https://ebookmass.com/product/high-entropy-alloyssecond-

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

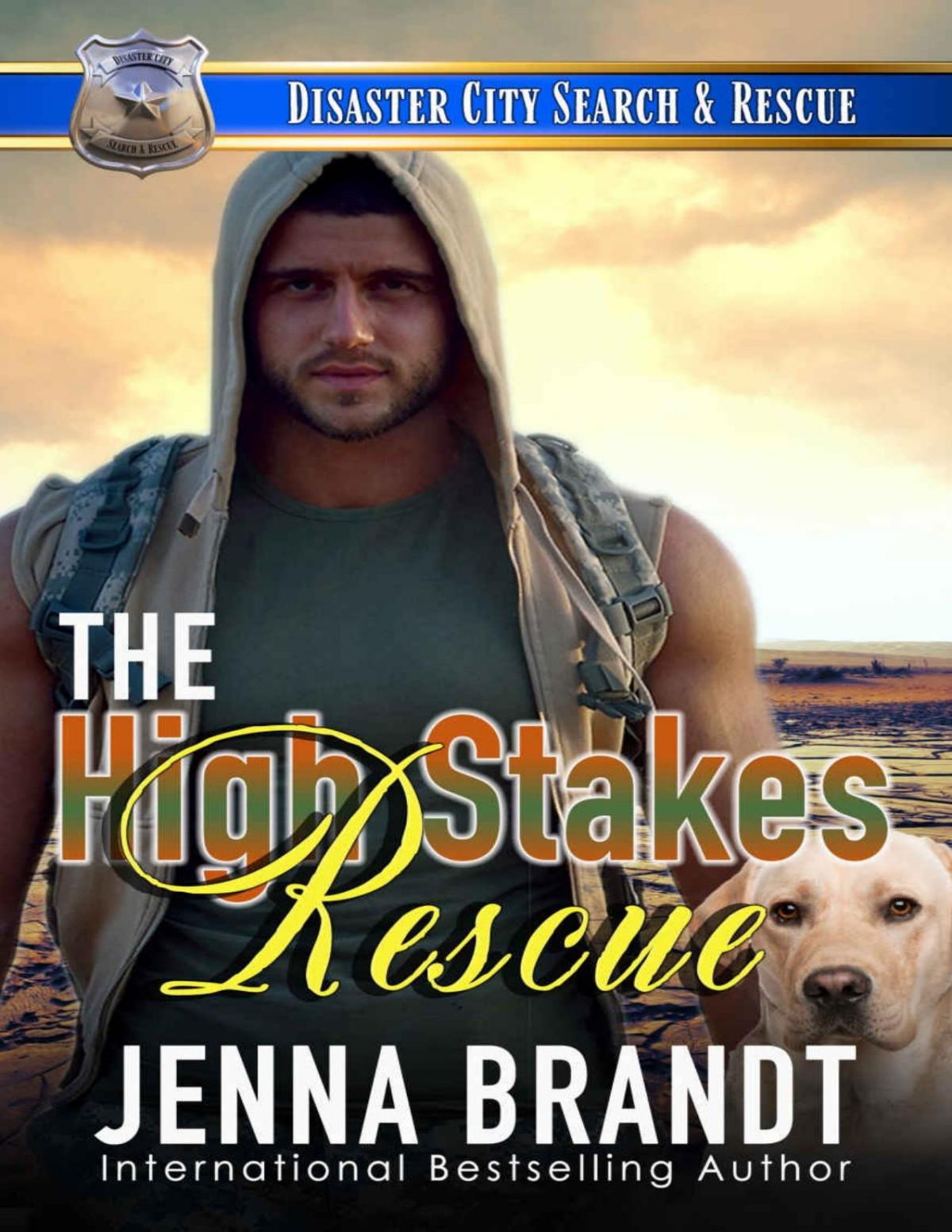

The High Stakes Rescue: A K9 Handler Romance (Disaster City Search and Rescue, Book 29)

1st Edition Jenna Brandt https://ebookmass.com/product/the-high-stakes-rescue-a-k9-handlerromance-disaster-city-search-and-rescue-book-29-1st-edition-jennabrandt/ ebookmass.com

ENTROPY ANALYSIS IN THERMAL ENGINEERING SYSTEMS 1ST Edition Yousef Haseli

https://ebookmass.com/product/entropy-analysis-in-thermal-engineeringsystems-1st-edition-yousef-haseli/

ebookmass.com

Statistical mechanics : entropy, order parameters, and complexity 2nd Edition Sethna

https://ebookmass.com/product/statistical-mechanics-entropy-orderparameters-and-complexity-2nd-edition-sethna/

ebookmass.com

Automotive Service: Inspection, Maintenance, Repair Book 6th Edition Tim Gilles

https://ebookmass.com/product/automotive-service-inspectionmaintenance-repair-book-6th-edition-tim-gilles/

ebookmass.com

(ENCHANTED CHRONICLES OF CRESCENT CITY Book 1) Amy Armstrong https://ebookmass.com/product/healing-hearts-a-sweet-paranormalromance-novel-enchanted-chronicles-of-crescent-city-book-1-amyarmstrong/

ebookmass.com

Invitation to Psychology 7th Edition – Ebook PDF Version

https://ebookmass.com/product/invitation-to-psychology-7th-editionebook-pdf-version/

ebookmass.com

Beautiful Nightmares (Fortuna Sworn Book 4) K.J. Sutton https://ebookmass.com/product/beautiful-nightmares-fortuna-swornbook-4-k-j-sutton/

ebookmass.com

Child Development 9th Edition, (Ebook PDF)

https://ebookmass.com/product/child-development-9th-edition-ebook-pdf/

ebookmass.com

Computational Frameworks. Systems, Models and Applications 1st Edition Edition Mamadou Kaba Traore (Eds.)

https://ebookmass.com/product/computational-frameworks-systems-modelsand-applications-1st-edition-edition-mamadou-kaba-traore-eds/

ebookmass.com

Interference in a Digital Age 1st Edition Jens David Ohlin (Editor)

https://ebookmass.com/product/defending-democracies-combating-foreignelection-interference-in-a-digital-age-1st-edition-jens-david-ohlineditor/

ebookmass.com

High-EntropyAlloys High-EntropyAlloys SecondEdition

B.S.Murty

DepartmentofMetallurgicalandMaterialsEngineering, IndianInstituteofTechnologyMadras,Chennai,India

J.W.Yeh

DepartmentofMaterialsScienceandEngineering, NationalTsingHuaUniversity,Hsinchu,Taiwan

S.Ranganathan

DepartmentofMaterialsEngineering, IndianInstituteofScience,Bangalore,India

P.P.Bhattacharjee

DepartmentofMaterialsScienceandMetallurgicalEngineering, IndianInstituteofTechnologyHyderabad,India

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

© 2019ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans, electronicormechanical,includingphotocopying,recording,oranyinformationstorageand retrievalsystem,withoutpermissioninwritingfromthepublisher.Detailsonhowtoseek permission,furtherinformationaboutthePublisher’spermissionspoliciesandour arrangementswithorganizationssuchastheCopyrightClearanceCenterandtheCopyright LicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions.

Thisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythe Publisher(otherthanasmaybenotedherein).

Notices Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchand experiencebroadenourunderstanding,changesinresearchmethods,professionalpractices,or medicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgein evaluatingandusinganyinformation,methods,compounds,orexperimentsdescribedherein. Inusingsuchinformationormethodstheyshouldbemindfuloftheirownsafetyandthesafety ofothers,includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors, assumeanyliabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproducts liability,negligenceorotherwise,orfromanyuseoroperationofanymethods,products, instructions,orideascontainedinthematerialherein.

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary ISBN:978-0-12-816067-1

ForinformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: MatthewDeans

AcquisitionEditor: ChristinaGifford

EditorialProjectManager: AliAfzal-Khan

ProductionProjectManager: AnithaSivaraj

CoverDesigner: AlanStudholme

TypesetbySPiGlobal,India

Forewordforthesecondedition Metallurgyhasbeenleadinghumancivilizationfromtimeimmemorial.Manknew howtoextractmetalsfromores,howtoalloymetalstomakethemsuitableforspecific needs,andhowtopreparehigh-puritymetalsandcompoundsforelectronicapplications.Lookingbackintothelastcentury,itmaybesaidthatdevelopmentsinmetallurgyandmaterialssciencehaveplayedasignificantroleinseveralareasand impactedtheeconomyandwell-beingofpeople.Everyotherbranchofscience andengineeringhasdependedonadvancesinmetallurgytobeappliedinitsdomain. Developmentofsuperalloysforjetengineapplications,developmentofcarboncarboncompositesforwingsofwide-bodiedaircrafts,high-temperaturesuperconductors,etc.areonlyafewexamplestoquote.Itshouldalsobementionedherethatthe availabilityofexcellenthigh-resolutiontechniqueshascontributedimmenselytothe understandingofthescienceandtechnologybehindthesedevelopments,particularly fromthepointofviewofstructure-propertycorrelationscoupledwithphase transformations.

