Leachingpractice

Thechemistryofprocessesaimedatthedissolutionof valuablemetalsfromvariousfeedmaterialswascoveredin Chapter6inVolume1.Inthischapter,thevariousmethods employedtocarryouttheleachingreactionswillbeoutlined Thechoiceofaparticularleachprocessandtheequipmentto beuseddependsontheperformancethatcanbeachievedbythe variousoptions.Themainfactorstobetakenintoaccountin assessingleachperformancearethefollowing.

• Degreeofdissolutionofdesiredspecies.

• Selectivityofleachingprocesswithrespecttothedesired species.

• Leachingtimerequiredtoachievethedesiredextraction.

• Operatingcost(lixiviants,power).

• Capitalcost.

Thereisgenerallyaneconomicoptimumthatdeterminesthe mostappropriatestrategyforleaching.Thus,fortheleachingof goldores,theobjectiveshouldbetomaximizeextractiongiven thatoperatingcostsaregenerallynothighrelativetothevalue oftheproduct.Ontheotherhand,inthecaseoftheleaching oflow-gradecopperores,theoperatingcostsarethemostimportantconsiderationandheapleachingistheonlyviableoption. Eveninthiscase,highacidconsumptioncanruleoutheapleachingforsomeores.

1.1Leachingmethods

Thetechniquesshownnextareappliedintheleachingofores andconcentrates.

Insituleaching: Lixiviantpumpeddirectlyintofracturedorebodyandpregnantsolutionrecovered.

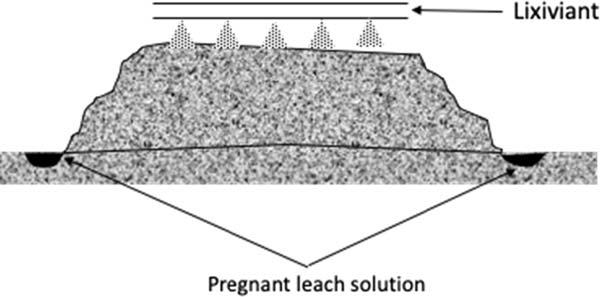

Heap(ordump)leaching: Lixiviantsprinkledoverheapsof mined(crushed)oreinheapsbuiltovertheimperviousbase.

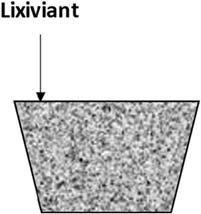

Vatleaching: Crushedore fillsalargevatthatisthen filledwith lixiviantandlefttoleach.Abatchprocessthatisnotvery common.

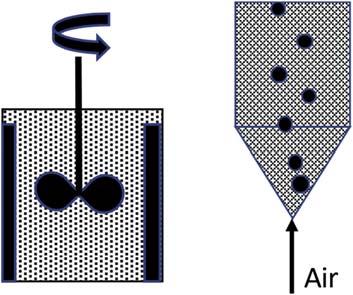

Agitationleaching: Milledorecontactedwithlixiviantin agitatedtanks(mechanicalorairsparging).Batchormultistage continuousreactors.

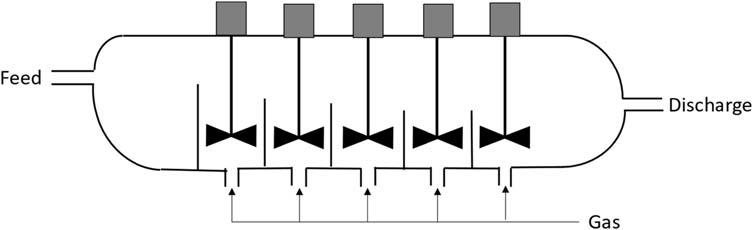

Pressureleaching: Milledoreorconcentratecontactedwithlixiviantinhigh-pressure,high-temperaturereactors(autoclaves) thataregenerallyoperatedincontinuousmode.

Bacterialleaching: Avariationofheaporagitationleachingin whichbacteriaassistintheleachingreactions.

