https://ebookmass.com/product/human-factor-and-reliability-

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

The Donkey in Human History: An Archaeological Perspective

Peter Mitchell

https://ebookmass.com/product/the-donkey-in-human-history-anarchaeological-perspective-peter-mitchell/

ebookmass.com

Analysis of Cosmetic Products 2nd Edition Amparo Salvador

https://ebookmass.com/product/analysis-of-cosmetic-products-2ndedition-amparo-salvador/

ebookmass.com

Through the Lens of Anthropology: An Introduction to Human Evolution and Culture 1st Edition, (Ebook PDF)

https://ebookmass.com/product/through-the-lens-of-anthropology-anintroduction-to-human-evolution-and-culture-1st-edition-ebook-pdf/ ebookmass.com

The Transnationalized Social Question: Migration and the Politics of Social Inequalities in the Twenty-First Century Thomas Faist

https://ebookmass.com/product/the-transnationalized-social-questionmigration-and-the-politics-of-social-inequalities-in-the-twenty-firstcentury-thomas-faist/ ebookmass.com

Pucker Up, Cowboy: A Steamy Hockey Instant Attraction Protector Novella (The Puckers Book 1) Zee Irwin

https://ebookmass.com/product/pucker-up-cowboy-a-steamy-hockeyinstant-attraction-protector-novella-the-puckers-book-1-zee-irwin/

ebookmass.com

Organic Electronics for Electrochromic Materials and Devices 1st Edition Hong Meng

https://ebookmass.com/product/organic-electronics-for-electrochromicmaterials-and-devices-1st-edition-hong-meng/

ebookmass.com

Harrison’s Pulmonary and Critical Care Medicine, 3e Joseph Loscalzo

https://ebookmass.com/product/harrisons-pulmonary-and-critical-caremedicine-3e-joseph-loscalzo/

ebookmass.com

Advances in Supercapacitor and Supercapattery: Innovations in Energy Storage Devices Mohammad Khalid https://ebookmass.com/product/advances-in-supercapacitor-andsupercapattery-innovations-in-energy-storage-devices-mohammad-khalid/

ebookmass.com

Exploring the Spatiality of the City across Cultural Texts: Narrating Spaces, Reading Urbanity Martin Kindermann

https://ebookmass.com/product/exploring-the-spatiality-of-the-cityacross-cultural-texts-narrating-spaces-reading-urbanity-martinkindermann/

ebookmass.com

At Home with Democracy : A Theory of Indian Politics 1st Edition D.L. Sheth (Auth.)

https://ebookmass.com/product/at-home-with-democracy-a-theory-ofindian-politics-1st-edition-d-l-sheth-auth/

ebookmass.com

HumanFactorandReliabilityAnalysistoPrevent LossesinIndustrialProcesses AnOperationalCulturePerspective

Thispageintentionallyleftblank

HumanFactorand ReliabilityAnalysisto PreventLossesinIndustrial Processes AnOperationalCulturePerspective

SalvadorA ´ vilaFilho

FederalUniversityofBahia,Salvador,Brazil

IvoneConceic¸a ˜ odeSouzaCerqueira

FederalUniversityofBahia,Salvador,Brazil

CarineNogueiraSantino FederalUniversityofBahia,Salvador,Brazil

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2022ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicormechanical,including photocopying,recording,oranyinformationstorageandretrievalsystem,withoutpermissioninwritingfromthepublisher. Detailsonhowtoseekpermission,furtherinformationaboutthePublisher’spermissionspoliciesandourarrangementswith organizationssuchastheCopyrightClearanceCenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www. elsevier.com/permissions .

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher(otherthanasmaybe notedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroadenourunderstanding, changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusinganyinformation, methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationormethodstheyshouldbemindfuloftheir ownsafetyandthesafetyofothers,includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeanyliabilityforanyinjury and/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceorotherwise,orfromanyuseoroperationof anymethods,products,instructions,orideascontainedinthematerialherein.

ISBN:978-0-12-819650-2

ForInformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: SusanDennis

AcquisitionsEditor: AnitaA.Koch

EditorialProjectManager: LenaSparks

ProductionProjectManager: BharatwajVaratharajan

CoverDesigner: MarkRogers

TypesetbyMPSLimited,Chennai,India

1.Introduction1

1.1Abriefdiscussion1

1.1.1Theorganizationinsertedinthe socialenvironment1

1.1.2Conceptualandmathematical modelsinhumanandoperational reliability1

1.1.3Riskmanagementincomplex processesandenvironments2

1.1.4Competencyanalysisand taskplanning2

1.1.5Analysisanddiagnosisof humanfactors3

1.2Discussiontimelineandschools5

1.2.1Ahistoricalvisionaboutschools relatedtooriginofhuman reliability5

1.3Workerroleinjobandsociety: humanerror8

1.3.1Humanactivity9

1.3.2Roleatworkandsociety9

1.3.3Departments,functions,and humanreliability11

1.4Riskmanagementonmateriallosses andoperations19

1.4.1Materiallossrisk19 References23

2.Humanreliabilityandcognitive processing25

2.1Humanreliability25

2.1.1Whystudyhumanreliability?25

2.1.2Classicconceptsofhumanreliability28

2.1.3Modeling—first,second,andthird generation31

2.1.4Standardizedplantanalysis.riskhumanreliabilityanalysismethod andacaseinachemicalfacility36

2.1.5Humanreliabilityinvolvedinthe culturallink38

2.1.6Operatordiscourse—fuzzy41

2.1.7Third-generationapplicationinthe calculationoforganizational efficiency,Oil&Gas48

2.2Humanreliabilityandcognitiveprocessing52

2.2.1Cognitiveprocessing52

2.2.2Introductiontocognitiveprocessing, cases,failure,andskill knowledgement,rules52

2.2.3Cognitivefunctionsanddecision processes60

2.2.4Learningandskill64

2.2.5Motivationanddecision65

2.2.6Decision-makingprocess66

2.2.7Cognitivemodeldiscussion71

2.2.8Humanbehaviordynamicsin thecompany74 References82

3.Factorsaffectingtheperformance oftasks85

3.1Humanandsocialtypology85

3.1.1Humantypology86

3.1.2Socialtypologyandarchetypes88

3.1.3Classificationofhumanerror90

3.1.4Conceptsandtheinvestigationof latentfailure93

3.1.5Socioeconomicenvironment: humanreliabilityanalysis95

3.1.6Investigationof socioeconomic-affectivecycleand cycleofthinkinganddecision making—utility101

3.1.7Executivefunctionanalysis102

3.1.8Environmentsinhumanand operationalreliability: humanerror104

3.1.9Diseases,badhabitsandcognitive academy105

3.2Taskassessment106

3.2.1General106

3.2.2PADOP—environmentsand cognitiveaspectsintask preparation-execution113

3.2.3Toolsforplanningthe standardtask122

3.2.4Decisionanalysisunderstress: emergencysimulation136

3.2.5ApplicationofPADOPforthe sulfuricacidplantcase138

3.3DiscussionaboutAPI770143

3.3.1Conceptsandassessmentfrom API770143

3.3.2AnalysisoftheAPI770survey144 References148

4.Processlossassessment151 4.1Context151

4.2Competenciestoassessprocesslosses155

4.2.1Premisesandcompetencies155

4.3Lossesintheprocessindustries157

4.3.1Processlossesintheoilindustry159

4.3.2Processlossesingasindustryfor energy163

4.3.3Processlossesinthe biofuelsindustry164

4.3.4Processlossesinthepetrochemical industry166

4.3.5Processlossesinthechemical industry167

4.3.6Processlossesinthepolymer industry167

4.3.7Processlossesinthemetallurgy industry168

4.3.8Riskoflossduetotechnology168

4.4Diagnosisofprocesslosses169

4.4.1Introduction169

4.4.2Knowledgeofthe productionprocess172

4.4.3Collectingdata—inputs172

4.4.4Measuringresults—outputs176

4.4.5Introductiontotoolsandmethods185

4.5Cases:diagnosticswithquantitative andqualitativeanalysis194

4.5.1Chemicalandpolymercase: diagnosisbasedonoperator’s discourse195

4.5.2Caseofmetallurgybasedon managerdiscourseandtechnical issues207

4.5.3Discussion211 References211

5.Learnedlessons:humanfactor assessmentintask213

5.1Routine,environments,humantypes, andclassoferrors213

5.1.1RoutinemanagementcaseGR: director’sbehavior(511—GR1)214

5.1.2Technicalandoperationalculture: solutionforwasteinthereaction (512—CTO2)215

5.1.3Emergencycase:situationin reactionstoichiometry(513—ER3)215

5.1.4Practicalskillscase:perception andmonitoring(514—HP4,HP5)216

5.1.5Routinemanagementcase: meetingtochangetimeinshift group216

5.1.6Operational—processcontrol: investigationoftheprocessand wastewater(516—COP7)218

5.1.7Problemanalysis:diagnosisand processmapping(517—AP8)219

5.1.8Problemanalysis:negotiationfor preventiveaction(518 AP9)220

5.1.9Operationalsafetycase:about safetyculture(519—SO10, SO11,SO12)221

5.1.10Inappropriatedesignandoperation: technologicalsolutions (5110 PJ13)223

5.1.11Organizationalchange:changein practicewithoutconsultingpast ritual(5111-PR14)223

5.1.12Routinemanagement,technicaloperationalculture:biasin execution(5112 VIO15/19)224

5.1.13Accidentcasesincontractors: inadequatestandardforservices (5113 AC20a21)227

