Industrialscale-upcontent andcontext

1.1Purposeandset-up

Thisbookismainlymeantforindustrialprocessinnovators.The methodsandguidelinesprovidedfortheminthisbookservethreepurposes. Thefirstpurposeistoprovideguidelinessothatprocessinnovationprojects canbeturnedintosuccessfulcommercialscalestart-ups,ratherthanfailures. Thesecondpurposeistoobtainthebestprocessconceptintermsofeconomicsandothercriteria,sothatthenewprocessisacceptedbysociety andiscompetitiveinthemarket.Thethirdpurposeistoprovideguidelines tohaveinnovationprojectexecutionsthatarelowestincostandin elapsedtime.

Theneedforthisbookismainlybasedonthestatisticsthat50%ofnovel processintroductionsaredisasters(Bakkeretal.,2014).Adisaster,here,is definedashavingmorethan30%costgrowthbeyondthebudgetandmore than38%scheduleslippage.Thestatisticshavebeengatheredfromover 12,000projectsfromallkindsofprocessbranchesbyIndependentProject Analysis(IPA),asreportedby Bakkeretal.(2014).Also,mega-scale projectsoftenfail,asreportedby Merrow(2011) and Lager(2012).Several projectshadnotreacheddesigncapacityeven5yearsafterthebeginningof thestart-up.

Theeffectsofacommercialscaleimplementationfailureforacompany canbeenormous.Itisnotonlytheadditionalcapitalinvestmentneededand therevenuelosses,butalsothelossoftrustofclientsthatthecompanyfaces regardingdeliveringtheirproductsaspromised.Italsomeansthelossoftrust oftopmanagementintheinnovationpowerofthecompany.Thiscan stronglyaffectthebudgetforfutureprocessinnovationprojects.Alsofor technologyproviders,animplementationfailurecanhavealargenegative effectonfuturesales.

Theset-upofthisbookfollowsthestage-gateapproach.Thestagenames areobtainedfrom Harmsen(2018).Forthefirststage,discoveryandconcept methodsandguidelinesarepresentedthatensurethatthebestconceptis identifiedandselected.Inthesubsequentstages,methodsandguidelines arepresentedtoreducetheriskofimplementationtosuchalowlevelthat start-upcostandstart-uptimesstaywithinthebudget.

Becausepartoftheinnovationprojectfailuresisduetotakingshortcuts oftheavailableguidelines,pitfallwarningsareaddedateachstage-gatechapter.Throughoutthebookstartingwith Section1.3.3,itexplainsandshows whyprojectinnovationshortcutsnearlyalwaysendincommercialdisasters.

Thenatureofthisbookisprescriptiveandnotdescriptive.Theguidelinesandmethodshavebeenprovenorareplausible.Theseguidelinesand methodscanbeusedtogenerateessentialdesigninformation,toassessrisks andtomitigateriskstosuchalowlevelthatcommercialimplementationis successful—andtheinnovationpathwayisrapidandefficient.Thisbookalso providesrealindustrialinnovationcaseswithadditionallearningpoints.The bookisadescriptionofanindustrialbestpracticeforscale-up.“Anindustrial practiceisacooperativehumanactivityinwhichdifferentprofessionaldisciplinesworktogethertodevelop,produceandsellaproduct”(Verkerk etal.,2017).Majorprofessionaldisciplinesinvolvedinspecificinnovation stagesare,therefore,mentioned.

Thebookisintendedforindustrialprocessresearchersanddevelopersof processindustrybranches.Specialattentioninthisbookisgiventopharmaceuticalandfinechemicalprocessesforeachinnovationstage.Furthermore, itwillbeofuseforcontractresearchersandtechnologyproviderstoseehow andwhentheycaninteractwithprocessindustrymanufacturersandengineeringcontractors.

Thebook,however,doesnotcontaindescriptionsonhowtomanage andorganiseindustrialresearch,development,design,andprocessengineering.Italsodoesnotcontaindetailedprocessdesignguidelinesforthecommercialscaledetaileddesign.Forthat,thereaderissuggestedtoreferother booksonindustrialmanagementandprocessengineeringsuchas Harmsen (2018), Bakkeretal.(2014), DalPont(2011a,b),and Lager(2010)

1.2Scale-updefinitionmethodologyandrisks

1.2.1Scale-updefinition

Often,thetermscale-upisusedtosimplystatethatalargerproduction capacityisemployed,withoutanyreferencetowhetherthisscale-upwas

successfulandhowthisscale-upwasachieved.Toalsoincludetheseelementsofscale-up,weusethefollowingdefinitioninthisbook:

Processscale-upisgeneratingknowledgetotransferideasintosuccessful commercialimplementations.

