https://ebookmass.com/product/high-temperature-oxidationand-corrosion-of-metals-2nd-edition-david-john-young/

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

High Temperature Gas-cooled Reactors Takeda https://ebookmass.com/product/high-temperature-gas-cooled-reactorstakeda/

ebookmass.com

Corrosion of Aluminium 2nd Edition Christian Vargel

https://ebookmass.com/product/corrosion-of-aluminium-2nd-editionchristian-vargel/

ebookmass.com

Electrocorrosion and Protection of Metals 2nd Edition Joseph Riskin Alexander Khentov

https://ebookmass.com/product/electrocorrosion-and-protection-ofmetals-2nd-edition-joseph-riskin-alexander-khentov/

ebookmass.com

Urban Ecology: Emerging Patterns and Social-Ecological Systems 1st Edition Pramit Verma (Editor)

https://ebookmass.com/product/urban-ecology-emerging-patterns-andsocial-ecological-systems-1st-edition-pramit-verma-editor/

ebookmass.com

New Challenges for Macroeconomic Policies: Economic Growth, Sustainable Development, Fiscal and Monetary Policies Gilles Dufrénot

https://ebookmass.com/product/new-challenges-for-macroeconomicpolicies-economic-growth-sustainable-development-fiscal-and-monetarypolicies-gilles-dufrenot/ ebookmass.com

Indian Economy Key Concepts | Sixth Edition (English) Karuppiah

https://ebookmass.com/product/indian-economy-key-concepts-sixthedition-english-karuppiah/

ebookmass.com

Focus on Middle East respiratory syndrome coronavirus (MERS-CoV) A. Bleibtreu

https://ebookmass.com/product/focus-on-middle-east-respiratorysyndrome-coronavirus-mers-cov-a-bleibtreu/

ebookmass.com

Three Single Wives Gina Lamanna

https://ebookmass.com/product/three-single-wives-gina-lamanna-4/

ebookmass.com

Chemical Youth: Navigating Uncertainty in Search of the Good Life 1st Edition Anita Hardon

https://ebookmass.com/product/chemical-youth-navigating-uncertaintyin-search-of-the-good-life-1st-edition-anita-hardon/

ebookmass.com

Test-Driven Development in Go Simion https://ebookmass.com/product/test-driven-development-in-go-simion/

ebookmass.com

HighTemperature Oxidationand CorrosionofMetals SecondEdition

DavidJ.Young

SchoolofMaterialsScienceandEngineering,University ofNewSouthWales,Sydney

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UK 50HampshireStreet,5thFloor,Cambridge,MA02139,USA

Copyright 2016,2008ElsevierLtd.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans, electronicormechanical,includingphotocopying,recording,oranyinformationstorage andretrievalsystem,withoutpermissioninwritingfromthepublisher.Detailsonhowtoseek permission,furtherinformationaboutthePublisher’spermissionspoliciesandourarrangements withorganizationssuchastheCopyrightClearanceCenterandtheCopyrightLicensingAgency, canbefoundatourwebsite: www.elsevier.com/permissions

Thisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythe Publisher(otherthanasmaybenotedherein).

Notices Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperience broadenourunderstanding,changesinresearchmethods,professionalpractices,ormedical treatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgein evaluatingandusinganyinformation,methods,compounds,orexperimentsdescribedherein. Inusingsuchinformationormethodstheyshouldbemindfuloftheirownsafetyandthesafety ofothers,includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors, assumeanyliabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproducts liability,negligenceorotherwise,orfromanyuseoroperationofanymethods,products, instructions,orideascontainedinthematerialherein.

BritishLibraryCataloguinginPublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

ISBN:978-0-08-100101-1

ForinformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/

Publisher: JohnFedor

AcquisitionEditor: KostasMarinakis

EditorialProjectManager: SarahWatson

ProductionProjectManager: AnithaSivaraj

Designer: MariaInesCruz

TypesetbyTNQBooksandJournals

Coverimage:Burnerrigtestsinbothheatingandcoolingpositions thermalbarriercoatedsuper alloyhot.CourtesyoftheNationalAeronauticsandSpaceAdministration,JohnH.Glenn ResearchCenteratLewisField(NASAIdentifierGRC-C-1999-2487).

Foreword Thedepletionofthefirsteditionprintrunandanenormousincreaseinpublishedresearchonhigh-temperaturecorrosionhavecombinedtomakea secondeditionofthisbookdesirable.Recentworkonmasstransportin aluminaand,moregenerally,onoxidegrainboundarydiffusionhascontributedimprovedclaritytoourunderstandingofhowprotectivealuminaand chromiascalesbehave.Similarly,newinvestigationsintowatervapoureffects onscalingprocesseshaveexpandedandrefinedourknowledge,althougha simple,coherentpictureremainselusive.Thesecontributions,andseveral others,havebeendrawnuponinupdatingtheoriginaltext.

Twonewtopicshavebeenadded,reflectingthelargebodyofpublished researchnowavailableandthetechnologicaldevelopmentswhichdrovethat work.Chapter10treatscorrosionbycarbondioxide,animportantissueifCO2 istobecapturedfromcombustiongasstreams.Inaddition,thethermal propertiesofcarbondioxide,alongwithitspressure-volume-temperature characteristics,makeitattractiveasaheattransferandworkingfluid.Forthese reasons,itisacandidateforuseinnuclearreactorsandconcentratedsolar thermalpowergeneration.Unfortunately,itisalsocorrosivetoavarietyof alloys.

AnewChapter12, CorrosioninComplexEnvironments,isconcernedwith thecorrosionphenomenaarisingfromthepresenceofionicmeltsandvolatilisinghalides.Interestinthesetopicshasarisenoutofthemuchincreased useofbothbiomassandmunicipalwasteasfuelsforthermalpowergeneration.Theresultingfluegasesanddepositscanberemarkablycorrosive,and boileroperatingtemperaturesarestrictlylimitedasaresult.

Asinthefirstedition,Ihavetriedtoacknowledgeimportantcontributions toourunderstandingmadebymanyresearchers,andIapologiseforany omissions.Thesecondeditionhasbenefitedfromcolleaguesaroundtheworld whohaveofferedhospitalityand/orgenerouslygaveexpertcommentary: BrianGleeson(UniversityofPittsburgh),DanielMonceau(INPT-CIRIMAT, Toulouse),BrucePint(OakRidgeNationalLaboratory),JoeQuadakkers (Forschungszentrum,Ju ¨ lich),MichaelSchutze(Dechema,Frankfurt)andJim Smialek(NASA,Lewis).Rectifyinganimportantomissionfromthefirstedition,Ithankmywifeandfamilyfortheirsupportandremarkableforbearance. DavidJ.Young

Preface Almostallmetalsandalloysoftechnologicalinterestoxidiseandcorrodeathigh temperatures.However,thenatureoftheirreactionproductsandtheratesat whichmetalsurfacesaredegradedvarywidely,andacapacityforpredictionis highlydesirable.Thisbookisconcernedwithprovidingafundamentalbasisfor understandingthealloy-gasoxidationandcorrosionreactionsobservedin practiceandinthelaboratory.Itspurposeistoenablethepredictionofreaction morphology,kineticsandrateasafunctionoftemperatureandthecomposition ofbothalloyandgas.

