HANDBOOKOF CHITINAND CHITOSAN PREPARATIONAND

PROPERTIES

VOLUME1

Editedby

SREERAG GOPI

CenterforInnovationsandTechnologies(CIT), ADSONaturalsPrivateLimited,Bangalore,India

SABU THOMAS

MahatmaGandhiUniversity,Kottayam,India

ANITHA PIUS

TheGandhigramRuralInstitute(DeemedUniversity),Dindigul,India

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

Copyright©2020ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicormechanical,includingphotocopying,recording,oranyinformationstorageandretrieval system,withoutpermissioninwritingfromthepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthePublisher’spermissionspoliciesandourarrangementswithorganizationssuchastheCopyrightClearanceCenterandtheCopyrightLicensingAgency,canbefoundat ourwebsite: www.elsevier.com/permissions

Thisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythe Publisher(otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperience broadenourunderstanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusinganyinformation,methods,compounds,orexperimentsdescribedherein.Inusing suchinformationormethodstheyshouldbemindfuloftheirownsafetyandthesafetyofothers, includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors, assumeanyliabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproducts liability,negligenceorotherwise,orfromanyuseoroperationofanymethods,products,instructions,orideascontainedinthematerialherein.

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress ISBN:978-0-12-817970-3

ForInformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: SusanDennis

EditorialProjectManager: KelseyConnors

ProductionProjectManager: SujathaThirugnanaSambandam

CoverDesigner: ChristianJ.Bilbow

TypesetbyMPSLimited,Chennai,India

Listofcontributorsix

1. Chitinandchitosan:origin,properties,andapplications1

SUNEETAKUMARIANDRUPAKKISHOR

1.1Introduction2

1.2Chitinandchitosan3

1.3Extractionofchitin5

1.4Chitosanpreparationmethods8

1.5Physicochemicalproperties8

1.6Characterizationofchitinandchitosan13

1.7Applicationofchitinandchitosan22 References28

2. Chitinandchitosan:chemistry,solubility,fiberformation, andtheirpotentialapplications35

HAKIMAELKNIDRI,ALILAAJEBANDAHMEDLAHSINI

2.1Introduction36

2.2Chitinandchitosan:chemistryandsolubility36

2.3Chitinandchitosan:fiberformation41

2.4Conclusions50 References50

3. PEGylatedchitinandchitosanderivatives59

ADIBH.CHISTY,RIFATA.MASUD,M.MEHEDIHASAN,M.NURUZZAMANKHAN, ABULK.MALLIKANDMOHAMMEDMIZANURRAHMAN

3.1Introduction60

3.2Chitinandchitosan61

3.3PEGylationandPEGylatedchitin/chitosanderivatives64

3.4FabricationofPEGylatedchitosanderivatives65

3.5CharacterizationofPEGylatedchitosanandchitinderivatives71

3.6ApplicationsofPEGylatedderivativesofchitosan86

3.7Conclusions93 References93

4. Solubility,chaincharacterization,andderivativesofchitin101 MIFENG,XINGMEILU,DANFENGHOUANDSUOJIANGZHANG

4.1Solubilityofchitin102

4.2Chaincharacterizationofchitin107

4.3Derivativesofchitin112

Acknowledgment125 References125

5. Solubility,degreeofacetylation,anddistributionofacetyl groupsinchitosan131

E.I.AKPAN,O.P.GBENEBOR,S.O.ADEOSUNANDODILICLETUS

5.1Introduction132

5.2Chemistryandstructureofchitosan132

5.3Acetylationofchitosan134

5.4Solubilityofchitosan145

5.5Conclusion153 References154

6. Chitinnanomaterials:preparationandsurfacemodifications165

ABULK.MALLIK,MD.NURUSSAKIB,MD.SHAHARUZZAMAN,PAPIAHAQUEAND MOHAMMEDMIZANURRAHMAN

6.1Introduction166

6.2Structureandpropertiesofchitin168

6.3Chitin-basednanomaterials169

6.4Preparationofchitin-basednanomaterials178

6.5Surfacemodificationofchitin185

6.6Conclusions189 References189

7. Importanceofelectrospunchitosan-basednanoscalematerials forseafoodproductssafety195

ZAFERCEYLAN,RACIYEMERAL,FATIHO ¨ ZOGULANDMUSTAFATAHSINYILMAZ

7.1Optimization196

7.2Determinationofelectrospinningparameters202

7.3Characterizationoffabricatednanoscalematerial(s)207

7.4Useofelectrospunnanomaterialsforseafoodproductssafety212

7.5Conclusion216 References217

8. Alternativemethodsforchitinandchitosanpreparation, characterization,andapplication225

GEORGEM.HALL,CLAUDIAH.BARRERAANDKEIKOSHIRAI

8.1Introduction226

8.2Chitinproduction226

8.3Currentchitosanproduction231

8.4Conclusions240 References241

9. Currentresearchontheblendsofchitosanasnew biomaterials247

A.RAJESWARI,SREERAGGOPI,E.JACKCINASTOBELCHRISTY,K.JAYARAJANDANITHAPIUS

9.1Introduction248

9.2Chitosanbiomaterial249

9.3Modificationofchitosan256

9.4Naturalpolymersblendswithchitosan258

9.5Chitosanblendswithsyntheticpolymers264

9.6Chitosan-basedhydrogels274

9.7Conclusions275 Acknowledgment275 References275

10. Chitinandchitosan-basedaerogels285

E.JACKCINASTOBELCHRISTY,A.RAJESWARI,SREERAGGOPIANDANITHAPIUS

10.1Introduction286

10.2Chitinandchitosan-basedaerogels:preparationprocess292

10.3Characterizationofchitinandchitosan-basedaerogels296

10.4Futureaspectsofaerogel324

10.5Conclusions327 Acknowledgments328 References328

11. Chitin,chitosan,marinetomarket335

G.M.OYATOGUN,T.A.ESAN,E.I.AKPAN,S.O.ADEOSUN,A.P.I.POPOOLA,B.I.IMASOGIE, W.O.SOBOYEJO,A.A.AFONJA,S.A.IBITOYE,V.D.ABERE,A.O.OYATOGUN, K.M.OLUWASEGUN,I.E.AKINWOLEANDK.J.AKINLUWADE

11.1Introduction336

11.2Originandsourcesofchitinandchitosan337

11.3Synthesisofchitinandchitosan339

11.4Propertiesofchitinandchitosan348

11.5Potentialapplicationsofchitinandchitosan354

11.6Economicpotentialofchitinandchitosan361

11.7Conclusions364 References364 Furtherreading376

12. Miscibility,properties,andbiodegradabilityofchitinand chitosan377

MUHAMMADARSHAD,MUHAMMADZUBAIRANDAMANULLAH

12.1Introduction378

12.2Physicochemicalpropertiesofchitinandchitosan378

12.3Biologicalpropertiesofchitinandchitosan385

12.4Biodegradabilityofchitinandchitosan389

12.5Concludingremarks392 References392

13. Chitinandchitosan:currentstatusandfutureopportunities401 RUCHIMUTREJA,ABHIJEETTHAKURANDARUNGOYAL

13.1Introduction402

13.2Propertiesofchitinandchitosan403

13.3Chitin,chitosan,andtheirderivatives405

13.4Applicationsofchitinandchitosan407

13.5Conclusionandfutureperspectives412 References413

14. Fungalchitosan:prospectsandchallenges419

JOSEPHSEBASTIAN,TAREKROUISSIANDSATINDERKAURBRAR

14.1Introduction420

14.2Currentcommercialproductionanditsdisadvantages426 14.3Greensynthesisofchitosan427 14.4Fungalchitosan429