Knowledgegenerationinvolvesliteraturereading,consultation,experimenting,designing,andmodelling.Themainpurposeofthisknowledge generationistobeabletoassessrisksandtoreduceriskstoacceptable levelsforthesuccessfulcommercialscaleimplementation.Theword “ideas”isstatedinthisdefinitionratherthan“concepts”,asconceptgenerationfromideasisalsoconsideredpartofthescale-up.Also,theterm“scaleupfromlaboratoryscale”isavoidedaslaboratoryexperimentsarealsopartof thescale-upknowledgegeneration.

Successfulimplementationmeansthatthecommercialscaleprocess meetsthedesigntargetswithintheplannedstart-uptime.

Thepurposeofindustrialprocessscale-upisthenmainlyriskreduction neededforsuccess.Forpeopleworkingintheprocessindustries,thisisa nearlytrivialstatementandMerrow’sbookonindustrialmegaprojects, basedonmorethan1000industrialcases,provesthat,indeed,indirectcommercialimplementationwithoutproperindustrialresearchanddevelopment,therisksoffailurearealwaystoohightotake(Merrow,2011).

Formostacademics,however,thisstatementisnottrivialatall, becauseintheacademicworldthepurposeofresearchistogenerate understanding,knowledge,andtheor y.Theword‘risk’doesnotenter inresearchpapersaboutprocessinnovationandisalsonotfoundinprocessinnovationbooks. Jainetal.(2010) donotcontainanydescriptionof agoalforinnovation. Vogel(2005) and Betz(2011) onlystatethatthe goalofindustrialresearchanddevelopmentistoachievecompetitive advantages.

1.2.2Scale-upmethodology

Thescale-upmethodologyofthisbookisbasedonknowledgegeneration forriskidentification,riskassessment,andriskreduction.Riskidentification ofanewprocessconceptisalreadyverydifficult,becausenotallrelevant informationwillbeavailable.Ifacertainpieceofinformationisnotavailable,thenitmaybeidentifiedasanunknown.Butforcertainriskseventhat informationmaybelacking;Ievendon’tknowwhatIdon’tknow. Table1.1 showsthesetwodifferenttypesofknowledgegaps,theirassociated risksandinformationplanstoclosetheknowledgegaps.

Table1.1 Typesofknowledgegaps,risks,andknowledgegenerationplan

KnowledgegaptypeRisktype

Knowledge generationplan

IknowwhatIdon’tknowSpecificandlimitedSpecificresearch Idon’tknowwhatIdon’tknowUnknownIntegratedprocesstest

Riskidentificationis,therefore,carriedoutseveraltimesduringthe innovationproject.Eachtimemoreinformationhasbeengenerated,more risksitemswillbeidentifiedandconsequentlyriskassessmentwillimprove. Iftherisksaretoohigh,riskreductionplanswillbemadeandexecutedinthe nextinnovationstage.TheriskdimensionsenvisagedareSafety,Health, Environmental,Economical,Technical,andSocial(SHEETScriteria definedin Harmsen,2018).Themethodologyfocuses,furthermore,on guidelinesandmethodsthatarecost-effectiveandefficient.Theeffectivenessisobtainedbyprovidingguidelinesonprojecttargetandconstraints.

1.2.3Stage-gateinnovationmethod

Innovationisdefinedhereasprojectmanagementfromideatocommercial implementation.Theinnovationeffectivenessandefficiencyareobtained bythestage-gateapproachdescribedby Harmsen(2018).Thismeansthat potentialfailuresfortheprojectarediscoveredasearlyaspossiblewithlittle effortand,iftheycannotbecorrected,theprojectstops.Forthestructureof thisbook,weusethemostelaboratestagenomenclaturemostlyusedforthe chemicalssectorasagenericstructure:

•Discovery

•Concept

•Feasibility

•Development

•Detaileddesign(includingprocurementandconstruction)

•Start-up

OtherindustrysectorssuchasfoodandOil&Gashavedifferentstagenames, butthestagesequenceandcontentareverysimilar.Theseare,therefore, easilytreatedinthisbookusingthegenericstructure.