Theterm‘oxidation’isusedinagenericsenseforanychemicalreaction whichincreasesthemetaloxidationstatebyformingacompoundsuchasan oxide,sulphide,carbide,etc.Alloyoxidationreactionscanbeconceivedofas occurringinthreestages.Initially,allreactivecomponentsofanalloyincontact withahotgasarelikelytoreactsimultaneously.Subsequently,morethermodynamicallystablecompoundsreplacelessstableones,andastateofnear equilibriumislocallyapproached.Thereactingsystemcanthenbemodelledasa seriesofspatiallyadjacentlocalequilibriumstateswhichvaryincrementallyin reactantchemicalpotentials.Duringthisstage,thereactionmorphologyand compositiondistributionareinvariantwithtime.Ultimately,this‘steadystate’is lost,andallreactivealloycomponentsareconsumedinafinalbreakdownstage.

Successfulalloysarethosewhichevidencelengthyperiodsofslow,steadystatereaction.Forthisreason,considerableemphasisisplacedonanalysingthe underlyinglocalequilibriumconditionandtestingitsapplicabilitytoparticular metaloralloy-oxidantsystems.Whenanalloy-gasreactionisatasteadystate, theconstantcompositionprofiledevelopedthroughthereactionzonecanbe mappedontotherelevantsystemphasediagramasa‘diffusionpath’.Frequent useismadeofthesepathsinunderstandingreactionproductdistributionsandin predicting,oratleastrationalising,reactionoutcomes.

Analysisofthealloyoxidationproblemrequiresamultidisciplinary approach.Physicalmetallurgy,materialsscienceandphysicalchemistryprovide thetoolswithwhichtodissectalloyphaseconstitutionsandtheirtransformations,oxidepropertiesandchemicalkinetics.Deliberateemphasisis placedontheuseofchemicalthermodynamicsinpredictingoxidationproducts anddescribingsolidsolutionphases.Equalattentionispaidtothedetailedunderstandingofdefect-baseddiffusionprocessesincrystallinesolids.TheintroductoryChapter1indicateshowthesevariousdisciplinescancontributetothe

analysis.ThelengthyChapter2reviewsthethermodynamic,kineticand mechanicaltheoriesusedinthisbook.Italsocontainstabulateddataandrefers toAppendicesonalloycompositionanddiffusion.

Afterthesepreliminaries,thebookisarrangedinasequenceofchapters reflectingincreasingcomplexity,whichequateswithgreatersystemcomponent multiplicity.Ananalysisofthereactionbetweenpuremetalsandsingleoxidant gasesisfollowedbyadiscussionofmetalreactionswithmixedoxidantgases andthen,inChapters5 7,anexaminationofalloyreactionswithasingle oxidant.MuchofthisdiscussionisbasedontheearlyworkofCarlWagner, whichstillprovidesagoodconceptualframeworkand,inseveralcases,auseful analyticalbasisforquantitativeprediction.However,aswillbeshown, increasingsystemcomplexityisaccompaniedbyaweakeningintheoretical completeness.Theproblemsarisefrommulticomponenteffectsandfrom microstructuralcomplexity.

Considerfirsttheeffectofincreasingthenumberofalloycomponents.A steady-statereactingsystemconsistingofabinaryalloyandasingleoxidantcan bemodelledinatwocoordinatedescriptionofboththermodynamicsand diffusionkinetics,providedthattemperatureandpressureareconstant.Substantialthermodynamicanddiffusiondataisavailableformanysuchsystems, andthisisusedindevelopingdiffusionpathdescriptions.Increasingthenumber ofalloycomponentsleads,however,tochemicalandstructuralinteractions amongthem,renderingtheexperimentalproblemmuchlesstractable,and diagrammaticrepresentationimpossible.Intheabsenceoftherequisiteextensivethermodynamicanddiffusiondata,theWagnertheorycannotbeapplied. Instead,higherorderalloysarediscussedfromthepointofviewofdilute additioneffectsonthebehaviourofbinaries.

Wagner’stheoryisbasedonlatticediffusion.However,thetransport propertiesofslow-growingoxidesarelargelydeterminedbytheirgrain boundariesand,insomecasesperhaps,microporosity.Additionalalloycomponentscanaffectboththeoxidegrainsizeandthediffusionpropertiesofthe grainboundaries.Adescriptionofthesephenomenais,atthisstage,largely empirical.

Thelatterpartofthebookisconcernedwiththeeffectsofothercorrodents andtemperaturevariations.Chapters8and9dealwithsulphurandcarbonbearinggases.Theveryrapiddiffusionratesinvolvedinsulphidationandcarburisationmakesthempotentiallythreateningcorrosionprocessesinanumber ofindustrialtechnologies.Offundamentalinterestarethecomplicationsarising outofthecomplexgas-phasechemistriesandthesometimesslowhomogeneous gas-phasereactions.Itbecomesnecessaryindiscussingthebehaviourofthese gasmixturestoconsidertheroleofcatalysts,includingthealloysinquestionand theircorrosionproducts.Itemergesthatnotonlythegasphase,butalsothegassolidinterfacecanbefarremovedfromlocalequilibrium.Inparticular,analysis ofthecatastrophic‘metaldusting’corrosioncausedbycarbon-supersaturated gasescallsfortheuseofnonequilibriummodels.

TheeffectsofwatervapouronoxidationarediscussedinChapter10.In manyrespectsthisistheleastwellunderstoodaspectofhigh-temperature corrosion.Thereasonforthedifficultyistobefoundinthemultiplewaysin whichwatermoleculescaninteractwithoxides.Preferentialadsorption, hydrogenuptake,latticedefectchanges,grainboundarytransportproperty changes,gasgenerationwithinoxideporesandscaleandscale-alloyinterface mechanicalpropertychangesneedalltobeconsidered.

Finally,theeffectsoftemperaturecyclingonoxidescalegrowthare consideredinChapter11.Acombinationofdiffusionmodellingwitharather empiricalscalespallationdescriptionisfoundtoprovideareasonablysuccessful wayofextrapolatingdataforparticularalloys.However,thereisaneedfor developmentofmorepredictivedescriptionsoftherelationshipbetweenspallationpropensity,alloypropertiesandexposureconditions.

Discussionisfocusedthroughoutondevelopinganunderstandingofthe fundamentalsofhigh-temperatureoxidation.Frequentuseismadeofexperimentalinformationonrealalloysinordertoillustratetheprinciplesinvolved. However,noattemptismadetosurveytheveryextensiveliteraturewhichexists foralloyoxidation.Thusmostexamplesconsideredconcerneitheriron-or nickel-basealloys,whereascobalt-basealloysarelargelyignored.Nickelaluminidesarediscussed,butotherintermetallicsareseldommentioned.Thescope ofthebookisfurtherlimitedbytheexclusionofsomeparticulartopics. Examplesinclude‘pesting’(disintegrationbygrainboundaryattack)ofsilicides, andextensiveoxygendissolutionbymetalssuchastitaniumandzirconium.No bookofmanageableproportionscaneverbecomplete,orevenfullyuptodate.

Itisremarkablethatsincetheearly,verysubstantialprogressmadebyCarl Wagnerandassociatesinunderstandingoxidationphenomena,theresearch efforthasnonethelesscontinuedtoexpand.Thereason,ofcourse,isthe continuingneedtooperateequipmentateverhighertemperaturestoachieve greaterefficienciesandreducedemissions.Theneedtodevelopsuitablematerialscanbeexpectedtodriveevenmoreresearchinyearstocome.

