HydrodynamicLubricationof Non-NewtonianFluids

PINGHUANG

SchoolofMechanicalandAutomotiveEngineering,SouthChina UniversityofTechnology,Guangzhou,China

QIANQIANYANG

SchoolofMechatronicEngineering,GuangdongPolytechnicNormal University,Guangzhou,China

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2023TsinghuaUniversityPressLimited.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans, electronicormechanical,includingphotocopying,recording,oranyinformationstorageand retrievalsystem,withoutpermissioninwritingfromthepublisher.Detailsonhowtoseek permission,furtherinformationaboutthePublisher’spermissionspoliciesandourarrangements withorganizationssuchastheCopyrightClearanceCenterandtheCopyrightLicensingAgency, canbefoundatourwebsite: www.elsevier.com/permissions .

Thisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythe Publisher(otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchand experiencebroadenourunderstanding,changesinresearchmethods,professionalpractices, ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgein evaluatingandusinganyinformation,methods,compounds,orexperimentsdescribedherein. Inusingsuchinformationormethodstheyshouldbemindfuloftheirownsafetyandthesafety ofothers,includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors, assumeanyliabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproducts liability,negligenceorotherwise,orfromanyuseoroperationofanymethods,products, instructions,orideascontainedinthematerialherein.

ISBN:978-0-323-99477-4

ForInformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: MatthewDeans

AcquisitionsEditor: GlynJones

EditorialProjectManager: NaomiRobertson

ProductionProjectManager: AnithaSivaraj

CoverDesigner: ChristianJ.Bilbow

TypesetbyMPSLimited,Chennai,India

PartIUniversalequationofnon-Newtonianhydrodynamic lubrication1

1.Viscosityoffluid5

1.1 Overview 5

1.2 ViscosityofNewtonianfluid6

1.2.1 Definitionofviscosity6

1.2.2 Unitsofviscosity7

1.3 Rheologicalpropertyofnon-Newtonianfluid8

1.3.1 Typesofnon-Newtonianfluids8

1.3.2 Viscosityofnon-Newtonianfluid11

1.4 Factorsinfluencingviscosity17

1.4.1 Relationshipbetweenviscosityandtemperature17

1.4.2 Relationshipbetweenviscosityandpressure18

1.4.3 Combinationalrelationshipofviscosity,temperatureandpressure19

1.5 Commonrheologicalexperimentdevices19

1.5.1 Coaxialcylinderrheometer19

1.5.2 Cone-platerheometer20

1.5.3 Parallelplaterheometer20 References 21 Furtherreading 22

2.Basicequationsofhydrodynamiclubrication23

2.1 Basicequationsandassumptionsofhydrodynamiclubrication23

2.1.1 Basicequations23

2.1.2 Basicassumptions24

2.2 Continuityequation25

2.3 Equilibriumequations27

2.3.1 Expressionofequilibriumequations27

2.3.2 Derivationofequilibriumequations27

2.4 Fluidconstitutiveequation29

2.4.1 Newtonianfluidconstitutiveequation29

2.4.2 Non-Newtonianfluidconstitutiveequations30

2.5 Boundaryconditionsofhydrodynamiclubrication35

2.5.1 Boundaryconditionsbetweenfluid-solidinterface35

2.5.2 Pressureboundaryconditions36

Reference 37

3.Reynoldsequationandnon-Newtonianhydrodynamiclubrication39

3.1 DerivationofReynoldsequation39

3.1.1 Analysisofbasicequations39

3.1.2 Eliminationofshearstress40

3.1.3 Eliminationofflowvelocities41

3.2 Generalnonlinearproblems43

3.2.1 Linearproblems43

3.2.2 Nonlinearproblems44

3.2.3 Non-Newtonianhydrodynamiclubrication45

3.3 DifficultiesduringderivationofReynoldsequationofnon-Newtonianhydrodynamic lubrication 46

3.3.1 Reynoldsequationofpowerconstitutiveequation46

3.3.2 DifficultiestoderiveageneralReynoldsequationofnon-Newtonianfluid49

Reference 52

4.Universalhydrodynamiclubricationequation53

4.1 Separatedflowvelocitymethod53

