GREENSUSTAINABLE PROCESSFOR CHEMICALAND ENVIRONMENTAL

SonochemicalOrganic Synthesis

Editedby INAMUDDIN

RAJENDERBODDULA

ABDULAHM.ASIRI

Elsevier

Radarweg29,POBox211,1000AEAmsterdam,Netherlands

TheBoulevard,LangfordLane,Kidlington,OxfordOX51GB,UnitedKingdom 50HampshireStreet,5thFloor,Cambridge,MA02139,UnitedStates

©2020ElsevierInc.Allrightsreserved.

Nopartofthispublicationmaybereproducedortransmittedinanyformorbyanymeans,electronicormechanical, includingphotocopying,recording,oranyinformationstorageandretrievalsystem,withoutpermissioninwriting fromthepublisher.Detailsonhowtoseekpermission,furtherinformationaboutthePublisher’spermissionspolicies andourarrangementswithorganizationssuchastheCopyrightClearanceCenterandtheCopyrightLicensingAgency, canbefoundatourwebsite: www.elsevier.com/permissions.

ThisbookandtheindividualcontributionscontainedinitareprotectedundercopyrightbythePublisher(otherthanas maybenotedherein).

Notices

Knowledgeandbestpracticeinthisfieldareconstantlychanging.Asnewresearchandexperiencebroadenour understanding,changesinresearchmethods,professionalpractices,ormedicaltreatmentmaybecomenecessary.

Practitionersandresearchersmustalwaysrelyontheirownexperienceandknowledgeinevaluatingandusingany information,methods,compounds,orexperimentsdescribedherein.Inusingsuchinformationormethodsthey shouldbemindfuloftheirownsafetyandthesafetyofothers,includingpartiesforwhomtheyhaveaprofessional responsibility.

Tothefullestextentofthelaw,neitherthePublishernortheauthors,contributors,oreditors,assumeanyliabilityfor anyinjuryand/ordamagetopersonsorpropertyasamatterofproductsliability,negligenceorotherwise,orfromany useoroperationofanymethods,products,instructions,orideascontainedinthematerialherein.

LibraryofCongressCataloging-in-PublicationData

AcatalogrecordforthisbookisavailablefromtheLibraryofCongress

BritishLibraryCataloguing-in-PublicationData

AcataloguerecordforthisbookisavailablefromtheBritishLibrary

ISBN:978-0-12-819540-6

ForinformationonallElsevierpublications visitourwebsiteat https://www.elsevier.com/books-and-journals

Publisher: SusanDennis

AcquisitionsEditor: KostasMarinakis

EditorialProjectManager: EmeraldLi

ProductionProjectManager: DebasishGhosh

CoverDesigner: ChristianJ.Bilbow

TypesetbySPiGlobal,India

Contributors

HilalAcidereli

SenResearchGroup,DepartmentofBiochemistry,DumlupınarUniversity,K € utahya,Turkey

MortezaMadadiAsl

DepartmentofPolymerScienceandEngineering,UniversityofBonab,Bonab,Iran

ElhamAzadi

OrganicPolymerChemistryResearchLaboratory,DepartmentofChemistry,IsfahanUniversity ofTechnology,Isfahan,Iran

SmritilekhaBera

SchoolofChemicalSciences,CentralUniversityofGujarat,Gandhinagar,India

AmarJyotiBhuyan DepartmentofChemistry,RajivGandhiUniversity,ArunachalPradesh,India

PubanitaBhuyan DepartmentofChemistry,RajivGandhiUniversity,ArunachalPradesh,India

MehmetHarbiCalimli

SenResearchGroup,DepartmentofBiochemistry,DumlupınarUniversity,K € utahya;Tuzluca VocationalHighSchool,IgdirUniversity,Igdir,Turkey

AnshuDandia

DepartmentofChemistry,CentreofAdvancedStudies,UniversityofRajasthan,Jaipur,India

AntonV.Dolzhenko

SchoolofPharmacy,MonashUniversityMalaysia,BandarSunway,Selangor,Malaysia; SchoolofPharmacy,CurtinHealthInnovationResearchInstitute,CurtinUniversity,Perth, WA,Australia

MuhammadFaisal

DepartmentofChemistry,Quaid-i-AzamUniversity,Islamabad,Pakistan

NehaN.Gharat

DepartmentofChemicalEngineering,InstituteofChemicalTechnology,Mumbai,India

ShyamL.Gupta GovernmentPolytechnicCollege,Kalimori,Alwar,India

MehdiHatami

DepartmentofPolymerScienceandEngineering,UniversityofBonab,Bonab,Iran

SaeedKhalili

DepartmentofPolymerScienceandEngineering,UniversityofBonab,Bonab,Iran

AnilKumar

SyntheticOrganicChemistryLab,FacultyofSciences,ShriMataVaishnoDeviUniversity,Katra, Jammu&Kashmir,India

BhagirathLimbani

SchoolofChemicalSciences,CentralUniversityofGujarat,Gandhinagar,India

ManzarMahmoudian

DepartmentofPolymerScienceandEngineering,UniversityofBonab,Bonab,Iran

ShadpourMallakpour

OrganicPolymerChemistryResearchLaboratory,DepartmentofChemistry;Research InstituteforNanotechnologyandAdvancedMaterials,IsfahanUniversityofTechnology, Isfahan,Iran

DhananjoyMondal

SchoolofChemicalSciences,CentralUniversityofGujarat,Gandhinagar,India

MinaNaghdi

DepartmentofChemicalEngineering,InstituteofChemicalTechnology,Mumbai,India x Contributors

OrganicPolymerChemistryResearchLaboratory,DepartmentofChemistry,IsfahanUniversity ofTechnology,Isfahan,Iran

KarunaN.Nagula

DepartmentofPharmaceutics,ParulInstituteofPharmacy&Research,Vadodara,Gujarat,India

MehmetSalihNas

DepartmentofEnvironmentalEngineering,FacultyofEngineering,IgdirUniversity,Igdir, Turkey

HaiTruongNguyen

DepartmentofOrganicChemistry,UniversityofScience,VietnamNationalUniversity,HoChi MinhCity,Vietnam

VijayParewa

DepartmentofChemistry,CentreofAdvancedStudies,UniversityofRajasthan,Jaipur,India

PravinD.Patil

DepartmentofBiotechnology,PriyadarshiniInstituteofEngineeringandTechnology,Nagpur, Maharashtra,India

