HYDROCARBON BIOREFINERY

ofBiomassforHydrocarbon Biofuels

EditedBy

SUNILK.MAITY

DepartmentofChemicalEngineering,IndianInstituteofTechnology Hyderabad,Sangareddy,Telangana,India

KALYANGAYEN

DepartmentofChemicalEngineering,NationalInstituteofTechnology Agartala,Agartala,Tripura,India

TRIDIBKUMARBHOWMICK

DepartmentofBioengineering,NationalInstituteofTechnology Agartala,Agartala,Tripura,India

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2022ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicormechanical, includingphotocopying,recording,oranyinformationstorageandretrievalsystem,withoutpermissioninwriting fromthepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthePublisher’spermissionspolicies andourarrangementswithorganizationssuchastheCopyrightClearanceCenterandtheCopyrightLicensingAgency, canbefoundatourwebsite: www.elsevier.com/permissions.

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher(otherthanas maybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroadenour understanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusingany information,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationormethodsthey shouldbemindfuloftheirownsafetyandthesafetyofothers,includingpartiesforwhomtheyhaveaprofessional responsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeanyliabilityfor anyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceorotherwise,orfromany useoroperationofanymethods,products,instructions,orideascontainedinthematerialherein.

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

ISBN:978-0-12-823306-1

ForinformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: CandiceJanco

AcquisitionsEditor: PeterAdamson

EditorialProjectManager: SaraValentino

ProductionProjectManager: NirmalaArumugam

CoverDesigner: VictoriaPearson

TypesetbySTRAIVE,India

Toourbelovedparents.

Contributors

R.S.Ajmal

DepartmentofChemicalEngineering,NationalInstituteofTechnologyCalicut,Kozhikode, India

WaqasAslam

AustralianInstituteforBioengineeringandNanotechnology(AIBN),TheUniversityof Queensland,Brisbane,QLD,Australia

NeerajAtray

BiofuelsDivision,CSIR-IIP,Dehradun,India

NunoBatalha

SchoolofChemicalEngineering,FacultyofEngineering,ArchitectureandInformation Technology,TheUniversityofQueensland,Brisbane,QLD,Australia

ThalladaBhaskar

MaterialResourceEfficiencyDivision,CSIR-IndianInstituteofPetroleum,Dehradun, Uttarakhand;AcademyofScientificandInnovativeResearch(AcSIR),Ghaziabad,India

AmanKumarBhonsle

AcademyofScientificandInnovativeResearch(AcSIR),Ghaziabad;BiofuelsDivision, CSIR-IIP,Dehradun,India

TridibKumarBhowmick

DepartmentofBioengineering,NationalInstituteofTechnologyAgartala,Agartala,Tripura, India

BhabatushBiswas

DepartmentofBioengineering,NationalInstituteofTechnologyAgartala,Agartala,Tripura, India

PareshButolia

SchoolofChemicalEngineering,SungkyunkwanUniversity,Seoul,SouthKorea

JyotiPrasadChakraborty

DepartmentofChemicalEngineeringandTechnology,IndianInstituteofTechnology(Banaras HinduUniversity),Varanasi,UttarPradesh,India

SudiptaDe

KAUSTCatalysisCenter(KCC),KingAbdullahUniversityofScienceandTechnology, Thuwal,SaudiArabia

GabrielFraga

SchoolofChemicalEngineering,FacultyofEngineering,ArchitectureandInformation Technology,TheUniversityofQueensland,Brisbane,QLD,Australia

KalyanGayen

DepartmentofChemicalEngineering,NationalInstituteofTechnologyAgartala,Agartala, Tripura,India

JoshuaGorimbo

ZhijiangCollege,ZhejiangUniversityofTechnology,Shaoxing,Zhejiang,China

ShelakaGupta

MultiscaleModellingforEnergyandCatalysisLaboratory,DepartmentofChemicalEngineering, IndianInstituteofTechnologyHyderabad,Kandi,Telangana,India

M.AliHaider

RenewableEnergyandChemicalsLaboratory,DepartmentofChemicalEngineering,Indian InstituteofTechnologyDelhi,HauzKhas,Delhi,India

OlusolaO.James

ChemistryUnit,FacultyofPure&AppliedSciences,KwaraStateUniversity,Malete,Kwara State,Nigeria

JanakiKomandur

DepartmentofChemicalEngineering,IndianInstituteofTechnologyGuwahati,Guwahati, India

MuxinaKonarova

AustralianInstituteforBioengineeringandNanotechnology(AIBN),TheUniversityof Queensland,Brisbane,QLD,Australia

AdarshKumar

MaterialResourceEfficiencyDivision,CSIR-IndianInstituteofPetroleum,Dehradun, Uttarakhand;AcademyofScientificandInnovativeResearch(AcSIR),Ghaziabad,India

PankajKumar

DepartmentofChemicalEngineering,BirlaInstituteofTechnologyandScience(BITS),Pilani, HyderabadCampus,Hyderabad,Telangana,India

AlekhyaKunamalla

DepartmentofChemicalEngineering,IndianInstituteofTechnologyHyderabad,Kandi, Sangareddy,Telangana,India