4.1.1 Basicprinciplesofseparatedflowvelocitymethod53

4.1.2 Stepstosolvenon-Newtonianhydrodynamiclubricationproblems withseparatedflowvelocitymethod55

4.1.3 Theoreticalbasisoftheseparatedflowvelocitymethod58

4.2 Derivationofuniversalhydrodynamiclubricationequation59

4.2.1 Derivationstepsofuniversalhydrodynamiclubricationequation60

4.2.2 Simplifieduniversalhydrodynamiclubricationequation62

4.2.3 Solutionofuniversalhydrodynamiclubricationequation63

4.3 Determiningconditionsofseparatedflowvelocitymethod65

4.3.1 Separatedflowvelocitymethodsatisfiesallbasicequations65

4.3.2 Boundaryconditions66

4.4 Commonnon-Newtonianuniversalhydrodynamiclubricationequations67

4.4.1 Powerconstitutiveequation67

4.4.2 Universalhydrodynamiclubricationequationsofcommonlyused non-Newtonianfluids68 PartIILubricationfailureduetolimitshearstress73

5Experimentalstudyonrheologicalpropertiesoffluids75

5.1 Non-Newtonianfluidexperimentsunderatmosphericpressure75

5.1.1 Preparationofnon-Newtonianfluids75

5.1.2 Experimentalresultsofnon-Newtonianfluids76

5.1.3 Viscosity-temperaturerelationshipofpolyethyleneoxidesolutions82

5.2 Experimentaldevicesoffluidrheologicalpropertyunderhighpressureand highshearrate84

5.2.1 Doubledisctype84

5.2.2 Impacttype86

5.2.3 Sheartype87

5.2.4 Capillarytype87

5.2.5 Puresheartype87

5.2.6 Impactandsheartype89

5.2.7 Impactandsqueezetype90

5.2.8 Fallingcolumntype91

References 94

6Interfaceslipmodelsandslipmeasurement95

6.1 Interfaceslipmodels95

6.1.1 Sliplengthmodel95

6.1.2 Limitshearstressslipmodel98

6.2 Experimentalstudyoninterfaceslip99

6.2.1 Interfaceslipmeasurement100

6.2.2 Influencingfactorsofinterfaceslip102

References 107

7Lubricationfailureofnon-Newtonianfluid109

7.1 Interfaceslipanditsconditions109

7.1.1 Interfaceslip109

7.1.2 Slipboundaryconditions111

7.1.3 Flowvelocitydistributionatslipzone112

7.2 Differenceofrollingandslidingforlubricationfailure114

7.2.1 Slide-rollratio114

7.2.2 Reynoldsequationofpurerolling115

7.2.3 One-dimensionalReynoldsequationofpurerolling115

7.2.4 Shearstressofhydrodynamiclubricationinpurerolling118

7.2.5 Lubricationfailureofnon-Newtonianfluidinsliding119

7.3 Criterialpointoflubricationfailure120

7.3.1 Stribeckcurveandlubricationfailure120

7.3.2 Frictioncoefficientofhydrodynamiclubrication121

7.3.3 Relationshipbetweenfrictioncoefficientandlubricationfailure122

7.3.4 Influenceoffrictioncoefficient123

Reference 127

8Analysisoflubricationfailureofnon-Newtonianfluidwithlimitshearstress129

8.1 Lubricationfailureofviscos-plasticfluid129

8.1.1 Constitutiveequationofviscos-plasticfluid129

8.1.2 Basicequationsofviscos-plasticfluid132

8.1.3 Numericalanalysisoflubricationfailureofviscos-plasticfluid137

8.2 Lubricationfailureofbucklingfluid140

8.2.1 Constitutiveequationofbucklingfluid140

8.2.2 Basicequationsofbucklingfluid142

8.2.3 Numericalanalysisoflubricationfailureofbucklingfluid144

8.3 Lubricationfailureofcircularfluid149

8.3.1 Circularconstitutiveequation150

8.3.2 Basicequationsofcircularfluid150

8.3.3 Numericalanalysisoflubricationfailureofcircularfluid151 References 153 PartIIICalculationmethodandprogram155

9Calculationmethodandprogramofhydrodynamiclubricationof non-Newtonianfluids157

9.1 Basicequations,numericalmethodandprogramofone-dimensional hydrodynamiclubrication157

9.1.1 Basicequations157

9.1.2 Numericalmethod159

9.1.3 Calculationprocedure160

9.2 Basicequations,numericalmethodandprogramoftwo-dimensional hydrodynamiclubrication165

9.2.1 Basicequations165

9.2.2 Numericalmethod167

9.2.3 Calculationprocedure167

10Calculationmethodandprogramofelastohydrodynamiclubrication ofnon-Newtonianfluid175