VirendraK.Rathod

DeeptiRathore

AlankarP.G.GirlsCollege,Jaipur,India

LakhinathSaikia

DepartmentofChemistry,RajivGandhiUniversity,ArunachalPradesh,India

FatihSen

SenResearchGroup,DepartmentofBiochemistry,DumlupınarUniversity,Kutahya,Turkey

MuhammadSyafiqShahari

SchoolofPharmacy,MonashUniversityMalaysia,BandarSunway,Selangor,Malaysia

RashmiSharma

SyntheticOrganicChemistryLab,FacultyofSciences,ShriMataVaishnoDeviUniversity,Katra, Jammu&Kashmir,India

RuchiSharma

DepartmentofChemistry,CentreofAdvancedStudies,UniversityofRajasthan,Jaipur,India

SergeiA.Smolnikov

SchoolofPharmacy,MonashUniversityMalaysia,BandarSunway,Selangor,Malaysia

ManishkumarS.Tiwari

DepartmentofChemicalEngineering,NMIMSMukeshPatelSchoolofTechnology Management&Engineering,Mumbai,Maharashtra,India

PhuongHoangTran

DepartmentofOrganicChemistry,UniversityofScience,VietnamNationalUniversity,HoChi MinhCity,Vietnam

Ultrasound-assistedorganicsynthesis

NehaN.Gharat,VirendraK.Rathod DepartmentofChemicalEngineering,InstituteofChemicalTechnology,Mumbai,India

1.Introduction

Traditionalmethodstocarryoutorganicsynthesisreactionsfacedrawbackssuchaslong reactiontime,non-satisfactoryyields,moresolvent,toxic/costlyreagentrequirements andhightemperaturesandontheotherhand,resultsinuneconomicalproducts.Use ofheterogeneoussystemsgivesrisetomasstransferresistanceissuesdependingonthe numberandtypeofphasespresent.Itmayalsoleadtoagglomerationofparticleswhich lowerssurfaceareaandeventuallyslowsdownthereactionrate.Toovercomeallthese issues,theuseofultrasound(US)isacost-effectivemethodtointensifyvariousreactions suchasaqueousandnonaqueoushomogeneousreactions,heterogeneousreactions, phase-transferreactions,metal-organicframeworks,bio-enzymatic,amongothers.

Applicationofsoundwavesalongwithitschemicaleffectsistermedassonochemistry. TheapplicationofultrasoundwaveswasfirsttriedintheearlyninetiesbyRichardsand Loomis.ThiswasfollowedbySchultesandFrenzelwhostudiedtheaqueoushydrogen peroxideformationat540kHz.Furthermore,in1936,SchultesandGohrobservedthat lightcouldbeproducedbythehigh-intensitysonochemicalreactionofliquidsinthe rangeof190–750nmwavelength.Thisphenomenonwastermedassonoluminescence. Thislongjourneyofsonochemistryhasbeenremarkableafterthe1980s,wherecavitationphenomenawasconsidered.

Ultrasoundhasbeenusedasaprocessintensificationtool,between20kHzand 5MHzfrequencyrange,fortheremovalofbiologicallyactivecompoundsnanoscale operationsandformationofmedicines.Chemicalreactivityincreasesbyultrasound throughtheformationandcollapseofcavitationbubblesinaliquidmedium.Thepropagationofultrasoundwavestakesplaceinaliquidmediuminalternatecompressionas wellasrarefactionandcavitiesareformed.Oncetheattractiveforcesoftheliquidovercomebyrarefactioncycle,thecavitiesgrowtoamaximumsizeandthenburstresulting inenergydissipation(Fig.1) [1–3].Duetoturbulence,correspondingwiththeliquid circulationassociatedwiththecreationandbreakdownofthebubbles,masstransferrates areimproved.Whetherultrasoundcanbeappliedtoacceleratethereactionchemicallyas wellasphysicallydependsonthelocalhotspotsandbyenhancingthemasstransferrates, respectively.Inadditiontoimprovementinmasstransferrates,italsogivesbettercatalyst

Fig.1 Formationofbubble,development,andcollapse. (ReproducedwithpermissionfromP. Chowdhury,T.Viraraghavan,Sonochemicaldegradationofchlorinatedorganiccompounds,phenolic compoundsandorganicdyes areview,Sci.TotalEnviron.407(8)(2009)2474–2492.)

effectiveness.Typically,theeffectsofcavitationinaqueousmediumincorporateelevated temperatures(2000–5000K),pressuresupto1800atmosphere.Ultrasoundisbeneficial toacceleratechemicalreactionsbyimprovingyields,loweringreactiontimesaswellas increasingselectivity.Duetoallthesereasons,ithasbeenpopularizedasanovelapproach fortheproductionoforganiccompoundssincethepastcoupleofdecades [4].Even though,theuseofultrasoundisbeneficialforlaboratory-scaleoperations;foritscommercialimplementationfororganicsynthesis,therearesomeengineeringconcernssuchas missingscale-upprocedures,efficientdesigns [5].

2.Extrinsicvariablesaffectingultrasoundirradiation

Theintensityofcavitationproducedbyultrasoundisdependentonvariousparameters. Theseparametersnotonlyaddinthecostoftheprocessbutalsodecidethescale-upof

thereactor.Thus,itisessentialtooptimizetheseparametersfortheparticularsystemto getmaximumyieldatminimumcost.WhilecarryingoutUS-assistedreactions,itis advisabletostudythefollowingparametersforthedevelopmentofnewanalytical applications.

2.1Influenceofsolvent

Thechangeinsolventalsochangesthephysicochemicalproperties,i.e.,density,vapor pressure,surfacetension,andviscositywhichaffectscavitationintensity,butchemical reactivityofthesolventhasanintenseeffectonultrasonication.Thesecondaryreactions ofsonolysisofwatervaporbetweenOH• andH• explainaqueousultrasonication.Atelevatedtemperature,solventdoesnotshowinertbehavior.Itcanbeovercomebyapplicationoflowvaporpressuresolvent(excepthalocarbons)whichreducestheir concentrationinthevaporphaseofultrasonication.Inordertolowertheviscosityof themedium,thesolventplaysanimportantrolebymakingituniformandmiscible [6].Therefore,theselectionofsolventhasgreatimportanceinultrasoundirradiation.

