https://ebookmass.com/product/handbook-of-silicon-based-

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Modelling and Mechanics of Carbon-Based Nanostructured Materials. A volume in Micro and Nano Technologies 1st Edition Edition Duangkamon Baowan

https://ebookmass.com/product/modelling-and-mechanics-of-carbon-basednanostructured-materials-a-volume-in-micro-and-nano-technologies-1stedition-edition-duangkamon-baowan/ ebookmass.com

Literatures of Urban Possibility Markku Salmela

https://ebookmass.com/product/literatures-of-urban-possibility-markkusalmela/

ebookmass.com

3D and Circuit Integration of MEMS 1st Edition Masayoshi Esashi

https://ebookmass.com/product/3d-and-circuit-integration-of-mems-1stedition-masayoshi-esashi/

ebookmass.com

Living for Pleasure: An Epicurean Guide to Life Emily A. Austin

https://ebookmass.com/product/living-for-pleasure-an-epicurean-guideto-life-emily-a-austin/

ebookmass.com

Negotiating Peace: A Guide to the Practice, Politics, and Law of International Mediation (Ebook PDF)

https://ebookmass.com/product/negotiating-peace-a-guide-to-thepractice-politics-and-law-of-international-mediation-ebook-pdf/

ebookmass.com

The Law and Special Education (2-downloads)

https://ebookmass.com/product/the-law-and-specialeducation-2-downloads/

ebookmass.com

Wings of Starless Night (Kingsdaughter Book 1) Sadie Sterling

https://ebookmass.com/product/wings-of-starless-night-kingsdaughterbook-1-sadie-sterling/

ebookmass.com

Stop People Pleasing: How to Start Saying No, Set Healthy Boundaries, and Express Yourself Chase Hill

https://ebookmass.com/product/stop-people-pleasing-how-to-startsaying-no-set-healthy-boundaries-and-express-yourself-chase-hill-2/

ebookmass.com

Neuroscience

For Dummies, 3rd 3rd

Edition

Frank Amthor

https://ebookmass.com/product/neuroscience-for-dummies-3rd-3rdedition-frank-amthor/

ebookmass.com

https://ebookmass.com/product/the-sermons-of-john-donne-volume-10/

ebookmass.com

HandbookofSiliconBasedMEMSMaterials andTechnologies

HandbookofSiliconBased MEMSMaterials andTechnologies

ThirdEdition

Editedby

MarkkuTilli

OkmeticOy,Vantaa,Finland

MerviPaulasto-Kro¨ckel

SchoolofElectricalEngineering,AaltoUniversity,Espoo,Finland

MatthiasPetzold

FraunhoferInstituteforMicrostructureofMaterialsandSystemsIMWS,Halle,Germany

HorstTheuss

InfineonTechnologiesAG,Regensburg,Germany

TeruakiMotooka

KyushuUniversity,Fukuoka,Japan

VeikkoLindroos

SchoolofChemicalEngineering,AaltoUniversity,Espoo,Finland

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2020ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicormechanical,including photocopying,recording,oranyinformationstorageandretrievalsystem,withoutpermissioninwritingfromthepublisher.Detailson howtoseekpermission,furtherinformationaboutthePublisher’spermissionspoliciesandourarrangementswithorganizationssuch astheCopyrightClearanceCenterandtheCopyrightLicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher(otherthanasmaybenoted herein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroadenourunderstanding, changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusinganyinformation, methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationormethodstheyshouldbemindfuloftheirown safetyandthesafetyofothers,includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeanyliabilityforanyinjuryand/or damagetopersonsorpropertyasamatterofproductsliability,negligenceorotherwise,orfromanyuseoroperationofanymethods, products,instructions,orideascontainedinthematerialherein.

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress ISBN:978-0-12-817786-0

ForInformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: MatthewDeans

AcquisitionsEditor: SimonHolt

EditorialProjectManager: EmilyThomson

ProductionProjectManager: AnithaSivaraj

CoverDesigner: ChristianBilbow

TypesetbyMPSLimited,Chennai,India

1 Propertiesofsilicon3

MarkkuTilliandAtteHaapalinna

1.1Propertiesofsilicon3 References16

2. Czochralskigrowth ofsiliconcrystals19

OlliAnttila

2.1TheCzochralskicrystal-growing furnace19

2.2Stagesofgrowthprocess23

2.3Selectedissuesofcrystalgrowth28

2.4Improvedthermalandgas-flow designs31

2.5Heattransfer32

2.6Meltconvection33

2.7Magneticfields38

2.8Hotrechargingandcontinuousfeed41

2.9Heavilyn-typedopedsiliconand constitutionalsupercooling43

2.10Growthoflargediametercrystals48 References58 Furtherreading60

3. Propertiesofsiliconcrystals61

JariPaloheimo

3.1Dopantsandimpurities61

3.2Typicalimpurityconcentrations63

3.3Concentrationofdopantsand impuritiesinaxialdirection65

3.4Resistivity67

3.5Radialvariationofimpuritiesand resistivity70

3.6Thermaldonors72

3.7Defectsinsiliconcrystals75

3.8Controlofvacancies,interstitials, andtheoxidation-inducedstacking faultring79

3.9Oxygenprecipitation82 3.10Conclusion88 Acknowledgments89 References89

4. Siliconwaferspreparation andproperties93

MarkkuTilli

4.1Siliconwafermanufacturingprocess93

4.2Standardmeasurementsofpolished wafers103

4.3Samplespecificationsof microelectromechanicalsystems wafers105

4.4Standardsofsiliconwafers105 References109

5. Epiwafers:preparationand properties111

DougMeyer

5.1SiliconepitaxyforMEMS111

5.2Siliconepitaxy—thebasics111

5.3Theepi polyprocess117

5.4Etchstoplayers118

5.5Epionsilicononinsulatorsubstrates120

5.6Selectiveepitaxyandepitaxiallayer overgrowth121

5.7Considerationsforchemical mechanicalpolishing122

5.8Metrology122

5.9Commerciallyavailableepitaxy systems127

5.10Summary129 References130

6.1 Thinfilmsonsilicon: silicondioxide133

SimoEranen

6.1.1Introduction133

6.1.2Growthmethodsofsilicondioxide133

6.1.3Structureandpropertiesofsilicon dioxides141

6.1.4Processingofsilicondioxides142 References143

6.2 Thinfilmsonsilicon:siliconnitride144

PekkaTo ¨ rma ¨

6.2.1Introduction144

6.2.2Growthofsiliconnitride144

6.2.3Structureandpropertiesofsilicon nitride147

6.2.4Processingofsiliconnitride147 References150

6.3 Thinfilmsonsilicon:poly-SiGefor MEMS-above-CMOSapplications150 PilarGonzalezandXavierRottenberg

6.3.1Introduction150

6.3.2Materialpropertiesofpoly-SiGe151

6.3.3Poly-SiGemicroelectromechanical systemsmanufacturing153

6.3.4SiGemicroelectromechanicalsystems demonstrators158

6.3.5Conclusionandfuturepoly-SiGe research160 References161

6.4 Atomiclayerdepositionofthin films163

RiikkaL.Puurunen,MattiPutkonenand MikaelBroas

6.4.1Introduction163

6.4.2Operationprinciplesofatomiclayer deposition164

6.4.3Atomiclayerdepositionprocessesand materials165

6.4.4Molecularlayerdeposition167

6.4.5Characteristicsofatomiclayer depositionprocessesandfilms167

6.4.6Atomiclayerdepositionreactors171

6.4.7Summary172 References173 Furtherreading174

6.5 Piezoelectricthinfilmmaterialsfor microelectromechanicalsystems174

AndreasVogl,FrodeTyholdt,HannahTofteberg, PaulMuraltandElmeriO ¨ sterlund

6.5.1Introduction174

6.5.2Shortintroductiontopiezoelectric theoryandimportantthin-film constants175

6.7.3AlN176

6.5.4PZT178

6.5.5Other(future?)piezoelectric materialsformicroelectromechanical systems183 References183

6.6 Blacksilicon186 ToniP.Pasanen

6.6.1Introduction186

6.6.2Fabricationmethods186

6.6.3Characteristicproperties188

6.6.4Applications191 References194

6.7 Thinfilmsforantistiction196 YuyuanLinandMichaelGrimes

6.7.1Introduction196

6.7.2Typicalcharacterizationtechniques198

6.7.3Self-assembledmonolayers199

6.7.4Ceramiccoatings205

6.7.5Fluoropolymercoatings206

6.7.7Summary208 References209

7. Thick-filmsilicon-on-insulator waferspreparationandproperties215 JariMakinenandTommiSuni

7.1Introduction215

7.2Overviewofsilicon-on-insulator215

7.3Siliconwaferparametersfordirect bonding220

7.4Fabricationofthick-filmBSOIby mechanicalgrindingand polishing223

7.5Bondingandetch-back silicon-on-insulatorprocess236

7.6Techniquesbasedonthin-film silicon-on-insulatorandsilicon epitaxy238

7.7Silicon-on-insulatorwaferswith buriedcavities242

7.8Silicon-on-insulatorwaferswithburied atomiclayerdepositionthinfilm244

7.9Conclusion244 References245

PartII

ModelinginMEMS

8. Multiscalemodelingmethods249

TeruakiMotookaandTsuyoshiUda

8.1Macroscopicandmicroscopic equations249

8.2Computationalmethodsandpractical examples250

8.3First-principlescalculationmethod254

8.4Concludingremarks260 References260

9. Mechanicalpropertiesofsilicon microstructures263

MariaGanchenkovaandRistoM.Nieminen

9.1Basicstructuralpropertiesof crystallinesilicon263

9.2Dislocationsinsilicon271

9.3Physicalmechanismsoffracturein silicon285

9.4Physicalmechanismsoffatigueof silicon294 References298

10. ElectrostaticandRF-propertiesof MEMSstructures305

IlkkaTittonenandMikaKoskenvuori

10.1Introduction305

10.2Modelsystemforadynamic micromechanicaldevice305

10.3Electricalequivalentcircuit308

10.4Electrostaticforce309

10.5Electromechanicalcoupling311

10.6Sensingofmotion312

10.7Pull-inphenomenon312

10.8Parasiticcapacitance313

10.9Effectofbuilt-inpotentialon capacitivelycoupledMEMS-devices314

10.10Short-rangequantum-mechanical effectsonnano-andmicromechanical structures314