Someofthemoreimportantpracticalmethodsusedto dissolveorleachvaluablecomponentsofanore,concentrate, orotherintermediateproductaresummarizedin Fig.1.1.The actualmethodtobeadopteddependslargelyonthevalueof thematerialtobetreatedwithlow-gradematerialsrequiring methodstotheleftandhighgradematerialstotherightofthe diagram.

1.2Typicalleachingprocesses

Thedissolutionofasolidspeciesisachemicalreactionthat canbeclassi fiedintooneofseveraltypessuchasacidleaching

In-Situ Lix.

Increasing value of material leached

Figure1.1 Selectionofleachingmethodwithgradeoffeedmaterial.

andoxidativeleachingasoutlinedinChapter6inVolume1.The chemistrythatispossibleinthedissolutionofasolidisoftenextensiveandvariedanddependsontheingenuityoftheresearcher. However,practicalconsiderationsdeterminedlargelybythecost ofthelixivianthaverestrictedthechoiceoftheleachingprocess. Table1.1 summarizessomeofthemoreimportantleaching processesthatareinoperationinvariouspartsoftheworld. Thedesignandoperationofleachingprocessesarecritically dependentonanunderstandingandapplicationofthekinetics ofthereactionstakingplaceinleachreactors.Inthefollowing sections,wewillshowhowkineticinformationcanbeusedto describehowwecandesignandoperatealeachingprocess.

1.3Batchleachingkinetics

InChapter6inVolume1,wedealtwiththeexpectedprofiles fortheleachingofparticlesforseveralcasesinwhichthe

Heaps Crush Crush Crush

Grind Grind Tank

Tank Lix. Ore Lix. Lix. Lix.

Table1.1Someleachingprocessesinoperation.

FeedLixiviantOxidantTemp.PressureEquipment

OxidizedCuoreDilH2SO4

NoneAmbientAtmos.Heaps

SulfideCuoreDilH2SO4 Ferric,bacteriaAmbientAtmos.Heaps

Cu,Ni,Co,Zn concentrates, mattes

DilH2SO4 Ferric,oxygen >100 C1 10bar.Tanks, autoclaves

ZinccalcineDilH2SO4

None40 90 CAtmos.Tanks

NimatteDilHClFerric,cupric <100 CAtmos.Tanks

NilateriteoreDilH2SO4 None250 C50bar.Autoclaves

ReducedlateriteoreNH3/CO2 Air,Cu(II)40 80 CAtmos.Tanks

UraniumoreDilH2SO4 Ferric þ MnO2 40 50 CAtmos.Tanks,insitu

OxidizedgoldoreNaCNAirAmbientAtmos.Heaps,tanks

RefractoryAuore, concentrates H2SO4/NaCNFerric/Air150 200 C/Ambient30 40bar/AtmosAutoclaves/ tanks

BauxiteNaOHNone150 200 C20 40barAutoclaves

RoastedVoreWaterNone50 90 CAtmos.Tanks,columns

ScheeliteSodaashNone200 C40barAutoclaves

RoastedLioresDilH2SO4 None <100 CAtmos.Tanks

rate-determiningstepiseithermasstransportorchemicalreaction.Inmanyrealcases(seelater)involvingoresand,toalesser extent,concentrates,thecurveoffractionleachedversustime doesnotconformtoanyofthetheoreticalforms.Underthese conditions,wehavetoresorttoempiricalrateequations.

Considertheleachingofatypicalgoldoreforwhichthe followingrateequationhasoftenbeenfoundtodescribethe rateofdissolutionofgoldfromcyanidepulp,

inwhich[Au]istheconcentration(massgold/unitmassofpulp) atanytime, t,and[Au]f isthecorrespondingconcentrationafter aninfinitetime,thatis,itistheultimateachievablebarrenconcentration(mainly “lockedgold” notaccessibletothelixiviant). kisarateconstant.

Thisequationcanbeintegratedtogive,

where[Au]o istheinitialconcentration.Thisequationcanbewrittenintheform

inwhichk0 ¼ k([Au]o [Au]f)andX ¼ ([Au] [Au]f)/([Au] o [Au]f)is thefractionofgoldleached.