10.1 Basicequations,numericalmethodandprogramofnon-NewtonianEHLinlinecontact175

10.1.1 Basicequations175

10.1.2 Numericalmethod179

10.1.3 Calculationprocedure180

10.2 Basicequations,numericalmethodandprogramofnon-NewtonianEHLinpointcontact188

10.2.1 Basicequations188

10.2.2 Numericalmethod189

10.2.3 Calculationprocedure191 References 198

11Temperaturecalculationmethodandprogramofhydrodynamiclubrication199

11.1 Basicequationsofhydrodynamiclubrication199

11.1.1 Basicequations199

11.1.2 Flowcontinuityequation201

11.2 Energyequationandcalculationmethod202

11.2.1 Energyequation202

11.2.2 Numericalcalculationofenergyequation204

11.2.3 Temperaturecalculationflowchart210

11.3 CalculationprogramofthermalhydrodynamiclubricationofNewtonianfluid210

11.3.1 One-dimensionaltemperaturecalculationprogram211

11.3.2 Two-dimensionaltemperaturecalculation213 Reference 218

12CalculationmethodandprogramofthermalhydrodynamiclubricationofnonNewtonianfluids219

12.1 Equations,numericalmethodandprogramofone-dimensionalthermalhydrodynamic lubricationofnon-Newtonianfluids219

12.1.1 Basicequations219

12.1.2 Numericalmethod221

12.1.3 Calculationprogram222

12.2 Equations,numericalmethodandprogramoftwo-dimensionalthermalhydrodynamic lubricationofnon-Newtonianfluids227

12.2.1 Basicequations227

12.2.2 Numericalmethod230

12.2.3 Calculationprogram231 Reference 238

13Calculationmethodandprogramofthermalelastohydrodynamiclubricationof non-Newtonianfluids239

13.1 Basicequations,numericalmethodandprogramofnon-NewtonianTEHLinlinecontact239

13.1.1 Basicequations239

13.1.2 Numericalmethod245

13.1.3 Calculationprogram245

13.2 Basicequations,numericalmethodandprogramofnon-NewtonianTEHLinpoint contact 264

13.2.1 Basicequations264

13.2.2 Numericalmethod270

13.2.3 Calculationprogram270 References 287

14Calculationmethodandprogramoflubricationfailure289

14.1 Lubricationfailurecalculationofviscos-plasticfluid289

14.1.1 Basicequations289

14.1.2 Discreteiterativeformula291

14.1.3 Calculationflowchart292

14.1.4 Sourceprogram293

14.1.5 PressuredistributionsofNewtonianfluidandviscos-plasticfluid295

14.2 Lubricationfailurecalculationofbucklingfluid295

14.2.1 Basicequations295

14.2.2 Discreteiterativeformula296

14.2.3 Calculationflowchart297

14.2.4 Sourceprogram299

14.2.5 PressuredistributionofNewtonianfluidandbucklingfluid301

14.3 Lubricationfailurecalculationofcircularconstitutivefluid302

14.3.1 Basicequations302

14.3.2 Sourceprogram303

14.3.3 PressuredistributionsofNewtonianfluidandcircularfluid306

Preface

Inhydrodynamiclubrication,non-Newtoniancharacteristicsoflubricantarevery common.However,duetothenonlinearityofconstitutiveequations,obtainingsolutionsfornon-Newtonianhydrodynamiclubricationproblemsisverydifficult.Even throughnumericalanalysis,itisnoteasytoobtainaconvergentsolution.Therefore non-Newtonianhydrodynamiclubricationhasalwaysbeenadifficultyinlubrication theory.