10.11Furthereffectsofelectrostatic nonlinearitiesfromapplicationspoint ofview317

10.12Applicationexample:capacitively coupledreferenceoscillator318

10.13RF-properties321 Acknowledgments322 References323 Furtherreading324

11. OpticalmodelingofMEMS325

TimoAaltoandJuusoOlkkonen

11.1Introduction325

11.2Opticalpropertiesofsiliconand relatedmaterials325

11.3Theoreticalbackground327

11.4Numericalmodelingmethodsfor opticalMEMS335 References343

12. Modelingofsiliconetching345

MiguelA.Gosa ´ lvez

12.1Introduction345

12.2Requirementsformodeling micromachining346

12.3Micromachiningasafrontpropagation problem347

12.4Anisotropicetching:geometrical simulators348

12.5Anisotropicetching:atomistic simulators350

12.6Asurveyofetchingsimulators360 References364

13. GasdampinginvibratingMEMS structures367

TimoVeijola

13.1Introduction367

13.2Dampingdominatedbygas viscosity367

13.3First-orderfrequencydependencies378

13.4Viscoacousticmodels381

13.5Simulationtools381 References383

14. Recentprogressinlarge-scale electronicstatecalculationsand data-drivensciences387

TakeoHoshiandSatoshiItoh

14.1Tutorialoflarge-scaleelectronicstate calculations387

14.2Fracturesimulationbylarge-scale electronicstatecalculation388

14.3Materialsimulationsbasedon data-drivenscience392 References395

15. MEMSlithography399

SamiFranssilaandSanteriTuomikoski

15.1Lithographyconsiderationsbeforewafer processing399

15.2Wafersinlithographyprocess400

15.3Processingafterlithography406

15.4Thickphotoresistlithography407

15.5Speciallithographyapproaches411 References414 Furtherreading416

16. Deepreactiveionetching417

FranzLaermer,SamiFranssila, LauriSainiemiandKaiKolari

16.1Etchchemistries417

16.2Equipment418

16.3Deepreactiveionetchingprocesses421

16.4Deepreactiveionetchingadvanced issuesandchallenges429

16.5Deepreactiveionetchingapplications436

16.6Post deepreactiveionetchingetch treatments440

16.7Choosingbetweenwetanddryetching441 References442 Furtherreading446

17. Wetetchingofsilicon447

MiguelA.Gosa ´ lvez,I.ZubelandEevaViinikka

17.1Basicdescriptionofanisotropicetching: faceting447

17.2Beyondfaceting:atomisticphenomena450

17.3Beyondatomistics:electrochemistry456

17.4Typicalsurfacemorphologies (I.ZubelandMiguelA.Gosa´lvez)457

17.5Effectsfromsiliconwaferfeatures (EevaViinikka)461

17.6Convexcornerundercutting463

17.7Examplesofwetetching464

17.8Popularwetetchants465

17.9Temperaturedependenceoftheetch rate470

17.10Concentrationdependenceoftheetch rate472

17.11Othervariablesaffectingtheetch-rate values474

17.12Experimentaldeterminationofetch rates474

17.13Convertingbetweendifferent measuresofconcentration475 References476

18. Poroussilicon basedMEMS481

GerhardMu ¨ ller,AloisFriedbergerand KathrinKnese

18.1Poroussiliconbackground481

18.2Poroussiliconsacrificiallayer technologies481

18.3Poroussiliconfabricationtechnology482

18.4Microscopicprocessesunderlying poroussiliconformation484

18.5Formationofsiliconmicrostructures488

18.6Applicationexamples495

18.7Summaryandconclusion500 References500 Furtherreading502

19. Surfacemicromachining503

ChristinaLeinenbach,HannuKattelusand RoyKnechtel

19.1Polycrystallinesiliconbased micromachining503

19.2Integrationconcepts506

19.3Metallicmicroelectromechanical systems507

19.4Silicon-on-insulatorwafer based surfacemicromachining510 References516

20. Vapor-phaseetchprocesses forsiliconMEMS519

PaulHammond

20.1Vapor-phaseetchtechnologies519

20.2VaporHFtechnologyfor MEMSrelease519

20.3XeF2 technologyforMEMSrelease524 References528

21. Inkjetprinting,laser-based micromachining,andmicro 3D printingtechnologiesforMEMS531

AndreasC.Fischer,MattiMantysaloand FrankNiklaus

21.1InkjetprintingforMEMSfabrication531

21.23Dmicromachiningusinglaser ablation533

21.33Dmicromachiningofglassusinglaser writingandetching535

21.43Dprintingusingmicro-lasersintering536

21.53Dprintingbasedon single-photonpolymerization— microstereolithography537

21.63Dprintingbasedontwo-photon polymerization—3Ddirect laserwriting538

21.73Dmicromachiningbyfocused ionbeammilling538

21.83Dmicromachiningbyfocusedion beamande-beam assisteddeposition540

21.93Dmicromachiningusingscanning probelithography540

21.10Emerging3Dprintingtechnologiesfor micro-andnanostructures541 References543 Furtherreading545

22. MicrofluidicsandbioMEMSin silicon547

SamiFranssila,CristinaE.Davis,MichaelK. LeVasseur,ZhenCaoandLeventYobas

22.1Siliconpropertiesandmachining547

22.2Siliconasamoldingmaster548

22.3Needlesandnozzles549

22.4Microreactors549

22.5Siliconbasedgaschromatography552

22.6Electrophoresisofbiomoleculesin siliconbasedsieves556

22.7MicrofluidicsintegrationwithCMOS559 Acknowledgments560 References560

PartIV

EncapsulationandIntegrationof MEMS

23. Silicondirectbonding567

ThomasPlach,KimmoHenttinen, TommiSuniandViorelDragoi

23.1Hydrophilichigh-temperaturewafer bonding567

23.2Hydrophobichigh-temperature bondingofsilicon569

23.3Low-temperaturedirectbondingof silicon569

23.4Directbondingofchemical vapor depositedoxides575

23.5Directbondingofchemical vapor depositedsilicon578 References579

24. Anodicbonding581

AdrianaCozmaandHenrikJakobsen

24.1Introduction581

24.2Themechanismoftheanodicbonding581 24.3Othermaterialcombinations583 24.4Glassesforanodicbonding583 24.5Bondingparameters584 24.6Bondquality,failuremodes,and characterization585

24.7Thethermalresidualstress585 24.8Thepressureinsidevacuum-sealed cavities586 24.9Theeffectoftheanodicbonding ontheflexiblemicromachined structures587 24.10Electricaleffects588 24.11Bondingwiththinfilms588 24.12Conclusion589 References590 Furtherreading592

25. Glassfritbonding593

RoyKnechtel,SophiaDempwolfandMarc Schikowski

25.1Bondingprinciple593 25.2Glassfritmaterials593 25.3Screenprinting595 25.4Thermalconditioning597 25.5Bondingprocess598 25.6Physicsofbonding601 25.7Characteristics602 25.8Conductiveglassfritbonding606 25.9Costofglassfritbonding607 References607 Additionalreference608

26. Metallicalloysealbonding609

WolfgangReinert,AmitKulkarni,VesaVuorinen, FabianLofinkandPeterMerz

26.1Introduction609 26.2Propertiesofmetallicsealbonds609 26.3Metalsystemsandjointdesign610 26.4Softsoldering611 26.5Eutecticbonding612 26.6Transientliquid-phasebonding616

26.7Thermocompressionbonding619 26.8Ultrathinmetalfilmbonding621 26.9Reactionbonding621 26.10Metallicsealringdesignandprocess technology622 References624

27. Emergingwaferbonding technologies627

ViorelDragoi,ChristophFlotgen,J.Burggraf, LauraOggioniandTadatomoSuga

27.1Roomtemperaturewaferbonding627

27.2Permanentadhesivewaferbonding631

27.3Temporarywaferbonding634 References638

28. BondingofCMOSprocessed wafers641

RoyKnechtelandSebastianWicht

28.1Generalaspects,requirements,and limitationsofCMOS-compatiblewafer bonding642

28.2CMOS-compatiblelowtemperature waferdirectbonding643

28.3AnodicbondingofCMOS-processed wafers644

28.4CMOSwaferglassfritbonding646

28.5AdhesivebondingofCMOSwafers648

28.6GeneralaspectsofbondingCMOS wafers649

28.7Conclusion650 References650

29. Wafer-bondingequipment651

ViorelDragoiandPaulF.Lindner

29.1Alignedwafer-bondingrequirements forMEMSapplications653

29.2Wafer-to-waferaligners655

29.3Waferbonders658

29.4Alignedwaferbonding:equipment solutionsforMEMSmanufacturing663

29.5Thefutureofwafer-bondingequipment solutionsforMEMSmanufacturing665 References667

30. Encapsulationbyfilmdeposition669

RobN.Candler,PaulHagelinandChristopher Cameron

30.1Introduction669

30.2Packagingneeds669

30.3Technologiesandmethods670

30.4Application:encapsulatedresonatorsfor frequencyreferences674

30.5Summary674 References674

31. DicingofMEMSdevices677

DevinMartin,ScottSullivan, IndranilRonnieBose,ChristofLandesberger andRobertWieland

31.1Introduction677

31.2Historyofdicing677

31.3Processflowandmethodsofdicing677

31.4Stealthdicing679

31.5Full-cutdicing680

31.6Effectsofdicing680

31.7Conclusions682

Subchapter:Plasmadicing682

31.8Introductiontoplasmadicing682

31.9Plasmadicingprocessoverview683

31.10Plasmadicing—advantagesand benefitsoftheprocess683

31.11Plasmadicing—limitationsand challenges684

31.12Plasmadicing—processingdetails684

31.13Plasmadicing—MEMSexample686

31.14Plasmadicing—methodologies686

31.15Plasmadicing—devicesideversus backsideprocessing688

31.16Plasmadicing—postprocessing cleaning688

31.17Plasmadicing—qualitycharacterization parameters688 References688

32. Three-dimensionalintegrationof MEMS691

HorstTheussandKlausPressel

32.1Introduction691

32.2ThethreelevelsofMEMSpackaging691

32.3Cavityformation693

32.4Fromcavitiestosurfacemountable devices696

32.5Fromdevicepackagingtosystemin packageandthree-dimensional697

32.6Low-stresspackaging703

32.7Conclusion705 References705

33. Fan-outwafer-levelpackagingas packagingtechnologyforMEMS707 HeikkiKuisma,Andre ´ CardosoandTanjaBraun

33.1Introduction707

33.2Fan-outwafer-levelpackagingas system-in-packagetechnology709

33.3Fan-outwafer-levelpackagingappliedto MEMSdevices710

33.4Caseexamples713 References719

34. Through-substrateviasbased three-dimensionalinterconnection technology721 PradeepDixit,HarindraKumarKannojiaand KimmoHenttinen

34.1Through-siliconvias721

34.2Classificationofthrough-siliconvias721

34.3Variousprocessingstepsin through-siliconviasfabrication723

34.4Overviewofvarious through-siliconviastechnologies728

34.5Reliabilityofthrough-siliconvias736

34.6Futureoutlookofthrough-siliconviasfor micro-electro-mechanical-systems738 References739

35. Outgassingandgettering743

EneaRizzi,LucaMauri,MarcoMoraja,Andrea Conte,AntonioBonucci,GiorgioLongoniand MarcoAmiotti

35.1Introduction743

35.2Gassourcesintomicroelectromechanical systemsdevices744

35.3Residualgasanalysisfor microelectromechanicalsystems748

35.4Outgassinganalysis749

35.5Getterfilmsformicroelectromechanical systemsdevices751

35.6Lifetime758

35.7Conclusion761 References761

37. Measuringoxygenandbulk microdefectsinsilicon775 HeleSavin,GudrunKissingerandVeli-Matti Airaksinen

37.1Introduction775

37.2Measuringinterstitialandtotaloxygen concentration775

37.3Measuringbulkmicrodefects776 References779

38. Opticalmeasurementofstaticand dynamicdisplacementinMEMS781 DavidHorsley

38.1Camera-basedmeasurements781 References786

39. MEMSresidualstress characterization:methodology andperspective787 Kuo-ShenChenandKuang-ShunOu

39.1Introduction787

39.2Microelectromechanicalsystems residualstresscharacterization techniques789

39.3Perspectiveandconclusion796 References797

40. Microscaledeformationanalysis803 DietmarVogel,MichaelDostandJuergen Auersperg

40.1Theimportanceoflocaldeformation measurements803

40.2Softwaretoolsapplyingdigitalimage correlation805

40.3Examplesofdeformation measurement810

40.4Localmeasurementof intrinsicstress811

36. Siliconwaferandthin-film measurements765 Veli-MattiAiraksinen

36.1Importantmeasurements765

36.2Wafershape765

36.3Resistivity766

36.4Thicknessofthinfilms770 References774

40.5Measurementofelasticmaterial propertiesondevices818 References820

41. Strengthofbondedinterfaces823 OrjanVallin,KerstinJonssonandRoyKnechtel

41.1Introduction823

41.2Solidandfracturemechanics823

41.3Doublecantileverbeamtestmethod824

41.4Tensiletestmethod825

41.5Blistertestmethod826

41.6Chevronteststructures827

41.7Bondstrengthtestingofanodicbonded wafersusingpatternedstep-like structures827