14.5Futureprospects446 14.6Conclusion447 14.7Acknowledgments448 References448 Onlineresource452

15. Preparation,properties,andapplicationof low-molecular-weightchitosan453

NGUYENCONGMINH,NGUYENVANHOAANDTRANGSITRUNG

15.1Introduction454

15.2Preparationoflow-molecular-weightchitosan454

15.3Propertiesoflow-molecular-weightchitosan460

15.4Applicationsoflow-molecular-weightchitosan461

15.5Agriculture463

15.6Conclusions464 References464 Index473

ListofContributors

V.D.Abere DepartmentofMineralProcessing,NationalMetallurgical DevelopmentCentre,Jos,Nigeria

S.O.Adeosun DepartmentofMetallurgicalandMaterialsEngineering, UniversityofLagos,Lagos,Nigeria

A.A.Afonja DepartmentofMaterialsScienceandEngineering,Obafemi AwolowoUniversity,Ile-Ife,Nigeria

K.J.Akinluwade DepartmentofResearchandDevelopment,Prototype EngineeringDevelopmentInstitute(NationalAgencyforScienceand EngineeringInfrastructure,NASENI),Ilesa,Nigeria

I.E.Akinwole DepartmentofMaterialsScienceandEngineering,Obafemi AwolowoUniversity,Ile-Ife,Nigeria

E.I.Akpan InstituteforCompositeMaterials,TechnicalUniversity, Kaiserslautern,Germany

MuhammadArshad DepartmentofAgricultural,FoodandNutritional Science,UniversityofAlberta,Edmonton,AB,Canada

ClaudiaH.Barrera BiotechnologyDepartment,LaboratoryofBiopolymers andPilotPlantofBioprocessingofAgro-IndustrialandFoodBy-Products, AutonomousMetropolitanUniversity,MexicoCity,Mexico

SatinderKaurBrar INRS-ETE,Universite ´ duQue ´ bec,Que ´ bec,QC,Canada; DepartmentofCivilEngineering,LassondeSchoolofEngineering,York University,Toronto,ON,Canada

ZaferCeylan FacultyofFisheries,DepartmentofSeafoodProcessing Technology,VanYuzuncuYilUniversity,Van,Turkey

AdibH.Chisty DepartmentofAppliedChemistryandChemicalEngineering, FacultyofEngineeringandTechnology,UniversityofDhaka,Dhaka, Bangladesh

OdiliCletus MaterialsandMetallurgicalEngineering,UniversityofLagos, Lagos,Nigeria

HakimaElKnidri Catalysis,MaterialsandEnvironmentLaboratory,Higher SchoolofTechnology,SidiMohamedBenAbdellahUniversity,Fez,Morocco

T.A.Esan DepartmentofRestorativeDentistry,ObafemiAwolowoUniversity, Ile-Ife,Nigeria

MiFeng CASKeyLaboratoryofGreenProcessandEngineering,StateKey LaboratoryofMultiphaseComplexSystems,BeijingKeyLaboratoryofIonic LiquidsCleanProcess,InstituteofProcessEngineering,ChineseAcademyof Sciences,Beijing,P.R.China;SchoolofChemicalandEngineering,University ofChineseAcademyofSciences,Beijing,P.R.China

O.P.Gbenebor MaterialsandMetallurgicalEngineering,UniversityofLagos, Lagos,Nigeria

SreeragGopi DepartmentofChemistry,TheGandhigramRuralInstitute— DeemedtobeUniversity,Dindigul,India

ArunGoyal CarbohydrateEnzymeBiotechnologyLaboratory,Departmentof BiosciencesandBioengineering,IndianInstituteofTechnologyGuwahati, Guwahati,India

GeorgeM.Hall CentreforSustainableDevelopment,UniversityofCentral Lancashire,Preston,UnitedKingdom

PapiaHaque DepartmentofAppliedChemistryandChemicalEngineering, FacultyofEngineeringandTechnology,UniversityofDhaka,Dhaka, Bangladesh

M.MehediHasan DepartmentofAppliedChemistryandChemical Engineering,FacultyofEngineering,BangabandhuSheikhMujiburRahman ScienceandTechnologyUniversity,Gopalganj,Bangladesh

DanfengHou CASKeyLaboratoryofGreenProcessandEngineering,State KeyLaboratoryofMultiphaseComplexSystems,BeijingKeyLaboratoryof IonicLiquidsCleanProcess,InstituteofProcessEngineering,Chinese AcademyofSciences,Beijing,P.R.China

S.A.Ibitoye DepartmentofMaterialsScienceandEngineering,Obafemi AwolowoUniversity,Ile-Ife,Nigeria

B.I.Imasogie DepartmentofMaterialsScienceandEngineering,Obafemi AwolowoUniversity,Ile-Ife,Nigeria

E.JackcinaStobelChristy DepartmentofChemistry,TheGandhigramRural Institute—DeemedtobeUniversity,Dindigul,India

K.Jayaraj DepartmentofChemistry,TheGandhigramRuralInstitute— DeemedtobeUniversity,Dindigul,India

M.NuruzzamanKhan DepartmentofAppliedChemistryandChemical Engineering,FacultyofEngineeringandTechnology,UniversityofDhaka, Dhaka,Bangladesh

RupakKishor DepartmentofChemicalEngineering,MANIT,Bhopal,India

SuneetaKumari DepartmentofChemicalEngineering,B.I.T.Sindri,Dhanbad, India

AliLaajeb Catalysis,MaterialsandEnvironmentLaboratory,HigherSchoolof Technology,SidiMohamedBenAbdellahUniversity,Fez,Morocco

AhmedLahsini Catalysis,MaterialsandEnvironmentLaboratory,Higher SchoolofTechnology,SidiMohamedBenAbdellahUniversity,Fez,Morocco

XingmeiLu CASKeyLaboratoryofGreenProcessandEngineering,StateKey LaboratoryofMultiphaseComplexSystems,BeijingKeyLaboratoryofIonic LiquidsCleanProcess,InstituteofProcessEngineering,ChineseAcademyof Sciences,Beijing,P.R.China;SchoolofChemicalandEngineering,University ofChineseAcademyofSciences,Beijing,P.R.China

AbulK.Mallik DepartmentofAppliedChemistryandChemicalEngineering, FacultyofEngineeringandTechnology,UniversityofDhaka,Dhaka, Bangladesh

RifatA.Masud DepartmentofAppliedChemistryandChemicalEngineering, FacultyofEngineering,BangabandhuSheikhMujiburRahmanScienceand TechnologyUniversity,Gopalganj,Bangladesh

RaciyeMeral FacultyofEngineering,DepartmentofFoodEngineering,Van YuzuncuYilUniversity,Van,Turkey

NguyenCongMinh InstituteofBiotechnologyandEnvironment,NhaTrang University,NhaTrang,Vietnam

RuchiMutreja DepartmentofBiotechnology,IndianInstituteofTechnology Roorkee,Roorkee,India

K.M.Oluwasegun DepartmentofMaterialsScienceandEngineering,Obafemi AwolowoUniversity,Ile-Ife,Nigeria

A.O.Oyatogun DepartmentofMaterialsScienceandEngineering,Obafemi AwolowoUniversity,Ile-Ife,Nigeria

G.M.Oyatogun DepartmentofMaterialsScienceandEngineering,Obafemi AwolowoUniversity,Ile-Ife,Nigeria

FatihO ¨ zogul FacultyofFisheries,DepartmentofSeafoodProcessing Technology,C¸ukurovaUniversity,Adana,Turkey

