https://ebookmass.com/product/ground-improvement-with-

Instant digital products (PDF, ePub, MOBI) ready for you

Download now and discover formats that fit your needs...

Process Improvement with Electronic Health Records 1st Edition

https://ebookmass.com/product/process-improvement-with-electronichealth-records-1st-edition/

ebookmass.com

Molecular Nutrition: Carbohydrates Vinood B. Patel

https://ebookmass.com/product/molecular-nutrition-carbohydratesvinood-b-patel/

ebookmass.com

Geotechnical Engineers Portable Handbook, Second Edition 2nd

https://ebookmass.com/product/geotechnical-engineers-portablehandbook-second-edition-2nd/

ebookmass.com

Beyond the ancient quarrel: literature, philosophy, and J.M. Coetzee First Edition Coetzee

https://ebookmass.com/product/beyond-the-ancient-quarrel-literaturephilosophy-and-j-m-coetzee-first-edition-coetzee/ ebookmass.com

A Cowboy's Forever Faithful (Sweet View Ranch Western Cowboy Romance book 1) (Sweet View Ranch Western Christian Cowboy Romance) Jessie Gussman

https://ebookmass.com/product/a-cowboys-forever-faithful-sweet-viewranch-western-cowboy-romance-book-1-sweet-view-ranch-westernchristian-cowboy-romance-jessie-gussman/

ebookmass.com

Electronic Principles 9th Edition Albert P. Malvino

https://ebookmass.com/product/electronic-principles-9th-editionalbert-p-malvino/

ebookmass.com

Gerente profesional de proyectos 1st Edition Juan Francisco Esquembre

https://ebookmass.com/product/gerente-profesional-de-proyectos-1stedition-juan-francisco-esquembre/

ebookmass.com

Core Radiology: A Visual Approach to Diagnostic Imaging

https://ebookmass.com/product/core-radiology-a-visual-approach-todiagnostic-imaging/

ebookmass.com

Critical Criminological Perspectives Jodie Hodgson Gender Power And Restorative Justice A Feminist Critique Palgrave Macmillan 2022 Desconocido

https://ebookmass.com/product/critical-criminological-perspectivesjodie-hodgson-gender-power-and-restorative-justice-a-feministcritique-palgrave-macmillan-2022-desconocido/

ebookmass.com

https://ebookmass.com/product/etextbook-978-1305089723-ethics-incounseling-psychotherapy/

ebookmass.com

GeotechnicalInvestigations andImprovementofGround Conditions Geotechnical Investigationsand Improvementof GroundConditions An imprint of Elsevier

AnjanPatel

WoodheadPublishingisanimprintofElsevier

TheOfficers’MessBusinessCentre,RoystonRoad,Duxford,CB224QH,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates TheBoulevard,LangfordLane,Kidlington,OX51GB,UnitedKingdom

© 2019ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans, electronicormechanical,includingphotocopying,recording,oranyinformationstorageand retrievalsystem,withoutpermissioninwritingfromthepublisher.Detailsonhowtoseek permission,furtherinformationaboutthePublisher’spermissionspoliciesandour arrangementswithorganizationssuchastheCopyrightClearanceCenterandtheCopyright LicensingAgency,canbefoundatourwebsite: www.elsevier.com/permissions

Thisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythe Publisher(otherthanasmaybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchand experiencebroadenourunderstanding,changesinresearchmethods,professionalpractices,or medicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgein evaluatingandusinganyinformation,methods,compounds,orexperimentsdescribedherein. Inusingsuchinformationormethodstheyshouldbemindfuloftheirownsafetyandthesafety ofothers,includingpartiesforwhomtheyhaveaprofessionalresponsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors, assumeanyliabilityforanyinjuryand/ordamagetopersonsorpropertyasamatterofproducts liability,negligenceorotherwise,orfromanyuseoroperationofanymethods,products, instructions,orideascontainedinthematerialherein.

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

ISBN:978-0-12-817048-9(print)

ISBN:978-0-12-817049-6(online)

ForinformationonallWoodheadpublicationsvisitour websiteat https://www.elsevier.com/books-and-journals

Publisher: MatthewDeans

AcquisitionEditor: GlynJones

EditorialProjectManager: AnaClaudiaGarcia

ProductionProjectManager: DebasishGhosh

CoverDesigner: VictoriaPearsonEsser

Introduction 1.1Introduction Groundimprovementisrequired,whereverproblematicsoils/rocksareencountered. Thebasicpurposeistomakethesubsurfaceconditionssuitableforconstructionpurposes.Therearevariousmethodsofgroundimprovementavailableandtheselection ofatechniqueoracombinationoftechniquesdependsuponseveralfactors.Thedifferentpurposesofgroundimprovementandabriefdescriptionofthedifferent methodsandtheirselectioncriteriaispresentedinthischapter.

1.1.1Purposeofgroundimprovement Ground-improvementmethodsarethosethatarecapableofimprovingcertaincharacteristics(e.g.increaseinbearingcapacity,reductionintotalaswellasdifferential settlement,reductioninpermeability,slopestability,preventionofsoilerosioncaused bypipingandseepage,reductionofupliftpressure,decreaseinliquefactionpotential ofsoil,reductionofswellingandcrackingofsoils,identificationofsuitabilityofsite tofacilitateconstructionworks,etc.)ofpoorgroundforcivilengineeringconstructionsandvariousinfrastructuredevelopments.Soagroundimprovementmethod ortechniqueisrequiredtoalterthestate,nature,ormassbehaviourofgroundmaterialsinacontrolledmannerinordertoachieveanexpectedandsatisfactoryresponse toexistingorprojectedenvironmentalandengineeringactions. Therearealternateoptionstogroundimprovementaswell.Theseare

a. toremoveandreplacethesoilmasswithanothertypeofsoilsorothergeomaterialsofa suitablequalityfortheconstructionwork

b. tobypassthepoorsoilwiththehelpofasuitabletechniquelikepilefoundation

c. toalterthedesign(heightandconfiguration)ofstructurestoovercometheground limitations

d. tochangetheconstructionsiteandlookforanewone.

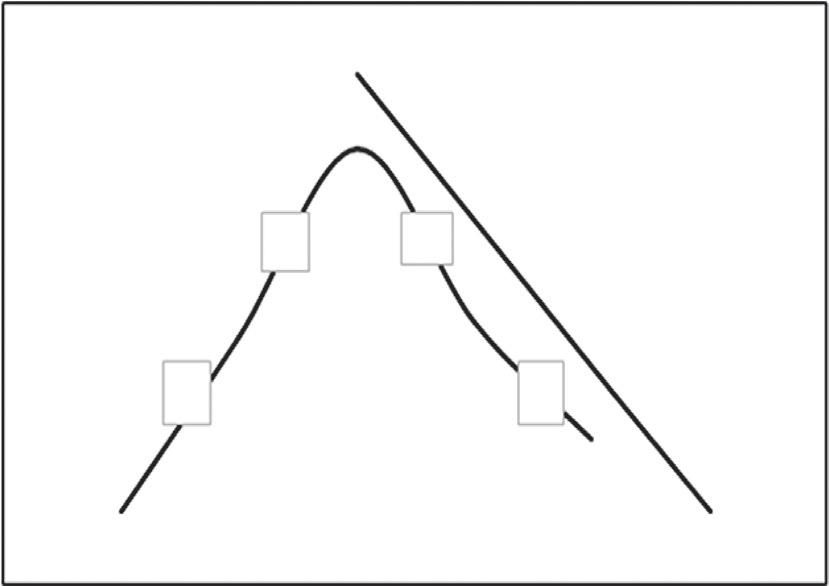

However,duetothescarcityoflandinpresentconditions,heavyloadingstructures, competitivedesign,theneedforspeedyconstruction,andvariouspoliticalandeconomicissues,aground-improvementtechniquemaybetheonlyfeasibleoptionfor civilengineeringconstructions.Thissituationisoutlinedin Fig.1.1,whichdemonstratesthatwhenthegroundisproblematicinmostofthecasesweneedtoimprove thesoilmassbyselectingaproperground-improvementtechnique(s).Theselectionof ground-improvementtechniquesdependsuponvariousfactorslikethecostandtime