41.8Reliabilityandtime-dependent strength830

41.9Summaryandoutlook831 References831 Furtherreading832

42. Hermeticitytests833

DirkKa ¨ hler,FabianLofinkand WolfgangReinert

42.1Introduction833

42.2Basicsofleakagemeasurement833

42.3Classificationofleakrates835

42.4Leakagetestmethods836

42.5Getterpumpsin microelectromechanicalsystem packages842 References842

43. MEMStestingandcalibration845

VesaHenttonen

43.1Front-endtesting845

43.2Finaltestingandcalibration846

43.3Futuretrendsandchallengesin MEMStesting850

44. MEMSreliability851

LasseSkogstro ¨ m,JueLi,ToniT.Mattilaand VesaVuorinen

44.1Classificationof microelectromechanical systemsdevices851

44.2Failuremechanismsandacceleration factors852

44.3Reliabilityofhermeticencapsulation858

44.4Reliabilitytestingof microelectromechanical systemsdevices860

44.5Methodsoffailureanalysis864

44.6Designforreliability867

44.7Furtherreading869 References871

PartVI

Processintegrationandcasestudies

45. Accelerometers879

Jean-PhilippePolizzi,BrunoFainandFederico Maspero

45.1Introduction879

45.2Accelerometersoperatingprinciples880

45.3Designparameters890

45.4Examplesoffabricationtechnologies891

45.5Packagingaspects894 References895

46. Gyroscopes899 GiorgioAllegato,CarloValzasinaandLucaZanotti

46.1Introduction899

46.2Gyroscopesapplications899

46.3Gyroscopeperformancerequirements900

46.4Gyroscopeworkingprinciplesand architecturedesign901

46.5Gyroscopetechnologyarchitecture:key featuresandintegrationrequirements904

46.6Systemintegrationexample: STMicroelectronicsTHELMAtechnology platform908

46.7Packagingandcalibration911

46.8Conclusion913 References913

47. Pressuresensors915

StephanGerhardAlbert,SebastianMarkusLuber andBernhardWinkler

47.1Sensorrequirements915

47.2Mechanicaltransducers916

47.3Capacitivepressuresensors917

47.4Piezoresistivepressuresensors925

47.5Concludingremarks934 References934

48. Microphones937 MarcFueldner

48.1Introduction937

48.2Microphoneapplicationsand performanceparameter937

48.3Microphonetechnologies938

48.4Capacitivemicroelectromechanical systemsmicrophoneprocessflow940

48.5Designandtechnologyofmicrophone membranes941

48.6Scalingthemembranesizetoincrease signal-to-noiseratio943

48.7Differentialmicroelectromechanical systemssensorforlowtotalharmonic distortionandhighAOP944

48.8Sealeddualmembranemicrophonefor highestperformance946

48.9Conclusion947 References947

49. Micromirrors949 HaraldSchenkandMatthiasSchulze

49.1Introduction:micro-opto-mechanicalsystemsandtheirfieldsofapplication949

49.2Electrostaticallydrivenmicroscanning mirrorsfabricatedbybulk micromachining949

49.3Micromirrorarraysmanufactured usingsurfacemicromachining960

49.4Closingremark967 References968

50. MEMS-aboveCMOSandnovel opticalMEMSsensorconcepts969

H.A.C.Tilmans,V.Rochus,R.Jansen,W.J. Westervelde,M.Mahmud-ul-hasan, S.Severi,B.Figeys,K.Lodewijks,S.Seema andX.Rottenberg

50.1Introduction969

50.2MonolithicSiGeMEMS-CMOS integration969

50.3MEMSsensorwithintegratedoptical readout974

50.4Conclusions982 References984

Index985

Listofcontributors

TimoAalto VTTTechnicalResearchCentreof FinlandLTD,Espoo,Finland

Veli-MattiAiraksinen SummaSemiconductorOy, Espoo,Finland

StephanGerhardAlbert InfineonTechnologiesAG, Neubiberg,Germany

GiorgioAllegato STMicroelectronics,AgrateBrianza, Italy

MarcoAmiotti SAESGettersS.p.A.,Lainate,Italy

OlliAnttila FinsilLtd.,Espoo,Finland

JuergenAuersperg FraunhoferENAS,TechnologieCampus3,Chemnitz,Germany

AntonioBonucci SAESGettersS.p.A.,Lainate,Italy

IndranilRonnieBose FraunhoferEMFT,Munich, Germany

TanjaBraun FraunhoferInstituteforReliabilityand Microintegration(IZM),Berlin,Germany

MikaelBroas DepartmentofElectricalEngineeringand Automation,AaltoUniversity,Espoo,Finland

J.Burggraf EVGroupE.ThallnerGmbH,SanktFlorian amInn,Austria

ChristopherCameron DepartmentofMechanical Engineering,StanfordUniversity,Stanford,CA, UnitedStates

RobN.Candler DepartmentofElectricalandComputer Engineering,UniversityofCalifornia,LosAngeles, CA,UnitedStates;CaliforniaNanoSystemsInstitute, LosAngeles,CA,UnitedStates

ZhenCao DepartmentofElectronicandComputer Engineering,TheHongKongUniversityofScience andTechnology,Kowloon,HongKong

Andre ´ Cardoso AmkorTechnologiesPortugal,Vilado Conde,Portugal

Kuo-ShenChen DepartmentofMechanicalEngineering, NationalCheng-KungUniversityTainan,Tainan, Taiwan

AndreaConte SAESGettersS.p.A.,Lainate,Italy

AdrianaCozma PolightASA,Horten,Norway

CristinaE.Davis DepartmentofMechanicaland AerospaceEngineering,UniversityofCalifornia, Davis,CA,UnitedStates

SophiaDempwolf X-FABMEMSFoundryGmbH Erfurt,Erfurt,Germany

PradeepDixit ElectrochemicalMicrofabrication Laboratory,DepartmentofMechanicalEngineering, IndianInstituteofTechnologyMumbai,Mumbai, India

MichaelDost ChemnitzerWerkstoffmechanikGmbH, Technologie-Campus1,Chemnitz,Germany

ViorelDragoi EVGroupE.ThallnerGmbH,Sankt FlorianamInn,Austria

SimoEranen VTTTechnicalResearchCentreof FinlandLtd,Espoo,Finland

BrunoFain SiliconComponentsDepartment,Grenoble AlpesUniversity,CEA,LETI,Grenoble,France

B.Figeys Imec,SSET,Leuven,Belgium

AndreasC.Fischer DepartmentofMicroand Nanosystems,KTHRoyalInstituteofTechnology, Stockholm,Sweden

ChristophFlo ¨ tgen EVGroupE.ThallnerGmbH,Sankt FlorianamInn,Austria

SamiFranssila DepartmentofChemistryandMaterials ScienceandMicronovaNanofabricationCentre,Aalto University,Espoo,Finland

AloisFriedberger EADSInnovationWorks,Munchen, Germany

MarcFueldner InfineonTechnologiesAG,Neubiberg, Germany

MariaGanchenkova DepartmentofAppliedPhysics, AaltoUniversity,Espoo,Finland

PilarGonzalez InteruniversityMicroelectronicsCentre (IMEC),Leuven,Belgium

MiguelA.Gosa ´ lvez LaboratoryofPhysics,Aalto University,Espoo,Finland

MichaelGrimes SPTSTechnologies,SanJose,CA, UnitedStates

AtteHaapalinna OkmeticOy,Vantaa,Finland

PaulHagelin SiTime,Inc.,SantaClara,CA,United States

PaulHammond SPTSTechnologies,Allentown,PA, UnitedStates

KimmoHenttinen OkmeticOy,Vantaa,Finland

VesaHenttonen AforeOy,Lieto,Finland

DavidHorsley DepartmentofMechanicaland AerospaceEngineering,UniversityofCalifornia, Davis,CA,UnitedStates

TakeoHoshi TottoriUniversity,Tottori,Japan

SatoshiItoh NationalInstituteofMaterialsScience, Tsukuba,Japan

HenrikJakobsen UniversityofSouth-EasternNorway, Notodden,Norway

R.Jansen Imec,SSET,Leuven,Belgium

KerstinJonsson APRAB,Enkoping,Sweden

DirkKa ¨ hler FraunhoferInstituteforSiliconTechnology ISIT,Itzehoe,Germany

HarindraKumarKannojia Electrochemical MicrofabricationLaboratory,Departmentof MechanicalEngineering,IndianInstituteof TechnologyMumbai,Mumbai,India

HannuKattelus VTTMEMSFAB,Espoo,Finland

GudrunKissinger IHP—Leibniz-Institutfu ¨ rinnovative Mikroelektronik,Frankfurt(Oder),Germany

RoyKnechtel X-FABMEMSFoundryGmbHErfurt, Erfurt,Germany;SchmalkaldenUniversityof AppliedScience,Schmalkalden,Germany

KathrinKnese RobertBoschGmbH,Automotive Electronics,Reutlingen,Germany

KaiKolari VTTTechnicalResearchCentreofFinland Ltd,Espoo,Finland

MikaKoskenvuori Nanofab,Micronova,Aalto University,Espoo,Finland

HeikkiKuisma MurataElectronicsOy,Vantaa,Finland

AmitKulkarni FraunhoferInstituteforSilicon TechnologyISIT,Itzehoe,Germany

FranzLaermer MicrosystemsTechnologies,Robert BoschGmbH,Stuttgart,Germany

ChristofLandesberger FraunhoferEMFT,Munich, Germany

ChristinaLeinenbach RobertBoschGmbH,Stuttgart, Germany

MichaelK.LeVasseur DepartmentofMechanicaland AerospaceEngineering,UniversityofCalifornia, Davis,CA,UnitedStates

JueLi DepartmentofElectricalEngineeringand Automation,AaltoUniversity,Espoo,Finland

YuyuanLin SPTSTechnologies,SanJose,CA,United States

PaulF.Lindner EVGroupE.ThallnerGmbH,Sankt FlorianamInn,Austria

K.Lodewijks Imec,SSET,Leuven,Belgium

FabianLofink FraunhoferInstituteforSilicon TechnologyISIT,Itzehoe,Germany

GiorgioLongoni SAESGettersS.p.A.,Lainate,Italy

SebastianMarkusLuber InfineonTechnologiesAG, Neubiberg,Germany

M.Mahmud-ul-hasan Imec,SSET,Leuven,Belgium

JariMa ¨ kinen OkmeticOy,Vantaa,Finland

MattiMa ¨ ntysalo DepartmentofElectronicsand CommunicationsEngineering,TampereUniversityof Technology,Tampere,Finland

DevinMartin DISCOHI-TECAmerica,Inc.,Santa Clara,CA,UnitedStates

FedericoMaspero InstituteforPhotonicsand Nanotechnologies,Milano,Italy

ToniT.Mattila DepartmentofElectricalEngineering andAutomation,AaltoUniversity,Espoo,Finland

LucaMauri SAESGettersS.p.A.,Lainate,Italy

PeterMerz AutechAG,Rupperswil,Switzerland

DougMeyer GalliaSemiconductor,Portland,OR, UnitedStates

MarcoMoraja SAESGettersS.p.A.,Lainate,Italy

TeruakiMotooka KyushuUniversity,Fukuoka,Japan

GerhardMu ¨ ller EADSInnovationWorks,Munchen, Germany

PaulMuralt EPFL,Lausanne,Switzerland

RistoM.Nieminen DepartmentofAppliedPhysics, AaltoUniversity,Espoo,Finland

FrankNiklaus DepartmentofMicroandNanosystems, KTHRoyalInstituteofTechnology,Stockholm, Sweden

