Improvementsin Bio-BasedBuilding BlocksProduction ThroughProcess Intensificationand SustainabilityConcepts

JUANGABRIELSEGOVIA-HERNÁNDEZ

DepartmentofChemicalEngineering,Universityof Guanajuato,Guanajuato,Mexico

EDUARDOSÁNCHEZ-RAMÍREZ

DepartmentofChemicalEngineering,Universityof Guanajuato,Guanajuato,Mexico

CÉSARRAMÍREZ-MÁRQUEZ

DepartmentofChemicalEngineering,Universityof Guanajuato,Guanajuato,Mexico

GABRIELCONTRERAS-ZARAZÚA

DepartmentofChemicalEngineering,Universityof Guanajuato,Guanajuato,Mexico

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2022ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans, electronicormechanical,includingphotocopying,recording,oranyinformationstorageand retrievalsystem,withoutpermissioninwritingfromthepublisher.Detailsonhowtoseek permission,furtherinformationaboutthePublisher’spermissionspoliciesandour arrangementswithorganizationssuchastheCopyrightClearanceCenterandtheCopyright LicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions

Thisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightby thePublisher(otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchand experiencebroadenourunderstanding,changesinresearchmethods,professionalpractices, ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgein evaluatingandusinganyinformation,methods,compounds,orexperimentsdescribed herein.Inusingsuchinformationormethodstheyshouldbemindfuloftheirownsafety andthesafetyofothers,includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,or editors,assumeanyliabilityforanyinjuryand/ordamagetopersonsorpropertyasamatter ofproductsliability,negligenceorotherwise,orfromanyuseoroperationofanymethods, products,instructions,orideascontainedinthematerialherein.