XinyingLiu

InstitutefortheDevelopmentofEnergyforAfricanSustainability(IDEAS),Universityof SouthAfrica(UNISA),FloridaCampus,Johannesburg,SouthAfrica

SwarnalathaMailaram

DepartmentofChemicalEngineering,IndianInstituteofTechnologyHyderabad,Kandi, Sangareddy,Telangana,India

SudipMaity

Gasification,CatalysisandCTLResearchGroup,CentralInstituteofMiningandFuelsResearch (DigwadihCampus),Dhanbad,Jharkhand,India

SunilK.Maity

DepartmentofChemicalEngineering,IndianInstituteofTechnologyHyderabad,Kandi, Sangareddy,Telangana,India

KaustubhaMohanty

DepartmentofChemicalEngineering,IndianInstituteofTechnologyGuwahati,Guwahati, India

MahluliMoyo

InstitutefortheDevelopmentofEnergyforAfricanSustainability(IDEAS),Universityof SouthAfrica(UNISA),FloridaCampus,Johannesburg,SouthAfrica

MuthusivaramapandianMuthuraj

DepartmentofBioengineering,NationalInstituteofTechnologyAgartala,Agartala,Tripura, India

GregPerkins

SchoolofChemicalEngineering,FacultyofEngineering,ArchitectureandInformation Technology,TheUniversityofQueensland,Brisbane,QLD,Australia

PanneerselvamRanganathan

DepartmentofChemicalEngineering,NationalInstituteofTechnologyCalicut,Kozhikode, India

JanakanS.Saral

DepartmentofChemicalEngineering,NationalInstituteofTechnologyCalicut,Kozhikode, India

TahirHussainSeehar

DepartmentofEnergyTechnology,AalborgUniversity,Aalborg,Denmark;Departmentof Energy&EnvironmentEngineering,DawoodUniversityofEngineering&Technology, Karachi,Sindh,Pakistan

AyazAliShah

DepartmentofEnergyTechnology,AalborgUniversity,Aalborg,Denmark;Departmentof Energy&EnvironmentEngineering,DawoodUniversityofEngineering&Technology, Karachi,Sindh,Pakistan

KamaldeepSharma

DepartmentofEnergyTechnology,AalborgUniversity,Aalborg,Denmark

BhushanS.Shrirame

DepartmentofChemicalEngineering,IndianInstituteofTechnologyHyderabad,Kandi, Sangareddy,Telangana,India

MalayilGopalanSibi

SchoolofChemicalEngineering,SungkyunkwanUniversity,Seoul,SouthKorea

JasvinderSingh

MaterialResourceandEfficiencyDivision,CSIR-IndianInstituteofPetroleum(CSIR-IIP), Dehradun;AcademyofScientificandInnovativeResearch(AcSIR),Ghaziabad,India

SatyanshSingh

DepartmentofChemicalEngineeringandTechnology,IndianInstituteofTechnology(Banaras HinduUniversity),Varanasi,UttarPradesh,India

SaqibSohailToor

DepartmentofEnergyTechnology,AalborgUniversity,Aalborg,Denmark

DeepakVerma

SchoolofChemicalEngineering,SungkyunkwanUniversity,Seoul,SouthKorea

Hydrocarbonbiorefinery: Asustainableapproach

AlekhyaKunamallaa,SwarnalathaMailarama,BhushanS.Shriramea, PankajKumarb,andSunilK.Maitya

aDepartmentofChemicalEngineering,IndianInstituteofTechnologyHyderabad,Kandi,Sangareddy,Telangana,India bDepartmentofChemicalEngineering,BirlaInstituteofTechnologyandScience(BITS),Pilani,HyderabadCampus, Hyderabad,Telangana,India