2 GeotechnicalInvestigationsandImprovementofGroundConditions

Problematic cases

Collapsible soil

Liquefiable soil

Filling materials

Loose deposits

Swelling soil

Soft and marshy ground

Karst topography

Nonuniform soil/rock strata

Potential for slope instability

Excessive seepage

High lift pressure

Erosion, piping

Options available

1. Remove and replace

2. Bypass

3. Change site location

4. Design alteration

5. Improve in situ soil properties (ground improvement)

Technical, practical, political and economical issues

Constraints Selection criteria

Cost, time, purpose, volume of treatment area, soil properties, accessibility, availability of materials, equipment and manpower, environmental factor, local experience and preference

Fig.1.1 Necessityandselectionofground-improvementtechniquesforconstructionprojects.

availabletocompletetheproject,reasonsforimprovingtheground,extentanddepth ofgroundtobetreated,geotechnicalpropertiesoftheexistinginsitusoils/rocks, accessibilitytotheprojectsite,availabilityofmaterials,equipmentsandmanpower requiredtoimprovetheground,environmentalfactors,localexperience,andpreferenceofcontractorsandengineers.

1.1.2Preliminaryevaluationforgroundimprovement Asmentionedpreviously,therequirementforandselectionofvariousgroundimprovementtechniquesarepurelysiteandprojectspecific.Itisessentialthatthesite characterizationiscompletedbeforeimplementationoftheground-improvementprocess.First,itneedstobedecidedwhethergroundimprovementisrequiredforthespecificprojectattheparticularsiteornot?Inordertodecidethisweneedtoanalyzethe variousparametersrelatedtothegroundthataffectthestabilityandserviceabilityof thestructures.Asimpleexampleofapreliminaryevaluationforgroundimprovement toconstructabuildinghasbeenpresentedasaflowchartin Fig.1.2.Similarmatrices canbeformedfordifferentstructurestobeconstructedindifferentsitestoevaluatethe necessityofgroundimprovement.

1.1.3Methodsofgroundimprovement Aclassificationofvariousground-improvementtechniquescanbedonebasedupon theirbasicprinciplesandthisispresentedin Table1.1. Allofthetechniquesmentionedin Table1.1 haveoneormorethanoneofthefollowingmainfunctions:

a. Toincreasethebearingcapacity

b. Tocontroldeformationsandaccelerateconsolidation

c. Toprovidelateralstability

Fig.1.2 Necessityofground-improvement:preliminaryevaluation.

d. Toformseepagecut-offandenvironmentalcontrol

e. Toincreaseliquefactionresistance

f. Tofacilitatetheworkingsiteconditions.

Dependinguponthespecificprojectrequirements,itisnecessarytoselectone,or morethanone,oftheground-improvementtechniquesforaparticularsitebyconsideringotherfactorsliketimeandcost,volumeanddepthofwork,etc.,asmentionedin theprevioussection.Someofthecommonmethodsalongwiththeirbasicpurposes aresummarizedin Table1.2.

Itisworthmentioningthataparticularground-improvementtechniquecanbeused onlyforaparticulartypeoragroupofsoils,asshownin Fig.1.3.

4 GeotechnicalInvestigationsandImprovementofGroundConditions

Table1.1 Classificationofground-improvementtechniquesbasedupontheirbasic principles

BasicprinciplesSomeofthemethods

ConsolidationWickdrainsorprefabricatedverticaldrains(PVD), vacuumconsolidation,preloading,surchargefill, electro-osmosis

DensificationVibro-compaction,vibro-flotation,dynamiccompaction, blasting

ReinforcementApplicationofgeosyntheticmaterialsandnaturalfibres, retainingwalls,soilnailing,soilanchoring,micropiles, stonecolumns

Chemicalstabilizationby deepmixingmethods

Chemicalstabilizationby grouting

Chemicallimeandcementpiles

Permeationgroutingwithparticulateorchemicalgrouts, compactiongrouting,jetgrouting,hydro-fracture grouting,etc.

ThermalstabilizationGroundfreezing,vitrification

Electro-treatmentElectro-kineticremediation,electro-heating, electro-kineticfencing,bioelectro-kineticinjection LoadreductionUseofEPS(expandedpolystyrene)geofoams,crumb rubbertire,sawedlumberwaste,foamglassaggregates, clamshells,LECA(lightweightexpandedclay aggregate),expandedshellclayandslates,cellular concrete,pumiceandindustrialwasteslikeslag,etc.

Similarly,themaximumeffectivedepthandtheeconomicalsizeofthetreatment areavariesfrommethodtomethod,assummarizedin Table1.3

1.1.4Scope l Developingnewmachinerytoexecutetheworkinlesstime,particularlyfordeep compaction

l Automationofequipmentforinsitumonitoringandqualitycheck

l Developmentofproperguidelinessoastoenhancetheeffectivenessofdifferentgroundimprovementtechniques.Also,theregularrevisionoftheexistingguidelinesisrequired, baseduponnewsitecondition,climaticconditions,andnewchallenges

l Innovatingnewconstructionmaterials,particularlyfromdifferentwastes

l Developmentofnewcost-effectivetechniquestoreplacetheexpensiveones,likefreezing, electro-osmosis,vacuumconsolidation,etc.Interdisciplinaryworktoexplorenewmethods likenanotechnologyandmicrobialgeotechniques,biorockformations,inventionofcatalyst andenzymesthatcanconvertsoilintorocklikematerials,etc.

l Tomakethesetechnologiesmoreenvironmentallyfriendly

l Analysisoftheeffectofclimatechangeonperformanceofdifferentsoilstabilizers,etc.

Table1.2 Purposesofsomeofthecommonmethodsforgroundimprovement

Methods

Vibrocompaction, blasting, preloading

Dynamic compaction

Soilnailing

Mechanical stabilization, micropiles,fibrereinforcement

Vacuum consolidation, electro-osmosis

Lightweightfill

Stonecolumns

Permeation grouting

Electro-heating

Jetgrouting,deep soilmixing,lime column

Groundfreezing

Vitrification

Gravel Sand

Vibro-compaction

Vibro-displacement compaction

Particulate grout

Chemical grout

Displacement grout

Preloading

Dynamic compaction

Electro-osmosis

Reinforcement

Thermal treatment

Remove and replace

Prewetting

Fig.1.3 Variousground-improvementmethodsaspertheirapplicabilitytodifferentsoilmass. BasedonMitchell,J.K.,1981.Soilimprovement:stateoftheartreport.In:Proceedingsof10th InternationalConferenceonSoilMechanicsandFoundationEngineering,Stockholm,4, pp.509–565.

Table1.3 Maximumeffectivedepthandeconomicalsizeoftreatmentareaforsomeofthe ground-treatmentmethods

Method

Maximumeffective depth/economicalsizeof treatmentareaMethod

BlastingAbout20–25mbutnot neartogroundsurface/ smallarea

Maximumeffectivedepth andeconomicalsizeof treatmentarea

PreloadingEconomicalforsmallarea

Vibratory roller 3m/anysizeDynamic compaction 30m/largearea

GroutingUnlimited/smallareaVibroflotation 30m/largearea

Electroosmosis 20m/smallareaStone columns 20m/mediumtolargearea

Heating/ freezing 15m/smallareaChemical limepiles 45m/mediumtolargearea

Soilcompaction 2.1Introduction Compactionistheprocessofapplyingmechanicalenergytoasoilmasssoasto rearrangetheparticlesandmakingitdensethroughtheexpulsionofairfromthevoids betweenthesoilgrains.Themainobjectivesofsoilcompactionaretoimprovethe engineeringpropertiesofanexistingsoilortofacilitatetheworkduringplacingof fills.Theobjectivesare

l toincreasetheshearstrengthandthereforebearingcapacityofsoil

l toincreasethestiffnessandthereforereducesettlement

l todecreasethevoidratiothusmakingthesoillesspermeable

l toincreasetheerosionresistanceofgeomaterials

l toimproveliquefactionresistanceofsoilbypreventingthebuildupoflargewaterpressures duringearthquakes.