Theparameters[Au]f andkcanbeobtainedfromasmall-scale batchleachcarriedoutundertypicalenvisagedplantconditions ofpulpdensity,cyanideconcentration,andpH.Forexample, thetimerequiredtoachievea50%dissolutionofgoldfroma batchofpulpforwhich[Au]o ¼ 5g/t,[Au]f ¼ 0.2g/t,and k ¼ 0.05/h,willbegivenby

Inapracticalsituation,thetimerequiredto fillandemptythe batchreactorwillhavetobeaddedtotheactualleachingtime. Thisgenerallyismostefficientwithlargereactors.

Thus,forabatchleachplanttotreat100t/hoftheabovepulp inatankthatcanhold950t(forcomparisonwithalatersection seeAppendix)ofpulp,theleachtimewillbe4.5h,whichwillleave 4.5hforcharginganddischargingthetank,thatis,anaverage pulp flow-rateof420t/hduringtheseoperations.

Noticethatinthecaseofabatchreactor,alloftheoreparticlesareexposedtothelixiviantforthesameleachingperiod.

Batchleachingisseldomusedinpracticeexceptforrelatively small-scaleoperationssuchas,forexample,thedissolutionofa preciousmetalconcentrate(goldand/orplatinumgroupmetals) in,forexample,achlorine/chloridesystem.Therequirementfor accurateaccountingofthemetalinvariousstagesofprocessing isalsoconsiderablysimpli fiedinbatchprocessing.Theformation ofmetastablespeciesinsolution(suchashydratedsilica)may alsobecontrolledmoreappropriatelyinabatchratherthanin acontinuousreactor.

1.4Continuousleaching micro-and macro fluids

Incontinuousleaching,theore,concentrate,orothermaterial containingthemetalormineraltobeleached(generallyasa slurry)andthelixiviantarefedcontinuouslyintoastirredtank reactor(CSTR)andtheleachedslurrydischargedcontinuously generallyintoanotherreactorinseries.

Theanalysisoftheperformanceofthistypeofreactordependsonthenatureofthe fluid. Microfluids consistofsolutions suchthatonecannotdistinguishonemoleculeofasolute,suchas anionorsolventmoleculefromanother.Thus,inaCSTRtreating amicro fluid,allreactantsareattheirexit(i.e.,low)concentrations,reactantsenteringareimmediatelydilutedtoexitconcentrationsbyperfectmixing,andthereactions,therefore, takeplaceatarelativelylowrate,asdictatedbythereactantconcentrations.The flowofamicro fluidisoftencharacterizedas nonsegregated.

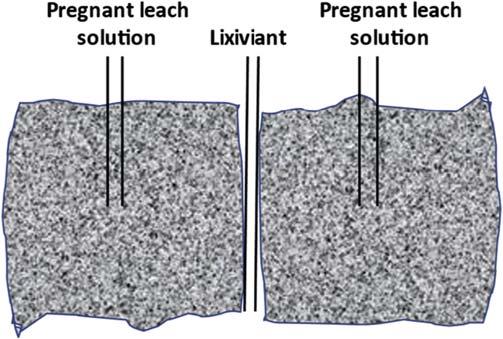

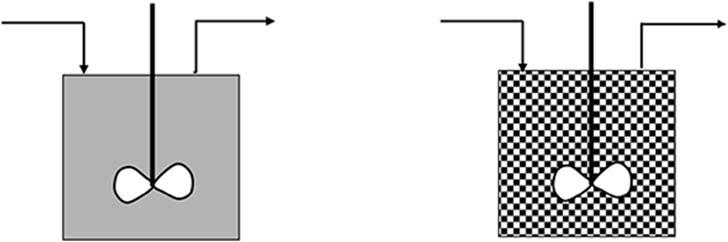

Ontheotherhand,asshownin Fig.1.2, macro fluids consistof suspensionsofparticleseachofwhichisdistinguishableandeach ofwhichisanaggregate(crystalinsomecases)ofalargenumber ofatomsormolecules.Thus,forexample,aparticleoforesuspendedinaslurrywillbehaveinaCSTRinthesamewayasa batchreactor.Thus,thereactantconcentrations(inthesolid phase)donotimmediatelydroptoalowvaluebutdecreaseas theywouldinabatchreactorandtheextentofreactionineach oftheoreparticlesinthereactordependsonlyonthelengthof stay(residencetime)inthereactor.Thisisequallytrueforany particleintheexitstream.Thus,thefractionalconversioninthe exitstreamisdeterminedbysummingtheconversionsofallthe particles(PopulationBalanceMethod).Thisisanexampleof segregated flow.