AnithaPius DepartmentofChemistry,TheGandhigramRuralInstitute— DeemedtobeUniversity,Dindigul,India

A.P.I.Popoola DeparmentofChemical,MetallurgicalandMaterials Engineering,TshwaneUniversityofTechnology,Pretoria,SouthAfrica

MohammedMizanurRahman DepartmentofAppliedChemistryand ChemicalEngineering,FacultyofEngineeringandTechnology,Universityof Dhaka,Dhaka,Bangladesh

A.Rajeswari DepartmentofChemistry,TheGandhigramRuralInstitute— DeemedtobeUniversity,Dindigul,India

TarekRouissi INRS-ETE,Universite ´ duQue ´ bec,Que ´ bec,QC,Canada

Md.NurusSakib DepartmentofAppliedChemistryandChemical Engineering,FacultyofEngineeringandTechnology,UniversityofDhaka, Dhaka,Bangladesh

JosephSebastian INRS-ETE,Universite ´ duQue ´ bec,Que ´ bec,QC,Canada

Md.Shaharuzzaman DepartmentofAppliedChemistryandChemical Engineering,FacultyofEngineeringandTechnology,UniversityofDhaka, Dhaka,Bangladesh

KeikoShirai BiotechnologyDepartment,LaboratoryofBiopolymersandPilot PlantofBioprocessingofAgro-IndustrialandFoodBy-Products, AutonomousMetropolitanUniversity,MexicoCity,Mexico

W.O.Soboyejo FacultyofEngineering,WisconsinPolytechnicInstitute, Menomonie,WI,UnitedStates

AbhijeetThakur CarbohydrateEnzymeBiotechnologyLaboratory, DepartmentofBiosciencesandBioengineering,IndianInstituteofTechnology Guwahati,Guwahati,India

TrangSiTrung FacultyofFoodTechnology,NhaTrangUniversity,Nha Trang,Vietnam

AmanUllah DepartmentofAgricultural,FoodandNutritionalScience, UniversityofAlberta,Edmonton,AB,Canada

NguyenVanHoa FacultyofFoodTechnology,NhaTrangUniversity,Nha Trang,Vietnam

MustafaTahsinYilmaz FacultyofEngineering,DepartmentofIndustrial Engineering,KingAbdulazizUniversity,Jeddah,SaudiArabia;Chemicaland MetallurgicalEngineeringFaculty,DepartmentofFoodEngineering,Yıldız TechnicalUniversity,Istanbul,Turkey

SuojiangZhang CASKeyLaboratoryofGreenProcessandEngineering,State KeyLaboratoryofMultiphaseComplexSystems,BeijingKeyLaboratoryof IonicLiquidsCleanProcess,InstituteofProcessEngineering,Chinese AcademyofSciences,Beijing,P.R.China;SchoolofChemicaland Engineering,UniversityofChineseAcademyofSciences,Beijing,P.R.China

MuhammadZubair DepartmentofAgricultural,FoodandNutritional Science,UniversityofAlberta,Edmonton,AB,Canada

SuneetaKumari1 andRupakKishor2

1DepartmentofChemicalEngineering,B.I.T.Sindri,Dhanbad,India, 2DepartmentofChemicalEngineering,MANIT,Bhopal,India