LauraOggioni STMicroelectronics,AgrateBrianza, Italy

JuusoOlkkonen VTTTechnicalResearchCentreof FinlandLTD,Espoo,Finland

ElmeriO ¨ sterlund DepartmentofElectricalEngineering andAutomation,AaltoUniversity,Espoo,Finland

Kuang-ShunOu DepartmentofMechanical Engineering,NationalCheng-KungUniversityTainan, Tainan,Taiwan

JariPaloheimo OkmeticOy,Vantaa,Finland

ToniP.Pasanen DepartmentofElectronicsand Nanoengineering,AaltoUniversity,Espoo,Finland

MerviPaulasto-Krockel DepartmentofElectrical EngineeringandAutomation,AaltoUniversity,Espoo, Finland

ThomasPlach EVGroupE.ThallnerGmbH,Sankt FlorianamInn,Austria

Jean-PhilippePolizzi SiliconComponentsDepartment, GrenobleAlpesUniversity,CEA,LETI,Grenoble, France

KlausPressel InfineonTechnologiesAG,Regensburg, Germany

MattiPutkonen DepartmentofChemistry,Universityof Helsinki,Helsinki,Finland

RiikkaL.Puurunen DepartmentofChemicaland MetallurgicalEngineering,AaltoUniversity,Espoo, Finland

WolfgangReinert FraunhoferInstituteforSilicon TechnologyISIT,Itzehoe,Germany

EneaRizzi SAESGettersS.p.A.,Lainate,Italy

V.Rochus Imec,SSET,Leuven,Belgium

GlennRoss DepartmentofElectricalEngineeringand Automation,AaltoUniversity,Espoo,Finland

X.Rottenberg Imec,SSET,Leuven,Belgium

LauriSainiemi DepartmentofChemistryandMaterials ScienceandMicronovaNanofabricationCentre,Aalto University,Espoo,Finland

HeleSavin DepartmentofElectronicsand Nanoengineering,SchoolofElectricalEngineering, AaltoUniversity,Espoo,Finland

HaraldSchenk FraunhoferInstituteforPhotonic Microsystems(IPMS),Dresden,Germany; BrandenburgUniversityofTechnologyCottbusSenftenberg,Cottbus,Germany

MarcSchikowski X-FABMEMSFoundryItzehoe GmbH,Itzehoe,Germany

MatthiasSchulze FraunhoferInstituteforPhotonic Microsystems(IPMS),Dresden,Germany

S.Seema Imec,SSET,Leuven,Belgium

S.Severi Imec,SSET,Leuven,Belgium

LasseSkogstrom MurataElectronicsOy,Vantaa,Finland

TadatomoSuga TokyoUniversity,Tokyo,Japan

ScottSullivan DISCOHI-TECAmerica,Inc.,Santa Clara,CA,UnitedStates

TommiSuni PicosunOy,Espoo,Finland

HorstTheuss InfineonTechnologiesAG,Regensburg, Germany

MarkkuTilli OkmeticOy,Vantaa,Finland

H.A.C.Tilmans Imec,SSET,Leuven,Belgium

IlkkaTittonen DepartmentofElectronicsand Nanoengineering,AaltoUniversity,Espoo,Finland

HannahTofteberg ForkbeardTechnologiesAS,Oslo, Norway

PekkaTo ¨ rma ¨ HSFoilsLtd,Espoo,Finland

SanteriTuomikoski DepartmentofChemistryand MaterialsScienceandMicronovaNanofabrication Centre,AaltoUniversity,Espoo,Finland;Murata Electronics,Vantaa,Finland

FrodeTyholdt SINTEFDigital,Microsystemsand Nanotechnology,Oslo,Norway

TsuyoshiUda AtomicScaleMaterialSimulationsCo., Ltd,Tokyo,Japan

O ¨ rjanVallin DepartmentofEngineeringSciences, A ˚ ngstromMicrostructureLaboratory,Uppsala University,Uppsala,Sweden

CarloValzasina STMicroelectronics,AgrateBrianza, Italy

TimoVeijola DepartmentofRadioScienceand Engineering,AaltoUniversity,Espoo,Finland

EevaViinikka CulminationInnovationOyLtd,Espoo, Finland

DietmarVogel FraunhoferENAS,Technologie-Campus 3,Chemnitz,Germany

AndreasVogl SINTEFDigital,Microsystemsand Nanotechnology,Oslo,Norway

VesaVuorinen DepartmentofElectricalEngineering andAutomation,AaltoUniversity,Espoo,Finland

W.J.Westervelde Imec,SSET,Leuven,Belgium

SebastianWicht X-FABMEMSFoundryGmbH,Erfurt, Germany

RobertWieland FraunhoferEMFT,Munich,Germany

BernhardWinkler InfineonTechnologiesAG, Regensburg,Germany

LeventYobas DepartmentofElectronicandComputer Engineering,TheHongKongUniversityofScience andTechnology,Kowloon,HongKong

LucaZanotti STMicroelectronics,AgrateBrianza,Italy

I.Zubel FacultyofMicrosystemElectronicsand Photonics,WrocławUniversityofTechnology, Wrocław,Poland

Preface

Thefirsteditionofthisbookwaspublishedin2010after 4yearsofpreparatorywork.Atthattime,themotivation topublishthehandbookwasthattherewasaneedfora bookcoveringstartingmaterialsandthemostimportant processstepsofbulkmicromachiningwithsupporting materialonmodeling,measuring,andencapsulationof MEMScomponentstogiveabroadoverviewtailoredto MEMSindustry.Thesecondeditionwaspublishedin 2015,whichshowedtherapidprogressintheMEMS industryaddingnewmaterialandupdatingselectedoriginalchapterswhilekeepingthebookstructuresame.

Thethirdeditionappearsnow10yearsafterthefirst edition.Moreover,inthisedition,themotivationand focusaresameasinthepreviouseditions;theestablished technologiesarepresented,andtheprospectivenewand emergingtechnologiesarealsointroduced.However,duringthecourseofyears,itbecameevidentthatweshould addanewpartcoveringtheprocessintegrationwith selectedcomponentsasexamplesofapplications.Atthe sametime,itwasdecidedthatthestructureandtheorder ofthechaptersshouldalsobechangedtobemorelogical. Nowthebookcontainsthefollowingsixparts:

● I:SiliconasMEMSMaterial

● II:ModelinginMEMS

● III:MicromachiningTechnologiesinMEMS

● IV:EncapsulationandIntegrationofMEMS

● V:CharacterizationofMEMS

● VI:ProcessIntegrationandCaseStudies

Thetechnologydevelopmenthasbeenfast,andthe developmentspeedhasincreasedduringthelastyears.The introductorychapterinthethirdeditiongivestheunderstandingwhyandhowthishashappened:duringtheearly yearsofMEMSbusiness,thevolumehasbeensmall,and companiesinvolvedhavebeenlimitedinresources.Now, inthisyear,itisestimatedthattheMEMScomponentlevelbusinessvalueisroughly13B$.Thelargerbusiness volume,intensecompetition,andthelargercompanies withappropriateresourcespavethewaytowarddevelopment.Thegrowingapplicationsinsmallerproducts,likein wearabledevices,demandsmallerMEMScomponentsand callfornewpackagingconcepts,forinstance.Duringthe firstedition,thebackboneoftheindustrywasstill

automotivebusiness,butwhenthesecondedition appeared,theconsumerbusinesswasgrowingfastand passingautomotivevolume.Nowtheconsumerbusinessis dominating,requiringfasterdevelopmentcycles,increasingvarietyofdevices,andputtingmorepressureoncosts.

Thethirdeditionhas13newchapters,6oftheminnew PartVI,whereaccelerometer,gyroscope,pressuresensor, microphone,micromirror,andMEMSaboveCMOSand opticalMEMSdevicesarepresented.Theimportanceof packagingandreliabilityoftheMEMSdeviceshasbeen increasing,whichleadstothenewchaptersandupdatesin theoldchapters.Furthermore,theoldchaptershavebeen updatedwhereverpossible.Somematerialsthatarerelevant todayarediminishingandhavebeendeleted.However,for theinterestedreaders,thismaterialinthesecondeditionis stillavailableinelectronicformat.

Thisbookaimstoprovideacomprehensive,balanced overviewofthematerialsandthekeytechnologiesto manufacturemodernsiliconbasedMEMSdevices.The bookwasoriginallycreatedandisstilltargetedfora broadaudience(i.e,bothbeginnersandmoreexperienced engineersandresearchesinthefield),addressingallrelevantareasinaconsistentmanneranddepth.

Astimehaspassedfromthefirstandsecondeditions, theeditorialresponsibilitieshavealsochanged.Theeditor teamisthankfultothedepartingeditorsofthesecondedition,Dr.Veli-MattiAiraksinenandProfessorSami Franssilafortheirearliercontributions.Professor MatthiasPetzoldfromFraunhoferIMWS,Halle, Germany,andDrHorstTheussfromInfineonAG, Munich,Germany,havejoinedtheeditorteamstrengtheningthethirdeditionwiththeirexpertiseinmaterial analysis,packaging,andcomponentknow-how.

Theeditorsregrettoannouncethedeceaseof ProfessoremeritusVeikkoLindroosinNovember2019, justwhenthefirstproofsofthiseditionwerecoming.He willberememberedincubatingmanystartupsinFinland, includingsiliconmaterialproduction.

Finally,theeditorteamwouldliketoexpresstheir gratitudetoallthosegivingtheirvaluabletimeandexperiencetoauthorthisbook.SpecialthankstoElsevierteam fortheirencouragementtopublishthisneweditionand alsofortheirprofessionalmanagementoftheprocess.

WhereissiliconbasedMEMSheadingto?

MerviPaulasto-Kro¨ckel1,MarkkuTilli2,GlennRoss1 andHeikkiKuisma3 1DepartmentofElectricalEngineeringandAutomation,AaltoUniversity,Espoo,Finland, 2OkmeticOy,Vantaa,Finland, 3MurataElectronicsOy, Vantaa,Finland

Microelectromechanicalsystems(MEMS)isatechnology requiringinterdisciplinaryskills,asitcombinesmechanical(moving)andelectricalpartswithstructuresinthe micrometerscale,fromaround0.1 µmtoseveralhundreds of µm.Whencriticalfeaturesizesare {1 µm,innanometerrange,thetechnologyiscalledNEMS(nanoelectromechanicalsystems).MEMSandNEMSdevicesareableto sense,control,andactuateonthemicroscaleandgenerate effectsonthemacroscale [1].MEMStechnologyisalso calledmicrosystemtechnologyespeciallyinEuropeand asmicromachinetechnologyinJapan.Inthischapter,and intheentirehandbook,thetermMEMSismainlyused.

ThefoundationsofsiliconMEMSwerelaidinthe 1950s,whenthebasicpropertiesandbehaviorofsilicon wasstudied,forexample,piezoresistivityofsiliconwas foundbySmith [2].ThefirstsiliconbasedMEMSwas madeinthelate1950sandinthe1960s.Forinstance,the firstcommerciallyavailablesilicondiaphragmpressure transducerwasdevelopedbyKulite-Bytrexin1959 [3] andtheresonantgatetransistorpatentwaspublishedin 1968 [4].Petersen’sseminalpaper [5] disseminatedkey informationonthestructuralpropertiesofsiliconlaying thefoundationsforsiliconbasedMEMStechnology. SiliconisalmostanidealmaterialforMEMS,itissufficientlyinert,elastic(noplasticdeformationatlowtemperaturesMEMSdevicesnormallyface),showsno fatigueorveryminimalindeviceoperation,anisotropic propertiescanbeutilizedbothindevicemanufacturing andindeviceoperation.