Thus,inaCSTRtreatingaslurry,thesolutionphasewould behaveasamicrofluidandthesolidphaseasamacrofluid. Thus,inanidealCSTRinwhichallparticlesoftheabovegold orehavethesameresidencetimetR (¼ Vol.ofreactor/Volumetric flowrateofslurry),theperformancewouldbeidenticaltothatof thebatchreactordiscussedearlier.

Figure1.2 Schematictodistinguishbetweenmicrofluid(left)andmacrofluid(right).

1.4.1ResidencetimedistributioninaCSTR

Inanidealcompletelymixedreactorvessel,anentering fluid elementisinstantaneouslybrokenupintotinyfragmentsthatare uniformlydistributedthroughoutthevolumeofthevessel.Some ofthese fluidfragmentsareimmediatelydrawnintotheeffluent streamwhileotherscirculatewithinthevesselforvariouslengths oftimebefore findingtheirwayout.Thus,atanyinstant,the reactoreffluentiscomposedof fluidparticlesthathavespent variouslengthsoftimeinthevessel.Incontrast,every fluid elemententeringa plug flow vesselfollowstheelementthat enteredbeforeitwithoutanyintermixingandexitsthereactor inexactlythesameorder.Atanyinstantthen,theexitstreamis madeupof fluidelements,allofwhichhavebeenresidentin thereactorforexactlythesamelengthoftime.Thetimespent inthereactorbya fluidelementiscalledits exitage.Thedistributionofexitagesofall fluidfragmentsinthereactoreffluentis calledthe residencetimedistribution (RTD)andisindicativeof themixingand flowdistributionpatternswithinthereactor.

Intheory,ina “perfectlymixedtank”,theresidencetimes coverthewholerangefromzerotoinfinity,althoughtheaverage ormeanresidencetime(tR)isthesameasforbatchtreatment, namelythemassofpulpinthetankdividedbythemass flowrate. Mixingtheoryshowsthatthewaytoovercomethe “shortcircuiting” thatoccursinasingletankistodividethesametotal volumeormassamonganumberoftanksinseries themore tanksthereareinseries,thehigherwillbetheproportionof pulpthatwillhavearesidencetimeclosetothemeanvalue.

Forthemeanresidencetime,tR ¼ V/Q,inwhichVisthevolumeof fluidinthetankandQthevolumetric flowrate,theactual residencetime/meanresidencetime ¼ t/tR ¼ q.

Theresidencetimedistributionfunction,E(q),istherelative proportionofthedischargepulphavingaresidencetimebetween q and q þ dq.Thatis,E(q).dq isthefractionoftheexit streamofagebetween q and qþdq.

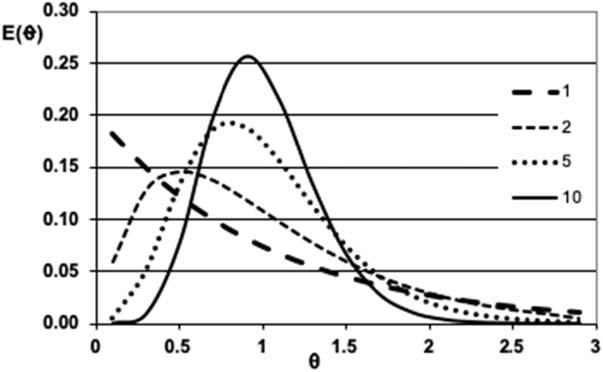

Foranidealplug flowreactor,theexpectedRTDfunction,E(q) isshownastheverticalarrowin Fig.1.3.

Ontheotherhand,foracompletelymixed(CSTR)reactor, E ðqÞ¼ 1 tR expð qÞ (1.4)

AgraphicalrepresentationoftheexpectedRTDfunctionfora completelymixedvesselisshownin Fig.1.3.