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress ISBN:978-0-323-89870-6

ForInformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: SusanDennis

AcquisitionsEditor: AnitaKoch

EditorialProjectManager: AndreaR.Dulberger

ProductionProjectManager: BharatwajVaratharajan

CoverDesigner: ChristianJ.Bilbow

TypesetbyMPSLimited,Chennai,India

Contents

Authorbiographiesix

1.Whyarebio-basedchemicalbuildingblocksneeded?1

1.1 Arebio-basedchemicalbuildingblocksneeded?1

1.1.1 Drop-inbio-basedchemicals5

1.1.2 Novelbio-basedchemicals5

1.1.3 C6andC6/C5Sugar8

1.1.4 Plant-basedoil9

1.1.5 Algaeoil10

1.1.6 Organicsolutions10

1.1.7 Lignin11

1.1.8 Pyrolysisoil12 References13

2.Processintensificationandsustainability15

2.1 Processintensificationandsustainabilityinbioblocks15 References23

3.Basicconceptsonsimulationof(bio)chemicalprocesses25

3.1 (Bio)chemicalprocesses25

3.2 Conceptofsimulationinbioprocesses(chemical)25

3.2.1 Simulationcategoriesforbiochemicalprocesses26

3.2.2 Processsimulationbiochemicalapplications28

3.3 Conceptofmodelingandtoolsinprocessbiochemicals31

3.4 Theroleofsimulationandprocessmodelingbiochemicals31

3.5 Theroleofprocessoptimizationbiochemicals32 References32

4.Bioethanol33

4.1 Bioethanol33

4.2 Petrochemicalrouteofethanolproduction34

4.2.1 Process,rawmaterial,andkinetics34

4.2.2 Performanceindexintheproductionofethanolthrough petrochemical36

4.2.3 Disadvantagesintheproductionofethanolthroughpetrochemical37

4.3 Conventionalbioethanolproductionprocess37

4.3.1 Rawmaterialfortheproductionofbioethanol37

4.3.2 Productionofbioethanolfromlignocellulosicbiomass39

4.3.3 Advantagesanddisadvantagesofbioethanolproduction44

4.4 Problemsoftheprocessforobtainingconventionalbioethanol46

4.5 Proposalstointensifytheprocessforobtainingbioethanol46

4.5.1 Synthesis47

4.5.2 Design50

4.5.3 Control54

4.6 Conclusions58 References58

5.Biobutanol61

5.1 Generalcharacteristics,uses,andapplications61

5.2 Productionofbutanolfromfossilsources64

5.3 Butanolproductionbythebiochemicalroute66

5.3.1 Metabolicpathwayofacetone-butanol-ethanolfermentation66

5.3.2 Conventionalrawmaterialtoproducebutanol67

5.3.3 Isopropanol-butanol-ethanolfermentation71

5.4 Processintensificationappliedtobutanolproduction72

5.4.1 Processintensificationinthereactivezone73

5.4.2 Processintensificationinthedownstreamprocess79

5.5 Controllabilitystudiesappliedtointensifiedalternativesforbiobutanol purification87

5.6 Conclusions89 References89

6.Furfural95

6.1 Introduction95

6.2 Usesoffurfural96

6.3 Currentfurfuralmarkets98

6.4 Stoichiometricandkineticsmodelsforfurfuralproduction100

6.5 Currenttechnologiesforfurfuralproduction102

6.6 Newintensifiedproposesforfurfuralproduction106

6.6.1 Advancesinfurfuralpurification106

6.6.2 Objectivefunctions110

6.6.3 Optimizationresults114

6.6.4 Advancesinfurfuralpurificationusinghybridextractive distillationschemes117

6.7 Conclusions121 References123

7.Levulinicacid127

7.1 Introduction127

7.2 Currentusesoflevulinicacid129

7.3 Currentlevulinicacidmarkets130

7.4 Kineticsmodelsforlevulinicacidproduction132

7.5 Currentforlevulinicacidproduction133

7.6 Newintensifiedproposalsforlevulinicacidproduction137

7.7 Conclusions144 References144

8.Ethyllevulinate147

8.1 Introduction147

8.2 Currentapplicationsandmarketsofethyllevulinate148

8.3 Kineticsmodelsforethyllevulinateproduction149

8.4 Currenttechnologiesforethyllevulinateproduction150

8.5 Currentadvancesinethyllevulinateproduction152

8.6 Conclusions155 References156

9.2,3-Butanediol157

9.1 Introduction157

9.2 Productionof2,3-BDfromfossilandrenewablesources160

9.2.1 Microorganismsusefulintheproductionof2,3-BD162

9.3 Rawmaterialfor2,3-BDproduction165

9.3.1 Nonrenewablerawmaterials166

9.3.2 Renewablerawmaterials168

9.4 Processintensification(PI)in2,3-BDproduction169

9.5 PIin2,3-BDrecovery170

9.6 Conclusions175 References175

10.Methylethylketone181

10.1 Introduction181

10.2 MEKproduction184

10.2.1 MEKproductionfromnonrenewablesources184

10.2.2 MEKproductionfromrenewablesources185

10.2.3 Productionokmethylethylketonethroughprocessintensified schemes188

10.3 PurificationofMEKthroughintensifiedprocess195

10.4 Conclusionandfutureinsights200 References200

11.Lacticacid203

11.1 Lacticacid203

11.1.1 Usesoflacticacid204

11.1.2 Marketanddemandforlacticacid205

11.2 Chemicalrouteoflacticacidproduction206

11.2.1 Process,rawmaterial,andreactions206

11.2.2 Performanceindexinlacticacidproductionviapetrochemical207

11.2.3 Disadvantagesintheproductionoflacticacidvia petrochemical207

11.3 Conventionalprocessofproductionoflacticacidviafermentation ofbiomass208

11.3.1 Rawmaterialfortheproductionoflacticacidviabiomass209

11.3.2 Lacticacidproductionviabiomass209

11.3.3 Advantagesanddisadvantagesoflacticacidproductionvia biomass212

11.3.4 Problemsintheproductionoflacticacidviabiomass212

11.4 Proposalsforintensificationoftheprocessofobtaininglacticacidvia biomass212

11.4.1 Synthesisanddesign213

11.4.2 Optimization216

11.5 Conclusions224 References224

12.Futureinsightsinbio-basedchemicalbuildingblocks227

12.1 Futureinsightsinbio-basedchemicalbuildingblocks227 References231

Index 233

Authorbiographies

JuanGabrielSegovia-Hernández,Professorin theDepartmentofChemicalEngineeringof UniversityofGuanajuato(México),hasexpertisein thesynthesis,design,andoptimizationofbioprocesses.Hehascontributedtodefiningsystematic methodologiestofound,inacompleteway,optimumsustainableandgreenprocessesfortheproductionofseveralcommodities.Healsoappliedhis methodologiestotheproductionofbiofuelsand biobasedbuildingblocks.Productsofhisresearcharemorethan140papers publishedinhigh-impact-factorindexedjournals,3bookswithprestigious internationalpublishers,and4patentregisters.Inaddition,heactsasa reviewerformorethan25topjournalsinchemicalengineering,energy, andappliedchemistry.Forhispioneeringworkandremarkableachievementsinhisareaofscientificresearch,hewaselectedNationalPresidentof theMexicanAcademyofChemicalEngineering(2013 15)andhasbeena memberoftheMexicanAcademyofSciencessince2012.Healsoisthe AssociateEditorof ChemicalEngineeringandProcessing:ProcessIntensification JournalandChemicalEngineeringResearchandDesignJournal (Elsevier).

EduardoSánchez-Ramírez,Professoratthe DepartmentofChemicalEngineeringatthe UniversityofGuanajuato(Mexico)since2017,has gainedconsiderableexperienceintheareaofsynthesis,design,simulation,control,andoptimization ofchemicalprocesses.Currentlypublishedcontributionsfocusontheproductionofbiofuelsand basechemicalsinthechemicalindustry.Hehas currentlypublishedmorethan35articlesin indexedjournals,9bookchapterswithrenowned publishers,andhasregistered2patents.Heactsasareviewerofindexed journalsintheareaofenergyandchemicalengineering.Heearnedhis PhDsummacumlaudein2017andhisNationalSystemofResearchers Level1,SNIMexicoin2019.HewasGuestEditorof Chemical EngineeringandProcessingProcessIntensificationJournal inMay2020.

CésarRamírez-Márquez,ResearchAssociatein theChemicalEngineeringDepartmentofthe UniversityofGuanajuato,Mexico,holdsanMEng andaPhDfromtheUniversityofGuanajuato, Mexico,underthesupervisionofProf.J.G. Segovia-Hernández.Hisresearchfocusesonsynthesis,design,simulation,optimization,andcontrolof chemicalprocesses.Currentlypublishedcontributionsfocusontheproductionofmaterialsforthe solarenergyindustryandbasechemicalsinthe chemicalindustry.Hehascurrentlypublishedmorethan25journal papers,4bookchaptersandpresentedworkatmorethan10international/regionalconferences,andregisteredfourpatents.