5.2Routinelearning:guidelinesforhuman reliability228

5.2.1Learningpoints228

5.2.2Routeofhuman,groupand organizationalerror234

5.3Lessonslearnedandvalidationofthe guidelines235

5.3.1Cognitiveandbehavioralacademy: routineandprogramfriendsof emergencypool237

5.3.2Applicationoftoolsforarchetype analysisandexecutivefunctionin theindustry248

5.3.3Communicationinroutine— environmentalaccidentwithHCl (Souzaetal.,2018b)251

5.3.4Investigationoftechnicalfailure andhumanerrorinthesulfuric acidplant255

5.3.5Industryalarmsandshutdown (Ammonia,HDT,Cyclohexane): H2 andCOcompressors261

5.3.6Taskcomplexity,lowefficiency, andaccidentinvestigation269

5.3.7Justcultureinmetallurgyandoil industries273

5.4Humanreliability,sociotechnical reliability,cultureofsafetydemands277

5.4.1Chemicalindustryandelectricity distribution278

5.4.2Petrochemicalindustry286

5.4.3Onshoreoffshoreoilandgas industry287

5.4.4Fertilizerindustryandrefining units294

5.4.5Metallurgicalindustryandchicken manufacturing296

5.4.6Publicsecurityagencies:security, mobilityandhealth, firefighter—PuA300

5.4.7Contextconclusion:researchversus society’sdemand304 References304

6.Humanreliability:SPAR-Hcases307

6.1Introduction307

6.1.1Reviewingthechapters307

6.1.2Humanerrorsinthecontextof criticalactivities309

6.2ConceptsandSPAR-Hcalibration310

6.2.1Operationalcontext311

6.2.2Calculationofhumanerror probability314

6.2.3SPAR-Hcalibration314

6.2.4Discussionofperformanceshaping factorsandcalibration315

6.3Casestudies324

6.3.1Chickenindustry325

6.3.2Uraniumindustry328

6.3.3Chemicalindustry331

6.3.4Refiningindustry333

6.3.5Fertilizerindustry337

6.3.6Coconutindustry342

6.3.7Packinglistservicesinthe manufactureofsportsproducts344

6.4Comparativeanalysis347

6.4.1Recommendations349

6.5Integratedreliability:thebeginning349

6.5.1Controlandmetricstoachieve integratedorsociotechnical reliability351

6.5.2Simulationoftheapplicationofthe integratedreliabilitymethod353

6.5.3Results354 References356

7.Humanreliability:chemicalsand oilandgascases359

7.1Methodologydescription359

7.1.1Guidingthealgorithmstoapply technologicaltoolsandsocial environment359

7.1.2Concept,tool,andprocedurefor technical,social,environment, andhumantypologies361

7.2Chemicalindustrycaseapplication391

7.2.1Abnormalitiesinventory392

7.2.2Abnormalitylogicincomplex processes393

7.2.3Aliphaticamines395

7.2.4Aromaticamines396

7.2.5Polycarbonates401

7.3Oilandgascaseapplication404

7.3.1Contextidentification:company, experience,ritualsand organizationalculture405

7.3.2Surveyoftechnical,humanand socialdata408

7.3.3Abnormaleventmapping, signs,andfailuremode (MEAandFMEA)412

7.3.4Processanalysis,logistics, operations,maintenanceandsafety (T3—AEP,T4—EVA)414

7.3.5Analysisofthetaskandresults423

7.3.6Analysisofhumanandsocialdata intheworkenvironment435

7.3.7Competenceanalysisandresults441

7.3.8Standardforbehavioranalysis445

7.3.9Abnormaleventclusteranalysis (T14)449

7.4Qualitativeresults:chemical industrycases451

7.4.1Managementaspectsfordecision451

7.5Quantitativeresults:oilandgascase457

7.5.1Failureenergyanalysis457

7.6Futurework:taskcross-assessment basedonparticleswarmmodel468

7.6.1Thepathofworkers469

7.6.2Thebridgetothefuture470 References471

8.Conclusionandproducts473

8.1Conclusion473

8.2Futurebook:humanfactorroutineand emergencyanalysis475

8.3Productsingeneral476

8.4Product1(Chapter4)—processloss mapping478

8.4.1Introductionandmethods478

8.4.2Methods478

8.4.3Discussion479

8.4.4Calculationbasedonmetallurgy case(Section4.5.2)480

8.5Product2—taskassessment—PADOP480

8.5.1Introduction480

8.5.2PADOPstandardandreview481

8.5.3Taskfailureassessment488

8.5.4Taskemergencyassessment490

8.6Product3—cognitivequality491

8.6.1Introduction491

8.6.2Cognitivequalityelements, functionsandsubfunctions492

8.6.3Staticcognitivequality—COGNQe494

8.6.4Discussionaboutdynamiccognitive quality—COGNQd494

8.7Product4—humanreliabilitySPARH495

8.7.1Operationalcontext496

8.7.2Performancefactorsassessment496

8.7.3Calculationandcalibration497

8.8Product5—social-technicalreliability498

8.8.1Cultureandmanagerprofile498

8.8.2Complexityofparametricequations498

8.8.3Individualreliabilities499

8.8.4Social-technicalreliability calculation500

8.9Product6—operational-technicalculture andprediction500

8.9.1Introduction500

8.9.2Methodologyandproducts502

8.9.3Managementprogramsforhuman andsociotechnicalreliability503 References506

Annex509 Listofabbreviations541 Glossary543 Index545

Abouttheauthors SalvadorA ´ vilaFilho—ChemicalEngineer(UFBA)andPetrochemicalProcessEngineer(Petrobras)—hasextensive knowledgeinthechemicalindustry.Heisspecializedinstatisticaltechniques(CQE/ASQ)toinvestigateabnormalities intheindustryandworkasanorganizationalconsultant(UCSal)fortransformationofculture.Hehasdevelopedauditingtechniques,effluentcontrol,andfugitiveemissionstoreduceenvironmentalimpactsintheindustry.Hehasalso developedatechniqueforanalyzingtheperceptionoftheoperatorsregardingroutinesthathaveanimpactonsafety, energy,andenvironment(UFBA).Asamanagerofindustrialfacilities,hecreatedamodelforcleanmanagement, includinghumanbehaviorandtechnologies.Hehasworkedasaprofessoringraduatecoursesinadministration,chemicalengineering,andindustrialengineeringatdifferentuniversities,especiallyinthesubjectsofrisks,reliability,and humanfactors.Meanwhile,humanaspectsareinvestigatedinthecoursesandpracticesofpsychoanalysisallowingto enterbythecognitivefaultinthebehavior,inthesocietyandthework.Hehaspartnershipsintheprivateinitiativein reliabilitycenteredmaintenanceandhumanreliability.doctoralresearchinthehumanandorganizationalculturesarea andprovidesconcepts,techniques,andmethodstokeepindustrialprocessesundercontrol.Hehaspresentedarticles werepresentedintheareasofhumanfactors,risk,processsafety,energyandwaterefficiencyandcurrentlyinculture andbehaviorchange.Hehasalsoworkintheenergysectoranddevelopedasolutionforproductivearrangements.He alsocontributedtoreducetheloadofnitrogenintheeffluentofthefertilizerindustrywithstatistics,processstudies, equipmenttechnology,investigationofprocedures,andeducationalcampaign(FriendsoftheLagoon).Asaprofessor andresearcherofUFBAinthedepartmentofmechanicalengineering,heconductsresearchandservicesintheareasof riskmanagement,organizationalcultureandhumanreliability,lossofprocess,energy,andwatersavings.Currently,he hascooperationwithRLAM(Refinery)inenergyefficiency,UOBAActiveNorthintheareaofreliabilityandrisk, SecretariatofPublicSecurityintheareaofriskinmega-eventandbehaviorofthepoliceforceoftheStateofBahia.In addition,hehasworkedontoolsandprojectsofpublicsafetyforpreparednessforemergencytoavoiddisasters.

IvoneConceic¸aodeSouzaCerqueira—GraduatedinNutritionfromtheFederalUniversityofBahia.Shehasbeena FederalPublicServantfortheMinistryofEducation—FederalUniversityofBahia,since1982andcurrentcoordinator ofthenucleusoffollow-upofundergraduatecoursesassessments—prorectoryofundergraduate—UFBA.SheisspecializedinhospitalmanagementbytheInstituteofCollectiveHealth/UFBA,1996,inclinicalnutritionbythe UniversityofNavarroandinpeoplemanagementbytheSchoolofAdministration,UFBA.Sheholdsamaster’sdegree inmedicineandhealth,FacultyofMedicine,UFBA.AmemberoftheCommunicationandHealthResearchGroup— UFBAInstituteofCollectiveHealth.Shehasexperienceininternationalhospitalaccreditationintheareasofeducation andprofessionalqualificationandfacilitiessecurity.Shehaspublishedarticlesinsecurity,riskinmega-event,human factor,leadership,andhumanreliabilityandwasadoctoratestudentinindustrialengineering—PolytechnicSchool— FederalUniversityofBahia-2017.1 2020.1.

CarineNogueiraSantino—GraduatedinProductionEngineeringfromSalvadorUniversityandmaster’sinindustrial engineeringfromUFBA:studyinlossmappinginthemetallurgicalindustry.DoctoratestudentinIndustrial Engineering/UFBA:studyinprocessoptimization.Shehasprofessionalexperienceinqualitycheckinginsteelindustry, involvingauditsandSixSigmaproject;shehas4yearsofexperienceinhumanresourcesintheareaofpeoplemanagement.MemberoftheResearchGroupGRODIN—PolytechnicSchool-UFBA—researchgroupatdynamicrisk,and topicsthataddressreliabilitysafetyandreductionofenvironmentalimpacts.Shehaspublishedarticlesintheareasof processsafety,humanreliability,andlossmapping.