Forthefoodsector,thestagesare(Verver,2018):

• Orientation:ideaandconceptgeneration

• Creation:processdevelopment:lab-scale,bench-scale,pilotplant

• Preparation:engineering,construction,commissioningstart-up

• Implementation:commercialproduction

FortheOil&Gassector,thestagesare(Bos,2014):

•Discovery

•Development

•Demonstration

•Deployment

Forpharmaceuticals,thestagesinvolved,obtainedfrom Levin(2006) and Kane(2016),are:

• Discoverystage:Thenewmoleculeisassessedonitsactivity.

• Pre-clinicalstage:Thenewactivemolecule(product)isdefined.

• ClinicalphaseIstage:Thenewproductanditsformulationaremadeina small-scalepilotplantfortests.

• ClinicalphaseIIstage:Thenewproductismadeinintermediatescalepilot plantforfurtherclinicaltesting.

• ClinicalphaseIIIstage:Newproductismadeatlargerscaleplantforstudieswithmanypatients.

• Approvalstage:Theproductisapprovedbytheregulatorybodyanddecisionforcommercialscaleproductionistaken.

• Manufacturingstage:Thenewproductisproducedandsold.

Specialattentionispaidineachchaptertoprocessinnovationstepsforall industrysectorsandtoprocessinnovationforpharmaceuticalindustry. Section4.7treatshowandwhentoconsiderprocessoptionsforthat industrysector.

Hereisabirds-eyeviewofgenericstagesandtheircontent.Inthediscoverystage,aproofofprincipleexperimentiscarriedoutatlaboratory scale.Intheconceptstage,onlyinformationisgeneratedforafeasibleprocessconceptdesign.Inthefeasibilitystage,acommercialscaledesignanda down-scaledpilotplantdesignandcostingaremade.Dependingonproductionscaleandoverallcomplexityofarespectiveindustrialprocess,onecan differentiatebetweenadedicatedintegratedpilotplantorpilotingofindividualunitoperations.Inthestage-gate,adecisiontoinvestinthepilot plant,giventheeconomicprospectofthecommercialplant,ismade. Theimplementationstageinvolvesdetailedengineering,procurementof equipment,construction,commissioning,andstart-up.

Forade-bottleneckingproject,itisadvocatedtoalsofollowallinnovationsteps,ratherthandirectlystartwiththeendofthedevelopmentstep; definingthefront-endloadingforthenextstep.Bystartingwiththediscoverystep,variousde-bottleneckingoptionsareconsidered.Intheconcept stage,thebestoptionsaredefinedandthebestselected.Inthefeasibility stage,thebestoptionisworkedoutinadesign,evaluated,andallrisks

areconsidered,andinthedevelopmentstage,somenewaspectscanbetested. Theseextrastepsmaytakeafewweekstoafewmonths,butwillimprovethe qualityofthede-bottleneckingprojectconsiderably.

Ineachsubsequentstage,moreinformationisgenerated,risksare moreclearlyidentified,andmorerobustlymitigatedtoacceptablelevels. Ifatanystage-gatetherisksareestimatedtobetoohigh,orthecostoffurtherdevelopmentishigherthanthefinalbenefitsofcommercialoperation, thentheprojectisstopped,sothatonlyasmallamountofmoneyislost.In thisway,innovationisnotonlyeffectivelybutalsoefficientlyexecuted. Thisstage-gateapproachfacilitates,furthermore,communicationabout thestatusoftheinnovationtointernalandexternalstakeholdersandto externalinnovationpartners.

1.2.4Scale-upanddesignrole

Makingdesignsplaysaroleineachinnovationstage.Makingadesignfirst revealsknowledgegaps,whichleadstoaplantofillthegaps.Second,the designresultisacommunicationmeans,asitshowswhattheinnovation isabout.Foreachinnovationstage,asectionondesignwill,therefore,be included.Asthestagespromote,thelevelofdetailinthedesignsincreases aswell.

1.2.5Scale-upbehaviourandrisks

Thissectionprovidessometechnicalinsightwhyprocessscale-upsoeasily goeswrongwhencriticalsuccessfactorsforscale-upinresearch,development,anddesignarenotfulfilled.Theinsightisprovidedbythefollowing aspectsofnewprocesses:

A: Chemicalreactivity,includingcorrosionrates,caneasilyvarybya factor109 bysmallchangesin,forinstance,watercontent,traceamounts oforganicacids,halides(chorine),ormetalions.Thesetracecomponentsmaybeinthefeedstotheprocessorformedintheprocess. Theeffectofthesecomponentscanberapidcorrosion,foaming,and/ orfouling,causingtheprocesstofail.Thisbehaviourmaynotshow upinlaboratorytestswithpurefeedstocksandshorttestdurations.