GabrielContreras-Zarazúa,Professorinthe DepartmentofChemicalEngineeringatthe UniversityofGuanajuato,Mexico,since2017, obtainedhisPhDdegreeattheUniversityof Guanajuato,Mexico.HeobtainedhisPhDdegree summacumlaudein2020.Hisresearchisfocused ondesign,simulation,andoptimizationofbiorefineriestoproducehigh-valueproducts. Additionally,hehasexperienceincontrolanalysis, lifecycleandsafetyassessments,anddesignand optimizationofsupplychainsappliedtobioprocesses.Currently,hehas publishedmorethan15articlesinindexedjournals,2bookchapters,and hasregistered1patent.Heisareviewerofindexedjournalsintheareas ofchemicalengineeringandprocessintensification. x Authorbiographies

Whyarebio-basedchemical buildingblocksneeded?

Contents

1.1 Arebio-basedchemicalbuildingblocksneeded?1

1.1.1 Drop-inbio-basedchemicals5

1.1.2 Novelbio-basedchemicals5 1.1.3 C6andC6/C5Sugar8

1.1.4 Plant-basedoil9

1.1.5 Algaeoil10

1.1.6 Organicsolutions10

1.1.7 Lignin11

1.1.8 Pyrolysisoil12

References13

1.1Arebio-basedchemicalbuildingblocksneeded?

Continuous,inspiring,andinterconnectedstep-by-stepchangesin thoughtandunderstanding,know-how,actions,andbehaviorhaveoften beeninstrumentalintransitionsfromoneparticularagetothenext inhumanhistory.Thisalsoappliestothepresentcenturyanditssustainabilitychallengesattheplanetary,regional,andlocallevels.Therefore,it isofgreatimportanceandrelevancetomoveforwardonthejourneythat hasbeenstartedgloballytoaddressanotinsignificantnumberofchallenges.Itis,however,essentialtogobeyonddescriptiveworkbycontinuingwithnovel,inspiring,andinterconnectedstepstofindsolutionsto overcomethesechallenges.Asthishugetaskalsorequiresmultidimensionalcommunication,understanding,andactionsacrossdifferentregions, cultures,disciplines,andknowledgeareas,thedevelopmentofacommon conceptualframeworksuchastheconceptofbioeconomyhasbeen acceptedgloballyasveryvaluable(Sierraetal.,2021).

ThegeneralorientationprovidedbytheUnitedNationsSustainable DevelopmentGoals(SDGs)isofspecialinterestandacalltoactionforall stakeholderstoreachtheSDGsby2030.Throughouthistory,finding

innovativesolutionsbasedonavailablebiologicalresourcestosuccessfully overcomechallengeshasbeenahallmarkofhumanachievements. Therefore,theaccumulatedtraditionalknowledgeandskillsandtherapid advancesinthelifescienceshavemadebiotechnologyakeyenabling technologytowardimprovingthequalityoflife.Bioeconomy,bringing togetherbioresources,biotechnology,ecosystems,andeconomy,has emergedasanattractivetop-levelpoliticalconceptforcreating,developing,andrevitalizingeconomicsystemsworldwidebymakinguseof renewablebiologicalresourcesinasustainableway.Asthereisnouniversaldefinition,weareverymuchinlinewiththeoneadoptedbythe GlobalBioeconomySummitin2015,whichdefinedbioeconomyas “the knowledge-basedproductionandutilizationofbiologicalresources,innovativebiologicalprocessesandprinciplestosustainablyprovidegoodsand servicesacrossalleconomicsectors” (Wohlgemuthetal.,2021).

Theevolutionfrompoliticalobjectivesofabioeconomythatisbased onknowledgeintherelevantsciencesandtechnologies,industries,and societiestobioeconomypolicies,strategies,andinitiativeshasbeen spreadingrapidlyworldwide.Biotechnologyisakeyenablingtechnology, notonlyforhighlydevelopedanddiversifiedbioeconomiesbutalsofor advancedandbasicprimarysectorbioeconomies.Fromthegivendefinition,itisobviousthatbioeconomyismuchmorethanbiotechnologyand includesothersciences,butitalsogoesbeyondinnovationsinsciences andtechnologiesbyincorporatingindustrial,organizational,political,and socialinnovations.

Animportantaspectofbioeconomyisnotonlytocollectandsummarizeexistingknowledgebutalsotopresentandevaluatenewstrategies andtechnologicalprocesses,andtosuggestandtoselectthebestdirectionsofchangeanddevelopment,takingintoaccountglobal,regional, andlocalspecificities.Resourcedistributionandallocation,increasingspecialization,andfacilitatedtransportationandtradeworldwidehaveshown thestrengthsofexchangingandsharingproductsandprovidedtremendousopportunitiesforeconomicgrowth.Aswellasstrengths,these developmentshavealsodemonstratedimbalances,weaknesses,andthreats toglobalsupplychains.Aholisticandinnovativebioeconomyapproach takesintoaccountvariousperspectivesacrossdifferentdisciplinesofscience,industry,andsocietytomakescience-basedpoliticaldecisionsand createsustainablenewopportunitiesandvaluecreationchains.Largeeconomicvalueiscreatedfrombiotransformationsofbio-basedandfossilbasedresourcestointermediariesandfinalproducts,whichenterthe

3 Whyarebio-basedchemicalbuildingblocksneeded?

industrialmanufacturingchaintowardassuitablegoods.Thisvaluecreationarisesinmanyareassuchashealth,nutrition,materials,energy,and environmentinevermorecomplexanddiversifiedbioeconomynetworks.Bio-basedindustriesisakeyenablingtechnologyinallofthese bioeconomynetworks(Sierraetal.,2021).