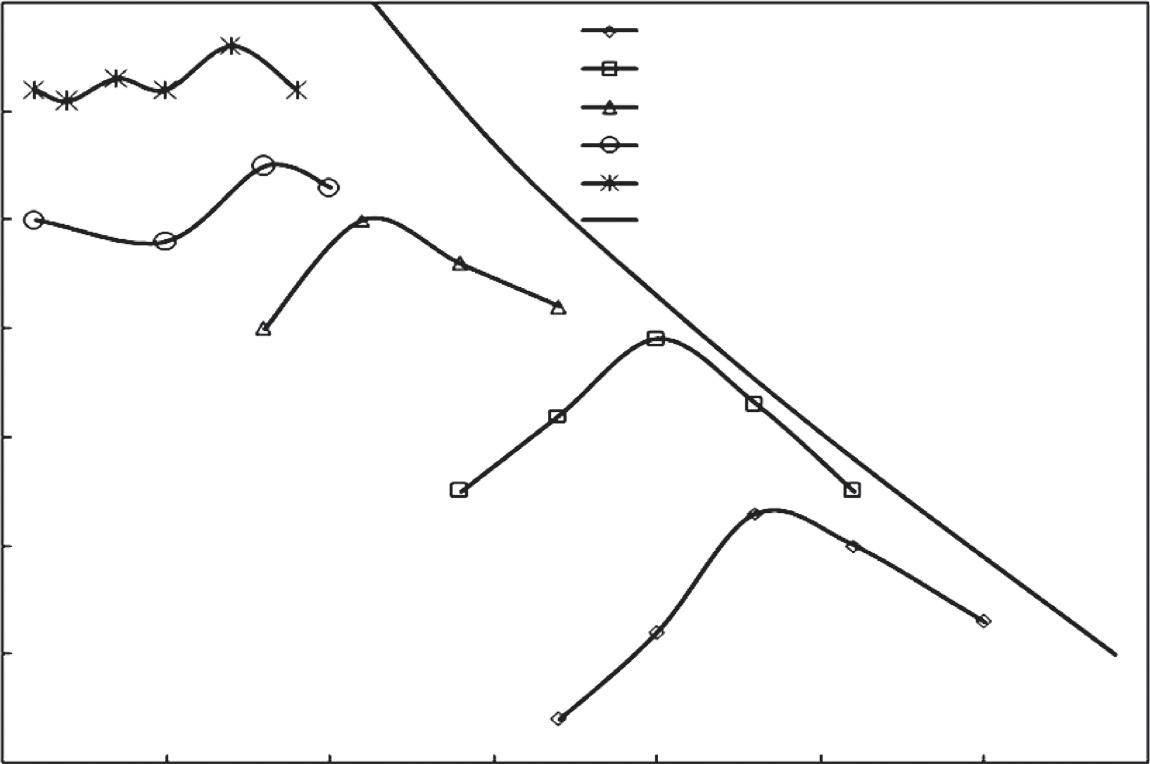

2.2Compactiontheory Inordertoexplainthetheoriesofsoilcompaction,itisnecessarytofirstunderstand therelationshipsbetweenthedrydensityandthemoisturecontent(knownascompactioncurves)asobtainedduringcompactioninthelaboratoryorinthesite.Thetypical curvesobtainedfromdifferenttypesofsoilhavebeendepictedin Fig.2.1.Withan increaseinwatercontent,thedrydensitykeepsonincreasinguptoacertainpoint (correspondingtotheoptimummoisturecontent(OMC)andthemaximumdrydensity(MDD))andthenitstartsdecreasing.Thezeroairvoidline,alsoknownasthe 100%saturationlineasshownin Fig.2.1,isalimitinglinecorrespondingtonoair inthesoil,i.e.allthevoidsarefilledwithwater.Itcanbeaddedherethatgranular soiltypicallyhavefairlysteepcompactioncurvesexhibitinglargechangesindensity withsmallchangesinmoisturecontent.Ontheotherhand,highlyplasticclaysexhibit fairlyflatcompactioncurves.TheMDDishigherforcoarsersoilsandcorrespondsto alowervalueofOMC.Somecohesionlesssoilscanexhibittwopeaksinthecompactioncurve(oneinverydryconditions,wheretherearenocapillarytensionstoresist thecompactioneffort,andtheotherattheOMC,whereoptimumlubricationbetween particlesoccurs).

Thecompactioninasoilmasscanbeachievedinvariousways,assummarizedin Table2.1.

Theeffectivenessofanyofthesecompactionmethodsdependsupon(1)thefrictionalforcebetweensoilparticlessupportedbythecapillaryaction,and(2)thelubricationeffectofthemoisturefilmaroundthesoilparticle,whichinturndependsupon thesize,shape,soilmineralogy,andtheporewater.AtOMC,theamountofwateris justsufficienttoneutralizethecapillaryforceandthecompactingforceisfully GeotechnicalInvestigationsandImprovementofGroundConditions. https://doi.org/10.1016/B978-0-12-817048-9.00002-0 © 2019ElsevierInc.Allrightsreserved.

2.00

High plastic clay

Low plastic clay

Clayey silty sand

Sand

Gravel

Zero air void or 100% saturation line

Fig.2.1 Typicalcompactioncurvesindifferenttypesofsoils.

Table2.1 Generalcompactionmethodsinlaboratoryandinthefield

BasicprincipleMethods/equipment

StaticloadingRubber-tyredrollers

Staticloadingandpress

ImpactloadingDynamiccompaction

Fallingweightandhammer

Rapidimpactcompactor

Pneumatic-tyredrollers(forcohesiveaswellasnoncohesivesoilin 15–30cmthicklayers) 8

Vibrating

Handandmechanicallyoperatedtampers(tocompactsoiladjacentto existingstructuresandareasthatarenotaccessibleeasilybyother ways)

Vibratinghammer

Hand-operatedvibrationplates

Motorizedvibratoryrollers

Vibratoryplatecompactor(tocompactgranularsoilstoveryhighdry density)

Rolling Smooth-wheelrollers(forfinishingoperationsaftercompactionoffill andforcompactinggranularbasecoarseforhighways)

Vibratoryrollers(forcompactinggranularsoilwithnofinesinlayers ofupto1mthickness)

High-energyimpactrollers(forcompactionatafasterrateandto greaterdepths)

Gyrating

Kneading

Kneadingand tamping

vibratingprobeorvibro-flot

Sheep-footrollers(applicabletocohesivesoilin15–30cmthick layers,usefulforwastecompactionatlandfills)

1. Hydration

2. Lubrication

3. Swelling

4. Saturation

Fig.2.2 Stagesofwetting duringcompaction. (BasedonHogentogler,C.A., 1936.EssentialsofSoil Compaction,Proceedings HighwayResearchBoard, NationalResearchCouncil, Washington,DC,309–316.)

utilizedtorearrangethesoilparticlesmakingitmoredenseincomparisonwiththe MDD.BeyondOMC,thethicknessofwaterfilmincreases;asitcannotbindthesoil particlesintoagroupthedensitythereforedecreases.Itshouldbenotedthatwhilst obtainingacompactioncurve,thesoilmasspassesthroughfourstagesofwetting,i.e. hydration,lubrication,swelling,andsaturation,asshownin Fig.2.2.

Inthestageofhydrationwaterisjustabsorbedbythesoilparticlesandsticksto theirsurface.Inthestageoflubricationpartofwateractsasalubricatingagent enablingtherearrangementofthesoilparticlesintoacloserproximitywithoutthe expulsionofalltheairfromthevoids.Inthestageofswelling,whichhappenstooccur beyondtheOMC,thesoilmassswellswiththeaircontentremainingconstant,and withtheadditionofmorewateratthesaturationstageallairisdisplacedduringcompactionandthesoilbecomessaturated.Moreover,thedecreasedeffectivenessofcompactionathighermoisturecontentsbeyondOMCisduetothetaperingofairand buildupofporewaterpressure.Theexplanationofcompactiontheoryintermsof physicochemicalandsoil-structureconsiderationstendstoshowthatinthedryofoptimumtheparticlesarerandomlyorientedrepresentingflocculatedstructure,whereas thesoilparticlesarearrangedinadispersedmannerinthewetofoptimum.