Thispageintentionallyleftblank

Preface Thisbookaimstodiscusshumanreliabilityandthemostsuitableworkingenvironmentintheindustrytoavoidhuman error.Wewilladdressthefollowingissues:

1. Generalconsiderationsonhumanreliabilityanalysis

2. Understandingoperatordiscoursefromroutinedatacollection

3. Cognitiveprocessingandthepossibilitiesforhumanerror

4. Theroleofhumanintheexecutionofthetaskandaspectsrelatedtosafety

5. Discussionofevents,incidents,andaccidentsinthechemicalindustrybasedonoperationalculture

6. Humanreliabilitymethod[Humanreliabilitymethod(SPAR-H)]andhumanfactoranalysisinindustry

7. CasediscussionoftheLPGindustryforoperationalculturebyapplyingthetool,operatordiscourseanalysis,for humanfactoradjustment

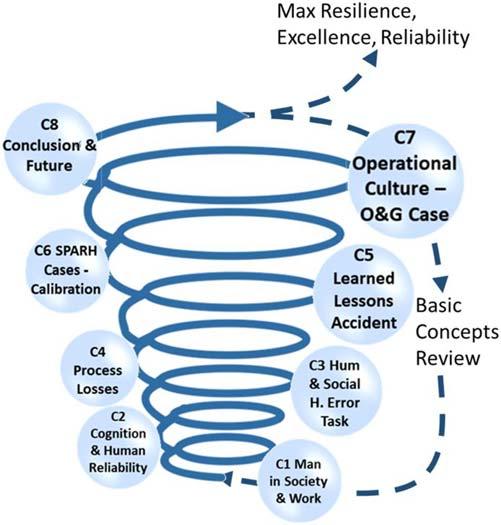

1Paradigms Thetheoreticalandpracticalknowledgeonhumanreliabilityandhumanfactorsareapproachedprogressivelyfrom Chapter1 to Chapter8,asshownin Fig.1.Afterreadingthebookandnoticingthetechniquesappliedineachtopic,it isconcludedthatduetoculturalchangesthatchangehumanbehavior,itisessentialtoreviewtasksandinvestigate humanfactors.Itisimportant,ifnecessary,toreturnandrevisetheconceptsinthediscussionofpreviouschapters,as Chapter1 andtoadvanceupwardsinthespiralshownin Fig.1,towardoperationalexcellence,organizationalresilience withthemaximumlevelofreliability,inthesociotechnicalproductionsystems.

FIGURE1 Theupwardspiralofknowledgeandapplications.

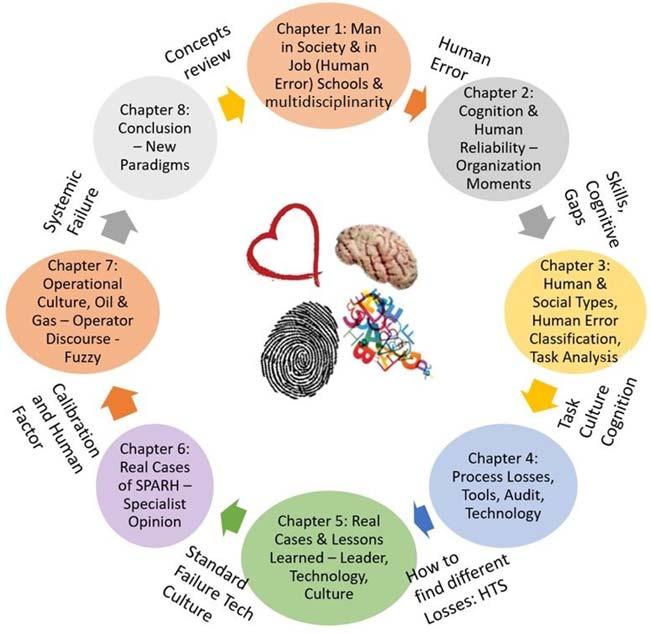

2Bookstructure Thisbookbreaksnewgroundwhendiscussingtherelationshipbetweensocial,organizational,andoperationalcultures forinferringaboutunexpectedfuturebehavior.Itattemptstoinclude,inconceptualmodels,anintuitive,affectivelearningwithcognitiveprocessing.Thissubjectivityshouldberecognizedthroughtoolsthatassistintheinvestigationof taskfailures.Theseaspectsarepresentedin Fig.2

Therelationshipbetweenprocesslosses,accidents,failures,anddeviancesindicatesapossiblecomplexityofthe failureincludingtheresultinghumanperformancefactorsandtechnologies,processes,andequipment.Severalcases arediscussedqualitativelybut,also,quantitativelyforthecalculationofhumanreliability.

Thebookpresentsmethodsandtechniquestominedata,measureorganizationalefficiency,andreducethenumber ofdatathatrepresentstheoperatingculture.Italsoattemptstorelatewhicharethepriorityhumanandorganizational factorsto,throughadjustments,returntheorganizationalefficiencytotheregionofnormality.

InthePreface,thesubjectsdiscussedinthebookarepresented.Eachpracticalscenarioconfirmstheconceptual modelsandmakesthereaderthinksofwaystoavoidtheaccident.Herewepresentalsoacknowledgment,glossary,list ofabbreviations,andsummaryofcompletebook.

Intheintroduction, Chapter1,humanreliabilityisdiscussedregardingmultidisciplinaryaspectssuchasthefollowing:(1)organizationwithinthesocialenvironment;(2)conceptualandmathematicalmodelsinhumanandoperational reliability;(3)riskmanagementincomplexprocessesandenvironments;(4)competencyanalysisandtaskplanning; and(5)diagnosisofhumanfactors.Multidisciplinarysciences,academicschools,andprivateandpublicinitiativesparticipateinthediscussiononhumanreliability,from1990to2016,andtheirbasesinsertedinthecomplexityofhuman factorsintheindustrialenvironment.

Theimportanceofhuman’sroleinorganizationalefficiencyincludesadiscussionofhisrolesinsociety,his departmentalfunctions,andthepossibilityofcausinghumanerror.Thisrecognitionaboutmultipleconnectionof human,fromsocietytoeconomicoutcome,indicatestheneedtoinvestigaterisksinadynamicformat.

Chapter2 dealswiththethemesofhumanreliabilityandcognitiveprocessing,discussingthechallengeofmathematicalmodelsinthethreegenerations.InthecaseoftheSPARHtechnique,basicconceptsabouthumanfactorsthat indicatethelevelofreliabilityarepresented.Inthecaseofthethirdgeneration,weindicatetheuseoffuzzymechanics,

FIGURE2 Concepts,subjects,paradigms,and resultsthroughoutthebook.

citingacasepresentedinthisbookin Chapter7 thatusestheoperatordiscourseanalysistechnique,whichsignalsthe resultingoperationalculture.Analysisoftheoperatordiscourseinaproductiveenvironmentinvolveshumanperformingthetaskinproductivesystems.Thistopicalsodiscusseswaystocollectdatafortheproductionanalysisincomplex systemsandtheconnectivityanalysisbetweenfactorsinproductionsystems.

Itisalsoin Chapter2 thatthethemecognitionandhumanerrorarepresentedthroughthelensofdifferentauthors thatsuggestschemas,mentalmaps,andcognitivemodels.Cognitiveprocessingisimportantforresearchingaboutthe causesofhumanerror.Manyhumanprofileshavetheirpsychologicalfunctionsalteredduetoastressfulenvironment thatcausesnonidentificationbetweenindividualandorganizationalvalues.Defectsincognitiveprocessingcause humanerrorsintheexecutionoftasks.Cognitionisinvolvedwithpsychologicalfunctionssuchasmemoryandattentionandisinfluencedbytheworkenvironmentandfamily.Theperceptionofsignalsincognitiveprocessingisdiscussedinactivitiesinvolvingtaskcontrol.Basedonauthorsofcognitivepsychology,somerulesarediscussedabout thememoryandattentionfunctioning,whichinfluenceslearning.ThecognitivemodelssuggestedbyHollnageland Avilaarepresentedandadaptedwithguidingexamples.Intheconclusionofthechapter,thepsychologicalfunctions arepresentedinadynamicwaybyenablingtheanalysisofthetask.Alogicdiagramisproposedfortheapplicationof thetechniquesinthischapter.

Chapter3 dealswiththeidentificationofthehumanandsocialtypologiesthatmayfacestressfulorroutineenvironments,whichhaveanimpactonteamperformance.Thecharacterizationofhumantypesandtheformsofindividualor groupdecisionmakingareaddressed.Byunderstandingthetypeofteamreactioninroutine,itinterconnectswith humanerrorthroughdifferenteventclassesthatarederivedfromthevariouscauses.Techniquesfortaskplanning,execution,andcontrolarediscussedtoachievegreatereffectivenessinfactoryoperationandbettersafetyinindustrial facilities.Thetaskisdiscussedrelatingtopossiblecognitivegaps,differentcomplexities,behavioralvariations,andthe triggerofhumanerrors.

Taskanalysisbeginswiththeverificationofhuman-centeredenvironments.Regionalcultureandbehaviorofthe groupsandoftheleadersareassessed.Massculturealsoproducesabnormalitiessuchasmemorygapsandattentiondifficulties.Thelossofaffectivebonds,consideredasaconsequenceofculturalbiases,canalsoinitiatehumanerrorsand bepartoftheaccidentconstruction.Humanperformancefactorshaveimpactonemergency,operational,tactical,and strategicsituations.