Bioprocessesarosefromthefieldofzymotechnology,whichbeganas asearchforabetterunderstandingofindustrialfermentation,particularly inrelationtothebrewingofbeer.Beerwasanimportantindustrial,and notjustsocial,commodity.Inlate-19thcenturyGermany,brewingcontributedasmuchtothegrossnationalproductasdidsteel,andtaxeson alcoholprovedtobesignificantsourcesofrevenue.Inthe1860s,institutesandremunerativeconsultancieswerededicatedtothetechnologyof brewing.ThemostfamouswastheprivateCarlsbergInstitute,foundedin 1875,whichemployedEmilChristianHansen,whopioneeredthepure yeastprocessforthereliableproductionofconsistentbeer.Lesswell knownwereprivateconsultanciesthatadvisedthebrewingindustry.One ofthese,theZymotechnicInstitute,wasestablishedinChicagobythe German-bornchemistJohnEwaldSiebel.

TheexpansionofzymotechnologycontinuedduringWorldWarIin responsetoindustrialneedstosupportthewar.MaxDelbrückgrewyeast onanimmensescaleduringthewartomeet60%ofGermany’sanimalfeed needs.Compoundsofanotherfermentationproduct,lacticacid,madeup foralackofhydraulicfluid,glycerol.OntheAlliedside,theRussianchemistChaimWeizmannusedstarchtoeliminateBritain’sshortageofacetone,a keyrawmaterialforcordite,byfermentingmaizetoacetone.Theindustrial potentialoffermentationoutgrew itstraditionalhomeinbrewing,and zymotechnologysoongavewayto “biotechnology” (Doran,2012).

Withfoodshortagesspreadingandresourcesfading,somedreamedof anewindustrialsolution.TheHungarianKárolyErekycoinedtheword “biotechnology” inHungaryin1919todescribeatechnologybasedon convertingrawmaterialsintoamoreusefulproduct.Hebuiltaslaughterhousefor1000pigsandalsoafatteningfarmwithspacefor50,000pigs, andheraisedover100,000pigsayear.Theenterprisewasenormous, becomingoneofthelargestandmostprofitablemeatandfatoperations intheworld.Inhisbook, Biotechnologie,Erekyfurtherdevelopedatheme thatwouldbereiteratedthroughthe20thcentury:biotechnologycould providesolutionstosocietalcrises,suchasfoodandenergyshortages.For Ereky,theterm “biotechnology” indicatedtheprocessbywhichraw materialscouldbebiologicallyupgradedintosociallyusefulproducts.

ThiscatchwordspreadquicklyafterWorldWarI,astheword “biotechnology” enteredGermandictionariesandwastakenupabroadby business-hungryprivateconsultanciesasfarawayastheUnitedStates.In Chicago,forexample,thecomingofprohibitionattheendofWorldWar Iencouragedbiologicalindustriestocreateopportunitiesfornewfermentationproducts,inparticularamarketfornonalcoholicdrinks.EmilSiebel, thesonofthefounderoftheZymotechnicInstitute,brokeawayfromhis father’scompanytoestablishthe “BureauofBiotechnology,” whichspecificallyofferedexpertiseinfermentednonalcoholicdrinks.

Thebeliefthattheneedsofanindustrialsocietycouldbemetbyfermentingagriculturalwastewasanimportantingredientofthe “chemurgic movement.” Fermentation-basedprocessesgeneratedproductsofevergrowingutility.However,thisflourishingindustryoffermentationto obtainbioproductsbegantocompeteeconomicallywiththeadvantages ofobtainingthesameproductsfromnonrenewablesources(oil)inamore efficientwayandatalowercost(Doran,2012).

Inrecentyears,duetothelargeincreaseinpetroleumcost,therehas beenareemergenceofinterestinlarge-volumeproductionoffermentationchemicals.Biotechnologyisprovidingnew,low-cost,andhighlyefficientfermentationprocessesfortheproductionofchemicalsfrombiomass resources.Moreover,withawiderangeofmicroorganismsalreadyavailableandmuchmorerecentlydiscovered,thefermentationofsugars representsanimportantroutefortheproductionofnewbioproducts. However,thecurrenteconomicimpactoffermentationbioproductsis stilllimited,inlargepartaresultofdifficultiesinproductrecovery.Thus, substantialimprovementstoexistingrecoverytechnologyareneededin ordertoallowchemicalsfromfermentationtopenetratefurtherinthe organicchemicalindustry(Cormaetal.,2007).

Thebio-basedindustryisanemergingsectororganizedaroundinterconnectedvaluechains,whichaimstotransformrenewablebiological feedstock,suchasforestry,agricultural,andaquaticbiomass,aswellas sidestreamsandbyproductsfromindustrialbioprocessing,andotherresiduessuchassludgeandmunicipalwaste,intobio-basedproducts,materials,fuels,andenergy,replacingtheirfossil-basedcounterparts.Theyoffer ahugepotentialtotacklesocietalandenvironmentalchallengesand,additionally,playanimportantroleinstimulatingsustainablegrowthand boostingthecompetitivenessofcountriesbyreindustrializingandrevitalizingruralandcoastalareasandprovidingnewjobopportunities.

