Integrationand OptimizationofUnit Operations

ReviewofUnitOperationsfromR&D toProduction:ImpactsofUpstreamand DownstreamProcessDecisions

Editedby

BarryA.Perlmutter President,Perlmutter&IdeaDevelopmentLLC,Matthews,NC,UnitedStates

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2022ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicor mechanical,includingphotocopying,recording,oranyinformationstorageandretrievalsystem,without permissioninwritingfromthepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthe Publisher’spermissionspoliciesandourarrangementswithorganizationssuchastheCopyrightClearance CenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher(other thanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroadenour understanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecome necessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusing anyinformation,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationormethods theyshouldbemindfuloftheirownsafetyandthesafetyofothers,includingpartiesforwhomtheyhavea professionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeanyliability foranyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceorotherwise,or fromanyuseoroperationofanymethods,products,instructions,orideascontainedinthematerialherein.

ISBN:978-0-12-823502-7

ForinformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: SusanDennis

AcquisitionsEditor: AnitaKoch

EditorialProjectManager: LindsayLawrence

ProductionProjectManager: KumarAnbazhagan

CoverDesigner: ChristianJ.Bilbow

TypesetbySTRAIVE,India

1.Crystallization

BrookeAlbin

1.1Fundamentalsandlaboratoryscale processdevelopment 1

1.1.1Crystallizerdesignbasics1

1.1.2Crystallizerdesigntradeoffs4

1.1.3Upstreamvariablesaffecting crystallization6

1.1.4Impactondownstream operations7

1.2Pilotscalecrystallizationstudies 8

1.2.1Objectivesforapilotplant8

1.2.2Scale-upcriteria9

1.3Commercializationofcrystallization

2.Fermentationanddownstream processing:Part1

AlanGabelman,Ph.D.,P.E.

2.1Introduction

2.3Fermentationmediaand

2.4Growthkineticsandsubstrate

2.5Fromvialtoproductionfermenter

2.6Oxygentransferandutilization

2.7Mixinginaerobicfermentation

2.8Sterilization

2.8.2Continuoussterilization47

2.8.3Filtersterilizationofliquids53

2.8.4Filtersterilizationofair56

3.Fermentationanddownstream processing:Part2

AlanGabelman,Ph.D.,P.E.