Thereweretwomaincompetingtechnologiestomake MEMSinthe1990s:surfacemicromachining,where structuresweremadeonthinfilms,typicallyonpolysiliconfilms,andbulkmicromachining,wherestructures wereetchedinsiliconwafers.Bulkmicromachining,the

oldertechnology,waswidelycommercializedinthe 1980s,firstinpressuresensorsandlaterinaccelerometers.Seideletal.contributedgreatlytounderstanding ofthebulkmicromachiningprocessesandfinallypublishedtheirresultsin1990intwopapersonanisotropic wetetchingofsiliconusingpotassiumhydroxidesolutions [6,7].La ¨ rmerdevelopedin1992theBoschprocess [8],adeepreactiveionetching(DRIE)technology,makingitpossibletocombinethebestfeaturesofsurfaceand bulkmicromachiningtechnologyinthesamedevice. EarlierapplicationsofDRIEtechnologywereinsurface micromachiningusingthickpolysiliconfilms,butlaterit pavedalsothewayforuseofsilicononinsulator(SOI) wafersinMEMS.

In2013Bogue [9] dividedMEMScommercialization intothreewaves.Wave1beganinthe1970swhenlowvolumeusesofhigh-costproductsstartedinindustryand aerospace,mainproductsbeingpressuresensors,strain gages,andaccelerometers.Wave2startedintheearly 1980swithhigh-volumeusesoflow-costpressuresensors (theearly1980s),accelerometers(theearly1990s),yaw sensors(thelate1990s),andairflowsensors(the1990s) intheautomotiveindustry.Wave3beganintheearly 2000swithveryhighvolumeofverylow-costaccelerometers,gyroscopes,andmicrophonesinconsumerelectronics.Now,in2019,wecouldaddfourthwave,which isstartingaroundthe2020s(Fig.1).Devicesarebuilt withMorethanMooreconcept [10],andkeydriversfor developmentareubiquitousMEMSforInternetofthings (IoT),autonomousdriving,andopticalcommunication.

MEMSdevelopmentwastrailingbehindsemiconductordevelopmentforseveralyears,andonlyduringthe past10 1 years,MEMSproductionhasenteredintoa realvolumescaleindustry—withrareexceptionssuchas

siliconwafer basedinkjetheadmanufacturingthatwere inproductionalreadymuchearlier.Therearemanyfactorsfortheslowtechnologicaladvancementofthe MEMSindustry.Salesandvolumeshavebeenrather smallcomparedtosemiconductorfield(industryvolume ofMEMSin2019was$13Bcomparedtosemiconductor industry$337B) [11,12].Therewerealmostnostandard processesuntilrecentyears,forindividualdevicesthere weretailoredprocessesvaryingfrommanufacturerto manufacturer.Intheindustry,thiswasknownas“Yole’s law,”whereeachdevicerequiresownprocess.Also, MEMSprocesseswereusuallynon-CMOScompatible (withexceptionofcertainsurfaceMEMSprocessesusing thinpolysiliconfilms);thussparecapacityofolder CMOS-linescouldnotbeutilized.Allinall,the manufacturinglandscapewasratherspecific,consisting ofsmallcompanieswithlimitedcapabilitiestoinvestin developmentandproductionandonlyafewsmallfoundries.Industrydrivers,ontheotherhand,wereconservativeautomotiveandindustrialapplicationsrequiringlong qualificationcyclesandsecondsourcing.Thisresultedin amarketfocusingontoofewdevicetypesandaslow introductionofinnovativenewdesigns.

Forafablessstartupcompany,turningaconceptoreven adevicedemonstratedinlabenvironmentintoproduction wasprohibitivelyexpensiveandtime-consuming,asoften alsoinvestmentintospecialproductiontoolswasrequired. IthasbeenestimatedaMEMSdevicetotake27yearstogo fromR&Dtothestartofcommercialization [13]

Smallproductionvolumeskeptalsowafersizessmall, upto150mm.Aninvestmentintoa200mmfacility becameeconomicalviablearoundthemid-2000s,about 30yearsaftersemiconductorindustry(1986IBMIC-plant vs2006STMEMS-plant).Devicecostreductionwasslow notonlybecauseofthemissingwafersizescalingbutalso duetoconservativepackagingconceptsandhightesting costs.AlsotheMEMSdevicescouldnotbescaleddown justbydecreasingthefeaturesizesaspredictedby Moore’slaw.Foraccelerometersandgyroscopes,inertial forcesalsowouldscaledowndrasticallyandsticking forceswouldstarttodominatewithdetrimentaleffectsto

performance.Similarsituationisfoundinsomeoptical deviceswherethenumericalaperturecannotbedecreased beyondacertainsize,ofteninthemillimeterrange, withoutaffecting,forexample,thesignal-to-noiseratio.

Costandsizereductionofdevicesbecameamustas consumerapplications,primarilymobilephone,developedasaninnovationdriverforMEMSinthemid2000s.Quality-andreliability-f irstmindsetoftheautomotiveindustrychangedtocost -first(alsosize-first)for consumerapplications.Alsonewtechnologies,suchas DRIE,SOI,andwafer-levelpackaging,wereintroduced intomarketenablingbothm iniaturizationandcost reduction.

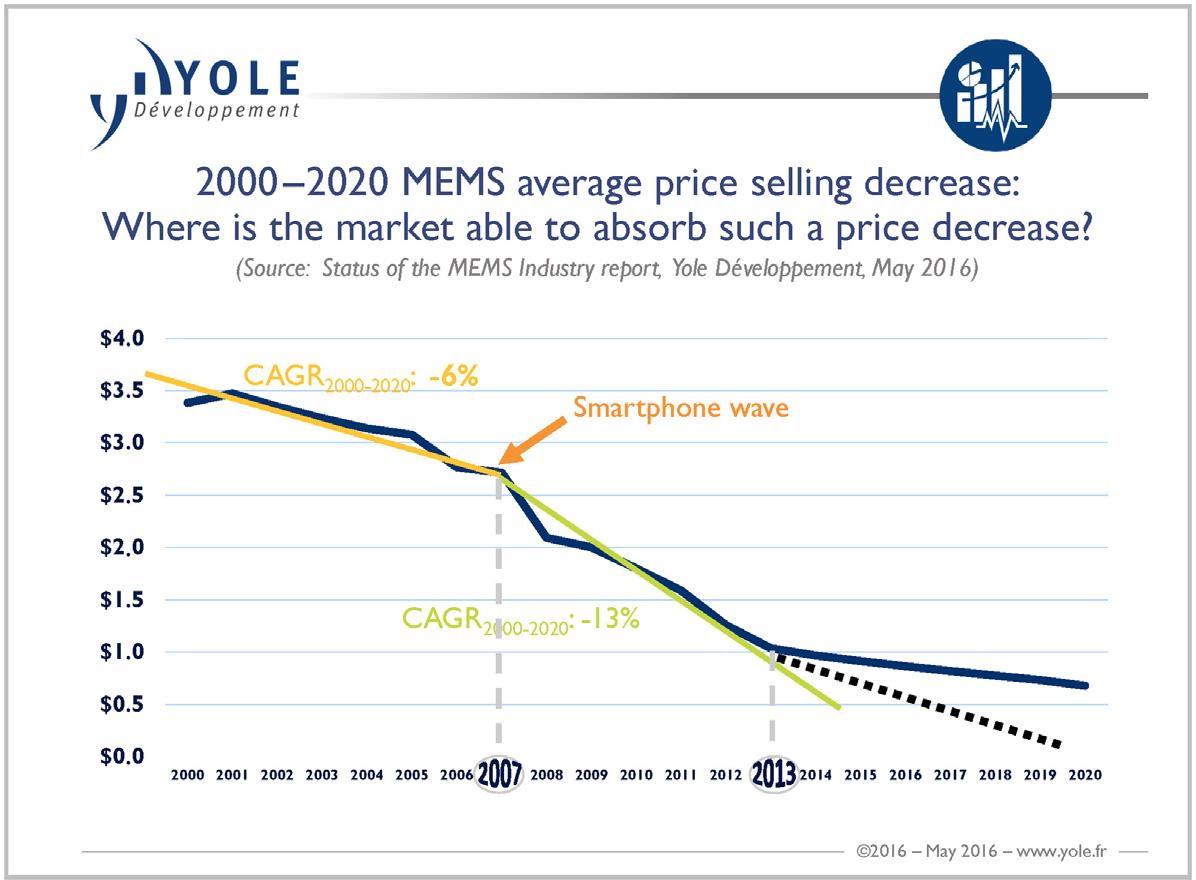

Foundriesservingthesemiconductorindustryhave increasinglyenteredintoMEMSvolumebusiness.As MEMSdevicemanufacturinghasdevelopedtoward CMOScompatibility,itispossibletoreuseagingsemiconductorlineswithaminimuminvestmentbarrier. DRIEtechnologyhaslargelyreplacedwetchemicalbulk micromachining,providingmorecommonalityintheprocessingofdifferentdevices,andmakingitpossibletofill the200mmmanufacturinglineswithreasonablenumber ofwaferstarts.Devicecostreductionspeedhasincreased, withfurtherpotentialforsignificantyearlycostreduction aspresentedin Fig.2

ApublicationandpatentanalysisreflectsthepreviouslypresenteddevelopmentoftheMEMSfield(Fig.3). Thepublicationvolumeshavebeenconstantlyrisingsince the1990sbuthavesaturatedoverallsincethemid-2000s. MEMSresearchhascontinuedtobestrong,buttherather constantyearlypublicationvolumessuggestthatthereis notahypetopicwithintheMEMSfieldnow.Itis notablethatalthoughpolymersubstratesandotheralternativestosiliconsubstrateshavebeenproposedfrequently [15,16],thenumberofstudieshasnotdeveloped substantially.Incontrast,opticalMEMSrepresentsan areaoflargeresearchactivitiesoverthelastcoupleof decadesand,inrecentyears,hashadmanynewapplicationsemergingbasedonthesedevices,aswillbediscussedlater.ThenumberofMEMSpatentshasincreased stronglysincethebeginningof2000,coincidingwiththe 19701990–20002005–152020–30

FIGURE1 FourwavesofMEMScommercialization.

WhereissiliconbasedMEMSheadingto?

FIGURE2 Averagesellingpricedevelopmentestimate2000 2020. ReprintedwithpermissionStatusoftheMEMSIndustryReport,Yole Developpement(Yole),2016ed. ,www.i-micronews.com . [14]

Number of patents

Number of p ublications

FIGURE3 BibliometricdataandpatentanalysisgeneratedfromtheScopusdatabase.Specifickeywordsearchstringswereusedingeneratingthe bibliometricdatabasefrom1990to2018.ThepatentdatawerelimitedtotheUSPatent&TrademarkOfficetoreducethenumberofmultipleresults duetopatentfamilies.

commercializationwaveofconsumerapplications.Still today,morepatentapplicationsaresubmittedyearly.So overall,thepublicationandpatentsituationinMEMS demonstratesanengineeringfieldthatontheonehand possessesarelativelyhighmaturityandhighpotentialfor newproductinnovationsandontheotherhandisstilla stronglydevelopingfield.

Morethan20yearsago,SensorsandActuatorsA, 1996issue1 2focusedonpapersonthefutureoutlookof MEMS.Whenlookingattheseforecaststoday,itcanbe statedthatauthorsmoreorlessunderestimatedthedevelopment.However,Ko [17] concludedintheissue,“From sensorsandactuatorstomicroelectromechanicalsystems (MEMS),tonanofabrication,smartmaterialsandsmart structures,thefutureofthefieldisunlimited.”Now,in 2019,thisstatementisstilltrue,andperspectivesareeven morepromisingthatforecastedinthepapersinthatissue. Differentscenarioshavebeenpresentedtoestimatethe futureglobalneedforsmartsensorsandactuators.Yole De ´ veloppement [18] estimatesthatthesemiconductor-

basedsensorsandactuatorsmarkettobe$100Bin2023 fromabout$50Bmarketin2018.PureMEMSmarket, excludingBAWdevices,willgrowfromabout$9.8B (2018)toaround$16Bin2023showinga9%annual growth(CAGR).Along-termscenariocouldturnouttobe moredramatic,iftheMEMSresearchcommunityand manufacturingindustrymanagetoutilizethestrengthsof thetechnologiesandtheinfrastructuresconsciouslyandto balancethechallenges.Inthefollowingparagraphs,some trendsandhigh-volumeopportunitiesarediscussedand reflectedwiththehelpoftheSWOTanalysis(Table1).