In Chapter3,analysisofhumanprofilesandculturalaspectsoccursroutinely.Humantypologyhelpsclassifyhuman errorsintovariousclasses,andtheconvergenceofthesefailuresanderrorsreceivestheelaborationofthederived humanerror.

Rasmussendescribesthedisciplinestobuildasafetycultureandaccidentinvestigation.Itsmodelshelpintheadequacyofenvironmentstoavoidstressofpeopleand,consequently,reduceequipmentriskstofailure.

Unfortunately,contrarytopopularbelief,redundantsafetydevicesmaybringnewchancesfortheaccidenttooccur throughthephenomenonof“cognitivelaziness.”

API770isamaterialworkedoninthebook,usedasareferencestandardforhumanreliabilitythatincludesquestionnairesfromeachareaofknowledge,allowingthediagnosisofsituationsthatmostaffecthumanerror.Alogicdiagramisproposedfortheapplicationofthetechniquesinthischapter.

Theissueofprocesslossesisdiscussedin Chapter4,anditisconcludedthatthemaincausesoflowreliabilityqualityandincreasedinputconsumptionarehumanerrors.Themaindifficultyisthelowvisibilityoftherootcauseof problems.Thishappensbecauseoperationalrisksareconsideredasdynamic.

Industrialcompetitivenessinaglobalizedworlddoesnotallowfortheexistenceoffailuresthatcauselosses. Processlossesaredirectlyrelatedtothecontrolofoperationsandrequireappropriatemethodsandtechniquesforroot causeidentification.Eachtechnologyhasitspeculiaritiesthatmustbeidentifiedbeforeinvestigationbecauseofthe needtotreatdataandinformation,oftennotavailableinthetechnologydescription.Itisintendedtoapplytechniques toidentify,measure,andtreatprocesslossesbydiscussingthedefinitionoflosses,peculiarityofeachindustrialsegmentincontinuousprocesses,competenciesforanalysisofprocesslosses,datacollectionmethodsandtechniques,and theidentificationoflossesandrespectivediagnostictools.

In Chapter5,lessonslearnedorroutineissuesinthechemicalprocessindustryarediscussed,byindicatingaspects ofhumanreliabilitysuchasculturalenvironment,leadershipprofile,decisionmodel,possiblehumanerrorsandhits, mindmapconstruction,organizationalculture,andothers.Routinesmayberelatedtosafetyandoperationalculture, suchasauditoryperceptionandplantstart-up,orqualityofcommunicationduringshiftchange.Somesituationsdiscussedmaybeintheareaoftechnology,suchasemergencyduetouncontrolledchemicalreaction,failuresindiagnosis andprocessmappingor,yet,changeintheO-ringdiameterofalternativepumpstypeAlfaLaval.However,itisknown thatmanyroutineissuesinvolvethemanagerialprofileandattitudesinthesafetyareasuchasdirector’scentralized

behavioratplantstart-up,consideringthatthelatterusedtobeoperator,supervisor,andengineer.Itisobservedthat, apparently,thereisrepetitionofpatternforabnormalitiesinthevariousdimensionstooccur.

Chapter6 bringstogetherresearchworkonhumanreliabilityofthecontinuousprocessandmanufacturingindustry. Thesteps,difficulties,andresultsarediscussedregardingtherefining,food,uranium,andfertilizerindustrycases.The reasontouseSPARHincalculatingthelikelihoodofhumanerroristhesimplicityofapplyingworkstationissuestothe teamofexecutorsandmanagers.TheapplicationofSPARHdoesnotrequiredatabaseandneedexpertopinion.This discussiongeneratesacalculationthatiscomparedtoeconomiclossesinoperationsandmayrecommendmethodcalibrationorifchecked,mayrecommendchangeinhumanfactors.DiscussingSPARHisimportanttodemonstrate throughmanagement,thebestindicators,thebestregions,andfunctionsforinvestmentinriskmanagement.Another importantworkistheintroductionofindicatorsthatincludehuman,process,operations,andequipmentreliability,that is,sociotechnicalreliability.ThischapterpresentsasimplifiedscriptforSPARHapplicationanditsrelationshipwith processlossandcognitivegapassessments.

Chapter7 summarizesthemethodsandtechniquesalreadydiscussedforcalculatinghumanreliabilitybasedon humanerrors,humanfactors,andprocesslossauditingtodiagnoseoperationalculture. Chapter7 discussestheapplication,intheLPGindustry,ofconcepts,techniquesandproceduresformaximumorganizationalefficiencyinproduction. Managementprogramsandtoolstoapplicationinthepredictionoffailuresituationsareproposed;thus,thestepsfor theimplementationofthemethodologydevelopedinindustrialplantarepresented.Anactivityroadmapforinvestigatingtechnical operationalcultureatanoilandgasindustryworkplaceispresented.

Consequently,thisdiscussionbringsthedefinitionofnewcriteriaforhumanmachineinterfacedesign,methodsto measurehumanreliabilityconsideringthetheoryoffuzzymechanics,andguidelineswithprimaryandsecondaryindicatorstotheadjustmentofhumanfactors.

Anondeterministicmethodthatbeginswithidentifyingsignalstomeasureemerginghazardenergycanidentifyand evaluateparallelabnormalitychainstobetterinstallthesafeguards.Turninglargenumbersofdataintosmallerquantitieswithprincipalcomponentanalyseshasenabledthegraphicalviewofoptimalpointapproximationoforganizational efficiencyusingthescatterplot.

Chapter8,theconclusionofthiswork,reviewstheparadigmsthatarebeingbrokenbynewconceptualmodelsand algorithmsforcalculation.Riskmanagementwillbepunctuatedwiththepracticalexercisesandtheresultsofapplying thesetechniques.Itisalsointendedtoincludepriordiscussiononthemeasurementofhumanfactors,networks,concept ofhazardenergyenablingelements,andcalculationsforintegratedorsociotechnicalreliability. Chapter8 includesa briefdiscussionaboutafuturebookandindicatestherelationshipbetweenthechaptersandrespectiveproducts,

Finally, Appendix1 presentsseveralmaterialsrelatedtodatacollectionwithrespectiveapplicationformstobe appliedinarealcasefromthereaderbasedonthetechniquesandconceptsdiscussed.Also,inthistopic,thereisa databaseorganizationandquestionsforexpertsfortheexaminationofoperationalculture.

Insummary,wepresent,in Fig.2,issuesapproachedthroughoutthebook:

● Thediscussionabouttheroleofhumaninsocietyandhowhisimbalancecanbecomehumanerror(Chapter1)helps tounderstandthemodelsofcognitiveprocessinginsertedinculturalenvironments(Chapter2).

● Managementdecisiondependsonhumanreliabilityindicatorscalculatedaftertheanalysisofhumanfactorsand recoveredin Chapter6

● Conceptsrelatedtothedecisionandexecutionofplannedactionsareincludedin Chapter2,indicatingthebirthof skillsandcognitivegaps.Ontheotherhand,theyfacilitatethediscussionofhumantypes(characteristicsofthe workerincarryingoutindustrialtasks)andsocialtypes(influenceofculture)todeviseproceduresforclassifying humanerrorasindicatedin Chapter3

● Fromtheevaluationofhumanerrorandthetask,itispossibletodiscusstheoriginofprocesslossesandtheirconsequences,andtheseaspectsarediscussedin Chapter4.

● Thequestionsoftheoperationalroutinefacilitatetheinvestigationofthepatternsthatleadtosystemicfailure, Chapter5

● TheapplicationsofSPARHin Chapter6 meetthedemandforindicatorsonhumanreliabilitytodirectinterventions andapplyresources.

● Andtheapplicationinoilandgas,in Chapter7,discussesthetechniqueofthethirdgenerationinhumanreliability relatedtotechnical operationalcultureandtheanalysistoolsontheoperator’sdiscourse.

● Theconclusionindicatestheimportanceofthisnewmethodologyandunfoldstheperspectiveonnewconceptsto measurehumanfactorsandfindtheregionswiththehighestintensityindangerenergy,tooptimizetheuseofscarce resources.

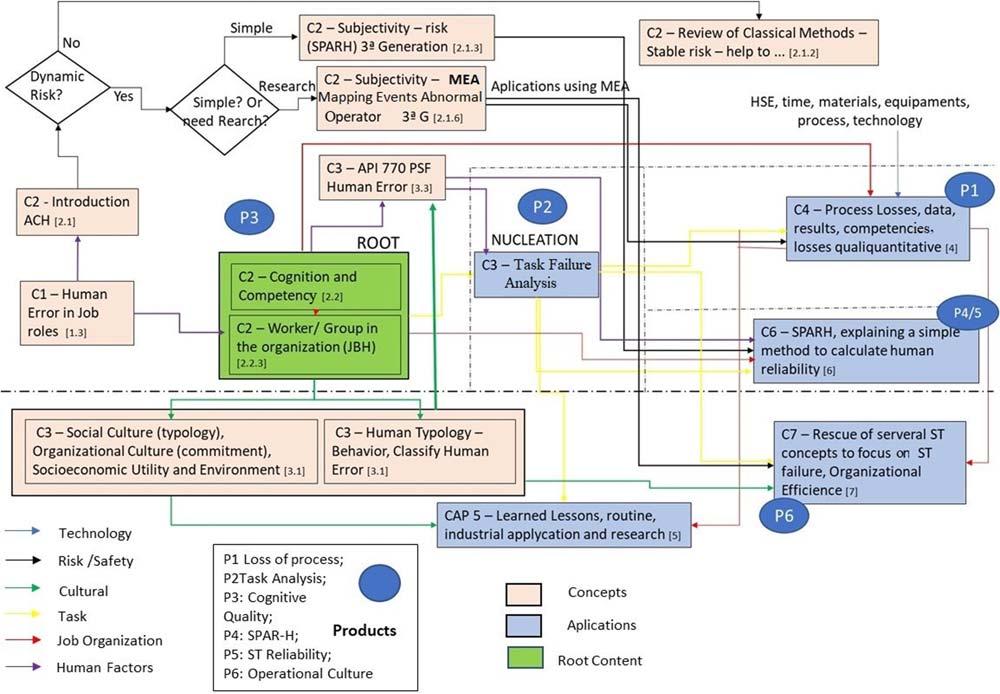

3Productsrelatedtothechapters Theproductsrelatedtothechaptersarediscussedfollowing Fig.3,stepbystep,includingwhatisneededinguiding theresearcher/student/manager/engineerintheinvestigationjourneyabouthumanfactorstoavoidprocesslosses.This explanationshowsbasicconceptsabouttheproductsofferedinthisbookwithguides:(product1)processlossmapping; (product2)taskassessment;(product3)cognitivequalityanalysis;(product4)applyingthehumanreliabilitySPARH method;(product5)sociotechnicalreliabilityapplication;and(product6)operationalcultureassessment.