Foralongtime,noeffectivemethodhasbeenfoundtosolvethelubricationcalculationofnon-Newtonianfluids.Althoughavarietyofconstitutiveequationsof non-Newtonianfluidshavebeenobtainedinpractice,theyareusuallysimplifiedas Newtonianfluidsforanalysisandcalculation.Aquasilinearizednon-Newtonian hydrodynamiclubricationproblemoftenleadstodeviationssothattheresultsmaydistortdesignandevenhavehiddenerrors.Therefore,findinganeffectivemethodto solvehydrodynamiclubricationproblemsofnon-Newtonianfluidsisanimportant taskoflubricationtheory.

Twodifficultiesinsolvingnon-Newtonianhydrodynamiclubricationare:(1) Non-Newtonianfluidbringsagreatobstacletoderivateananalyticalequationbecause ofthenonlinearityofitsconstitutiveequation;(2)EvenifaReynolds-likeequation hasbeenobtained,aconvergencesolutioncannotbeeasilyobtainedbecauseofnonlinearity.Inthepast,whensolvinganyhydrodynamiclubricationproblem,people alwayswanttodeduceaReynolds-likeequationsimilartoNewtonianfluid,andthen solveitwithonlyonepressurevariable.InordertodeduceaReynolds-likeequation ofnon-Newtonianfluid,exceptforsomespecialnon-Newtonianfluids,itsexpression isusuallynotsuitableforobtainingastablenumericalsolution.

Thisbookisdividedintothreeparts.Thefirstpartisthebasictheories,including Chapters1 4.First,viscosityofnon-Newtonianfluidisanalyzedindetail,andthe conceptsoftheincrementalviscosityandthetotalviscosityareputforward.TheoriginaldefinitionofviscositycomesfromNewtonianfluidandisnotsuitablefornonNewtonianfluids,sowemustclearlyunderstandthedifferencesbetweenNewtonian fluidviscosityandnon-Newtonianfluidviscosity.Otherwise,itisdifficulttostudy themindepth.

TheseparatedflowvelocitymethodisaneffectivemethodforsolvingnonNewtonianhydrodynamiclubricationproblems.AfteranalyzingthestepstosolvehydrodynamiclubricationofaNewtonianfluid,explainingdifficultiesofnon-Newtonian hydrodynamiclubricationandconsideringthe particularitiesofhydrodynamiclubrication problems,weproposetheseparatedflowvelocitymethodforsolvingnon-Newtonian

hydrodynamiclubricationproblems.Thus,theuniversalequationsforsolvinghydrodynamiclubricationproblemsofnon-Newtonianfluidsarederived.

Thesecondpartisaboutlubricationfailure,including Chapters5 8. Theoretically,Newtonianfluidwillnotbringaboutlubricationfailure,butthisis inconsistentwiththeactualsituationinpractice.Thisprovokespeopletosearchfor thecausesoflubricationfailure.Thenon-Newtoniannatureisoneoftheseimportant causes.Basedontheanalysisofconstitutiveequationsofnon-Newtonianfluidwith limitshearstress,alubricationfailuremechanismcausedbylimitshearstresshasbeen discussedindepth.First,wegiveanimportantconclusionthatpurerollingdoesnot havelubricationfailurewhichiscausedbylimitshearstress,andonlyslidingcauses suchlubricationfailure.Thisconclusionishelpfultodeeplyunderstandtheinfluence ofthenon-Newtonianproperty.Moreover,relationshipsbetweenfrictioncoefficient, load,filmthicknessandlubricationfailurearealsodiscussedbyanalyzingvariationof loadcarryingcapacityofhydrodynamiclubricationfilm.Finally,sometestersfor experimentallymeasuringlimitshearstressareintroducedin Chapter8

Thethirdpartcoverscalculationmethodsandprograms,including Chapters9 14 Calculationformulas,numericalmethodsandsolutionprogramsofcommonnonNewtonianhydrodynamiclubricationproblemsarepresentedbyusingtheabove method.Thecalculationresultsobtainedbytheseprogramsshowthattheuniversal equationbasedontheseparatedflowvelocitymethodcanbesuccessfullyappliedto thecalculationofpressuredistribution,filmthicknessandtemperatureriseofnonNewtonianhydrodynamiclubricationproblems.Comparedwiththepastcalculation methodsfornon-Newtonianhydrodynamiclubricationproblems,thepresentmethod hasadvantagesofaunifiedformat,simplecalculationsteps,goodconvergenceand accuracy.