1.Chitinandchitosan:origin,properties,andapplications

1.1Introduction

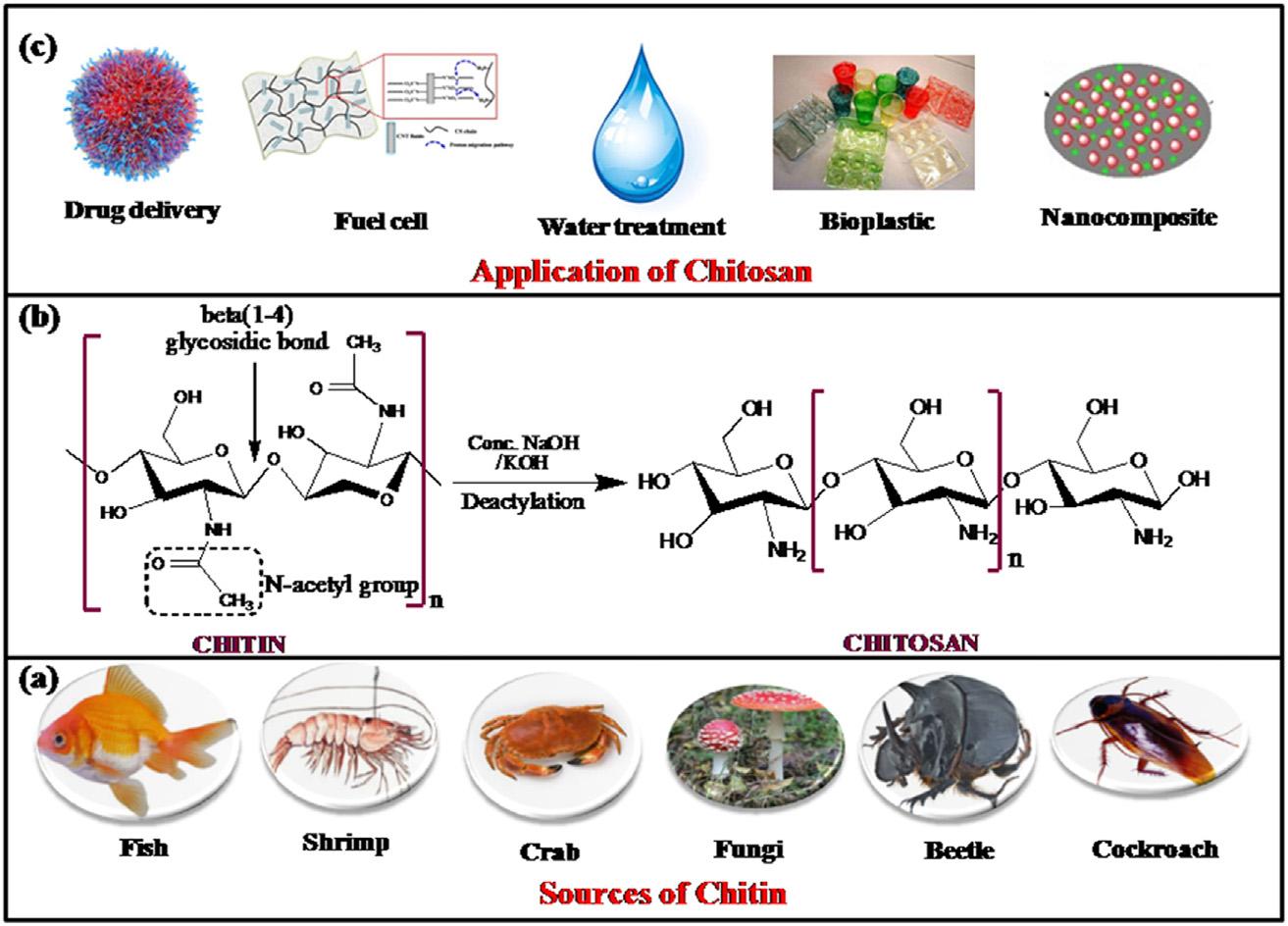

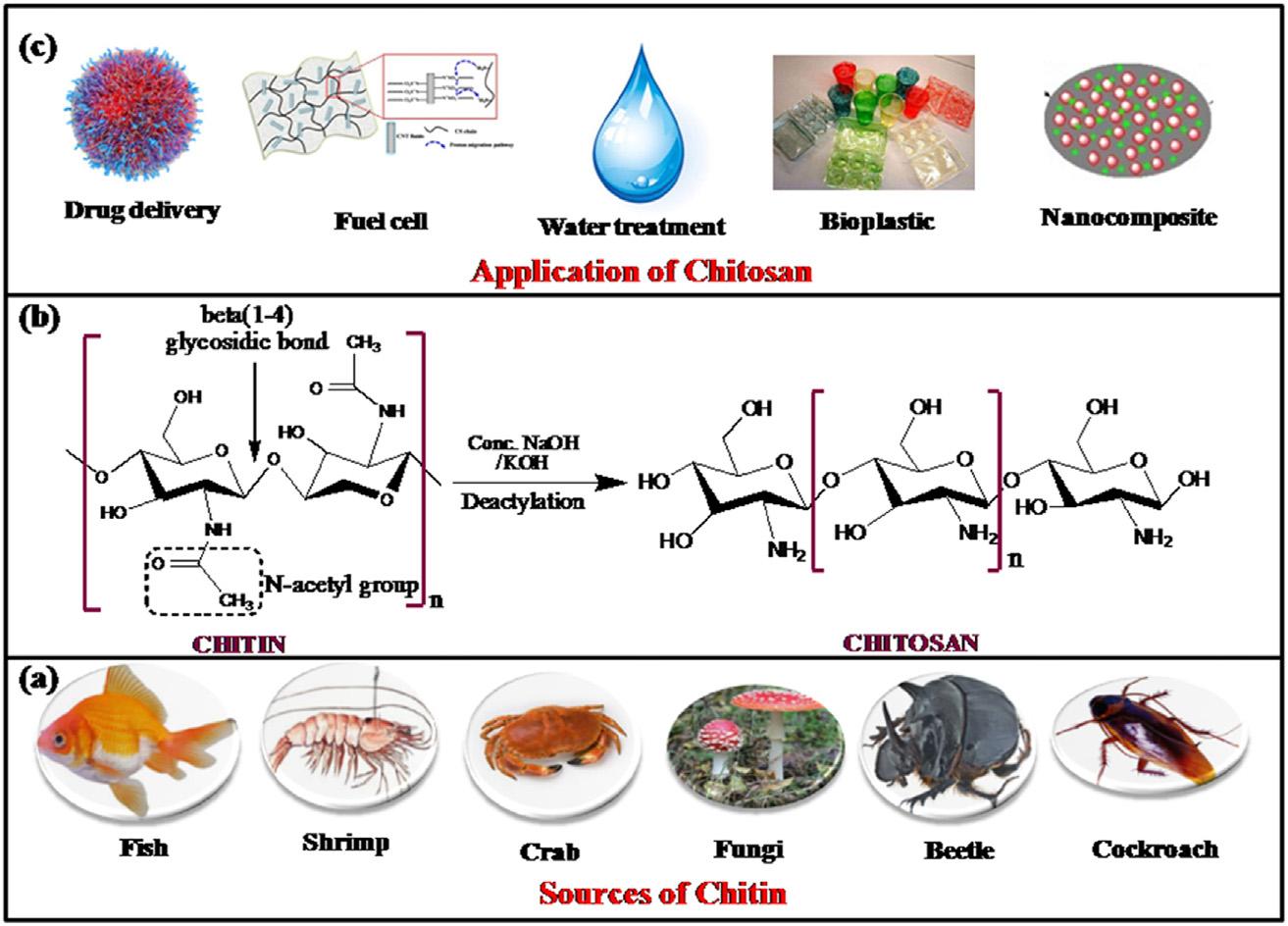

Chitinandchitosanarenaturallyabundantandrenewablepolymers. Theyhaveexcellentpropertiessuchasbiodegradability,biocompatibility, andnontoxicity [1].Chitinisacopolymerof N-acetyl-D-glucosamineand D-glucosamineunitslinkedwith β-(1-4)glycosidicbonds,asshownin Fig.1.1[2],where N-acetyl-D-glucosamineunitsarepredominantinthe polymericchain [3].Thedeacetylatedformofchitinreferstochitosan (Fig.1.1).Chitinandchitosancanbefoundassupportingmaterialsin manyaquatic,terrestrial,andsomemicroorganisms [4],asshownin Fig.1.1A.Almostasmuchchitinisestimatedtobeproducedannuallyas cellulose.Ithasbecomeofgreatinterestnotonlyasanunderutilized resourcebutalsoasanewfunctionalbiomaterialwithhighpotentialin variousfields [5].

Chitinisawhite,hard,inelastic,nitrogenouspolysaccharidefoundin theexoskeletonandintheinternalstructureofinvertebrates.Theproductionofchitosanfromcrustaceanshellsobtainedasafoodindustry wasteiseconomicallyfeasible,especiallyifitincludestherecoveryof carotenoids.Therearemanyapplicationsinwastewatertreatment,such astheremovalofmetalions [6,7] anddyes [8],asamembraneinpurificationprocesses [9],inthefoodindustry(anticholesterolandfatbinding),asapackagingmaterial,asapreservativeandfoodadditive [10], inagriculture(seedandfertilizercoating) [11],forcontrolledagrochemicalrelease [12],inthepulpandpaperindustry(surfacetreatmentadhesivepaper) [2],incosmetics(bodycreamsandInmaculadaAranaz, lotions,etc.),intissueengineering [13],inwoundhealing [14],andas excipientsfordrugdelivery [15] andgenedelivery [16].Additionally,It canbeeasilyprocessedintogels [17],membranes [18],nanofibers [19], beads [10],microparticles,nanoparticles,scaffolds [15],andsponges [20],asshownin Fig.1.1C.

FIGURE1.1 (A)Sourcesofchitin,(B)deacetylationofchitin(synthesisofchitosan), and(C)applicationofchitosan.

Themainobjectiveofthischaptertogiveabriefintroductionabout chitinandchitosananditssynthesis.Thephysicalandchemicalpropertiesofchitosandeterminedbyusingdifferentanalyticaltechniquesare alsodiscussed.Finally,themostrecentapplicationsofchitinandchitosanarediscussed.

1.2Chitinandchitosan

Chitin(C8H13O5N)n,isderivedfromtheGreekword“chiton,”meaning acoatofmail.Itisanaturalpolysaccharideof β-(1-4)-N acetyl-D-glucosaminemonomers,firstidentifiedbythechemistHenriBraconnotin1811 [21].Itsstructureissimilartocellulosebutwith2-acetamido-2-deoxy-β-Dglucose(NAG)monomerunits(Fig.1.1B).Chitinhaslimitedapplications becauseofitsacetylgroups,butthroughthedeacetylationprocesschitinis convertedintochitosan.Duringthedeacetylationprocess,theacetylgroup presentinchitinisconvertedintohydroxyl( OH)andamino( NH2) groupsinthechitosan.Themodificationofthereactivefunctionalgroups presentinchitosanopensthepossibilityofbroadapplicationinmany fields.Chitosan’sstructuralmodificationispossiblebychemicalmethods

4 1.Chitinandchitosan:origin,properties,andapplications

andmostofthenewapplicationsfocusonthepropertiesandmodification ofitscomposites [22].