Lookingatthepresentcenturyandtheresearchareascoveredinthelastdecadeand ahalf,itisnotanunderstatementifIsaythatthetopicof“High-EntropyAlloys” (HEAs)aka“MultiprincipalComponentAlloys”hasbeenthemainattractionofseveralresearchgroupsallovertheworld.ThenumberofpublicationsonHEAsinrecent yearsin ActaMaterialia hasfarexceededthatofanyothertopic.Iamdelightedto writethisForewordfortheSecondEditionofthefirstbookon High-EntropyAlloys TheForewordfortheFirstEditionwaswrittenbyBrianCantoroftheUnited Kingdom.

ThebasicdifferencebetweenconventionalsinglebasealloysystemsandHEAis thatthelatterdealswithcompositionsatthecenterofamulticomponentphasediagram.Severalfactorsleadtotheformationofsingle-phaseHEA.Yeh,independent inventorofHEA,attributedthistofourcoreeffects:highentropy,sluggishdiffusion, highlatticedistortion,andcocktaileffects.Severalofthealloyschosenbyhimturned outtobesinglephase,butsomerevealedadditionalphasesonexaminationbyhighresolutiontechniques.Thus,therearechallengesinunderstandingtheevolutionof phasesinHEAs.However,HEAshavegivenimpetusfortheevaluationofmulticomponentphasediagrams,andnewmulticomponentthermodynamicdatabases arebeingdevelopedbyagenciessuchasThermo-Calc.Thesealloyshavealsoopened newavenuestoprobeintodiffusionandmechanicalbehaviortounderstandthedislocationdynamicsandphasetransformationsinmulticomponentsystems.

EarlyworkonHEAsbyseveralgroupswasmainlyfocusedon3-dtransition metalspartlyduetoourfamiliaritywiththesemetals,stainlesssteels,andsuperalloys. ThesecrystallizedinFCCorBCCstructures.Themechanicalpropertiesof3-dHEAs

wereonlymarginallybetterthantheexistingalloys,buttheiroxidationandcorrosion resistanceinafewcaseswerebetterthanconventionalmaterials.Improvementsin strengthinFCCalloyswereobtainedbyparticulatestrengthening,whileductility inBCCwasbroughtinbyeutecticmicrostructure.However,theso-calledCantor alloycontainingFeCrMnNiCoshowedhighstrengthandhighductilityoverawide rangeoftemperatures.Thisleadsonetoconcentrateonthedeformationmechanisms thatoperateinHEAsforabetterdesignofthealloys.

Withtheinteresttodevelopalternativestosuperalloys,whichhavereachedasaturation,afewresearchersfocusedtheirattentiononrefractoryHEAscontainingHf, Nb,W,Cr,Zr,etc.astheyexpectedthesetoyieldbetterhigh-temperatureproperties. Whilethestrengthlevelswerehigh,ductilitywasfoundtobelow.Itwasrealizedthat equiatomiccompositionsarenotlikelytoyieldthedesiredpropertiessuitableforspecificapplicationsandcompositionsweretailoredtoobtaintherequisiteproperties. Ifeelonehastobeinnovativeandintuitiveinselectingthecompositionsofalloys. Possibly,minoradditionsofsomeelementssuchasC,B,andREinHEAsmayyield improvedproperties.Iexpectgreateremphasisbyresearchersonthisaspectinthe comingyears.

Thelastchapterinthisbookisonapplication.Thereshouldbeaconcentratedeffort ontheuseofHEAcoatingsforenvironmentalprotection,astheunderlyingstructureis wellestablishedandHEAsmayextendtheirusefullife.Atthesametime,focused emphasisisneededtodeveloprefractoryHEAsastheiruseislikelytoincrease theefficiencyofenergysystemsandatthesametimereducepollutionlevels.The industries,R&Dlaboratories,andacademicinstitutionsshouldjoinhandsinbringing HEAstothemarketasearlyaspossible.

Thefirsteditionofthebookbroughtoutin2014had10chaptersandwrittenby threeauthors.Ithasbeenexpandednowbyaddingthreemorechapters,withanadditionalauthor.Alltheappendixeshavebeenupdated.Inaddition,Ishouldalsopoint outthat Chapter5 includesinformationontheuseof“ArtificialIntelligencein HEAs,”whichwouldbeusefultoresearchersinthefield.

R.Krishnan

FormerDirector,GasTurbineResearchEstablishment,Bengaluru,India

Forewordforthefirstedition Inthe1970s,Ibecameexcitedabouttheideaofmulticomponentalloys.Irealizedthat thematerialsweusearealmostallbasedonasinglecomponentwithaprimarypropertyandanadmixtureofsmallamountsofothercomponentstoprovidesecondary properties.Effectively,allourknownmaterialsareatthecornersandedgesofamulticomponentphasediagramconsistingofallpossiblecomponents.Thismeansthat thereareavastnumberofpossiblematerialsinthemiddleofthisphasediagramthat haveneverbeeninvestigated.Itturnsoutthatthisunknownfieldofmaterialsistruly enormousandthenumberofunexploredmaterialsismanytimesgreaterthanthenumberofatomsintheuniverse.

Thisexplainswhywekeepdiscoveringexcitingnewmaterials:high-temperature superconductors,glassyalloys,quasicrystals,compoundsemiconductors,andsoon. Andwewillkeepfindingexcitingnewmaterialsaslongaswehavethecourageas experimenterstotryinnovative,newmixturesofconstituents.InowtelleveryPhD studentinmaterialssciencetobeaggressiveandambitiousinexploringthisamazing arrayofpotentialnewmaterials.

Inthe1970s,Ifoundithardtopersuadeotherpeopletobesimilarlyenthusedbymy ideasonthetopicofmulticomponentalloys.Icouldnotgetfunding,andIcouldnot getresearchcolleaguestoundertakepreliminaryexperiments.Everyonewantedto workinmuchbetterknownfields.Everyonewasveryconservative.Finally, Ipersuadedayoungundergraduatestudent,AlanVincent,todopreliminarywork. Heimmediatelyfoundexcitingresultsincludingthefirsthigh-entropyalloys.Nearly 20yearslater,Ipersuadedanotheryoungundergraduatestudent,PeterKnight,to repeatthework.Andfinally,acoupleofyearslater,mylong-standingresearchcolleague,IsaacChang,repeatedtheexperimentsforathirdtimebutmorecarefullyand withmoretimetodocumenttheresultsfullyandinapublishableway.Wepresented theresults,firstfoundbyAlanVincentin1979,ataconferencein2002,whichwas publishedin2004,morethan25yearssincemyfirstidea.Inparallel,Professor S.Ranganathan(myoldfriend,Rangu)andProfessorJ.W.Yeh(mynewfriend, Jien-Wei)publishedindependentlypaperson,respectively,materialcocktailsand high-entropyalloys,closelyrelatedandessentiallysimilarconceptstomyideaofmulticomponentalloys.

Inthelastfewyears,asaconsequenceoftheoutstandingcontinuingworkbyJienWei,thefieldofmulticomponentandhigh-entropyalloyshastakenoff,withliterally hundredsofpublicationseachyear.Mostnotably,Vincent,Knight,Chang,and Idiscoveredinthelate1970sasingleFCCsolidsolutionconsistingofsixcomponents inequalproportions,namely,FeCrMnNiCo.Thisalloyhasbeenshowntohaveoutstandingmechanicalproperties,withhighstrengthandhighductility.Irealizedinthe

late1970sthatthemechanicalbehaviorofthismaterialwouldbeveryunusual.Metal andalloymechanicalpropertiesdependprimarilyonthebehaviorofdislocationsand howtheymoveinresponsetostress,buttheconceptofadislocationasalinedefect withaconsistentcorestructurebecomescomplexwhentherearemanydifferentcomponentsdistributedonasinglelattice.