B: Thenumberofparametersinaprocesseasilyexceedsa100.The combinedbehaviourofsmallchangesinparametersoftencannotbe predictedwellbymodels,e.g.duetotheirstrongnon-linearinteractive behaviourandthelackofthermodynamicandphysicaldatatosupport thecomputationalmodels.

C: Dynamictimescalesforcomponentstobuildupintheprocesscanbe verylong,intheorderofmonths,inparticularwhenrecyclestreamsare involved.Thesebuild-upswillnotshowupinshortdurationlaboratory scaletests.

D: Thehydrodynamicbehaviourandtheireffectonmasstransfer,heat transfer,mixing,andresidencetimedistributionoftenchangewith scale-up,causingapoorperformanceofreactors,heatexchangers, andseparators.

E: ThecombinedeffectofA,B,C,andDcannotbepredictedby models.

AspectsA–Caredealtwithin Chapters2and3.AspectsDandEaretreated in Chapters3–5 1.3Processindustrysystems

Valuechainsarestringsofintermediateproductmassflowconnections betweencompaniesandthefinalconsumers.Eachcompanyaddseconomic valuetothemassflows.Thesevaluechainsfromnativefeedstocktoconsumerproductscanbeshortandinvolveonlyafewbranchessuchasinbasic foodproducts.

Itcanalsobeverylongsuchasinconsumerfoodproductsmanufacturedfrommultipleingredients,suchasinfantformula,orinconsumables(e.g.soap),wherethestepsinvolvecrudeoilrefining,steamcracking, higherolefinconversiontoalcohol,andthenblendingwithfragrancesand otheradditives,eachwiththeirownsupplychain.

If,forinstance,thecrudeoilfeedstockischangedintoarenewablefeedstock,theningeneralthisalsomeansthatnewconnectionsbetweenindustry branchesmustbenegotiated.Thesameholdswhenanewproductforanew marketisdeveloped.However,newproductdevelopmentisoutsidethe scopeofthisbook.

Innovationinvolvingnewpartnerstakes,ingeneral,considerabletimeas companiesthathithertohadnocontactandhavetheirownvocabularynow mustlearntocommunicate.Thelargestmiscommunicationsoccurwhen bothusethesameterm,butmeantotallydifferentthingsaboutit.

Anexamplefrommyownexperienceisofthetermscale-up.Inajoint researchprogrammeforanewprocessofapetrochemicalcompanyanda pharmaceuticalprecursorproductioncompany,wediscussedthenextstep aftertheresearch.Thepetrochemicalcompanyconsideredthescale-upabig

stepinvolvingmanyyears.Thepharmaceuticalprecursorcompanyconsideredthisasmallstep.Afteralongdiscussion,thepetrochemicalcompany said:“Butscale-upinvolvesdesigningandbuildingapilotplant”,upon whichtheothercompanypeoplesaid:“Wealreadyhavethepilotplant”. Thenitbecameclearthatbothusedtheword“scale-up”,buttheymeant differently.

Thetermlifecycleis,ingeneral,usedincombinationwiththeword analysisorassessment.Inlifecycleassessment(LCA),allprocessstepsfrom nativefeedstocktodestinationsuchaswasteincineration(calledcradle-tograve)ortoendofcyclerecycleandreuse(calledcradle-to-cradle)aretaken intoaccountandalsoallmassinputsfromnatureandallmassoutputsto nature.Thedifferencesbetweenlifecyclesandvaluechainsarethat,firstly, lifecyclesareaboutallmassflowsrelatedtoallsteps,whereasvaluechainsare abouteconomicallyaddedvaluesbyeachstepand,secondly,thatlifecycle assessmentisusedtodeterminethetotalenvironmentalimpactofaproduct overthewholelifecycle.

1.3.2Industrialcomplexes

Inindustrialcomplexes,manyprocessesareconnectedinmanyways.Often, processesareownedbydifferentcompanies.Thecomplexesoftencontaina crudeoilrefinery,asteamcracker,producingolefinsfromasidestreamof theoilrefinery,andseveralchemicalprocessesconvertingolefinstochemicalintermediateproductssuchaspolymers,solvents,resins,andothers.The processesareconnectedwithmanydifferentstreamstoeachother.Inthe Rotterdamindustrialcomplex,forinstance,anintermediateproducer Huntsmanisconnectedwith18differentstreamstotheotherplantsin thecomplex(Harmsen,2010a).