ThisbookcanprovidetheoreticalandnumericalanalysisforresearchonnonNewtonianhydrodynamiclubrication.ItwaswrittenbyPingHuangandQianqian Yang.PingHuangwrote Chapters1to8and14.QianqianYangwrote Chapters 9 13.Theresearchcontentofthisbookisfinanciallysupportedby “Computational Tribology” (No.51575190)oftheNationalNaturalScienceFoundationofChina. Moreover,thebookquotestheexcellentachievementsofmanytribologists. Dr.WanglongZhanalsoprovidedgreathelpwithdatacollectionduringcompletion ofthebook.Theauthorsthankallofyouverymuch!

Duetocomplexityofnon-Newtonianhydrodynamiclubricationandlimitationof theauthors,itisinevitablethatsomemistakesexistinthebook.Wehopethereaders willnothesitatetoputforwardvaluableopinionsandsuggestions.

PingHuangandQianqianYang March,2022,Guangzhou

Introduction

Theprimarygoalofthisbookistodeduceauniversalhydrodynamiclubrication equationforsolvingnon-Newtonianhydrodynamiclubricationproblemsbasedonthe separatedflowvelocitymethod,whichsolvesthedifficultiesofderivingaReynoldslikeequationofnon-Newtonianhydrodynamiclubrication.Theuniversalequation canbeusedtosolvethehydrodynamiclubricationproblemsofbothNewtonianand non-Newtonianfluids.Inaddition,inthisbookwealsocarryoutadetailedanalysis ofviscosityofnon-Newtonianfluidsandputforwardtheconceptsoftheincremental viscosityandthetotalviscosity.Thenon-Newtonianpropertyoffluidisoneofthe primaryreasonsforlubricationfailure.Wehaveanalyzedloadcarryingcapacitiesof hydrodynamiclubricationfilmofdifferentfluidsandpointoutthatthelubrication failuremechanismofnon-Newtonianfluidsisrelatedtothelimitshearstress.We havealsointroducedvarioustestinginstrumentsformeasuringlimitshearstress. Finally,somenumericalmethodsandcalculationprogramsusingtheseparatedflow velocitymethodarepresented.Withtheseprograms,hydrodynamiclubrication,elastohydrodynamiclubrication,thermalelastohydrodynamiclubricationandlubrication failureofcommonnon-Newtonianfluidscanbecalculatedandanalyzed.

Thisbookcanbeusedasteachingmaterialorasateachingreferencebookfor postgraduatesorstudentsmajoringinmechanicalengineeringorrelated.Itcanalsobe usedasareferenceforengineersandtechniciansengagedinthecalculation,analysis andresearchofnon-Newtonianhydrodynamiclubrication.

Thispageintentionallyleftblank

1.2ViscosityofNewtonianfluid

1.2.1Definitionofviscosity

Fluidlubricantgenerallydoesnothaveafixedshapeanditcanflow.Oneofthemost importantpropertiesofafluidlubricantisitsviscosity.Whenitflows,duetotherelativemotionbetweenmoleculesoffluidorontheinterfaceoffluidandsolid,shear ratewillbeproduced;theviscosityoradhesionisthereasonforresistancetofluid flowsoastoproduceshearstress.

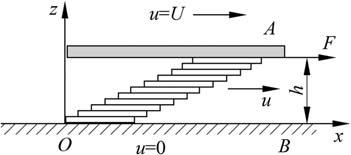

Newtonproposedamodelforviscousfluids,inwhichheproposedthattheviscousfluidmotionrelativelyslidesinmanyverythinlayers,asshownin Fig.1.1.In thefigure,aflatplatewithanarea A onthetopofthefluidmovesatavelocity U undertheactionoftheforce F.Acrossthefilmthickness h,anothersurfaceisfixedat thebottomofthefluid.Thetwosurfacesareparallel.Duetotheviscosityofthefluid, internalfrictionalactionwillexistbetweeneachslidinglayer.Motionwillbetransmitted totheadjacentlayersthroughthisaction,whichcausesthefastermovinglayertodecelerate,andtheslowermovinglayertoaccelerate.Aflowvelocitydistributioniseventuallyformed.IfthefluidisNewtonian,theflowvelocity u willchangeinastraightline asshowninthefigure.