ProfessorsMurty,Yeh,andRanganathanhavenowwrittenabookonthisnew groupofmaterials.Thebookcoversthestructure,processing,andpropertiesofthe materials,insofaraswehavebeenabletoexplorethem.Somemulticomponentalloys aresolidsolutionswithhighentropy.Somearenot.Ineithercase,therearewonderfullyexcitingnewstructuresandpropertiestobefound.Thisbookisthefirstabout thisfield.Itcontainsmanyvaluableandinterestinginsights.Butultimately,itcan onlyhintatthefullrangeofnewmaterialsthatremaintobediscovered.Theauthors shouldbecongratulatedondoinganimportantjobthatwillhelpusonourexciting, exploratoryjourneyintothematerialsofthefuture.

Prof.BrianCantor ViceChancellor,UniversityofBradford,UnitedKingdom

Prefaceforthesecondedition Thehigh-entropyalloy(HEA)fieldhasbeengrowingleapsandbounds.ThefirsteditionofHEAbookhasbeenpublishedin2014,mostlybasedonthepublicationsuntil 2013.Thenumberofpublicationsinthelast5years(2014–June2018)issixtimes (morethan2600)thatofthepublicationsthathavecomeoutinthefirstdecadeof thefield(about400from2003to2013).Thishasnecessitatedthereleaseofthesecond editionofthebook.Thecurrenteditionaddsonthenewresearchthathasbeenbrought outinthelast5yearstothefirstedition.

Whilethenumberofnewequiatomiccompositionsthathavebeeninvestigatedin thelast5yearshasnotbeenmany,researchersrealizedtheneedtodevelopnonequiatomiccompositions(andwithminoradditionsofcertainelements)tobring outsignificantimprovementsinvariousproperties.NewsubclassesinHEAssuch aseutecticHEAs,HEAsuperalloys,TWIP-andTRIP-typeHEsteels,dual-phase HEAs,lightHEAs,andHEAoxideshavebeendevelopedinrecentyears.

TheeffortsonpredictingthephaseformationinHEAsthroughthermodynamic calculationsandattemptstocalculatemulticomponentphasediagramsthrough CALPHADapproacheshavesignificantlygrown.Thermo-Calchasbroughtouta newHEAthermodynamicdatabase(TCHEA)toassistresearchersinthecalculations inmulticomponentspace.Inadditiontofirstprinciplecalculations,researchersalso startedexploringartificialintelligenceasatooltounderstandthebehaviorofHEAsin termsofphaseformationandproperties.

InadditiontotheexistingroutesforthesynthesisofHEAs,newroutessuchas carbothermalshocksynthesistopreparenanoparticlesofHEAsand3-Dprinting throughadditivemanufacturingroutesdevelopedrecentlyhavewidenedthescope ofthefield.Inadditiontothetraditionalapplications,HEAsarebeingexploredfor avarietyoffunctionalapplicationssuchasmagnetic,thermoelectric,andbiomedical applications.

Itisalsopertinentheretosaythatanumberoflarge-scaleinitiativesarebeingtaken invariouscountriesthroughpublicandprivatepartnershipstobringoutbothscientific andtechnologicaladvancesinthisfield.Inrecentyears,almosteveryconferencein metallurgyhasspecialsessionsonHEAs.Inaddition,exclusiveconferences/symposia/workshopsarebeingconductedregularlyinthisfieldtosharetheknowledgebeing gainedbyvariousresearchers.MentioncanbemadeofbiennialInternationalConferenceonHigh-EntropyMaterials(ICHEM),thefirstoneheldinTaipei,Taiwan,in 2016andthesecondonebeingheldinJeju,Korea,inDecember2018.InIndiaalso, asimilarbiennialInternationalWorkshoponHigh-EntropyMaterials(IWHEM) startedin2015atChennaiandsubsequentlyatHyderabadin2017,andthenext onewillbeheldinKanpur.Awebsite(https://mme.iitm.ac.in/hea/)isbeingmaintainedbythegroupofB.S.Murtyintheresearchactivitiesinthisfield,withparticular

emphasisonIndianresearchactivity.Thiswebpageisupdatedmonthly,andonecan getalistofup-to-datepublicationsinthisfieldfromthissource. ThissecondeditionoftheHEAbookbringsoutalltherecentadvancesinthis excitingnewclassofalloys.Weareconfidentthatitwouldexcitethereader.

B.S.Murty, J.W.Yeh, S.Ranganathan, P.P.Bhattacharjee

Prefaceforthefirstedition Alloystraditionallyhavebeenbasedonasolventelementtowhichvarioussolute atomsareaddedforimprovingspecificproperties.Thus,alloysareusuallynamed afterthemajorelementinthealloy,forexample,Fe-base,Al-base,Cu-base, Mg-base,andNi-basealloys.Twopeople,inrecenttimes,havechangedthewaypeoplelookatalloys,andtheyareProf.BrianCantorandProf.Jien-WeiYehbycoming upwithequiatomicandnonequiatomicmulticomponentalloys.Incidentally,though eachofthemstartedworkingonthesealloysindependentlyatdifferenttimes(Cantor startingin1981andYehstarting1996),theirworkcametoopenliteratureinthesame year,2004.Interestingly,evenbeforethepapersofthesetwopioneersgotpublishedin 2004,Prof.S.Ranganathanfelttheimportanceofthisnewclassofalloysandwrote abouttheminhisclassicpaper“Alloyedpleasures:multimetalliccocktails”in2003, whichhasbeencitedmorethan100timesnowasthefirstpublicationonthisclassof alloys.

Yehchristenedthesealloysas“high-entropyalloys(HEAs),”rightlyso,astheconfigurationalentropyofthesealloysisexpectedtobeveryhighattheirrandomsolution states.Suchahighentropyisexpectedtoletthealloystendtoformsimplesolidsolutions(crystallineoramorphous)ratherthancomplexmicrostructureswithmanycompounds.Theconcepthascaughttheattentionofmanyinthelastonedecadewitnessed about400–500papersbeingpublishedonHEAswithvariouselementalcombinations. Twomajorobservationscanbemadefromallthiswork,namely,thealloysdoform simplesolidsolutionsinmostofthecases,andthenumberofphasesobservedinthese alloysismuchlessthanthemaximumpredictedfromtheGibbsphaserule.

Therearealsoclearindicationsthatthehighentropyinthesemulticomponent equiatomicandnonequiatomicalloysisnotabletoactlikeaglueholdingalltheatoms togetherinasinglesolidsolution,andtherearereportsontheformationsoftwoor morephasesinwhichintermetallicphasesandevensegregationofcertainelements mightform.Thiscouldberelatedwiththevariousthermodynamicandkineticfactors. Therehasbeenintenseactivityinthepastfewyearstopredictthephasesthatcanform insuchmulticomponentalloysthroughvariousmodelingapproachesincludingintegratedcomputationalmaterialsengineering(ICME)usingvarioustoolssuchas CALPHAD, ab-initio,moleculardynamics,MonteCarlo,andphase-fieldapproaches, whichhavebeensupportedbyMaterialsGenomeInitiative(MGI).

Besidesthesciencecuriosity,researchersalsowishthatHEAscansubstituteconventionalmaterialsinadvancedapplicationssothatthelimitationsinservicelifeand operationconditionscouldbeovercomebyprovidingsuperiorperformance. Anumberofprocessingroutes,includingconventionalmeltingandcasting,mechanicalalloying,variouscoatingtechniques,andevencombinatorialmaterialsscience approaches,arebeingusedtosynthesizeandprocessthisnewclassofalloys.There

Acknowledgmentsforthesecond edition TheauthorsaregratefultoDr.R.Krishnanforreadilyagreeingtowriteaforewordfor thesecondeditionofthebook.Hehasalsomadeimmensecontributionsbycritically examiningeachchapterandhelpingtoimproveitsquality.Wearealsogratefultoall theauthorsofvariouspublicationsthatwerefertointhisbook.

Prof.Murtywouldliketospeciallythankhisgroupmembers,Dr.Nagini,Dr. Satish,Dr.Ram,Gopi,LavaKumarandAdil,whohavehelpedincollectingthearticlesandgoingthroughthewrite-uptobringittogoodshape.Amongall,Lava Kumar’shelpisimmense,andProf.Murtyisindebtedtohimforit.

Dr.PinakiBhattacharjeewouldliketothankhisgroupmembers,Seelam, Narayanswamy,Veerasham,andJaydeep,fortheirimmensehelpincollectingtherelevantresearchpapers.