1.7.2

Abbreviation

2,5-DMF 2,5-dimethylfuran

2,5-DMTHF 2,5-dimethyltetrahydrofuran

2-MF 2-methylfuran

2-MTHF 2-methyltetrahydrofuran

5-EMF 5-ethoxymethylfurfural

ABE acetone–butanol–ethanol

FTS Fischer-Tropschsynthesis

GVL γ-valerolactone

HAA hydroxyalkylation-alkylation

HDO hydrodeoxygenation

HMF 5-hydroxymethylfurfural

LA levulinicacid

MMT millionmetrictons

MON motoroctanenumber

RON researchoctanenumber

1.1Introduction

Transportationfuelsplayanextremelyvitalroleinpresentsociety.Gasoline,diesel,and jetfuelaremajorliquidtransportationfuelsatthemoment.DieselistheprimarytransportationfuelinIndiathataccountsformorethan75%oftransportationfuelsconsumed inthecountry.Ontheotherhand,gasolineisthemajortransportationfuelintheUnited States.Thesetransportationfuelsarethemajorenergy-consumingsector,accountingfor about28%oftheworld’senergyconsumption [1].Theyaremainlyproducedfromcrude oil.However,somecountriesintheworldblendalimitedamountofbiomass-derived fuelswiththesetransportationfuels.Petroleumis,however,limitedandnonrenewable. Thecurrentconsumptionrateindicatesthatexistingpetroleumreserveswillbe exhaustedwithinthenext50years [1].However,reservoirssometimesproducemore petroleumthantheestimatedreserveduetotheapplicationofenhancedrecoverytechniques.Moreover,newpetroleumreservoirsarediscoveredfromtimetotime.Therefore,petroleummaylastalittlelongerthan50years.Moreover,thesetransportationfuels areresponsibleforemissionsofcarbondioxide,NOx,unburnedhydrocarbons,andparticulatematterintotheatmosphere.Theseemissionsareaccountableforglobalwarming andunhealthyairquality,causingvarioushealthissues.Petroleumreservesarealsolimitedinmanycountriesintheworld.Forexample,Indiaimportsabout84%ofthepetroleumconsumedinthecountry.Therefore,theproductionoftransportationfuelsfrom

renewablesourcesisessentialforthesustainabilityofhumancivilizationandmaintenance ofcleanairquality.

Biomassistheonlycarbon-basedrenewableenergysourcewiththepotentialtoprovidetransportationfuels,calledbiofuels.Itmaybeemphasizedthatpetroleumhasbeen originatedfrombiomass.Thebiofuelsarecarbon-neutral.Thecarbondioxideemitted fromthesebiofuelsisreusedforthegrowthofbiomass,therebypreventingglobalwarmingandmaintainingconsistentairquality.Thebiofuelsfurtherofferadvantages,suchas theutilizationofwastebiomassandimprovementintheruraleconomy.Thebiomasscan alsoproviderenewableorganicchemicals,heatenergy,andelectricity.Incontrast,other renewableenergies,suchassolar,wind,hydrothermal,etc.,provideonlyenergyinthe formofelectricityandheat.Biomassisthusconsideredthemostpromisingrenewable energysource.Inancienttimes,humancivilizationwasdependentonbiomassforits energyneeds.Untilnow,biomassremainstheprimaryenergysource,mostlyforcooking,inseveralunderdevelopedordevelopingcountries.Currently,biomassdelivers around10%oftheworld’senergyor50%ofrenewableenergy.Biomassandwaste accountforabout22%ofenergyconsumptioninIndia [2].TheEuropeanRenewable EnergyCounciltargeted50%contributionofrenewableenergyintheworld’senergy consumptionby2040.Anticipatingthepotentialsofbiomass,theInternationalRenewableEnergyAgencyproposedsubstitutingabout22%oftransportationfuelswithbiofuels by2050 [3].Thischapterthusprovidesanoverviewofthevariousbiomasssourceswith theiravailabilityandchemicalstructureanddifferenttypesofbiorefineryfortheproductionofnumerousbiofuels.Thischapter,specifically,introducesanovelhydrocarbon biorefineryconceptformanufacturinghydrocarbonbiofuelsandbuilding-blockchemicalsfrombiomassandtheroleofheterogeneouscatalysisinthisbiorefinery.

1.2Biomass

Thedefinitionofbiomasshasbeenwidenedsincetheevolutionofbioenergyconcepts. Biomassisarenewableorganicmatterthatbroadlyincludesplants,microorganisms,and animalwastes.Basedontheirsource,biomassisclassifiedasenergycrops,wastes,and residuesobtainedfromagriculturecropsandforestmanagement,wastesgeneratedfrom industriesandmunicipality,andaquaticplants(Table1.1) [4,5].

1.2.1Typesofbiomass

Energycrops.Energycropsarecultivatedwittinglyforbioenergyproduction.These energyplantationsarelow-cost,short-rotation,andhigh-yieldingvarietiesthatneed nominalmaintenance.Thesededicatedcropsencompasswood,perennialforage,sugar, starch,andoil-basedenergycrops.Thewoodyenergycropshaveawidegeographical distributionwithhighpotentialyields.Theyarecultivatedonarotationalbasisforpulp production.Theperennialforageenergycropsareadaptableinthewastelandandrequire

Table1.1 Differenttypesofbiomassbasedontheirsource.

Energycrops

Oilcrops Oilseedrape,sunflower,castoroil,olive,coconut,groundnut, jatropha,soybeanoil,palmoil,cottonseedoil,linseedoil,field mustard,palmoil,etc.

SugarcropsSweetsorghum,sugarbeet,sugarcane,etc.

StarchcropsWheat,sweetpotato,corn,rice,barely,maize,etc.

WoodycropsHybridwillow,silvermaple,sweetgum,hybridpoplar,silvermaple, easterncottonwood,blackwalnut,greenash,sycamore,pine, miscanthus,etc.

GrasscropsBamboo,switchgrass,kochia,wheatgrass,canarygrass,coastal Bermudagrass,alfalfahay,thimothygrass,commonreed,Indian shrub,giantreed,immaturecereals,etc.

Agriculturewasteandresidue

Stalk Bean,corn,cotton,kenaf,mustard,sunflower,triticale,etc.

Straw Bean,corn,oat,rice,sesame,sunflower,wheat,mint,paddy,rape, rye,etc.

Shellandhusk

Almond,cashewnut,coffee,olive,peanut,walnut,sunflower, cotton,etc.

Fiber Flax,palm,kneafbast,jutebast,coconutcoir,etc.