1.3.3Processes

Thesimplestdefinitionofaprocessisasystemofconnectedunitoperations thatconvertsafeedstockintoaproduct.

Formostapplications,bothfeedstockandproducthaveclearspecificationsandcanbeboughtandsoldonthemarket.However,manyproducts mustmeetperformancespecifications,e.g.nutritionalvalueoftaste.For thoseproducts,anewprocessalsomeansextensiveproducttestingtoensure thattheproductisacceptedbythemarket.Evenforanewprocessforan existingspecificationproduct,someproducttestingbytheclientswillbe needed.Specificationsdonotcompletelydefineaproduct.Newtracecomponentsmaybepresentintheproduct,forwhichnospecificationhas

yetbeendefined.Theclientmayalsohaveexpectationsfromtheexisting product,whicharenotdefinedbythespecification,suchasdescribedin Section8.1.

If,also,theproductisnew,thenproductdevelopmentisneeded.How toexecuteacombinationofproductandprocessinnovationisgivenindetail by Harmsen(2018).

1.3.4Unitoperations

Processtechnologiesofalltheseindustrieshaveincommonthefactorthat theyarebasedonclassicunitoperations.Eachprocessconsistsofoneor moreunitoperations.Eachunitoperationhasitsowngenericknowledge baseofacombinationoftransportphenomenaofmassandheatandmomentumandtheircorrespondingthermodynamics.Incaseofreactors,chemical conversionisaddedtothesephenomena.

Unitoperationsbasedonfluidmechanicsincludefluidtransport(suchas pumpingandpipe-flow),mixing/agitation,filtration,clarification,thickeningorsedimentation,classification,andcentrifugation.Operationsbased onheattransferincludeheatexchange,condensation,evaporation,furnaces orkilns,drying,coolingtowers,coolingandevaporativecrystallisation,and freezingorthawing.Operationsthatarebasedonmasstransferinclude distillation,solventextraction,leachingandabsorptionordesorption, adsorption,ionexchange,humidificationordehumidification,gaseousdiffusion,crystallisation,andthermaldiffusion.Operationsthatarebasedon mechanicalprinciplesincludescreening,solidshandling,sizereduction/ grinding,flotation,filtration,andextrusion.Designmethodsfortheseunit operationscanbefoundinhandbookssuchasPerry’sChemicalEngineeringHandbook.

Formostcommercialscaleunitoperationsconcept,designcomputer packagesareavailableinso-calledflowsheetcomputerprograms.Scaleupoftheseunitsstill,however,hasrisksiftheunitoperationhasnotbeen appliedatcommercialscaleforthatapplicationand,inmostcases,pilotplant developmentisrequiredtovalidatethedesignmethodsappliedandtoidentifytheunknown-unknownstotheextentpossible. Chapter4 provides methodstodecideonwhetherapilotplantisneeded.

1.3.5Majorprocessequipment

Eachunitoperationconsistsofacombinationofmajorprocessequipment connectedbypipesandflanges.Adistillationunitoperation,forinstance, willconsistofacolumnwithinternals,aheatexchangeratthetopand

thebottom.Itmayhavepumpstocirculatethefluidflowsthroughtheheat exchangers.Thesetypesofequipmentarecalledmajorprocessequipment. Atscale-up,majorprocessequipmentwillalsoincreaseinsize.Reliable designandconstructionofthelargescaleisofutmostimportanceforsuccessfulimplementation.

1.3.6Dispersedsystemlevel

Thedispersedsystemlevelisaboutbubblesinaliquid,catalystparticlesina reactor,andotherdispersedphasesinacontinuousphase.Masstransferand mixingareimportantphenomenaatthissystemlevel.Thesephenomenaare veryimportantfortheprocessperformanceandare,ingeneral,scaledependent(andapplication-dependent).