Thepolarityofthesolvent,alongwithdenaturationconditionsaretheparameters thatneedtobeconsideredwhileselectingthesolventforUS-assistedenzymaticreactions.Inacomparisonofoilwithmethanolasareactant/solventforthesynthesisofbiodiesel,thebubblegetscollapsedatahigherrateinmethanolthanthatofoil.Asthe viscosityofmethanolislowerthanoil,therateofbubblecollapseinmoreinmethanol. Therefore,methanolispreferredasasolventincaseofbiodieselformationduetothe advantagesofenhancedinterfacialareaandrateofreaction [7]

2.2Influenceofpower

Chemicaleffectsonareactioncanbecausedbysupplyingsufficientacousticenergyso thatthecavitationthresholdofthemediumisovercome.“Cavitationalzone”isthe regionwherecavitationoccursaroundtheradiatingsource.Thisenhanceswithincreasingintensityofdissipation.Cavitationalintensitycanbeincreasedbyincreasingultrasonicpower.Also,withanincreaseinpower,enhancementintherateofreactionis observedandduetocontinuoususeofpowerforalongtime,rateofreactiondecreases [8] whichresultsinthegenerationofthecloudofcavitationbubblearoundtheprobe. Collapsingofthosecavitationbubblestakesplacenearhighpowerdissipation [9].With anincreaseinexposuretime,bubbleformation,aswellasimplosion,increases.Also,due toprolongeduseofultrasound,denaturingofcatalystalongwiththetransducersoccurs [10].Thereactorconfigurationanditsspecificapplicationaretheparametersresponsible foroptimumpowerdissipation [11].Acousticenergypresentinreactionmixturegets decreasedduetodecouplinglosses [12]

Overallliteraturehypothesizesthatfrequency,dutycycle,catalystloading,andmolar ratioaretheimportantparameters.Bykeepingthemconstant,theinfluenceofultrasonic

powerinorganicsynthesishasbeenoptimized.Effectofpoweronthereleaseofiodine bysonolysisofaqueousKIwasreported [13].Also,theinitialpowerdissipationwasproportionaltoiodinerelease,till40Wandremainedconstanttill100Wwhichdropped significantlyafter100W.

Enzymecatalyzedreactions,preferloweroptimumpowerdissipationbecauseenzymesshowthenegativeeffectathigherpowerdissipation.Severalreportssuchas [14] lipasecatalyzedesterificationreactionofmethylcaffeate(MC)withmethanolalongwith caffeicacidusingNovozym435undertheinfluenceofultrasoundirradiationhavebeen reported.Theimpactofpoweronreactionhasbeenstudiedbytheincreaseinpower underpulsemodeat25kHzfrequencyandtemperatureof5°Cwhichresultedinenhancedyield(99%conversion)at150-Wpowerdissipationunderthetimeintervalof9h.

Inthecaseofheterogeneousreactions,asimilartrendwasrepeated,whichshowed 93%yield(highest)at75Wasoptimumpowerdissipation.Beyond80W,therewasno furtherimprovementobserved.Theinfluenceofultrasonicpowerontheformationof methylbutyratecatalyzedbyamberlyst-15overtherangeof50–145Winputpowerat 22kHzfrequencywasstudied [15],wheretheenhancementinconversion,till100W wasobservedandbeyondthatconversion,wasfoundtodecrease.

Alltheabove-reportedtrendsshowthatwithanincreaseinpowerdissipationuptoa certainoptimumvalue,conversionoftheUS-assistedorganicsynthesisreactionsreaches themaximumvalue.Beyondcertainoptimumpowerdissipation,conversiongets reduced,whichdependsonthespecificclassofreactioncarriedout.Therefore,thereactorconfiguration,i.e.,numberandpositionofthetransducersandthetypeofreactionare thefactorsonwhichoptimumpowerdissipationwouldbedependent.Laboratory-scale investigationsinreactorswhicharealmostsameasthedesignofthecommercial-scale unitcangiverisetotheactualvalueofpowerdissipation.

2.3Influenceoffrequency

Ultrasonochemicalwavesproducefrequenciesintherangeof16–100kHzwhich enhancethecavitationeffect.Frequencyactsastheoriginofthedramaticimpactof powerdissipationonchemicalreactivity.Inthecaseofradicalformationmechanism, higherfrequenciesarepreferredastheyfacilitateandaccelerateagivenreaction.

Thebubbleformationisproceededbypassingultrasonicwavesviaamediumwhich beginswithgrowthanddisruptionofthebubble [16].Theclassificationofultrasonicfrequencieshasbeendonebasedonitslarge-scaleoperationinthreegroupssuchaspower ultrasonication(16–100kHz),high-frequencyultrasonication(100kHz–1MHz),and diagnosticultrasonication(1–10MHz) [17].Whennegativepressureoftherarefaction exceedstheattractiveforcesbetweenthemoleculesoftheliquid,voidsgetformed. Asthefrequencyincreases,cavitationgoesondecreasing,duetolesspressureproduced

byrarefactioncyclewhichisrequiredtoattaincavitationandsometimestherateofthe compressionexceedsthedurationwhichisrequiredforthecollapsingofbubbles [18]. Thereforethemainphenomenaofacousticstreamingarisewherecavitationproduced byultrasonicwaveshavingfrequency16–100kHzresultsintheformationoflargercavitationbubbleswithelevatedtemperatureandpressureconditions [19].Inthecaseof homogeneousliquids,frequencyplaysanimportantroletoattainoptimumcavitation becausehomogeneousultrasonicationiscarriedoutbeyondoptimum(offset)value. Toovercomethiscounteractingbehavior,thereisaneedtospecifyanoptimumrange offrequencies.

Inthesonochemicaldegradationofcarbontetrachloride,theauthorshaveclaimed thatat500kHz,thehigherdegradationrateisobservedascomparedto20kHz.Similarly, decompositionofchlorobenzeneandremovalof2-chlorophenolwasreported [20,21] whichdemonstratesthatforradicals,higherfrequencyispreferableasdominantchemical effectsoccurthatparticularlyintensifytheoxidationreactionswhereamajorcontrolling factoristhehydroxylradicals.Forheterogeneousreactions,theoppositetrendshave beenobservedintheliterature.

Also,thesynthesisof4-methylcinnamoylglycerolusingenzymeoverthefrequency of20–40kHzin48hhasbeenreported.Asfrequencyincreasesfrom20to35kHz,conversionincreasesandbeyond35kHz,itdecreasesbecauseatthisfrequencydeactivation oftheenzymeoccurs,duetophysicaleffectsandhighshearforces [22]

Overviewingtheseliteraturetrends,itcanbesaidthatforenzymaticreactionsorheterogeneousreactions,frequenciesintherangeof20–50kHzarepreferred.Physical effectsarerequiredinordertoeliminatemasstransferresistancesandtoretainthecatalyst activity.Similarly,inthecaseofhomogeneousreactionsorheterogeneousreactions, whichinvolveradicalmechanisms,higherfrequencies(200–500kHz)resultinenhanced reactionrates [23].

2.4Influenceofdutycycle

Theexistentexposuretimeofultrasonicationinonecycleisknownasthedutycycle. TheON/OFFtimeofultrasonicationcanbeadjustedtochangethedutycycle [24].FormationofthebubbletakesplaceinONtimewhereasitsenlargementiscarriedoutin restingtime(OFFtime).InUSsonochemistry,theconversionofaproductincreasesas thedutycycleincreases.Atthesametime,itmightaffectthetransducers,whichleadto wearandteareffects.Toavoidthiseffect,anothertypeoftransducerssuchaspulsemode isreported [25,26].Inordertoenhancethetransducerslife,thereactionshouldcarryout atminimumdutycycle.