3.1Fermenterdesign 69

3.1.1Fermenterswithoutmechanical mixers73

3.2Fermenterinstrumentation,controland operation 75

3.2.1Temperature77

3.2.2pH78

3.2.3Dissolvedoxygen concentration79

3.2.4Mixerspeed80

3.2.5Pressure80

3.2.6Gasflowrate81

3.2.7Liquidflowrate82

3.2.8Foam83

3.2.9Exitgascomposition85

3.2.10Level86

3.2.11Substrateconcentration87

3.2.12Powerinput88

3.2.13Redoxpotential89

3.3Continuousculture 89

3.4Downstreamprocessing 93

3.4.1Monosodiumglutamate94

3.4.2Phenethylalcohol100

3.5Concludingremarks 108

108 References 109

4.Liquidfiltration

JoseM.Sentmanat

4.1Doyouneedafilter? 113

4.2Labtestingbeforeyouchoosethe filter 113

4.3Choosingthefilter 116

4.3.1Plateandframefilterpress116

4.3.2Filterpresses116

4.3.3Platefilters117

4.3.4Pressureleaftypefilter117

4.3.5Nutschefilter118

4.3.6Polishingfilter118

4.4TheABCsofliquidfiltration 118

4.5Themechanicsofliquidfiltration 119

4.5.1Precoat119

4.5.2Filtration120

4.5.3Cleaning120

4.5.4Standby121

4.6Troubleshooting 121

4.7Thefiltercake 121

4.8Preventativemaintenanceprogram 122 Furtherreading 123

5.Cake-buildingfiltertechnologies

JoseM.SentmanatandBarryA.Perlmutter

5.1Batchprocessingoffiltercakes 125

5.2Containedfilterpressesforcake washing,dewatering,anddrying 126

5.3Nutschefilterandfilterdryers 127

5.4Continuousprocessingoffiltercakes 128

5.4.1Vacuumbeltfilters128

5.4.2Horizontalvacuumbeltfilters129

5.4.3Rotaryvacuumdrumfilters131

5.4.4Rotarypressurefilter131

5.4.5Pressurizedvacuumdrum filter131

6.Centrifugation

BadrieLuckiram,BSc,MSc,CEng,MIChemE

6.1Centrifugechoiceandanalysisof availableequipment 133

6.1.1Horizontalbasketcentrifuges135

6.1.2Verticalbasketcentrifuges135

6.2Typicalcentrifugeoperation 138

6.3Technicalconsiderationsofequipment selection 138

6.3.1Designbasisdocument138

6.4Otherconsiderationsofcentrifuge operation 141

6.4.1Centrifugeinerting141

6.4.2Generaloperation141

6.4.3Safetyinterlocks142

6.4.4Outofbalancemonitor142

6.4.5Ploughparked142

6.5Finalremarks 142

7.Dryers

HongbenZhou

7.1Purposeofdrying 145

7.2Dispersedsolid-liquidsystem 145

7.3Dryingprocesses 147

7.4Convectivedryingwithhotgas 147

7.5Conductiveandradiativedrying 150

7.6Evaporationofliquidfromasolid packing 151

7.7Dryingfacilities 153

7.7.1Grain-sunningground153

7.7.2Traydryer154

7.7.3Beltdryer156

7.7.4Rotarydryer(kiln)156

7.7.5Fixedbeddryer159

7.7.6Fluidizedbeddryer161

7.7.7Pneumaticconveyorasdryer162

7.7.8Spraydryer165

7.7.9Impactmillasdryer166

7.7.10Rotatingvesseldryer168

7.7.11Platedryer168

7.7.12Rollerdryer170

7.7.13Screwconveyorasdryer170

7.7.14Agitatedmixerasdryer171

7.8Troubleshooting 174

7.8.1Heattransfer174

7.8.2Levelofvacuum175

7.8.3Formationofagglomeratesand crust175 References 176

8.Pressurefilterdryer

BadrieLuckiram,BSc,MSc,CEng,MIChemE

8.1Generalconsiderationsofusinga pressurefilterdryer 177

8.1.1Pharma-specific considerations178

8.2Principlesofthepressurefilter dryer 179

8.3Filterchoiceandanalysisofavailable equipment 182

8.3.1Selectionoffilterdryertype182

8.4Technicalconsiderationsofequipment selection 183

8.5Generaloperationofapressurefilter dryer 183

8.5.1GMPissuesandcleaning189

8.5.2Filtersafetyinterlocks189

8.5.3Operationalissues190

8.6Finalremarks 190

9.Processautomationsystems

NickHarbud

9.1Processautomationinproduction facilities 191

9.2Processcontrolsystem (continuousprocess) 191

9.2.1Controllingtheprocess191

9.2.2Operatingtheplant193

9.2.3Integratingautomation systems194

9.2.4Enterpriseinterfaces195

9.2.5Typesofprocesscontrol system195

9.3Processcontrolsystems (batchprocess) 197

9.4Safetyinstrumentedsystems 201

9.4.1Identifyingthehazards203

9.4.2Assessingtherisks203

9.4.3Highintegritypressureprotection systems205

9.4.4Cybersecurityriskassessment206

9.4.5Validationandproving206

9.5Alarmmanagementsystems 207

9.6Machineryprotection 209

9.6.1Vibrationmonitoringsystem209

9.6.2Compressorandturbinecontrol systems209

9.7Measurement,andotherfunthingsto dowithinstruments 212

9.7.1Diagnostics—Isitworking?213

9.7.2Controlinthefield214

9.7.3Thegrowthofdigital communicationsprotocols214

9.7.4HART214

9.7.5Fieldbus215

9.7.6Ditchingthewires216

9.7.7Instrumentassetmanagement systems(IAMS)217

9.8Theeffectoftechnologyonprocess automation 217

10.Processautomationlifecycles

NickHarbud

10.1Planningforprocessautomation 219

10.1.1Operationsandmaintenance philosophy219

10.1.2Identifykeyautomationsystems andtechnology219

10.1.3Identifyadvancedcontrol schemes220

10.1.4Estimatesystemsize221

10.1.5Siteplanningoverall philosophy221

10.2Frontendengineeringdesign 226

10.2.1Basicautomation requirements226

10.2.2Advancedprocesscontrol226

10.2.3TheMAC,andwhyyoushould useone226

10.2.4Otherautomationsystems227

10.2.5Functionalsafety228

10.2.6Changemanagementfor processautomation228

10.3Deliveryphase,detailedengineering, andprocurement 229

10.3.1Processautomationdesign documentation229

10.3.2Automationsystemdesign andsoftwareconfiguration230

10.3.3Factoryacceptancetesting230

10.3.4Shipmentandsite preservation231

10.4Installationandcommissioning 231

10.4.1Manpowerplan231

10.4.2Infrastructureandoverheads plan232

10.4.3PASmediaplan233

10.4.4PASchangemanagement plan233

10.4.5PASsecurityplan233

10.4.6PASintegrationplan233

10.4.7PASmaintenanceplan234

10.4.8PASuseradministration plan234

10.4.9PASturnoverplan235

10.5Automationsystemoperationand obsolescence 235

10.5.1Hardwaremaintenance andobsolescence235

10.5.2Softwaremaintenanceand change235

10.5.3Disasterrecovery236 10.6Conclusion 237

11.Processautomationplatforms MikeWilliams

11.1Background 239

11.2Staffingofamanufacturingfacility 239

11.3Findingthebalance 240

11.4Thenewparadigmofautonomous operations 240

11.5Upgradingthelevelofautomation 245

11.6Wheretostartwhenconsidering investmentinhigherlevelsof autonomy 246

11.7Conclusions 247

12.Mixingandblending

StephanieShira

12.1Introduction:Whymixing matters 249

12.2Upstreamconsiderations 249

12.2.1Beforetheshafts250

12.2.2Thefirstshaft250

12.2.3Distributivevsdispersive mixing253

12.3Thesecondshaft 254

12.3.1Highspeeddispersionandlow speedscraping:Thetraditional dual-shaftmixer254

12.3.2Moreintensedispersion (doubletheshafts,quadruple thebladesofatraditional disperser):Thedual-shaft disperser255

12.3.3Dual-shaftdispersercasestudy andperformancereview258

12.4Thethirdshaft 258

12.5Additionalmixerdesign considerations 258

12.6Rheologyconsiderations 260

12.7Overmixingisjustasbadas undermixing:Knowthefinishing point 261

12.7.1Kitchenconnection261

12.7.2Casestudy:“Pancakelumps” ontheproductionfloor261

12.7.3Compensatingbehaviorsresult frominadequateproducts262

12.8Reliablescale-up 262

12.8.1Hydraulicramdischarge press263

12.9Mechanicalaspectsand troubleshooting 264

12.9.1Bladehealth264

12.9.2Understandingshear(ratesand flowregimes)265

12.10Casestudy:Whypushtoward efficiency? 266

12.10.1Theoldway:Paradigm266

12.10.2Thenewway:Breakthe paradigm269

12.10.3Whatwassaved?270

12.10.4Inconclusion:Every perspectivematters271

12.11Finalremarks 271

13.Processdevelopmentand integrationbymathematical modelingandsimulationtools

NimaYazdanpanah

13.1Fundamentalsandworkflow 273

13.2Thestepsforbuildingamathematical model 275

13.3Steady-stateanddynamic simulations 277

13.4Processsimulationfor optimization 277

13.4.1Constructionoftheoptimization problemandits components279

13.5Processdevelopmentworkflowfor continuousmanufacturing 280

13.5.1Processintegrationandsteadystatesimulation281

13.5.2Dynamicprocessmodeling andcontrol283

13.6CorrelationbetweenCQAs,CPPs, CMAs 286 References 292

14.Processsafety

KaushikBasak

14.1Lab-scaleoperations 293

14.1.1Safetyandhazards293

14.1.2Keyissuesforlab-scale operation294

14.2Pilotplantoperations 297

14.2.1Safetyandhazards297 14.2.2Keyissuesforpilotplant operations299

14.2.3Pilotplantsizing,issues, decisions,andtrade-offs301

14.3Productionscaleoperations 303

14.3.1Safetyandhazards303

14.3.2Keyissuesforproductionscale operation304 References 305

15.Processcommissioning

BadrieLuckiram,BSc,MSc,CEng,MIChemE

15.1Commissioning 307

15.2Competency 307

15.3Checkspriortothestartof commissioning 308

15.4Commissioningprotocols 308

15.5Specificprocessengineering responsibilities 309

15.6Handoveroftheplanttotheuser 309

15.7Overallrecommendationsforprocess engineers 310

Appendix:ExampleCommissioning ProtocolforanewHydrochloricAcid TankerOffloadingPump 310

16.Holisticprocessintegrationand optimization:Large-scalehybrid processapplications

UgurTuzun

16.1Introduction 317

16.2Lifecyclesofgenericactivitiesfor large-scalebulkchemicals production 318

16.3Systemsintegrationdesignfor specialtyproductsmanufactureand sales 321

16.4Gatedprocessdevelopmentwith digitalinterlinks 321

16.5Digitalcontrollifecyclesofintegrated large-scaleproductionplants 327

16.5.1Configuring communications327

16.5.2Multivariabledevices communication328

16.5.3Loopconverters328

16.5.4Multiplexers328

16.6Environmentalimpactmonitoring andcontrol 329

16.6.1Greenprocessapplicationsin processindustries330

16.6.2Industrialemissionscontrol strategiesusingdigital platforms330

16.6.3Digitalenvironmentalsensor technologies330

16.6.4Digitalplatformconstruction formultivariateprocessand environmentaldatasets331

16.6.5Couplingenvironmentaland processchemistry333

16.6.6Environmentalemissions recordsandHAZOPstudies333

16.7Systemsintegrationofplant operationswithineco-industrial parks 334 16.8Conclusions