LivestockwasteChickenmanure,pigmanure,sheepmanure,cattlemanure,bones, meatbonemeal,etc.

Forestwasteandresidue

Forestwaste Woodblocks,woodchipsfromthinning,logsfromthinning,barks, earlythinningbranches,leaves,bushes,etc.

Industryandmunicipalitywasteandresidue

FoodindustryresidueCookingoil,proteins,tallow,wetcellulosicmaterial(beetroottails), animalfat,oilgheewaste,fruitandvegetablescrap,fiberobtained fromextractionofsugarandstarch,etc.

Paperandwood industryresidue

Fibrouswastefrompaperandpulpindustries,wastewoodfrom sawmills,wastewoodfromtimbermills(bark,woodchips,slabs,and sawdust),paperandpulpsludge,etc.

OtherindustrywasteTanningwaste(leatherparticles,wasteliquor,andfleshingresidue), soapindustry(oilandgrease),wastewatersludge,etc.

MunicipalitywasteSewagesludge,wastepaper,yardwaste,gardengrassesandplants, dairywaste,woodpalletsandboxes,fiberboard,plywood, paperboardwaste,stalefood(uneatenbread,rice,andvegetables), etc.

Marinebiomass

MarinebiomassMarineandfreshwateralgae(microalgaeandmacroalgae), cyanobacteria,marinemicroflora,giantkelp,othermarine microorganisms(marineyeast),duckweed,waterhyacinth,sweet waterweeds,etc.

minimumwaterandnutrientsfortheircultivation.Typicalexamplesoftheseenergy cropsarebamboo,switchgrass,wheatgrass,sweetsorghum,andmiscanthus [4,6]. Theoil,sugar,andstarch-basedcropsarecultivatedacrosstheglobeforfoodpurposes. Theseenergycropsthusposefoodversusfuelconflicts.Somecountries,however,producetheseenergycropsinexcessofhumanconsumptionforbioenergyapplications.For example,Brazilproducessugarcaneforbioethanolproduction.TheIndianGovernment promotedjatrophacultivationinwastelandsforbiodieselproduction.Jatrophaoilisinedibleandhencedoesnotposefoodversusfuelconflict.

Agriculturewastesandresidues.Aconsiderableamountofbiomasswastesandresiduesis coproducedduringtheharvestingofcrops.Theseagro-wasteshave,however,limited utilization.Theyareeitherusedascattlefodderorfuelforcookinginremotevillages. Themajorityofthesebiomassesarestilleitherburnedinthefieldordumpedintothe wasteland.Ricehuskisthemostprominentagro-residue,anditaccountsforabout 25%ofricebymass [7].Sincecornisgrownworldwide,cornstoverisoneofthemajor agro-residues.Animalmanureisalsoincludedinagriculturewastes [4,7].Animal manure,suchascowdung,iscurrentlyusedforbiogasproduction.Theagricultural wastesandresiduesareinedibleandhenceanattractivebiomassforabiorefinery.This biomasshas,however,lowdensityandisgeneratedinremoteagriculturefields.The transportationofthisbiomassfromaremotelocalitytoacentralbiorefineryisthusexpensive.Moreover,thisbiomassisseasonal.Thestoragefacilityforthisbiomassisthusobligatoryfortheuninterruptedoperationofabiorefinery.

Forestwasteandresidue.Forestwastesandresiduesareanotherpertinentbiomass.The loggingresiduesgeneratedfromharvestoperation,fuelwoodderivedfromforestlands, stumps,andearlythinningofbranchesareprimaryforestresidues.Incontrast,woodprocessinggeneratessecondaryresidues.Theseoperationsareessentialtomaintainforest healthandproductivity.Thebarkandwoodhaveahighheatingvalueandaresuitable forthermalenergyapplications.Solidwoodisthemainsourceofenergyforthesmallscaleindustriesinunderdevelopedanddevelopingcountries.Thelowrecoverabilityand costoftransportation,logging,andcollectionactivitiesaremajorhurdlesforthisbiomass. Theutilizationofthisbiomassatornearsourceinadecentralizedbiorefineryisthus desirable.

Industryandmunicipalitywaste.Theorganicchemicalindustriesandmunicipalities generatealargevolumeoforganicwasteswithonlyasmallamountofinorganicmaterials [8].Solidwastes,greenwastes(nutshells,grasscutting,etc.),sewagesludge,andindustry wastesareexamplesofindustryandmunicipalitywaste.Themunicipalitysolidwastes comprisewastefood,paper,plastic,andtextiles.Foodwastesaregeneratedinvarious stepsofthefoodprocessingchain,suchasmanufacturing,logistics,storage,andpostconsumerstage [5,9].Thewastesgeneratedinthepulpindustry,bagasseproducedinthe sugarcaneindustry,andcoproducts(fattyaciddistillate,protein-richcake,gum,soap stock,etc.)oftheoilseedprocessingindustryareexamplesofindustrialwastes.