Writingthisbookhasbeenalargetask,anditscontentinevitablyreflectsmy ownexperience,aswellastheideasandresultsofothers.Ihavetriedto acknowledgeimportantcontributionstoourunderstandingmadebymany researchers,andapologiseforanyomissions.Myownresearchinthisareahas benefitedfrominteractionwithmanytalentedstudents,researchfellowsand colleagues,allacknowledgedbydirectreference.Ithasalsobeensustainedin largepartbytheAustralianResearchCouncil,abodytobecommendedforits willingnesstosupportfundamentalresearch.Thisbookhasbenefitedfrom colleaguesfromaroundtheworldwhoofferedhospitalityand/orgenerously gaveexpertcommentaryasIwrote:BrianGleeson(IowaStateUniversity),Jack Kirkaldy(McMasterUniversity),DanielMonceau(CIRIMAT,Toulouse), ToshioNarita(HokkaidoUniversity),JoeQuadakkers(Forschungzentrum, Julich),JimSmialek(NASA,Lewis)andPeterTortorelli(OakRidgeNational Laboratory).

xviii Preface

Finally,Iacknowledgewithgratitudeandaffectiontheinspirationprovided bymymentorsandfriendsatMcMasterUniversity,WaltSmeltzerandJack Kirkaldy.

DavidJ.Young

August2007

AbbreviationsandAcronyms APT Atomprobetomography

CTGA Continuousthermogravimetricanalysis

CVD Chemicalvapourdeposition

EBSD Electronbackscattereddiffraction

EDAX EnergydispersiveanalysisofX-rays

EELS Electronenergylossspectroscopy

EPMA Electronprobemicroanalysis

FIB Focusedionbeam

IGCC Integratedgasificationcombinedcycle

ppm Partspermillion(unitofrelativeconcentration)

ppma Partspermillionbyatoms

ppmm Partspermillionbymass

PVD Physicalvapourdeposition

SAD Selectedareadiffraction

SCC SupercriticalCO2

SEM Secondaryelectronmicroscope

SIMS Secondaryionmassspectrometry

TBC Thermalbarriercoating

TEM Transmissionelectronmicroscope

TGA Thermogravimetricanalysis

TGO Thermallygrownoxide

XPS X-rayphotoelectronspectroscopy

XRD X-raydiffraction

YSZ Yttria-stabilizedzirconia

Symbols GREEKSYMBOLS a Coefficientofthermalexpansion

a Enrichmentfactorformetalininternaloxidationzone

d Thicknessofgasphaseboundarylayer

d Deviationfromstoichiometryinoxide

hi Electrochemicalpotentialofcomponent i

hg Viscosityofgas

g Surfacetension,freeenergyperunitsurfacearea

gi Activitycoefficientofcomponent i

l Interplanardistance,jumpdistance

l x =t 1 2 ,forparametricsolutionstoFick’sequation

mi Chemicalpotentialofcomponent i

n Stoichiometriccoefficientinchemicalreactionorcompound

vg Kinematicviscosityofgas

niv Kineticfrequencyterm

vP Poisson’sratio

j Electrostaticpotential

r Density

s Mechanicalstress

q Fractionofsurfacesites

x Extentofreaction

x Molefractionofoxide BO insolidsolution A1 x Bx O

εc Criticalstrainformechanicalfailureofscaleorscale-alloyinterface

εik Wagnerinteractioncoefficientsforsolutecompounds i and k

εOX Mechanicalstraininoxide

SYMBOLS

A Surfaceareaofoxidisingmetal

ai Chemicalactivityofcomponent i

a0 o ; a00 o Boundaryvaluesofoxygenactivityatmetal-scaleandscale-gas interfaces

Bi Mobilityofspecies i

Ci Concentrationofcomponent i

C 0 , C 00 Boundaryvaluesofconcentrationatmetal-scaleandscale-gasinterfaces.

D Diffusioncoefficient

d Grainboundarywidth

DA Intrinsicdiffusioncoefficientforspecies A

DA* Tracerorself-diffusioncoefficientofspecies A

Dij Diffusioncoefficientrelatingfluxofcomponent i toconcentration gradientincomponent j

D Chemical(orinter)diffusioncoefficient

Do Diffusioncoefficientforsoluteoxygeninalloy

Do,i Diffusioncoefficientforoxygenalonganinterface

E Electricfield

EOX Elasticmodulusofoxide

EA Activationenergy

e0 Freeelectron

F TheFaraday(96,500C)

f Fraction

fv Volumefraction

G TotalormolarGibbsfreeenergy

GOX Shearmodulusofoxide

Gv Freeenergyperunitvolume

gBO Volumefractionofinternallyprecipitatedoxide,BO

H Totalormolarenthalpy

hl Positivehole

ijS Species i adsorbed(bound)tosurfacesite iozInternaloxidationzone

Ji Fluxofcomponent i

K Chemicalequilibriumconstant

k Rateconstant

k Boltzmann’sconstant

kc Parabolicrateconstantformetalconsumption,corrosionrateconstant

kl Linearrateconstantforscalethickening

km Gaseousmasstransfercoefficient

ks Surfaceareafractionofoxidespalled

k ði Þ p Parabolicrateconstantforinternaloxidation

kp Parabolicrateconstantforscalethickening

kw Parabolicrateconstantforscalingweightgain

kv Vaporisationrate

Kp Equilibriumconstantatfixedpressure

Ksp Solubilityproduct

KIC Fracturetoughness,criticalstressintensityfactor

Lij Generalmobilitycoefficient,Onsagerphenomenologicalcoefficient

L Lengthofmaterialoverwhichgasflows

l Halfthicknessofalloysheet

MWMolecularweight

mi Molarconcentrationofcomponent i

ml , m0 Numberofchargeunitsonlatticepointdefectspecies

n Numberofmoles

Ni Molefractionofcomponent i

NAV Avogadro’snumber

NM,i MolefractionofcomponentMatscale-alloyinterface

NM,min MinimummolefractionofcomponentMrequiredtosupportgrowthof externalMOscale

N ðoÞ M MolefractionofcomponentMoriginallypresentinalloy

N ðsÞ O Molefractionofdissolvedoxygenatalloysurface

P Pressure

pDA/DB,ratioofmetalself-diffusioncoefficientsinternaryoxide

pi Partialpressureofcomponent i

PT Totalpressureofgasmixture

Q Activationenergy

q Charge

R Generalgasconstant

ri Rateconstantforindicatedgas-solidreaction

S Totalormolarentropy

S Spacingofperiodicmicrostructure

S Surfacesite

S X M Species S locatedoncrystallatticesiteM,witheffectivecharge X

T Temperature

t Time

t *Timeattemperatureincyclicexposureconditions

U Totalormolarinternalenergy

Ui Buildingunitincrystallinecompound

V Volume

v Velocity

Vi Molarvolumeofphase i

W Weight

X Scalethickness

x Positioncoordinate

XM Metalsurfacerecession

Xss Steady-statescalethicknesswhengrowthbalancedbyevaporation

X(i) Depthofinternaloxidationzone

y Positioncoordinateforscale-alloyinterfacerelativetotheoriginal, unreactedsurfacelocation

yz/zs (or x/X),positionwithinscalenormalisedtoitsthickness

Z Effectivecharge,valence

z Positioncoordinateinreferenceframewithoriginatscale alloy interface

TheNatureofHigh TemperatureOxidation Athightemperatures,mostmetalswillinevitablyoxidiseoverawiderangeof conditions.Thepracticalissuesofmateriallifetimesandcorrosionprotection methodsthereforecentrearoundtherateofoxidation,andhowtocontrol reactionmorphology.Answerstothesecondquestionturnouttoberather interestingandinvolvetheneedforafundamentalunderstandingoftheprocessesinvolvedandwaystomodifythem.Thegeneralnatureoftheproblem canbeappreciatedfromaconsiderationofsomepracticalexamples.