Prof.Yehwouldliketothankhisresearchassistant,Hsuan-ChuChen,forupdating thestatisticalanalysisofpublishedSCIandEIpapersonhigh-entropyalloysand relatedmaterials.HealsothankshisPhDstudent,Ko-KaiTseng,forpreparing newfigures.

Prof.RanganathanisthankfultoMs.S.VaralakshmiandDhairyasheelPatilfor theirhelpincompilingthechapters.

B.S.Murty, J.W.Yeh, S.Ranganathan, P.P.Bhattacharjee

Acknowledgmentsforthefirst edition TheauthorsaregratefultoProf.BrianCantorforreadilyagreeingtowriteaforeword forthebook,inspiteofhishecticscheduleasViceChancellorofUniversityofBradford, theUnitedKingdom.Wearealsohighlyindebtedtoalltheauthorsandpublishersof variousworksthatwereferto,whohavesignificantlyimprovedthequalityofthebook.

Prof.Murtywouldliketospeciallythankhisgroupmembers,Mayur,Guruvidyathri, Anirudh,Arul,Ameey,andDr.Sanjay,whohaveuntiringlyhelpedatvariousstages. Meetingthedeadlineofthepublisherwouldnothavebeenpossiblewithouttheirhelp. Hewouldalsoliketogratefullyacknowledgethecollaborationwithhisstudents, Varalakshmi,Praveen,Pradeep,Sriharitha,Ashok,Durga,andRaghavan,and collaboratorsDr.RaviSankarKottada,Prof.M.Kamaraj,andProf.K.C.HariKumar ofIITMadras;Dr.SheelaSingh,Dr.N.Wanderka,andProf.J.BanhartofHelmholtzZentrumBerlin;andProf.D.RaabeofMax-Planck-InstitutfurEisenforschung, D€ usseldorf.Hethanksallofthemforjoininghiminthisexcitingjourneysofar. Heisalsoindebtedtohisfamilymembersfortheirpatienceandcontinuoussupport.

Prof.Yehwouldliketothanktwoimportantgroupmembers,Prof.Su-JienLinand Prof.Swe-KaiChen,fortheirlong-termcontributionsintheresearchonhigh-entropy alloyssince1995.HealsoexpressessincerethankstoProfs.Tsung-ShuneChin,JanYiawGan,Tao-TsungShun,Chun-HueiTsau,Shou-YiChang,TungHsu,andWenKuangHsuandallgraduatedstudentsfortheirsignificanteffortsandcontributionsin HEA-relatedresearch.Inaddition,hespeciallythanksDr.Chun-MingLinandPhD studentChien-ChangJuanfortheirhelpinsearchingrelatedpapers,plottingfigures, andprovidingsuggestionsforthisbook.Finally,healsogratefullythankshisbeloved wifeanddaughtersforalltheirencouragementandsupportsduringwritingthisbook.

Prof.Ranganathanrecordshisgratitudetonumerousteachers,colleagues,and studentswhoinstilledhimanabidinginterestinphysicalmetallurgy.Specialthanks areduetoT.R.Anantharaman,P.RamaRao,AlanCottrell,DavidBrandon,Robert Cahn,A.L.Mackay,GarethThomas,J.W.Cahn,P.RamachandraRao, K.Chattopadhyay,D.Shechtnan,K.H.Kuo,andA.Inoue.Gratefulthanksare expressedtomembersofhisfamilySucharita,Satyajit,Bratati,Viswajit,andGopika forthesupportinwritingthisbook.

TheauthorsaredeeplyindebtedtoDr.R.Krishnanforhismeticulousreadingof theentirebookandthankhimprofuselyforhisusefulsuggestions.

B.S.Murty, J.W.Yeh, S.Ranganathan

Listofabbreviations AI artificialintelligence

AM additivemanufacturing

ANN artificialneuralnetworks

APS atmosphericplasmaspraying

ATT acceleratedtechnologytransition

APT atomprobetomography

BCC body-centeredcubic

BMGs bulkmetallicglasses

CALPHAD CALculationofPHAseDiagrams

CNFs carbonnanofibers

COF coefficientoffriction

CPA coherentpotentialapproximation

CR coldrolling

CTCR cryogenictemperaturemultipasscaliberrolling

CTS carbothermalshock

CVD chemicalvapordeposition

DC directcurrent

DFT densityfunctionaltheory

D-G Darken-Gurry

DLF directlaserfabrication

DR dendritic

DSC differentialscanningcalorimetry

DTA differentialthermalanalysis

DSS disorderedsolidsolution

EBSD electronbackscatterdiffraction

EBW electronbeamwelding

ECCI electronchannelingcontrastimaging

EDS energydispersivespectroscopy

EHEAs eutectichighentropyalloys

EMI electromagneticinterface

EMPA electronprobemicroanalysis

FCC face-centeredcubic

FSP flamespraypyrolysis

GB grainboundary

GCP geometricallyclose-packed

GFA glassformingability

GTAW gastungstenarcwelding

HAADF high-angleannulardark-field

HIP hotisostaticpressing

H-R Hume-Rothery

HCP hexagonalclose-packed

HEAS highentropyalloys

HEBMGs highentropybulkmetallicglasses

HECs highentropyceramics

HEDs highentropydiborides

HENs highentropynitrides

HEOs highentropyoxides

HESAs highentropysuperalloys

IC integratedcircuit

ICHEM internationalconferenceonhigh-entropymaterials

ICME integratedcomputationalmaterialsengineering

IMs intermetallics

IR interdendritic

IWHEM internationalworkshoponhigh-entropymaterials

JCPDS jointcommitteeonpowderdiffractionstandards

LAMMPS large-scaleatomic/molecularmassivelyparallelsimulator

LENS laserengineerednetshaping

LPE latticepotentialenergy

LPS liquidphaseseparation

MA mechanicalalloying

MaxEnt maximumentropy

MC MonteCarlo

MD moleculardynamics

MGI materialgenomeinitiative

MICRESS MICRostructureEvolutionSimulationSoftware

ML machinelearning

MM mechanicalmilling

MMNPs multimetallicnanoparticles

NSP nebulizedspraypyrolysis

ODF orientationdistributionfunction

ODSHEAs oxide-dispersion-strengthenedhighentropyalloys

PHACOMP phasecomputation

PM powdermetallurgy

RCP reversecoprecipitation

RE rareearth

RHEAs refractoryhighentropyalloys

RMS rootmeansquare

RMSD rootmeansquaredisplacement

RTCR roomtemperaturecaliberrolling

SAED selectedareaelectrondiffraction

SC staticcompaction

Listofabbreviations

Listofabbreviations

SEBM selectiveelectronbeamwelding

SEM scanningelectronmicroscopy

SFEs stackingfaultenergies

SLM selectivelasermelting

SPS sparkplasmasintering

SRS strainratesensitivity

SS solidsolution

SWC shockwavecompaction

TCHEA thermodynamicdatabaseforhighentropyalloys

TCP topologicallyclose-packed

TCR temperaturecoefficientofresistance

TDB thermodynamicdatabase

TEM transmissionelectronmicroscopy

TGA thermogravimetricanalysis

TIGW tungsteninertgaswelding

TRIP transformationinducedplasticity

TTT timetemperaturetransformation

TWIP twinninginducedplasticity

UFM ultrafinemicrostructure

VEC valenceelectronconcentration

VHP vacuumhotpressing

XRD X-raydiffraction

Abriefhistoryofalloysandthe birthofhigh-entropyalloys 1.1Introduction 1 Alloyingisthegreatestgiftofmetallurgytohumankind.TheEnglishinsistsonunalloyedpleasures,therebyimplyingthatthesensationofpleasuremustbepureandnot admixedwithotheremotions,exactlytheoppositerulesinmetallurgy,wherepure metalshavefewusesbutlotmoreuponalloying.Thepowerofthisideaofalloying isnotconfinedtometals.Thesameprincipleofalloyingappliesinpolymersand ceramics.Itcanbecarriedfurtherbymixingtwoclassesofmaterialstocreateavarietyofcomposites.