Marinebiomass.Marinebiomassreferstodiversifiedgroupsofaquaticspecies,photosyntheticalgae,andcyanobacteria.Thesizeofthisbiomassrangesfrommicroscopic(cyanobacteria,microalgae,etc.)tomacroscopic(macroalgaeandbrown,red,blue,andgreen seaweeds).Bothmicroandmacroalgaehavemorethanonemillionspecies [8,10].These speciescouldbeapotentialsourceoftriglycerideandcellulosicbiomass.Theycangrow inwastewater,coastalseawater,salinewater,andnonarableland.Innutrient-richwater, microandmacroalgaegrowwithahighcelldensityofupto107 cells/mL [11].The growthrateofalgaeisalsoveryhighwithashortharvestingcycle(1–10days).

1.2.2Chemistryofbiomass

Thebiomassiscomposedofadiverserangeoforganiccompoundswithaninsignificant amountofinorganicsubstances.Carbon,hydrogen,andoxygenaremajorelementsin biomasswithaminorquantityofnitrogenandsulfur.Carbohydrates,lignin,lipid,proteins,andfatsaremajorconstituentsofbiomass.Theamountoftheseconstituentsinbiomassdependsontheirtypes,growthstage,source,andgeographiclocation.Thefour categoriesofbiomassarecommonlyusedinabiorefinery:triglyceride,sugar,starch, andlignocellulose.

Triglycerides.Thetriglyceridesincludevariousinedibleandediblevegetableoil,waste cookingoil,wasteoils(trapgrease,yellowgrease,etc.),microalgaeoil,andanimalfats. Atriglyceridemoleculecontainsoneglycerolunitandthreesameordifferentfattyacids linkedbyanesterbond(Fig.1.1).Thefattyacidscontainalinearcarbonchaininthe rangeofC8–C24.Palmitic(C16:0),stearic(C18:0),oleic(C18:1),andlinoleic(C18:2)acids areprimaryfattyacidsintriglycerides.Bothsaturatedandunsaturatedfattyacidsarepresentintriglycerides.Thetriglyceridesalsocontainfreefattyacids.Thenumberofdouble bonds,thecarbonchainlengthoffattyacids,andtheextentoffreefattyacidsdependon thetypesoftriglycerides(Table1.2).

Sugarandstarch.Sugar(C12H22O11)ismadeoftwosix-carbonsaccharides,namely α-glucose(C6H12O6)and β-fructose(C6H12O6.).Theyarebondedby α1glucosidic and β2fructosidicbonds(Fig.1.1).Sugarisobtainedfromsugarbeet,sugarcane,sweet sorghum,etc.Ontheotherhand,instarch, α-glucosemonomersarelinkedby α1,4and α1,6glucosidicbondstoformpolymericstructures.Twoprincipalcomponentsare presentinstarch:amylose(20%–25%,water-soluble)andamylopectin(75%–80%, water-insoluble).Amylosecontainsonly α1,4glucosidicbonds,whileamylopectincontainsboth α1,4glucosidicand α1,6glucosidicbonds [4].Starchisfoundinpotato,rice, wheat,beans,etc.

Lignocellulose.Lignocellulosebiomassisacompositeofcellulose(40%–50%),hemicellulose(25%–35%),andlignin(15%–25%)withasmallamountofprotein,pectin,and extractives [4,15] (Fig.1.1).Thecarbohydrates(i.e.,celluloseandhemicellulose) providemechanicalandstructuralstrengthtotheplant,whilethenoncarbohydrate

Amylose

Hemicellulose monomers Starch

Lignin monomers

Fig.1.1 Chemistryofbiomass.

Coumaryl alcohol

Coniferyl alcohol

Table1.2 Chemicalcompositionofbiomass [9,12–14]

Biomass

Vegetableoil,wt%

3.5–7.61.3–6.514–4344–

a C8:0 ¼ 4.6–9.5wt%,C10:0 ¼ 4.5–9.7wt%.

(i.e.,lignin)givesstabilitytothesestructures.Thecompositionoflignocellulosebiomass ispresentedin Table1.2.Celluloseisalong-chainpolysaccharidewithahighdegreeof polymerization(nearly10,000).Itisalinearpolymerof D-glucopyranoseformedby β1,4 glycosidiclinkage.Cellulosehasacrystallinestructurewithfourdifferentforms:Iα,Iβ,II, andIII [16].Thecrystallinestructuresareformedbyintraandintermolecularhydrogen bonding.Thetightpackingofpolymericchainsandcrystallinestructuremakescellulose recalcitrantfordegradationandinsolubleinwater.Inplants,itispresentaselementary fibrilsconsistingofasinglecellulosechainorbundlesofelementaryfibrils,i.e.,microfibrils.Thesecomplexesofferstrengthandchemicalstabilitytoplants [17].