Knowingmoreabouthumanerrorsallowsopeninga“range”ofopportunitiesandapplicationsoftechniquesfor solutionsintheindustry.Thisbookcoversanintroductiontothestudyofhumanerror,andhowitpresentsitselfinthe rolesofsociety,work,andfamily[1.3].Humanerrorcanbeconsideredasagenericterm,inwhichitencompassesall occasionswhenaplannedsequenceofmentalorphysicalactivitiesfailstoachieveitsgoal.Thestudyofhumanerror in Chapter1 introducestheaddressingofhumantrust[2.1]inindustrialsettings.Thehumanreliabilityanalysis(HRA), discussedin Chapter2,canbedefinedasameasureofprobabilityforthemalfunctionofahumansystem.Inthisway, intheworkenvironment,thefailurederivedfromtheactionofhumancangenerateseverallosses,amongwhichthe mostimpactfulistheaccident.Thereforeitisessentialtoidentifythereliabilityoftheoperationalteam,knowingthe taskscenarioandanorganizationalstructurethatcomprisesit.

Fortheresearcher/manager/studenttoassesshumanreliability,itisnecessarytoidentifythetypeofriskinthe industrialenvironment,whichinthisbookisdiscussedasdynamicorstable.Dynamicriskcanbecharacterizedbythe instabilityofvariablesinaprocess,suchasthetaskroutine,equipment,staff,andmanagement.Stablerisk,ontheother hand,isamorepredictablerisk,withcontrollablevariables,suchasinsuper-automatedprocesses.Afterdefiningthe typeofrisk,thisisthemomentwhenyou,theresearcher/manager,willidentifythetypeofriskinyourprocessandfollowinthetutorialthesuggestionsforstartinganinvestigation.

FIGURE3 Tutorialaboutchapters,investigationprocess,andproducts.

Thebook’sapproachisaroundprocesseswithdynamicrisks.Therefore,forthedevelopmentofaninvestigation withdynamicriskprocesses,twoinvestigationmethodsareindicated:SPARH[2.1.3;4],whichisamethodforassessinghumanreliabilityandhumanperformancefactors,andhaseasyapplicationofdatacollection,suchasquestionnairesandinterviews;andtheabnormaleventmapping[2.1.6;4;7],whichisbasedontherecordsofsignsof noncomplianceorsignsthatindicateintermediatestatesfornoncompliance.Itisworthmentioningthatthestable riskapproachwascarriedoutin Chapter2 withareviewofclassicmethods,suchasthetechniqueforhumanerror-rate prediction(THERP)method.

Tounderstandhowerrorsandlossesoccurinadynamicriskenvironment,itisnecessarytohaveknowledgeinthe cognitivedimension[2.2],thatis,inthecognitivesystemofhuman;andalsounderstandhowitbehavesingroupsin anorganization[2.2.3].Anindividual’scognitivesysteminvolvestheindividual’saffective,social,andtechnicalrelationships.Thebehaviorofhumanintheworkenvironmentisanimportantaspectthatisinsertedinmattersofoccupationalsafetyandhealth.Ontheotherhand,productivityrequiresmovementsoftheworkerthatintegrateperception, memory,andattention.Theergonomicdesignforperceivingprocesssignals,adjustingthecontroldevices,andmovementsdefinebasiccriteriatoachievesuccessinperformingroutinetasksattheworkstation.Withtheseimportantquestions,itisnecessaryfortheresearchertoassessthecognitivequalityoftheteaminvolvedinthetask,thusrecognizing thedifficultiesandopportunitiestobeexploredinthisteam.

Acknowledgment Firstandforemost,wewouldliketothankallthefamilymembersfortheirvaluablesupportthroughouttheproject.

WealsoacknowledgethesupportofJose ´ RafaelNascimentoLopesandLuizFernandoPelerinePessoaatallthe levelsoftheproject,especiallyatthebeginningandduringmeetingsandforprovidingimportantcontactsforthepreparationoftheinitialchapter,whichwewillcertainlycountoninfutureprojects.

Inaddition,weacknowledgethefinancialsupportofCNPq,NationalCouncilfortheDevelopmentofResearchand Technology,viaaresearchgrantfortechnologicaldevelopmenttothebookprojectleader,Dr.SalvadorA ´ vilaFilho, registeredasDT2intheperiod2017 20and2020 23.Wealsorecognizethefinancialsupportforresearch,through CNPq’sUniversalNoticeintheperiod2015 18fortheconstructionoftheproject.

InadditiontothepartnershipstheFAPESBandCAPESresearchagencieshaveplayedanimportantroleinfunding scholarshipssuchasmasteranddoctoratescholarshipsforindustrialengineeringprogramforCarineSantinoasthe author.ScientificinitiationforthegraduatestudentinProductionEngineering,PIBIT,LucasMenezes,workedastranslatorcollaboratingontheproject.

WealsothanktheindustrialengineeringprogramoftheFederalUniversityofBahia,whichbroughttogetherthe groupofauthors,CarineSantinoandIvoneCerqueira,undertheleadershipofDr.A ´ vilaFilhoduringthegraduate program.

WewouldliketothanktheundergraduateandgraduatestudentsJadeA ´ vila,Ju ´ liaA ´ vila,RitaA ´ vila,andLucas Menezesfortheirhelpineditingthebook,elaborationoffigures,andsupervision.WeespeciallyhighlighttheimportantroleoftheundergraduateLucasintranslatingthematerialsforthisproject.

Wearegratefultoallthepartnerinstitutions,NationalandInternationalUniversities(TexasAMUniversity,Poznan University),BrazilianandInternationalIndustries,CompaniesingeneralandGovernmentAgenciesinparticularPublic Security,forenablingthevalidationoftheconcepts,tools,andprocedurespresentedinthisbook.

WethankVivienSusanMacIverfortheEnglishlanguagereview.

Aspecialmessagetotheauthors: “Thepersistenceandacceptanceofthechallengeofthisproject,despitethe restrictionsinEconomicsandintheManagementofEducationalInstitutions,isproofthatBrazilianCultureproduces high-qualitycharactersworldwide!”

Postmortemmessage: “TheunionasacouplegavecomforttotheauthorIvonetobeinthisproject.ThelackofGil reinforcedtheimportanceforitscompletion,andwhereverheis,wewantapeacefulrestandthecertaintythathewas alsopartoftheconstructionofthisbook.”

Thispageintentionallyleftblank

Chapter1 Introduction 1.1Abriefdiscussion Thediscussiononhumanfactorsthatcan,directlyorindirectly,causeerrorsintheexecutionofatask,ismultidisciplinaryandcurrent,intendedtoprovokethecuriosityofreaderstosearchformoreinformationonthesubject.Itis importanttodealwiththecomplexityofworkingwithhumanfactorsindynamicsocialenvironments.

Thetopicsinthisbookincludediscussiononthefollowing:(1)theorganizationinsertedinthesocialenvironment, (2)conceptualandmathematicalmodelsinhumanandoperationalreliability,(3)riskmanagementincomplexprocessesandenvironments,(4)analysisofcompetenciesandtaskplanning,and(5)diagnosisonhumanfactors.

1.1.1Theorganizationinsertedinthesocialenvironment Companies(hereconsideredwiththesamemeaningas“industries”and“organizations”)areprofit-seekinginstitutions, whichtransformmaterialsintoready-to-useproducts.TheseCompaniesalsoexecuteactivitiesinassembly,product manufacturing,maintenanceservices,andchemicaltransformationprocesses.Theseproductsandservicesareforthe useofsociety,complyingwiththespecificationsforuseandfollowingthelegislationdeterminedbythesocialenvironment,alteringdemandsaccordingtothelocalrequirementsandinaccordancewithglobalmarketlaws,basedoneconomicandenvironmentalrestrictions.

SocialdemandsarepresentedtotheCompanybythelegislationthatis,generally,alteredinareactivemanner; throughcompulsorystandardsthatrequirestandardsofbehaviorbytheCompanyanditsemployees;andfromdemands ofthecommunitythatemergeinalatentwayandreachtheworkforce.

Changesintheeconomicenvironmentinfluencethesocialenvironmentbyalteringhumanbehaviorduringthe accomplishmentofthetask.Individualstendtocommithumanerrorssuchasslips,communicationmistakesandinabilitytoworkunderhighlevelsofstress.