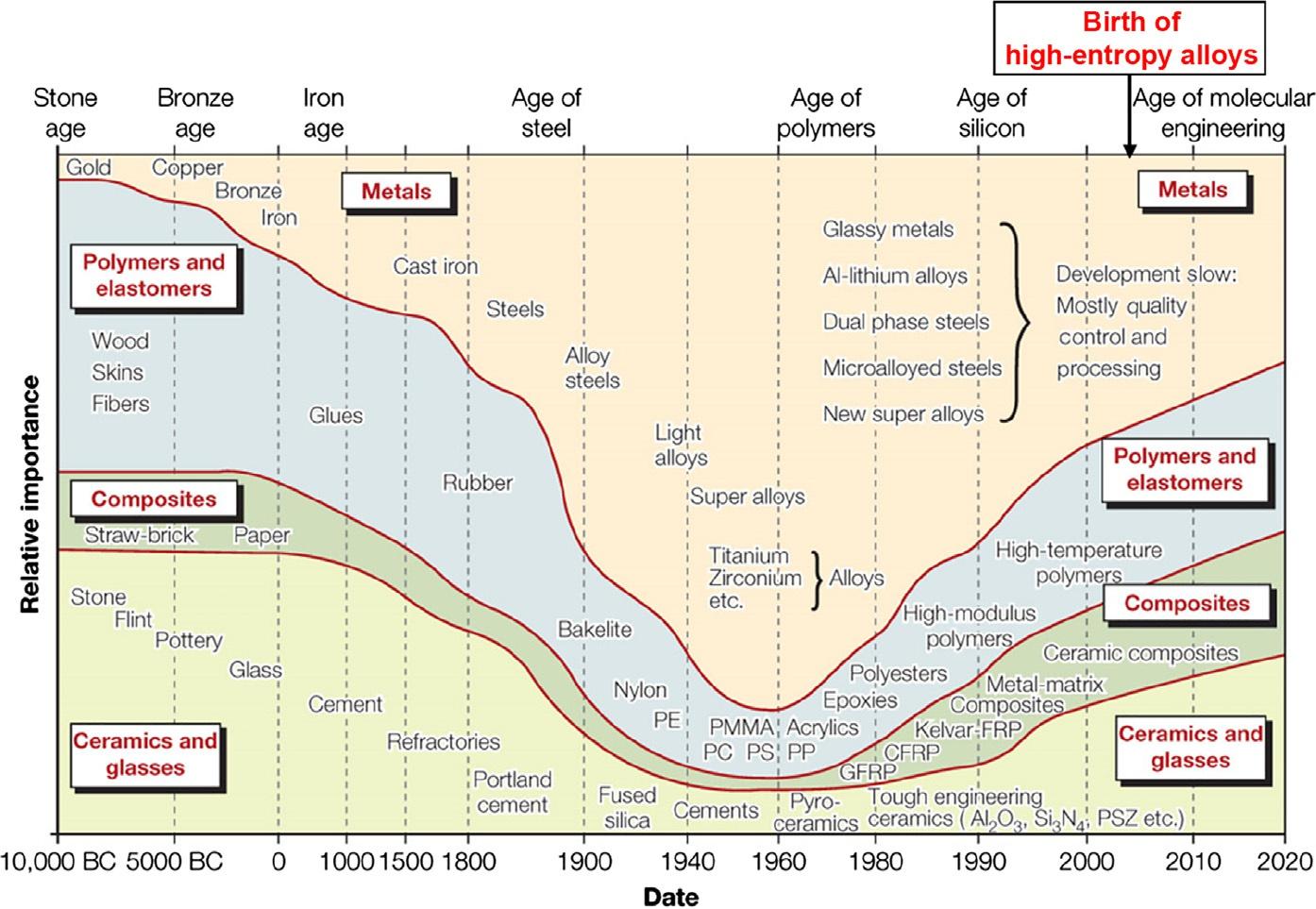

Thecivilizationaljourneyofthesocietybeganwiththediscoveryofnativemetals suchasgoldandcopperaspuremetals.Nowadays,wehaveaccesstoanincredible numberandvarietyofmaterials.Ashbymap(Ashby,2011)shownin Fig.1.1 givesa panoramicviewofthedevelopmentintheuseofmaterialsover10millennia. Agraphicdepictionofthedifferentclassesofmaterialsfromceramicstometals,polymers,andmorerecentlycompositesisvividlydisplayed.Thepassagefromdiscovery throughdevelopmenttothedesignofmaterialscanbenoted. Ashby’s(2011) mapin termsofstrengthversusdensityshownin Fig.1.2 demonstratesthefillingofmaterialpropertyspaceinavividfashionfrom50,000BCEuptothepresentscenario.Intimescale,thelargestfillinghasoccurredinthepast50yearsduringwhichenvelopesof metals,ceramics,andcompositeshadalargeexpansion,andnewenvelopesofsyntheticpolymersandfoammaterialstakeasignificantspace.Butthefilledareaalso seemstoapproachsomefundamentallimitsbeyondwhichitisdifficulttogofurther (Ashby,2011).

Inmanyways,thehistoryofalloyingisthehistoryofmetallurgyandmaterials science.Booksandtreatiseshavebeenwritten.Anelegantandbriefhistoryisby Ashby(2008). Cahn(2001) hasofferedamagisterialsurveyof“TheComingofMaterialsScience.” Ranganathan(2003) wroteonalloyedpleasures—anodetoalloying.In thefollowingsections,afewepisodesinthisepicjourneyarecovered.

1.2Thecomingofalloys Nativealloyssuchastumbagaandelectrumarealloysofgold-copperandgold-silver, respectively.Whenplatinumwasdiscoveredin1735,itwascomparedwithsilver. Also,mixturesofplatinummetalsarefoundtooccurinnature.Itisanearlyexample ofmulticomponenthigh-entropyalloys(HEAs),sinceplatinumisoftenfoundas alloyswiththeotherplatinumgroupmetalsandironmostly.

2

Fig.1.1 HistoricalevolutionofengineeringmaterialsmarkedwiththebirthofHEAspublished in AdvancedEngineeringMaterials (Yehetal.,2004b). AdaptedfromAshbyM.F.,2011.MaterialsSelectioninMechanicalDesign,fourthed., Butterworth-Heinemann,Elsevier,Oxford,UK.

Fig.1.2 Theexplosioninthediversityofmaterialsinthemodernera(Ashby,2011): (A)prehistoricera(50,000BCE)and(B)currentstatus.

Alloyingwasanaccidentaldiscovery.Intheprimitivefiresinthecaves,oresof coppergotmixedwithoresofarsenic,zinc,andtin.Thefirstalloyofcopperandarsenic(arsenicalbronze,3000BCE)wasentirelyaccidental.Amoreintentionalalloying oftinwithcopper(tinbronzesin2500BCE)gavebirthtotheBronzeAge,asbronze wassuperiorinitsmechanicalproperties.

Thesevenmetalsfoundinantiquityweregold,copper,silver,iron,lead,tin,and mercury.Theeighthmetal,zinc,isaddednotonlybecauseoftheuniqueIndiancontextbutalsobecausethediscoveryofothermetalshadtoawaittheadventofthescientificrevolutionforafewcenturies.

Itisinterestingtomentionthatintermetallicsofcopper-tinalloyshadbeenusedin ancienttime.MirrorsweremadeofbronzesindifferentpartsoftheOldWorldincludingIndiaandChina,duetotheirhigherhardness,whichmakesiteasyingettingmirror finishtoreflectlikesilver.ArchaeometallurgicalinvestigationsbySharadaSrinivasan onvesselsfromSouthIndianmegalithsoftheNilgirisandAdichanallur (1000–500BCE)showedthattheywereofwroughtandquenchedhigh-tinbetabronze,rankingamongtheearliestknownartifacts.Thisisanearlyapplicationofan intermetallic.Whenthesulfideoresofcopperandnickelweresmeltedtogether,it ledtocopper-nickelalloyinthefourthcenturyinChina.Zincwasaddedinthe 12thcenturytoformsilveryandrust-resistingalloyknownaspaktong(whitecopper), whichwaswidelyusedinEuropebeforestainlesssteelwasinvented.