HemicelluloseisabranchedpolymercontainingC5 (xyloseandarabinose,C5H10O5) andC6 (glucose,mannose,andgalactose,C6H12O6)sugars.Thesesugarsareacetylated withuronicacid.Theheterogeneouscombinationofmonosaccharidesinhemicellulose isformedby β1,4glycosidicand β1,3glycosidicbonds.Itisanamorphouspolymerthat canreadilyhydrolyzetomonomersugars [17].Theabundanthemicelluloseinhardwood isxylan,inwhichxylosesugarsarelinkedatoneandfourpositions.Whilesoftwood hemicellulosemostlycontainsglucomannan,apolymerof D-glucoseand D-mannose

bondedby β1,4glucosidicbonds,ligninisabundantinlignocellulosebiomass.Itisanoncrystallineandthree-dimensionalpolymerofphenylpropanoidunits.Thethreeunitsthat formtheligninstructureareconiferylalcohol,sinapylalcohol,andcoumarylalcohol. Thelignincontentandcompositionvarywiththetypesofbiomass.Thehardwoodlignin containsacombinationofconiferyl(25%–50%)andsinapylalcohol(50%–75%).The softwoodligninhasahighpercentageofconiferylalcohol(90%–95%),whilegrasslignin hasallthreebuildingblocks,i.e.,coniferyl(25%–50%),sinapyl(25%–50%),andcoumaryl (10%–25%)alcohol [18]

1.2.3Availabilityofbiomass

BiomassisdistributedinvastterritoriesonEarthwithalargenumberofspecies.Therefore,itisdifficulttoassesstheexactavailabilityofbiomassonarenewablebasis.Ingeneral,wastebiomassfromagriculture,forest,industries,andmunicipalitiesisabundant withoutmuchimpactontheenvironmentandfoodproducts.Thisbiomassisthusappropriateforabiorefinery.In2014,theUnitedStatesconsumed5.6millionmetricton (MMT)cornand0.216MMTbiomasstoproducebio-basedproductsandgasoline blendstocks,respectively [19].In2013,theindustrialsectorintheUnitedStatesutilized approximately85.3MMT(dry)woodandwoodwastetogenerate539trillionBtuthermaland15.4trillionBtuelectricalenergy,whiletheresidentialsectorproduced349.5 trillionBtuthermalenergyfrom44.8MMT(dry)woodandwoodwaste.TheUnited Statesfurthergenerated254MMTmunicipalsolidwastein2013.About34%ofthese wasteswerediscardedforlandfilling,andtheremainingwereusedforeitherenergy recoveryorcompost [19].In2016,theUnitedStatesgeneratedapproximately 3.3MMTwoodpellets.Nearly85%ofthesewereresiduesoriginatedfromthesawmill, woodproductmanufacturing,andlogging,whiletheremaining15%weregenerated fromlogsharvestedforindustrialapplications [20].TheUnitedStatesproposedtogenerate1.3billiontonsdrybiomassby2030forbioenergyapplication.Itincludes87MMT grains,106MMTanimalmanureandfoodprocessingwaste,368MMTforestwaste, 377MMTenergycrops,and428MMTcropresidue [21]

In2017,theglobalbioenergysupplywas55.6EJwith48.2EJcontributionfrom solidbiofuels(woodpellets,woodchips,fuelwood,etc.).Thecontributionsofliquid biofuels,municipalitywaste,biogas,andin dustrialwastewere3.65,1.45,1.33,and 1.07EJ,respectively [22].Ontheotherhand,thecontributionofrenewableelectricity was0.33EJglobally [22] .In2017,biomasssupplied5%oftotalprimaryenergy consumedintheUnitedStateswithabout47%,44%,and10%contributionfrom wood,wood-derivedbiomass,andmunicipalwaste,respectively [23].In2018,the UnitedStatesproduced38.1MMTofoilequivalentbiofuel,whichwasthehighest

intheworld(39.9%).Brazilwastheworld’ssecondhighestbiofuelproducer (21.4MMTofoilequivalent,22.4%) [24,25].

InIndia,theestimatedannualavailabilityofbiomassfromagriculture,forest,and wastelandwas242MMTin2010–2011andisanticipatedtobe281MMTby 2030–2031 [26].RiceandwheatarethemostcultivatedcropsinIndiawhichaccount for41%ofthecultivatedarea,whiletheremaining15.9%,13.8%,and10.2%accountfor oilseed,pulses,andcommercialcrops,respectively [11].In2010–2011,theestimated productionofricestrawwas172.8MMT,ofwhich80.8%and11.1%wereusedasfodder andfuel,respectively,andtheremaining8%wereusedforotherpurposes.About 139.2MMTwheatstrawwasgeneratedin2010–2011,anditisestimatedtobe 193.7MMTby2030–2031 [26].In2015–2016,thetotalcropresiduesinIndiawereestimatedas816.4MMT.Thesugarcaneandcottonresiduesaccountfor282MMT [11,26]. UptoMay2019,theinstalledcapacityofrenewablepowerwas78.4GWinIndiawith 46%,37%,and12.8%contributionfromwind,solar,andbiomass,respectively.India estimatesaprojected175GWrenewablepowerby2022with10GWfrombiomass. Theprincipalfeedstockisbagassefromsugarmills [27].In2015–2019,theaverageannual ethanolconsumptiongrowthwashighercomparedtotheproductiongrowth(8%)in India [27].Thecombinedeffectofenhancedfiscaldeficitowingtotheincreaseincrude oilimportanddepreciatingrupeemakestheIndianGovernmentfocusonbiofuels.The primaryfuelconsumptioninIndiawas809.2MMTofoilequivalent,whichisnearly 5.84%ofglobalconsumptionin2018with27.5MMTofoilequivalentcontribution fromrenewables [25].TheIndianannualbiofuelproductiongrowthrate(19.7%in 2007–2017)washigherthantheglobalgrowthrate(9%).In2018,biofuelproduction inIndiawas1023MMTofoilequivalent,whichwas1.1%ofglobalbiofuelproduction [25].TheNationalBiofuelPolicyinIndiaproposed20%mixingofbioethanolwithgasolineand5%mixingofbiodieselwithdieselby2030 [24,27].During2013–2014,only 1.53%ethanolwasblendedwithgasoline.Itwasincreasedto3.5%in2015–2016and droppedto2.07%in2016–2017 [24].