Newtechnologytrendsandemergingbusinessareas suchaslowcarbonsociety,autonomousdriving,AI, AR/VR,andIoTpresenthighdemandforcurrentandfurtherdevelopedversionsoftheexistingMEMSdevices. ThehypearoundIoTisstartingtoceaseanditisbecomingpartofoureverydaylife.ManyMEMStechnologies willbeonhighdemandtodevelopgridsofwirelesssensornodesthatcansenseandreportdetailedinformation amongeachotherandwiththeendusersforconcepts fromindustrialinsituhealthmonitoringandpredictive maintenancetosmarthomesandcities.Homeautomation offersevenasurprisinglyvirginplatformforhighperformanceandhighlyintegratedsensors.Asstand-alone

TABLE1 SWOTanalysisofMEMS.

Strengths

● SiliconMEMSdevicesarescalableindieandwafer size.costsdown

● BusinessstartstoresembleICbusiness:fablesscompanies, IDMs,foundries

● Miniaturizationpotentialstillsignificant

● Versatilityandvariabilityofthetechnology

● NewMEMSmanufacturingtechnologiesallowCMOS compatibility

● Strongresearchinfrastructurewithfablinesinseveralcountries

● R&Dfundingencouragingtocross-disciplinarycooperation quitewelldeveloped

Opportunities

● Newemergingbusinessareas:IoT,autonomousdriving,AI, andAR/VR

● NewconceptswithRFMEMS,optics,andMEMScombined, piezoactuation

● Newpackagingconcepts

● HybriddevicesintegratingMEMS,IC,energyharvestingand storage,RF

● Stillsignificantroomforcostreduction

● Significantpotentialforstartups,merge,andacquisition possibilities

● RoomfornationalandmultinationalR&Dfunding

● Newsoftwarebusiness,sensorfusion,anddecision-making

● Reuseopportunitiesfordesignswithlongdevelopmenttimes

devicessuchashomeappliances,lighting,andheating, venting,andairconditioningsystemswillbeintelligently connected,thesensorsinvolvedwillneedtomeasure multiplephysicalquantitieswithhighsensitivityandona constantbasis.Thesensormodulescanincludehuman tactilesensingandspecificwake-upfeaturesbasedon opticaldetection [19,20].Thiswillrequirelowpower ubiquitoussensorsintegratedwithMCUsandRFparts. AnotherexampleofnewapplicationsforexistingMEMS solutionswithinIoTisvoiceandgesturecontrol,which areexpectedtotakeoversmalltouchscreensandother controlpanelsinfuture.Here,microphoneorbetter microphonearray [21,22] isakeytoachievingoptimal performance.Voice-controlledsolutionswillbemost likelybasedonminiaturized,stableperformanceMEMS microphones,butalsotheyinvolvepotentiallyother MEMScomponentssuchasMEMSradarforspeakerdiarization [22].Tocopewiththeincreasingrequirements anddemandfordigitalMEMSmicrophonesandtoreduce parasiticsfromtheinterconnects,highdensity,even monolithicintegrationofthemicrophonechipandthe controlchip,isexpected.

Autonomouscarwillhaveextensiveimpactontechnologydevelopmentpushingthesensorperformance

Weaknesses

● Averageproductdevelopmentcycleslong

● Volumeperdevice/technologyremainslow,business prerequisitesoftennotmet

● Foundryservicesneedfurtherdevelopment

● Standardizationstillinearlystages,forexample,fewpin-to-pin compatibledevices

● “Yole’slaw”stilllimitsinsomedesignssecondsourcing

● Infrastructuralrenewalslow,componenttestingneeds specializedtools

● Researchfundingavailable,butlevelofchallengeslow,toofew projectsfailing

● Forceoutputlimitedforpotentialactuatorapplications

Threats

● Lackofcompetencewithmultidisciplinaryskills

● Delaysofnewdeviceintroductionsbecauseoldmilkcowsare notkilled

● Largecompaniesbasetechnologydevelopmenttoostrictlyon businesscases

● Companieslackingvisionorcourage

● Nofoundriescapableofofferingmanufacturingtosmall/ mediumscalevolumes

● Patenttrolls

● Architecturalchangesandendproductspecificationchanges removetheneed

● Designtimeandcostincreasingduetofunctionalsafetyand otherrequirements

AI,Artificialintelligence; AR,augmentedreality; IDM,Integrateddevicemanufacturer; IoT,Internetofthings; VR,virtualreality.

aheadinmanysegments.Forinstance,futurecarswillbe connectedalmostinrealtimetodifferentnetworks,with targetingtominimumlatencytimes,downto1ms [23] Toachievethis,servercentersneedtohavesatellitemini serversdistributedclosetocars.RFMEMSandoptical MEMSdevicesareneededtoachievenecessarylatency anddatavolume.Carswillcommunicatewithothervehicles,roadinfrastructureandcreatereal-timeperceptionof theenvironment.Thissituationawarenessiscreatedwith aidofmultitudeofsensors,andmanyofthoseareMEMS sensors.Toguaranteereliableinformation,thisperception willbecreatedwithindependentsensors.Thusinformationfromcamerasinvisualanduptofarinfraredrange areused,(scanning)radars,laserscanners,ultrasoundsensors,inertial(accelerometers,gyroscopes),temperature, andpressuresensorsarecombinedwithinformationgatheredwithradio.TheperformanceofthecurrentMEMS devicesneedstobeimprovedvastly,forexample,stabilityofthegyroscopeswithafactor10ormore [24]. Systemsbuildonsensorsneedtobefail-operational,fail safeisnotenough.Essentially,carwillbeinthefuturea movingfifth-generation(5G)(or6G)basestation.

Autonomouscarnotonlyreceivesanddigestinformationbutitcanalsosenddataformultitudeofpurposes.Car willbe,forexample,amovingweatherstationwhensendingdatatoinfrastructure.Thiswillmakeroadcondition monitoringandweatherforecastingmoreaccurateasthe measuringgridwillbedenseanddataactual.Inorderto processdataefficiently,new,advancedsoftwareisneeded; machinelearningandAIareplayingacentralrole.

AlsoalargepartoftheotherapplicationsofAI,many ofthemtargetingtoperformautonomouslyunstructured tasks,willrelyonsensor-generateddata.Muchof acquireddatawillbebasedoncommonMEMSsensor technologies,thoughwithimprovedaccuracy,higher sensitivity,andfasterresponsetime.FormatureMEMS technologies,thismeansdesignandspecification improvements,aswellasadvancedintegrationtocomputingandnetworkingdevices.Torealizetheseimprovements,progressisrequiredspecificallyinmanufacturing andintegrationmethods.Newinnovationsareexpected specificallyforopticalsensorapplications,suchasAIbasedfacialrecognitionusingathree-dimensional(3D) sensortomapauser’sface.Facialrecognitionandother optical3Dsystemsareexpectedtogrowtoa$1.5Bbusinessby2022 [25] withmuchofthelong-termgrowth potentialcomingoutsideofconsumerapplications. Advancedversionsof3Dopticalsensingwillrequirethe developmentoflightmanipulatingMEMSdevicesand theirintegrationwithlasersourcesanddiodereceiversin aminiaturizedopticalpackage.

ARandVRarenotonlyservingcreativeindustries suchasgaming,buttheyarealsoincreasinglyemerging intoindustrialdesign,real-estatebusiness,education,

healthcare,andmilitarynavigation.TheAR/VRbusiness hasbeenestimatedtogrowintoa$80Bmarketby 2025—hardwarerepresenting56%ofthevalue [26] Here,severaldifferenttypesofsensorsarerequiredfor the3Dimagevisualizationanduser’sinteractionsinthe environment.Highlysensitiveaccelerometersandgyroscopesareneededfortrackingofmovementandorientation,opticalandthermalsensorsareneededtoexplorethe surroundingsandlocateobjects.Similartoautonomous navigationforrobotics,progressinVRandARiscurrentlymainlydrivenbyalgorithmdevelopment.However, manynecessaryattributes,suchaslownoisemeasurementsandfastcommunicationtoaGPU,aredependent onfurtherdevelopmentsinMEMSandtheirintegration. Furthermore,projectionandimagealignmentforARwill requirenewopticalMEMSdevices,suchasmicromirrors.

MergingMEMSwithmicro-opticshasindeedopened upapromisingdirectionnowreemergingafteraninitial investmentboominthe2000s.Theminuteforcesneeded tosteerandmanagelightareidealforaMEMSactuator withlimitedforceoutputcapability.IntegrationofwaveguidesandMEMSallowsmodificationoflightpropagationinwaveguidesbymechanicalactuationandprovides opportunitiessuchasopticalswitches.Theearlyoptical MEMSdevelopmentworkdidnotleadtomanymarket entries,ascosttargetscouldnotbeachievedandcapacity ofthefiberlinescouldbeincreasedbyothermeans.But now,theemergingautonomousdrivingmaygiveanew opportunitytoMEMSmirrorsasseveralparallelimaging technologieswillbeused:cameras,radars,andlidars. Scanninglidarsareimagingdevicesbasedonpropagation andreflectionoflaserlightpulsesthataresteeredand collectedbyaMEMSmirror.Theremightbeanopportunitytopiezo-MEMSindrivingthemirrorstohighangularamplitudeatlowvoltage.

Besidestheautonomousdrivingandother3Dsensing applications,asignificantbusinessdriverisnowcloud computing [27].Datacentersneedmassivecomputing powerinhyperscaledatacenters,andthisisachieved withdirectopticalsignalswitchingandroutingforlarge reconfigurableall-opticalnetworksforfasttelecommunicationcapabilities.

Healthcaresegmentpresentsanothersignificant growthopportunityforMEMS.Healthcarecostinour agingsocietywillgrowtosignificantpartoftheGNP. Manynewgamechangersareneededtoreducedays spentinhospitals,preventiveandearlywarningmethods anddevicesfordiseases,betterandcheapermethodsand devicesfordiagnosisandtherapy.Minimuminvasivesystemshaveagoodpotentialtoreducecosts.RoboticsystemsandsmartcathetersrequirenewMEMSdevices suchasPMUTsandCMUTs(piezo-andcapacitively actuatedultrasoundsensors),forcesensors,pressuresensors,accelerometers,andgyroscopesthataresmall,

sensitive,stable,andreliable.MicrofluidicMEMSison riseforpoint-of-careandbedsidemedicaldiagnosis wheremicromanipulators,includingchannels,valves, pumps,andreservoirsaswellassensors,arerequiredto handle,transport,accuratelyrelease,andanalyzesmall volumesoffluid [28]

Noveldrugdeliverymethodshavebeenresearched intensivelyasMEMS-baseddevicescanprovideaccurate controlofthedosesandreleaserates [29,30].While thepromiseshavenotmaterializedsofarinalarge scale,therearesolutionssuchasminimallyinvasivetransdermalpatches,forexample,includingstimuli-responsive microneedles,whichcanbeseenaspotentialfor clinicalapplicationsinanearfuture [31].Ingeneral, implantablebiomedicalelectronicdevicescontaining MEMShavenotdiversifiedmuch,sinceapplicationssuch ascardiacpacemakerandMEMShearing-aidtransducer.It isexpectedthatcontinuousminiaturizationcombinedwith wirelesscommunicationmeanswillmakenewsubcutaneous implantspossible.Theprogresshasbeenslowmainlydueto thetightregulatorycontrolsforactiveimplantablemedical devices,butalsoduetosomeunsolvedbiocompatibility issues,specificallyincaseswherethesensoryelementsare exposedtobiologicalanalyte [32].