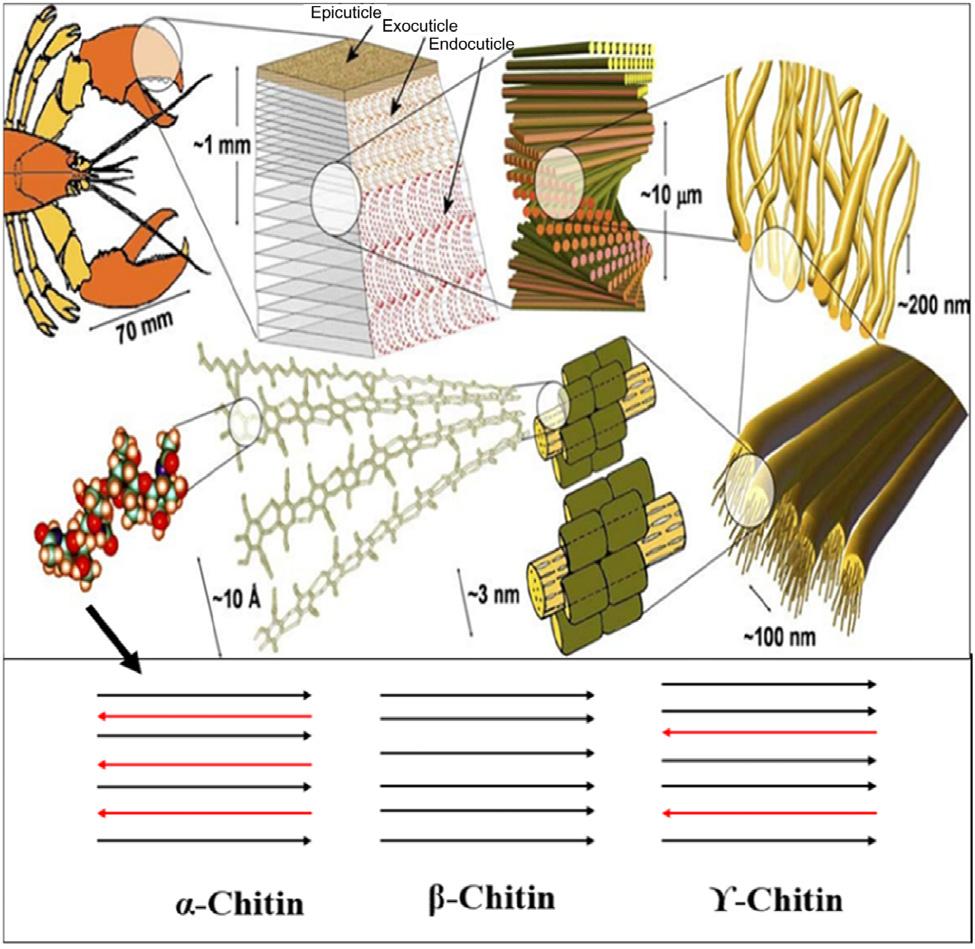

1.2.1Sourcesofchitin

Chitinisusuallyisolatedfromtheexoskeletonsofarthropods’chitin-based tissue(30% 40%protein,30% 50%calciumcarbonate,and20% 30% chitin),suchascrustaceans,mollusks,insects,andcertainfungi [2,23 26].It isabiologicalnanocompositematerialstrictlyhierarchicallyorganizedwhich revealsvariousstructurallevels.Atthe molecularlevelisthepolysaccharide chitinitself(Fig.1.2).Thenextstructurallevelisthearrangementofc.18 25 ofsuchmoleculesintheformofnarrowandlongcrystallineunits,whichare wrappedbyproteins,formingnanofibrilsofabout2 5nmdiameterand about300nmlength.Thenextstepinthescaleconsistsoftheclusteringof someofthesenanofibrilsintolongchitin proteinfibersofabout50 300nm diameter(Fig.1.2).

Chitinismainlyoccursinthreedifferentpolymeric α, β-,and γ-forms. Thechainsarearrangedinstacksorsheetsin α-chitinandadjacentsheets alongthec-axishavethesamedirectioninaparallelarrangement. The α-chitinoccursintheexoskeletonsofcrustaceans(e.g.,crabs, lobsters,andprawns).Inthecaseof β-chitin,theadjacentsheetsalong

FIGURE1.2 Hierarchyofthemainstructurallevelsandmicrostructureelementsofthe exoskeletonmaterial [25].

thec-axispresentinoppositedirectionsinanantiparallelarrangement anditcanbefoundinsquidpen,certaindiatoms,andvestimentiferans (aclassofdeep-seaanimal) [27].Howevereverythirdsheetisinthe oppositedirectiontotheprecedingsheetsin γ-chitin.Itmainlyexistsin fungiandyeast [28].

1.3Extractionofchitin

Cuticlesofvariouscrustaceanslikecrabs,shrimps,andlobsterand fishscalesarethemajorsourcesofchitin.Crustaceanscarryanexoskeletoncomposedofproteins,chitin,andcalciumcarbonatewhich bindtogethertoformanexternalshell [26].Proteinandchitosanbind togetherandasmallpartoftheproteinisavailableinthepolymercomplex.Hence,chitin’sseparationfromtheshellrequirestheelimination oftwomajorconstituents,proteinandminerals.Proteinisremovedby adeproteinizationprocessandmineralsareremovedbyademineralizationprocess.Insomecasesanadditionalprocessofdecolorizationis carriedouttoremovepigments.Avarietyofmethodshavebeen adoptedtoproducechitin.Amongallmethodschemicalandbiological processesareprimaryfortheproductionofchitin.Moreover,among thetwomethodbiologicalmethodsthesequenceoftheprocessoffers someadvantagesspecificallyintimeconsumptionandqualityofchitin produced.Thereforeextractionalwaysbeginsbychoosingcrustacean shells.Foranyparticularseparation,shellsofidenticalsizeandspecies arepreferred.Inthecaseofshrimpshell,theseparationiseasierasthe shellwallisthinnerbuttheyieldislessincomparisonwithcraband lobster.However,crabandlobsterallowabetterqualityofchitintobe recovered.Thustheavailabilityofcrustaceansremainsakeyfactorfor theextractionofchitin [29].

1.3.1Chemicalextraction

1.3.1.1Demineralizationprocess

Demineralizationofshellsisbasedonacidictreatmenttoremoveminerals likecalciumcarbonateandcalciumphosphate.Themostcommonreagents areHCl,HNO3,H2SO4,CH3COOH,andHCOOH.Thenthedemineralized shellisfilteredundervacuumandwashedwithdistilledwaterfor30min untilthepHbecomeneutral.Thenthedemineralizedshellsaredriedinan ovenataround60 Cfor24h. ð1:1Þ

Thisreactionuseshydrochloricacidtodecomposecalciumcarbonate intocalciumchloridewiththereleaseofwaterandcarbondioxide [30].

Similarlymineralsalsoreactwiththeacidandproducesolublesalts. Thesaltsareremovedbyfiltration.Chitinisrecoveredbywashingwith distilledwateranddrying [31].Thedemineralizationprocessdiffers withdifferenttypesofshells,timeofextraction,temperature,shellsize, concentrationofacid,andsolute/solventratio.Hence,thesolute/solventratioisbasedonstoichiometry(2molofacidfordecomposed 1molofcalciumcarbonate).Thedemineralizationprocessgenerally occursathightemperatureasthisallowsthesolventtodiffuseintothe chitinmatrixmoreeasilyanddiffusiondependsontheparticlesize. Moreover,ahighconcentrationofacid,hightemperature,andprolongedprocesstimeadverselyaffectthepropertiesofchitin [32].

1.3.1.2Deproteinizationprocess

Deproteinizationofdemineralizedshellsiscarriedoutbyusingan alkalitreatmentwithcommonreagentssuchasNaOH,Na2CO3, NaHCO3,KOH,K2CO3,Ca(OH)2,Na2SO3,NaHSO3,CaHSO3,Na3PO4, andNa2S.Theproteinisremovedfromdemineralizedshellsusing KOH/NaOHwithconstantstirringfor2hataround90 Candfiltered undervacuumwithdistilledwateruntilpHneutral.Thenthedeproteinizedshellisdriedintheovenataround60 Cfor24h.Duringthe deproteinizationprocesscleavageofchemicalbondsoccursbetween proteinandchitin.KOH/NaOHhasthetendencytodepolymerizeand degradethechitin.Thedeproteinizationprocessreactionconditionis dependentonthesourceofthecrustaceans.Hence,alkalitreatment leadstothepartialdeacetylationofchitinwithlowmolecularweight (Mw) [33].