Consideranumberofimixedtanksinseriesthatareassumed tobecompletelymixedandtoeachhavethesamevolume.Thus,

ResidencetimedistributionforasingleCSTR.

ifthetotalvesselvolumeisV,eachtankhasvolumeVi ¼ (V/N). TheRTDfunctionforthissituationcanbederivedandisgivenby

AfamilyofRTDcurvesforanumberoftanksinseriesis shownin Fig.1.4.

Thefractionof fluidthathasaresidencetimebetween q1 and q2 isgivenbythatareaunderthecurvebetween q1 and q2 relativetothetotalareaunderthecurve.Thesevaluesareshown in Table1.2 forseveralintervals.

Figure1.4 Residencetimedistributionsfortanksinseries.

Figure1.3

Table1.2Fractionof fluidwithvariousresidencetimes.

Reactors,N

0.10 0.20.18140.05960.02480.00460.0001

0.30.2 0.40.14850.12860.09670.04990.0094

0.50.4 0.60.12160.14570.14800.13140.0773

0.70.6 0.80.09960.13750.16040.18530.1979

0.90.8 1.00.08150.11890.14630.18760.2563

1.11.0 1.20.06670.09760.12040.15520.2148

1.31.2 1.40.05460.07740.09260.11220.1334 1.51.4 1.60.04470.05990.06780.07360.0667 1.71.6 1.80.03660.04560.04790.04490.0283 1.91.8 2.00.03000.03420.03290.02590.0106

2.12.0 2.20.02460.02530.02210.01420.0036 2.32.2 2.40.02010.01860.01450.00760.0011 2.52.4 2.60.01650.01360.00940.00390.0003 2.72.6 2.80.01350.00980.00600.00200.0001

2.92.8 3.00.01100.00540.00120.00030.0000 >3.00.04900.02240.00890.00150.0000

Itisapparentthatasthenumberoftanksincreases,thedistributionofresidencetimesbecomessharperwithalargerfraction ofthepulphavingaresidencetimeclosetotR.

Forareactioninthetankthatisa first-orderprocess,itcan beshownthatnoerrorisintroducedbyassumingthatallparticleshavethesame(mean)residencetime. Thisisnottrueforany otherreactionorder(seeAppendixfordetails).

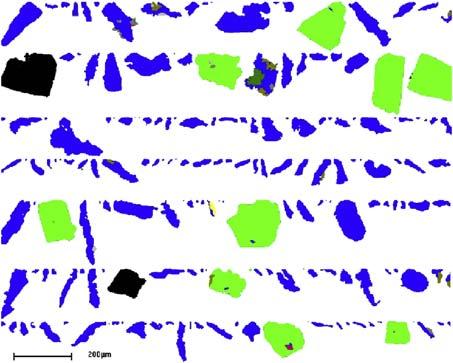

Thesituationwithreactionsinvolvingsolidparticlesisfurther complicatedbythefactthatapulpinvariablycontainssolidswith anonuniformparticlesizedistribution,probabledifferent shapes,andevenadistributionofreactivities.Thus, Fig.1.5 showsamineralliberationanalyzerpictureofthegoldparticles (blue)inatypicalgoldconcentrateproducedbygravity separation.

Thus,onecouldexpectto findadistributionofresidence times,particlesizes,shapes,andreactivitysuchasshownin Fig.1.6.

Itisnotdif ficulttovisualizethatthelargerparticleswillprobablyhavealongerresidencetimeinthetankandmay,iflarge

Figure1.5 Distributionofparticlesizesandshapesinagold(blue(darkgrayinprint))concentrate.Thegreen particles(lightgrayinprint)arepyrite.

Fraction Within Each Class

Particle size,

shape,reactivity

Figure1.6 Schematicdistributionofvariouscharacteristicsofore/concentrateparticles.

enough,settleinthebottomofthetankwhilethe fineparticles willprobablyhaveashortermeanresidencetime.Thiseffect will,inpart,acttocompensateforthenormalRTDinthatwe wantthelargerparticlestohavealongerresidencetime.For thisreason,thecomplicationscausedbytheRTDeffectareoften ignored.