5 Whyarebio-basedchemicalbuildingblocksneeded?

Therealitythatcanbeseeninthesebio-basedprojectsisthatnew valuechainsaremuchmoreinterconnected.Thesevaluechainsarise fromtheconnectionsbetweendifferenttypesoffeedstockanddifferent processingandbiorefiningtechnologies,transformingthemintoawide varietyofbio-basedchemicalbuildingblocks(CBBs),materials,foodand feedingredients,andconsumerproducts(e.g.,cosmetics)forawiderange ofmarketsectors,therebyproducinganever-increasingnumberofnew bio-basedvaluechains.Thisalsocorrespondstotherealityofthebiobasedsectordevelopment;hencetherelevanceofCBBsintheconceptof bioeconomy.

ACBBisamoleculethatcanbeconvertedtovarioussecondarychemicalsandintermediates,and,inturn,intoabroadrangeofdifferent downstreamuses.Thelargestmarketsforbio-basedCBBsareintheproductionofbio-basedpolymers,lubricants,andsolvents.Thischapterlooks attwotypesofbio-basedCBBs:drop-inbio-basedchemicalsandnovel bio-basedchemicals(UnitedStatesDepartmentofEnergyEnergy EfficiencyandRenewableEnergy,2004).

1.1.1Drop-inbio-basedchemicals

Drop-inchemicalsarebio-basedversionsofexistingpetrochemicalsthat haveestablishedmarkets.Astheyarechemicallyidenticaltoexisting hydrocarbon-basedproducts,theirusecanreducefinancialandtechnologicalrisksandpromotefasteraccesstomarketsforproducers.

1.1.2Novelbio-basedchemicals

Novelbio-basedchemicalsbearhigherfinancialandtechnologicalrisks forproducersbutcanbeusedtoproduceproductssuchasaconicacid andmethylenesuccinicacidthatcannotbeobtainedthroughtraditional chemicalreactionsandproductsthatmayofferuniqueandsuperiorpropertiesthatareunattainablewithfossil-basedalternatives,suchas biodegradability.

ThereisanexistingmarketforCBBs,butitcanbeconsideredrelativelyimmature,withdevelopmentlevelsvaryingaccordingtothebuildingblockconsideredandrangingfromproofofconceptinthelaboratory tofullcommercialproduction.Strongcooperationwithinthevaluechain fromfeedstockproducertoenduserisrequiredfornewCBBstosuccessfullyenterthemarket.

In2013,thedemandforbio-basedCBBsinEuropewas1029 MEUR,equivalentto35%ofthetotalglobalproduction.Themarket grewatacompoundannualgrowthrateofapproximately18.6%per annumbetween2008and2015.Ithasbeenestimatedthatby2030the bio-basedCBBsmarketinEuropecouldreachbetween4.8and 10.4BEUR.Themarketvaluecouldbegreaterthanthisifthevarious hurdlestothedevelopmentofbio-basedCBBsareaddressed.Thegreatest driverforthemarketuptakeofbio-basedCBBsistoovercomeincreasing volatilityinfossil-fuelpriceandsupply.Marketpricesforchemicalsrise whenfossilsupplyistight,sothesubsequentincreasinguncertaintyand volatilityofcrudeoilpricesislikelytopushcommoditychemicalcompaniestowardbringinginalternativestotraditionalfossilfuelstoensurethat theircustomershaveastableproductsupply.

Oneofthekeyhurdlestotheproductionofbio-basedCBBsisthat offeedstockavailabilityandcost.MostofthecurrentlyavailablebiobasedCBBsarebasedoncommodityagriculturalproductssuchassugars andvegetableoilswhichcanvarysignificantlyinpriceandareexpensive.GiventhatmanyCBBsarebulkch emicals,alargeamountoffeedstockwillbeneeded.Thereareconcernsbysomethatthepotential forsupplyingextrasugarandoilsislimited,thoughothersbelievethat thereisstillmuchpotentialforyieldimprovementinsuchcommodities. Theuseofwasteandresiduestream swouldbeattractiveastheyare bothcheapandwidelyavailable.Thea bilitytointercha ngefeedstocks accordingtoavailabilitywouldalsobe useful.Manytechnicalchallenges, especiallyrelatingtodownstreamprocessingneedtobeovercometo helppromotetheuseofalternativefe edstockstreamsandreduceprocessingcosts,butevenifthesechallenges aresuccessfullyaddressed,itwill benecessarytopersuadehighlyconservativeprocessorstochangethe productionprocesstoaccommodateanewfeedstockoraproduct withnewproperties.Acombinationofhighfeedstock,conversionand downstreamprocessingcostsmeanth atthecostofproducingbio-based chemicalsiscurrentlymoreexpensivethanprocessesusingfossil-fuel feedstocks.Opportunitiesforbio-basedpremiumstoovercomeprice differentialsforCBBsareconsideredtobelowerthanforothermarkets, forinstancebioplastics,becauseth eCBBproducerisfurtherawayfrom thefinalconsumer.

Thegreatesthurdletopromotinginvestmentsinbio-basedchemicals howeverisregulatoryuncertaintyandinstabilitythroughitseffectson pricinganddemandforproducts.Vaguenessintermssuch “waste” ,

Whyarebio-basedchemicalbuildingblocksneeded?

7

“residues”,and “ green ” failtoprovidesufficientinvestmentcertainty, whileatpresentincentivesforbioenergyandbiofuelmarketsmeanthat thesesectorscanpaymoreforfeedstockthannonincentivedmarketssuch asbio-basedchemicalsresultingfromfeedstockpricesthatareartificially inflated.