2.3Effectonsoilproperties Itcanbeseenfrom Fig.2.2 thatthesamedrydensitycanbeachievedcorrespondingto twomoisturecontents,oneatthedryofoptimumandotheratthewetofoptimum. Clayscompacteddryofoptimumhaveaflocculatedfabric,whichgenerallycorrespondstohigherpermeability,greaterstrengthandstiffness,andincreasedbrittleness. Ontheotherhand,clayscompactedwetofoptimumhaveadispersedfabric,which correspondstolowerpermeability,lowerstrengthandstiffness,butmoreductility.

Thechangeinstrength,stiffness,permeability,compressibility,andswellingof soilscorrespondingtothedryorwetofoptimumissummarizedin Table2.2.

Table2.2 Effectofcompactiononsoilproperties

SoilpropertiesEffects

Strength

l Thestrengthatdryofoptimumishigherthanwetofoptimum

l Atlargestrains,theultimatestrengthofsoilcompacteddryandwet ofoptimumarealmostequal

l Highercompactionenergiescanproduceslightlylowerstrength whenafine-grainedsoiliscompactedatawatercontenthigherthan theoptimum

l Ifmaterialcompacteddryofoptimumbecomessaturated,thereisa decreaseinstrength,whichcanbelessthanthatofthesamesoil compactedwetofoptimum

l Onwetofoptimum,soilcompactedbykneadingactionhasless shearstrengthascomparedtosoilcompactedbystaticcompaction method

Stiffness

Permeability

Compressibility

l Thestiffnessatdryofoptimumissubstantiallylargerthanwhen compactedwetofoptimum

l Ifmaterialcompacteddryofoptimumbecomessaturated,thereisa decreaseinstiffness,whichcanbelessthanthatofthesamesoil compactedwetofoptimum

l Permeabilityatconstantcompactiveeffortdecreaseswithincreasing watercontentandreachesaminimumatabouttheoptimummoisture content

l Ifthecompactioneffortisincreased,thepermeabilityofsoil decreases

l Soilsonthedrysidearelesscompressible.However,the compressibilityofsoilincreasesinthehigh-andlow-pressurerange ondryofoptimumandwetofoptimum,respectively

l Compactionbykneadingorimpactmethodcreatesamoredispersed structureandhenceariseincompressibility

Swelling/ shrinkage

l Soilscompacteddryofoptimumhavemoreswellingpotentialbut shrinklessondryingcomparedwiththosecompactedwetof optimum

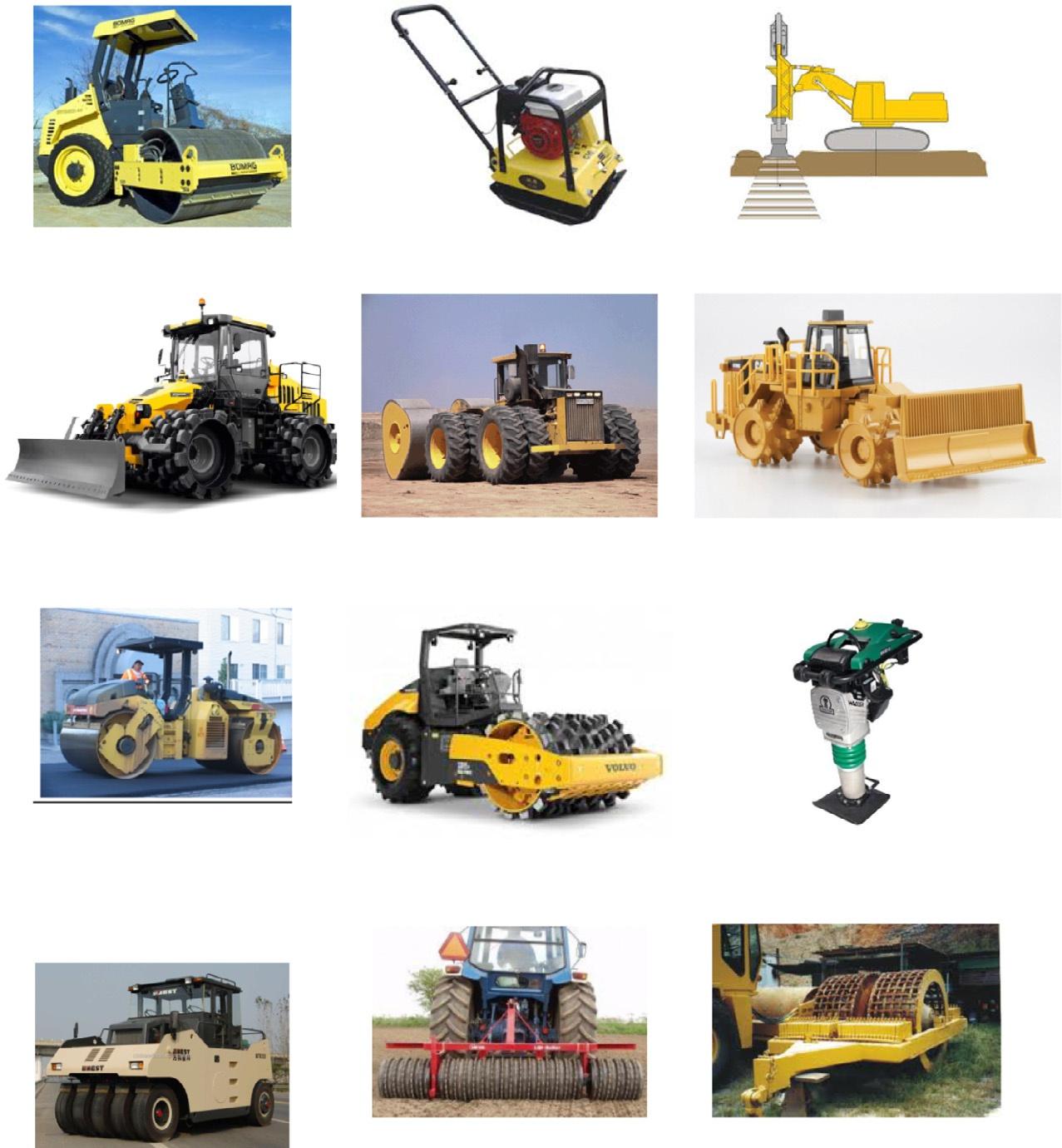

2.4Instrumentsandmethods Thevariousmethodsofsoilcompactionarealsoincludedin Table2.1.Thedifferent typesofsoilcompactinginstrumentsaredepictedin Fig.2.3. Itmustbenotedthattheeffectivedepthofcompactionvariesfrommethodto method.Forexample,smoothwheelrollercompactseffectivelyonlyto 200–300mm,whereastheimpactrollercanprovidedeeper(2–3m)compaction. So,thecompactionofthickfillsmustbedoneinaseriesoflifts.Generally,thethicknessofeachliftvariesfrom0.15to0.3mdependinguponthetypesofsoil,relative compactionthatisrequired,fieldcompactionenergy(typeofcompactionequipment

andnumberofpasses)andtheQA/QC(qualityassurance/qualitycontrol)plan.As such,byusingconventionalvibratoryrollers,High-energyimpactcompaction,rapid impactcompaction,dynamiccompaction,andvibro-flotation,soilcanbecompacted uptoaneffectivedepthof1.5,1.5–5,4–6,6–12,and10–20m,respectively.The vibro-compaction,vibro-flotation,anddynamiccompactionmethodsarediscussed inaseparatesectionlaterinthischapter.Theothermethods,whichgenerallyoperate byrollingontheearthsurface,requirethatpropermoisturecontent(correspondingto OMC)ismaintainedinthefield.Moreover,itshouldbenotedthatitisdifficultto achieveahighlevelofcompactioninthethinliftoveraweaksubgradeandthehigh stressesinthelowersoilmayproduceshearfailureandexcessiverutting.Hence,itis essentialtomonitorthecompactionofeachliftduringfillplacement.Nowadays,it hasbecomeveryeasytomonitortheinsitucompactiononareal-timebasisbyusing intelligentcompaction(IC),especiallyforroadconstruction.Theintelligent

Pneumatic tyred roller

Vibratory roller Vibrating plate compactor Rapid impact compactor

Tamping roller High energy impact roller Landfill compactor

Smooth wheel rollers Sheep-footed roller

Upright rammer

Lift roller

Grid roller

Fig.2.3 Differenttypesofsoilcompactinginstruments.

compaction(IC)instrumentisbasicallyamodernvibratoryrollerequippedwithan integratedmeasurementsystem,anonboardcomputerreportingsystem,globalpositioningsystem(GPS)basedmapping,andoptionalfeedbackcontrol.TheICroller helpsinreal-timecompactionmonitoringandtimelyadjustmentstothecompaction processbyintegratingmeasurement,documentation,andcontrolsystems.