Wearablehealthmonitoringandwellbeingdevicesfor sportsandrecreationarebecomingincreasinglypopular foreverydayuse.Fitnesstrackers,smartwatches,oronepurposedevicessuchascufflessbloodpressuremeters areallloadedwithMEMSsensors.Newapproachesfor wearabledeviceshaverecentlybeingdeveloped [33] or areemerging—abletomonitorqualityofsleep,orto measureelectrocardiogram,atrialfibrillation,andlowand highheartratewithhighspecificityandsensitivity ( . 98%) [34].Alsointhesekindsofapplications,sensors relyheavilyonRF-communication.

Therealizationofthe5GmobilecommunicationsystemwillrequirenewRFcomponents,suchasRFfilters, switches,inductors,andvaractors.Itislikelythatmanyof thesecomponentsareintegratedonthesamedie.Siliconis astrongcandidateasasubstrate,althoughglassisalso usedinsomedesigns,especiallyinswitches.Newdevices areneededinbothhandsetsandbasestationsaswellasin backbonenetworks.Basestationsandhandsetswill employnewantennadesignshavingbeamformingcapability.TherewillbeneedforMEMSRFswitchesandtuners forantennaimpedancematching.Alsonewfiltersare needed;anexampleofnewFBARfilterisutilizinga hybridstructure,thinfilmlithiumniobateonsilicon,an SOI-likestructure [35].YoleDe ´ veloppementforecastsa growthfrom$2.4to15BforRFMEMS,includingBAW devicesin2023 [18].Substantialamountofresearchand developmentisstillneededinRFMEMSarea.

Piezoactuationofferscurrentlymanyunusedpossibilitiesfrommoreefficientinertialsensorstoenvironmental

energyharvesting.MEMSseemsanevidentcarrierto integratemechanicalenergyharvesters,whichcouldbe usedinpoweringsmall,long-lastingelectronicdevices suchasmeasurementequipmentinremoteorhostile environmentsandenableautonomous,self-sufficient wirelesssensornetworksforIoT.Differenttransduction mechanismshavebeenemployedandmuchresearchhas beendevotedtodesignMEMSresonatorswithsufficient amountofgeneratedpowerandcapableofadaptingthe frequencyleveltomatchtheambientvibrationfrequency. Here,miniaturizationpresentsatrade-offbetweenreductionofthepowerrequirementsofubiquitouselectronic devicesandincreasingoperatingfrequencyofthevibratingstructures.Recently,MEMSvibrationpowergeneratorshavebeenreportedtoyieldpowerdensitiesranging fromhundredsof µW/cm3 toseveralmW/cm3;someof themusingacombinationofmultipleenergyconversion mechanisms [36].Ifcombinedwithaneffectiveenergy storagesolution,suchasasupercapacitor,thisindicatesa leveluseableinpracticalapplicationsofwirelesssensor modules,includingRFcommunication.Still,thechallengeremainsontheusefulenergysourceastheresonancefrequencyoftheMEMSstructuresistypically muchhigherthanavailableenvironmentalvibration energy.Designfeaturestoincreaseproofmassandanchor structurestomaintainlinearbehaviorarethemaincountermeasurestoadaptthefrequency.

Thepreviouslyreviewedopportunitieswillrequire newhybridmaterialsolutionsandheterogeneousintegrationoftechnologies.Siliconwillcontinuetobethemain substratematerialforaverylongtime,butapartfromSi,a varietyofdifferentmaterialswillbeused,suchaspiezoelectricthinfilms,newwaferbondingmaterials,orprotectivecoatings,fortactilesensorsandimplantabledevices. However,theheterogeneousintegration,thustheMore thanMooreapproach,maycauseevenlargerchangeinthe manufacturinglandscapeinanearfuture.

Thecurrentstate-of-the-artMEMSintegrationstrategy isembeddedwafer-levelpackagingoreWLP(discussed inChapter33:Fan-outwafer-levelpackagingaspackagingtechnologyformicroelectromechanicalsystems). AlthoughthisapproachnicelyintegratesMEMSand CMOScomponentsintoasinglepackage,therearea numberoflong-termchallengesasdiesbecomethinner. First,thinnerdiesaremoresusceptibletoresidualstress effectsfromtheinherentcoefficientofthermalexpansion mismatches,suchasthemismatchbetweentheSi,dielectricandredistributionlayers,andsoldermaterial.In MEMSdevices,mechanicalstresswillcausedeterioration ofperformancemuchbeforeanytraditionalfunctional failureswilloccur.Second,therearetheassociatedimpurityproblemswithmoldingcompoundsthatpotentially resultindecreasedperformanceandfinallyincorrosionrelatedfailures.Thelong-termgoalshouldfocuson

eliminatingtheseissueswhileprovidingenhancedperformanceandhigherintegrationinasmallerpackage.In future,heterogeneouslyintegrateddevicechips,ICsand MEMS,areputinthepackagesidebysideorstacked resultinginhermeticallysealedmultichipstacks,different layersdedicatedfordifferentfunctions,forexample,for computing,sensing,energystorage,andcommunication.

Asdiscussed,sizereductionhasbeenakeyenablerto reducecostandhighvolumeproductionofMEMS. Continuedminiaturizationwillberequiredtoachievetrue ubiquitoussmartsystemsandmakeproductspossible, whichhavenotbeendoablesofar.PackagingandintegrationtechnologiesthatarecapableofprovidingsimultaneouslyhigherdegreeofMtMintegrationand miniaturizationneedtobeincreasinglybasedonmicrofabrication.Onesolutionmaybeanallsiliconpackage. Suchapackagehastheadvantageoflowerresidualstressesasabulkofthematerialissiliconwithareduced dependenceonmoldingcompoundsastheencapsulation isdonewiththesiliconitself.Inadditiontothisanallsiliconpackagecouldexploitsilicon-thinningprocesses,for ultrathinpackages,andtheadvancesofstandardCMOS processestoreduceprocessingcosts.Allsiliconpackage couldintegrateMEMSwithanaloganddigitallayers meaningnotonlythattheperformance,forexample, latencyandpowerconsumptionimprovesbutalsothe physicalpackageinterconnectswouldbelimited,thus reducingtheneedforfanningoutorevenallpackage interconnectswhatsoever.Anillustrationoftheallsilicon packagecanbeseenin Fig.4.Suchapackagewouldbe realizedbyasiliconwaferstackingprinciple,which wouldutilizeanumberofbondingtechniques.Multiple logiclayers,includingintegratedmemoryunits,couldbe stackedandintegratedusingthrough-siliconviaand fusionbondingtechnologies.Integratedsiliconpassive componentscouldbedesignedintothesiliconstack, removingtheneedforexternaldiscretedevices.Wafer bondingofmicrobumpsoftheembeddedpassivelayers

withredistributionlinescouldbeutilizedforChip-onWaferorWafer-on-Wafer.Finally,theMEMSsensorand actuatorintegrationcouldcompletetheautonomousor systemMEMS.AutonomousMEMSwouldbeafullsiliconcomponentthatisabletooperateasanindependent entity.Thehermeticallyencapsulatedsystemcouldbe implantedorembeddedanywherethusfurtherenabling ubiquitouselectronics.

Similarconceptideaswerebroughtupearlierby BSAC(BerkeleySensor&ActuatorCenter)atUC Berkeley.Thevisionarysmartdustprojectaimedtodemonstratethatacompletesensor/communicationsystem canbeintegratedintoamillimeter-scale“mote” [37]

Whensensorswillbeubiquitous,theimpactonsocietyandhumanbehaviorislargerthanwhenfixedline phoneswerereplacedwithmobilephonesconnectedin realtimetoInternet.Dronescanbescaleddowntoasize offleeusingMEMSmicromotors,otheractuators,and sensors.Accelerometersandgyroscopesputoneachfingernailcansensemotionandtransmitdata.Small(and cheap)sensorscanbeputinallpackages,forexample, foodtomonitortheconditionofthecontents. Applicationswouldbevirtuallyunlimited.Theresult wouldbewhatBryzekvisionedin2012whenhestarted theTrillionSensorsInitiativetosupportapathtoabundanceofsensors [38].Literally,allsocietalchallenges thattheglobalcommunityhastosolvearedirectlyor indirectlyrelatedtodevicesequippedwiththeabilitiesto detect,sense,andunderstandtheenvironmentandto makeoursurroundingsmoreresponsive,safer,and healthierwhileimprovingtheenergyefficiency.MEMS sensorsarenotchangingtheworldalone,buttheyhave synergisticeffectwithdevelopmentsinAI,VR/AR,and machinelearning.

ComingbacktotheSWOTanalysis(Table1),many thingsapartfromthetechnologiesaredecisivelyimportant tobeabletoturnthefutureopportunitiesintosuccessful businesses.Innovationshouldbestronglydrivenfrom

differentactors.Withanimprovedmanufacturinginfrastructure,smallcompanieshavebetterprospectstomove fastertovolumeproductioninafoundryinsteadneeding tobuildanewprocesslinetorealizetheidea.Still,availabilityofflexiblemanufacturinglinesabletoprovidesupportinthephaseofsmallandmediumvolume manufacturingwouldbehelpfultoreducethetimetomarketofnewproductconcepts.InnovationwithinlargercompaniesoftentakesplacethroughacquiringsmallerMEMS companieswithpromisingproducts,aswehaveseenin pastfewyears.Whilethiscanbeexpectedtocontinue, morerevolutionaryproductdevelopmentconceptsshould resultfromtheestablishedcompaniesownR&Dactivities.

Third-partyresearchfundingisinaveryimportant positiontofosterMEMSinnovation.Agoodamountof nationalandmultinationalresearchanddevelopment fundinghavebeenavailableinEuropeandotherareas stronginMEMS.Still,infutureinvestments,oneshould encouragetheapplicantstodevelopboldnewconcepts andplatformsinsteadofsupportingincrementalimprovements.WhileMEMSstillisinanearlydevelopment phase,bothtechnologyandindustrywise,itrequires morehighrisk,highchallengeprogramsdecliningprojectstargetingtobusiness-as-usual.

Furtheronthethreatsforthefuturedevelopmentof MEMS,detrimentaltotheadvancementoftheentire MEMSfieldisifriskavoidancestrategiesandprotection ofthecurrentlywellrunningproductsleadstohindering essentialdevelopmentsteps.Iflargecompaniestietechnologydevelopmentdecisionstoostrictlyonbusiness cases,alsotheirownrenewalisnottakingplace.Similar situationiscausedifastart-upcompanyisacquiredbya largecompanyjusttoceasethepromisingdevelopment forwhatcanbecalledartificialrespirationoftheexisting products.Visionaryengineersandmanagementare neededtotakefulladvantageoftheuniquepossibilities anddevelopMEMSbeyondlinearmarketandtechnology forecasts.AsSteveJobsissaidtostate,marketresearch maybeuseless,becausecustomersdonotknowwhat theywantuntilitisshowntothem.

Forfuturecompetitivecompaniesinthesemiconductorandelectronicsfield,theminiaturizedsmartsystem containingMEMSisaprospectivepathfordiversification,climbingupthevaluechainorupdatingtheirproductportfolio.Decisiveforthesecompaniesistobuild systemknowledge,thusapartfromtakingthefulladvantageofMEMStechnologies,oneneedstobeabletointegratethemefficientlywithothercomponents,power sources,RFcommunication,andembeddedsoftware.In multisensorsystems,thiswillalsoneedknowledgeof advancedsignalprocessingsuchassensorfusionmethodology [39] knowledgesothattheprocessingofsensorsignalscanpartiallyalreadybeimplementedonthe embeddedprocessor.