CurrentglobalCBB(excludingbiofuels)isestimatedtobearound 50milliontons.Notableexamplesofbio-basedchemicalsincludenonfoodstarch,cellulosefibers,andcellulosederivatives,talloils,fattyacids, andfermentationproductssuchasethanolandcitricacid.However,the majorityoforganicchemicalsandpolymersarestillderivedfromfossilbasedfeedstocks,predominantlyoilandgas.Nonenergyapplications accountforaround9%ofallfossil-fuel(oil,gas,andcoal)useand16%of oilproducts.Globalpetrochemicalproductionofchemicalsandpolymers isestimatedataround330milliontons.Theprimaryoutputisdominated byasmallnumberofkeybuildingblocks,namelymethanol,ethylene, propylene,butadiene,benzene,toluene,andxylene(UnitedStates DepartmentofEnergyEnergyEfficiencyandRenewableEnergy,2004). Thesebuildingblocksaremainlyconvertedtopolymersandplasticsbut theyarealsoconvertedtoastaggeringnumberofdifferentfineandspecialtychemicalswithspecificfunctionsandattributes.Fromatechnical pointofview,almostallindustrialmaterialsmadefromfossilresources couldbesubstitutedbytheirbio-basedcounterparts.However,thecost ofbio-basedproductioninmanycasesexceedsthecostofpetrochemical production.Also,newproductsmustbeproventoperformatleastas goodasthepetrochemicalequivalenttheyaresubstitutingandtohavea lowerenvironmentalimpact.

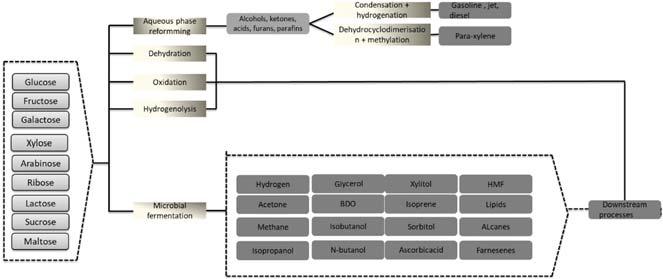

Historicallybio-basedchemicalproducershavetargetedhigh-value fineorspecialtychemicalsmarkets,oftenwherespecificfunctionality playedanimportantrole.Asproofoftheaforementioned Fig.1.1 shows someofthemostcommonsugarobtainedfrombiomassandtheirrespectivedownstreamprocessesusedtoproducehigh-valuecommodities. Currently,thelowpriceofcrudeoilactedasabarriertobio-basedcommoditychemicalproductionandproducersfocusedonthespecificattributesofbio-basedchemicalssuchastheircomplexstructuretojustify productioncosts.

Bio-basedCBBcanbeclassifiedbasedonanumberoftheirkeycharacteristics(InternationalEnergyAgency BioenergyReport,2007). Majorfeedstocksincludeperennialgrasses,starchcrops(e.g.,wheatand maize),sugarcrops(e.g.,beetandcane),lignocellulosiccrops(e.g.,

Figure1.1 Mainsugarsobtainedfrombiomassandtheirrespectivemaindownstreamprocesses.

managedforest,shortrotationcoppice,switchgrass),lignocellulosicresidues(e.g.,stoverandstraw),oilcrops(e.g.,palmandoilseedrape), aquaticbiomass(e.g.,algaeandseaweeds),andorganicresidues(e.g., industrial,commercial,andpost-consumerwaste).Thesefeedstocks includefive-andsix-carboncarbohydratesfromstarch,sucrose,orcellulose;amixedfive-andsix-carboncarbohydratesstreamderivedfrom hemicelluloses,lignin,oils(plant-basedoralgal),organicsolutionsfrom grasses,pyrolyticliquids.

1.1.3C6andC6/C5Sugar

Six-carbonsugarplatformscanbeaccessedfromsucroseorthroughthe hydrolysisofstarchorcellulosetogiveglucose.Glucoseservesasfeedstockfor(biological)fermentationpr ocessesprovidingaccesstoavariety ofimportantCBBs.GlucosecanalsobeconvertedbychemicalprocessingtousefulCBBs.Mixedsix-andfive-carbonplatformsareproduced fromthehydrolysisofhemicellulose s.Thefermentationofthesecarbohydratestreamscanintheoryproducethesameproductsassix-carbon sugarstreams;however,technical, biological,andeconomicbarriers needtobeovercomebeforetheseopportunitiescanbeexploited. Chemicalmanipulationofthesestreamscanprovidearangeofuseful molecules.

1.1.3.1Fermentationproducts

ThenumberofCBBsaccessiblethroughfermentationisconsiderable. Fermentationhasbeenusedextensivelybythechemicalindustryto

9 Whyarebio-basedchemicalbuildingblocksneeded?

produceseveralproductswithchemicalproductionthroughfermentation. Modernbiotechnologyisallowingtheindustrytotargetnewandpreviouslyabandonedfermentationproductsandimprovetheeconomicsof productswithcommercialpotential.Coupledwithincreasingfossilfeedstockcosts,costreductionsintheproductionoftraditionalfermentation products,suchasethanolandlacticacid,willallowderivativeproductsto captureneworincreasedmarketshares.Improvingcoststructureswill alsoallowpreviouslyabandonedproductssuchasbutanoltoreenterthe market.Manyseethefutureabundantavailabilityofcarbohydrates derivedfromlignocellulosicbiomassasthemaindriver.Fermentationalso givestheindustryaccesstonewCBBspreviouslyinaccessibleduetocost constraints.Thedevelopmentofcost-effectivefermentationprocessesto succinic,itaconic,andglutamicacidspromisesthepotentialfornovel chemicaldevelopment.