1.3.1.3Decolorization

Decolorizationofchitinisthefinalstageofchitinpreparation. Acetoneoranotherorganicsolventmixtureisusedtoremovethepigments.Decolorizingisdonewithacetonefor10 20minandthendrying for2hatambienttemperature.

1.3.2Biologicalextraction

Thechemicaltreatmentprocessofchitinhasmanydrawbacks.Chemical chitinpurificationisextremelyhazardous,energyconsuming,andthreateningtotheenvironment,duetothehighconcentrationofmineralsandcaustic employed.Biologicalextractionisanalternativemethodtoextractchitin fromcrustaceans’shells.Itovercomes theenvironmentalproblemsassociated withacidicandalkalitreatment.The advantagesofbiologicalmethods

includetheproductionofchitinwithhigherreproducibility.Moreover,the solubilityofchitinislimitedandthebiologicalapproachislimited.

1.3.2.1Enzymaticdemineralization

Mineralandproteinpresentinthecrustaceanshellsaredissolvedby organicacidwithmicroorganismssuchaslacticacid-producingbacteria. Thisenzymaticdemineralizationreactioninvolvesorganicacidand microorganismreactingwithcalciumcarbonatepresentintherawshells andcalciumsaltsprecipitatetheorganicacid.Theprecipitatedsaltsare removedbytheculturemediumwithspecialcare.Theprecipitated organicsaltsarealsoremovedbywashingandareusedaspreservative andantiicingagents [34].

1.3.2.2Enzymaticdeproteinization

Intheenzymaticdeproteinizationprocess,proteases(alcalase,pepsin, papain,pancreatin,devolvase,andtrypsin)frombacteriacaneliminate proteins.Commonly,proteolyticenzymesareobtainedfromplants, microbes,andanimalsources.Theyremoveproteinsandreducethe stepsinpreliminaryprocesses.Alcalaseisgenerallypreferredforthe productionofchitin,proteinhydrolyzate,andastaxanthinrecovery.Its hydrophobicaminogroupcontrolshydrolysis.Alcalaseisaserineendopeptidaseobtainedfrom Bacilluslicheniformis.Itisselectedduetoits specificityforterminalhydrophobicaminoacids.Itgenerallyleadsto theproductionofnonbitterhydrolyzateandallowsaneasycontrolof thedegreeofhydrolysis.RawshellsaredemineralizedafterdeproteinizationusingHCltreatmentandtheresidualproteincontentis higherinthechitinisolatedwiththeenzymaticdeproteinizationthan thatobtainedwithalkalitreatment [35].

1.3.2.3Fermentation

Theenzymeprocesshasahighcostduetotheenzymes.Thecostof usingenzymescanbedecreasedbyperformingdeproteinizationusinga fermentationprocess [36].Fermentationmethodsareseparatedintotwo majorcategories:lacticacidfermentationandnonlacticacidfermentation. Fermentationofcrustaceanwasteresultsinasolidfractioncontaining crudechitinandtheproductionofliquorrichinnaturalprotein,mineral, andpigments.Moreover,theactionofthelacticacid-producingbacteriais twofold [37].Theyproduceaspectrumofproteasesthatdetachprotein fromthesolidchitin CaCO3 complexbypartialhydrolysis.Thusextractionbybiologicalactivityisgaininginimportanceoverchemicaltreatment.Itisaneco-friendlyprocessandtheby-productscanberecovered andrecused [38].

Chitosanispreparedbyadegreeofacetylation.Acetylgroupsare removedduringthedeacetylationprocessandMwchangesduetothedepolymerizationreaction.Therearetwoprocesses,thatis,theenzymaticprocessandchemicalprocess,andchitosanisproducedbychemicalprocess. Itispreferableforlarge-scaleproduction.

1.4.1Chemicalandbiologicaldeacetylationofchitin

Glycosidicbondsareattractedtowardacidsandalkalis.Chitinisprocessedhomogeneouslyorheterogeneously.Inthehomogeneousmethod, chitinisdiffusedinconcentratedalkaliat25 Cfor3handallowedtodisperseincompressediceataround0 C [39].Intheheterogeneousprocess thechitinistreatedwithhothigh-concentrationalkaliandthenwashed withdistilledwateruntilthepHisneutral.Itisdifficulttoproducehigher deacetylatedchitosan.Theaddition ofthiophenolasacatalystduringthe processwouldminimizethedegradationbytrappingoxygenandenhance theeffectivedeacetylation.Theeffectivedeacetylationprocessofchitin achievesthepreparationofchitosanifthealkaliconcentrationisfourtimes greaterthanthetotalaminogroupinthepolysaccharideatatemperature around100 Cforthedurationof1h.Itisrecommendedtouselowconcentrationalkaliandashortcontacttimebetweenalkaliandpolymer [40]

Chemicaldeacetylationhasmanydisadvantageslikehighenergyconsumptionandenvironmentalpollutionproblems [41].Analternative methodofenzymedeacetylationhasbeendevelopedtoovercomethese drawbacks.Chitindeacetylationenzymeactsasacatalysistohydrolyze Nacetamidebonds [42].Thisenzymeisextractedfromthefungi Mucorrouxii, Absidiacoerulea, Aspergillushidulans,andtwostrainsof Celletotrichumlindemuthianum.Thisenzymeisthermallystableandhasabindingaffinity toward β-(1,4)-linked N acetyl-D-glucosominepolymers [43].Mostofthe timetheenzymeprocessiscarriedoutinbothbatchandcontinuousculture. InthebatchprocesstheMwofchitosanislowerwithrespecttotime. Moreover,chitosanofhigherMwisobtainedinaspecificcultureeven thoughtheyieldiscomparativelylow [44].

1.5Physicochemicalproperties

Chitinisacolorless,crystallineoramorphouspowderthatisinsoluble inwater,organicsolvents,diluteacids,andalkalis.Itdissolvesinconcentratedmineralacidswithsimultaneousdegradationofthepolymer [45] Althoughchitosanisinsolubleinwater,itdoesdissolveinaqueous

organicacids,forexample,aceticandformicacids,aswellasinorganic acids.Chitinandchitosanpreparationcanvaryduetothesource,with compositionaldifferences.Similarly,thephysicochemicalcharacteristics ofchitinandchitosandifferbetweencrustaceanspeciesandpreparation methods [46].Severalstudieshaveclearlydemonstratedthespecific characteristicsoftheseproducts.TheMwanddegreeofdeacetylation (DD)varywithprocessconditions [46 48].Thephysicochemicalcharacteristicsofchitinandchitosaninfluencetheirfunctionalproperties [24,49].MwandDDvarywithprocessconditionsordifferentextraction methods [24].Chitosan’sapplicationdependsonphysical,biological, andchemicalpropertiesandchitosandependsontwoparameters, suchasDDandMw [50].