1.3Biorefinery

Coalisusedmainlytoproduceelectricityinthermalpowerplants.Incontrast,thepetroleumrefineryrefinescrudeoiltoproduceaspectrumofproducts,primarilyfuels,suchas liquefiedpetroleumgas,gasoline,kerosene,jetfuel,diesel,andfueloil.Thesefuelsfind applicationinthetransportationsector,cooking,illumination,andindustry.Besides,the petroleumrefineryproducesnaphthaasfeedstockforpetrochemicalindustries.Onthe otherhand,naturalgasisusedasfeedstockforpetrochemicalindustriesandroadtransportationfuelintheformofcompressednaturalgas.Inthepetrochemicalindustry,naphthaandnaturalgasarefurtherprocessedtoproducethreebasicbuilding-blockchemicals: (i)synthesisgas(H2 +CO),(ii)olefins,suchasethylene,propylene,butylenes,and

Table1.3 Platformchemicals.

Ethanol

Furfural

5-Hydroxymethylfurfural

Furandicarboxylicacid

Glycerolandderivatives

Lacticacid

Isoprene

Biohydrocarbons

Succinicacid

Hydroxypropionicacid/aldehyde

Levulinicacid

Sorbitol

Xylitol

butadiene,and(iii)aromatics,suchasbenzene,toluene,ethylbenzene,andxylenes. Thesebuilding-blockchemicalsarethefoundationfororganicchemicals,fertilizers, polymers,andcommoditiesforoursociety.

Anovelmanufacturingconceptisdevelopingthroughouttheworldtosubstitute thesefossilfuelswithbiomass.Thisconceptisknownasthebiorefinery [3,4].Thebiorefineryshouldideallyproduceaspectrumofproductsthatarecurrentlyobtainedfrom fossilfuels,suchasbiofuels,organicchemicals,polymers,materials,heatenergy,andelectricity.Thebiorefineryidentified12primarybiomass-derivedorganicchemicals,called platformchemicals(Table1.3) [28].Theseplatformchemicalsareproducedfromthe carbohydratefractionofbiomassusingacombinationofchemicalandbiochemicalprocesses.Theglycerolis,however,coproducedinthetransesterificationprocess(10wt%of biodiesel).Theseplatformchemicalshavevastderivativepotentialstoproduceorganic chemicals,polymers,andcommodityproducts.Theplatformchemicalscanalsobetransformedintovariousbiofuels.Thebiorefineryisthusanalogoustotheintegratedpetroleumrefineryandpetrochemicalindustry.Thebiorefinerycanbeclassifiedbasedon eitherfeedstock,products,orthenatureofprocessingtechnologies.Ingeneral,thespecificbiorefineryisexpectedtoprocessbiomasswithasimilarchemicalnature.Sothe biorefineryisspeculatedbasedonthespecificchemicalnatureofbiomass,suchasthe sugarandstarch-basedbiorefinery,lignocellulose-basedbiorefinery,andtriglyceridebasedbiorefinery [3,4].Theseindividualbiorefineriescanbefurtherclassifiedbased oneithertargetedproductsortypesofprocessingtechnologies.

1.3.1Sugarandstarch-basedbiorefinery

Sugarandstarch-basedbiorefineriesarewellknownbecauseofbioethanol.Thestarchbasedfeedstockundergoeshydrolysistoformaqueoussugars.Aqueoussugarsare extractedfromsugar-basedfeedstockthroughphysicalseparationmethods.Aqueous sugarsarefermentedtovastrangesofproducts.Strainsusedinfermentationdetermine thetypesofproducts.Bacterialstrainsareusedforacetone–butanol–ethanol(ABE)fermentationwithcoproductionofhydrogen,whileyeastfermentationyieldsethanol. Bioethanolandbiobutanolareusedasbiofuelandsolvent.Theyarealsoreformedto synthesisgasandcatalyticallyconvertedtopetrochemicalbuilding-blockchemicals,such

asethylene,butylenes,andaromatics [29–31].Fermentationofsugarsalsoproducesvariousplatformchemicals,suchassuccinicacid,lacticacid,glutamicacid,itaconicacid,and 3-hydroxypropanoicacid(Table1.3).Ametabolicallyengineeredstrainproduceslinear orbranchedhigherbio-alcoholsfromsugars.Aqueous-phasecatalysisofsugarsproduces aromaticsandalkanes [32].Hydrogenisproducedbytheaqueous-phasereformingof sugars.5-Hydroxymethylfurfural(HMF)isproducedbydehydrocyclizationofhexose sugars.ThedecompositionofHMFproduceslevulinicacid(LA).Microbialprocessing ofhexosesugarsproducesliquidbiofuels [33]