1.1METALLOSSDUETOTHESCALINGOFSTEEL Carbonsteelisproducedinprodigiousquantities(about1.7 109 tworldwide in2014).Almostallofitiscastintolargepiecessuchasslabs,whichare subsequentlyreheatedtoaround1000 1200 Ctobeformedintomoreuseful shapes(Fig.1.1).Thereheatingoperationiscarriedoutindirectfiredfurnaces wheresteelworksgases,orsometimesnaturalgas,arecombustedwithexcess air.Thecombinationofhightemperature,heatingtimesofaroundtwohours, andoxidisinggasesleadstothegrowthofathickironoxidescaleonthesteel. Theamountofsteelconsumedinthiswayisabout1 2%ofthetotal. Obviously,withsteellossesof17 34Mtin2014,plustheaddedcostof removingthescaleandrecyclingit,thereisconsiderableeconomicmotivation tocontrolorslowthisprocess.However,therearedifficulties.

Asdiscussedlater,andasisintuitivelyreasonable,thesteelscalingrate dependsonthreevariables:steelchemistry,temperatureandthegas

atmosphere.Thefirstcannotbechanged,becauseitiscriticaltothefinalsteel properties.Temperatureisdeterminedbysteelchemistryandisthereforealso fixed.Changesingascompositionshould,however,bepossible.Thereactions producingthefurnaceatmospherescanbedescribedas

where x representsthesurplusofoxygenabovestoichiometricrequirements forcompletecombustion.Innormalpractice,excessair(x > 0)isusedto ensurecompletecombustion.However,itwasrecognisedlongago [1] thatfor x < 0,theatmospherewouldbemuchlessoxidisingandtheextentofscaling mighttherebybelessened.

Inanalysingthissuggestion,werecognisethatitisnecessarytocalculatethe furnacegaspartialpressureofoxygen, pO2 ,asafunctionof x andtemperature, thatthepossibleoxidesofironmustbeidentified,andthattherangesof pO2 valuesatwhichtheyexistneedtobeestablished.Thenecessary pO2 valuescanbe calculatedfromtheequilibriumof reactions[1.1]and[1.2] andthoseoftheiron oxideformationreactions,usingthetechniquesofchemicalthermodynamics describedinChapter2.Suchananalysisshowsthatitisnotpossibletolower pO2 belowthevalueatwhichironoxidisesandstillhavesufficientcombustiontoheat thesteel.Giventhatsteelscalingcannotbeprevented,itisimportanttoknowhow therateofscalegrowth(andsteelconsumption)varieswith pO2 andtemperature.

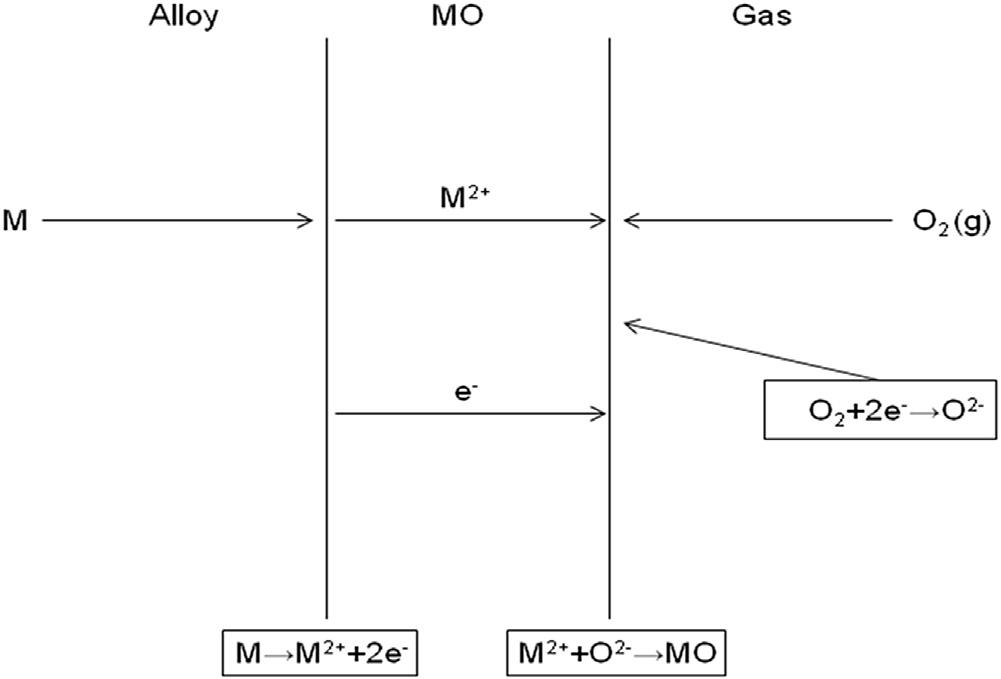

Aschematiccross-sectionalviewofagrowingoxidescaleisshownin Fig.1.2.Theoveralloxidationprocesscanbesubdividedintoseveralsteps:

1. Deliveryofoxidanttothescale gasinterfaceviamasstransferinthegas phase.

2. Incorporationofoxygenintotheoxidescale.

3. Deliveryofreactingmetalfromthealloytothealloy scaleinterface.

4. Incorporationofmetalintotheoxidescale.

5. Transportofmetaland/oroxygenthroughthescale.

Evaluationoftheratesatwhichthesestepsoccurinvolvescalculationof thegasphasemasstransfer,solid-statemasstransferordiffusionintheoxide andalloyandconsiderationoftheinterfacialredoxreactions

wheree representsanelectron.Theredoxreactionsarerapidanddonot usuallycontributetoratecontrol.Otherscale gasinteractionscanbedealt

FIGURE1.2 Reactionsandtransportprocessesinvolvedinthegrowthofanoxidescale.

withusingthemethodsofsurfacechemistry.Gasphasemasstransferratescan becalculatedfromthemethodsoffluiddynamics,whilstmasstransferinthe solidoxideandalloyisdescribedusingdiffusiontheory.

Theprincipalconstituentofanironoxidescaleat T > 570 Ciswu ¨ stite, FeO,inwhichtheFe2þ speciesdiffusesrapidlyathightemperatures.Athigh valuesof pO2 ,diffusioninFeOcontrolstherateatwhichthisoxideaccumulates [2].However,inacombustiongas,where pO2 canbequitelow,reactionwiththe oxidantspeciesCO2 and/orH2Oisslowerthanwustitediffusion,andcontrols thescalingrate [3].Thusitappearspossiblethatsteelscalingcanbeslowedby operatingreheatfurnacesundersubstoichiometriccombustionconditions.Of course,theeconomicfeasibilityofthisprocessalterationwouldhavetobe establishedthroughquantificationoftheactualbenefittobeexpected(aswellas thecosts).Suchanexerciserequirestheabilitytopredictscalingratesasa numericalfunctionofprocessvariables,aprincipalconcernofthisbook.