Ultimately,availablehumancapitalisthemostimportantsinglefactorforsuccess.Theinnovationswillbe generatedthere,wheretheuniversities,researchinstitutes, andsmallandlargecompaniesfindawaytonurturecompetencesandmultidisciplinaryskillswhichtheexciting MEMSandsmartsystem’sfieldrequires.

References

[1]PrimeFaradayPartnership:AnIntroductiontoMEMS. ,www. primetechnologywatch.org.uk.

[2] C.S.Smith,Piezoresistanceeffectingermaniumandsilicon,Phys. Rev.94(1953)42 49.

[3]A.D.Kurtz,J.Mallon,C.Gravel,KuliteSemiconductorProducts, ElectromechanicalTransducersandHousings,USPatent 3654579.

[4] H.C.Nathanson,R.A.Wickstrom,Aresonant-gatesiliconsurface transistorwithhigh-Qband-passproperties,Appl.Phys.Lett.7 (1965)84 86.

[5] K.E.Petersen,Siliconasamechanicalmaterial,Proc.IEEE70 (1982)420 457.

[6] H.Seidel,L.Csepregi,A.Heuberger,H.Baumgartel,Anisotropic etchingofcrystallinesiliconinalkalinesolutions,I.Orientation dependenceandbehaviourofpassivationlayers,J.Electrochem. Soc.137(1990)3612.

[7] H.Seidel,L.Csepregi,A.Heuberger,H.Baumgartel,Anisotropic etchingofcrystallinesiliconinalkalinesolutions,II.Influenceof dopants,J.Electrochem.Soc.137(1990)3626.

[8] F.Larmer,MEMSatBosch InventedforLife,IEEEMEMS, 2018,p.237.

[9] R.Bogue,RecentdevelopmentsinMEMSsensors:areviewof applications,marketsandtechnologies,Sens.Rev.33(4)(2013) 300 304.

[10]ITRS,WhitePaper“More-Than-Moore”.Availablefrom: ,http:// www.itrs2.net/uploads/4/9/7/7/49775221/irc-itrs-mtm-v2_3.pdf..

[11]Statista,Micro-ElectromechanicalSystems(MEMS)Market RevenuesWorldwideFrom2014to2024,byApplication(in MillionUSDollars).Availablefrom: ,https://www.statista.com/ statistics/796333/worldwide-mems-market-revenues-by-revenue/ . (viewed12.08.19).

[12]Statista,SemiconductorIndustrySalesWorldwide1987-2020. Availablefrom: ,https://www.statista.com/study/11803/globalsemiconductor-market-statista-dossier/ . (viewed12.08.19)

[13] E.Mounier,FutureofMEMS:AMarket&Technologies Perspective,MEMSTechSeminar,Milano,Italy,2014.

[14]StatusoftheMEMSIndustryReport,YoleDe ´ veloppement (Yole),2016ed. ,www.i-micronews.com.

[15] B.J.Kim,E.Meng,ReviewofpolymerMEMSmicromachining, J.Micromech.Microeng.26(2016)013001.

[16] C.Ge,E.Cretu,Asacrificial-layer-freefabricationtechnologyfor MEMStransduceronflexiblesubstrate,Sens.ActuatorsA286 (2019)202 210.

[17] W.Ko,Thefutureofsensorandactuatorsystems,Sens.Actuators A56(1996)193 197.

[18]StatusoftheMEMSIndustryReport,YoleDe ´ veloppement (Yole),2018ed. ,www.i-micronews.com.

[19] C.Chi,X.Sun,N.Xue,T.Li,C.Liu,Recentprogressintechnologiesfortactilesensors,Sensors18(2018)948.

[20] M.Sohgawa,A.Nozawa,H.Yokoyama,T.Kanashima,M. Okuyama,T.Abe,etal.,MultimodalMeasurementofProximity andTouchForcebyLight-andStrain-SensitiveMultifunctional MEMSSensor,IEEESensors,Valencia,Spain,2014.

[21] S.C.Lo,S.K.Yeh,J.J.Wang,M.Wu,R.Chen,W.Fang, BandwidthandSNREnhancementofMEMSMicrophonesUsing TwoPoly-SiMicromachiningProcesses,2018IEEEMicro ElectroMechanicalSystems(MEMS),Belfast,NorthernIreland, 2018.

[22] E.Zwyssig,SpeechProcessingUsingDigitalMEMSMicrophones (DoctoralDissertation),UniversityofEdinburgh,2013.

[23] I.Parvez,A.Rahmati,I.Guvenc,A.I.Sarwat,H.Dai,Asurvey onlowlatencytowards5G:RAN,corenetworkandcachingsolutions,IEEECommun.Surv.Tutor.20(2018)3098 3130.

[24]A.Torkkeli,MurataElectronicsOy,PersonalCommunication.

[25] M.Tagliavini,LightSensorsforConsumer&MobileReport,IHS Markit,2018.

[26] H.Bellini,W.Chen,M.Sugiyama,M.Shin,S.Alam,D. Takayama,Virtual&AugmentedReality:UnderstandingtheRace fortheNextComputingPlatform,GoldmanSachs,2016.

[27] M.Abu-Tair,P.Perry,P.Morrow,S.McClean,B.Scotney,G. Parr,etal.,Opticalspaceswitchesindatacenters:issueswith transportprotocols,Photonics6(2019)16.

[28] S.L.Karsten,M.C.Tarhan,L.C.Kudo,D.Collard,H.Fujita, Point-of-care(POC)devicesbymeansofadvancedMEMS, Talenta145(2015)55 59.

[29] H.J.Lee,N.Choi,A.S.Yoon,I.J.Cho,MEMSdevicesfordrug delivery,Adv.DrugDeliv.Rev.128(2018)132 147.

[30] F.Munoz,G.Alici,W.Li,Areviewofdrugdeliverysystemsfor capsuleendoscopy,Adv.DrugDeliv.Rev.71(2014)77 85.

[31] J.Yang,X.Liu,Y.Fu,Y.Song,Recentadvancesofmicroneedles forbiomedicalapplications:drugdeliveryandbeyond,Acta Pharm.Sin.B9(2019)469 483.

[32] B.D.Ratner,A.S.Hoffman,F.J.Schoen,J.E.Lemons(Eds.), BiomaterialsScience AnIntroductiontoMaterialsinMedicine, Elsevier:AcademicPress,2013.

[33] https://ouraring.com/

[34] https://support.apple.com/en-us/HT208955.

[35]T.Baron,E.Lebrassesur,F.Bassignot,H.Wang,S.Ballandras,J. Fan,etal.,WidebandlithiumniobateFBARfilters,Int.J. MicrowaveSci.Technol.2013(2013),articleID459767.

[36] J.Iannacci,Internetofthings(IoT);Internetofeverything(IoE); tactileInternet;5G a(notsoevanescent)unifyingvision empoweredbyEH-MEMS(energyharvestingMEMS)andRFMEMS(radiofrequencyMEMS),Sens.ActuatorsA272(2018) 187 198.

[37] https://www-bsac.eecs.berkeley.edu/programs/smartdust.html.

[38] J.Bryzek,R.Grace,Thetrillionsensorsinitiative,Commer. Micromanuf.Int.7(2014)42.

[39] S.Sarkka,BayesianFilteringandSmoothing,Cambridge UniversityPress,Cambridge,2013.

Chapter1

Propertiesofsilicon

MarkkuTilliandAtteHaapalinna OkmeticOy,Vantaa,Finland

1.1Propertiesofsilicon

SiliconisanabundantelementfoundintheEarth’scrustin variouscompounds.Worldwidepolysiliconproductionin 2017wasaround445,000twithamarketsizeofUS$6.5 billion.Mostofthesiliconisusedforphotovoltaicapplicationsandthequalityislowerthanthatrequiredinthe semiconductorindustry.Thesemiconductorgradesilicon productionusableforsemiconductorandmicroelectromechanicalsystems(MEMS)applicationswasaround 70,000t.TodaymostofthesiliconusediseitherN-or P-type,dopedwithantimony,arsenic,phosphorus(N-type), orboron(P-type);thedopantconcentrationrangesbetween 1013 and1020 dopantatoms/cm3 Si.Intrinsic(nointentional doping)orveryslightlydopedhighresistivitysiliconabove 1kΩ cmisusedinsmallamountsespeciallyinradiofrequency(RF)applications.Statisticspertainingtosilicon canbefound,forexample,inthe USGeologicalSurvey 2018MineralsYearbook [1,2]

Quartz,orsilicondioxide,isthemostcommonstartingrawmaterialforpurifiedsiliconforsemiconductor andsensorapplications,andtheSiemensprocessisthe mostcommonlyusedinsemiconductor-gradesiliconproduction.IntheclassicalSiemensprocess,metallurgicalgradesilicon,madefirstinanelectricarcfurnaceby reducingquartzwithcoke,isturnedtosilicon-hydrogenchloridecompoundsinfluidizedbedreactors,andthose compoundsareconvertedtoTCS(trichlorosilaneor SiHCl3).TCSispurifiedbydistillation,duringwhich concentrationsofimpuritycompoundshavingeithera lowerorhighertemperatureofvolatilitythanTCS (38.4 C)arereduced.PurifiedTCSisfedtogetherwith hydrogenintoareactor.Inthereactor,TCSdecomposes ontohotsiliconfilamentsformingapurepolysiliconrod. Thisrodisthenusedasarawmaterialforcrystalgrowth, eitherinrodformorincrushedpieces.Therearealternative,newertechniquesforpurifyingsilicon;onevariantis similartotheSiemensprocessbutusessilane(SiH4)asa precursor.Insomeprocesses,heatedsiliconfilamentsare

replacedbysiliconparticlesfloatinginfluidizedbedreactors;theseprocessesyieldgranularpolysilicon.

Theresultofthepurificationprocessishigh-puritysiliconcontainingverysmallamountsofforeigndissolved atoms.Ifthesinglecrystalsaremanufacturedbya Czochralski(CZ)technique,whichismostcommonly used(c90%ofthecrystals),theimpuritylevelincreases, asthegrowthismadefromaquartzcruciblehavingsome impurities.Theresultis,however,stillacceptable. Typically,mostofthecontaminationofthesilicontakes placeduringactualdevicemanufacturing.Ofimpurities, metalsaregenerallyharmful,withrareexceptions,and theirconcentrationshouldbeaslowaspossible,typically muchlessthan1012 atoms/cm3 Si.Oxygencomingfrom theCZ-crystalgrowthstepasanimpurityhasadualrole: ithasbeneficialeffects(strengtheningofthesiliconlatticeathightemperatures,getteringeffectinsemiconductoruse)butalsohasdetrimentaleffects(donorformation, defectgeneration).Nitrogenisasecondexampleofan impurity,anditcanbeusedinsmallquantitiestoenhance siliconproperties,especiallyin integratedcircuit(IC) applications.

Thecurrenthighdemandforlow-costsolar-gradesiliconencouragestheexploitationofalternativesourcesand newpurificationtechniques.Currently,thesemethodsare notabletoproducesemiconductor-gradesiliconpure enoughforMEMSapplications,althoughinsolarapplications,thesenewmethodsalreadyshowpromisingresults. WoditschandKoch [3] andIstratovetal. [4] listsomeof theavailablesolarsiliconpurificationtechniques.

SiliconisanidealmaterialforvariousMEMSapplications.Siliconisasemiconductorwhoseresistivitycanbe adjustedbydopingfromsub-mΩ cmtoseveralkΩ cm;it isquiteinertinanormalenvironment,hard,transparent inaninfraredregime,andelasticatroomtemperature withnoplasticdeformationandwithhighfracture strength.Finally,aprotectivestablesilicondioxidecan begrown.Siliconcrystalhasanisotropicproperties— mechanical,chemical,andelectrical—whichcanbe