17.Fromideato1milliontonyear commercialplant JoepFontFreide

17.1Theframework 339

17.2Theexecution 341

17.2.1Conceptandlaboratory stage341

17.2.2Microreactorstage341

17.2.3Pilotplantstage342

17.2.4Demonstrationplantstage343

17.3Atlast:Safetyfirst 344

18.Scale-upchallenges:Examples fromrefiningandcatalysis KaushikBasak

18.1Challengesinrefiningscale-up 345

18.2Challengesincatalystscale-up 348

19.Scale-upchallenges:Wastewater KaushikBasak

19.1Challengesinwastewater treatment 351 References 353

20.Hemp/biomassprocesssteps JayVanderVlugt

20.1Hempcultivationoverview 355

20.2Extraction 356

20.2.1Ethanol356

20.2.2Gaseoushydrocarbon extraction357

20.2.3Liquidhydrocarbon extraction358

20.2.4Subcriticalandsupercritical carbondioxide359

20.2.5Cosolventinjection360

20.2.6Solvent-lessprocesses360

20.2.7Drysifting360

20.2.8Coldwater(kief)extraction361

20.2.9Distillation362

20.3Innovationsandotherextraction technologies 364

20.3.1Ultrasonicprocessing364

20.3.2Hybridmicrowave365

20.3.3Targetedcannabinoidsalt precipitation365

20.3.4Winterization-purification367

20.3.5Organicsolvent nanofiltration367

20.4Cannabinoidisolation 368

20.4.1Decarboxylation370

20.5Conclusions 370

20.5.1Hazardousinstallation requirements370

20.5.2Contaminationandother processissues371

References 372

21.Techno-economicanalyses

RonLengandJohnAnderson

21.1Introduction 373

21.1.1Usesofatechnoeconomic assessment373

21.1.2Decisionmaking374

21.2Technologyassessment 376

21.2.1Definitionofnew technology376

21.2.2Feasibility:Thefirstscreen377

21.2.3Technologyscalabilityto full-scalemanufacturing377

21.2.4Technicalsuccess parameters377

21.2.5Typesoftechnologyrisk378

21.2.6Riskmanagementplan379

21.2.7Licensedtechnology382

21.2.8Investmentinastart-up technology383

21.2.9Duplicationofexisting technology:Acaution383

21.2.10Typesofprojects383

21.2.11Typesofprocess technology384

21.2.12Batchvs.continuous mode385

21.2.13Technologypackage386

21.3Makingcost-of-manufacturing estimatesduringtheearlystagesofa project 387

21.3.1Identifyingvariableandfixed costs387

21.3.2Variablecosts388

21.3.3Fixedcosts392

21.4Puttingthecoststogether:Example problems 397

21.5Handlinguncertaintiesduringearly projectstages 399

21.6Combiningcostswithrevenuesto computeeconomicindicators 405

21.6.1Introductiontoeconomic indicators405

21.6.2Thereareonlytwokey questions405

21.6.3Riskandreward:Isthereany data?405

21.6.4Financialindicators: Definitions405

21.6.5Internalrateofreturn(IRR)or discountedcashflowpercent (DCF%)406

21.6.6Finalsummary409 References 411

22.Projectmanagement

VenkataRamanujamandBobBarnes

22.1Introduction 413

22.2Theprojectengineeringprocess 413

22.2.1Integratingcourseworkin chemicalprocess engineering415

22.3Predictivetools 418

22.4Industriesservedbyprocess engineers 419

22.5Processplantcomponents 419

22.6Processsafetyandprocessengineering workflow 420

22.7Puttingitalltogetherwithpractical knowledge 421

22.7.1Selectingthesiteorlivingwith theselectionhandedtoyou421

22.7.2Siteissues423

22.7.3Commonconcerns:Funding, controlofsite424

22.7.4Communityissues:Tax incentives,salestax,resources, andworkforcesupply425

22.8Engineering:In-houseresourcesand EPCfirms 425

22.8.1Formingtheteam425

22.8.2Selectingtheengineering, procurement,andconstruction (EPC)firm425

22.8.3Theall-importantP&ID development426

22.8.4Controlsandcontrolroom concerns426

22.8.5QA/QCneeds426

22.8.6Facilitiesandequipmentfor operationsand maintenance427

22.8.7Hazardanalysis:Isitrequiredor justagoodpractice427

22.8.8Projectmanagement427

22.8.9Scheduling427

22.9Projectexecution 428

22.9.1Organizationand planning428

22.9.2Siteworkandutilitysupply428

22.9.3Foundationsandsteel erection428

22.9.4Settingequipment429

22.9.5Piping429

22.9.6Powerdistribution429

22.9.7Controlnetworkingandfield instruments430

22.9.8Projectcontrols:Schedule andbudget430

22.9.9Operatortraining430

22.9.10Commissioning,qualification batchesandtestingand start-up431

23.Decommissioning

BarryA.Perlmutter

23.1Optionsfordecommissioning 433

23.2Howtobegindecommissioning 433

23.2.1Decontamination433

23.2.2Finalstepsofthe decommissioningproject436

Index437

Contributors

Numbersinparenthesesindicatethepagesonwhichtheauthors’ contributionsbegin.

BrookeAlbin (1),Research&Development,MATRIC (Mid-AtlanticTechnology,Research&Innovation Center),SouthCharleston,WV,UnitedStates

JohnAnderson (373),Engineering&ProcessSciences, DowChemical,Midland,MI,UnitedStates

BobBarnes (413),Project&ProcessConsultant,ProvationsLLC,Gregory,TX,UnitedStates

KaushikBasak (293,345,351),PrincipalEngineer (SMPO),Shellplc.,ShellTechnologyCentre, Bangalore,India

JoepFontFreide (339),FFTechnology,Guildford,United Kingdom

AlanGabelman,Ph.D.,P.E. (13,69),GabelmanProcess Solutions,LLC,WestChester,OH,UnitedStates

NickHarbud (191,219),C.Eng.,F.I.Chem.E.,Newbury, UnitedKingdom

RonLeng (373),Engineering&ProcessScience,Dow Chemical,Midland,MI,UnitedStates

BadrieLuckiram,BSc,MSc,CEng,MIChemE (133, 177,307),Pharmaceutical&ProcessEngineer,London, UnitedKingdom

BarryA.Perlmutter (125,433),Perlmutter&IdeaDevelopmentLLC,Matthews,NC,UnitedStates

VenkataRamanujam (413),McDermottInc.,Houston, TX,UnitedStates

JoseM.Sentmanat (113,125),LiquidFiltrationSpecialist, LLC,Conroe,TX,UnitedStates

StephanieShira (249),MyersMixers,Cudahy,CA,United States

UgurTuzun (317),ChurchillCollege,Universityof Cambridge,Cambridge,UnitedKingdom

JayVanderVlugt (355),CannabinoidSciences,Nectar HealthSciencesInc.,Victoria,BC,Canada

MikeWilliams (239),ProcessAutomation,ARC Advisory,Dedham,MA,UnitedStates

NimaYazdanpanah (273),EngineeringandDevelopment, Procegence,ChevyChase,MD,UnitedStates

HongbenZhou (145),BHS-SonthofenProcessTechnologyGmbH&Co.KG,Herrsching,Germany

Preface

Overmycareerof40yearsintheprocessindustry,writinghasalwaysbeenapassionforme.Itrepresentsanopportunityto conveyconcepts,ideas,andtechnicalinformationinamannerthatmakessensetotheaudience.WhileIneverhadany formalizedjournalismorwritingtraining,thisskillsomehowdevelopedonitsownthroughmycontinuinglearning, reading,andspeaking/presentingonthetopicsofsolid-liquidseparation,centrifugation,drying,andotherprocess equipmentandtechnologiesaswellasbusinessdevelopmentandinnovation.Thisworkhasspannedover40countries on6continents.

IbeganwritingwhenIwasayoungEnvironmentalScientistwiththeUSEnvironmentalProtectionAgency(USEPA). Duringthoseyears,IissuedCodeofFederalRegisterrulesandjustifications,approved,ofcourse,bytheBranchManager andeventuallytheRegionalAdministrator.Severalofmyreportsarestillavailableshouldyoubeeagertoread“EPA905/ 5-81-002:EconomicImpactofImplementingVOCGroupIIRulesinOhio”or“EPA905/9-82-005:AirQualityNonAttainmentAreasinRegion5.”

FromtheUSEPA,IjoinedPallCorporationandcontinuedmywritingintheirmarketinggroupwhereIissuedmyfirst filtrationpaperin1982,WER5300—PrinciplesofFiltration.ThispaperhadtobeapprovedbyDr.Pallbeforeitwasissued. Mywritingcontinued,andoneofmytaglineswas“liketheSheriffintheWildWest,myroleistobringorderfromchaosin thefiltrationindustry.”

Mytechnicalandmarketingapplicationarticles—morethan150todate—culminatedin2015withthepublicationof myfirstbookforElsevier,thehandbookof Solid-LiquidFiltration.PartofElsevier’sPracticalGuidesinChemicalEngineering,whereeachbookprovidesafocusedintroductoryviewonasinglesubject,theHandbookrequiredalmost1yearto write.Thefunandchallengeofthattaskhavefurtherbeenrewardedwithyear-to-datesalesofmorethan900copies.

Nowhereweareatthecurrentbook, IntegrationandOptimizationofUnitProcessOperations.Onthestrengthofthe handbook’smarketacceptance,Elsevieraskedmetoproposeasecondbook.Theysuggestedthatbaseduponmy experience,Ieditabookuniquetothechemicalprocessindustry(CPI).Iwelcomedtheopportunity.

Theprobleminthemarketplace,asIseeit,isthetypeofengineerstrained.Intheearly1970s,companieswantedstaff withan“I-shaped”skilllevel.Someonewith“I-shaped”skillshasadeep(vertical)expertiseinoneareaandpracticallyno experienceorknowledgeinotherareas.Thispersonistypicallyknownasaspecialist.Inthe1980s,theindustrywanted “T-shaped”professionals.TheverticalbarontheTrepresentsstrongknowledgeinaspecificdiscipline.Thehorizontalbar representsawide(horizontal)yetshallowknowledgeinotherareas.Thisallowsthepersontobeabletocollaborateacross otherdisciplinesandacquirenewskillsorknowledge.Now,however,withtherapidproliferationoftechnological advancesandthecross-disciplinarynatureofwork,weneed“Key-shaped”engineerswhohaveseveralareasofexpertise withvaryingdegreesofdepth.Thisbookaddressesthisneed.

First,whatthisbookisnotisanothertextbookfordesigningequipmentandtechnology.Therearemanyreferences, universitycourses,etc.,forthisworkandteachingthe“nutsandbolts”ofpumps,heatexchangers,distillationtowers, thermodynamics,etc.

Thisbooktakesadifferentapproachtoshareup-to-dateandpracticalinformationonchemicalunitoperationsfromthe R&Dstagetoscale-upanddemonstrationtocommercializationandoptimization.Ateachstage,theinformationpresented differsasthetechnologyandissuesfacedatthelabscalechangeincommercializationandoptimization.Thisbooktakesa broaderviewandencouragesa“Key-shaped”approachtochemicalengineering.

Asthechemicalindustrychangesandbecomesmoreintegratedworldwide,informationexchangeisneeded.This exchangemustincludenotonlyprinciplesofoperation,butalsopracticalknowledgetransfer.Thisbookaddresses thisneed.