Aconstitutiveequationisusuallyusedtodescribetherelationshipbetweenshear stressandshearrateofafluid.Iftheshearstress τ isproportionaltotheshearrate _ γ , wesaythatthefluidobeysNewton'slaw.Itsdynamicviscosity η isequalto:

or

where, τ istheshearstress,whichthetangentforceperarea, τ 5 F/A; F isthetangent force; γ 5 du dz istheshearrate,thatis,theshearstrainchangeswithtime t; u isthefluid velocity; z istheverticalcoordinate,whichisperpendicularto u,theratioofshear stresstoshearrateisdefinedastheviscosity η offluid,ordynamicviscosity;and U is

Figure1.1 Newtonianfluidmodel.

thevelocityoftheuppersurface.Allfluidsthatobey Eq.(1.1) arereferredtoas Newtonianfluids.Thosethatdonotarecallednon-Newtonianfluids.

Inengineering,theratioofthedynamicviscosity η ofafluidtoitsdensity ρ is oftenused,whichiscalledthekinematicviscosityandiscommonlyexpressedas ν Theexpressionofthekinematicviscosityis:

1.2.2Unitsofviscosity

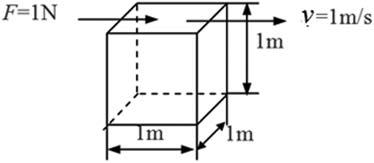

Theunitofthedynamicviscositycanbeobtainedfromitsdefinition.Asshownin Fig.1.2, iftheunitoftheforce F isnewton,thelengthandwidthoftheelementare1meterand theunitoftimeisseconds,thentheunitofthedynamicviscosityisN s/m2 orPa s.

Therangeofdynamicviscositiesoffluidsisquitewide.Forexample,thedynamic viscosityofairisabout0.02mPa s,thatofwateris1mPa s:thedynamicviscosities ofcommonlubricantsarefrom2to400mPa s,whilethedynamicviscosityof meltedasphaltisupto700mPa s.

Inengineering,thecentimeter-gram-second(CGS)systemisoftenused,wherethe unitofthedynamicviscosityisPoise,simplyPorcP(onepercentofP).

Iftheimperialunitsareused,theunitofthedynamicviscosityisReyn,thatis:

Theunitofthekinematicviscosity ν ism2/sintheinternationalunitsystem. Becausethedensity ρ ofmineraloilisoftenfrom0.7to1.2g/cm3,thetypicaldensity isabout0.85g/cm3.Thereforethekinematicviscosityanddynamicviscositycanbe approximatelyconvertedbythefollowingequation:

Figure1.2 Unitofdynamicviscosity.

IntheCGSunitsystem,theunitofthekinematicviscosityisStokeorSt,thatis:

Infact,onepercentofStorcStiscommonlyused,wherecStis1mm2/s. ThefluidsthatobeyNewton'slawarereferredtoasNewtonianfluids.Thosethat donotconformtoNewton'slawsarecallednon-Newtonianfluids.Theactualviscosityoffluidsisoftenaffectedbyvariousexternalfactors(temperature,pressure,etc.)so thatitisnotaconstant.However,thechangesofviscositycausedbytheexternalfactorsdonotaffectthepropertiesoffluid.Thereforetheoutsidefactorsdonotchange thepropertiesoffluid,thatis,whetherafluidisNewtonianornon-Newtonianis onlydeterminedbyitsinternalproperties.

Ifviscosityvarieswiththeshearrateorshearstress,itnolongermeetstheviscosity definitionoftheNewtonianfluid.Thereforeitsfluidmodelorconstitutiveequationis non-Newtonian.