Also,keepingtheultrasound“on”foralongtimecandamagethetransducers,thus usingrecentinstrumentswithbetterqualitytransducersshouldbepreferred [27,28]

Similarly,reportshavebeenvalidated [25] thatwithanincreaseintheultrasonicduty cycle,enzymeactivitygetsreducedasaresultofthephysicaleffectsofshearandturbulence.Thesynthesisofisoamylbutyratehasbeenstudied [29],where83%asanoptimum dutycyclehasbeenreported.Thesameresultofanoptimumdutycycleinheterogeneouslycatalyzedformationofmethylbutyratehasbeenreported [15] andinvestigated thatwithanincreaseinthedutycycleovertherangeof25%–75%,conversionincreases from72%to91.64%andasobserved,beyond75%dutycycle,conversiongetsreduced. Typically,itcanbeestablishedthatdependingontheconfigurationofthereactoralong withthetypeofreactionsysteminthepresenceofacatalyst,theoptimumdutycycle wouldbeintensifiedtoobtainbenefitsofultrasoundoperations.

2.5Influenceoftemperature

Thoughtemperatureandthechoiceofsolventareinterrelatedvariables,bothareessential.Withariseinsolventvaporpressure,themaximumbubblecollapsetemperatureand pressuredecreases.Therefore,inareactionwheresonochemicalactivationtakesplace throughcavitationalcollapseandalow-boilingsolventispresent,lowtemperatureis beneficial.Conversely,highboilingsolventsarepreferredwherereactionrequireselevatedtemperatures.Inthecaseofheterogeneousreactions,anexternalsurfaceofacatalystoraninorganicsolidreagentgetsaffectedbysonicationwhereabalanceshouldbe maintainedsothatpropercavitationtakesplaceaswellasthethermodynamicsofthe reactiondoesnotgetaffected.Also,theenergyrequiredtoinitiatecavitationisenhanced byapplyingexternalpressuretoareactionsystem,whichultimatelyenhancesthehydrostaticpressureoftheliquid.Thehighesttemperaturesandpressurescanbefacedatthe timeofbubblecollapsewhenthresholdenergyexceedstheavailableirradiationsource andcorrespondinghydrostaticpressureincreasesthesonochemicaleffect.

InUS-assistedreactions,theeffectofbulkliquidtemperatureisalsodependentonthe temperatureofthecounteractingreagent [9].Withariseinthereactiontemperature, chemicalkineticsgetenhancedasinthecaseofconventionalreactionsystems,but thecavitationalintensitydecreases.Aninverseeffectoftemperatureoncavitationintensitytakesplaceduetoformationofvaporouscavities,whichreducesbubblecollapse [30].

Novozyme435-assistedhydrolysisofsoybeanwiththehelpofmethanol(1:6)using 40kHzfrequencyhasbeenreported [31].Thereactionwascarriedoutovertherangeof 30–70°C,andthehighestactivitywasobservedat40°Candreducedbeyond40°C, whichmightbeduetodecreaseinviscosityathighertemperatureswhichimproves emulsification.Infinitesimalincreaseintemperaturecausesthebettercollisionsof enzymealongwiththesubstrateswhichresultinenzyme-substratecomplexwith increasedenzymeactivityat40°C [32].

Fromtheaboveexamples,itcanbeeffectivelyconcludedthatthemaximumrateof reactioncanbeobtainedatanoptimumtemperature.InUS-assistedorganic

homogeneousorheterogeneouschemicalsynthesis,duetoreducedcavitationalactivity, theconversiongetsreducedaswellasinUS-assistedenzymaticroute,alowertemperatureispreferredasanoptimumtemperature.Beyondthisvalue,thereducedrateof reactionisseenduetodenaturationofenzymesathighertemperatures.

3.Originsofthechemicaleffectsinsonochemistry

Theearlierassumptionaboutultrasoundwasthatitcanbecommonlyusedtoassistthe reactionsassociatedwithsolidreagentsonly;thisisnotparticularlycorrect.Alargenumberofgroupsareseekingtoachieveknowledgeofsonochemistry,whichcanhelpthem toanticipatethetypeofreactionaffectedbysonication.Luchehasclassifiedsonochemical reactionsintothreecategoriesbaseduponthecavitationalchemicaleffects.Otherthan chemicaleffects,therearesomemechanicaleffectsrelatedtocavitationbubblecollapse whicharetreatedasphysicaleffectsandevaluatedtobenegativesonochemistry.Those negativeeffectsarealsosignificant,whichhavebeenusedintheanalysisandincludedin thebelowthreereactioncategoriesaffectingsonochemicalenrichment.

1. Homogeneousreactionsinvolvingradicalmechanismarealteredbyultrasoundirradiation.However,sonicationdoesnotinfluenceionicmechanisms.Inthehomogeneousliquidsystem,thecollapsingofthecavitationbubbleleadstoimmediateinflow ofliquidtocoverthevoidspaceformedthroughthecollapsingcavity.Therupturing ofbondsincompoundstakesplaceduetoshearforcesproducedbythisinflowinthe surroundingbulkliquid.Thesimilareffecthasbeenobservedinthereactionofpolymericmaterialdecomposedinthefluid [33] (Fig.2).

In the cavity extreme conditions on collapse 5000°C and 2000 atmospheres

In the bulk media intense shear forces

Fig.2 Cavitationinhomogeneousphase. (ReproducedwithpermissionfromS.V.Sancheti,P.R.Gogate, Areviewofengineeringaspectsofintensificationofchemicalsynthesisusingultrasound,Ultrason. Sonochem.36(2017)527–543.)

2. Heterogeneousreactionprogressesviaionicintermediates.Theyareaffectedbya decreaseintheparticlesizeaswellasenhancementinmasstransferrate,whichare thephysicalimpactsofcavitation.Insuchreactions,theselectionofoperatingparametersiscrucialduetolessimportanceofthechemicaleffectsofsonication.

Inphase-transferheterogeneousreactionsduetothecollapseofacavitationalbubble,layerdisruptionalongwiththerapidblendingproducesultrafinemixtures(Fig. 3).Formaintainingstability,surfactantsareemployedinmakingtheemulsion. Enhancementinthesurfaceareaoccursasaresultofthegenerationoffineemulsions, givingthedesiredintensification.Duetocavitationaleffects,phase-transferheterogeneousreactionsrequirelesscatalyst.