Thesehumancharacteristicsconfronttheneedforcompetenciestoactincomplexprocessesandwithlegalconstraints,suchastheavailabilityofwaterandenergythatdefinethechallengesforfutureorganization.

Regardingthepossibilitiesofmanagerialactionstoavoidfailure, Silva(2015) discusseshowroutinesworkinthe Company,whichincludesaspectsofformalandinformalleaderships.Managerialdecisionsshouldfollowstandardized proceduresastothechoiceofalternativeswithlesssocialandenvironmentalimpact.

However,itisnotalwayspossibletoachievethisgoal,especiallywhentheactionsareofurgentdemand.Formal leadershipsormanagersshouldbesensitivetofastandcontinuouschanges,thatsocietyandthemarketrequirefrom thisorganization.Thesechangesdemandtransformationoftheworkteambehaviorandintuitiveemergencyactuation skill,whichwasnormallynotvaluedinthepastandcontinuesnottobevaluedtodate.

Someculturesinheritinadequatetracesoftheirhistory(paternalism,avoidingconflicts,centralization),thatare transferredtothecompany’sworkintheformofvicesthatmustbeidentifiedandneutralized.

Rasmussen(1997) indicatestheneedtounderstandthevarioussubjectsofhumanknowledgetoplanthetaskand meetthelawsandsocialrules.Oneofthereasonsforomissioninthecommunicatingoffailuresinthestepsofthetask orprocedureisthenecessarysocialadjustment,butnotauthorizedbythecompany,becauseofthe“false”risksthat considertherigidityinwritingtheprocedure.

1.1.2Conceptualandmathematicalmodelsinhumanandoperationalreliability Thedifficultyinpredictingfailureinthedynamicsocialenvironmentrequiresscientiststoprepareconceptualand/or mathematicalmodelsthatattempttosimulatethebehaviorofmaninaccomplishingthetask(Hollnagel,1993;Swain 1 HumanFactorandReliabilityAnalysistoPreventLossesinIndustrialProcesses.DOI: https://doi.org/10.1016/B978-0-12-819650-2.00009-2 © 2022ElsevierInc.Allrightsreserved.

andGuttmann,1983),basedonexpert’sopinionandondatabasesuse.Somemodelsaredeterministicandneedadaptationstowithstandoscillationsofbehavior(Pallerosi,2008).Fordeterministicmodels,generalizationdifficultiesoccur.

Othermodelsusefuzzylogictotranslatetheindustryoperator’sdiscourseintovaluesthataltertheprobabilityof failure(A ´ vila,2010;MoslehandChang,2004),oreventoavoidfailuresfromheuristicsinroutineactivitiessuchas truckloadingofHCl(Hydrochloricacid)ortheweldingofequipmentinmaintenance(More ´ ,2010).

Ogleetal.(2008) discussesamodelthatdealswiththeinfluenceoftheautomationlevelintheindustry,onthepossibilityofoccurrenceofhumanerror,andanalyzestheseverityoftaskswhenconsideringmanual,semiautomatic,or automaticactivities.

Ontheotherhand,local,regional,andglobalbadhabitsarediscussedandaddressedafterunderstandingtheconceptualmodelsindicatedby Maraisetal.(2006) thatsuggeststheweakeningofarchetypestoavoidsocialfailureand humanerror.

1.1.3Riskmanagementincomplexprocessesandenvironments Risksexistbecausedangerscanturnintoanabnormaleventwithdifferentimpacts,fromdeviancetoaccidentwithsick leave,orevenadisaster.Thedangersarehiddenincomplexprocesses(Perrow,1984)thathinderthedefinitionofbarriersorsafeguards,suchasmanagerialactionsandtechnicaldevicestoavoidaccidents.

Thedifficultyinvisualizingtheprocessesandtheirdangerscanbeaconsequenceofthetypeofcontrolandthe respectivelevelofprocessautomation.Thislowvisibilityindicatesthatthecomplexityoftheproductivesystemcan inducelatentfailureintheindustry,whichisdifficulttofind,suchas“aneedleinahaystack.”Inaddition,thesocial environmentwithitsincreasedcomplexity,causedbycommunicationnoises,canbeaninduceroffailuresinthetask.

Llory(1999) discussesaboutlatentaspectsoffailureintheorganizationalmovements,duetolackofalignmentby leaderships,incorrectmanagerialdecisionsandthevarioushumantypesinshiftgroupleadingtotheerror. Llory (1999) questionsthecurrentmodelofaccidentinvestigationthatdoesnotconsidertherealityinfactanddoesnotidentifytherootcauseofaccidents.

Industriesmustdiscussthesocialmovements,theformationofleadershipsandtheriskperception.Infact,companiesonlycareaboutobjectiveevidence.Theyonlygenerateintheiranalysisoffailures,incidentsandaccidents,observationsontheeventsthathappened.Companiesdonotdetectemergingsocialorindividualmovementstopredict futurefailures.

Dodsworthetal.(2007) and BevilacquaandCiarapica(2018) discussedtherelationbetweensafetycultureand humanfactorsinthetaskandinvestigatedpossibleresultsintermsofaccidentreduction. Schonbeck(2007) presenteda methodtorevisethesafetyintegritylevelafteranalyzing:organizationalandhumanaspects,energyoffailureinthe classicmodelofriskmanagementandanalysisofeventsthatcomposetheaccident. Lees(2005) indicatestheimportanceofthesignsintheanalysisofthefailureanatomyand Leveson(2004) proposesatechniquetoconstructthis anatomy.

Ergonomicsstudiestheworkstationandbothphysicalandcognitiveenvironment,wherethe n interventionofman onthemachineoccurs,lookingfor,throughanalyses,improvementstoavoiddiscomfort(IidaandBuarque,2016).This scienceisconcernedwithmetrics,butitalsoinsertsaspectsofsocialrelationsatwork.

Thehumanreliabilityimprovementprogramsmeasuretherateofoperationalfailure,theprobabilityofhumanerror andthemeantimebetweenfailures(MTBF),besidesstudyingsocialrelationsattheworkstationandtheimpactonthe successofthetask.

Daniellou(2007) discussedthephilosophicalapproachtoErgonomicsbyintroducingthediscussiononwhichisthe mostappropriatepatternforthework. Carvalhoetal.(2006) presentthattheobservationsofthecontrolroomare importantaspects,suchassmallemergencies.Theyalsodiscussedthelevelofadherencebetweentheformalizedprocedureandtheworkperformedinnuclearpowerplantoperations.

1.1.4Competencyanalysisandtaskplanning Complexprocessesrequirehigherperceptionofeventsandontherespectiveanatomyofthefailure;therefore,they demandnewtaskplanningcompetencies. Muchinsky(2004) discussestheplanningofpersonnelselectionanddevelopmentactivitiestoachieveamaximumlevelofeffectivenessintheexecutionoftasks.Theprojectionofpeopledevelopmentintaskperformanceisnotbeingachievedduetovariousfactors,forexample,workersdonotdecidewith efficiencyinstressenvironment,donothavecapacitytoinnovateinproblemsthathappenincomplexprocesses,do nothavecapacitytoworkingroup,ordonotcooperateintheteamroutine.

Consideringresearchwithoilindustrystaffgroups,suchasengineersorpsychologists,itisobservedthatthereare variousorganizationalfactorsthatmakepeopledevelopmentdifficult.Amongthesefactors,wecandiscussinadequate measurementofknowledgeinpersonnelselection;inadequatetrainingprogramstoachievethegoalofmaximumeffectivenessinthetask;team’slackofcommitmentinlearning;andchangesintechnologyimposinghighamountofinformationtobelearnedatthesametime.

Moreover,socialrelationsarenotconsideredduringthedevelopmentoftheroutinetask,regardingtheleadership aspectsoftheteamandthequalityofcommunicationinthegroup.Beyondthesehumanfactors,technicalinformation andthecompany’spoliciesarealsopartofatechnical-operationalculturethatneedstobeunderstood. Valle(2003) statesthatthereisatechnicalcultureforeachtypeoftechnologyandcompany.Thisculturecanreduceorincreasethe team’sperformanceinrelationtotheexpectationonthecompetenciesforthetask.

Theeconomicandsocialoscillationsdemandnewskillsthataredynamicandthathelpinestablishingnewstandardstomaintainindustrialprocessesundercontrol.Theworkteamhasblocksoffixedconceptsusedtoaccomplish thetask.Addedtotheseconcepts,thereisnewinformationregardingappropriatesocialrelationsatwork.

Thelessonslearnedmustbetransferredtotheoperationalmassbyindicatingregionswithhigherprobabilityof socio-technicalfailures,forexample,duetocorrosion,fatigueandhumanerrors.Therefore,thewaysthatfailuresmay occurarewidespread,indicatingonlywhatarethecriticalequipmentandprocessesandwhatarethepossiblesuperficialrelationbetweenehumanerrorsandthetechnicalfailures.

Nowadayscompaniesshouldvalueabroadertrainingfortechnicians,beyondthefixedconceptsacquiredinclassicalcourses,alsothebestwaytooperateanindustrialplant.Itisimportanttoknowhowtorelatethecausalnexusof operationalandofequipmentfailurewithsocialandorganizationalfactors.

Taskplanningissuccessfulwhenproceduresareelaboratedandeffectivelyperformedaccordingtoitswritten designorsequence.Similarly,aspectsofriskontaskregardingthefailureofequipment,productsandpeopleshould obtainconsensusintheimplementationofthenewproceduresinshiftteams(Embrey,2000).Inthisway,thedefinition ofprocedures,requirements,goalsandtheirauxiliarydocuments(checklists,bookcases,drawings,andothers)transformthetaskinsuccessfulactivity.