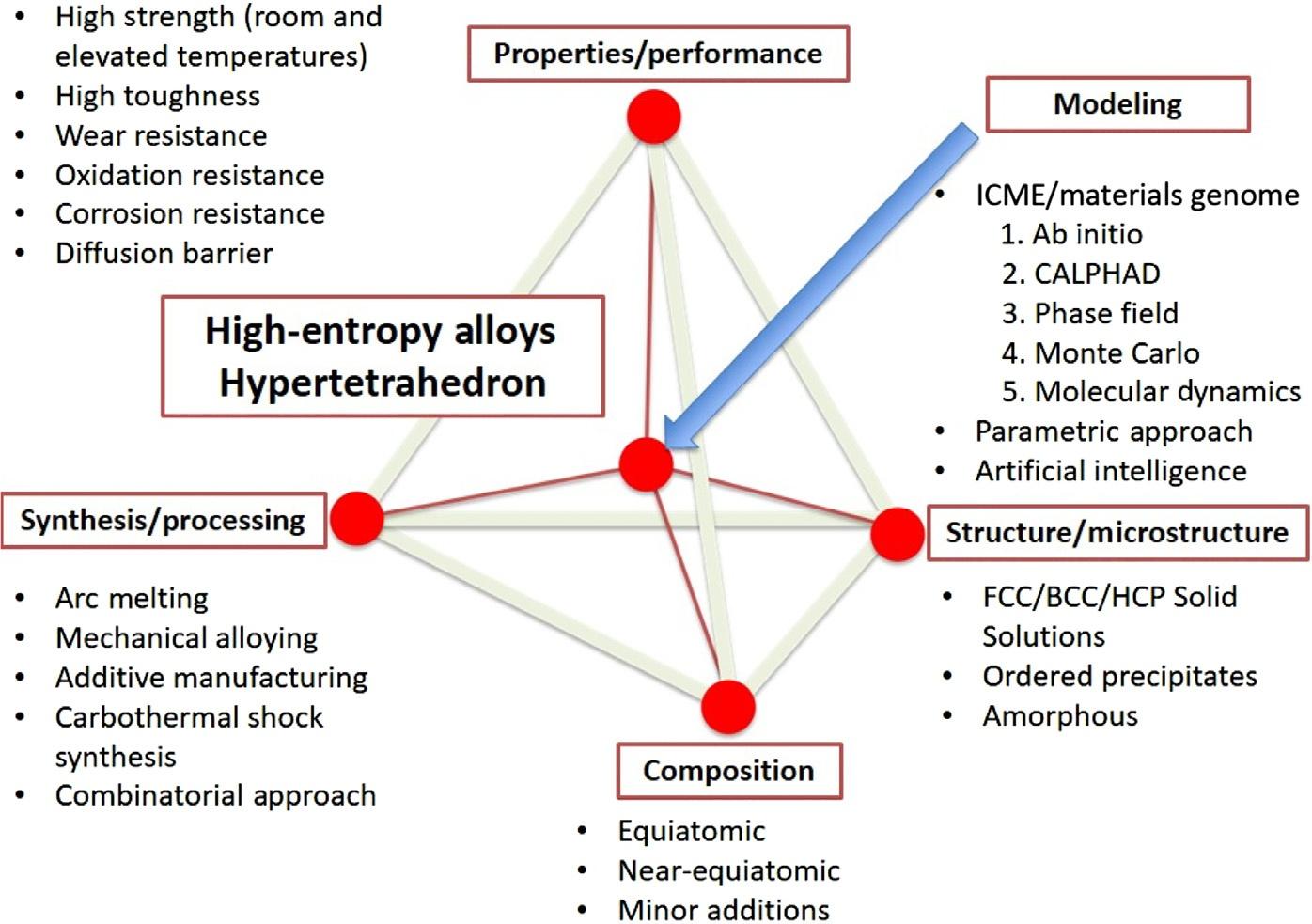

Wroughtironwasproducedasearlyas1000BCE,andcastironandcaststeelwere producedonemillenniumlater.Steelwasanaccidentalalloyofironwithcarbon.Thisis allthemoreastonishingascarbonwasnotrecognizedasanelementuntilrecently.This accidentaldiscoveryalsoledtotheproductionofwootzsteelinIndiaaround300BCE. Thishasbeenrightlycelebratedasthemostadvancedmaterialoftheancientworld,as thissteelwasusedtofashiontheDamascusswords.Thedecipheringofwootzsteelby Europeanscientistsledtothecorrelationbetweenstructureandpropertiesatfirstand subsequentlybetweencomposition,processing,structure,andproperties. Fig.1.3 shows thatmaterialshypertetrahedronthatlinkstheabovefourwithmodelingisnecessaryto understandtheperformanceofwootzsteel(RanganathanandSrinivasan,2006; SrinivasanandRanganathan,2014).Thefacetsoftheultrahigh-carbonsteels,Buchanan furnace,theFe-Cphasediagram,themicrostructureofdendritesintheas-caststateand spheroidizedcementiteintheforgedstate,thesuperplasticelongation,andthedamascenemarksareemphasizedforthestronginterconnectionsamongthem.Itcanberegardedasaclassicexampleofthematerialtetrahedronbutincludingafifthvertexof modeling(e.g.,CALculationofPHAseDiagrams(CALPHAD)methodtocalculate phasediagram)tomakeitahypertetrahedron.

Whenthefirstindustrialrevolutionbeganinlaterhalfof18thcenturyinEngland, moreandmoreelementswerefoundandproducedbyhumankind.Fromthese“new” elements,numerousmetallicmaterialsincludingengineeringandadvancedalloys havebeendeveloped.Theyweresynthesizedwithdifferentcompositionsandproducedbyvariousprocessingroutes.Uptonow,about30alloysystems,eachsystem basedononeprincipalmetallicelement,havebeendevelopedandusedforavarietyof products(HandbookCommittee,1990).

Severalalloysofengineeringimportancehavebeendeveloped.MichaelFaraday createdsomeofthefirstalloysteelsinhiseffortstoreproducethewootzsteelfrom Indiaandishailedasthefatherofalloysteel.AlalloyswereproducedafterthecommercializationofHall-Heroultprocessinthemid-1880sandunderwentlargeprogress inprecipitation-hardenablealloyssuchasAl-Cu-(Mg)andAl-Zn-Mg-(Cu)forlight andstrongairframesintheexplosiveexpansionoftheairplaneindustryduringand

• Mechanical: superplasticity

• High strength

• Toughness

• Damascus swords

Materials hypertetrahedron wootz steel

• Crucible

• Forging

Fig.1.3 Thematerialhypertetrahedronforwootzsteel. FromSrinivasan,S.,Ranganathan,S.,2014.Indian’sLegendaryWootzSteel-AnAdvanced MaterialoftheAncientWorld.UniversitiesPress(India),Hyderabad,India.

afterWorldWarI(1914–1917).High-speedsteelforcuttingtoolswasfirstproduced intheearly1900s.Tomeetthechallengeforevenhighercuttingspeed,cementedor sinteredcarbidesofWC/Cocompositeswereintroducedinthe1930s.Atthesame time,superalloydevelopmentbeganintheUnitedStatesinthe1930sandwasacceleratedbythedemandsofgasturbinetechnology.Ferritic,austenitic,andmartensitic stainlesssteelswerealmostsimultaneouslydevelopedaround1910.

1.3Specialalloysandcomposites Besidestheabovemodernengineeringalloys,severalspecialalloysystemswithspecificcompositions,structures,andpropertieshavebeendevelopedwithintensive researchinrecent50years.Theyareintermetallics,quasicrystals,andmetallicglasses asdescribedinthefollowingsections.Inaddition,thissectionalsogivesabriefintroductiontocomposites.

1.3.1Intermetallicsandquasicrystals Intermetalliccompoundsarebasicallycompoundsoftwoormoremetallicelements. Theyarebrittlebynature.Besidestheancientintermetallicmirrorsmadeofhigh-tinbronzementionedinthelastsection,theyhavegivenrisetovariousnovelmaterial

• Ferrite and carbide

UHCS-1.8C with DAMASK

• Ultra high carbon steel

steel making

developmentsinmoderntimeincludingmagneticAlNiCoalloysandtheLaNi5 for nickel-metalhydridebatteriesandvariousaluminides,Ni-Al-,Ti-Al-,andFe-Al-based compounds,forelevated-temperaturelight-weightapplicationsinturbineengines.

Anotherclassofintermetallicsincludesthosethatdemonstrateso-calledforbidden rotationalsymmetries(suchas5-and10-foldrotationalsymmetries)andquasiperiodictranslationalsymmetry.Thesewerediscoveredby Shechtmanetal.(1984) in1982asdescribedinhisnotebook,whenhefirstobserveda10-foldelectron diffractionpatternfromarapidlysolidifiedAl-Mnalloy.Thesewerechristenedas quasicrystals.Thisobservationhasshakenthebeliefsofcrystallographerstothe extentthatthedefinitionofacrystalhasbeenmodifiedin1990,basedonthediscoveryofthisnewclassofmaterials.Therehasbeenintensiveresearchontheseexciting materialsinthepastfourdecades,bothtowardtheunderstandingofthestructureand propertiesofthesematerials.