1.3Rheologicalpropertyofnon-Newtonianfluid

Non-NewtonianfluidreferstoafluidthatdoesnotmeetNewton'slaw,thatis,the relationshipofitsshearstressandshearrateisnotlinear.Suchfluidswidelyexist.The viscosityofaNewtonianfluidisaconstant.However,theviscosityofanonNewtonianfluidisnotaconstant,butanonlinearfunction,whichdescribestherelationshipbetweenshearstressandshearrate.Thefunctioniscalledtheconstitutive equationandtheconstitutiveequationofaNewtonianfluidisaconstant.

1.3.1Typesofnon-Newtonianfluids

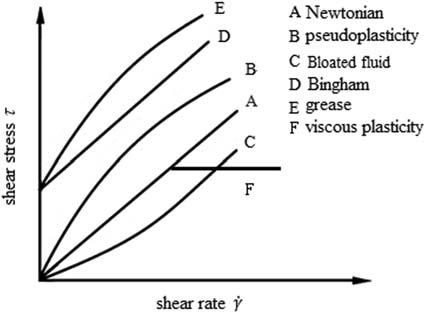

Theconstitutivecurvesofseveralcommonfluids,whichindicatetherelationship betweenshearstressandshearrate,areshownin Fig.1.3.Amongthem,LineAisthe Newtonianfluid.FortheNewtonianfluid,itsrelationshipbetweenshearstressandshear rateislinearevenifitsviscosity, η sometimesisnotaconstant.Forexample,itmay changewithvariationoftemperature,pressureandotherenvironmentalparameters.

Therelationshipbetweenshearstressandshearrateofnon-Newtonianfluidsis nonlinear.Itmayhaveayieldshearstresssothatthecurvestartsatanonzeropointas inCurveDorE.Furthermore,somerelationshipsofshearstressversusshearratemay changewithtime.Experimentalmeasurementsshowthatnon-Newtonianfluidsoften exhibitpseudoplasticity,expansion,viscous-elasticity,yieldandotherdifferentforms, asinCurveBtoFin Fig.1.3

Wewillbrieflyintroducesomecommonlyusednon-Newtonianfluidsandtheir characteristicsasfollows.

Figure1.3 Shearstress-shearratecurvesforcommonfluidtypes.

1.3.1.1Pseudoplasticfluid

Pseudoplasticity,alsoknownasshearthinning,isamajormanifestationofnonNewtonianfluids,asseeninCurveBin Fig.1.3.Mostsyntheticlubricantsareshear thinningfluids.Theviscosityofthiskindoffluidwilldecreasewithincreasingshear rate.Underthesameconditions,thefilmofashear-thinninglubricantisthinnerto carrythesameloadthanthatofnone.

1.3.1.2Bloatedfluid

Bloatedisalsoknownasshearthickening,asinCurveCin Fig.1.3.Incontrastto shear-thinningfluids,theviscosityofthiskindoffluidwillincreasewithincreasing shearrate.Thereforeunderthesameconditions,thefilmthicknessofashearthickeninglubricantisthickerthanthatofashear-thinninglubricant.

1.3.1.3Binghamfluid

AsshowninCurveDin Fig.1.3,BinghamfluidisnamedafterE.C.Bingham,who proposedthiskindofmaterial.Binghamfluidislikearigidmaterialifshearstressis lowsothatshearratecanbeconsideredzero.However,thefluidwillyieldwhen whentheshearstressislargeenough.Theshearstressyieldingiscalledtheyieldstress. Afteryielding,itislikeaviscousfluidandtheshearrateincreaseslinearlywithincreasingshearstress.Thusitsconstitutivecurveisastraightlinebutdoesnotstartfromthe origin.Theyieldstressisafunctionofitsperformancesaswellasitspressureandtemperature.ExperimentsshowthattheyieldstressofBinghamfluidsisfrom4 3 105Pa to2 3 107Pa.

1.3.1.4Grease

AsshowninCurveEin Fig.1.3,thegreasecanbethoughtofasanoverlayof Binghamfluidandpseudoplasticfluid,whichhasbothyieldstressandshearthinning characteristics.SimilartotheBinghamfluid,greasekeepstheoriginalshapeasasolid whenthesurfaceisstationary.Whilethesurfacemoves,greaseactslikeapseudoplastic fluid.