1.1.3.2Chemicaltransformationproducts

Six-andfive-carboncarbohydratescanundergoselectivedehydration, hydrogenation,andoxidationreactionstogiveusefulproducts,suchas: sorbitol,furfural,glucaricacid,hydroxymethylfurfural,andlevulinicacid (InternationalEnergyAgency BioenergyReport,2007).

1.1.4Plant-basedoil

Theoleochemicalindustryisamajorproducerofbio-basedproducts.The majorityoffattyacidderivativesareusedassurfaceactiveagentsinsoaps, detergents,andpersonalcareproducts.Majorsourcesfortheseapplications arecoconut,palmandpalmkerneloil,whicharerichinC12 C18saturatedandmonounsaturatedfattyacids.Importantproductsofunsaturated oils,suchas:soybean,sunflowerandlinseedoil,includealkydresins,linoleum,andepoxidizedoils.Rapeseedoil,highinoleicacid,isafavored sourceforbiolubricants.Commercializedbifunctionalbuildingblocksfor bio-basedplasticsincludesebacicacidand11-aminoundecanoicacid,both fromcastoroil,andazelaicacidderivedfromoleicacid.Dimerizedfatty acidsareprimarilyusedforpolyamideresinsandpolyamidehotmeltadhesives.Inapplicationssuchaslubricantsandhydraulicfluids,plantoilcanact asadirectreplacementformineral(petroleum-derived)oilorrequireonly minorchemicalmodification.Asachemicalfeedstock,thetriacylglycerol molecule themajorcomponentofmostplantoils iseither(1)cleavedto glycerolandfattyacidsor(2)convertedtoalkylestersandglycerolbytransesterification.Theutilityofthefattyacidsandestersisdeterminedprimarily

bytheirchainlengthandfunctionality.Givenadvancesinplantgenetics andoilprocessing,thereisconsiderableinterestindevelopingplantoilsfor themanufactureofpolymerssuchaspolyurethanes,polyamides,andepoxy resins.Thereisalsoanimportantsubcategoryofoilseedsthatproducenaturalwaxes,suchasliquidwaxfromjojobaseedsandsolidwaxescollected fromtheleafsurfacesoftheCarnubaPalmandseveraldesertshrubs.These tendtobeusedinspecializedhigh-valueapplications,suchascosmetics. Theirexcellentlubricityandstabilityinlubricantapplicationshaveledto interestinengineeringwaxesterproductionincommercialoilseedcrops (InternationalEnergyAgency BioenergyReport,2007).

1.1.5Algaeoil

Therearemorethan40,000differentalgaespeciesbothinseawaterand freshwater.Algaebiomasscanbeasustainablerenewableresourceforchemicalsandenergy.Themajoradvantagesofusingmicroalgaeasarenewableresourceare:

1. comparedtoplants,algaehavehigherproductivity;

2. microalgaecanbecultivatedinseawaterorbrackishwateronnonarable land;anddonotcompeteforresourceswithconventionalagriculture;

3. theessentialelementsforgrowtharesunlight,water,CO2,andinorganicnutrientssuchasnitrogenandphosphorouswhichcanbefound inresidualstreams;

4. thebiomasscanbeharvestedduringallseasonsandishomogenous andfreeoflignocellulose.

Themaincomponentsofmicroalgaearespeciesdependentbutcan containahighproteincontent,quantitiescanbeupto50%ofdryweight ingrowingcultureswithall20aminoacidspresent.Carbohydratesas storageproductsarealsopresentandsomespeciesarerichinstorageand functionallipids,theycanaccumulateupto50%lipids,andinveryspecific casesupto80%(thegreenalgae Botryococcus)accumulateslongchain hydrocarbons.Othervaluablecompoundsincludepigments,antioxidants, fattyacids,vitamins,antifungals,antimicrobials,antiviraltoxins,andsterols (InternationalEnergyAgency BioenergyReport,2007).

1.1.6Organicsolutions

Theorganicsolution(pressjuice)containsvaluablecompounds,suchas carbohydrates,proteins,freeaminoacids,organicacids,minerals,hormones,andenzymesdependingonwhetherthebiomassusedasthe

feedstockisfreshorsilage.Solublecarbohydratesandproteins main componentsoffreshplantjuice canbeusedasafermentationmedium orforgeneratingfeedproducts.Silagepressjuicehasbeendemonstrated asfeedstockfortheproductionofbiochemicalsandfuels.Theorganic solution(pressjuice)containsvaluablecompounds,suchascarbohydrates, proteins,freeaminoacids,organicacids,minerals,hormones,andenzymes dependingonwhetherthebiomassusedasthefeedstockisfreshorsilage.

Solublecarbohydratesandproteins maincomponentsoffreshplant juice canbeusedasfermentationmediumorforgeneratingfeedproducts.Silagepressjuicehasbeendemonstratedasfeedstockfortheproductionofbiochemicalsandfuels.Lacticacidanditsderivatives,aswellas proteins,aminoacids,bioethanols,andenergyviaanaerobicdigestion,are themostfavorableendproductsfromtheorganicsolutionplatform (InternationalEnergyAgency BioenergyReport,2007).