Fig.3 Cavitationindual-phasicliquidsystem. (ReproducedwithpermissionfromS.V.Sancheti,P.R. Gogate,Areviewofengineeringaspectsofintensificationofchemicalsynthesisusingultrasound, Ultrason.Sonochem.36(2017)527–543.)

3. Thereactionsthatinvolvearadicalmechanismorradical,aswellasionicmechanism, getinfluencedbysonication.Radicalreactionsareaffectedbythechemicaleffectsof ultrasoundirradiation,whereasionicreactionsareinfluencedbyenhancedmasstransferrates.

Forheterogeneoussystemsinthepresenceofsolids,thebubblecollapsemaybe symmetricorasymmetric.Thesizeandtypeofthematerialinshockwavesraisethe motionofsolidparticlesinsolution.Thebreakdownofthebubbleduetosucha motionofsolidparticleresultsintheavailabilityofincreasedareaforreactionand activationofthecatalystcanalsobedonebyphysicaleffects.Thatresultsinthecleaningofthesurfacesandalsoenhancestransportratesthatdependontheinterruptionof theboundarylayers(Fig.4).

Powerful disruption of phase boundary

Inrush of liquid from one side of collapsing bubble forces powerful jet onto solid surface

Fig.4 Cavitationinheterogeneoussystems. (ReproducedwithpermissionfromS.V.Sancheti,P.R. Gogate,Areviewofengineeringaspectsofintensificationofchemicalsynthesisusingultrasound, Ultrason.Sonochem.36(2017)527–543.)

4.Reactordesignandconfiguration

Therearemanydevicesavailabletocarryoutultrasonicirradiation.Theyareknownas sonochemicalreactors.Theclassificationofsonochemicalreactorsdependsonthenature ofirradiationlikedirectandindirect.Directmodereferstothedirectcontactofultrasonictransducerwiththereactionmedium.Inindirectmode,itreferstoeitheracontact betweenseparatereactorhavingreactants,whichissuspendedintoultrasonicvesselfilled withacouplingliquidorsonicationvesselitselfcontainingliquidmixture.Sonochemical reactorsaregenerallydividedintothreedesigns.

1. Ultrasoniccleaningbath.

2. “Cup-horn”sonicator.

3. Directimmersionultrasonichorn.

Inallcases,theoriginalsourceoftheultrasoundisapiezoelectricmaterial,usuallyalead zirconatetitanateceramic(PZT),whichissubjectedtoahighACvoltagewithanultrasonicfrequency(typically15–50kHz).Thepiezoelectricsourceexpandsandcontractsin thiselectricfieldandisattachedtothewallofacleaningbathortoanamplifyinghorn.

4.1Ultrasoniccleaningbath

Fortheindirectirradiation,asonicationbathisaveryfrequentlyusedsonochemicalreactor.Itisaninexpensiveinstrumentinwhichtheultrasoundisappliedwiththehelpof transducers(Fig.5).ItisusedprimarilyinlaboratoryultrasoundoperationsofUS-assisted heterogeneoussystems.Averylessamountofenergyissuppliedtotheactualreaction mixturewithinthemediumascomparedtoultrasonichorn(whichareusedindirect irradiationmode).Dependingonthesizeofthevesselandthenumberoftransducers, distributionofthecavitationalactivitytakesplaceinthecaseofultrasoundbath.

Solid surface Diffusion layer

Fig.5 Ultrasoniccleaningbath. (ReproducedwithpermissionfromE.M.Hussein,K.S.Khairou, Sonochemistry:synthesisofbioactiveheterocycles,Synth.Commun.44(15)(2014)2155–2191.)

Alongwiththebenefitsofultrasoundbath,thereareseveralpotentialdrawbackslike variableacousticintensity.Itvariesfrombathtobathandonemanufacturertoanother. Therefore,theissueofreplicabilityfromonebathtoanothermayarise.Also,theplacementofthereactionflask,temperature,theheightofboththebathliquidandofthesolutionwithinthereactionvesselarecriticalparameters [34,35].Coolantsareusedfor thermostating,astheyarepassedthroughcoppercoilswithoutcontactingwalls.In thecaseofhomogeneousliquids,marginalacousticintensitiesarepresentforthegenerationofcavitation.Also,incaseofsolids,thetensilestrengthoftheliquidattheinterface causesthecavitationwellbelowthresholdsascomparedtosimplesolutions.However, forheterogeneousultrasoundirradiation,thesonicationbathcanbeconsideredwithlimitedpotential.

4.2 “Cup-horn ” sonicator

Togethighcavitationalintensityatlowoperatingvolumes,ultrasonichornsaremost commonlyusedforlaboratory-scaleoperations.Bykeepingthefrequencyofirradiation constant,thepowerdissipatedwithinthereactionmixturecanbevariedwithanintroductionoftheacousticenergydirectlyintotheliquid.Thediameteroftheprobeandthe heightoftheliquidinthereactorarethecontrollingfactorsintermsofcavitationalactivityandapplicationpointofview.Thereisacertainlimitationinthecaseofthehorn

systemwherecontaminationshouldbestrictlyprohibited.Duetoextensiveuseofhigher levelsofpowerdissipation,erosionofmetaltakesplaceintoliquidalongwiththepitting ofthetip [36].Also,theshapeofthehorncontrolsthecavitationalactivityalongwiththe transferofenergyconsideringtheminimumeffectonthesurfaceerosion.Cuphornsarea knownmodificationwhereasmallsonicationbathisdrivenbyahornextendingthrough itsbase(Fig.6).Initially,itwasusedincelldisruption,butnowadaysithasfoundapplicationinsonochemistryinindirectirradiation,butmorepowerdissipationoccursin comparisonwiththetypicalsonicationbath.Anultrasonichornismuchbetterwith highercapabilityforprocessedvolume.Inthecaseofultrasonicprobeinstandardpiezoelectrictransducers,itismadeupofTitaniumcrucible.Incomparisonwithultrasonic cleaningbath,itisadvantageousintermsofacousticintensities,frequencycontrol,aswell asthermostatingcapacity.Asthereisnocontactbetweenradiatingsurfaceandreaction solution,theresultingintensitiesaresmallerthanthatofdirectimmersionultrasonic horn.Therefore,homogeneousultrasoundirradiationisdisadvantageousintermsof activeness.Butitisalsoadvantageousasitisfreefromcontaminationagainsttheerosion ofthetitaniumhorn.

Fig.6 UltrasonicprobeCuphorn. (ReproducedwithpermissionfromP.Chowdhury,T.Viraraghavan, Sonochemicaldegradationofchlorinatedorganiccompounds,phenoliccompoundsandorganic dyes areview,Sci.TotalEnviron.407(8)(2009)2474–2492.)