1.2HEATINGELEMENTS Theuseofmetalsaselectricalresistanceheatingelementsiscommonplacein smalldomesticappliancesandlaboratoryfurnaces.Ofcoursethemetalsused mustresistoxidationinair.Twogroupsofalloysarewidelyusedforthispurpose:nickelalloyscontainingaround20w/o(weightpercent)chromiumand ironalloyscontainingabout20w/oCrand5w/oAl.Aspuremetals,eachofFe, Ni,CrandAloxidisesinair,butatvastlydifferentrates.Oxidationratemeasurementsarediscussedlaterinthischapter,butforthemoment,itissufficientto useacomparisonofdifferentoxidescalethicknessesgrowninaparticulartime. Datafor100hreactionat800 CinpureO2 at1atmareshownin Table1.1. Itisclearthatpureironwouldbequiteunacceptableasaheatingelement, andthataluminiumandchromiumappearmuchmoreattractive.However,

4

TABLE1.1 MetalOxideScaleThicknesses

thesearenotpracticalchoices:aluminiummeltsat660 Candpurechromium isbrittleandcannotbeformedatroomtemperature.Nickelhasneitherof thesedeficienciesandmighthaveanacceptablescalingrateforsomeapplications.However,likemostmetalsinthepurestate,nickelhasquitepoorhigh temperaturestrengthandcannotbeused.Ontheotherhand,appropriate alloyingcanprovidebothstrengthandoxidationresistance.

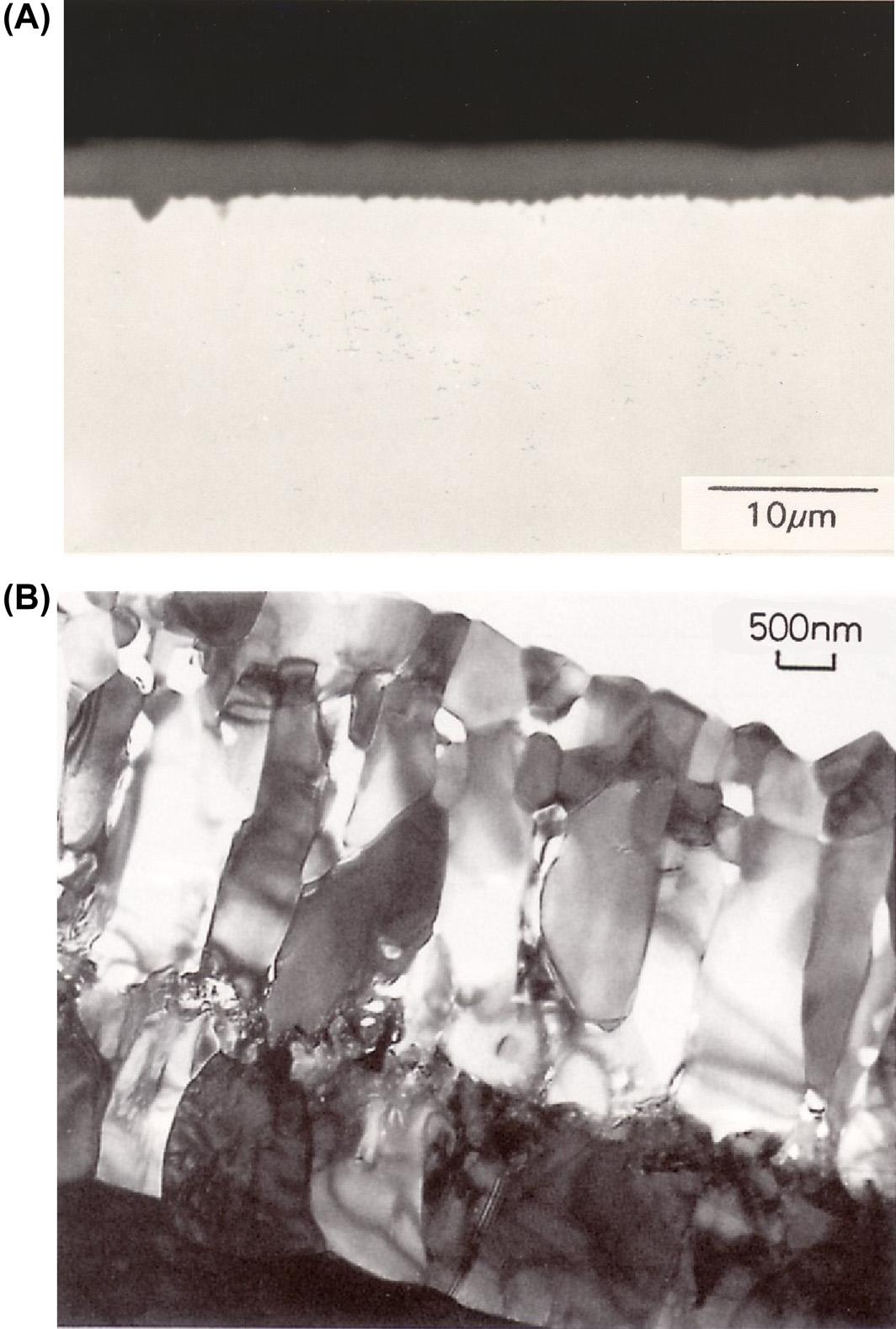

Cross-sectionalviewsofoxidisedsurfacesofNi-28CrandFe-20.1Cr5.6Al-0.08Laalloys(allcompositionsinweight%)areshownin Fig.1.3. Single-phaseoxides,Cr2O3 andAl2O3,respectively,growasalmostuniform scales,providingsatisfactorilyslowalloyconsumptionrates.Itwouldbe usefultobeabletopredictwhatconcentrationsofchromiumandaluminium arerequiredtoachievetheirpreferentialoxidationandtherebyavoidreaction ofthenickeloriron.Todealwiththissituation,itwillbenecessarytoconsider thethermodynamicsofcompetitiveoxidationprocessessuchas

þ 3NiO ¼ Cr2 O3

whereunderliningindicatesthemetalispresentasanalloysolute.Anadditionalfactorcanbeexpectedtocomplicatethisprediction.Selectiveoxidation ofametalimpliesitsremovalfromthealloyandaloweringofitsconcentrationatthealloysurface.Thusitwillalsobenecessarytoconsiderthe diffusionprocessesinbothalloyandoxide.

1.3PROTECTINGTURBINEENGINECOMPONENTS Thegasturbineenginesusedtopropelaircraftandtogenerateelectricpower havebeendevelopedtoaremarkableextentsincetheirinventioninthemid20thcentury.Asshownin Fig.1.4,fueliscombustedwithinaturbineto producealargevolumeofhotgas.Thisgasimpingesonangledbladesinthe hot(turbine)stageoftheengine,causingittorotateanddrivethecompressor stage,whichdrawsinairtosupportcombustion.Powerisobtainedfromthe engineeitherasrotationalenergyviaadriveshaft,orasthrust,generatedby thejetofhotexhaustgas.

2Cr

þ 3Ni[1.5]

FIGURE1.3 Cross-sectionofslow-growingprotectivescales:(A)OpticalmicrographofCr2O3 onNi-28Crafter24hat900 Cand(B)Brightfieldtransmissionelectronmicroscopyviewof Al2O3 onFe-20Cr-6Al-0.08Laafter400hat1150 C [4] PublishedwithpermissionofScience Reviews.