1.3.7Chemistrylevel

Thechemistrylevelisthesmallestsystemscaleofrelevancetoprocesses.At thislevel,chemicalreactionsaredescribed.Often,thesereactionsarefacilitatedbyacatalyst.Thecatalystitselfisconsumedinthisconversion,but enhancesormoderatesthevariousreactionvelocitiesbychangingtheactivationbarriers.Ifthecatalystspeedsupthedesiredreactionrelativetothe undesiredreaction,italsoincreasesthereactionselectivity.Catalyststypicallyareverysensitivetosmallchangesinconditionssuchastemperature andtolowconcentrationsofimpurities,whichmaycomefrominputsto theprocess,fromcorrosionofconstructionmaterials,andfromundesired reactionsinhotareassuchasdistillationbottoms.

1.4Partnersandstakeholdersforinnovation

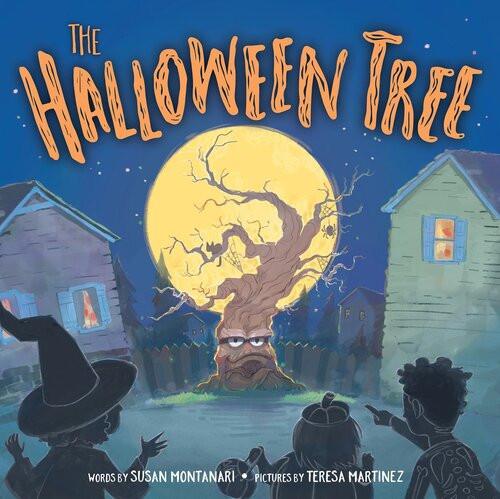

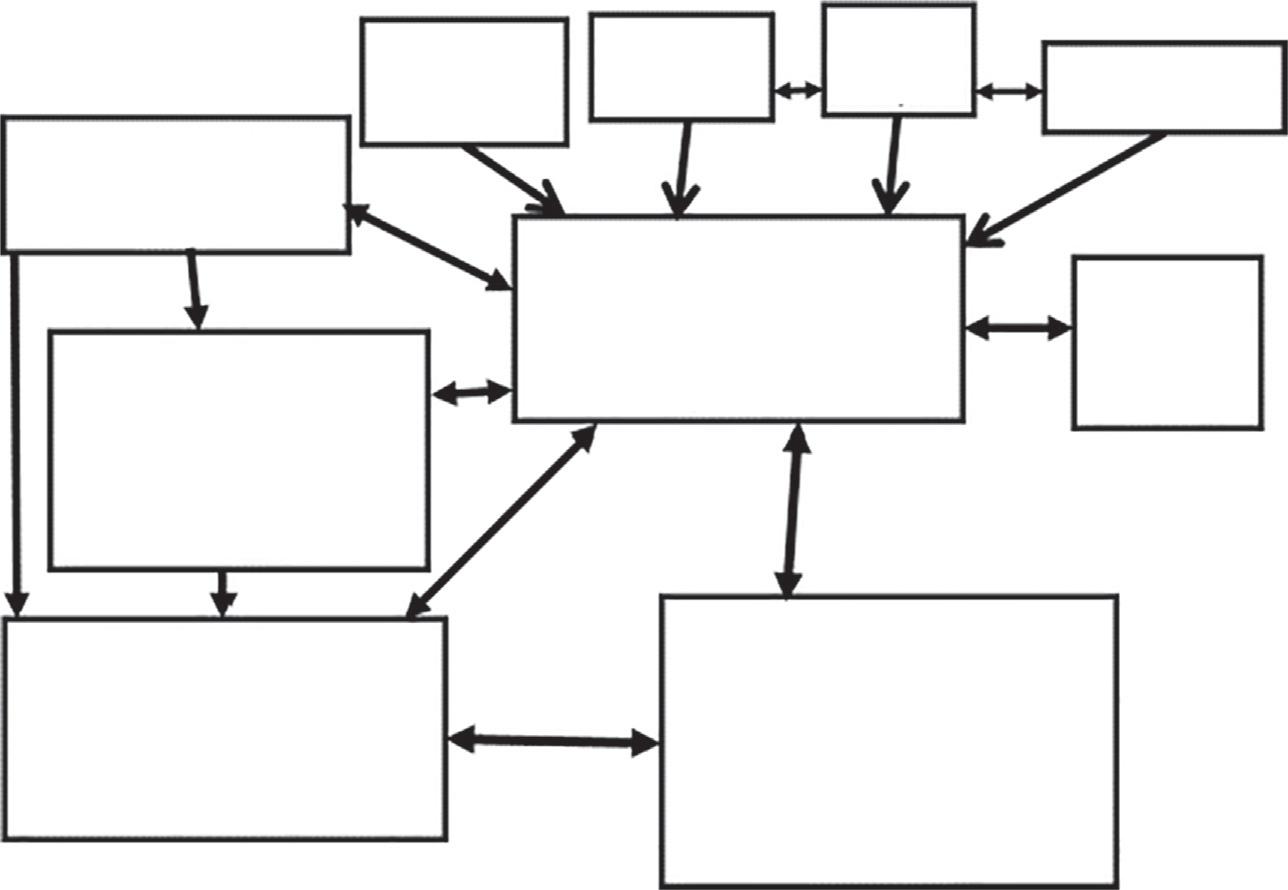

Thefollowingindustrypartnersandstakeholderscanbedistinguished:

Academia Contract Research

Concepts theory New feedstock Publicity Vote complain Laws Process development process design Start-up Operation

Organisations Technology providers

Suppliers NGO Civilians Government Clients Manufacturer

Development test

Experimental tests Pilot plant Critical engineering aspects

Engineering contractors

Detailed design Procurement Construction Dismantling Feedback Stop buying

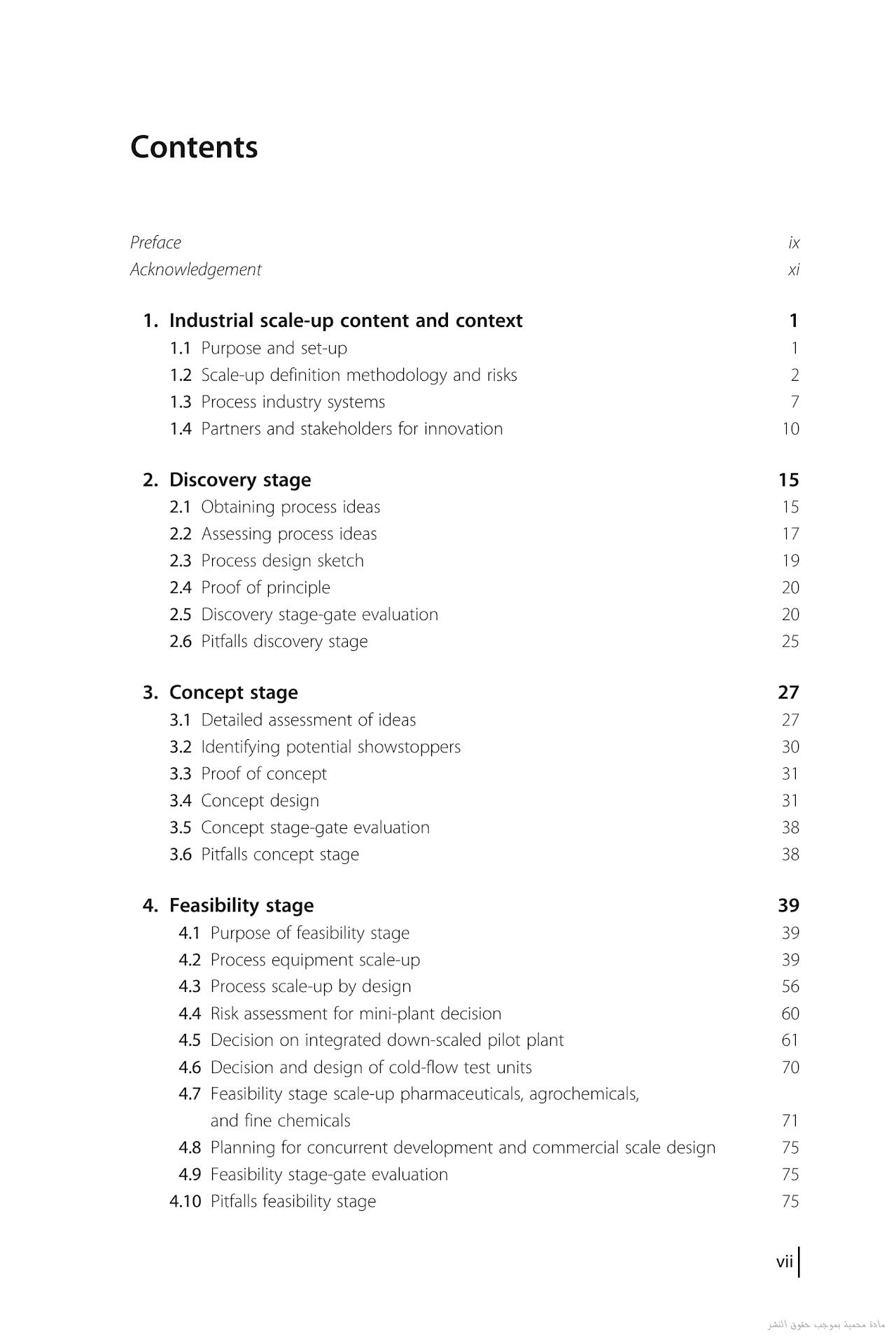

Fig.1.1 Rolesandrelationsinnovationpartnersandstakeholders.