EngineersmustbeabletoaskquestionsofI-shapedandT-shapedprofessionalstodevelopcreativesolutions.Thisbook addressestheneedsofengineerswhowanttoincreasetheirskilllevelsinvariousdisciplinessothattheycandevelop, commercialize,andoptimizeprocesses.

Sometheoryisincludedtoprovidethenecessarybackgroundofthespecificunitoperation,butasstatedpreviously,this isnotthemainemphasis.Eachchapterdiscussespracticalaspectsandillustratestheimpactsofupstreamprocessdecisions ondownstreamoperations.Chaptersalsoincludetroubleshootingateachprocessstageandsuggestquestionstoaskto developcreativesolutionstoprocessproblems.

Theengineerusingthisbookwillbeabletotakethecontentandapplyittothetaskathand.Forexample,ifyouare workingonaprocessandneedinformationonelectricalandcontrols,youwillfindthis.Ifyouareanewprojectmanager, youwillfindachapteronhowtodevelopaprojectfrombeginningtofinalacceptanceandstart-up.Whetheryouareastartuporproducingmillionsoftons/year,youwillfindthenecessaryguidance.Ihopethatthiswillbeyour“go-tobook”along thewayasyougrowandexpandyourskillsandcareer.

Theorganizationofthechaptersfollowsthatofachemicaloperatingcompanynomatterthesizeoftheoperation.It beginswithcrystallizationandfermentation.Then,therearediscussionsoftheprocessequipmentfollowedbyautomation, mixingandblending,processmodelingandsafety,andcommissioning.Wethendiscussoptimization,projectmanagement,techno-economicanalysis,and“puttingitalltogether.”Thebookconcludeswithachapterondecommissioning whichisimportant,asprocesseschange,productschange,andthemarketitselfchanges.

Twomoretopicsinthebookdeserveaseparatemention.First,thereisachapteronhemp,cannabis,CBDorcannabidiols,andbiomass.Thisisanewandflourishingindustry,andmanyofthereadersofthisbookmaybedrawnintothis processarea.Finally,wediscusssustainabilityandholisticintegrationandoptimizationofchemicalprocessesandconsumerproductmanufacturing.Thischapterexplorestheimpactsofenvironmental,socio-ecological,andeconomicissues ondecisionmakingrequiringtheapplicationofholisticsystemsmodelinginprocessandproductdesigntoevaluatethe relatedconsequences.

Finally,thetext,asyouwillsee,variesfromchaptertochapter,asallcontributingauthorscomefromdifferingbackgroundsandexperiences.This,Ibelieve,itoneofthegreateststrengthsofthisbook.BesidestheUnitedStates,wehave authorsfromIndia,Germany,UnitedKingdom,Ireland,Netherlands,andCanada.Theirexperienceencompassesprocess engineers,technologysuppliers,plantmanagers,academia,governmentalagencies,consultants,andstart-uptoFortune 500companies.Eachauthorbringsauniqueapproachtoproblemsolvingandplantoperations.Anapproachandexpertise theyhavesograciouslytakenthetimetoshare.

Asoneauthorcommented:“We,asacommunity,reallyhavearesponsibilitytohelpandsupportyoungerengineers and/orpeoplewhoarethinkingofgoingintotheprofession.Weparticularlyneedtomentorpeoplefromnon-traditional backgroundswhojustneedsomeencouragementandsupport,otherwisethereisthedangerofthembecomingdiscouraged andfallingawayfromtheprofession.Weneeddiversityinthisprofession.”

Thisbookembracesthatdiversity.Thankyoutoalltheauthorswhospenttimeresearchingandwritingtocontribute yourchapters.Youarethebackboneofthisbook.Ihaveenjoyedworkingwithyouandtrulyhopethatourpathswill crossagain.

ThankingeveryoneI’veworkedwithovermy40yearsfortheirguidance,influence,help,andassistancewouldtakea bookitself.AsIreflectonmycareerandthemanyworldwidefriendsthatIhavehadthepleasureofmeetingoverallthese years,Iamtrulygratefultoeachoneofyou.Letmesaythattheword“friends”inmymindarecolleagues,customers, competitors,suppliers,publishers,editors,andmanyotherswhohavehelpedmetosucceed.Ihavebeenfortunatethrough hardwork,longhours,andapersonalgoalofmakingeachandeveryoneofourcontactsaninformativeandproductive experiencetobuildmanylong-lastingrelationshipsand,moreimportantly,invaluablefriendshipsoveralltheseyears.It hasbeentheserelationshipsthatkeepmestrivingtogivebacktoourengineeringcommunity.

Aheartfeltthankyoualsotomyparents,mywifeMichelle,andmyfamily,friends,trainers,andyogisforsupportingme alltheseyearsandbeingpartofmylife.Youallhaveheardthestories,andwhileyoumaynothavefullyunderstoodall,you havebeenthereformeforever.Thankyou,thankyou,andthankyouagain.

InowmustgiveonefinalthankstoJennGodduwhostartedwithmein2014asmytechnicalassociate,editor,friend, andall-aroundwriterasIpublish,blog,post,andtweet.Herskillsarecompletelybeyondreproach.

And,tothereadersofthisbook,Ihopethattheinformationfromtheexperiencesofthecontributingauthorswillhelp youtosucceedinyourcareersandpersonalgrowth.Thankyou.

BarryA.Perlmutter,Editor

Perlmutter&IdeaDevelopmentLLC,Matthews,NC,UnitedStates

Crystallization

BrookeAlbin

Research&Development,MATRIC(Mid-AtlanticTechnology,Research&InnovationCenter),SouthCharleston,WV,UnitedStates

Crystallizerprocessdesignrequiresattentiontomanyvariedfactors.Thischapterdiscussesfundamentalsandlaboratory scaleprocessdevelopment,pilotscalecrystallizationstudies,andcommercializationofcrystallizationprocessestoprovide anoverviewoftheconsiderationsinthisareaofsolidsprocessing.

1.1Fundamentalsandlaboratoryscaleprocessdevelopment

Thedesignofanindustrialcrystallizationunitdependsgreatlyonthecharacteristicsofthefeedsuppliedfromtheupstream processandhasdirectconsequencesfordownstreamoperations.Forthisreason,bothnarrowandbroadperspectivesare neededtoensureadesignthatwillbeimplementedsuccessfully.Thecrystallizeroperationmustberobustwithintheentire rangeofoperatingconditionsitissubjectedto.Forexample,ifupstreamconcentrationvaries,thecrystallizermustbeable torespondtothatinsomewayinordertocontinuetooperatesmoothlyandnotcauseupsetsdownstream.

Thedesignofacrystallizerstartsinthelaboratory.Thelabsettingoffersmaximumflexibilityformakingchangesto design,adjustingconditions,andcloselyobservingbehaviorofthesystem.Laboratorycrystallizerequipmentisoftenconstructedofglass,whichprovidesasignificantadvantageinearlystagesofprocessdevelopmentwhenmuchcanbelearned byvisualinspection.Nucleation,crystalgrowth,agitation,slurrythickness,andtendencyforfoulingcanallbestudied insitu.Rangesforoperatingconditionscanstarttobeapproximatedoftenwithinthefirstfewtests,andmanyitemsof concerncanbeidentifiedatthisstagesoproperdesignconsiderationscanbemade.