Accordingto Lees(1996),thecompetenciesdemandedbythetaskplannersaredifferentinrelationtothecompetenciesfortheirvalidationduringexecution.Inplanning,abroadknowledgebaseisrequired,whileintheexecution/ reviewofproceduresexperienceandskillsintheroutineperformanceisrequired.Forthesakeofcostreduction,the companymayerroneouslyassigntheplanning,executionandrevisionofprocedurestonewoperators/engineers,which bringpossibilitiesoffailureinthetaskduetonon-acceptanceofprioroperators,misuseorevenuseofinappropriate taskintheoperationalscenario.

1.1.5Analysisanddiagnosisofhumanfactors Somepathologiesresultingfromhumanrelationsconflictsinthesocialenvironmentarerepeatedattheworkplace.Itis importanttounderstandthemainpsychopathologies(symptomsofneurosesandpsychoses)tolearnaboutthetypesof humanerrorsthatarecommittedinthisenvironment.

Ontheotherhand,information,andknowledgeaboutthefunctionsinherenttocognitiveprocessing(Sternberg, 2008)aresought,suchasperception,attention,memory,andthementalmaptoimprovetheanalysisofsocialfaultin theaccomplishmentofthetask.

Thedefinitionandidentificationofhumantypesintheteamassistsintheimprovedallocationofpeopleintheir respectivetasks. FadimanandFrager(1986) and Jung(2002) presenthumantypeswiththeemergenceoftheirrespectivehumanerrorsinsocialactivity,andthat,eventually,mayinfluencetheperformanceofindividualsandgroupsin theworkroutine.

Disturbances,originatedfromspecificpersonalitytraits,maybeassociatedwithorganicpathologiesandalinkconnectingthetypeofaffection,behavior,andpossiblediseasesinthebody(Haynaletal.,2001).Thisknowledgeresulting frompsychosomaticmedicinecanhelptheareaofoccupationalhealth,operationandcompanysafety,regardingthe bestmodeofroutinemanagement.

Itisimportanttotalkaboutthecharacteristicsoftheseaffectionnetworks,theconsequencesinthebodyandthe behaviorfordiagnosticworkinhumanreliability.Ontheotherhand,informationbasedoninterviewsorpollsmay havelowqualitybecauseitdoesnotrepresentthehumantypepresentintheworkplace.

Thestudyofhumanerrordemandsnewtechniquesthataremoreassertive.Itisnecessarytoprovokestress,and investigateitseffect(Souzaetal.,2002)onbehaviorandonorganicdisturbances,andmeasuretheimpactbystress level,directlyandindirectly,inthedecisionstocarryoutemergencytasks(A ´ vila,2010).

Datacollectiontostudybehaviorandtodiagnosehumantypesandtheirsocialrelationships(socialandhuman latentsituations)isbasedonbusinesstechniquesthatinvolvesubjectssuchas:

● behaviorunderstressinemergencies(A ´ vila,2010),

● formalandinformalleadershipbasedontheFIROB(FundamentalInterpersonalRelationsOrientation-Behavior) technique,

● groupaggregationordisaggregation,

● commitmentanalysis,

● qualityinformalandinformalcommunications,and

● self-analysisofthepsychologicalqualityoftheworker.

Pasquinietal.(1997) analyzedifferenttypesofhumanmachineinterface,incontrolpanels,consideringthequality oftheteam’scognitiveprocessingandthequalityoforalandwrittencommunication. Sternberg(2008) presentsintrinsicfactorsintheanalysisofcognitiveprocessingwhenverifyingthepossibilitiesofhumanerrors,theimpactofitsconsequencesandthesuggestionofbarriersforitsprevention.

Reason(2003) and Dekker(2002) discussedthestudyofhumanerrorandthetreatmenttopreventitsrecurrence,in thecompany.Theseauthorsaffirmthatcompaniestreatedhumanerrorbyattributingguilttotheinjuredparties,and currently,theyanalyzetheerrorinsearchoftheenvironmentpromoterofthisevent.Thedefinitionofthemodesof occurrenceofhumanerrorisfundamentalforthepreparationofalgorithmsthatexercisethepredictionoffailure (Hollnagel,1993;MoslehandChang,2004;Pallerosi,2008).

Thediagnosisofcognitivegapsandhumanfactorsaimstoidentifyhumanandenvironmentalcharacteristicsthat inducefailureandthatcanbeavoided,mitigated,orhavetheireffectsmitigatedthroughspecificprograms.Theemotionalbalanceintheshiftteamofanindustrycanpotentiatesituationsofcomfort,createsituationsunfavorabletocognitivetraps,andincreasethequalityofcognitiveandintuitiveprocessing(A ´ vila,2010).

Thediscussionaboutstressismadeby Lorenzo(2001) whenhepresentstheexternalandpsychologicalstressors; Souzaetal.(2002) whenidentifyingpsychopathologiesandbehaviorsarisingfromstress;and Pallerosi(2008) inan attempttoquantifythelevelofstressatwork.

Theanalysisoffailuresinthechemicalindustrydemandedthepreparationofastandardformanagerialaction.The API770Guide(Lorenzo,2001)indicatessituationsofthisindustrythatcanprovokehumanerrorandtreatstheinfluenceofstressfulenvironmentsorstressfulsituationthatcausesthebeginningoftheprocessoffailure.

A ´ vila(2011) discussessituationsofchangingpatternsinthechemicalandpetroleumindustryandindicateswaysof analyzinghumanfactorsforenvironmentalimpacts,accidents,operationalfailures,andequipmentingeneral.Insome cases,thepreparationofeducationalandmotivationalprogramsisindicatedasamanagerialactiontochangeoldbad habitsinstalledintheoperationalcultureand/orinthebehaviorofpeopleandgroups(Fig.1.1).

Afterthisdiscussion,itisperceivedthatalltopicscited—itemsfrom(a)to(e)—havesignificantimportancefor goodconductionandexecutionofactivitiesandintherisk,controlpreviouslyknownbythecompany.Inyouropinion, whichofthetopicswouldbethe“top”oftheicebergtounleashhumanerror?Moreover,whyisthat?

FIGURE1.1 BOY1timetothink!

1.2Discussiontimelineandschools Thehumanreliabilitythemeemergesbasedonvariousmovementsofschoolsofadministration,securityengineering, intheareasofproductionadministrationandpsychology.Thismovementinducesresearchonhumanfactorsinthe analysisofthetask.

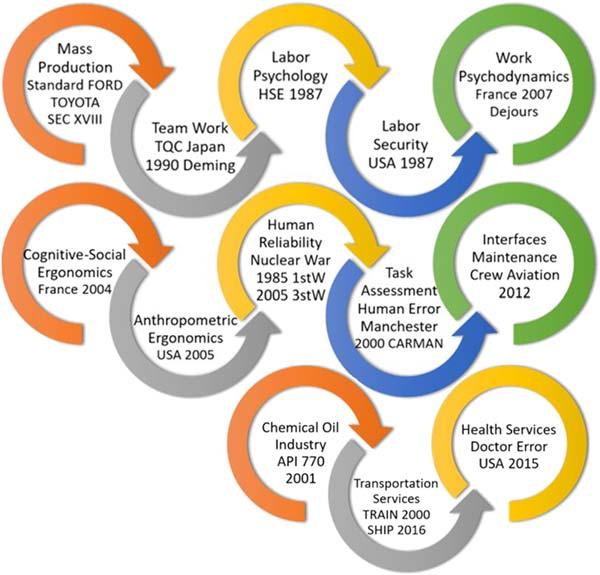

1.2.1Ahistoricalvisionaboutschoolsrelatedtooriginofhumanreliability Thedescriptionoftheschoolsandactivitiesinhumanreliabilityisbasedonaninterpretationwithoutscientificbasis, therefore,anintuitiveanalysisofthefindingsandpracticesperformed. Fig.1.2 presentsinstitutions,segmentsofthe economyandschoolsinvolvedwithtechniquesintheareasofadministration,engineering,ergonomics,psychology, andsafetyguidedtohumanreliability.

Intermsofcountriesdealingwiththeseissues,theUnitedKingdomshouldberememberedwithitsmassproduction,theUnitedStateswithFordismandJapanwithToyotismandTotalqualitycontrol.IntheSocialarea,thepsychologyofAmerican-EnglishworkandthepsychodynamicsofworkinFrance.Inergonomics,theFrenchcognitive-social discussionandtheAmericanobjective-anthropometricalergonomicsforInterfaceandcontrolroomprojects.Finally, thesubjectofhumanreliabilityledbythenuclearenergyareaattheUnitedNations,representedbytheCommitteeon theSafetyofNuclearInstallations(CSNI)andtheanalysisofthetaskinthechemical-oilindustryinEngland (Manchester).

Somecognitivemodelsexplainhumanerror,asbyHollnagelinNordiccountries,suchasSwedenandNorway. SomeEconomySectorsincludedhumanfactorsdiscussionandhumanreliability,taskanalysis:AmericanAviation introducedtheReliabilityCenteredMaintenance(RCM)anddiscussedhumanreliability;AmericanChemicaland PetroleumIndustryanalyzedstressfulenvironments(Lorenzo,2001);RailTransportationDepartmentintheUnited StatesandSouthKorea;CommercialMaritimeTransportationintheUnitedKingdom,discussedtaskandjustculture (SeahorseProject).Finally,theanalysisofmedicalerrorshasbeenintenseintheUnitedStates,inhospitalsanduniversitieswithinhealthsciences.