Theefficiencyoftheengine,whichistheproportionofthethermalenergy convertedtomechanicalpower,isrelatedtothetheoreticalmaximumwork available,givenby

max ¼ T To T q [1.6] where q istheheatexchanged, To istheambienttemperatureand T theoperating temperature.Itisclearthatthehighertheturbineoperationtemperature,the

greateristheefficiencypotentiallyavailable.Sincehigherefficiencyisthe equivalentoflowercostandlessgreenhousegasproductionperunitofoutput, itsdesirabilityhasdrivenasteadyincreaseinturbinegastemperatures.However,becausethistemperatureislimitedtowhateverthematerialsofthefirsthot stagecomponentscanwithstand,anincreaseinmaterialscapabilityhasalso beennecessary.

Thehistoryofdevelopmentsinturbinebladematerialsandthetemperaturesatwhichtheyhaveoperatedaresummarisedin Fig.1.1.Inadditionto alloycompositionalchanges,thedevelopmentofthesematerialshasseenan evolutioninproductiontechnologyfromwroughtthroughconventionallycast anddirectionallysolidifiedtosinglecrystalproduction.Currenthotstage materialsarenickel-basedsuperalloys,whichpossessexcellenthightemperaturestrength.Thisisnecessarytowithstandtheenormouscentrifugalforces generatedbythehighrotationalspeeds,around10,000rpminthecaseofjet engines.Themetallurgicaldesignwhichprovidesthestrengthofthesesuperalloysissuchthattheyoxidiseatunacceptablyrapidratesatoperating temperature.Thisproblemhasbeensolvedbyprovidingacoatingofoxidation resistantalloyonthecomponentsurfaces.

Turbinetemperaturesarenowexceedingthecapabilitiesofsuperalloy components,andithasbecomenecessarytocoolthem.Thisisdoneby pumpingairorsteamthroughcoolingchannelsrunningthroughthecomponent interiorsandprovidingthermalinsulation(athermalbarriercoatingorTBC)on topoftheoxidation-resistantcoating.Thewholeassemblyisshownschematicallyin Fig.1.6.TheTBCistypicallyaceramicmadeofY2O3-stabilisedZrO2; theoxidationresistantcoating,knownasabondcoat,isanaluminium-rich material(severaldesignsarepossible);andthesuperalloysarecomplex, nickel-basedalloyscontainingchromium,aluminiumandnumerousotherelements.Someexamplesofsuperalloyandbondcoatcompositionsaregivenin Table1.2.AdditionalsuperalloycompositionsareshowninAppendixA.

FIGURE1.4 Schematicdiagramofgasturbineengine.

S.C(NIMS)

FIGURE1.5 Progressiveincreasesintemperaturecapabilitiesofsuperalloysforturbineengine blades. ReproducedwithpermissionoftheNationalInstituteofMaterials(NIMS),Japan.

FIGURE1.6 Cross-sectionalviewofTBCsystemforgasturbineblade.

Manufactureofthesesophisticatedcomponentsiscomplex.Thesuperalloy itselfiscast,usingadirectionalsolidificationprocess,oftenasasinglecrystal [5].Thebondcoatcanbeappliedinvariousways [6].Chemicalvapour deposition(CVD),inwhichaluminiumfromavapourphasespeciesdiffuses intothealloysurface,formsanaluminidediffusioncoating.Thesecoatingscan bemodifiedbytheincorporationofplatinumandthecodepositionofadditional

metalsfromthevapourphase.MorecomplexcoatingchemistriescanbeachievedbyphysicalcodepositionofvariousMCrAlYcompositionsinwhichM indicatesFe,NiorCo,oramixturethereof.Thesecoatingsaredepositedby sputtering,plasmasprayingorphysicalvapourdeposition,usingahighvoltage electronbeamtovapourisethesourcematerial.Theoutersurfaceofthebond coatisoxidisedtoformathermallygrownoxide(TGO)whichisthesurfaceto whichtheTBCadheres.Thethermalbarriercoatingisdepositedbyeither electronbeamphysicalvapourdepositionorplasmaspraying [7]

Athightemperatures,variousinteractionsbetweenthesematerialscanbe expected.Interdiffusionbetweenthesuperalloyanditsaluminium-richcoating canproducenewphasesaswellasdrainingthecoatingofitsessential aluminium.SomebondcoatconstituentsandmetalsdiffusingfromthesuperalloythroughthebondcoatcandissolveintheTBCtoformmixedoxides. Understandingandpredictingtheseinteractionsrequiresknowledgeofthe phaseequilibriarelevanttoeachparticularsystem.Finally,becausetheTBCis porous,oxygenfromthehotcombustiongaspenetratestothebondcoat surface,causingoxidescalegrowth.Ahighdegreeofresistancetothis oxidationprocessisanessentialfunctionofthebondcoat.Alloftheseprocessesareaccompaniedbyvolumechanges,whichhavethepotentialto mechanicallydisruptthejunctionbetweentheTBCandtheunderlyingoxide scale.ThisinturncanleadtopartialorevencompletelossoftheTBC, subsequentoverheatingofthesubstratemetalandcomponentfailure.Inorder topredictandtherebymanagetheseconsequences,itisnecessarytounderstandthedetailedmechanicsofstressdevelopmentwithinthesuperalloy substrate-bondcoat-TGO-TBCsystemandthewaysinwhichthatstressis accommodatedbydeformationorfractureofoneormoreofthesystem components.

1.4HYDROCARBONCRACKINGFURNACES Manychemicalandpetrochemicalprocessesareoperatedathightemperatures inordertoachievereasonableproductionratesor,asincrackingfurnaces,to promoteendothermicreactions.Cracking(orpyrolysis)furnacesareusedto produceolefinessuchasethyleneandpropylene,whicharesubsequentlyused tomakethecommoditymaterialspolyethyleneandpolypropylene.The crackingreactioncanbewritten

andisaccompaniedbycarbonformation:

Toslowthelatterreaction,steamisaddedtothehydrocarbonfeedstock. Thehydrocarbon-streammixtureisheatedbypassingitthroughatube whichissuspendedwithinafirebox.Asseenin Fig.1.7,tubeunits(orcoils)

arelarge.Thetubesarearound100mmdiameter,with10mmwallthickness andabout10mlong.Thesetubesareexpectedtosurviveforfiveyearsor morewhilstoperatingatwalltemperaturesranginguptoabout1100 C.They mustthereforepossessadequateresistancetocreepdeformation(undertheir ownweight),tooxidationoftheirexternalsurfacebycombustiongasandto attackbybothcarbonandoxygenontheirinnersurface.

Thematerialsusedforpyrolysisfurnacetubesarecentrifugallycastheat resistingsteelsornickelbasealloys,allausteniticalloyscontaininghigh chromiumlevels.Processeconomicsareenhancedbyhigheroperatingtemperatures,creatingademandforimprovedheat-resistantalloys.Thisdemand hasdrivenashiftinmaterialselectionforthecentrifugallycasttubesfromHK grade(25%chromium,20%nickel)toHPgrade(25%chromium,35%nickel) steel,andmorerecentlytoalloyscontaining45or60%nickelandaround25% chromium.Thesehighernickellevelsareintendedtoachievehighercreep

FIGURE1.7 Pyrolysistubeunitbeinginstalledinsteamcrackerfurnace.

strength.Considerationoftheprocessgascompositionrevealsthattheoxygen partialpressureiscontrolledbytheequilibrium