1.3.2Metallicglasses Thefirstreportedmetallicglasswasanalloy(Au75Si25)producedatCaliforniaInstituteofTechnologybytheresearchgroupofPolDuwez(Klementetal.,1960),which wascooledrapidlyfromtheliquidstateatarateofaround106 K/stoavoidcrystallizationandpossessnoncrystallineorglass-likestructure.Amongthedifferentmetallicglassesdevelopedlater,thesoftmagneticmetallicglassofiron,nickel, phosphorus,andboron,knownasMetglas,wascommercializedinearly1980sand isusedforlow-losspowerdistributiontransformers.In1974,H.S.Chenfirstreported thatbulkmetallicglassrodsindiametersrangingfrom1to3mmcanbeproducedin variousglassyternaryalloysincludingPd-Au-Si,Pd-Ag-Si,andPt-Ni-Psystems (Chen,1974).Afterthisdiscovery,multicomponentglassyalloysbasedonlanthanum,magnesium,zirconium,palladium,iron,copper,titanium,etc.withcritical coolingrateintherangeof1–100K/s,comparablewithoxideglasses,havebeen developedandresearched.

1.3.3Composites Metals,ceramics,andpolymersindividuallyhaveanumberoflimitations,whichhave ledtothedevelopmentofcomposites,whichareacombinationoftwoofmoreofthese combinations.Compositesareusuallyclassifiedbasedonthematrixofthecomposites.Accordingly,wehavemetalmatrixcomposites,polymermatrixcomposites,and ceramicmatrixcomposites,eachofwhichhasfoundaplaceinvariousapplications, whereinmetals,polymers,andceramicshavenotbeenabletomeettherequirements ofsuchapplicationsindividually.Polymermatrixcomposites,particularlyglassfiberreinforcedcomposites,arebeingusedinanumberofapplicationsintransportindustry includingaerospaceduetotheirlightnessandhighspecificstrength.Metalmatrix compositeswithlightmetalssuchasAl,Mg,andTiasmatricesandcarbonand SiCasreinforcementsarealsoplayinganimportantroleintransportandotherindustries.Incontrasttotheabovetwoclassesofcomposites,whichareusedmostlyfor theirhighspecificstrength,ceramicmatrixcompositesmostlyfindtheirapplications

forultrahigh-temperatureapplications.Intherecentpast,nanocomposites,inwhich eitherthereinforcementorboththematrixandreinforcementareinthenanoscale, havefoundvariousstructuralandfunctionalapplications.

1.4ThecomingofmulticomponentHEAs Fromtheabovedescriptionofconventionalandspecialalloys,historicallyoverfive millennia,thealloydesign,alloyproduction,andalloyselectionwereallbasedonone principal-elementorone-compoundconcept.Thisalloyconcepthasgeneratednumerouspracticalalloyscontributingtocivilizationanddailylife.Butitstilllimitsthe degreeoffreedominthecompositionofthealloyandthusrestrictsthedevelopment ofspecialmicrostructures,properties,andapplications.Consequently,materialsscienceandengineeringofalloysisnotfullyexploredsincethosealloysoutsidethisconventionalschemehavenotbeenincluded.

1.4.1KarlFranzAchard Itshouldbementionedthatinthelateeighteenthcentury,aGermanscientistandalso metallurgistFranzKarlAchardhadstudiedthemulticomponentequimassalloyswith fivetosevenelements(Smith,1963).Hecouldbemostprobablythefirstonetostudy multiprincipal-elementalloyswithfivetosevenelements.Inmanyways,heisthe predecessorfortheresearchesofJien-WeiYehonHEAs.Morethantwocenturies separatethem.In1788,Achardpublishedalittle-knownFrenchbook“Recherches surlesProprietesdesAlliagesMetallique,”thefirstcompilationofdataonalloysystemsinBerlin.Hedisclosedtheresultsofalaboriousandcomprehensiveprogramon over900alloycompositionsof11metals,includingiron,copper,tin,lead,zinc,bismuth,antimony,arsenic,silver,cobalt,andplatinum.Becauseofhighcost,hestudied fewercompositionswithsilver,cobalt,andplatinum.Forotherelements,hemade representativealloysofeverypossiblecombinationofcomponentsuptosevencomponents.Besidesmanybinary,ternary,andquaternaryalloys,hemadequinary,sexinary,andseptenaryalloysonlyinequalproportionsinweight.Allthealloyswerein theas-castcondition,andonthese,hecarriedouttestsfordensity;hardness;strength; impactresistance;ductility;theresistancetoabrasion;thedegreetowhichthealloy couldbepolished;andfinallytheresultsofexposingapolishedsurfacetodryair, moistair,moistairwithHClacidfumes,andmoisthydrogensulfide.Inthisbook, hepointedoutthatthepropertiesofalloysarequitedifferentfromthoseofthepure metalsandareunpredictable.Onlyexperimentcaninstructus.Thisbookismainlya reportwithoutanydiscussion.Alltheexperimentalresultsweregivenintabularform. AlthoughthisbookwaswritteninFrenchinsisteduponbyFredericktheGreat,unfortunately,itwasvirtuallyignoredbymetallurgistseverywhere.Thisrareworkwas broughttolightonlyin1963byProfessorCyrilStanleySmith(Smith,1963).

Towardtheendofthe20thcentury,twoentirelyindependentinvestigationsby BrianCantorintheUnitedKingdomandJien-WeiYehinTaiwanmadeadisruptive breakwiththeclassicaltraditionofalloying.Abrandnewalloyconcept“HEAs”has

beenproposedandexploredandhasledtoaflurryofexcitement. Fig.1.4 givesthe numberofyear-wisejournalpublicationsintheareaofHEAs.Thefigureshows extraordinarygrowthinthepastdecade.ThekeywordsusedareHEAsandequiatomic multimetallicalloys.Anumberofreviews/overviewshavebeenpublishedinthisarea, whichcanbeviewedat https://mme.iitm.ac.in/hea/html/global/reviews.html,themost comprehensiveofthesebeingoneby MiracleandSenkov(2017).Aneditedvolumein thisfieldwiththetitle“High-EntropyAlloys:FundamentalsandApplications”has beenbroughtoutby Gaoetal.(2016a) throughSpringer.Anumberofconferences haveHEAsasoneoftheimportantsessions.Yehhasinitiatedabiennialinternational workshopseries,InternationalConferenceonHigh-EntropyMaterials(ICHEM),in 2016,whichwasheldinTaiwan.Thesecondintheserieshasrecentlybeenheld inDecember2018inKorea.ResearchersinIndiaareveryactiveinthisfieldwith thepioneeringworkofB.S.Murty,whoinitiatedabiennialworkshopseries,InternationalWorkshoponHigh-EntropyMaterials(IWHEM),whichwereheldsofarin 2015(Chennai)and2017(Hyderabad).Awebsitereflectingtheresearchactivities onHEAs,particularlyfromIndia,isbeingmaintainedbythegroupofB.S.Murty (https://mme.iitm.ac.in/hea/),whichisupdatedmonthly.Alistofallthepublications inthisfieldcanbeobtainedatthissite.

Fig.1.4 Year-wisepublicationsintheareaofHEAs.

1.4.2BrianCantor

Thefirstworkonexploringthisbravenewworldwasdonein1981byCantorwithhis studentAlainVincent.Theymadeseveralequiatomicalloysmixingmanydifferent componentsinequalproportions.Inparticular,theworldrecordmulticomponent alloyconsistingof20differentcomponentseachat5%isheldbythisstudy.Itwas noticedthatonlyonealloywithacompositionofFe20Cr20Ni20Mn20Co20 formsasingleface-centeredcubic(FCC)structure;Vincentwasanundergraduateprojectstudent,andtheworkwasonlywrittenatthattimeinhisthesisatSussexUniversity.