1.1.7Lignin

Ligninoffersasignificantopportunityforenhancingtheoperationofalignocellulosicbiorefinery.Itisanextremelyabundantrawmaterialcontributingasmuchas30%oftheweightand40%oftheenergycontentof lignocellulosicbiomass.Lignin’snativestructuresuggeststhatitcouldplaya centralroleasanewchemicalfeedstock,particularlyintheformationof supramolecularmaterialsandaromaticchemicals.Uptonow,thevast majorityofindustrialapplicationshavebeendevelopedforlignosulfonates. Thesesulfonatesareisolatedfromacidsulfitepulpingandareusedina widerangeoflowervalueapplicationswheretheformbutnotthequality isimportant.Around67.5%ofworldconsumptionoflignosulfonatesisfor dispersantapplicationsfollowedbybinderandadhesiveapplicationsat 32.5%.Majorend-usemarketsincludeconstruction,mining,animalfeeds, andagricultureuses.Theuseofligninforchemicalproductionhassofar beenlimitedduetocontaminationfromsalts,carbohydrates,particulates, volatiles,andthemolecularweightdistributionoflignosulfonates.Theonly industrialexceptionisthelimitedproductionofvanillinfromlignosulfonates.Inadditiontolignosulfonates,kraftligninisproducedasacommercialproductforuseasanexternalenergysourceandfortheproductionof value-addedapplications.Theproductionofmorevalue-addedchemicals fromlignin(e.g.,resins,compositesandpolymers,aromaticcompounds, andcarbonfibers)isviewedasamedium-tolong-termopportunitythat dependsonthequalityandfunctionalityoftheligninthatcanbeobtained (InternationalEnergyAgency BioenergyReport,2007). 11 Whyarebio-basedchemicalbuildingblocksneeded?

1.1.8Pyrolysisoil

Biomasspyrolysisisthethermaldepolymerizationofbiomassatmodest temperaturesintheabsenceofaddedoxygen.Thespectrumofproducts frombiomasspyrolysisdependsontheprocesstemperature,pressure,and residencetimeoftheliberatedpyrolysisvapors.Abiorefinerybasedon pyrolysisoilisdesignedmuchlikeatraditionalrefinery.Firstbiomassis convertedintopyrolysisoil,whichcanbeadecentralizedprocess. Second,pyrolysisoilfromdifferentinstallationsiscollectedatthebiorefinerywhereitwillbedividedintodifferentfractions.Eachfractioncan beupgradedwithadifferenttechnologytofinallyderivetheoptimal combinationofhigh-valueandlowvalueproductsfromthepyrolysisoil. Themajorhigh-valuecompoundswhichareforeseenarephenols, organicacids,furfural,Hidroximetilfurfural(HMF),andlevoglucosan. Themajoradvantagesofapyrolysistransformationisthepossibilityof decentralizedproductionoftheoilinregionswhereabundantbiomassis readilyavailable,makingitpossibletokeepthemineralsinthecountry oforiginandcreatingthepossibilit yofcost-effectivetransportofthe resultingliquids.Thebasisforcreatinghigh-valuecompoundsisthe cost-effectivefractionationofthepyrolysisoil.Fractionationwillresult invariousqualitiesofoilneededforfurtherupgradingintofinechemicals,petrochemicals,automotivefuelsandenergy(InternationalEnergy Agency BioenergyReport,2007 ).

In Fig.1.2,thegeneralclassificationofbio-basedCBBsisshownin summaryform.

Insummary,althoughmanychemicalsthatarecurrentlyproduced frompetroleumwilllikelybeproducedfrombiomassinthefuture, severalchallengesstillremaintoacceleratecommercialization.The developmentofahigh-performancestrainisstillthegreatestchallenge thatrequiresmuchtime,effort,andmoney.Systemsmetabolicengineeringandotheradvancedtoolsandstrategiesthathavebeencontinuouslydevelopedwillplayimportantrolesinmorerapidlyand inexpensivelydevelopingindustrialstrains.Economicalpreparationof fermentablesubstratesfromnonfoodbiomassremainstobeadvanced further.Insteadofutilizingfermentablecarbohydrates,theuseof wastebiomassandevencarbondioxidewillbemoreactivelypursued. Microbialfermentationmostlyrequireswater,andthustheuseand reusestrategyoffermentationwaterneedstobeactivelydeveloped.

Whyarebio-basedchemicalbuildingblocksneeded?

Figure1.2 Classificationofbio-basedchemicalbuildingblocks.

Althoughsuchchallengesstillremain,itisgreattoseetheenormous progressthathasbeenmadeinthebio-basedproductionofmanyofthe platformchemicals.Weareindeedmovingtowardabio-basedeconomy.

References

Corma,A.,Iborra,S.,Velty,A.,2007.Chemicalroutesforthetransformationofbiomass intochemicals.Chem.Rev.107,2411 2502.

Doran,P.,2012.BioprocessEngineeringPrinciples,2ndeditionAcademicPress. InternationalEnergyAgency,(2007),Bioenergyreporttask42:biorefinery,bio-basedchemicalsvalueaddedproductsfrombiorefineries.

Sierra,A.R.,Zika,E.,Lange,L.,deAzua,P.L.R.,Canalis,A.,Esteban,P.M.,etal.,2021. Thebio-basedindustriesjointundertaking:ahighimpactinitiativethatistransforming thebio-basedindustriesinEurope.NewBiotechnol.60,105 112. UnitedStatesDepartmentofEnergyEnergyEfficiencyandRenewableEnergy,(2004) Report:topvalueaddedchemicalsfrombiomass,volumei resultsofscreeningfor potentialcandidatesfromsugarsandsynthesisgas.

Wohlgemuth,R.,Twardowski,T.,Aguilar,A.,2021.Bioeconomymovingforwardstep bystep aglobaljourney.NewBiotechnol.61,22 28.

Thispageintentionallyleftblank