Fig.1.1 showstheirpotentialrelationsinprocessinnovation.Thesepartners andstakeholdergroupswillbeshortlydescribedinrelationtoprocessinnovation.Manufacturersarecompaniesthatconvertfeedstocksfromsuppliersinto productsfortheirclients.Often,thesecompanieshavearesearchanddevelopmentdepartmenttogeneratenewprocesses.Also,employeesdirectly involvedinthemanufacturingprocessareasourceofprocessinnovationideas. Manufacturersintheprocessindustriesareclassifiedintobranches. Themajorbranchesarethefollowing:

-Crudeoilrefining

-Metalorerefining

-Paperandpulp

-Bulkchemicals

-Fineandspecialtychemicals

-Pharmaceuticals

-Food

-Agriculturalproducts(feed)

-Consumables

-Ceramics

Eachbranchhasitsowncharacteristicsintheprocesscapacitiesemployed, thewaytheyoperate,andthewayresearchanddevelopmentarecarriedout.

Duetothesedifferences,technologiesproveninacertainbranchoftenfail whenappliedinadifferentbranch.

Clientsofmanufacturerscanbeindustrialcompaniesorconsumers. Industrialcompaniescaninitiateprocessinnovationatthemanufacturer byaskingforalowercostoftheproduct,oralowerenvironmentalimpact oftheproduct,orbetterproductperformance.Theyarealsoveryimportant stakeholdersinprocessinnovation,asshownintheliquid-liquidextraction caseof Chapter8

Suppliersoffeedstocksare,ingeneral,notsourcesofinnovationat themanufacturer.Butthemanufacturercaninitiateprocessinnovation byaskingasupplierforalowercostorlowerenvironmentalimpact. Innovationswithalarge totaleffectoncostandenvironmentwillmore andmorebecarriedoutbycollaborationsoveralargerpartofthe supplychain.

Governmentcanplayaroleinprocessinnovationbymorestringentlaws onsafety,health,andenvironmentandbysubsidisingprocessinnovation. Civilianslivingnearbytheprocesscanplayaroleininnovationaskingfor asafer,healthier,andenvironmentallyfriendlierprocess.

Non-governmentalorganisations(NGO)canbeasourceofinnovation inthesamewayascivilians.

Technologyproviderscanbeverysmallinnovativefirmsspecialisedin onenovelprocesstechnologyorlargerfirmswithmanyinnovativeprocess technologies.Somehavegoodrelationswithuniversitygroups,providing themwithnewideasfori nnovationstovalorise.Theyoftenhavetheir processtechnologiesprotectedbypatentsandotherformsofintellectual propertyrights,suchascopyrightso ndrawingsandsoftware.Theyprovidethetechnologiestoproductmanufacturersandtoengineering contractors.

Engineeringcontractorsfortheprocessindustriesareoftenverylarge companieswhooftencarryoutcompleteEPC(Engineering,Procurement, Construction)processprojectsformanufacturers,whichincludeprocess design,equipmentprocurement,andconstruction.Theymayhaveaprocess innovationdepartment,butoftentheyhaverelationswithtechnologyproviderstogenerateprocessinnovations.

Contractresearchorganisations(CRO),ingeneral,obtainprocessconceptsfromothers,suchasuniversitiesandmanufacturers,anddevelopprocessestotheendofapilotplantstageortosmall-scalecommercial

implementations.Thedevelopmenteffortmaybepaidbythemanufacturer directly.TheCROcanalsodeveloptheprocessattheirownexpenseand thensellthetechnology(protectedbypatents)tomanufacturers.

Academicresearchoftengeneratesradicallynovelprocessconcepts, oftenontheirowninitiative.Theconceptsareoftenintheembryonicstate. Itneedsotherstoconverttheseconceptsintofeasiblesolutions.