1.1.1Crystallizerdesignbasics

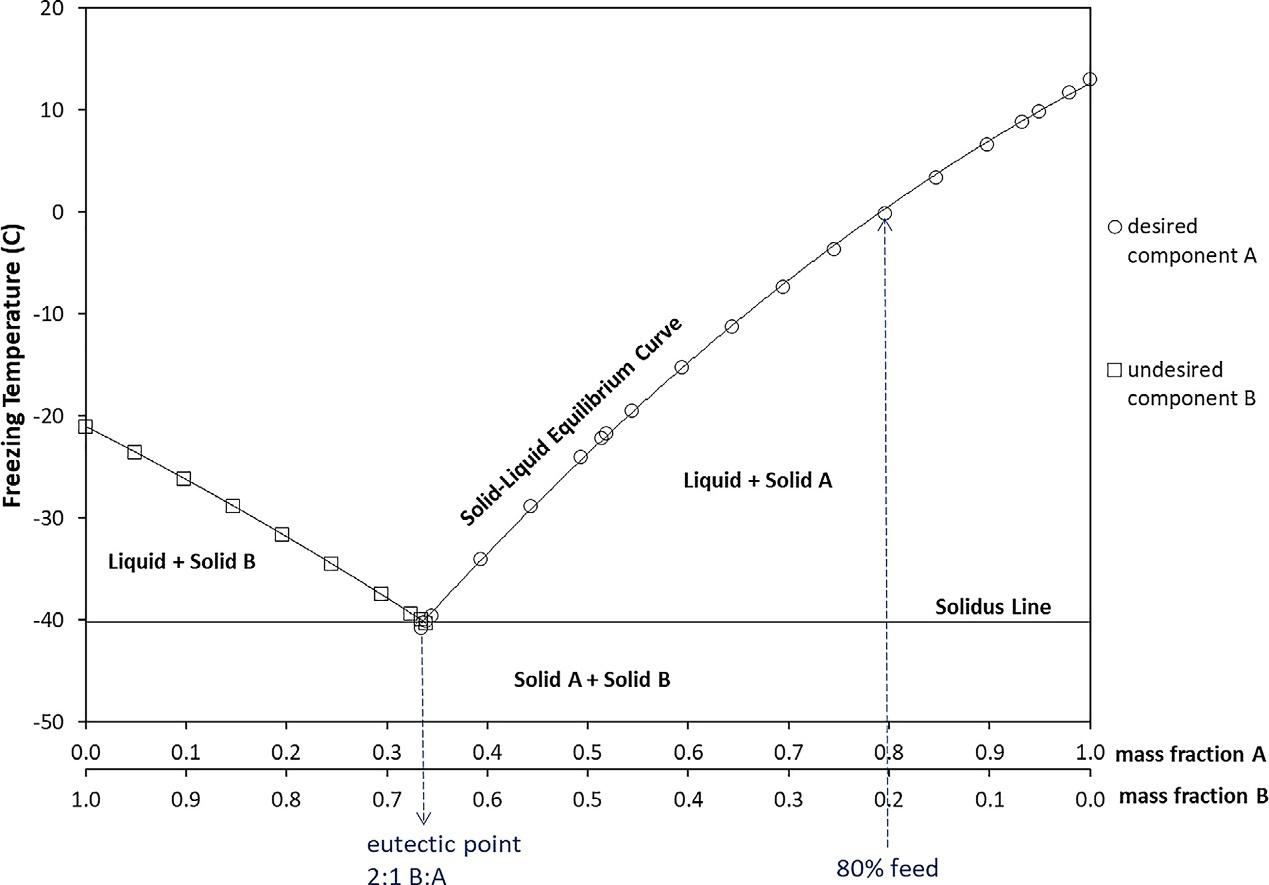

Crystallizationisachievedbyexploitingdifferencesinsolubilityofcomponentsinasolution.Itcanbeausefulmethodfor separatingcomponentsorpurifyingaparticularmaterial.Itisoftenusedforrecoveringasolidproductofhighpurity,butin somecases,theobjectiveistoremovesolidimpuritiesfromaliquidstream.Ineithercase,theseparationoccurswhen supersaturationisgeneratedtosolidifyonecomponentinpureform.Thisprocessisgovernedbythephysicalproperties ofthecomponentsinthesolution.Aphasediagramistheidealstartingpointfordevelopinganycrystallizationprocess. Aphasediagramforatypicalbinaryeutecticsystemisshownin Fig.1.1.Itshowsthesolid-liquidequilibriumdata (solubilitycurves)foreachofthemajorcomponentsinsolution.Thisprovidesimportantinformationregardingtheconditionsrequiredforcrystallizingthedesiredcomponent,anditestablishesthelimitsofwhatcrystallizationcanachievein termsofyield(recovery).Forasolutionofagivenconcentration,thediagramindicatesthetemperatureatwhichcrystallizationwillbegin.Iftemperatureisloweredfurther,moresolidswillform,leavingalessconcentratedliquid(mother liquor)behind.Thetheoreticalyieldcanbedeterminedbyperformingamaterialbalancethataccountsforthestarting concentrationofthesolutionandendingconcentrationofthemotherliquoratagivensetofconditions.Theeutecticindicatesthepointatwhichbothcomponentswillcrystallizeandseparationcannotbeachieved.Thisrepresentstheconditions atwhichthemaximumtheoreticalyieldcanbeattained.

Considertheexamplein Fig.1.1,whichassumesafeedsolutioncontaining80wt%ofcomponentA.Purecrystalsof componentAwillstarttoformasthesolutioniscooledto0°C.CrystalsofcomponentAwillcontinuetoformastemperatureislowereduntilthesolutioniscooledtoitseutecticpointat 40°C.Atthispoint,bothAandBwillcrystallize, producingasolidphasethatcontainsa2:1ratioofB:A.

Phasediagramscansometimesbefoundintheliterature,butitispreferredthatsolubilitydataaregeneratedexperimentallytoensuretheyarerepresentative.Thisespeciallyappliestofeedsthatcontaingreaterthan1%–2%ofimpuritiesor havemorethantwocomponents,sincethephysicalpropertiesaremorelikelytobeaffected(Bamforth,1965).

Todeterminesolubilityexperimentally,thesolutionissubjectedtoatemperaturesufficientforinducingcrystallizationand isallowedtimetoequilibrate.Asolid-liquidseparationisperformed,andtheresultingmotherliquorisanalyzedto determinetheresidualconcentration.Thus,byrepeatingthisatvarioustemperatures,freezingtemperatureversusconcentrationcanbeplotted.Lesspreferably,areasonableestimateoftheoreticalsolubilitydatacanbecalculatedusingthevan’t HoffEquation,where x2 isthesolublemassfraction, D Hf istheheatoffusion, R istheidealgasconstant, T issaturation temperature,and TM isthepuremeltingpointtemperature.

H f RT T T M 1

Theoreticaldatacanprovideusefulinsightinthepreliminarystagesofdevelopment,butitisrecommendedthatdataare laterverifiedinthelaboratory.

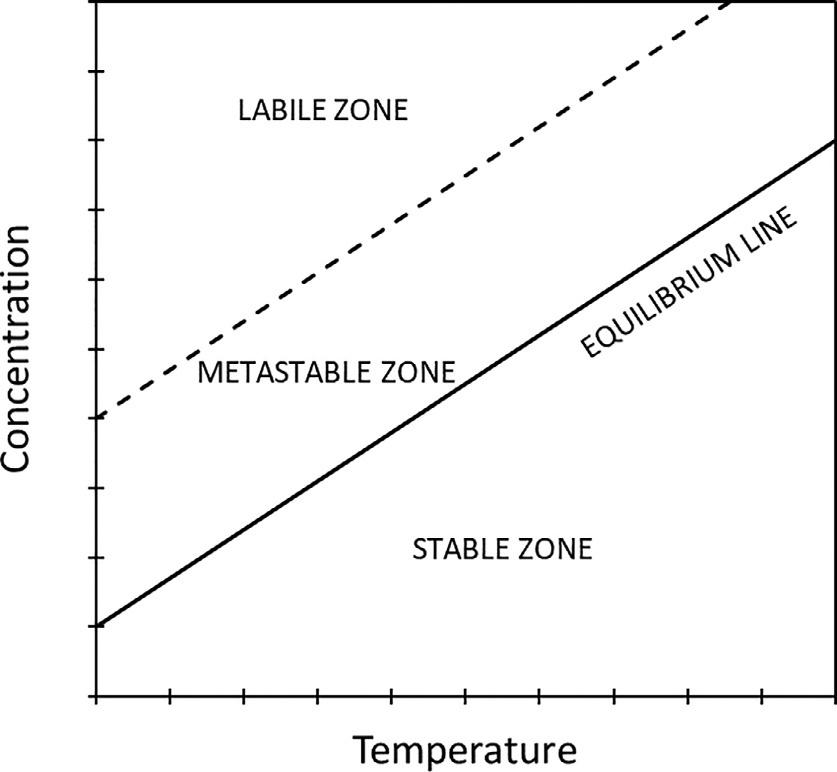

Whendevelopingacrystallizationprocess,itisalsoessentialtodefinethemetastableandlabilezones. Fig.1.2 depicts thesezonesonaphasediagram.Themetastablezoneindicatestherangeofconditionsinwhichasolutioncansustain supersaturation.Chemicalsolutionswithlargemetastablezonesrequireconcentrationsthatgreatlyexceedequilibrium beforenucleationspontaneouslyoccurs.Supersaturatedsolutionsoccurringinthemetastablezonearestableunlessdisturbed.Thelabilezonerepresentstheregionbeyondthethresholdconcentrationatwhichthesupersaturatedsolutionwill nolongerremainstableandnucleationwillautomatically“kick-off.”Whenhighlysupersaturatedsolutionsself-nucleate, theyarelikelytoundergoarapid,uncontrolledcrystallizationthattendstoproducefinecrystalsofpoorquality.In commercialprocesses,thisgenerallymustbeavoided.Therefore,seedingisfrequentlyusedtoenableamorecontrolled crystallizationthatpreventsexcessivenucleationandpromotesgoodcrystalgrowth.Seedinginvolvestheadditionof homogeneousorheterogeneouscrystalstoactasnucleationsitesforgrowingcrystals.Tobeeffective,seedcrystalsshould beaddedwhileoperatinginthemetastablezone.