Inarealagitatedtankreactor,however,thereisoftenadegree ofshort-circuitingofthepulpduetoinef ficientblendingofthe incomingpulpwiththecontentsofthetankcoupledtoinappropriatepositioningofthefeedandexitpoints.Thesettlingof largerparticlescanalsooftenresultinasignificantfractionof

thetankvolumebeingunavailableforreaction.Thisis,asexpected,moreprevalentinthe firsttankinaseriesandtheperiodicuseoftracerteststoestablishtheactivevolumeofthe tankwillenablethisproblemtobehighlighted.

Itisapparentthatafulltreatmentofthekineticsofleaching ofarealoreorconcentratewillrequireinformationontheparticlesizedistribution.Givenallthepreviouslymentionedcomplicationswhendealingwithrealleachsystems,theadded complexityofthepopulationbalancemodelscannotgenerally bejustified.TheAppendixoutlinestheapplicationofconventionalCSTRtheoryforthetreatmentofleachingreactions bearinginmindthepreviouslymentionedproblemsinparticulatesystems.

1.5Counter-currentleaching

Thepreviouslymentionedleachingprocessesinvolvecocurrent flowoftheoreorconcentrateandthelixiviant.Whilethis isoftenaconvenientmethodofoperating,greaterefficiencies intermsofoverallleachingrecoveryandmaximumutilization ofthelixiviantcanbeaccomplishedbycontactingthelixiviant withtheoreinacounter-currentfashion.Thus,

• Maximum extraction isachievedbycontactingaleachresidue withfresh,concentratedlixiviant.

• Maximum utilization ofthelixiviantcanbeachievedbycontactingfresh,reactiveoreorconcentratewithlixiviantthat hasalreadybeenusedinapriorstage.

Thus,considertherealexampleshownin Fig.1.7 ofathreestageleachingcircuitforazinccalcinethatisdesignedto maximizezincrecoveryandutilizeallthelixiviantwhilestillminimizingthedissolutionofironbylimitingthepHtovaluesabove3 inthe firststageleachandprovidingasolutionofthedesired compositionforpurificationbeforeelectrowinning.

Asthisisthe firstexampleofatypicalhydrometallurgical flowsheet,itisworthspendingsometimeonthedetails.Ignoreinthe firstinstancetheoperationsshownindashedlines theseare usedtobleedironfromthecircuitandarenotessentialinterms ofcounter-currentleachingandweshallreturntothissection later.Intermsofoverallleachinginonestage,oneissimply reactingthecalcinewithacidinthespentelectrolytefromelectrowinningthatcontainsexcessacidgeneratedattheanodeduringelectrowinning.However,inthiscase,inthe firstleachstage, thecalcineiscontactedwith(a)solutionfromthesecondstage leachthatcontainsexcessacidandzincdissolvedinthe first

Spent Electrolyte

1st Stage Leach, 50o C, pH 4

LLL S

2ndStage Leach, 80o C, 10 g/L acid LLL L S

3rdStage Leach, 80oC, 50 g/L acid

Calcine, NH 4 +

LLS L LLL S Residues

Figure1.7 Athree-stagecounter-currentleachingprocessforzinccalcine.

stageand(b)smallamountsofspentelectrolytetocontrolthepH ofthesolutionleavingthe firststage.Thepulpleavingthe first stageis filtered(orsettled)toseparatethesolutionfromthe leachresidue.Thesolutionnowcontainsupto200g/Lzinc andissenttothepurificationstageoftheplantandthereafter toelectrowinning.

Thesolidresiduefromthe firststagestillcontainszincandis subjectedtoleachingundermoreextremeconditionstodissolve mostoftheresidualzinc.Thesolutionusedtodissolvethiszincis madeupofasolutionfromthethirdstageleachandsomespent electrolyte.Thepulpfromthisstageissubjectedtosolid/liquid separationandthesolutionisroutedtothe firststageandasmall amountissentforironremoval.Thesolidfromthissecondstage isthefeedtothethirdstageinwhichanyresidualrefractoryzinc isdissolvedathightemperatureandacidityusingthespentelectrolyte.Aftersolid/liquidseparation,thesolutionphaseisusedin thesecondstageleach,andthesolidiswashedandreportedas the finalresidue.