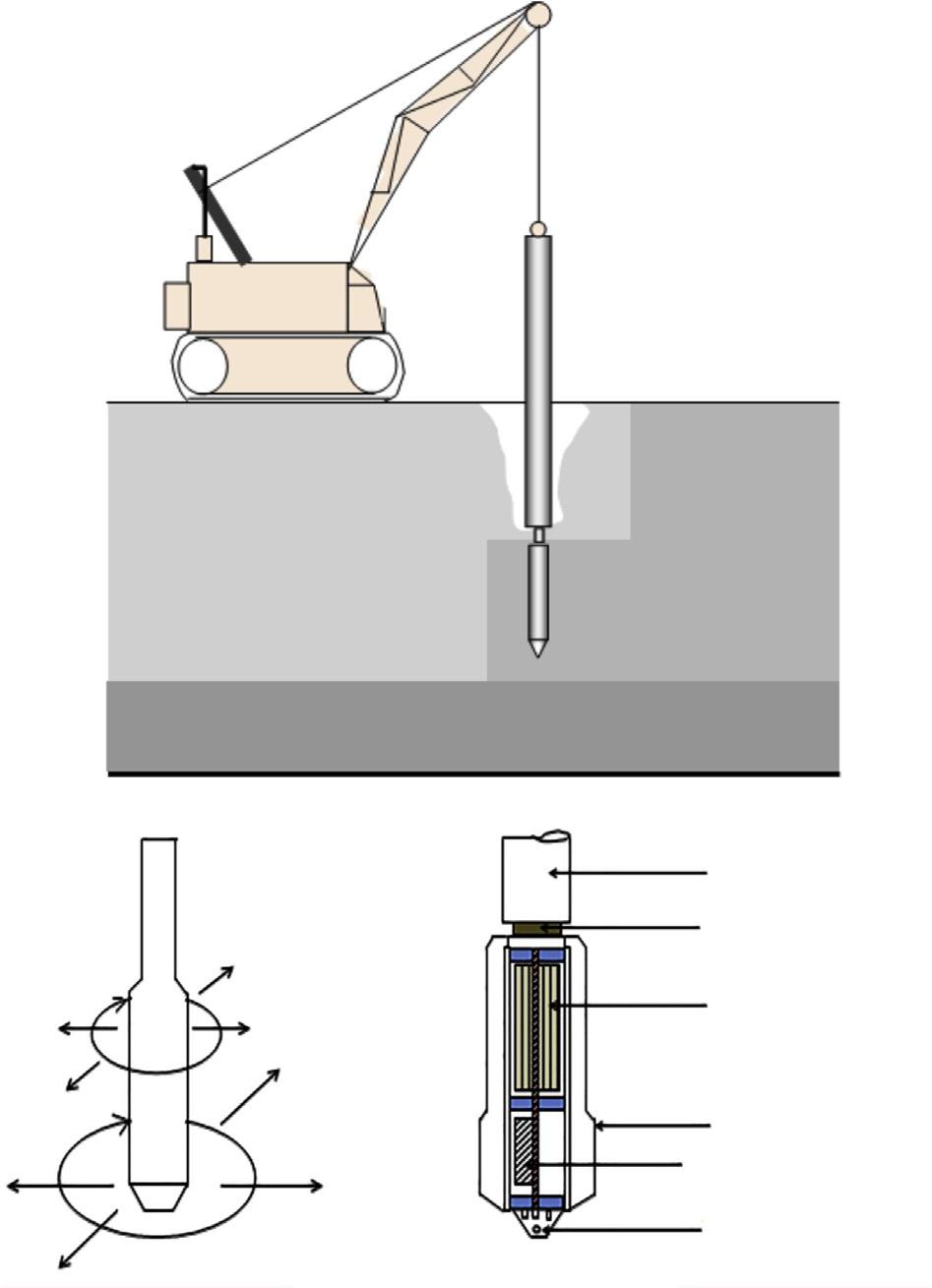

2.5Vibro-techniquesforcompaction Vibro-compactionisamethodofgroundimprovementwherethecohesionlesssoil getscompactedbymeansofadown-holevibratorknownasvibro-flot.Waterunder highpressureisjettedsidewaysanddownwardsfromthevibro-flottoassistthepenetrationprocess,asshownin Fig.2.4.

Thevibro-flotsareusually30–45cmindiameterandabout3–5mlongcontaining weightsmountedeccentricallyonacentralshaftdrivenbyelectricorhydraulicpower

Fig.2.4 Vibro-compactionmethod.

Vibro-compaction operation

Schematic view of vibrator

andsuspendedbyacrane.Vibrationcausesrearrangementofthesoilparticlesand duringtheprocesssmallersizedparticlesfillthevoidsbetweenthelargersizeparticlesandthusminimizethevoidratio.Thisisillustratedin Fig.2.5.

Thebenefitsofusingthevibro-compactionmethodforgroundimprovementas comparedtoothermethodsarethat(1)as pecificdegreeofgroundimprovementcan beachievedasrequiredbytheproject,(2)itistimeandcosteffective,and(3)itcan eliminatethenecessityofexcavationa ndreplacementonsite.Withthehelpof vibro-compaction,thebearingcapacityofnoncohesivesoilscanbeincreasedand thesettlementcanbereducedunderstructuralloads.Also,ithelpsinmitigatingliquefactionanddifferentialsettlement.Vibro-compactioncanbeimplementedfor variousapplicationslikebuildings,embankments,bridgeabutments,retaining walls,etc.However,theeffectivenessof thevibro-compactiontechniquedepends upontheinsitusoilcharacteristicsand mostlyonfinecontentbeingpresentin thenoncohesivesoils.Inordertogetgood resultswithvibro-compactionthesilt andclaycontentinthesoilshouldnotbe >10%– 15%and3%,respectively.Moreover,atshallowdepth(upto2mfromthe groundsurface)thevibro-compaction methodmaynotbeeffectivebecauseofthelackofverticalconfinement.Therelativeeffectivenessofvibro-compactionunderdifferentgroundconditionsispresentedin Table2.3

Fig.2.5 Particlerearrangementduringsoilcompaction.