Afterthisinitialexperiment,therewasahiatus.Similarstudiesonawiderrangeof alloyswererepeatedwithanotherundergraduateprojectstudent,PeterKnight,at Oxfordin1998.Heachievedsomesimilarresultsandsomenewonesandpublished hisresultsinathesisatOxford.Finally,IsaacChangrepeatedtheworkagaininabout 2000atOxfordandfinallypublishedtheresultsintheopenliteraturebypresentingat theRapidlyQuenchedMetalsconferenceinBangalorein2002,whichwasthenpublishedinthejournal MaterialsScienceandEngineeringA inJuly2004(Cantoretal., 2004).Inthispaperentitled“Microstructuraldevelopmentinequiatomicmulticomponentalloys,”severalimportantconclusionsweredrawn.Afivecomponent Fe20Cr20Mn20Ni20Co20 alloy,onmeltspinning,formsasingleFCCsolidsolution, whichsolidifiesdendritically.Basedonthiscomposition,awiderangeofsixtonine componentalloysbyaddingotherelementssuchasCu,Ti,Nb,V,W,Mo,Ta,andGe exhibitthesamemajorityFCCprimarydendriticphase,whichcandissolvesubstantialamountsofothertransitionmetalssuchasNb,Ti,andV.Moreelectronegative elementssuchasCuandGearelessstableintheFCCdendritesandarerejectedinto theinterdendriticregions.Besides,alloycontaining20components,thatis,5at.% eachofMn,Cr,Fe,Co,Ni,Cu,Ag,W,Mo,Nb,Al,Cd,Sn,Pb,Bi,Zn,Ge,Si, Sb,andMg,andanotheralloyconsistedof16elements,thatis,6.25at.%eachof Mn,Cr,Fe,Co,Ni,Cu,Ag,W,Mo,Nb,Al,Cd,Sn,Pb,Zn,andMg,aremultiphase, crystalline,andbrittlebothinas-castconditionandaftermeltspinning.Surprisingly, however,thealloysconsistedpredominantlyofasingleFCCprimaryphase,containingmanyelementsbutparticularlyrichintransitionmetals,notablyCr,Mn, Fe,Co,andNi.Finally,thetotalnumberofphasesisalwayswellbelowthemaximum equilibriumnumberallowedbytheGibbsphaseruleandevenfurtherbelowthemaximumnumberallowedundernonequilibriumsolidificationconditions.

ItisalsoimportanttopointoutthatCantorcameupwithanothernovelideaof equiatomicsubstitutionlater,intheearly2000s(Kimetal.,2003a),asamethodof exploringmetallicglass.Thesecompositionsarealsointhisvastunchartedregion ofmaterialspace.

1.4.3Jien-WeiYeh J.W.Yehindependentlyexploredthemulticomponentalloyworldsince1995 (Yehetal.,2004b; Hsuetal.,2004).Basedonhisownconceptthathighmixing entropyfactorwouldplayanimportanteffectinreducingthenumberofphasesinsuch high-orderalloysandrendervaluableproperties,hesupervisedamasterstudent

K.H.Huangin1996tostarttheresearchandseethepossibilityofsuccessinthefabricationandanalysisofHEAs.Around40equiatomicalloyswithfivetoninecomponentswerepreparedbyarcmelting.Investigationsweremadeonmicrostructure, hardness,andcorrosionresistanceinas-caststateandfullyannealedstate.Thealloy designismainlybasedoncommonlyusedelements.Fromthosedataofaround 40compositions,20alloysbasedonTi,V,Cr,Fe,Co,Ni,Cu,Mo,Zr,Pd,andAl, withorwithout3at.%Baddition,wereselectedasexperimentalalloysintheMSthesisofHuangin1996(HuangandYeh,1996,publishedasMSthesisofNationalTsing HuaUniversity,Taiwan).

Basedonthisstudy,typicaldendriticstructurewasseenintheas-caststructure.All alloyshavehighhardnesslevelintherangefrom590to890HVdependingonthe compositionandfabricationconditions:as-castorfullyannealed.Fullannealingtreatmentingeneralretainedsimilarhardnesslevelofas-caststate.Highernumberofelementsincreasedthehardness,butnine-elementalloysmoreorlessdisplayedasmall decreaseinhardness.SmalladditionofBhasledtosomeincreaseinhardness.

Inthediscussiononthesetrends,highhardeningduetolargelatticedistortionand strongerbondingwasproposed.Allthesealloysingeneraldisplayedverygoodcorrosionresistanceassessedbytheweightlossafterimmersioninfouracidicsolutions ofHCl,H2SO4,HNO3,andHF,eachin0.01and1M,for24h.Theadditionofpassive elementsandthebenefitoflowfreeenergyduetohighentropywerethoughttocontributetocorrosionresistance.Thisstudythusledtovaluablesuggestionsabouthighentropyeffect,latticedistortioneffect,andslowdiffusioneffect.Afterthisstudy,two morestudiesweremadebefore2000ondifferentaspectsofHEAandweresubmitted astheses(Laietal.,1998; Hsuetal.,2000,allpublishedasMSthesesofNational TsingHuaUniversity,Taiwan).During2001–2003,ninedifferentstudieswereconductedbyYeh’sgroup:fivestudiesonHEAbulkalloyconcerningwithdeformation behavior,wearbehavior,andannealingbehavior;twostudiesonHEAthinfilms depositedbymagnetronsputtering;andtwoonHEAthermalspraycoatings (Huangetal.,2001; Chenetal.,2002; Tungetal.,2002; ChenandLin,2003; HuangandYeh,2003; Hsuetal.,2003; Linetal.,2003, Tsaietal.,2003a; Tsai etal.,2003b,allpublishedasMSthesesofNationalTsingHuaUniversity,Taiwan). Until2017,Yehhassupervised98MSthesesand12PhDthesesinthisexcitingareaof HEAs.BesidesthesupervisionbyYeh,aportionofsomeofthesethesesonHEAsand relatedmaterialswerealsosupervisedbyhiscolleaguesandcollaborators,namely, S.K.Chen,S.J.Lin,T.S.Chin,J.Y.Gan,andT.T.Shun.

Yehhadsubmittedthe“HEAconcept”paperto Science onJanuary2003butwas notacceptedby Science.Afterthis,hesubmittedthesamepaperto Advanced Materials andthenagreedthetransfertothesisterjournal, AdvancedEngineering Materials,forpublication.InMay2004,thispaperentitledwith“Nanostructured high-entropyalloyswithmultiprincipalelements—novelalloydesignconceptsand outcomes”waspublished.ItbecomesthefirstonetoelucidatetheconceptofHEAs byprovidingexperimentalresultsandrelatedtheory(Yehetal.,2004b).Besidesthis, anotherpaperentitled“Multiprincipal-elementalloyswithimprovedoxidationand wearresistanceforthermalspraycoating”waspublishedin AdvancedEngineering Materials inFebruary2004(Huangetal.,2004).ButthetermofHEAwasnotused

inthispaper.Twopapersentitled“Wearresistanceandhigh-temperaturecompression strengthofFCCCuCoNiCrAl0.5Fealloywithboronaddition”and“Formationofsimplecrystalstructuresinsolid-solutionalloyswithmultiprincipalmetallicelements” werepublishedin MetallurgicalandMaterialsTransactionsA laterinthesameyear (Hsuetal.,2004; Yehetal.,2004a).Beforethesubmissionofthefirstoftheabove paper,YehhadappliedforHEApatentsinTaiwan(10December1998),Japan,the UnitedStates,andmainlandChina.

1.4.4SrinivasaRanganathan ItshouldbementionedthatS.Ranganathanhasalsospentlongtimetothinkandlook intosuchmulticomponentalloysunexploredbypeople.Throughthecommunications anddiscussionsonthisunknownfieldwithJ.W.Yeh,hepublishedapaperentitled “Alloyedpleasures—multimetalliccocktails”tointroducethreenewalloyareas:bulk metallicglassesbyA.Inoue,superelasticandsuperplasticalloys(orgummetals)by T.Saito,andHEAsbyJ.W.Yehin CurrentScience inNovember2003(Ranganathan, 2003).ThisbecomesthefirstopenpublicationinjournalsonHEAs,whichledtothe activationofthisnewfield.

Inthisarticle,hesaidthatthemulticomponentalloysrepresentanewfrontierin metallurgy.Theyrequirehyperdimensionstovisualize.Ifweuseacoarsemeshof 10at.%formappingabinarysystem,theeffortinvolvedinexperimentaldeterminationofphasediagramsrisessteeply.Thus,theeffortofexperimentaldeterminationof

Fig.1.5 ThematerialhypertetrahedronforHEAs.

Fig.1.6 Thecoverof30March2018issueofthejournal Science,showingamulticomponent alloypreparedbycarbothermalshocksynthesis.

aseven-componentsystemwillbe105 timesthatofabinarydiagramandwillalone needasmucheffortashasbeenspentoverthelast100yearsinestablishing 4000 binaryand 8000ternarydiagrams.Whilethecomputationofphasediagramsfrom firstprincipleshasmadeimpressiveprogressinthelastdecade,thecalculationof higherordersystemsisadauntingtask.Inthisscenario,wehaveexplorerslike A.Inoue,T.Saito,andJ.W.Yehpointingtoexcitingnewalloyswithapplications.