Theseconceptsareoftenpresentedintheclassicundergraduatechemistrylabexperimentinwhichasupersaturated solutionispreparedandscratchingthesideofabeakerorflaskinitiatescrystalformation.Inthisexample,thescratching freestinyglassparticlesthatcanactasseedcrystals.Oncecrystalsbegintoform,thesoluteconcentrationdecreasesand, givenenoughtime,thesolutionwillreachequilibriumandsupersaturationiseliminated.

FIG.1.1 Atypicalbinaryeutecticphasediagram.

FIG.1.2 Phasediagramshowingthestable,metastable,andlabilezones. Crystallization Chapter 1 3

Bystudyingthephasediagram,onecaninferthatchangingeithertemperatureorconcentrationisnecessarytoaccomplishsupersaturationandinitiatesolidsformation.Infact,thisisthedesignbasisofmostcrystallizerunits.Traditional industrialcrystallization,thefocusofthissection,commonlyoperatesonthebasisofevaporation,indirectcooling,or evaporative(direct)cooling.Thebestapproachforagivensystemisdeterminedbyitssolubilitydata.Whenthesolubility changesverylittleasafunctionoftemperature,evaporationwillberequiredforgeneratingsupersaturation.

Ontheotherhand,whenthesolubilityisastrongfunctionoftemperature,coolingisappropriate.Aruleofthumbisto chooseevaporativecrystallizationwhensolubilitydecreaseslessthan0.005g/g °Candtousecoolingcrystallizationwhen thedecreaseisgreaterthan0.005g/g °C(Genck,2011).Evaporativecoolingisusuallypreferredtominimizethetendency forfouling.However,sometimesevaporativecoolingisnotpracticalbecausetherequiredvaporpressureistoolow,the materialisunstableatthetemperaturerequiredforevaporation,orduetootherlimitations.Inthatcase,indirectcooling shouldbeconsidered.Otherlesscommontypesofcrystallizationincludesaltingout,reactivecrystallization(precipitation),andcrystallizationfromthemelt.

Crystallizationprocessescanbedesignedtooperateinabatchmodeorcontinuousmode.Batchoperationoffersthe mostflexibilityandissuitedwelltosmallerproductionunits.Continuousoperatingmodehasamuchnarrowerrangeof operatingconditions,butitisoftenmorecost-effectiveforlargescaleproductionandcanbesimplertooperatesinceitruns atsteadystate.Unitsthatproduceroughly10–15MMlbs/yearormoreareoftencandidatesforcontinuousoperation. Rarely,batch-automaticoperationisemployedinsomespecializedsystems,suchasthefallingfilmmeltcrystallizer. Inthiscase,thecrystallizeritselfoperatesinbatchmodebutcanbeintegratedseamlesslyintoacontinuousprocessby usingmultipleholdingtanksandinvolvingcomplexsequencing.

Themostcommoncontinuouscrystallizerisaforcedcirculation(FC)crystallizer.Thistypeofcrystallizerinvolvesthe simplestdesignandisusedforstraightforwardprocessesthatdonothaverestrictiveparticlesizerequirements.Forced circulationcrystallizerstypicallyproduceparticlesizesrangingfrom105to500 mm(Genck,2004).Whenlargercrystal sizeisimportant,otherdesignssuchasadraft-tubebaffle(DTB)orOSLO(Krystal)aremoresuitable.Thedraft-tubebaffle designproducescrystalsizesontheorderof300–4000 mm,andanOSLOcrystallizergivesacrystalsizerangeof 180–4000 mm(Genck,2004).Bothdesignsincorporateclassifiedproductremovalmethodsthatseparateproductbased onsettlingvelocitiestoyieldlargercrystalsizeandnarrowercrystalsizedistribution(CSD).Finesdestructioncanalso beimplementedineitherofthedesignstofurthercontroltheCSD.Perry’sChemicalEngineers’Handbookprovidesa thoroughreviewofvariouscrystallizerdesigns.“AClearerViewofCrystallizers”byGenckisrecommendedforadditional reading.Vendorwebsitesalsoprovideusefulcontentonthistopic.

1.1.2Crystallizerdesigntradeoffs

Theprimarydesigncriteriaforacrystallizerincludepurity,yield(recovery),andcapacity.Sincetheseaspectsofacrystallizationprocessareinterrelated,prioritizationisimportantforstrikingtherightbalanceindevelopingaviableprocess. Forexample,extremepuritymaybeattainable,butitoftencomesatthecostofyieldandthroughput.Extrarecrystallization stepsmightberequiredtoreachthehighpurity,resultinginlossofyieldwitheachadditionalprocessingstep.Operations willbecomemoreintensiveandthroughputwilldecrease.Likewise,ifyieldisthemainfocus,itmightmakesensetocompromiseonpurityandthroughput.Sincehighratesofrecyclemightbeneededtoachievetheyield,impuritieswouldbe expectedtogoup,soachievinghighpuritybecomesincreasinglydifficult.Anotherobviousfactoriscost.Ifallthreecriteriaaremaximized,bothcapitalcostsandoperatingcostscaneasilybecomeprohibitive.

Nonetheless,therearemeasuresthancanandshouldbetakentopromoteoptimizationoftheoverallsystemin termsofpurity,yield,andcapacityfactors.Tobeginwith,a crystallizationprocessmu stbedevelopedtofacilitate sufficientcrystalgrowth.Someproc essesdemandstrictspecificationsf ortheCSD.Evenifitisnotspecified, acceptableparticlesizeandshapearealmostalwayscriticalfactorsforensuringgoodperformanceinthecrystallizer anddownstream.

Bothnucleation(theproductionofnewparticles)andgrowth(increasingthesizeofexistingparticles)arecriticaltothe finalCSDthatisobtained.Thelevelofsupersaturationneedstobecontrolledcarefullytogiveacceptableratesofnucleationversusgrowth.Whenparticlesform,thegoalistorelievesupersaturationprimarilybydepositingmoleculeson existingparticles.Thisresultsinparticlegrowthinsteadofproducingmoresmallindividualcrystals.Toachievethis,crystallizationshouldbecarriedoutinthemetastableregion.Ideally,aconstant,minimalamountofsupersaturationshouldbe maintained,whetherbatchorcontinuousmode,toachieveadesirableCSDandproduceconsistentresults.Ifgrowthistoo fast,inclusionsandocclusionscanoccur,hinderingpurity.Inclusionsareimpuritiesthatarechemicallyincorporatedinto thecrystalstructure.Occlusionsarethosethatarephysicallytrappedinsideacrystal.

Ifsupersaturationistoohighandoperationsshiftintothelabileregion,nucleationcanbeinducedsuchthatsignificant finescan“crashout”ofsolution.Thisleadstovariousproblemsandultimatelynegativelyimpactspurity,yield,and capacity.Seedingcanbeessentialforcontrollingsupersaturationduringstartupsothatacceptableprocessperformance isattained.Otherwise,highsupersaturationcouldberequiredtoinitiatecrystalformation,potentiallycausingoneofthese uncontrollednucleationeventsinwhichhighnumbersoffinesareproduced.

Inbatchprocesses,seedingisoftenperformedatthestartofeachbatchtomanagesupersaturation.Afterstartup,the coolingorevaporationratedictatesthelevelofsupersaturation.Inaddition,residencetimealsoinfluencesgrowthand particlesize.Adequateresidencetimeforgrowthisessential.Incontinuousprocesses,whenconditionsareconstant,supersaturationiscontrolledbymanyvariablesincludingslurrydensity,mixing,andresidencetime.Sincegrowthoccursatonly 2 mm/min,residencetimescommonlyrangefrom1to10h(AmericanInstituteofChemicalEngineers,2019).Theimportanceofslurrydensitywithrespecttogrowthrelatestotheabilityofmoleculestofindanexistingparticleuponwhichto solidifyandgrowversusproducinganewparticle.