Table2.3 Effectivenessofvibro-compactionindifferenttypesofsoils

GroundtypeRelativeeffectiveness

SandsExcellent

SiltysandsMarginaltogood SiltsPoor

ClaysNotapplicable

MinesoilsGood(ifcleangranular)

DumpedfillDependentonnatureoffill

GarbageNotapplicable

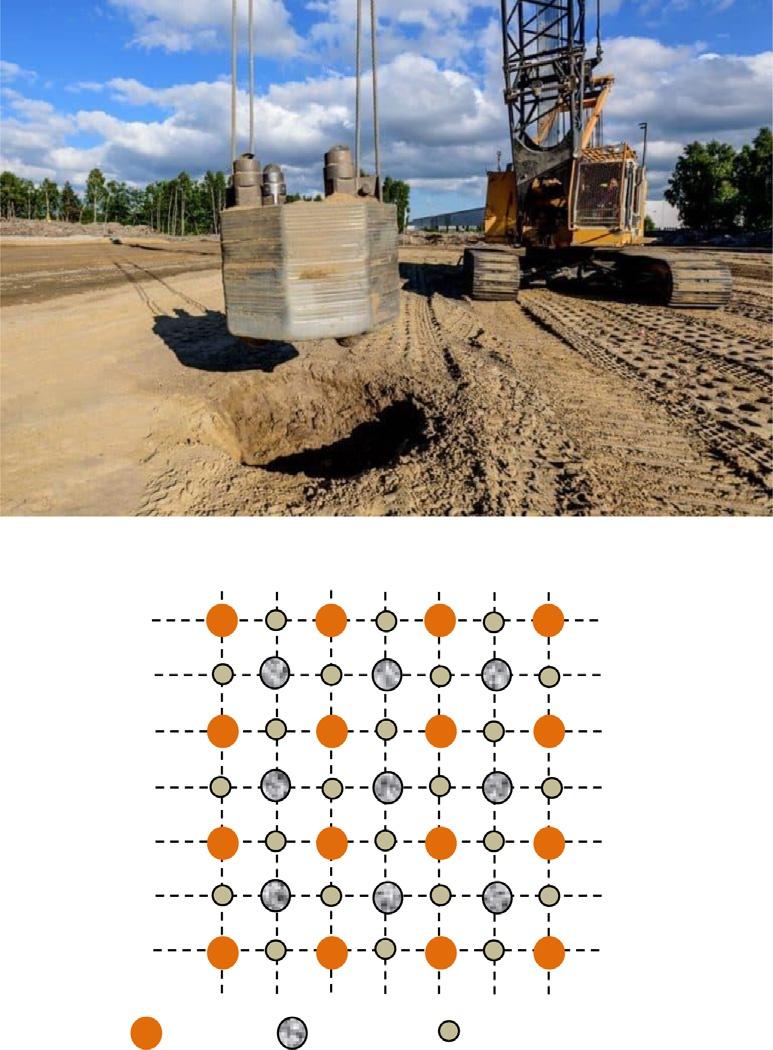

2.6Dynamiccompaction Indynamiccompaction,alargeweightusuallyof100–400kNisdroppedrepeatedly fromaheightofabout5–30montothegroundusingapredeterminedgridpattern,as depictedin Fig.2.6,inordertodensifythesoilmassortoimproveitscompactness.

Themaximumeffectivedepthofcompactionusingdynamiccompactioncanbe determinedbyusingtheformulaasfollows:

where W isthedroppedweightintonnes, H istheheightofdropinmetresandthe value n isafactorthatdependsuponthetypeofsoil.Thisdepthisalsoinfluenced byotherfactorssuchasthestratigraphyofthesoil,thedegreeofsaturation,the wayinwhichtheweightisdropped,andthepresenceofanydampingsoillayers. Thevalueof n generallyvariesfrom0.4to0.8.Thenumberofdropsateachgridpoint locationcanbecalculatedusingEq. (2.2) asfollows:

where E istheappliedenergy, N isnumberofdropsateachgridpointlocation, W is droppedweight, H istheheightofdrop, P isnumberofpasses,and S isthegridspacing.Thedroppointspacingisgenerallyselectedas1%to2%timesthediameteror widthofthedroppedblock.

Thedynamiccompactionmethodcanbeusedforvariousapplicationssuchasfor thetreatmentofindustrialwarehouses,portandairportplatforms,roadsandrailways embankments,heavystoragetanks,nonorganicheterogeneousfillorman-madegroundcontaininglargesblocksasobstructions,andsoilsthataresusceptibletoliquefaction.Themajoradvantageofadoptingthedynamiccompactionmethodisitsveryhigh productionrate(itcanbeusedtotreatanareaof >104 m2/month).Moreover,this methodiseffectivebothinsaturatedandnonsaturatedsoils.Insoftground,the methodofdynamiccompactionhasbeenprovedasabetteralternativetopreloading, foundationpiling,orsoilundercuttingandreplacement.

E ¼ N W H P ðÞ=S2

Fig.2.6 Dynamiccompaction. (A)Droppingofweightfromacertain weight(Menard),(B)Droplocations.

However,thedisadvantageordifficultyinadoptingthedynamiccompaction methodisthatitrequiresanintensiveinsitutestingprogramme(standardpenetration test,conepenetrationtest,pressuremetertestorloadsettlementtest,etc.)toverify thatthedesiredimprovementhasbeenachievedinthefield.Moreover,constantmonitoringisrequiredtocheckfortheformationofcrater,groundheave,groundvibration, inducedsettlement,andporepressuredevelopmentduringtheoperationofthis methodonthesite.Thismethodbecomesmorecomplicatedinsiltyandclayey depositsbelowthegroundwaterduetoitsrelativelylowpermeability.Insuchcases, iftheenergylevelisveryhigh,insteadofdensifyingthesoilmass,itmaybringthe groundtoaliquefactionstateforalongerdurationwithnegligibleporepressuredissipation.Totacklethisproblemwickdrainsassociatedwithdynamiccompactionare sometimesprovided.Also,thedroppingoftheweightcanbescheduledintophases allowingacertainperiodoftimeforthedissipationofporepressuresateachdrop pointlocation.Otherwise,thedynamiccompactionmethodismodifiedtowhatis knownashighenergypillars,where,withthehelpofhightampingenergy,largediameterstonepillarsarecreatedinasoftsoil.Incaseswherethewatertableisclose tothegroundsurface,dewateringisdonetolowertheleveltemporarilytoatleast2m belowthesurfaceorthegroundlevelisraisedtobringtheplatformsuitablyabovethe watertabletoallowforthedroppingofweights.

Dropping of weight from a certain weight (Menard)

Drop locations (A)

(B)

(levelling)

2.7Blasting Inthemethodofblastingforgroundimprovement,whichisalsoknownasexplosive compaction,thesequentialdetonationofexplosivesiscarriedoutincasedboreholes tocausegroundcompaction(Fig.2.7).Theexplosivechargesarespacedverticallyata distanceofabout3–8mintodrilledorjettedholes,whicharekept4–15mapart,and backfilledbeforedetonation.Theexplosivecompactioniseconomicalcomparedto othermethods,particularlywhendoneonalargescale,anditcantreatsoilstoadepth ofupto40m,whichothermethodscannotreach.Twoorthreeroundsofblastingmay berequiredtoachievethedesireddegreeofdensificationataparticularsite.The radiusofinfluenceoftheblasting,R,canbeestimatedusingthefollowingformula:

where M isthemassofexplosivechargesinkgand C isaconstantdependinguponthe typesofexplosiveusedandthegroundconditions.

Inthepast,thistechniqueofblastinghasbeensuccessfullyusedforearthdams, minetailings,bridges,buildings,portfacilities,andoffshoreoilstructures.Blasting ismosteffectiveinloosesandswithasiltcontentof <20%andaclaycontentof <5%. However,themajorlimitationofthismethodisthatduetothestrongvibrationsduring detonation,itmaydamagenearbystructuresormaycausesignificantgroundmovement.Soitisessentialtoseethatthechargesarefiredsequentiallyinaproperpattern thatcanoptimizecompactionwithoutcausingdamagetonearbystructuresandpublic utilities.Moreover,thereshouldbescopefordrainingthelargevolumeofwaterthat mayappearonthesurfaceduetotime-dependentdissipationofexcesswaterpressure producedduringtheprocessofblasting.Keepinginmindthepointsmentionedabove,

Fig.2.7 Blastingor explosivecompactionatthe siteforground improvement(Elliottetal., 2009).

theinstrumentationrequiredforblastingincludes(1)surfacegeophonestomeasure vibrationresponseatcriticallocations,(2)transducerstomeasureresidualporepressuresgeneratedbytheblasting,(3)hydrophonesinstalledinwater-filledcasingsto identifychargedetonations,(4)Sondextubestomeasureatdepththesettlementat thatfollowstheblasting,and(5)inclinometerswhereblastingiscarriedoutnear slopestomeasureslopemovements.