1.5.1Molecularweight

Chitosananditsderivativeshavebeenusedinawidevarietyof applicationsbuttheeffectivenessofthesematerialshasbeenfoundto bedependentupontheirDD,crystallinity,andMw [51].DDandMwof chitosanaregreatlyaffectedbyreactionconditionsliketemperature, reagentsconcentrations,repetitionofalkalinesteps,time,andatmosphericconditionsofthedeacetylation [52].Chitosanispreparedby chemicalandenzymaticprocesses [1].Thechemicalprocesshasseveral drawbackssuchaslowproductyieldsandpoorstructuralorder(glucosering).Additionally,acidicandalkalitreatmentsduringthechemicalprocesscouldbeasourceofenvironmentalproblems [24].The enzymaticprocessisanalternativewaytosynthesizechitosanwhichis moreenvironment-friendly [53].Duringtheenzymaticprocesslactic acid-producingbacteriaareusedforthedemineralizationofcrustacean shellsinsteadofacidictreatment.Theobtainedlacticacidreactswith calciumcarbonateyieldingcalciumlactate,whichcanbeprecipitated andremoved.Duringthedeproteinationofcrustaceanshells,proteases frombacteria(Pseudomonasaeruginosa K-187, Serratiamarcescens,FS-3, and Bacillussubtilis)areused. Serratia sp.and Bacillus sp.arebacteria thatalsoproducechitindeacetylaseandcanbeusedtogeneratechitosan [54].Theeffectivedeacetylationisattainedbyintermittentlywashingtheintermediateproductwithwaterduringthealkalitreatment [55].TheaverageMwofchitosanis B500kDawith100%ofDDA.The DDAincreasesrapidlytoabout68%duringthefirsthourofalkalitreatment(50%NaOH)at100 Candfurtherslowlyincreaseswithtime [48]. ThereareseveralmethodsusedforthecalculationofMw,suchaslight scattering,gelpermeationchromatography(GPC),andcapillaryviscometry.Capillaryviscometryisthesimplestandmostwidelyusedmethod todeterminetheMwofchitosan.Duringanalysis,anUbbelohde-type

capillaryviscometerisusedtomeasurethepassagetimeofsolutions flowingthroughthecapillaryat25 C.Differentviscositysolutionsofchitosanareusedatvariousconcentrationsrangingfrom0.00125%to0.15%in 0.1Maceticacid 0.2MNaClsolutions.Thecapillaryviscometerisfilled withthesampleandisequilibratedinawaterbathat25 C.Thesolution andsolventflowtimesaremeasuredtocalculaterelativeviscosity.The Mark Houwink Sakuradaequationgivenbelowprovidestherelation betweenintrinsicviscosity(η)andMw [51]:

BasedonMw,chitosanisclassifiedintothreedifferenttypes,namely low-molecular-weightchitosan(LMWC; , 50kDa),medium-molecularweightchitosan(MMWC;50 250kDa),andhigh-molecular-weightchitosan (HMWC)( . 250kDa).SeveralauthorshavereportedthatLMWChas enhancedproperties,suchasantibacterialandantifungal [56],antitumor [57],lipidmetabolism,intestinaldisaccharidase [58],andmucoadhesive properties [59].ApartfromthistheMwalsoplaysanimportantrolein thebiopolymer’srheologicalproperties.Itdirectlyimpactsthedevelopment ofchitosan-basedbiomaterials [60].LMWCisusedasananticreasingagent toproduceafinishingagentandthenappliedintheanticreasingtreatment ofcottonfabrics.HMWCisusedinquaternizedchitosanfilmswithpropertiesofwatersolubilityandfreeradicalscavenging,andHMWCisalsoused forhigh-performancecellsanditseffectsonpolymeraggregationand phaseseparation.

1.5.2Viscosity

Chitosanisthebestknowndeacetylatedderivativeofchitin,asone ofitsuniquepropertiesisitspolycationicnaturewhendissolvedin acidicsolution(thevalueofpKa 5 6.0).Hencethisbiopolymerisfavorableforabroadvarietyofindustrialandbiomedicalapplications.When chitosanisdissolvedinacidicsolution,itgivesaviscoussolution.The viscosityofthesolutionisrelatedtotheMw,DD,concentration,pH, andtemperatureofchitosansolution.

Theviscosityofchitosansolution,atthemolecularlevel,isadirect measureofthevolumeofthepolymermolecules,whichinturnisgovernedbythemolecularsizeorchainlength.Theviscosityofthepolymersolutioniswidelymeasuredbyacapillaryviscometeranditsvalue isusedtodeterminetheaverageMwofpolymerbyusingthe Mark Houwinkequation(Eq.(1.1)):

Where Mv istheaverageMwofthepolymerand α and k areconstants (α 5 0.83and k 5 1.4 3 10 4 for0.25Maceticacidand0.25Msodiumacetatesolventsystem).Theintrinsicviscosity[η]canbedeterminedfrom thefollowingequation(Eq.(1.2)):

where η (dL/g)isthesolutionviscosityand ηs isthereferencesolvent viscosityand C isthesolutionconcentration.Asindicatedin(1.2),when (η ηs)/ηsC,thatis,reducedviscosity(ηred)isplottedagainstconcentration(C),theinterceptcorrespondsto[η].The[η]valueisdirectly usedindeterminingtheMwofdifferentgradesofchitosan.Someofthe typicalchitosanviscositieswithdifferentMwsaresummarizedin Table1.1[61]

Flowactivationenergy(Ef)ofviscouschitosansampleisanalyzedby theArrheniusequation(Eq.1.3):

where A and R arethepreexponentialfactoranduniversalgasconstant absolutetemperature(inKelvin).Thevalueof Ef oftwodifferentgrade ofchitosan91%DOAand70%DOAwas25and15kJ/mol,respectively,asreportedbyWeiWang [62].Thismeansthattheentanglement ofchainsincreaseswiththeincreasingDDofchitosanbecauseofthe natureofthepolymer.

Theviscosityandflowpropertiesoftheconcentratedsolutionsofchitosan withdifferentdegreesofdeacetylationaredifferent.Theviscositiesandthe non-Newtonianflowpropertiesofthesolutionsincreasewiththeincreasing DDofchitosan.Ontheotherhand,additionalsaltdecreasestheviscosities andthenon-Newtonianflowpropertiesofthesolutionsofchitosan.

TABLE1.1 Intrinsicviscosityandviscosityaveragemolecularweightofdifferent gradesofchitosan.

ChitosanIntrinsicviscosity[η],dL/gMolecularweight, MV

CHT-19.40654,127

CHT-24.72285,231

CHT-32.55135,839

CHT-41.5071,676

CHT-50.53520,698

1.5.3Solubility

Thethree-dimensionalchitincrystallinematrixconsistsofacombination ofstronghydrogenbondsandcohesiveforcesofacetyl(OQC),hydroxyl ( OH)andamine( NH)functionalgroups.Thesefunctiongroupslink with NH OQCand OH OQCbyhydrogenbondsinthethreedimensionalmatrix.Purechitincontainsaround90% N-acetylgroupsinits backboneandsomedeacetylationreactionstakeplaceduetotheextraction processofchitinfromthenaturalsources.

ThefirststudyonthesolubilityofchitinwasperformedbyAustin,who testedthesolubilityofchitinindifferentorganicsolvents [63].Itwasa well-organizedevaluationofchitin’ssolubilityindifferenttypesofsolvents,suchasdichloroacetic(DCA)andtrichloroacetic(TCA)acidsinthe presenceorabsenceofalcohol,etc.Lateron,manystudieswereconducted withthesameintentionsbymanyotherresearchersandchitin’ssolubility wasverifiedinmanysolventssuchasdimethylacetamide(DMA)/LiCl mixture,CaBr2 H2Osaturatedmethanol,hexafluoroisopropylalcohol andhexafluoraceton,lithiumthiocyanate,phosphoricacidand N-methyl2-pyrrolidone,etc. [64].Althoughthedissolutionofchitinispossibleby thesesolvents,manyofthemaretoxic,scarcelydegradable,corrosive,or mutagenic.Thereforethechoiceofanappropriatesolventforchitinand chitosansolubilizationisimportantandaprimaryissueforlab-scale researchandscalingupforindustrialpractices [65].