Agitationandcirculationarefactorsthathavebothchemicalandmechanicaleffectsonparticlesize.Properagitation andcirculationmustbeusedtodispersesupersaturationandmaintainsolidsinsuspension,butexcessivemixingcancause mechanicalabrasionandcrystalbreakageandcanpotentiallyinducesecondarynucleation.Primarynucleationrefersto crystalproductionthatoccursduetosupersaturation,whilesecondarynucleationoccursduetocrystal-crystalcollisionsor crystal-impellercollisions.

Evenifreasonabledesignconsiderationhasbeengiventotheabovefactors,sometimesfurtherimprovementstothe CSDareneeded.ProductclassificationenhancestheCSDbyremovingtheproductslurryfromalocationinwhichsettling occurs.Afinesdestructionsystemisoftenassociatedwithaclassifyingcrystallizer.Finesdestructiondissolvessmallparticlesbyheating(ordilution)andreturnssupersaturatedsolutiontothesystemwhereitencountersexistingparticlesthat growlargertoabsorbthesupersaturation. Fig.1.3 showsaDTBcrystallizerthathasaclassificationzoneandincorporates finesdestruction.Inthisdesign,largerparticlesaretakenasproduct,andfineparticlesareremoved,redissolvedintheheat exchanger,andrecirculatedbacktothecrystallizer.Anelutriationlegisanothertypeofclassifierthatisusedinsome crystallizerstoincreaseitsclassifyingcapability.Anelutriationleg,sometimesreferredtoasa“saltleg,”canbeintegrated intovariouscrystallizerdesigns,asin Fig.1.3.Itoperatesbasedonfluidizationofparticlestoachieveseparationdueto particlesize(i.e.,settlingvelocity).

Productioncapacityrequirementshelpestablishthefoundationforthecrystallizerdesign.Itisimportanttohaveawelldefinedmaterialbalancetodevelopasystemwiththedesiredcapacity.Onceequipmenthasbeenspecified,changestoany ofthesystemvariablescanlowerthesystem’sprocessingcapacity.Changestofeedrateorfeedconcentrationwilldirectly impactproductioncapacity.Practicalupperlimitsmustbeimposedforfeedratetoensurethatthesystemperformswelland meetstheperformancetargetsforparticlesize,purity,andyield.Thoughmostsystemscanmanageadecreaseinvolumetric

throughput,therecanbeunintendedconsequences.Inacontinuoussystem,iffeedratesbecometoolow,residencetimes couldincreasetothepointthatcrystalbreakagebecomesdetrimentaltotheCSDandcanbeproblematicfordownstream solid-liquidseparation.Inadequateheattransfercanalsolimitthroughput,creatingbottlenecksthataffectdownstreamprocessing.Feedconcentrationnotonlyhasadirectbearingonthematerialbalance,butitwillalsoaffectslurrydensity,in turn,affectingsecondarynucleationandcrystalgrowthandhavingimplicationsonsolid-liquidseparation.Inbatch systems,residencetimeisanimportantfactorneededforestablishingbatchcycletimeanddeterminingcapacityoftheunit.

Oftenacrystallizersystemwillcomprisemorethanonecrystallizerstage.Multiplerecoverystagesmightbenecessary toachievethetargetyieldswhilelimitingtheslurrydensitytoamanageablelevel.Thus,additionalcoolingorevaporation willbeconductedinsubsequentstagestorecoveradditionalcuts(crops)ofcrystals.Thiscaseusuallyoffersanopportunity forheatintegrationamongstages.Similarly,crystalpurityrequirementscannecessitateadditionalpurificationstages, knownasrecrystallization.Recrystallizationconsistsofdissolvingcrystalsbackintosolutionsotheycanbecrystallized againtofurtherrejectimpuritiesandimprovequality.

Recycleiscommonincrystallizationandisprimarilyusedtoenablehigheryields.Itisoftenagoodsolutionwhenone ormoreofthefollowingsituationsapply:

l Thetargetforproductrecoveryisveryhigh.

l Solubilityofthedesiredcomponentinsolutionishighenoughthatitcannotberecoveredatpracticaloperatingconditions(temperatureorpressure).

l Theavailableutilitiesrestricttheoperatingconditionssuchthatvacuumisnotlowenoughorthecoolingwatertemperatureisnotlowenoughtoreachthetemperaturesneededtorecoverthetargetamountofproduct,orsteamlimitations resultininadequateevaporation.

l Thesolutionissubjecttodegradationatthetemperaturesneededforfurtherconcentration(whenevaporationisused).

Thedrawbacksofrecycleincludetheneedforlargerequipment(toprocessthehigherfeedrateswhilemaintainingadequateresidencetime)andthepotentialnegativeeffectonqualitysincetheimpurityconcentrationswillincrease.Apurgeis necessarytopreventimpuritiesfromcontinuingtobuildupinsolution.

Atthelaboratoryscale,recyclecanbedifficulttostudy.Atthelabstageofprocessdevelopment,testsarefrequently conductedwithastep-by-stepapproachinwhichthevariousstagesarerunindependently.Moreover,truecontinuousoperationisoftenimpracticalatverysmallscalesbecauseofthedifficultyincontrollingverysmallflowratesandmaintaininga

FIG.1.3 DTBcrystallizerwithanelutriationleg.

balancedsysteminventory.Forcrystallizationinparticular,smallcontinuouslabunitsusingsmalltubingdiameterandlow slurryflowratesarepronetoplugging.Thus,recycleisbestdevelopedinthepilotplant,whereoperationsaremorerepresentativeofacommercialprocess.

Anotherimportantaspectofdesigningacrystallizersystemissolid-liquidseparations.Filtrationorcentrifugationare typicallyused,andthechoiceoffilterorcrystallizerdesignwilldependonmanyfactors.Crystalsizeandshape,density, slurrythickness,andrequireddrynesswillallbeconsidered.Goodseparationefficiencyisneededtoprovideadequate productpurity,dryness,andyield.

Laboratoryscalevacuumfilters,pressurefilters,andbasketcentrifugesareavailableandaregoodchoicesforpreliminarytesting.However,thesearenotrepresentativeofcommercialequipment.Theytypicallyonlyoperatebatchwise,and theG-force,pressure,orvacuumconditionscommonlyusedinalabsettingareoftenimpracticalatlargescale.

Typically,5–10wt%ofmotherliquorisretainedonthecrystals,andsomesolidsretainsignificantlymore.Sinceseparationefficiencyisnever100%,washingthecrystalsistypicallycarriedouttohelpremoveimpuritiespresentinthe residualmotherliquor.Mostoften,thewashmediumwillbethesamesolventascontainedinthefeed.Extensivewashing canresultindecreasedrecovery,particularlyiftheproductishighlysolubleinthewashsolvent.Therefore,thequantityof washwatershouldbelimitedtotheminimumamountneededforproducingacceptablequalitycrystals.Tomitigatethis loss,usedwashwater(orotherwashsolutions)canberecycledbacktothecrystallizers.Sometimesanotherliquidinwhich thesubstanceisrelativelyinsolubleisusedforwashingtopreventdissolution,butthistypicallyrequiresasolventrecovery unitwhichaddscostandcomplexity.Solid-liquidseparationandwashingoperationsarealsobeststudiedinthepilotplant whentheequipmentdesignsaresimilartothatofacommercialplantandthematerialbalancehasbeendefined.

1.1.3Upstreamvariablesaffectingcrystallization

Mostunitoperationsaredesignedtooperateproperlywithinalimitedrangeofconditionsandwhensystemvariablesdrift outsidethatrange,itcanbedetrimentaltoperformance.Crystallizationisnoexception.Thepotentialforupstreamvariationsshouldbeunderstoodandconsideredinthedesignphase.Someflexibilityindesignmaybefeasible,butoperating constraintswillneedtobeestablishedtoensureacceptablesystemperformance.Anychangeinthefeedthatentersacrystallizercanpotentiallyimpactthecrystallizeroperation.Feedpropertieslikefeedrate,soluteconcentration,impurityconcentration,viscosity,andtemperaturecancompromiseoperationandaffectproductyield,capacity,andquality.

Generally,abatchsystemismoreflexibleandcanbetteradjusttochangesinthefeed.Acontinuoussystem,however,is intendedtooperateatsteadystateoveranarrowrangeofconditionsandisnotabletotoleratesignificantvariationsinits feedcompositionorotherproperties.Manysystemsareverysensitivetothesechangesanddeviatingfromthestandard operatingwindowcanhaveasevereimpact.Specialaccommodationsshouldbemadetoeitherminimizechangesordesign thesystemtohandlevariability.Processcontrolstrategies(Zhangetal.,2014)oradditionalprocessingstepscanbeimplementedtoassurethesystemoperatessmoothly.