Schoolsrelatedtohumanreliability.

FIGURE1.2

1.2.1.1MassproductionintheUnitedKingdomandFordismintheUnitedStates

ThetechniqueswerebornintheEighteenthCentury,duringtheIndustrialRevolution,aimedtowardthespecialization ofcertainfunctionstoincreaseproduction.Inthisperiod,therewasthedevelopmentofsteammachines,butthepace ofworkwasintenseandtherewasnoconcernabouttheimpactsoftheactivityonhealthandsafety.Incontinuitywith thephenomenonofmassproduction,theAmericanindustrystartedFordismbyoverloadingtheworkteamandachievingconsecutiveproductionrecords.Inthesetwocases,inEnglandandtheUnitedStates,therewasagreatereffortto organizethetaskinproductioncellswiththeirrespectivejobs.Itwasaperiodoflearningandapplyingpatternsinthe routinetoachievequalityinthefinalproduct.

1.2.1.2Toyota,totalqualitycontrolandtotalproductivitymaintenanceinJapan

Althoughtheinitialperiodofmassproductionhadbeensuccessful,thereweremanyincidentsandproductivitylosses. Duetotheseproductqualityandproductivityaspectsoftheteam,therevolutionofqualityarisesthrough Deming (1990).TheJapaneseindustrieshaveappliedtheseprinciplesandstatisticaltechniquesfortheeconomicrecoveryof thecountryfollowingtheSecondWorldWar.

TheJapanesepeoplehadcooperativecultureandfoundthatmostofthedeficienciesintechnologywerediscovered andmitigatedthroughdevelopingteamwork.ThussystemssuchasTQC(totalqualitycontrol)andTPM(totalproductivitymaintenance)werecreatedthatfocustheiractionsonteamwork.Anexampleoftheeconomicresumptionin JapanistheToyotaPhilosophy,wherethemappedproductioncellspossessoperatorswithspecificcharacteristics. Therewasaneedtodeveloptechniquestoincreasetheefficiencyofteamworkthroughleaderswithspecificprofiles. Despitethepositiveresultsinthisperiod,thereareeventsthatescapethecontroloftheTQCorTPM,whichisthe analysisoftheenvironmentsontheworker’sbehaviorduringtheaccomplishmentofthetask.

1.2.1.3Psychologyandsafetyofwork,discussionoriginatedintheUnitedStatesandEurope Humanerrorsinproductioninfluencedthequalityoftheproductsandtheproductivityoftheteam.Inthisscenario, Americanmanufacturingentrepreneurshiredresearchtodiagnosethereasonsfortheseprocesslosses.Thequestion wasthelossofmotivationforthework,andthelevelofteamworkinvolvementintheproductiontask(Herzberg,1987; Maslowetal.,1987).

Ontheotherhand,theincreaseofaccidentsconcernedEuropeanandAmericanCompanieswiththeneedfornew guidelinesincludingriskmanagement.Atthisstage,themobilizationwasaroundthesupervisionoflaboractivities. Theworkisorganizedaccordingtorulesthatmustbefollowed.Inthecaseofnon-conformityinsafety,therewouldbe theattributionofguiltandpenalty.Laborstandardswerealteredtoinvestigateaccidentsbyassigningthefaultmainly totheinjuredpartyandnotanalyzingtheworkenvironmentwiththerespectiveproductionfactors.

1.2.1.4PsychodynamicsatworkinFranceandEngland TheIndustrialRevolutioninitiatedinEnglandgeneratedphysicaleffortstoachievethegoalsforproduction,generating dissatisfactionofworkersandpolitical-labormovementsintheunions(Marxism).InFrance,humanitarianmovements wereinitiatedaftertheIndustrialRevolutionthatreflectedintheworkenvironment.Studiesandapplicationsofwork psychodynamicsweredonetomitigatetheimpactsonhealth,safety,andqualityoflife.Therelationsbetweenhealth, workandlifearediscussedby Dejours(2007) basedonadynamicvision,theFrenchpsychodynamics.Itispossibleto perceivethepossibilitiesoftheworkasapsychicstructuringfactor,inwhichthepossiblereferralsoflearningtoward pleasureandhealthoccurred.

1.2.1.5Cognitiveergonomics(France) Frenchergonomicswasbornbasedonthepsychological,cognitiveandsocialdiscussion,whileAmericanergonomics wasbuilttodefinephysiologicalpatternsthatavoiddiscomfortintheoperationsperformedattheworkstation,named asAnthropometricalandphysiologicalanalysis.Despitetheefforttoreducediscomfort,itwasnotpossibletoexplain thecausesoffatigueandhumanerrorwithoutdiscussingthefactorsrelatedtotheplanningandexecutionofthetask (Daniellou,2007).

Cognitiveergonomicswasbornfromthediscussionabouttherelationsbetweencapitalandworkandthemeasure ofsufferingorsatisfactioninrelationtotheworkperformed.Thesephilosophicaldiscussionsdidnotdescribetheefficiencyandreliabilityoftheworkactivitiesanddidnotmediatethefailurerateorserviceofthemanmachineinterface.

SocialrelationsintheworkplaceareapproachedinFrenchcognitiveergonomics,inwhichtheroleofmanwasanalyzedconsideringthepossibilityofexceptionsinrelationtothestandard;hencetherearenomajorconcernsaboutthe measurement,thendeliveringspecificpatternsforeachtypeofinstallationforeachregion.

1.2.1.6Americananthropometricalergonomics Anthropometryisthestudyofdistances,colors,times,figurestocomposethedesignofcomputerscreensintheindustrialcontrolroomstofacilitatethehumanmachineinterface.Americanergonomicsdefinesmetricstandardstoenable thedesignofequipmentattheworkplace(PheasantandSteenbekkers,2005).

Theseprojectsarepreparedbasedontheaveragecriteriaofthelocalculture(height,distance,color,timbre)without consideringtheworker’sphysicaltypeexceptions.Theexceptionsconsideredinthisdiscussioncanavoidmajoraccidentsintheindustry.Thusthedesigncriteriacannotbeveryrigid,thusadmittingcertainvariabilityfortheadopted parameters.

1.2.1.7Humanreliabilityinnuclearpowerplants(CNSI/ONU) TheCSNIbegantoworryaboutHumanFactorsandscaletheprojectsoffuturenuclearplants.Thisoccurredafteraccidentswherehumanandmanagerialerrorwerepartofthemaincauses.

Thetypeofoperationandnuclearfissionreactionscanbringchainconsequencesandaffectthelocalandglobal communityinanimpactfulway.Theindustriesinthisareainducedacademicresearcherstoworkinmodelingevents andavoidtheirrepetition.Theseindustriesdemandedtheformulationofconceptualandmathematicalmodelsin researchintheacademiccommunitytoincreaseknowledgeaboutthehumanfactorintheaccomplishmentofthecriticaltaskandthatcancausetheaccident.Adatabaseoffaultincriticaltaskwasconstructed.

Humanreliabilityiswithdrawnfromthephilosophicaldiscussionandgoestothepracticeconsideringthepossibility thatexceptionscausetheaccident.Theschoolsthatdevelopedmodels,betweentheendofthe20thcenturyandthe beginningofthe21stcentury,fortheanalysisofhumanreliabilitywereconcernedwithcollectingthespecialists’opinion.Oneofthemainflawscommentedinthereportsofthenuclearindustryisthequalityofthedatathatdoesnot reflectallthetasksituationsduetothevariabilityofhumanbehavior.

1.2.1.8AnalysisofthetaskinEngland,Manchester,andSheffield Theanalysisofcriticaltasksisimportanttoavoidpossibleprocesslossesincluding,mainly,accidents.Itisknownthat abetterunderstandingofthetasksreducesthelossofimageandcapitalandincreasestimeforaccidentstohappen; decreasesmateriallossesandbadimageinenvironmentalaccidents;italsodecreaselossofenergyandabetterimage withthelowerfuelconsumptionanddecreaseinCO2 emissionstotheatmosphere.

SchoolsinManchesterandSheffieldhaveworkedinthefieldofindustrytaskanalysis,butwithoutsuccessincorrelatingitwiththeirsafetyculture.Theauthorsofthetaskplanningandanalysisareaarefrom Embrey(2000) and Lees (1996) Schools. Embrey(2000) presentedthatconsensuswiththestaffisveryimportantfortheelaborationofsafeguardsincriticaltasksinvolvingtechnologies,peopleandequipment.

1.2.1.9CognitivemodelsabouthumanerrorinNordiccountries Suggestedmodelsfortaskplanningandthebestdecisionagainstcrisisscenariosfacilitatestandardization,trainingand selectionofappropriatepeopleforleadershipintheseactivities.Themodelsfortaskanalysismustcommunicatewith thecognitivemodelsfordecision-makingorfortheautomaticexecutionduringemergency.Humantypesarenotdiscussedinthesemodels.Humanreliabilityinvestsinthediscussionabouttheanalysisofthetaskbyconsideringthecognitiveprocessofeachteaminthecompany.

1.2.1.10HumanerroranalysisinUSaviation Anairplanecrashhasahighsocialimpactduetotheamountsofhumanlosses.ThustheworkofHumanreliability beganinthefollowingareas:intheprojectsoftheaeronauticalindustry;inthecontrolofairspace;intheaircraftoperationintermsofpilot-crewcommunication;andinaircraftmaintenancetoincreaseavailability.Thehighimpactof poorlyperformedtasksbythesupervisorybodiescontrollingoperationsonairplanes,ledtodetailedstudiesofMan MachineInterfaceinthecontrolofaircrafts.