Therearetwomonomerunitspresentinthechitinbackboneindifferent fractionsnamely2-acetamino-2-deoxy-D-glucopyronase(N-acetyl-D-glucosamine)and2-amino-2-deoxy-D-glucopyronase(N-amino-D-glucosamine) [66].Thefirstonegroup,2-acetamino-2-deoxy-D-glucopyronase,displays insolubilityduetothestronghydrogenbondsbetweentheacetylgroupsof thesameoradjacentchitinchains.Intheotherunit N-amino-D-glucosamine ishydrophilicinnatureandpositivelychargedinacidicsolution.Thedominationofthehydrophiliccharacterwithahighamountof N-amino-D-glucosamineunitsinthechitinbackbone makeitsolubleinthespecificacidic solution.Thepercentageof N-amino-D-glucosamineunitinthechitinbackbonecanbedeterminedbyDDA.Itistherationof N-amino-D-glucosamine to N-acetyl-D-glucosamine,whilethedegreeofacetylationrepresentsthe detectionfrom100(100-DDA).WhenDDAisbetween60%and90%,anew chemicalentity“chitosan”isformedanditissolubleinorganicacidssuch asaceticacid.Chitosancanbedissolvedinaqueousdilutedacidsasapolycationat B50%DDAormoreduetothepresenceof N-amino-D-glucosamineunits [64].Theotherparameters,suchastemperature,timeof deacetylation,alkalicontraction,andpriortreatment,appliedtochitinisolationandDDalsoaffectthesolubilityofchitosan.Thereforethefractionof N-amino-D-glucosamineunitshasalargeinfluenceonthesolubilityandthe solution’sproperties. 12 1.Chitinandchitosan:origin,properties,andapplications

1.6Characterizationofchitinandchitosan

1.5.4Water-bindingcapacityandfat-bindingcapacity

Water-bindingcapacity(WBC)andfat-bindingcapacity(FBC)of chitinandchitosanismeasuredbyamodifiedmethodofWangand Kinsella [67].Inatypicalprocess,waterorfatabsorptionisinitiallycarriedoutbyweighingacentrifugetubecontaining0.5gofsampleand adding10mLofwaterorsoybeanoilandmixingwithavortexmixer for1mintodispersethesample.Thecontentsareleftatambienttemperaturefor30minwithshakingfor5severy10min,beforebeingcentrifugedat B3200rpmfor25min.Afterthesupernatantisdecanted, thetubeisweighedagain.WBCandFBCarecalculatedasfollows [24].

WBCdifferedwithproductsrangingfrom381%to673%forchitins andfrom458%to805%forchitosans [24].ChitosanhasahigherWBC thanchitin.TheWBCvaluesaredifferentforeachsource(chitin)and chitosan.ThedifferencesinWBCbetweenchitinandchitosanarepossiblyduetodissimilaritiesincrystallinity,thenumberofsalt-forming groups,andtheresidualproteincontentoftheproducts [68].

FBCforproductsofchitinswereintherangeof316% 320%,whereas chitosanshowsdissimilarbindingcapacitiesrangingfrom314% 535%. ThisapparentlysuggeststhatchitincanorcannothavehigherFBCthan chitosandependingontheproducts [24].

1.6Characterizationofchitinandchitosan

Afterseveraldecadesofintenseresearchconcerningthesynthesis, characterization,andapplicationofchitinandchitosan,acompleteand detaileddescriptionofthepolymeranditscharacteristicscannotbe deducedyet;evenfromthosestudiesperformedbyusingadvanceexperimentaltechniquessuchasX-raydiffractionorhigh-resolutionscanning electronmicroscopy(HRSEM).Asaconsequence,suitableatomistic modelshavebeendevelopedtotrytodescribetheiratomicstructurein ordertounderstandtheirdifferentpropertiesandtohelpintailoring themforspecificpurposes.

Adetaileddescriptionofchitinandchitosanmustinclude(1)characteristics oftherawchitinandtheproducedchitosan,bymeansofsurfacefunctional group;(2)thermalanalyses;(3)structuralanalysis;(4)Mw;(5)viscosity;and (6)themorphologyoftheproduct.

Abriefdescriptionofdifferentcharacterizationtechniquesisdiscussed below.

1.6.1Fourier-transforminfraredspectroscopy(FT-IR)analysis

FT-IRanalyticaltechniqueisusedtounderstandthefunctionalgroups presentinthechitinandchitosan.Thechitins(α-, β-,and γ-chitin)canbe distinguishedbyFT-IRspectraandtheseareshownin Fig.1.3.Inthecase of α-chitin,twoseparatepeaksareobservedat B1662and B1630cm 1 . Theyrepresenttheamide-Ibandpresentinthe α-chitin.Itisassociated withtheoccurrenceoftheintermolecularhydrogenband CO...HNand CO HOCH2 [71].Inthecaseof β-chitin,asinglebandisobservedat 1656cm 1 duetothehydrogenbondpresentbetweentheamidegroup ( CQO)oftheneighboringintrasheetchain [27].The NHstretching bandat3264and3107cm 1 isclearlyobservedinboth α-and β-chitin.The bandsat703and750cm 1 representthebendingvibrationof OHgroups andNH groupspresentinthe α-chitin,respectively.Whileinthecaseof β-chitin,theyareshiftedto682and710cm 1 [71].However, β-chitinshows asinglebandatapproximately1656cm 1 whichisassociatedwiththe intermolecularhydrogenbondofCO...HN [69].The β-chitinhavethe weakerinter-andintramolecularhydrogenbondingandamoreloosely orderedstructurecomparedwith α-chitin. γ-Chitinshowsthetwosharp peaksat1660and1620cm 1 fortheamide-Iband,whichisalsoavailable inthe α-chitin.

Apartfromtheexpecteddecreaseinthebandintensityat1665and 1550cm 1 forchitin(amide-I),theyappearedatnearly1604,1598,and 1592cm 1 forchitosan.Thisdemonstratestheeffectivedeacetylationof chitin.Moreover,thebandsassignedtothestretchingvibrationsofthe glycosidicbondofchitosanpolysaccharidestructureat1151,1098,and 1021cm 1 weakeneddistinctlyafterthedeacetylationprocess.The bandsnearlydisappearedat3260and3107cm 1,originatingfrom N Hstretchingafterdeacetylationindicatingthedisturbedthe regularhydrogenbondofN Hinthechitin.

Inthe α-chitinspectra:twoseparatepeaksareobservedat1662and 1630cm 1.Theyareassociatedwiththeoccurrenceoftheintermolecular hydrogenband CO...HNand CO.....HOCH2.Moreover,asinglebandis observedat1656cm 1 incaseofthe β-chitin.Itiscommonlyrelatedtothe stretchingofthe COgrouphydrogenbondtoamidegroupoftheneighboringintrasheetchain [27].Thestrongbandat1430cm 1 isnotedfor β-chitin, whileasharpbandat1416cm 1 presentinthecaseof α-chitin [28]. TheNH stretchingbandat3264and3107cm 1 isclearlyobservedinthe α-chitinbutinthecaseof β-chitin,itisnoteasilyseen(Fig.1.3A).Thebandat 703cm 1 duetothe OHoutofplaneand750cm 1 duetoNH outof planeisshowsinthe α-chitin.Whileinthecaseof β-chitin,itisshiftedto