Whilethisapproachisefficientintermsofleaching,theintroductionofasolid/liquidstepbetweeneachcounter-currentstage introducesanadditionalunitoperationthatcanbebothinef ficientandcostlyforpulpsthataredifficultto filterorsettle.The

Calcine

introductionofadditionalwaterforwashingthe filtercakes furthercomplicatestheprocess.Forthisreason,countercurrentleachingisnotappliedaswidelyasmaybeanticipated.

1.6Bacterialoxidationandleaching

Bioleaching istheextractionofametalfromsulfideoresor concentratesusingmicroorganismsthatcatalyzetheoxidation ofsulfideminerals.Anassociatedprocessis biooxidation inwhich sul fidemineralsassociatedwithbutnotnecessarilypartofthe mineralofinterestisoxidizedordissolved.Inbiooxidationofrefractorygoldores,bacteriaareusedtosolubilizeanironsulfidein whichthegoldparticlesarelocatedandthusmakethegoldavailableforcyanideleaching.Likewise,incoaldesulfurization,bacteriaareusedtooxidizethepyritecontaminantinthecoalthus makingthesulfursolubleasferricsulfate.

Bioleachingisusedtodayincommercialoperationstoprocess oresofcopper,nickel,cobalt,zinc,anduranium;whereas,biooxidationisusedingoldprocessingandcoaldesulfurization. Sincebioleachingisanaturalprocess,anundesirableeffectis thecreationofso-calledaciddrainagefromtheslowoxidation ofsulfidemineraloutcropsandfromabandonedtailingsdumps. Bioleachprocessingdiffersdependingonthetypeofresource tobeprocessed.

Dumpleaching wasterock,low-gradeore,orconcentrator tailings(lowgrade,oxides,andsecondarysulfides)areleached fromwastedumps.

Heapleaching newlyminedrun-of-the-mine(ROM)material (intermediategrade,oxides,andsecondarysul fides)isplacedasa heaponanimperviousnaturalsurfaceorapadandleached.ROM maybeleachedasminedormaybepartiallycrushedandmixed withacidbeforedepositingontheheap.

Agitatedleaching concentratesareleachedinatankusing mechanicalagitation.

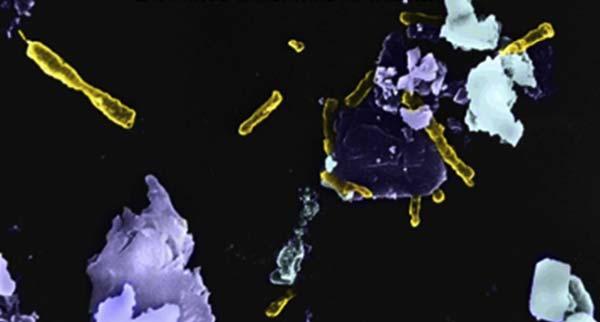

Wastedumpleachinguses mesophilic (ambienttemperature, 35 45 C)microorganisms,thatis,bacteria.Heapleachingof oremayinvolve mesophiles ormoderate thermophiles (hightemperature,50 60 C)microorganisms.Leachingofchalcopyrite andotherprimarysulfideconcentratesrequiresextreme thermophiles (>70 C).Aphotographofthiobacillusferrooxidansbacteria attachedtosulfidemineralsisshownin Fig.1.8.

Insummary,bioleachinginvolves

• Oxidativedissolutionofsul fideswithferricions.

• Reoxidationofferrousbydissolvedoxygencatalyzedbyspecificbacteria.

Figure1.8 Bacteria(yellow(lightgrayinprint))associatedwithsulfideminerals.

• Useofmicroorganismsofwhichthiobacillusferrooxidansand sulphooxidansaremostcommon.

• SourceofCO2,pHabout1.5 2,temperature35 45 C,nutrients(N,P,K),dissolvedO2 greaterthan1ppm.