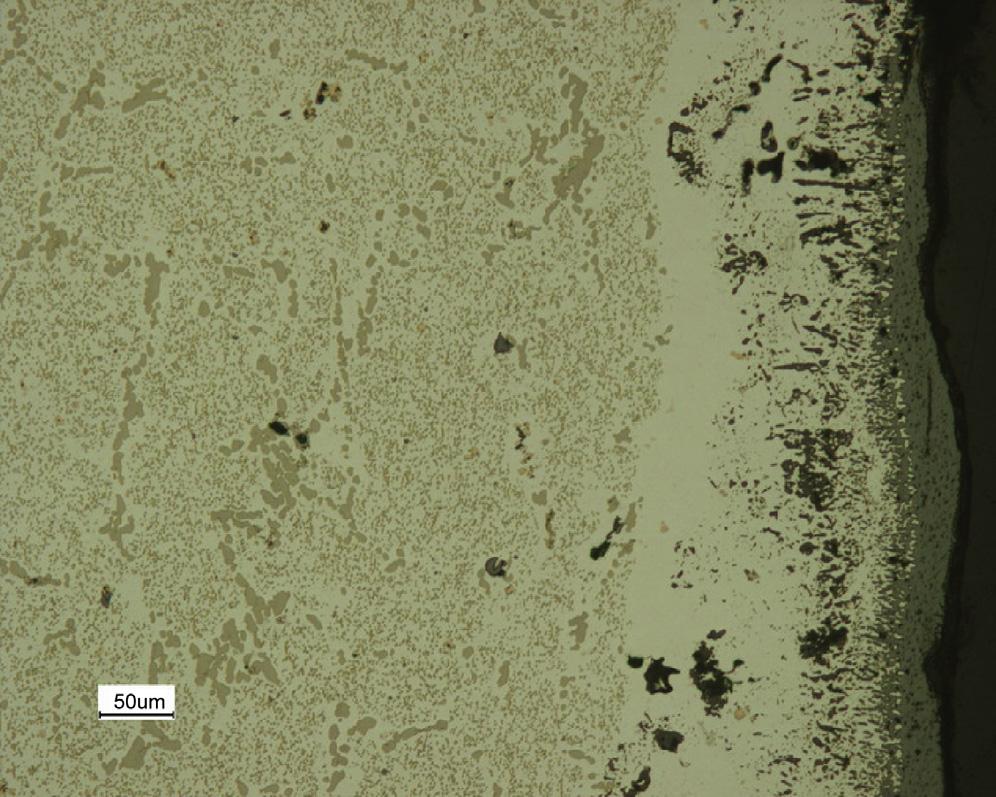

and pO2 z10 24 atmat1000 C.Thecarbonactivityiscontrolledby reaction [1.8] ,and ac ¼ 1.Undertheseconditions,thema inalloyconstituentwhichis reactiveischromium,andallofthecompoundsCr2O 3,Cr7C3 andCr23 C6 are possibleproducts.Thepracticalfindingsarethatanexternalchromiumrichoxidescalegrowsearlyinthelifeofthetube,butthatchromium carbidesprecipitatewithinthealloy,be neathitssurface,la teron.Theresults ofalaboratorysimulationoftheprocessareshownin Fig.1.8.Questions arisingfromtheseobservationsonwhathappenstothealloymightinclude thefollowing.Whydothealloyconstit uentsotherthanchromiumapparently notreact?Whyarethecarbidesformedasdispersedprecipitatesandnotas scalelayers?Whyarecarbidesformedbeneaththeoxideandnotviceversa? Howdoescarbonpenetratetheoxidelayertoreachthealloyinteriors?Why istherealayerofapparentlyunreactedalloyimmediatelybeneaththescale? Inaddition,andasalways,wewishtoknowtheratesatwhichscalegrowth andinternalcarbideprecipitationoccur,andhowtheserateswillvarywith changesintemperature,alloycompositionandgasconditions.

Toanswerthesequestions,itisnecessarytoconsiderfirstthechemical thermodynamicsgoverningreactionsbetweenametalandtwodifferentoxidants.Secondly,adescriptionoftheratesofmasstransferofchromium,

FIGURE1.8 Cross-sectionofcastheat-resistingsteel(HPModgrade)afterlaboratoryexposure tosteam-hydrocarbonmixtureat1100 Cfor500cyclesofonehoureach.

oxygenandcarbonwithinthesolidphasesisrequired.Finally,aknowledgeof theprocesseswherebyprecipitatesnucleateandgrowwithinmetalsisneeded, alongwithanabilitytopredictwhichprecipitatephasescancoexistwith whichalloycompositions.

1.5PREDICTIONANDMEASUREMENT Emergingfromaconsiderationoftheexamplesaboveistheneedtopredict whichreactionproductsresultfromhightemperatureoxidation(orcarburisation,sulfidation,etc.),whetherthoseproductsareformedasexternalscale layersorinternalprecipitates,howfasttheyformandwhattheirmechanical stabilitywillbe,allasfunctionsofalloycomposition,temperatureandgas conditions.Thetheoreticalbasisfortherequisitepredictivemethodologiesare reviewedinChapter2.Thenecessarythermodynamic,kineticandmechanical dataarenotalwaysavailableforcomplex,multicomponentsystems,and furtherexperimentalinvestigationwillbenecessary.Nonetheless,theoretical predictionisstilluseful,asitprovidesqualitativeindicationsoftheexpected effectofexperimentalvariables.Evenifthesearenomorethanhypotheses, theyprovidearationalframeworkforexperimentaldesign,therebyenabling efficientplanningoflaboratoryinvestigations.

Atthesametime,itisadvisabletobeawareofthepossibilitiesaffordedby modernexperimentaltechniques.Usefultheoriesprovidepredictionswhich canbetested,andthemorethoroughlywecantestatheory,themoreconfidencewearelikelytohaveinit.Theoreticaltreatmentsshouldthereforebe exploredwiththeaimnotonlyofachievingthedesiredperformancepredictions,butalsooffindingotherimpliedoutcomeswhichcanbemeasured. Thepointhereisthat‘performance’intermsofcomponentlifetimemightbe tensorevenhundredsofthousandsofhours.Otherpredictedresults,suchas compositional,microstructuralorphaseconstitutionalchangeinalloyorreactionproduct,willbeevidentmuchmorerapidly.Theirverificationtherefore providesanearlyindicationoftheprobabilityofoxidationlifetimebeing achieved.

1.5.1OxidationRates Thecourseofanoxidationreaction

followsakineticratelaw

where x isameasureoftheextentofreactionattime, t.Thus

where n isthenumberofmoles.Itisnecessarytodeterminethequantitative formofthefunction f(t).

Inprinciple,areactioncanbefollowedbymeasuringconsumptionofmetal oroxygenorbyobservingoxideaccumulation,asafunctionoftime.Iftheoxide isagas,thenmetalconsumptioncanbefollowedcontinuouslybyattachingthe metalsampletoabalanceofappropriatesensitivity,heatingitinthereactiongas andmeasuringtheweightloss.Anapparatussuitableforthisexperimentis shownin Fig.1.9.Inthemorecommoncase,theoxideissolid,andmetal consumptioncannotbedirectlyobservedinthisway.Instead,ametalsample couldbereactedforatime,andtheamountofmetalremainingaftersubsequent removaloftheoxidemeasured.Aseriesofsamplesreactedfordifferenttimes wouldthenyieldakineticplot.Difficultiesinremovingallofthescalewithout damagingtheunderlyingmetalrenderweightchangemeasurementsofthissort inaccurate.Analternativetechniqueistomeasurethedifferenceinmetalsection thicknessbeforeandafterreaction.Giventhatthedifferenceswillbesmall, perhapsoforder10 mm,comparedtotheusualspecimenthicknessofsome millimetres,measurementerrorscanbelarge.However,thistechniquehasbeen successfullyappliedtotheoxidationofthinfoils [8]

Theconsumptionofoxidant dnO2 canbefollowedbyobserving DpO2 at constantvolume,orthevolumechangerequiredtomaintain pO2 constant. Giventhevastlydifferentdensitiesofsolidsandgases,itisclearthatthis techniqueisrestrictedtocasesofsmall dx,unlesstheoxidantcanbe replenished.Similarreservationsapplytotheuseofthistechniquewhenthe reactiongasisamixture:as dx increases,thegaschangescomposition.