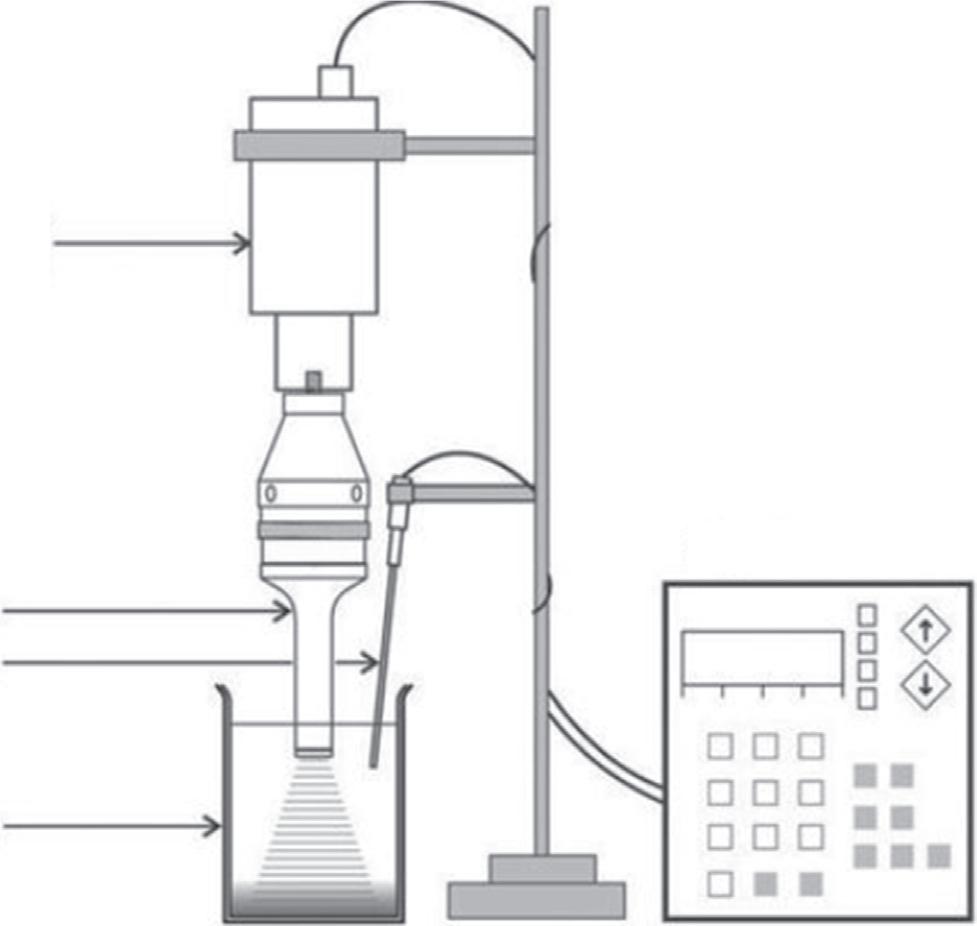

4.3Directimmersionultrasonichorn

Itisaverypowerfulultrasonicreactorspeciallyusedinachemicallaboratoryinaninert atmosphere(Fig.7).Likeacuphorn,directimmersionultrasonichornisalsodesignedby biochemistsforcelldisruption.Itisreadilyavailableatareasonablecost.Evenvariable shapesoftitaniumhornsandsizesofpowersupplyareprovided.

Forlarge-scaleoperations,theuseofdirectimmersionultrasonichornprovidesthe flexibilityofoperatingatmulti-litercapacity.Thishorngiveshighandvariableintensities atafrequencyof20kHz.Duetomorepowerdissipation,thenecessityoftemperature controllertocooldownthereactionariseswhichdependsonthetypeofconfiguration. Also,itshowsthedrawbackoferosionofthetitaniumtipwithoutchemicaleffects, whichshowsenhancedtensilestrengthwithlessreactivityofTimetal.Thecommercial applicationofthesehornsinvolvescelldisruptiononlargescale,degassingofliquids,dispersionofsolidsintoliquids,andemulsificationofimmiscibleliquids.Thedirectimmersionultrasonichornismostwidelyfoundinindustrialultrasonicreactionsthanatthe laboratoryscale.

Directimmersionultrasonichorns. (ReproducedwithpermissionfromE.M.Hussein,K.S.Khairou, Sonochemistry:synthesisofbioactiveheterocycles,Synth.Commun.44(15)(2014)2155–2191.)

Digital disruptor (piezoelectric ceramic)

Titanium horn

Temperature probe

Heavy duty beaker

Digital control unit

Fig.7

5.ClassificationofUS-assistedorganicsynthesis

Applicationofultrasoundforintensifyingdifferentprocessesresultsinvariousorganic synthesisreactions.Theuseofhighlyintensivesonochemistryinaqueousornonaqueous mediumgivesbenefitsofbenignreactionconditions,lesstimewithenhancedyield, whichmostlydependsonphysicaleffectsthattakeplaceinultrasonication.Here,we areclassifyingreactionsintohomogeneousandheterogeneoussystems.

5.1Homogeneous

Sonochemicaleffectsinhomogeneousliquidsystems,usuallyoccuratdifferentsites. Thosesitesaregivenbelow.

1. extremeconditionsinsidethecollapsingbubble;

2. attheinterfaceinbetweenthecavityandpresentbulkliquid;and

3. inthebulkliquidwheremechanicaleffectsprevail.

Further,wewillproceedwiththeclassificationofUS-assistedhomogeneousorganicsynthesisintoaqueousandnonaqueoushomogeneoussystems.Theydepictthedifferent typeofcavitationeventineachcase.

5.1.1Aqueous

Aqueousirradiationoforganiccompoundsfrequentlygivesrisetoextremelyoxidizedor degradedproductsinmultipleamounts.Inthecaseofaqueousmedia,thereisanoverall deficiencyofspecificityforultrasonicirradiationbecausewhilecarryingoutsonolysisof water,wetendtogetintenselyreactiveintermediatesatrespectablerates.

In1982,aqueoussonochemistrywasreported,inwhichstereoisomerizationofmaleic acidtosynthesizefumaricacidbyultrasoundirradiationusingBr2 wascarriedout.Inthis reaction,thefrequencyusedoveraverywiderangeandBr0 isanefficientcatalystforthe isomerizationobtainedfromsonolysis,whichmakesthisreactionuniqueinsonocatalysis, asgivenbelow.