2.8Fieldcompactionanditscontrol Inthissection,thefieldmonitoringofcompactionparticularlyrelatedtotherollers,is discussed.Bydeterminingtherelativedensity(RD),itcanbeascertainedwhetherthe requireddensityhasbeenachievedinthefieldornot.

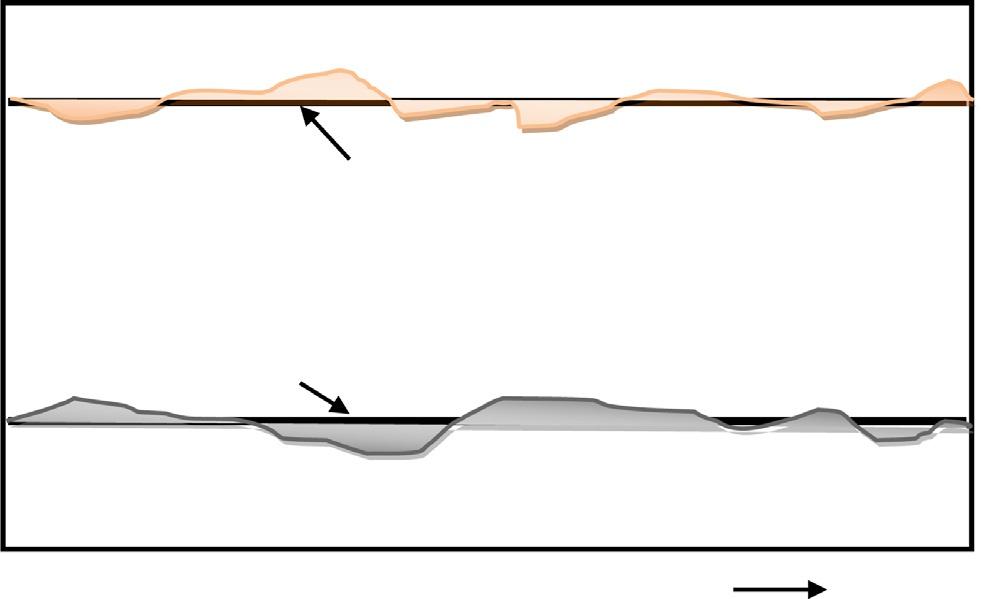

Thedensitythathasbeenachievedinthefieldcanbeobtainedwiththehelpofvarious instrumentslikesandcone,balloondensometer,Shelby/drivetube,andnucleargauge. Similarly,themoisturecontentisdeterminedusingavarietyofmethodslikenuclear gauge,speedymoisturetester,hotplate,orovendrying.Usingtheseinstruments,the moisturecontentanddensitycanbecheckedatsuitableintervalsalongasection(as shownin Fig.2.8),theresultsofwhicharethenusedtorectifythecompactionprocess (no.ofpasses,liftthickness,weight,operativefrequency,amountofsprinkledwater, soilgradation,etc.)inordertoachievethedesiredresults.Moreover,asmentionedin theprevioussection,GPS-basedsystems,suchasintelligentcompaction,canbeused asaQA/QCtollinthefield.

Goodspecificationsarenecessarytoensureanexpectedlevelofperformanceand forQA/QC.Thespecificationscangenerallybecategorizedas(1)method

Fig.2.8 Compactioncheckalongasectionline.

specifications,(2)resultspecifications,and(3)performancespecifications.The methodspecificationdescribesindetailtheequipmentandprocedurestobefollowed inordertoobtainthedesiredresultinthefield(e.g.compactiveeffortofsixpasses usinga1-tonlightvibratoryrollerwithaworkingspeedof2km/handvibratingfrequencyof50Hzshallbemadeoneach30cmliftofthesoil).Ontheotherhand,the resultspecificationdirectlystatestheresulttobeachievedinthefield(e.g.adrydensityof95%ofMDDasdeterminedbyASTMD698-12e1shallbeobtainedforeach liftofsoil).Theresultspecificationisshorterandeasiertowriteanditallowsthecontractorsomelibertytoinnovatehisorherprocessandhisorherintentionisjusttogive thefinaldesiredresults.Theperformancespecificationdescribestheconstruction qualitycharacteristicsthathavebeendemonstratedtocorrelatesignificantlywith thelong-termperformanceofthestructure(e.g.thepavementshallsupport2million equivalentsingleAxleloadswithoutdevelopingfatiguecracksorrutdepthsexceeding5mm).

Itistobeconcludedinthissectionthatwiththeinclusionofsophisticatedtechnologylikelasers,digitalvideo,imageanalysis,andGPS,theQA/QChasbecomesimple,accurate,andlesstimeconsuming.ConventionalmethodslikeCBR,plateload tests,fallingweightdeflectometer,anddynamicconepenetrationtestsaregradually beingreplacedwiththesenon-conventionalmethods.

Furtherreading Degen,W.S.,1997.56mdeepvibrocompactionatGermanligniteminingarea.In:Proceedings of3rdInternationalConferenceonGroundImprovementGeosystems,pp.128–133, London.

Elliott,R.J.,Clarke,L.,Gohl,B.,Fulop,E.,Singh,N.K.,Berger,K.C.,Huber,F.,2009.ExplosivecompactionoffoundationsoilsfortheseismicupgradeoftheSeymourfallsdam. In:Proceedingsofthe35thAnnualConferenceonExplosivesandBlastingTechnique, InternationalSocietyofExplosivesEngineers,Denver,Colorado,17pp. FederalHighwayAdministration,2004.DynamicCompaction.UniversityPressofthePacific, UnitedStates.

Gohl,W.B.,Jefferies,M.G.,Howie,J.A.,Diggle,D.,2000.Explosivecompaction:design, implementationandeffectiveness.Geotechnique50,657–665. Hogentogler,C.A.,1936.EssentialsofSoilCompaction,ProceedingsHighwayResearch Board.NationalResearchCouncil,Washington,DC,pp.309–316.

Narin,W.,Court,V.,Mitchell,J.K.,1994.Explosivecompaction:densificationofloosesaturatedcohesionlesssoilsbyblasting.In:GeotechnicalEngineeringReportUCB/GT/94-03. UniversityofCalifornia,Berkeley.

Priebe,H.J.,1995.TheDesignofVibroReplacement.GroundEngineering,London.

Soilstabilization 3.1Introduction Thestabilizationprocessreferstothemixingoftwoormoredifferentsoilsortothe mixingofasoilwithanothergeomaterialorwithchemicalsthatcanamenditsgeotechnicalpropertiesaspertheprojectrequirements.Themajorreasonsfordoingsoil stabilizationareasfollows:

l Enhancementofthestrengthandhencebearingcapacity,aswellassomeoftheotherengineeringproperties,ofsoils.

l Dustcontrolforagoodworkingenvironment.

l Waterproofingforconservationofnaturalormanmadestructures.

l Topromotetheuseofwastegeomaterialsinconstructions.

Soilstabilizationisaverycommonprocessforalmostalltheroadprojects.Broadly, alltypesofsoilstabilizationcanbeclassifiedintotwogroups,i.e.mechanicalstabilizationandchemicalstabilization.Inmechanicalstabilization,thegradingofasoilis changedbymixingitwithothertypesofsoilsofdifferentgrades.Bydoingso,a compactedsoilmasscanbeachieved.Ontheotherhand,chemicalstabilizationis associatedwiththemodificationofsoilpropertiesbytheadditionofchemicallyactive materials.Insoilstabilization,itisveryimportanttounderstandthematerialpropertiesinvolvedinthemixtureandtheoutcomeaftermixing.Moreover,itisimportantto findouthowthematerialisgoingtoperformafterstabilization.Atthesametime,the effectsoftheprocessonthenearbystructuresandsurroundingconditionsneedtobe evaluated.Accordingly,decisionscanbetakenontheselectionofmaterialsandthe correspondingdoses.Inadditiontotheselectionofmaterialsandthedoses,thereare manyotherfactorsgoverningtheeffectivenessofthismethode.g.mixingandspreading,selectionofroller,compactionlayerthickness,compactioneffort,sequenceof operation,curing,environmentalandclimaticconditions,etc.