Forexample,thefollowingreactionsoccurduringthebiooxidationofpyrite, FeS2 ðsÞþ 14Fe3þ D 8H2 O ¼ 15Fe2þ D 2H2 SO4 D 12Hþ (1.6) 14Fe2 D þ 7=2O2 þ 14Hþ ¼ 14Fe3þ D 7H2 O(1.7) thatis,overall,

2FeS2 ðsÞþ 15=2O2 D H2 O ¼ Fe2 ðSO4 Þ3 þ H2 SO4 (1.8)

N.B.Inthecaseofpyrite,acidisproducedandmustbe neutralised.

Inthecaseofpyrrotite,

2FeSðsÞþ 9=2O2 þ H2 SO4 ¼ Fe2 ðSO4 Þ3 þ H2 O(1.9) acidisconsumedandmustbeprovidedtokeepthepHintheoptimumregion.

Someofthemostimportantadvantagesofbiooxidationor leachingprocessesare

• Rapidoxidationofiron(II)toiron(III)

• Bacterialoxidationofelementalsulfurlayers

• Lowercapitalcostsforsmalltomediumsizeplants

• Relativelysimple,low-techprocess

• Environmentallyacceptable

Ontheotherhand,therearesomedisadvantagessuchas

• Slowkinetics(severaldaysunderfavorableconditions)

• Sensitivitytoprocessvariations(temperature,lossofaeration, poisonssuchascyanideandsalinity)

• Limitedsolidscontent(<20%)

• Producessolubleiron(III)thatrequiresremovalanddisposal.

• Bioleachingdoesnotrecoverthepreciousmetalsintheore

1.6.1Processparametersforbiologicaloxidation

Theplantsizeisdeterminedbytheoreorconcentrate throughputandtherateofoxidationofsulfidesulfur.Therelative proportionsofeachmineralpresentdeterminetheprocessacid consumption/production,oxygendemand,andcoolingrequirementsasshownin Table1.3.

Majordesignrequirementsofreactorsare:

• Agitationtosuspendsolidsand,moreimportantly,todisperse largevolumesofairoroxygen.

• Coolingcoilstodissipateheatgeneratedbyexothermicreactionsandagitationthatisnotlostbyevaporation,heatingof air,andfeedpulp.

Table1.3Reagentandpowerrequirements.

• Residencetime

• Corrosionresistanceofthematerialsofconstructiongiven acidicconditions.

1.6.2Biooxidationreactorkineticsanddesign

Therateofbiologicaloxidationofasulfidemineralcanoften beexpressedintermsofthe “logisticrateequation”

wherevistherateofoxidation, Xisfractionoxidized, Xm isthemax.fractionthatcanbeoxidized,and k isabacterialgrowthrateconstant

Considerasingle-stageCSTRreactorcontainingavolumeVof pulpthatis flowingatarateQ(volume/unittime)throughthe reactor.

Fromthemassbalanceatsteady-state,weobtaintheCSTR equation,

and,substitutingthepreviousrateequation,

inwhichtR ¼ V/Qisthemeanresidencetime.

Fork ¼ 1/tR,X ¼ 0,andthisisreferredtoasthebacterialcell “wash-out” conditionthatis,theoperatingpointatwhichthe dilutionrate,1/tR,isequaltothemaximumrateofgrowthof thebacterialcells.Thus,

(a) Forthreeequalreactorsinseries:

Cellwash-outwilloccurfortR ¼ 1/k andthesystemresidence timewillbe3tR

(b) Foraprimaryreactorthatistwicethesizeofthesecondary reactorscellwash-outwilloccurforatotalresidence time ¼ 2/k ¼ 2tR wheretR istheresidencetimeintheprimary reactor.

Thisisthebasisforthecommondesignoftwoprimaryreactorsinparallelfeedingsecondaryreactorsofthesamesizeinseries.Thisensuresthatwash-outofthebacteriawillnotoccurat thedesign flowratesforasinglereactor.

Fig.1.9 illustratesthisphenomenonforabioleachreactorin whicharefractorygoldconcentrateisoxidized.Thegoldrecovery shownisthatobtainedbycyanidationoftheresiduefrombiologicaloxidation.Youshouldattempttointerprettheoperating