Therearemanystudies,whichreportedtheeffectsofultrasoundthroughvarioussolvolysisreactions.Oneofthemappliedinbothultrasoundirradiationandcatalyticwet peroxideoxidationforabreakdownof4-hydroxybenzoicacidwherethedetermination ofenhancedrateforthehydrolysisofacetatesandsaponificationoffatshasbeen studied [37]

In2013,thesynthesisofNovelHomoallylicAlcoholDerivativesusingwaterasa mediumwasestablishedbycomparingbothconventionalandUS-Assistedapproach [38].Thereactionwascarriedoutinaqueousmedia,withdifferentcarbonylcompounds

Br'2 2Br' +

withallylicbromidesthroughUS-assistedBarbierreaction.The α-bromoketones reactedwithsodiumbenzenesulfinateinthepresenceofCuI/2,6-lutidine.Simply,sulfonationof α-bromoketoneswascarriedoutwhichproduced β-keto-sulfoneswithsatisfactoryyields.Therefore,thisaqueousmediasulfonationreactionwasbeneficialin termsofexcellentyields,lesserreactiontime,andmoresimpleincomparisonwith thetraditionalone(Scheme1).

1b:R=PhSO2 4:R=F

5a:R=PhSO2 b:R=F 6a-e 5and6R aPhSO2 bF cBr dCH3 eH

Scheme1 Sulfonationof α-bromoketonesinpresenceofultrasonication.

In2017,theformationofnaphthoquinonecombinedoxazinederivativesunderan aqueousmediumbyusingsonicationhasbeeninvestigated [39].Developmentofenergy efficient,aswellastheenvironmentallysafeprocedure,hasbeencarriedoutthroughthe reactionof2-hydroxy-1,4-naphthoquinone,aromaticamineandformaldehydeinasingleapproachusingwaterasanaqueousmediaunderultrasoundirradiation(Scheme2).

Scheme2 Formationofnaphthoquinonecombinedoxazinederivativesusingultrasonicirradiation.

Laterin2017,synthesisofBis(Indolyl)Methanesand3,3-Bis(Indolyl)oxindolesin thecatalyst-freemediumusingAqueousEthylLactatehasbeeninvestigated [40].Inthe reportedapproach,indolesreactedwithaldehydesorisatinsinwaterandethyllactate undertheinfluenceofultrasonication.Inadditiontobenefitsofaqueousmediaalong withtheultrasonication,thisapproachisfreefromthecatalyst,havingabroadsubstrate scopeandapplicableforindustrialsynthesis(Schemes3–5).

Scheme3 Ultrasound-assistedformationofBis(Indolyl)Methanes.

Scheme4 FormationofBis(Indolyl)Methanesinwaterandethyllactateusingultrasonication.

Scheme5 Formationof3,3-Bis(Indolyl)oxindolesinwaterandethyllactateusingultrasonic irradiation.

Also,in2017,thelatestachievementsintheultrasonicallyirradiatedorganicsynthesis usingaqueousmediumhavebeenreported [41].Thereareseveralreportsavailableonthe applicationofanaqueousmediainUS-assistedorganicreactions.Basedontheknowledgeofgreenchemistry,waterisconsideredasthesafestsolventascomparedtoothers. Therefore,itisasustainableapproachthatholdsanactiveassociationbetweenhighly intensiveultrasonicationandaqueousmedium.Also,theapplicationofultrasoundirradiationalongwiththewaterleadstoaneco-friendlyprotocol.

Recentlyin2019,theformationofcrucialheterocyclessuchasQuinoxaline, 1,4-oxazine,1,4-thiazine,and1,4-dioxinderivativesusingcatalyst-freemediuminwater undertheinfluenceofultrasonicationhasbeenstudied [42].Therewerevariousmethods reportedforthesynthesisofthesame.However,thesemethodshavecertaindrawbacks. Therefore,forthesynthesisoftheseheterocycliccompounds,easyandenergy-efficient methodsarerequired(Scheme6).

Scheme6 Thereactionofninhydrinando-phenylenediamineinpresenceofultrasonication.

Thereforetheapplicationofwaterasasolventthanothervolatileorganicsolventsis appreciableingreenchemistry [43–46].However,aqueousmediumgivesincreased reactionrateasaresultofstronghydrogenbonding.Also,theultrasoundusingwater offersbenefitsofnontoxicity,recyclabilitywiththepurificationofproducts [47–52]

Nowadays,catalyst-freeaqueousmediumhasgainedimportanceinlaboratoryscaleas wellasindustrial-scaleduetopropertieslikerapid,energy-efficient,cheap,improved selectivity,environmentallybenign,andeasyisolationofproduct [53,54].

5.1.2Nonaqueous

Homogeneousnonaqueoussonicationwasnotreportedfrequentlyuntilthepastfewyears. In1937,PorterstudiedthesevenfoldaccelerationduetoCurtiusrearrangementof C6H5CON3 toC6H5NCOandN0 2 [32].Laterin1965,WeisslerhasreportedsomesolventswhicharetooslowindegradationlikeCH3CNandCC14 [34].In1967,theinitiationofexplosionsoftetranitromethaneandnitroglycerinewasinvestigated.Also,in1974, thedepolymerizationofhighmolecularweightpolymerswasobserved [55].Principally, aqueoussolutionswithvolatileorganicsolventshavenotbeenreportedforsonochemistry.

Thisledtoageneralbeliefthatwatercanonlyactasahightensilestrengthliquidtosupport intensecavitationalcollapse.Duetohighvaporpressures,alargegroupoforganicliquids reducesthestrengthofcavitationalcollapse.Butithasnowbeenestablishedthatcavitation willbeaccomplishedbyorganicliquidsviafreeradicalsatlowtemperaturethroughbond homolysis.In1983,thesonolysisofalkaneshasbeenstudied,whichisthesameprocessas extremelyhigh-temperaturepyrolysis.Also,in1979,thesonolysisandpyrolysisofbiacetyl, whichproducesacetone,hasbeenreportedandcomparedwiththesonolysisandradiolysis ofmenthonein1980.Thechemistryinvolvedinnonaqueoussonochemistrycanbe tedious,asseeninthetarrypolymerizationofvarioussubstitutedbenzenesreportedbyseveralauthors.Theresultsobtainedfromtheanalysisofaqueoussonochemicalreactionsare challengingtounderstandbecauseofthecomplicationofthesecondaryreactions.Therefore,inthecaseofnonaqueousliquids,theratesofdegradationcanbeadjustedtoslow downquitebelowthanwaterbyproperselectionofsolventaswellasbymaintaining lowvolatility.Highlystableliquidscanbeobtainedatlowertemperatureslikedecane at 10°C.Itisadvantageousbecauseinsteadofthesecondaryreactionsoccurringwithsolventfragments;theprimaryultrasoundirradiationofdecomposedsubstratescanbeinvestigated.Infutureaspectsofsonochemicalstudies,wecanlookforwardtoincreasetheuseof nonaqueoussonochemistrywiththeapplicationoflow-volatilityorganicliquids.

