnonconjugatedlignin.Becausethelignocellulosesandligninareintimatelyincorporatedin plantstructures,avarietyofprocessingmethodshave beendevelopedtoisolatelignin. Table1 demonstratesdiversesourcesofligninfromrawbiomass

Table2 PolymericComponentsofVariousSoftwoodandHardwoodSpecies(Sjostrom,1993;Koch,2008)

SpeciesCommonNamesExtractivesLigninCelluloseGlucomannanGlucuronoxylanPolysaccharides Softwoods

Abiesbalsamea

Pseudotsuga menziesii

Tsuga canadensis

Juniperus communis Commonjuniper3.232.133.016.410.73.2

Pinusradiate Montereypine1.827.237.420.48.54.3

Pinussylvestris Scotspine3.527.740.016.08.93.6

Piceaabies Norwayspruce1.727.441.716.38.63.4

Piceaglauca Whitespruce2.127.539.517.210.43.0

Larixsibirica Siberianlarch1.826.841.414.16.88.7

Hardwoods

Acerrubrum Redmaple3.225.442.03.122.13.7

Acersaccharum Sugarmaple2.525.240.73.723.63.5

Fagussylvatica Commonbeech1.224.839.41.327.84.2

Betulaverrucosa Silverbirch3.222.041.02.327.52.6

Betulapapyrifera Paperbirch2.621.439.41.429.73.4

Alnusincana Grayalder4.624.838.32.825.82.3

Eucalyptus globulus Bluegum1.321.951.31.419.93.9

Acaciamollissima Blackwattle1.820.842.92.628.22.8

forlowerdigestiontemperatures,oftenbelow140 C insteadof170 Corgreaterwithoutit.Thekineticsof theAcetosolvprocesshavebeenstudiedforbothhardwood(eucalyptus)andsoftwood(pine)(Vazquezetal., 1997).Theproposedmechanismisbasedonasequence offirst-orderreactionsinvolvingformationofsoluble ligninspeciesthroughlignin hydrolysis,lignincondensationinsolution,andsubsequentreprecipitation. Effectivedelignificationwasobservedat180 Cand 0.1%HCl,whereasincreasingtheHClconcentrationto 0.2%allowedforatemperaturereductionto140 C,but longerreactiontimescanactuallyreduceyielddueto ligninrecombination.

TheMilox(orFormacell)processtakesitsname fromtheMilieuPureOxidativeprocessdeveloped bytheFinnishPulpandPaperResearchInstitute (KCL)(Sundquist,1986).Itisbasedonuseofperoxyformicacidtoperformtandemdelignification andbleaching.Peroxyacidsreactwithnucleophiles having p-electronsviaoxygentransfer,andin acidicmediathestrongelectrophile þOHisformed. Adiversityoffunctionalgroupsresultfromthis oxidationreaction,includingquinones,carboxylic acids,andalkenes,andformationofrecombination by-productsisminimizedthroughefficientsolubilizationinthewater/formicacidmedium.

Generationofperoxyformicacidisaccomplished byreactingformicacidwithhydrogenperoxide accordingtothereaction: whichhasaforwardrateconstantat22 Cthatis50 timesgreaterthantheanalogousreactionofaceticacid andhydrogenperoxide(SuchyandArgyropoulos, 2002).Peroxyformicacidcanbereadilyseparated fromthereactionmixturebydistillation,andhasbeen appliedtothereactorasaconcentratedsolution. However,theseconcentratedsolutionscanbeexplosive,andmorerecentapproachesrelyongeneratingit insitu.Seistoetal.(SeistoandPoppiusLevlin,1997) establishedmultistageprocessesbasedonimpregnationofbiomasswithformicacidandintroductionof hydrogenperoxidefollowingbyadditionofwaterand cookingatupto120 Cforperiodsrangingfrom60to 180min.Thiswasappliedtothehybridgrass Miscanthus giganteus,andacomparisonwithnative ligninshowedthattheweightandnumberaverage molecularweights(Mw andMn)haddecreasedfrom

31742gmol 1 and2681gmol 1 to7636gmol 1 and 1417gmol 1,respectively,asaresultoftheMilox processing.Inaddition,theconcentrationofcarboxylicacidsitesincreasedfrom0.18mmolg 1 to 0.35mmolg 1 andtotalphenolicgroupsincreasedfrom 0.84mmolg 1 to1.31mmolg 1,whiletheconcentrationofaliphatichydroxylgroupswasreduced from5.54mmolg 1 to1.66mmolg 1.Clearlyeven organosolvprocessingcan havesignificantimpacton thechemicalfunctionalityoflignins.

Alkalineconditionshavealsobeenexploredin organosolvprocesses.Forexample,theOrganocell processfirstimpregnatesbiomasswithamixture ofwaterandmethanol,orsometimesethanol,at temperaturesof110 140 C.Thenalkali,suchas sodiumhydroxide,andanthraquinoneareaddedin thedigesterwherethepulpingliquor,containingup to30%methanolbyvolume,isheatedto170 Cat pressuresoforder10barfor2h.Itisthoughtthatthe methanolmaydirectlyparticipateinthedelignificationbyformingmethylethergroupsatcarbocation siteswherelignincondensationcouldoccur.This wouldmaintainalow-molecularweightofthelignin fragmentscomparedtothoseformedbykraftor sulfitepulping.

2.5SteamExplosionLignin (HydrothermalProcess)

Thesteamexplosionprocessrequireshighly compressedwater,200 2000psi,andhightemperature,180 230 C,duringtheshortprocessingtime of1 20mininthepresenceofacatalyst(Wayman andLora,1978,1979,1980;Dataretal.,2007;Zhang etal.,2007;Ruizetal.,2008).Hydrolysis,arylether cleavageandhomolyticcleavageofC Cbond, demethoxylation,alkylation,andcondensationreactionsoccurduringthesteamprocess(Wangetal., 2009;Kangetal.,2011).Whilethearomaticgroups intheligninarenotdegradedbysteamexplosion process, b-O-4etherlinkagesandCa Cb bondsare beingcleavedduringtheprocess.Theresultinglignin hasasimilarcharacterasorganosolvlignin,low molecularweight,andgoodsolubilityinorganic solvents(WaymanandLora,1978;Shimizuetal., 1998).Steamexplosionhasgreatpotentialbecause thisprocessisthefirststeptoproducebiofuelpriorto fermentationofpolysaccharide(GlasserandWright, 1998).Afewexamplesofligninsubunitsthatcanbe