1.3.2Lignocellulose-basedbiorefinery

Alignocellulosebiomassprovidesawidespectrumofproducts.However,thecomplex structureofthelignocellulosebiomassisthemainbottleneck.Thecombustionofthe lignocellulosebiomassproducesheatandelectricity.Thegasificationproducessynthesis gas,whichisfurtherconvertedtoethanolandhigheralcoholsandliquidbiofuelsthrough theFischer-Tropschprocess.Fastpyrolysisandliquefactionofthelignocellulosebiomass producebio-oil.Bio-oilisupgradedtobiofuels,aromatics,andorganicchemicalsusing hydrodeoxygenation(HDO)andzeoliteupgrading [34].Pretreatmentoflignocellulose biomassformshydrolysatecontainingsugars.Anaerobicfermentationofhydrolysateproducesbiogasandhydrogen.Furtherhydrolysisofpretreatedlignocellulosebiomass reducesthestructuralcomplexityandproducesligninandsugars(hexoseandpentose). Aqueoussugarsarefermentedtoethanol,butanol,acetone,andhydrogen.Aqueousphasedehydration/hydrogenationofsugarsproducesC1–C6 alkanes.Zeoliteupgrading ofsugarsproducesaromaticsandhydrocarbons.Aqueous-phasereformingandmicrobial processingproducehydrogenandliquidbiofuels,respectively [33,35].Furfuraland HMFareC5 andC6 furansandobtainedbydehydrationofC5 andC6 carbohydrates, respectively,inthepresenceofacidcatalysts [36].LAisobtainedbysubsequentdehydrationoffurans.BiofineCorporationproducesLAonalargescaleusingaseriesof tworeactors(70%–80%yield) [37].Inthefirstreactor,carbohydrateisconvertedto HMFat483–503Kinthepresenceofmineralacids.HMFisthenconvertedtoLAin thesecondreactorat468–488Kwithmorethan60%yield.Ligninisconvertedtoaromaticsthroughzeoliteupgrading.Depolymerization,hydrogenation,andsolvolysisof ligningivegasoline-rangefuelandphenolics.

1.3.3Triglyceride-basedbiorefinery

Triglyceridesaretransformedintobiofuels,value-addedproducts,andorganicchemicals. Thecakeorresidueobtainedfromoilseedisusedasfertilizer,feed,orfeedstockstothe lignocellulosebiorefinery.Transesterificationoftriglyceridesforbiodieselproduction hasgainedenormousattentioninthisbiorefinery.Hydrolysisoftriglyceridesproduces

Table1.4 Classificationofbiorefinerybasedontypesofbiofuels.

Biorefinery

Biorefineryfor traditionalbiofuels

Biorefineryforfueladditives

Hydrocarbon biorefinery

Biofuels

Biodiesel,bioethanol,biobutanol,dimethylether,etc.

γ-Valerolactone,furaniccompounds(2-methylfuran, 2-methyltetrahydrofuran,2,5-dimethylfuranand2,5dimethyltetrahydrofuran),5-ethoxymethylfurfural,alkyllevulinates, glycerolether/acetal,etc.

Greenliquefiedpetroleumgas,greengasoline,greenkerosene, greenjetfuel,greendiesel,etc.

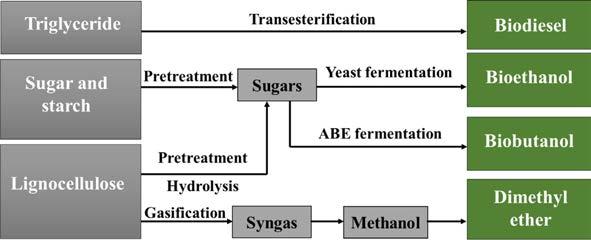

Fig.1.2 Biorefineryfortraditionalbiofuels.

fattyacidsthatarehydrogenatedandisomerizedtogreendiesel [38].Fattyacidsarealso usedtoproducemanyvalue-addedproductslikesoaps,emulsifiers,surfactants,etc. GreendieselandgreengasolinearealsoproducedbydirectHDO,catalyticcrackingover solid-acidcatalysts,andpyrolysisoftriglycerides [39].Steamanddryreformingoftriglyceridesproducesynthesisgas [40,41]

1.3.4Biorefineryforbiofuels

Thebiorefinerycanbebroadlyclassifiedintothreetypesbasedonthenatureofbiofuels produced:(i)biorefineryfortraditionalbiofuels,(ii)biorefineryforfuel-additives,and (iii)hydrocarbonbiorefinery(Table1.4) [42].

1.4Biorefineryfortraditionalbiofuels

Thebiorefineryfortraditionalbiofuelsisshownin

Fig.1.2.Thefuelpropertiesofthese biofuelsarecomparedwithgasolineanddiesel,aspresentedin Table1.5.