1.3.1.5Viscos-plasticfluid

AsinCurveFin Fig.1.3,theviscos-plasticfluidisasimplificationofcommonnonNewtonianfluids.Itissimilartoanelastoplasticmaterial.Atasmallshearrate,the viscos-plasticfluidcanbeconsideredaNewtonianfluid.However,withincreasing shearrate,plasticitybecomesthemainfactor,especiallyattheinterfacebetweenfluid andsolid.Whenthefluidshearstressonasolidsurfacecannotincreasewithan increaseinshearrateanymore,interfaceslipoccurs.Themaximumshearstressis calledthelimitshearstress, τ L.Inelastohydrodynamiclubrication,thelubricantwill showsolid-likecharacteristicsduetotheexistenceoftheviscosity-pressureeffectand thesurfaceeffect.Moreover,becauselubricantflowsthroughthecontactareafora veryshortperiodoftimeandthelubricantfilmisverythin,thefluidwillbehaveasa viscos-plasticfluid.

1.3.1.6Thixotropyfluidandrheopexyfluid

Theshearrateofathixotropyfluidisthefunctionoftime.Theincrementofitsshear stresswillgraduallydecreasewithincreasingshearrate.Incontrast,inarheopexyfluid shearstressneedstograduallyincreasetokeeptheshearrateasaconstant.Athixotropyfluidcanbethoughtofasatime-sensitiveshearthinningfluid.Butitsviscosity couldnotrespondimmediatelyaccordingtotheshearrate.However,theviscosityof ashearthinningfluiddecreaseswithanincreaseoftheshearrate,andthisresponseis immediateandrepeatable.Theviscosityofathixotropyfluidnotonlyvarieswith shearrate,butalsowithtime.Becausethefluidstructurecanbedamagedbyshear stress,iftheshearstressislargeenough,thestructurecanbecompletelydestroyed.At thispoint,thethixotropyfluidcanexhibitthepropertiesofNewtonianfluidovera periodoftime.Suchastructurecanberestoredtoitsoriginalcondition,thatis,itcan recoverafteralongenoughtimeunderalowshearstress.Experimentsshowthat greasehasthixotropy.

1.3.1.7Viscoelasticfluid

Theviscoelasticfluidshowsboththeelasticpropertiesofsolidsandtheviscouspropertiesoffluids,anditsmainperformancesarecreepandrelaxation.Thestudyofthe viscoelasticmaterialfornon-Newtonianhydrodynamiclubricationisusefulforsome speciallubricantsinpractice.Althoughthereisnodetailedexperimentalverification,it

Table1.1 Classificationsandcharacteristicsofmainnon-Newtonianfluids.

ClassificationTypeCharacteristicsApplications

ViscousfluidShearthinningdecreasesastheshearrate increases

Shearthickeningincreasesastheshearrate increases

Viscos-plastic fluid

Timedependent fluid

Binghamwithyieldstress,like viscousfluidwhenthe shearstressisgreaterthan theyieldstress

Greasewithyieldstress,likeshear thinningfluidwhenthe shearstressisgreaterthan theyieldstress

Thixotropyviscosityincreasesasthe shearstressisappliedfor anextendedperiodof time

Rheopexyviscositydecreasesasthe shearstressisappliedfor anextendedperiodof time

Viscoelastictime-relatedstresswith relaxationandcreep

Siliconeoil,most synthetic lubricants

Cornmealaqueous solution,etc.

Porcelain,graphite, paint

Grease,some emulsions

Printerink, gypsumpaste

Castoroil,slip, mud

Somespecial lubricants

isgenerallybelievedthattheeffectofviscoelasticityonfilmthicknessofhydrodynamic lubricationisnotsignificant.

In Table1.1,classificationsandcharacteristicsofcommonnon-Newtonianfluids havebeengiven.

1.3.2Viscosityofnon-Newtonianfluid

Viscosityisnaturallythemostimportantcharacteristicoflubricant.Itistheparameter todescribefluidresistance.ThedefinitionofviscosityforNewtonianfluidsisvery clear,thatis,theratioofshearstresstoshearrate,asshownin Eq.(1.8).

However,thedefinitionofviscosityofanon-Newtonianfluidisnotdefinitively given.ItisoftenassumedthatthefluidsotherthanCurveAarenon-Newtonianfluids