5.2Heterogeneous

Thehasteningofheterogeneousreactionusingultrasoundisanemergingtechnique.Itis accompaniedbyphysicaleffectssuchasformationofemulsionsatliquid-liquidinterfaces, cavitationalerosionandfinally,purificationtakesplaceatliquid-solidinterfaces.Asthe formationofshockwavedamagesaswellasdeformssolidsurfaces,thesurfaceareaof friablesolidsgetsincreased.

TheheterogeneoussonochemicalreactionisaveryknowntypeofUS-assistedreaction,inorganicororganometallicchemistry.Further,US-assistedreactionscanbe appliedtotheleachingprocesstointensifytheireffectonleaching.Heterogeneous US-assistedreactionsarefurtherdividedintothreecategories,whicharestatedbelow.

5.2.1Metal-organicframeworks

Materialscientistshavenewlydevelopedaporousmaterialknownasmetal-organicframeworks(MOFs).InMOF’s,metalionstogetherwithorganicmultidentateligands,are boundedthroughcoordinatebonds.Theseorganic-inorganichybridcompoundsarecrystallineinnature.Theyprovidehighsurfaceareaswithbetterfunctionality,poresize,selectivityrangeofshape/size,andimprovementinactivityascomparedtobasemetaloxides. However,theyhaveapplicationasahostinavarietyofguestmolecules [56–58],further usedinadsorption,catalysis,magnetism,sensing,anddrugdelivery [59–61].Natureofthe metal-organicframeworkdecidesthephysicalparametersofMOFslikemagneticsusceptibility,conductivity,andopticalcharacteristics [62].MOF’sactasabridgebetweenzeolites(havingsmallporesize)andsilicates(possesshugesize).MOF’sexhibitreduced chemical,thermal,andhydrothermalstabilityincomparisonwithotheroxides [63]

ForthemanufacturingofMOF’s,transitionmetals,alkalineearthmetals,p-blockelements,actinidesaswellasmixedmetalsareusedsincethepasttwodecades.Itcanbe preparedbylowvapordiffusionandsolvothermaltechniques [64] butneedtobemaintainedatelevatedtemperatureandpressure.Therefore,nowadays,nanoparticleswith particularmorphologiesaresynthesizedbytheUS-assistedmethod [65,66].

In2016,themostsimpleandcommercialmethodfortheformationofnanoMOFs usingultrasonicsonochemistryhasbeenreported [67].Recentlyin2018,Ultrasoundassistedamidefunctionalizedmetal-organicframeworkusedfornitroaromaticsensing. Whilesynthesizingnanoplatesofzinc(II)-basedMOF’sthroughtheultrasonicmethod, surfactantswerenotinvolvedatambienttemperatureandatmosphericpressure. Therefore,FieldEmissionScanningElectronMicroscopy(FE-SEM),powderX-ray diffraction,thermogravimetricanalysis(TGA),elementalanalysis,andFTIRspectroscopyarethemethodsusedtoanalyzeincreasedcontrolofparticlesizeandmorphology. Similarly,byusingdifferentprecursorconcentration,amide-functionalized nanometal-organicframework,[Zn2(oba)2(bpfb)] (DMF)5,TMU-23,(H2oba ¼ 4,40oxybis(benzoicacid);bpfb ¼ N,N0 -bis-(4-pyridylformamide)-1,4-benzenediamine, DMF ¼ N,N-dimethylformamide),wasreportedbyapplicationofultrasound sonochemistry.Also,thedecreaseinflorescenceintensityandanincreaseinselectivity ofsensingcapacityofnitroaromaticcompoundslikenitrophenol,nitroaniline,and nitrobenzeneinacetonitrilesolutionisinvestigated [68] (Scheme7).

5.2.2Phase-transfercatalysis

Mutuallyinsolublecompoundsreactwitheachotherthroughphase-transfercatalysis (PTC).Sinceitisusedinthesynthesisofpharmaceuticals,agriculturalchemicals,flavorings,dyes,perfumes,andenvironmentalprocesses;itwasattemptedtoimprovethe

Scheme7 SynthesisofTMU-23viabothwayshydrothermalaswellasultrasonication.

phase-transfercatalystsefficiency.“Multisite”phase-transfercatalyst(MPTC)isthe newlydevelopedPTCmethod,wherecatalyticefficiencyhasbeenincreased,dueto multiplemoleculesbeingabletobetakenintotheorganicphaseinonecycle [69–73].Asultrasoundsonochemistryreportedadvantageslikehighreactionrate,yield, andselectivity;therefore,itsapplicationsinorganicsynthesishasbeenpredominant.The combinationofPTC,alongwithultrasonicationhasbeenformedtobeaneffective methodfororganicconversion [74–78].Also,PTCassistedbysonicationgivesbenefits ofhighmasstransferrate.In2000,Cannizzaroreactioncarriedoutbyphase-transfer catalysiswithsonochemistryhasbeenestimatedthatthereactionrateincreasedby 20-kHzultrasonicwave [79].Inthecaseofepoxidationanddichlorocyclopropanation of1,7-octadieneandethoxylationofp-chloronitrobenzenebyphase-transfercatalyzed ultrasonication,increasedrateofreactionwasobserved [80–82].Phase-transfercatalysts carriedbyhighlyintenseultrasonicwavesalsopromotesWilliamsonethersynthesis.Due toitspotentialandversatiletechnology,ultrasoundhasearnedimportanceinpolymerizationindustries [83],homopolymers,blockcopolymers [84],hydrogels [85],and polymer-inorganiccomposites,etc. [86].Liquid-liquidphase-transfercatalysis(LLPTC) combinedwithultrasoundirradiationalsoenhancestherateofreaction,butfroman applicationpointofviewisrarelyseenintheliterature.

However,theapplicationofPTCalongwithultrasoundmethod,hasachieved exceptionalattentioninboththecommercialaswellasacademicpointofview,due toitsstrongandflexiblenature.Italsoprovidesmultiplebenefitsthatfavoritsuseindifferentpolymerizationtechniquestosynthesizepolymers.Tothebestofourknowledge, thecombinedapproachofPTCandultrasoundislimited.

In2017,thenovelprocessesinphase-transfercatalyticreactionsundertheinfluenceof ultrasonicationhavebeenstudied [87].Theenhancedyieldatreducedorganicsolventand lessreactiontimewasreported.Theethoxylationreaction,inwhich4-chloronitrobenzene reactswithpotassiumethoxidehasbeenevaluatedinthepresenceofPTCusingultrasound irradiationconditions(28kHz,200W),thatresultedinethoxy-4-nitrobenzene(Scheme8)

Ultrasoundirradiation

Scheme8 Ultrasound-assistedreactionof4-chloronitrobenzenewithpotassiumethoxideinpresence ofPTCtoformethoxy-4-nitrobenzene.