1.gas bottle

2.catch bottle

3.condenser + flask

4.water bath for flask

5.water pump

6.water bath condenser

7.furnace

8.microbalance

9.specimen

10.amplifier

11.computer

FIGURE1.9 Schematicviewofthermogravimetricapparatusformeasuringweightuptake duringhightemperaturereactioninacontrolledgasatmosphere.

Byfarthemostcommonmethodofmeasuringoxidationratesisthe observationofoxideaccumulationwithtime.Gravimetricmeasurementscan beperformedcontinuouslywithamicrobalanceordiscontinuouslyby weighingaseriesofsamplessubjectedtodifferentreactiontimes.Continuous measurementsyieldamoreaccuratedefinitionof Eq.[1.11],butthetimelapse exposureapproachcanbeusedtosimultaneouslyreactalargenumberof differentalloys.Moreoverthemultiplesamplesobtainedforeachalloycanbe usefulincharacterisingthereactionproducts.When dx/dt isverysmall,the measurementprecisionprovidedbyahighqualitymicrobalanceisdesirable, althoughitcanbedifficulttoachieve.

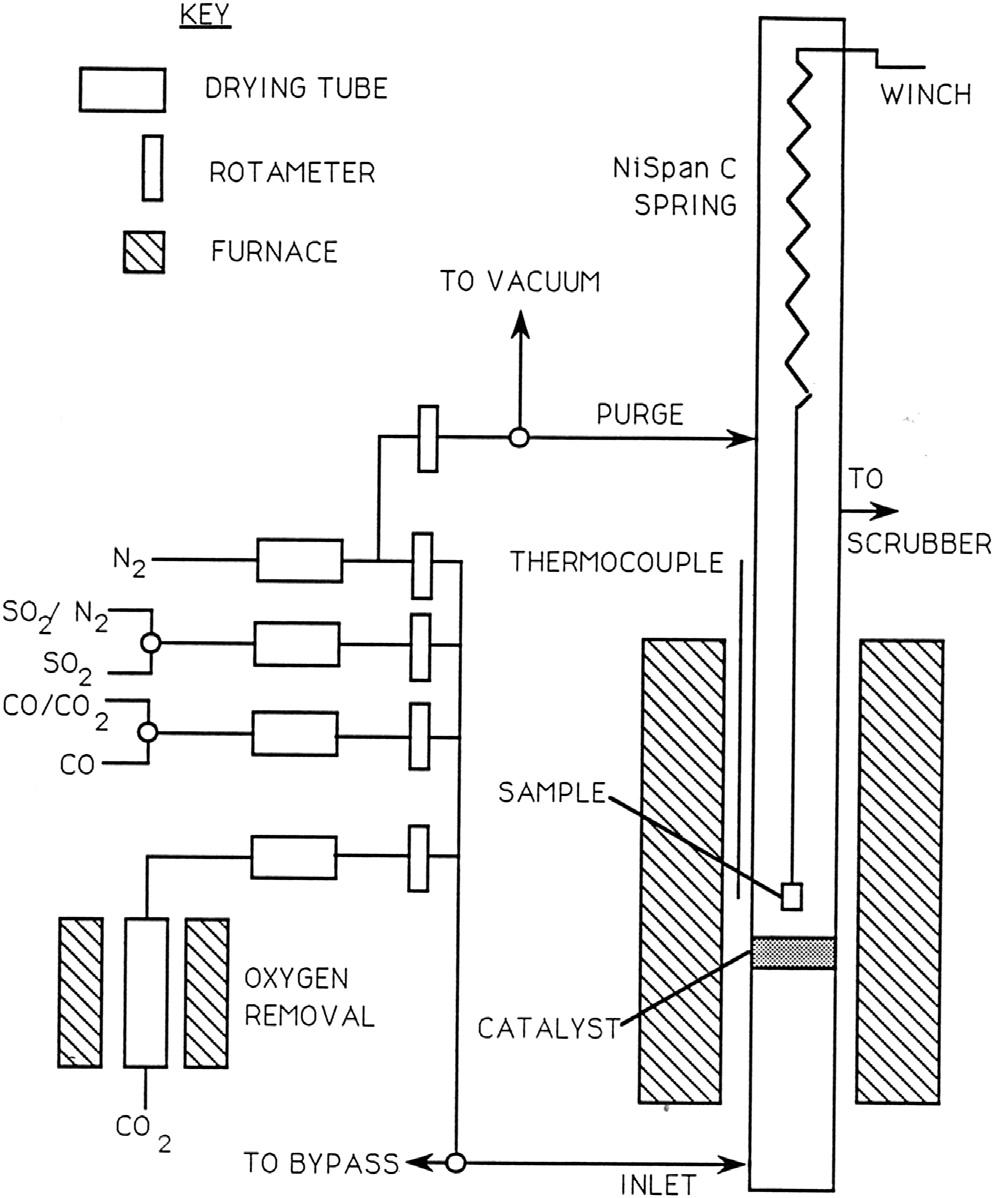

Microbalancesareexpensive.Theymustbeprotectedagainstcorrosionby thereactiongasbypassingacounterflowofunreactivegasthroughthebalance chamber,asshownin Fig.1.9.Inthecaseofparticularlycorrosivespecies suchasSO2 orH2S,itisadvisabletouseacheapspringbalancesuchasthat shownin Fig.1.10.Theelongationofahelicalspringisobservedasasample

FIGURE1.10 Schematicviewofspringbalanceassemblyforobservinghightemperature oxidationkinetics.

suspendedfromitreactsandbecomesheavier.Thespringisusuallymade fromsilicafibreorNiSpanCwire,thelatterbeinganalloywithanelastic modulusinsensitivetotemperature.

Theobservedweightchange, D W,varieswithspecimensurfacearea, A, andthemeasuredquantityisreportedas D W/A .Ifnometalvolatilisation occurs,theweightchangecorrespondstooxidantuptake,anditfollowsfrom Eq.[1.12] that

Thelossofmetalcanthenbeexpressedintermsofweightperunitsurface area, DWM/A,usingtheatomicweight,AWM,

Thislossisequivalenttoadecreaseinvolumegivenby

where rM isthemetaldensity.Recognisingthatuniformremovalofmetal fromaflatsurfaceresultsinarecessionofthesurfacebyadepth

itisseenthat

Similarly,thethickness X ofauniform,single-phaseoxidescalegrownona flatsurfacecanbecalculatedas

whereMWOX isthemolecularweightand rOX thedensityoftheoxide. Oxidescalethicknessescanbemeasureddirectly,byexaminingmicroscopicimagesofcross-sectionssuchasthoseshownin Figs.1.3and1.8.This technique,whichisdescribedbelow,isrelativelysimpleandeconomical.For thisreason,andalsobecausediffusionequationsareexpressedintermsof positioncoordinates,itispreferably torephrasethegeneraloxidationrate Eq.[1.11] as