3.2Mechanicalstabilization Asmentionedearlier,theobjectiveofmechanicalstabilizationistoachievedense well-gradedmaterialbymixingandcompactingtwoormoresoilsand/oraggregates. Adetailofthismethodispresentedinthefollowingsections.

3.2.1Mechanism First,byaddingdifferentgradesofmaterialsadense-packedmaterialisachieved. Second,withadditionofasmallamountoffinematerials,i.e.siltsandclays(binder), properbindingofthenoncohesivesoils/aggregateswilltakeplace,whichenhances thestrengthofthematerial.Strong,angularparticlesofsandsandgravels,imparting GeotechnicalInvestigationsandImprovementofGroundConditions. https://doi.org/10.1016/B978-0-12-817048-9.00003-2 © 2019ElsevierInc.Allrightsreserved.

internalfrictionandincompressibilitytothemix,canbewellstabilizedwiththeadditionofasuitabledoseofthebinder.Manyotherlocallyavailablematerials,likemine tailings,coral,shell,clinker,slags,constructiondebris,etc.,havebeensuccessfully stabilizedbyusingthistechnique.Themechanicalstabilityofmixedsoildepends uponseveralfactorslike(i)themechanicalstrengthandpurityoftheconstituentmaterials,(ii)thepercentageofmaterialsanditsgradationinthemix,(iii)thedegreeofsoil bindingtakingplace,(iv)themixing,rolling,andcompactionproceduresadoptedin field,and(v)theenvironmentalandclimaticconditions.Useofgeosyntheticmaterials inmechanicalstabilizationisaparticularmethodwherethesoilstrengthandother engineeringpropertiesarefurtherenhanced(duetoparticlesinterlocking,confinement,frictionalresistance,tensilestrength)withtheinclusionofthegeosynthetic materialslikegeogrids,geotextiles,etc.

3.2.2Proportioningofmaterials Theratioofdifferentsoils/aggregatesinthemixneededtoachievemaximumdensity isknownasproportioning.AspertheFuller’srule,thetheoreticalgradationformaximumdensityisdeterminedas:

where ρ isthepercentageofparticlesfinerthanthesize d (mm), D isthediameterof largestparticle,and n isthegradationindexthatdependsupontheshapeofparticles.

Moreover,thesoils/aggregatescanbemixedonatrialanderrorbasicandthen testedfortherequiredstrengthandotherpropertiesofthemix.Thepercentageof twodifferentmaterials A and B inamixinordertoachieveagradationasperthe specificationcanbeobtainedasfollows:

where Σ a isthesummationoftheabsolutevaluesof S a (a isthepercentagepassing ofmaterial A throughdifferentsizesand S istheaverageofthecorrespondinggradationlimitasperspecification).Inasimilarmanner Σ b isalsodetermined.

Iftherearethreematerialsinthemix,i.e. A, B,and C,thenthepercentofthese materialscanbedeterminedasfollows:

Inasimilarmannerthepercentofmaterialsinanymixcanbedetermined.

Soil B, PI=0

80 60 40 20 02468

Soil A, PI=8

(%) % of material passing 425 µ sieve for Soil A

Soil A (30%) + Soil B (70%) [PI=6.4]

Soil A, LL=28

Soil A (30%) + Soil B (70%) [LL=24]

Soil B, LL=8

(%) 1012140481216202428

Fig.3.1 Plasticitydeterminationofacombinationofsoils(FM5-410).

Ontheotherhand,plasticityofamixcomposedoftwoormoredifferentsoilscan bedeterminedasfollows:

PI ¼ A0 ax + B0 by + C0 cz

A0 a + B0 b + C0 c

where A0 , B0 ,and C0 aretherespectivepercentagesofmaterials A, B,and C; a, b, c are therespectivepercentagesofmaterials A, B,and C passingthrougha425 μ sieve;and x, y,and z aretheplasticityindex(PI)ofmaterials A, B,and C. Plasticityofthemixcanalsobedeterminedgraphically.Forexample,theliquid limit(LL)andPIofamixcomposedoftwodifferentsoils,i.e.30%ofsoil‘A’(having LL ¼ 28andPI ¼8)and70%ofsoil‘B’(havingLL ¼ 8andPI ¼0),ispresentedin

Fig.3.1.Thepercentageofmaterialfinerthan425 μ presentinthesoilwithhigher plasticity(i.e.SoilAinthisexample), P,isobtainedasfollows:

P ¼ QA0 a

QA0 a + QB0 b

where A0 and B0 aretherespectivepercentagesofmaterials A and B inamixofsay Q grams; a and b aretherespectivepercentagesofmaterials A and B passingthrougha 425 μ sieve.

3.3Chemicalstabilization Asmentionedearlier,chemicalstabilizationreferstothealterationofsoilproperties bychangingitschemicalmake-upwithdifferentadditiveslikelime,cement,flyash, etc.,orbytheadditionofchemicals,resins,andenzymes.

3.3.1Mechanism AroraandScott(1974) havereported18differentchemicalmechanisms(i.e. exchangeofcations,exchangeofanions,adsorption,fixation,formationofnewminerals,cementation,saltconversion,modificationofwaterfilms,adsorptionofwater films,enrichmentofporewaterwithions,modificationofcapillaryforces,modificationoftheelectricalsurfacetensionofclayminerals,modificationoftheelectrical forcesbetweenparticles,modificationofchemicallyboundwater,adsorptionof chemicallyboundwater,neutralizationofacids,neutralizationofbases,andproton exchange),thatmaycausestabilizationofclays.Further,theflocculationofparticles, generationofheatduringchemicalreactions,etc.,maytakeplace.Oneoracombinationofthesemechanismsmaytakeplacedependinguponthetypesoftheadditives mixedwiththesoils.

3.3.2Limestabilization Theadditionoflimeisasuitabletechniqueforthestabilizationoffine-grainedsoils. Thelimemaybeusedindifferentforms,e.g.hydratedhigh-calciumlime, monohydrateddolomiticlime,calciticquicklime,anddolomiticquicklime.Thecalciuminthelimeexchangeswiththeadsorbedcationsoftheclaymineralcausingthe claytoflocculate,andthusreducingthePIofclays.Inthiswayclaysbecomemore workableandmixable.Theswellingpotentialofclaysalsodecreaseswiththeaddition oflime.Moreover,withconsumptionofwaterandgenerationofheatduringhydration ofquicklime,thesoilbecomesmorerigid.LimeincreasesthepHvalueofsoilpore waterreleasingsilicafromtheclaymineral.Thereleasedsilicathenreactswiththe calcium(presentinlime)toproducecement,whichstrengthensthesoilwithproper curingofthemix.

Therequiredlimecontentcanbedeterminedonatrialanderrorbasis,keepingin viewthestrengthrequirementofthetreatedsoils.Quicklimeismorereactiveascomparedtothehydratedlime.Henceifquicklimeisusedthequantitycanbereducedto 75%ofthehydratedlime.AspertheEadesandGrimtestmethod(ASTMC977-02), ifthepHreadingsare12.40orhigher,thelowestpercentagethatgivesapHof12.40is thepercentagerequiredtostabilizethesoil.IfthepHreadingsdonotgobeyondapH of12.30andtwopercentagesgivethisreading,thelowestpercentagetogiveapHof 12.30isthepercentagerequiredtostabilizethesoil.IfthehighestpHreadingisapH of12.30andonlythehighestpercentagelimeusedgivesapHof12.30,additional testingisrequiredusinghigherpercentagesoflime.

Limestabilizationisparticularlyusedin roadprojectsformodifyingthepropertiesofsubgradesoils,subbasematerials,andbasematerials.Inadditiontothe enhancementofstrength,limestabilizatio nalsoimprovesthematerialresistance tofracture,fatigue,andpermanentdeformation.Inaddition,limeisoftenused incombinationwithotheradditiveslikecementandbitumentocompensatefor thedeficiencyofeachotherortoincrease theeffectivenessofthestabilization process.