Inthelaboratorysetting,range-findingexperimentscanbeconductedtogaininsightregardingacceptablerangesof operation.Later,whenmultipleunitoperationsareintegratedinthepilotplant,itbecomesfeasibletoassessthenatural extentofvariation,evaluatemitigationmethods,andultimatelydemonstratethatconsistentperformancecanbeachieved. Ataminimum,therangesoffeedrates,composition,andtemperatureoftheincomingfeedmustbeknownandaccounted forinthecrystallizerdesign.Asnotedabove,achangeinfeedrate(throughput)caneasilyupsetacrystallizationsystem.Feed ratechangescanoccurwhenthereareinterruptionsorbottlenecksupstreamandmustbeplannedforinadvance.Iffeedrate increasesandthesystemdoesnotadjust,theresidencetimewillbereduced,andcrystalgrowthcanbehindered.Supersaturationwillrise,andalthoughthegrowthratewillincrease,theincreaseinnucleationrateisexpectedtobegreater(Ny ´ vlt, 1992).Evaporationorcoolingcapacitymightbeinadequate,andthiswillbereflectedintheslurrythicknessandproduct yield.Insufficientslurrythicknesscanimpactcrystalgrowth,favoringnucleationratherthangrowth.

Conversely,areductioninfeedrateistypicallyeasiertomanagebutwillresultinhigherresidencetimeifnoadjustment ismade,whichmayormaynotbeacceptable.Operatingwithsignificantturndowncanbedifficult.Loweringtheliquid leveltomaintainanappropriateresidencetimemightbeagoodwaytomanageareducedfeedrate,dependingonthe crystallizertype.Shuttingdownacontinuouscrystallizershouldbeavoidedwheneverpossible,sinceittakessignificant time( 10residencetimes)toreachsteadyoperationuponrestart.Surgetanksmightberecommendedtoprovidemore flexibilityinmoderatingswingsinfeedrates.

Onecanenvisionmanyscenariosinwhichfeedconcentration(i.e.,soluteconcentration)mightvary,suchaswhenthere isadisturbancethatcauseslowerselectivityinanupstreamreactionstep.Feedconcentrationcanaffectoperationinseveral ways.Incrementalincreasesinfeedconcentrationcanpotentiallyincreaseproductyield.However,asconcentrationrise becomesgreaterandexceedsthelimitsofthecrystallizerdesign,itispossibleformanyproblemstooccur.Risingconcentrationwillincreasesupersaturation,affectingparticlenumberandsize.Asnotedabove,assupersaturationincreases,

growthratewillincreasebutisunlikelytocompensatefortheincreasednucleationratesothatmore,smallerparticlesare produced.Incrustations(harddepositswhichformonthecrystallizerinternals)canoccurduetohigherlevelsofsupersaturation.Slurrythicknesswillincreaseandcouldcreatemixingorpluggingissues.

Ingeneral,theslurrythicknessshouldbelimitedtoaround20–35wt%ofsolids.However,DTBcrystallizerscanhandle somewhathigherslurrythicknessofupto25%–50%(Genck,2011).Thisrestrictionfrequentlyrequiresthattheproductis recoveredinmultiplestages.Thenumberofstagesofrecoveryisdeterminedprimarilybasedontheslurrythicknessthat canbepracticallyhandledand,toalesserextent,ontheamountofrecyclethatisacceptable.Recyclingsaturatedmother liquorcanhelpmanagefeedconcentrationandslurrythicknesstosomedegreebutwilldriveupthecrystallizersize requirementandincreasethelevelofimpurities.

Inotherinstances,changesinimpurityconcentrationscouldoccur.Switchingtofeedfromanewsupplier,processinga differentbatchoffermentationbroth,chargingnewcatalyststoupstreamreactors,orcyclingofreactionconditionsareall plausiblescenariosforcausingchangesinimpurities.Changesinimpurityprofilescanaffectthesize,shape,andmost notably,thepurityofthefinalcrystals.

Theprimarymethodbywhichimpuritiesareincorporatedduringcrystallizationisviaadsorptionofresidualmother liquor.Inthiscase,increasedwashingisusuallyaneffectiveremediationstrategy.Incontrast,impuritiescausedbyocclusionsorinclusionscannottypicallyberemovedviawashing.Occlusionstypicallytraponly <5wt%ofmotherliquor,but whenimpurityconcentrationsrise,thiscanhaveasignificantimpactonfinalpurity(Urwinetal.,2020).Inclusionsareless commonduetothelimitationoffittingaforeignmoleculeintoacrystallatticebutcanoccurwhenimpuritieshavesimilar structuresandchargesastheprimarysolidproduct.Bothocclusionsandinclusionscausesurfacedefectsthatcanalter crystalsizeandmorphology.Reducingsupersaturationandslowingdownthegrowthratecanhelpminimizethesetypes ofimpurities.

Itisdifficulttoanticipatetheeffectofvariousimpuritiesonthecrystalqualityandmorphologywithoutconducting carefulstudies.Partitioncoefficientsofkeyimpuritiescanbedeterminedexperimentallyandcanhelpspecifythe acceptablerangesthatcanbetoleratedintheincomingfeed.

Temperatureisanothercriticalconditionthatmustbedefinedfortheincomingfeed.Feedliquormustbeheldatseveral degreesaboveitssaturationtemperaturetopreventcrystallizationinthefeedline.Insulationofthefeedlineisusually recommended,andheattracingmayberequiredinsomecases.

Maintainingtheenergybalanceofthesystemisessentialasitimpactstheproductionrateandsupersaturation.Crystallizercontentsheatingorcoolingmustbedoneinsuchawayastominimizesupersaturation.Forsurfacecoolingand indirectcoolingcrystallizers,heatexchangersmustlimitthe DTtoonlyafewdegreestopreventhighsupersaturationand incrustations.Forevaporativecrystallizers,thetemperatureincreaseshouldbekeptlowforsimilarreasons;highsupersaturationataboilingsurfacecancauseflashingandentrainmentandwillcontributetoscaling.

Moreover,viscosityisafunctionoftemperature,aswellascomposition,concentration,andslurrydensity.Theviscosityofthecrystallizercontentsinfluencesthehydrodynamicsandmasstransferandhasconsequencesforthegrowth kinetics.Highviscositycanalsointerferewithnucleation.Growthwillbeslowerasviscosityincreases,soresidencetimes needtobelongerandparticlesaregenerallysmaller.Forced-circulationcrystallizersandscraped-surfacecrystallizerscan begoodchoicesforprocessinghighviscosityslurries.

Inadditiontodesigningarobustcrystallizersystemthatcanadjusttochanges,variousupstreamcontrolstrategiescan beimplementedifsignificantexcursionsinfeedconditionsareanticipated.Surgetankscanhelpmanageshort-terminterruptionsandsmoothoutfluctuationsinfeedcompositionandconcentration.Preconcentrationordilutionmightbenecessarytoprovideamoreconsistentfeedconcentrationandensuresteadystateoperationsinthecrystallizer.Finally,if highlevelsofimpuritiesareaconcern,distillationmightbenecessarytoproduceafeedthatisamenabletocrystallization.

1.1.4Impactondownstreamoperations

Theperformanceofthecrystallizersetstherequirementsfordownstreamoperations.Solid-liquidseparation,drying,solids transport,anddissolutionarealldirectlyaffectedbytheCSDandothercrystalproperties.

Solid-liquidseparationprocessesarequitesensitivetothepropertiesofthesuspension.Inparticular,theparticlesize, sizedistribution,andmorphologyofthecrystalsareofgreatconsequencetotheperformanceofcentrifugesandfilters, commonchoicesforcrystallizationprocesses.Theabilityforthemotherliquortodrainorseparatefromthesolidsdepends onthesizedistributionandthetendencyforpackingoftheparticles,theviscosityoftheliquid,thedensitydifference betweensolidandliquidphases,theparticles’surfacepropertiesandinteractionswithsurroundingfluid,andthemethod ofseparation.Solidspackingdensity(compressibility)dictatesporosityofthecakeandisakeyconcerninsolid-liquid separations.Withregular-shapedparticles,andparticleswithaCSDthatallowstightpacking,permeabilitybecomes lowsuchthatmotherliquorremovalisimpeded.Thesepointsregardingdewateringalsoapplytothewashingstep,which